Polypropylene Contamination in Post-Consumer Polyolefin Waste: Characterisation, Consequences and Compatibilisation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Prepatation of Virgin, Regranulate and Compatibilised Blends

2.3. Melting Enthalpy and FT-IR Band Ratio Characterisation and Calibration Curve Generation

2.4. Tensile (Impact) Mechanical Testing of the Virgin, Regranulate and Compatiblised Blends

2.5. Thermal Degradation Analysis of the Regranulate

2.6. Morphological and Elemental Analysis of the Regranulate and Compitablised Blends

3. Results and Discussion

3.1. Characterisation of Polypropylene Contamination in Post-Consumer Waste

3.2. Thermal Degradation Properties and Inorganic Content of Post-Consumer Waste

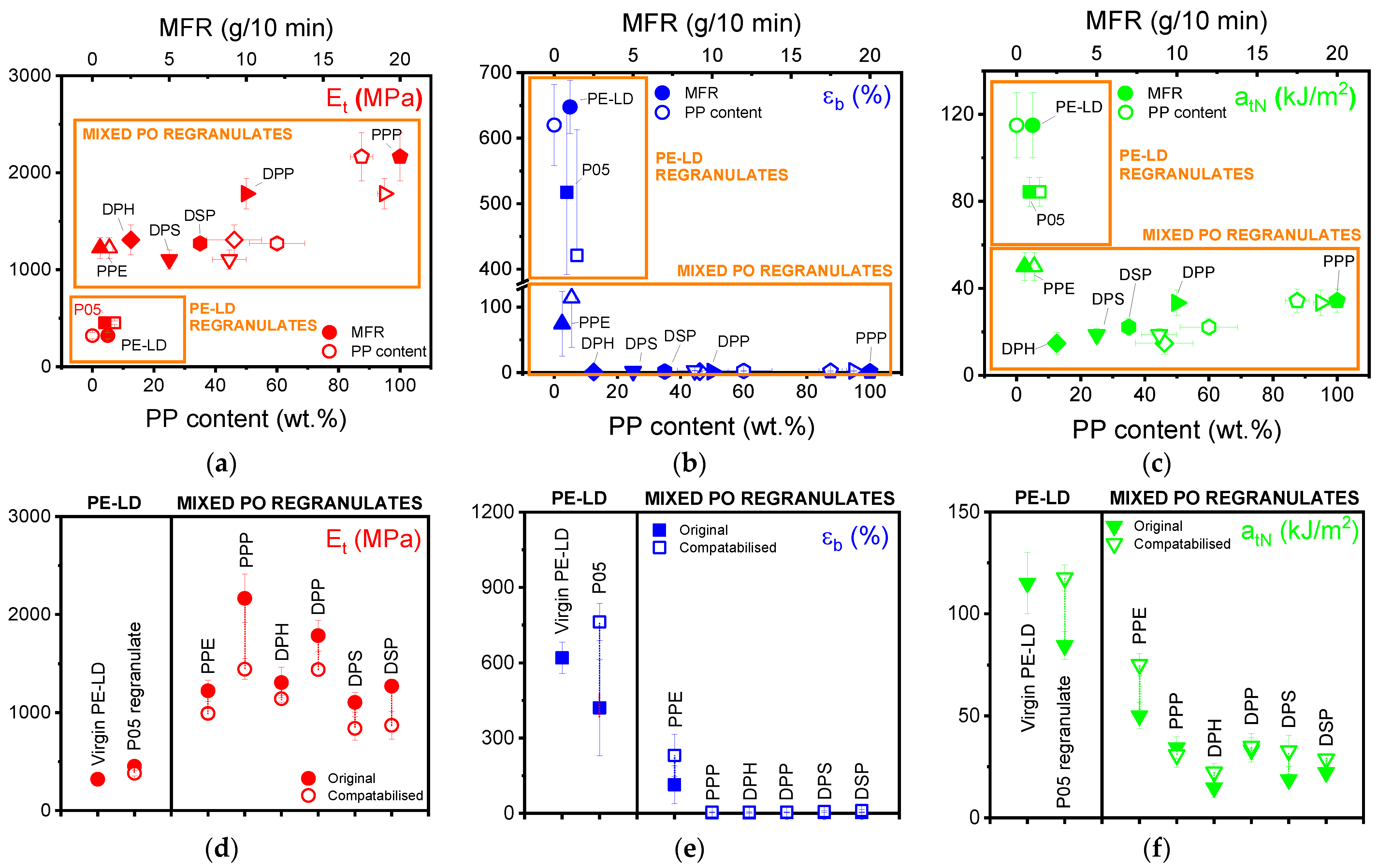

3.3. Effect of Polypropylene Contamination on Tensile and Tensile Impact Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions—A European Strategy for Plastics in a Circular Economy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2018%3A28%3AFIN (accessed on 15 June 2021).

- European Commission. Directive (EU). 2018/852 of the European Parliament and of the Council of 30 May 2018 Amending Directive 94/62/EC on Packaging and Packaging Waste. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:32018L0852 (accessed on 15 June 2021).

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, 1207–1221. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gall, M.; Freudenthaler, P.J.; Fischer, J.; Lang, R.W. Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates. Polymers 2021, 13, 1574. [Google Scholar] [CrossRef] [PubMed]

- Kazemi, Y.; Kakroodi, A.R.; Rodrigue, D. Compatibilization efficiency in post-consumer recycled polyethylene/polypropylene blends: Effect of contamination. Polym. Eng. Sci. 2015, 55, 2368–2376. [Google Scholar] [CrossRef]

- Archodoulaki, V.-M.; Jones, M.P. Recycling viability: A matter of numbers. Resour. Conserv. Recycl. 2021, 168, 105333. [Google Scholar] [CrossRef]

- Karaagac, E.; Koch, T.; Archodoulaki, V.M. The effect of PP contamination in recycled high-density polyethylene (rPE-HD) from post-consumer bottle waste and their compatibilization with olefin block copolymer (OBC). Waste Manag. 2021, 119, 285–294. [Google Scholar] [CrossRef] [PubMed]

- De Camargo, R.V.; Saron, C. Mechanical–Chemical recycling of low-density polyethylene waste with polypropylene. J. Polym. Environ. 2020, 28, 794–802. [Google Scholar] [CrossRef]

- Satya, S.K.; Sreekanth, P.S.R. An experimental study on recycled polypropylene and high-density polyethylene and evaluation of their mechanical properties. Mater. Today Proc. 2020, 27, 920–924. [Google Scholar] [CrossRef]

- Gall, M.; Lang, R.W.; Fischer, J.; Niehoff, A.; Schmidt, S. Characterization of post-use polyethylene and polypropylene recyclate blends for pipe applications. In Proceedings of the 19th Plastic Pipes Conference PPXIX, Las Vegas, NV, USA, 24–26 September 2018. [Google Scholar]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Signoret, C.; Caro-Bretelle, A.-S.; Lopez-Cuesta, J.-M.; Ienny, P.; Perrin, D. MIR spectral characterization of plastic to enable discrimination in an industrial recycling context: II. Specific case of polyolefins. Waste Manag. 2019, 98, 160–172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Camacho, W.; Karlsson, S. NIR, DSC, and FTIR as quantitative methods for compositional analysis of blends of polymers obtained from recycled mixed plastic waste. Polym. Eng. Sci. 2001, 41, 1626–1635. [Google Scholar] [CrossRef]

- Kisiel, M.; Mossety-Leszczak, B.; Frańczak, A.; Szczęch, D. Quantitative analysis of the polymeric blends. Prog. Rubber Plast. Recycl. Technol. 2019, 35, 75–89. [Google Scholar] [CrossRef]

- Luijsterburg, B.; Goossens, H. Assessment of plastic packaging waste: Material origin, methods, properties. Resour. Conserv. Recycl. 2014, 85, 88–97. [Google Scholar] [CrossRef]

- Larsen, Å.G.; Olafsen, K.; Alcock, B. Determining the PE fraction in recycled PP. Polym. Test. 2021, 96, 107058. [Google Scholar] [CrossRef]

- The International Organization for Standardization. ISO 1133-1:2011 Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method; The International Organization for Standardization: London, UK, 2011. [Google Scholar]

- ASTM International. ASTM D7399-18 Standard Test Method for Determination of the Amount of Polypropylene in Polypropylene/Low Density Polyethylene Mixtures Using Infrared Spectrophotometry; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Higgins, F. Determination of Percent Polyethylene in Polyethylene/Polypropylene Blends Using Cast Film FTIR Techniques; Agilent Technologies: Danbury, CT, USA, 2012. [Google Scholar]

- The International Organization for Standardization. ISO 527-2:2012 Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics; The International Organization for Standardization: London, UK, 2012. [Google Scholar]

- The International Organization for Standardization. ISO 8256:2004 Plastics—Determination of Tensile-Impact Strength; The International Organization for Standardization: London, UK, 2004. [Google Scholar]

- Kyu, T.; Hu, S.R.; Stein, R.S. Characterization and properties of polyethylene blends II. Linear low-density with conventional low-density polyethylene. J. Polym. Sci. Part B Polym. Phys. 1987, 25, 89–103. [Google Scholar] [CrossRef]

- Garofalo, E.; Di Maio, L.; Scarfato, P.; Di Gregorio, F.; Incarnato, L. Reactive compatibilization and melt compounding with nanosilicates of post-consumer flexible plastic packagings. Polym. Degrad. Stab. 2018, 152, 52–63. [Google Scholar] [CrossRef]

- Siesler, H.W. Infrared and Raman spectroscopy of polymers. In Practical Spectroscopy; Marcel Dekker Inc.: New York, NY, USA, 1980; Volume 4. [Google Scholar]

- Kamleitner, F.; Duscher, B.; Koch, T.; Knaus, S.; Archodoulaki, V.-M. Long chain branching as an innovative up-cycling process of polypropylene post-consumer waste—Possibilities and limitations. Waste Manag. 2017, 68, 32–37. [Google Scholar] [CrossRef] [PubMed]

| Calibration Curve | Material | Sample Compositions | Regranulates Analysed with Curve |

|---|---|---|---|

| PP type | PE-LD 290E | PE-LD with 2, 5, 8, 10, 12, 15, 20 and 25 wt.% PP | P01 (Table 2) |

| PP 601CF | |||

| PP HC600TF | |||

| PP HA104E | |||

| PP BA202E | |||

| PP RD208CF | |||

| PE-LD regranulate | PE-LD 290E | PE-LD with 2, 5, 8, 10, 12, 15, 20 and 25 wt.% PP | P01, P03, P05 (Table 3) |

| PP HF700SA | |||

| Mixed PO regranulate | PE-HD GF4750 | PE-HD with 2, 8, 10, 20, 30, 40, 50 60, 70, 80, 90, 92, 95 and 98 wt.% PP | PPE, PPP, DPH, DPP, DPS, DSP (Table 3) |

| PP HF700SA |

| Method | Type | Material | MFR (g/10 min) | Crystallinity (%) | Equation | PP in P01 (wt.%) |

|---|---|---|---|---|---|---|

| Melting enthalpy | Homo | PP HD601CF | 8.0 | 45.4 ± 1.5 | 3.88 ± 0.26 | |

| PP HC600TF | 2.8 | 44.0 ± 1.6 | 3.40 ± 0.09 | |||

| PP HA104E | 0.8 | 42.7 ± 0.5 | 3.47 ± 0.09 | |||

| Block | PP BA202E | 0.3 | 37.3 ± 0.2 | 4.15 ± 0.14 | ||

| Random | PP RD208CF | 8.0 | 33.9 ± 0.1 | 8.91 ± 0.39 | ||

| FT-IR band ratio | Homo | PP HD601CF | 8.0 | 45.4 ± 1.5 | 3.69 ± 0.90 | |

| Block | PP BA202E | 0.3 | 37.3 ± 0.2 | 3.85 ± 0.87 | ||

| Random | PP RD208CF | 8.0 | 33.9 ± 0.1 | 5.30 ± 0.90 |

| Type | Material | MFR (g/10 min) | Calculated PP Content (wt.%) | |

|---|---|---|---|---|

| Melting Enthalpy | FT-IR Band Ratio | |||

| PE-LD regranulate | Regranulate P01-1 | 0.8 a | 3.0 ± 0.9 | 2.7 ± 1.7 |

| Regranulate P01-2 | 3.1 ± 0.8 | 4.6 ± 0.2 | ||

| Regranulate P01–3 | 2.6 ± 0.8 | 4.5 ± 0.6 | ||

| Regranulate P03-1 | 5.9 ± 0.5 | 6.5 ± 0.1 | ||

| Regranulate P03-2 | 5.6 ± 0.5 | 7.2 ± 0.7 | ||

| Regranulate P03-3 | 5.7 ± 0.7 | 6.8 ± 0.3 | ||

| Regranulate P05-1 | 6.1 ± 2.8 | 7.3 ± 1.3 | ||

| Regranulate P05-2 | 6.4 ± 1.7 | 7.4 ± 0.2 | ||

| Regranulate P05-3 | 4.6 ± 1.3 | 6.9 ± 2.4 | ||

| Mixed PO regranulate | Purpolen PE (PPE) | 0.5 a | 6.9 ± 5.3 | 5.5 ± 1.2 |

| Purpolen PP (PPP) | 20 b | 91.4 ± 0.8 | 87.5 ± 3.7 | |

| Dipolen H (DPH) | 2.5 a | 70.1 ± 1.9 | 46.1 ± 9.0 | |

| Dipolen PP (DPP) | 10 b | 93.8 ± 0.3 | 94.9 ± 2.3 | |

| Dipolen S (DPS) | 5 b | 67.9 ± 0.4 | 44.5 ± 5.5 | |

| Dipolen SP (DSP) | 7 b | 82.3 ± 0.6 | 60.0 ± 9.0 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karaagac, E.; Jones, M.P.; Koch, T.; Archodoulaki, V.-M. Polypropylene Contamination in Post-Consumer Polyolefin Waste: Characterisation, Consequences and Compatibilisation. Polymers 2021, 13, 2618. https://doi.org/10.3390/polym13162618

Karaagac E, Jones MP, Koch T, Archodoulaki V-M. Polypropylene Contamination in Post-Consumer Polyolefin Waste: Characterisation, Consequences and Compatibilisation. Polymers. 2021; 13(16):2618. https://doi.org/10.3390/polym13162618

Chicago/Turabian StyleKaraagac, Erdal, Mitchell P. Jones, Thomas Koch, and Vasiliki-Maria Archodoulaki. 2021. "Polypropylene Contamination in Post-Consumer Polyolefin Waste: Characterisation, Consequences and Compatibilisation" Polymers 13, no. 16: 2618. https://doi.org/10.3390/polym13162618

APA StyleKaraagac, E., Jones, M. P., Koch, T., & Archodoulaki, V.-M. (2021). Polypropylene Contamination in Post-Consumer Polyolefin Waste: Characterisation, Consequences and Compatibilisation. Polymers, 13(16), 2618. https://doi.org/10.3390/polym13162618