New Insights on Expandability of Pre-Cured Epoxy Using a Solid-State CO2-Foaming Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

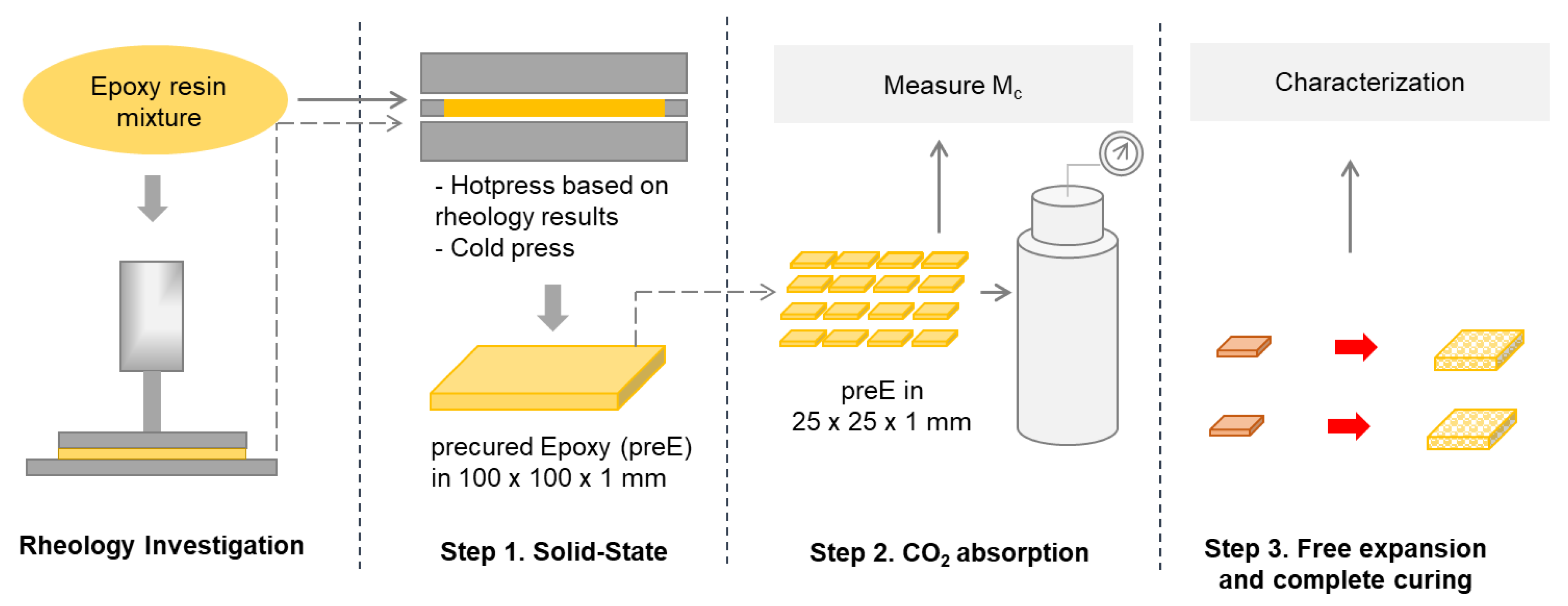

2.2.1. Fabrication of Epoxy Foam by Using Solid-State CO2 Foaming Technique

2.2.2. Characterization and Testing

- a.

- Rheological behavior of DGEBA and polyamide

- b.

- PreE properties

- c.

- Properties of epoxy foam:

3. Results and Discussion

3.1. Rheology Analysis of Epoxy—Ancamide 260A and PreE

3.2. Glass Transition Temperature and Onset Temperature of Further Curing of PreE

3.3. Molecular Weight between Crosslinks by Solvent Method

3.4. CO2 Absorption Content of PreE

3.5. Effect of Foaming Temperature on Density of Epoxy Foams Prepared by Solid-State Foaming Technique

3.6. Morphology of Epoxy Foams

3.7. The Role of Storage Modulus in the Solid-State CO2-Foaming Technique

3.8. Proposal of the Relationship between Storage Modulus at Foaming Temperature and Density

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Breiss, H.; El Assal, A.; Benzerga, R.; Sharaiha, A.; Jrad, A.; Harmouch, A. Ultra-porous and lightweight microwave absorber based on epoxy foam loaded with long carbon fibers. Mater. Res. Bull. 2021, 137, 111188. [Google Scholar] [CrossRef]

- Klempner, D.; Frisch, K.C. Handbook of Polymeric Foams and Foam Technology; Carl Hanser Verlag: Munich, Germany; Vienna, Austria; New York, NY, USA; Barcelona, Spain, 1991; ISBN 3-446-15097-8. [Google Scholar]

- Kurek, K.; Bledzki, A. Mechanical behavior of polyurethane- and epoxy foams and their glass fiber composites. Mech. Compos. Mater. 1994, 30, 105–109. [Google Scholar] [CrossRef]

- Du, N.U.L.; Teo, S.C. Oil palm biomass-reinforced palm oil based polyurethane composite foam and structural sandwich. In Oil Palm: Production, Impacts and Challenges; Wong, M.Y., Ed.; Nova Science Publisher, Inc.: New York, NY, USA, 2018; pp. 251–287. ISBN 978-1-53613-879-5. [Google Scholar]

- Aalto-Korte, K.; Engfeldt, M.; Estlander, T.; Jolanki, R. Polyurethane Resins. In Kanerva’s Occupational Dermatology; John, S., Johansen, J., Rustemeyer, T., Elsner, P., Maibach, H., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Fregni, S.; Fanget, A. Superior processing new all-MDI solutions for automotive seating with low emission of volatile organic compound (VOC). In Proceedings of the Polyurethanes Technical Conference, Houston, TX, USA, 28–30 March 2000; pp. 1–17. [Google Scholar]

- Owen, C.M.; Beck, M.H. Occupational allergic contact dermatitis from phenol-formaldehyde resins. Contact Dermat. 2001, 45, 294–295. [Google Scholar] [CrossRef] [PubMed]

- Lan, D.N.U.; Fauzi, M.S.; Viet, C.X.; Raps, D.; Altstädt, V. Viscoelastic epoxy foams by an aqueous emulsion foaming process. J. Cell. Plast. 2019, 56, 105–118. [Google Scholar] [CrossRef]

- Mazzon, E.; Habas-Ulloa, A.; Habas, J.-P. Lightweight rigid foams from highly reactive epoxy resins derived from vegetable oil for automotive applications. Eur. Polym. J. 2015, 68, 546–557. [Google Scholar] [CrossRef]

- Ismail, O.M.S.; Abdel Hameed, R.S. Environmental effects of volatile organic compounds on ozone layer. Adv. Appl. Sci. Res. 2013, 4, 264–268. [Google Scholar]

- Huang, R.; Li, P. Elastic behaviour and failure mechanism in epoxy syntactic foams: The effect of glass microballoon volume fractions. Compos. Part B Eng. 2015, 78, 401–408. [Google Scholar] [CrossRef]

- Yu, Q.; Zhao, Y.; Dong, A.; Li, Y. Mechanical properties of EPS filled syntactic foams prepared by VARTM. Compos. Part B Eng. 2018, 136, 126–134. [Google Scholar] [CrossRef]

- Samsudin, S.S.; Ariff, Z.M.; Zakaria, Z.; Bakar, A.A. Development and Characterization of Epoxy Syntactic Foam Filled with Epoxy Hollow Spheres. J. Exp. Polym. Let. 2011, 5, 653–660. [Google Scholar] [CrossRef]

- Shahapurkar, K.; Garcia, C.D.; Doddamani, M.; Kumar, G.C.M.; Prabhakar, P. Compressive behavior of cenosphere/epoxy syntactic foams in arctic conditions. Compos. Part. B Eng. 2018, 135, 253–262. [Google Scholar] [CrossRef]

- Geleil, A.; Hall, M.; Shelby, J. Hollow glass microspheres for use in radiation shielding. J. Non-Cryst. Solids 2006, 352, 620–625. [Google Scholar] [CrossRef]

- Raps, D.; Hossieny, N.; Park, C.B.; Altstädt, V. Past and present developments in polymer bead foams and bead foaming technology. Polymer 2015, 56, 5–19. [Google Scholar] [CrossRef]

- Bethke, C.; Goedderz, D.; Weber, L.; Standau, T.; Döring, M.; Altstädt, V. Improving the flame-retardant property of bottle-grade PET foam made by reactive foam extrusion. J. Appl. Polym. Sci. 2020, 137, 49042. [Google Scholar] [CrossRef] [Green Version]

- Raps, D.; Köppl, T.; Anda ARde Altstädt, V. Rheological and crystallisation behaviour of high melt strength polypropylene under gas-loading. Polymer 2014, 55, 1537–1545. [Google Scholar] [CrossRef]

- Bethke, C.; Sanchez-Vazquez, S.A.; Raps, D.; Bakis, G.; Bard, S.; Du Ngoc, U.L.; Volker, A. Effect of Resin and Blocked/Unblocked Hardener Mixture on the Production of Epoxy Foams with CO2 Blocked Hardener in Batch Foaming Process. Polymers 2019, 11, 793. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ito, A.; Semba, T.; Taki, K.; Ohshima, M. Effect of the molecular weight between crosslinks of thermally cured epoxy resins on the CO2-bubble nucleation in a batch physical foaming process. J. Appl. Polym. Sci. 2014, 131, 40407. [Google Scholar] [CrossRef]

- Lyu, J.; Liu, T.; Xi, Z.; Zhao, L. Effect of pre-curing process on epoxy resin foaming using carbon dioxide as blowing agent. J. Cell. Plast. 2016, 53, 181–197. [Google Scholar] [CrossRef]

- Sea, B.I.; Lan, D.N.U.; Ong, H.L. Production of epoxy spherical mesoporous as a spherical membrane separator. Microporous Mesoporous Mater. 2015, 204, 149–155. [Google Scholar] [CrossRef]

- Núñez, L.; Gómez-Barreiro, S.; Gracia-Fernández, C.A. Study of the influence of isomerism on the curing properties of the epoxy system DGEBA(n = 0)/1,2-DCH by rheology. Rheol. Acta 2005, 45, 184–191. [Google Scholar] [CrossRef]

- Ekbote, R.P.; Donley, G.J.; Liu, D.Y.; Rogers, S.A.; Krogstad, D.V. Re-entrant solid behavior of 3D-printable epoxy inks. Rheol. Acta 2020, 59, 631–638. [Google Scholar] [CrossRef]

- McAdams, L.V.; Gannon, J.A. Epoxy Resins. In Encyclopedia of Polymer Science and Engineering, 2nd ed.; Mark, H.F., Bikales, N.M., Overberger, C.G., Menges, G., Eds.; John Wiley & Son: New York, NY, USA; Chichester, UK; Brisbane, Australia; Toronto, ON, Canada; Singapore, 1985; Volume 6, pp. 322–382. [Google Scholar]

| 20 kPa | 30 kPa | 40 kPa | |||

|---|---|---|---|---|---|

| 60 °C | - | 45.0 | 46.0-gel | 47.5 | 48.7 |

| 70 °C | 27.2-gel | 27.5 | - | 29.7 | 30.3 |

| 80 °C | 14.0-gel | 15.0 | - | 15.3 | 15.6 |

| 60C20k | 60C30k | 60C40k | 70C20k | 70C30k | 70C40k | 80C20k | 80C30k | 80C40k * | |

|---|---|---|---|---|---|---|---|---|---|

| St.M30 °C, kPa | 279.0 | 512.0 | 538.0 | 397.0 | 577.0 | 597.0 | 619.0 | 642.0 | 687.0 |

| Tcross, °C | 53.9 | 52.8 | 48.7 | 47.3 | 47.3 | 47.3 | 45.5 | 44.5 | - |

| St.Mcrs, kPa | 71.4 | 115.8 | 249.9 | 264.4 | 268.6 | 383.9 | 475.0 | 621.5 | - |

| Tlow, °C | 71.3 | 72.3 | 74.4 | 71.8 | 72.4 | 74.4 | 74.4 | 74.4 | - |

| St. Mlow, kPa | 40.9 | 61.8 | 106.7 | 118.5 | 138.5 | 160.0 | 199.6 | 319.6 | - |

| Resin | 60C20k | 60C30k | 60C40k | 70C20k | 70C30k | 70C40k | 80C20k | 80C30k | 80C40k | |

|---|---|---|---|---|---|---|---|---|---|---|

| Tg, °C | −11.3 | 3.6 | 6.3 | 6.4 | 7.7 | 7.7 | 8.2 | 9.3 | 9.5 | 13.9 |

| Tonset, °C | 58.1 | 56.2 | 52.1 | 51.1 | 57.2 | 55.7 | 55.5 | 48.3 | 51.9 | 52.2 |

| % cure | - | 65.27 | 71.32 | 72.59 | 69.15 | 72.87 | 73.89 | 74.42 | 75.38 | 76.11 |

| 60C20k | 60C30k | 60C40k | 70C20k | 70C30k | 70C40k | 80C20k | 80C30k | 80C40k | |

|---|---|---|---|---|---|---|---|---|---|

| Mc | 5577.5 | 3348.1 | 2956.1 | 4130.8 | 2701.5 | 2544.6 | 2483.9 | 2283.9 | 2039.0 |

| CO2 % | 10.75 | 11.19 | 11.28 | 11.21 | 12.17 | 11.41 | 11.27 | 11.15 | 11.08 |

| f40 °C | f50 °C | f60 °C | f70 °C | f80 °C | f90 °C | f100 °C | |

|---|---|---|---|---|---|---|---|

| 60C20k | 0.56 | 0.56 | 0.54 | 0.44 | 0.43 | 0.50 | 0.55 |

| 60C30k | 0.39 | 0.38 | 0.33 | 0.36 | 0.39 | 0.32 | 0.40 |

| 60C40k | 0.51 | 0.37 | 0.35 | 0.42 | 0.38 | 0.35 | 0.33 |

| 70C20k | 0.56 | 0.57 | 0.43 | 0.45 | 0.41 | 0.39 | 0.42 |

| 70C30k | 0.46 | 0.45 | 0.44 | 0.41 | 0.39 | 0.44 | 0.38 |

| 70C40k | 0.51 | 0.40 | 0.44 | 0.44 | 0.38 | 0.42 | 0.37 |

| 80C20k | 0.51 | 0.42 | 0.39 | 0.36 | 0.34 | 0.44 | 0.53 |

| 80C30k | 0.75 | 0.62 | 0.53 | 0.51 | 0.56 | 0.64 | 0.67 |

| 80C40k | 0.76 | 0.65 | 0.56 | 0.55 | 0.54 | 0.50 | 0.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, U.L.N.; Bethke, C.; Altstädt, V.; Ruckdäschel, H. New Insights on Expandability of Pre-Cured Epoxy Using a Solid-State CO2-Foaming Technique. Polymers 2021, 13, 2441. https://doi.org/10.3390/polym13152441

Du ULN, Bethke C, Altstädt V, Ruckdäschel H. New Insights on Expandability of Pre-Cured Epoxy Using a Solid-State CO2-Foaming Technique. Polymers. 2021; 13(15):2441. https://doi.org/10.3390/polym13152441

Chicago/Turabian StyleDu, Uy Lan Ngoc, Christian Bethke, Volker Altstädt, and Holger Ruckdäschel. 2021. "New Insights on Expandability of Pre-Cured Epoxy Using a Solid-State CO2-Foaming Technique" Polymers 13, no. 15: 2441. https://doi.org/10.3390/polym13152441

APA StyleDu, U. L. N., Bethke, C., Altstädt, V., & Ruckdäschel, H. (2021). New Insights on Expandability of Pre-Cured Epoxy Using a Solid-State CO2-Foaming Technique. Polymers, 13(15), 2441. https://doi.org/10.3390/polym13152441