New Aspects on the Direct Solid State Polycondensation (DSSP) of Aliphatic Nylon Salts: The Case of Hexamethylene Diammonium Dodecanoate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Starting Materials

2.2. Polyamide Salt Preparation

2.3. Direct Solid-State Polymerization (DSSP)

2.3.1. Micro Scale (TGA) Runs

2.3.2. Laboratory Scale Runs

2.4. Characterization Techniques

2.4.1. Fourier Transform Infrared Spectroscopy (FT-IR)

2.4.2. Concentration of End Groups

2.4.3. Solution Viscometry

2.4.4. Thermal Properties

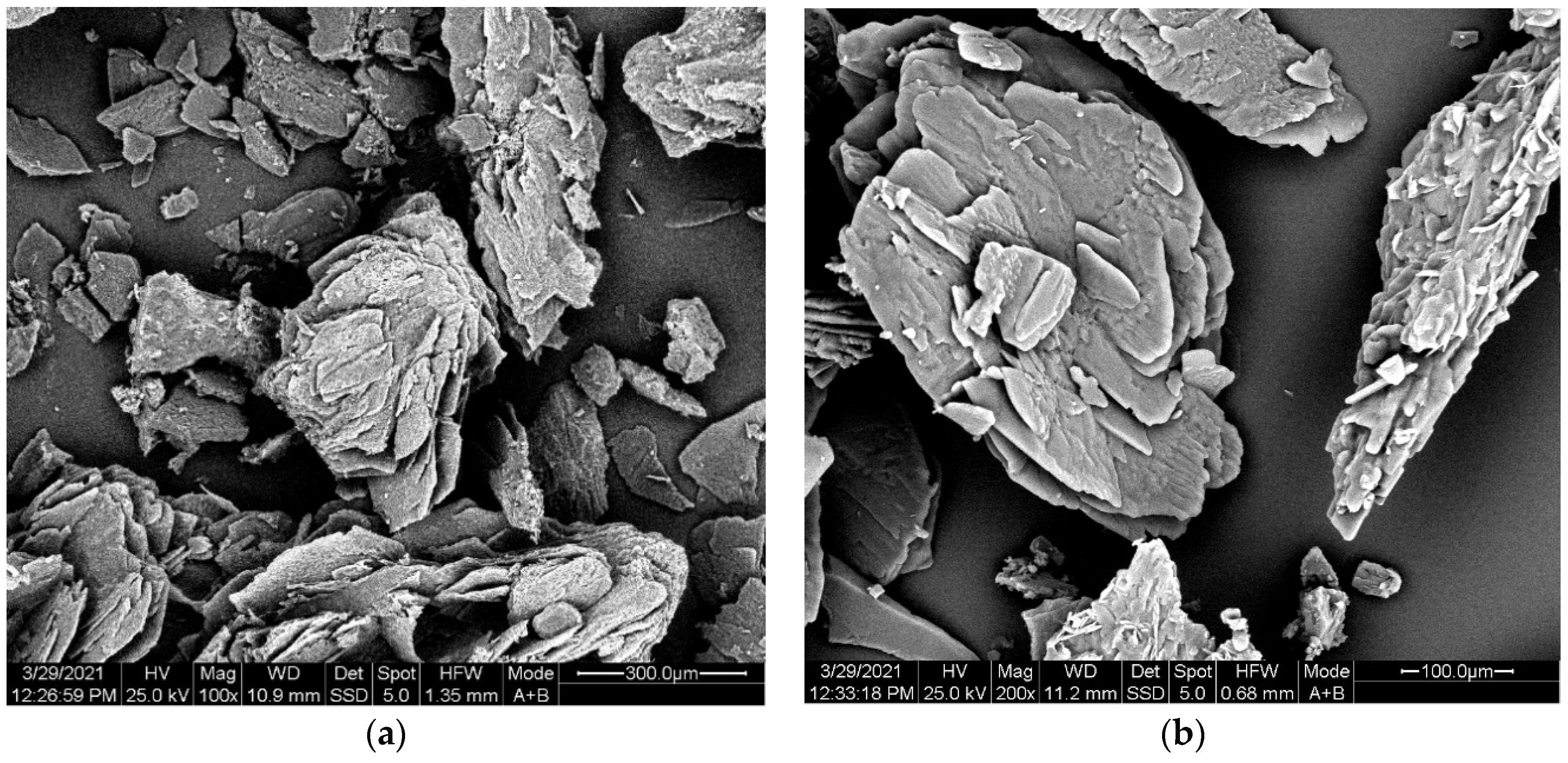

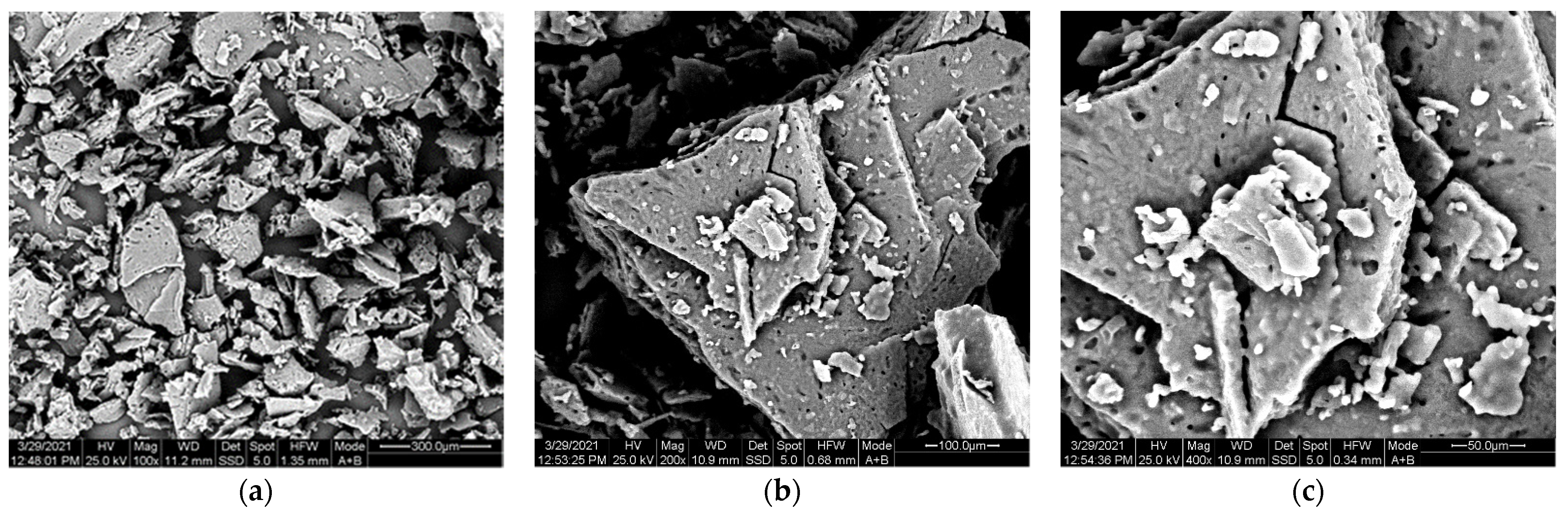

2.4.5. Scanning Electron Microscopy

3. Results

3.1. Polyamide Salts Preparation

3.2. DSSP in Micro Scale

3.2.1. TGA Runs

3.2.2. Characterization of TGA Products

3.3. DSSP in Laboratory Scale

3.3.1. Effect of Reactor Design: Scouting Experiments

3.3.2. DSSP in Reactor 2

3.3.2.1. Evaluation of Time–Temperature Profiles Tested

3.3.2.2. Effect of Nitrogen Flow Rate

3.3.3. Demonstration of a Feasible Two-Step DSSP Process

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kampouris, E.M. New solid state polyamidation process. Polymer 1976, 17, 409–412. [Google Scholar] [CrossRef]

- Papaspyrides, C.D.; Kampouris, E.M. Solid-state polyamidation of dodecamethylenediammonium adipate. Polymer 1984, 25, 791–796. [Google Scholar] [CrossRef]

- Kampouris, E.M.; Papaspyrides, C.D. Solid state polyamidation of nylon salts: Possible mechanism for the transition solid-melt. Polymer 1985, 26, 413–417. [Google Scholar] [CrossRef]

- Papaspyrides, C.D.; Kampouris, E.M. Influence of acid catalysts on the solid-state polyamidation of dodecamethylenediammonium adipate. Polymer 1986, 27, 1433–1436. [Google Scholar] [CrossRef]

- Papaspyrides, C.D.; Kampouris, E.M. Influence of metal catalysts on solid state polyamidation of nylon salts. Polymer 1986, 27, 1437–1440. [Google Scholar] [CrossRef]

- Papaspyrides, C.D. Solid-state Polyamidation of Hexamethylenediammonium Adipate in the Presence of Acid Catalysts. I. Preparation of the Catalyst Containing Monomer. J. Polym. Sci. Part C Polym. Lett. 1987, 25, 363–367. [Google Scholar] [CrossRef]

- Papaspyrides, C.D. Solid-state polyamidation of nylon salts. Polymer 1988, 29, 114–117. [Google Scholar] [CrossRef]

- Papaspyrides, C.D. Solid state polyamidation of aliphatic diamine aliphatic diacid salts: A generalized mechanism for the effect of polycondensation water on reaction behaviour. Polymer 1990, 31, 490–495. [Google Scholar] [CrossRef]

- Papaspyrides, C.D. Solid-state polyamidation of unsaturated nylon salts: The role of polycondensation water. Polymer 1990, 31, 496–500. [Google Scholar] [CrossRef]

- Papaspyrides, C.D. Solid State Polyamidation Processes. Polym. Int. 1992, 29, 293–298. [Google Scholar] [CrossRef]

- Katsikopoulos, P.V.; Papaspyrides, C.D. Solid-state Polyamidation of Hexamethylenediammonium Adipate. II. The Influence of Acid Catalysts. J. Polym. Sci. Part A Polym. Chem. 1994, 32, 451–456. [Google Scholar] [CrossRef]

- Papaspyrides, C.D. Solid State Polyamidation. In Polymeric Materials Encyclopedia; Salamone, J.C., Ed.; CRC Press: Boca Raton, FL, USA, 1996; pp. 7819–7831. [Google Scholar]

- Bletsos, I.V.; Papaspyrides, C.D. Low Water Diamine-Dicarboxylic Acid Salt Preparation. U.S. Patent 5,801,278, 1 February 1998. [Google Scholar]

- Tynan, D.G.; Papaspyrides, C.D.; Bletsos, I.V. Polymer Mixing Apparatus and Method. U.S. Patent 5,941,634, 24 August 1999. [Google Scholar]

- Papaspyrides, C.D.; Vouyiouka, S.N.; Bletsos, I.V. New Process for the Production of Dry Hexamethylenediammonium Adipate. J. Appl. Polym. Sci. 2003, 88, 1252–1257. [Google Scholar] [CrossRef]

- Papaspyrides, C.D.; Vouyiouka, S.N.; Bletsos, I.V. Preparation of Polyhexamethyleneadipamide Prepolymer by a Low-Temperature Process. J. Appl. Polym. Sci. 2004, 29, 301–306. [Google Scholar] [CrossRef]

- Vouyiouka, S.N.; Karakatsani, E.K.; Papaspyrides, C.D. Solid state polymerization. Prog. Polym. Sci. 2005, 30, 10–37. [Google Scholar] [CrossRef]

- Vouyiouka, S.N.; Papaspyrides, C.D.; Weber, J.; Marks, D. Polyamide Solid State Polymerization: Evaluation of Pertinent Kinetic Models. J. Appl. Polym. Sci. 2005, 97, 671–681. [Google Scholar] [CrossRef]

- Vouyiouka, S.N.; Papaspyrides, C.D.; Pfaendner, R. Catalyzed Solid-State Polyamidation. Macromol. Mater. Eng. 2006, 291, 1503–1512. [Google Scholar] [CrossRef]

- Papaspyrides, C.D.; Vouyiouka, S.N.; Bletsos, I.V. New aspects on the mechanism of the solid state polyamidation of PA 6,6 salt. Polymer 2006, 47, 1020–1027. [Google Scholar] [CrossRef]

- Vouyiouka, S.N.; Koumantarakis, E.; Papaspyrides, C.D. Preparation and Solid-State Polyamidation of Hexamethylenediammonium Adipate: The Effect of Sodium 5-Sulfoisophthalic Acid. J. Appl. Polym. Sci. 2007, 104, 1609–1619. [Google Scholar] [CrossRef]

- Vouyiouka, S.N.; Papaspyrides, C.D.; Weber, J.N.; Marks, D.N. Solid state post-polymerization of PA 6,6: The effect of sodium 5-sulfoisophthalic acid. Polymer 2007, 48, 4982–4989. [Google Scholar] [CrossRef]

- Fink, J.; Phaedner, R.; Simon, D.; Papaspyrides, C.; Vouyiouka, S. Process for the Preparation of Polyamides in the Presence of a Phosphonate. W.O. Patent 006,647-A1, 18 January 2007. [Google Scholar]

- Papaspyrides, C.; Vouyiouka, S. Solid State Polymerization; Papaspyrides, C.D., Vouyiouka, S.N., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009. [Google Scholar]

- Boussia, A.C.; Vouyiouka, S.N.; Porfiris, A.D.; Papaspyrides, C.D. Long-Aliphatic-Segment Polyamides: Salt Preparation and Subsequent Anhydrous Polymerization. Macromol. Mater. Eng. 2010, 295, 812–821. [Google Scholar] [CrossRef]

- Papaspyrides, C.; Vouyiouka, S. Encyclopedia of Polymer Science and Technology, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Boussia, A.C.; Konstantakopoulou, M.O.; Vouyiouka, S.N.; Papaspyrides, C.D. Nanocatalysis in Polyamide 6.6 Solid-State Polymerization. Macromol. Mater. Eng. 2011, 296, 168–177. [Google Scholar] [CrossRef]

- Papaspyrides, C.D.; Porfyris, A.D.; Vouyiouka, S.; Rulkens, R.; Grolman, E.; Vanden Poel, G. Solid state polymerization in a micro-reactor: The case of poly (tetramethylene terephthalamide). J. Appl. Polym. Sci. 2016, 1, 1–14. [Google Scholar] [CrossRef]

- Papaspyrides, C.D.; Porfyris, A.D.; Rulkens, R.; Grolman, E.; Kolkman, A.J. The Effect of Diamine Length on the Direct Solid State Polycondensation of Semi-Aromatic Nylon Salts. J. Polym. Sci. Part A Polym. Chem. 2016, 54, 2493–2506. [Google Scholar] [CrossRef]

- Porfyris, A.D.; Papaspyrides, C.D.; Rulkens, R.; Grolman, E. Direct solid state polycondensation of tetra- and hexa-methylenediammonium terephthalate: Scaling up from the TGA micro-reactor to a laboratory autoclave. J. Appl. Polym. Sci. 2017, 134, 45080. [Google Scholar] [CrossRef]

- Porfyris, A.D.; Vouyiouka, S.; Papaspyrides, C.; Rulkens, R.; Grolman, E.; Vanden Poel, G. Investigating alternative routes for semi-aromatic polyamide salt preparation: The case of tetramethylenediammonium terephthalate (4T salt). J. Appl. Polym. Sci. 2016, 42987, 1–11. [Google Scholar] [CrossRef]

- Volokhina, A.V.; Kudryavtsev, G.I.; Skurato, S.M.; Bonetskaya, A.K. The polyamidation process in the solid state. J. Polym. Sci. 1961, 53, 289–294. [Google Scholar] [CrossRef]

- Volokhina, A.; Kudryavstev, G.; Raeva, M.; Bogdanov, M.; Kalmykova, V.; Mandrosova, F.; Okromchedidze, N. Polycondensation reactions in the solid phase: V. Polycondensation of the diamine salts of therephthalic acid and hexahydroterephthalic acids in the solid state. Khim. Volokna. 1964, 6, 30–33. [Google Scholar]

- Pipper, G.; Mueller, W.F.; Dauns, H. Catalytic Solid State Process for the Preparation of Linear Polyamides. U.S. Patent 5,128,442, 7 July 1992. [Google Scholar]

- Kosinski, L.; Soelch, R.R. Low Temperature Nylon Polymerization Process. W.O. Patent 94/21711, 29 September 1994. [Google Scholar]

- Weber, J. Kirk-Othmer Encyclopedia of Chemical Technology; Wiley: New York, NY, USA, 1996; Volume 19, p. 463. [Google Scholar]

- Zheng, W.; McAuley, K.B.; Marchildon, E.K.; Yao, K.Z. Effects of End-Group Balance on Melt-Phase Nylon 612 Polycondensation: Experimental Study and Mathematical Model. Ind. Eng. Chem. Res. 2005, 44, 2675–2686. [Google Scholar] [CrossRef]

- Kumar, S.; Maiti, S.N.; Satapathy, B.K. Super-toughening polyamide-612 by controlling dispersed phase domain size: Essential work of fracture assessment. Mater. Des. 2014, 62, 382–391. [Google Scholar] [CrossRef]

- Rusu, G.; Rusu, E. Evaluation of thermal and dielectric behaviour of some anionic nylon 612 copolymers. Mater. Des. 2010, 31, 4601–4610. [Google Scholar] [CrossRef]

- Kumar, S.; Satapathy, B.K.; Maiti, S.N. Correlation of morphological parameters and mechanical performance of polyamide-612/poly (ethylene—octene) elastomer blends. Polym. Adv. Technol. 2013, 24, 511–519. [Google Scholar] [CrossRef]

- Song, P.; Wang, C.; Chen, L.; Zheng, Y.; Liu, L.; Wu, Q.; Huang, G.; Yu, Y.; Wang, H. Thermally stable, conductive and flame-retardant nylon 612 composites created by adding two-dimensional alumina platelets. Comp. Part A App. Sci. Manuf. 2017, 97, 100–110. [Google Scholar] [CrossRef]

- Billmeyer, F.W. Methods for Estimating Intrinsic Viscosity. J. Polym. Sci. 1949, 4, 83–86. [Google Scholar] [CrossRef]

- Shi, Y. Phase behavior of polyamide 6/612 blends. Plast. Eng. 2016, 72, 46–49. [Google Scholar] [CrossRef]

- Ikawa, I. High Pressure Solid State Polymerization of Polyamide Monomer Crystals. In Solid State Polymerization; Papaspyrides, C., Vouyiouka, S., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2009; p. 181. [Google Scholar]

- Cui, X.; Li, W.; Yan, D.; Yuan, C.; Di Silvestro, G. Synthesis and Characterization of Polyamides X 18. J. Appl. Polym. Sci. 2005, 98, 1565–1571. [Google Scholar] [CrossRef]

- Cui, X.; Yan, D. Synthesis and Characterization of Novel Odd—Even Nylons Based on Eicosanedioic Acid. J. Appl. Polym. Sci. 2004, 93, 2066–2071. [Google Scholar] [CrossRef]

- Cui, X.; Yan, D.; Xiao, D. Synthesis and characterization of novel polyamides based on tridecanedioic acid: Nylons 3 13, 5 13, 6 13, 7 13, 9 13, 10 13, 11 13. e-Polymers 2004, 13, 7–15. [Google Scholar] [CrossRef]

- Chen, G.; Tang, K.; Niu, G.; Pan, K.; Feng, X.; Zhang, L. Synthesis and Characterization of the Novel Nylon 12 6 Based on 1,12- Diaminododecane. Polym. Eng. Sci. 2019, 59, 192–197. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, P.H.; Spoljaric, S.; Seppälä, J. Redefining polyamide property profiles via renewable long-chain aliphatic segments: Towards impact resistance and low water absorption. Eur. Polym. J. 2018, 109, 16–25. [Google Scholar] [CrossRef]

- Patil, A.M. Synthesis and Characterization of Bio-based Polyester and Polyamide from Citric Acid and Mannitol. Orient. J. Chem. 2018, 34, 538–543. [Google Scholar] [CrossRef]

- Pagacz, J.; Raftopoulos, K.N.; Leszczyn, A.; Pielichowski, K. Bio-polyamides based on renewable raw materials. Glass transition and crystallinity studies. J. Therm. Anal. Calorim. 2016, 123, 1225–1237. [Google Scholar] [CrossRef] [Green Version]

- Larsen, H. Preparation of Salt Solution Useful for Making Nylon. U.S. Patent 4,442,260, 10 April 1984. [Google Scholar]

- Alsop, A.W.; Blanchard, E.N.; Cohen, J.D.; Young Lin, C.; Marks, D.N.; Stouffer, J.M. Process for Preparing Polyamides. U.S. Patent 6,069,228, 30 May 2000. [Google Scholar]

- Dujari, R.; Cramer, G.; Marks, D. Method for Solid Phase Polymerization. W.O. Patent 98/23666, 4 June 1998. [Google Scholar]

- Monroe, G.K. Solid Phase Polymerization of Polyamides. U.S. Patent 3,031,433, 24 April 1962. [Google Scholar]

- Greenewalt, C.E. Process for Preparing Linear Polyamides. U.S. Patent 2,245,129, 10 June 1941. [Google Scholar]

- Bush, G.E.; Schwier, C.E.; Lembcke, R.M.; Cook, S.W. Continuous Polyamidation Process. U.S. Patent 6,169,162 B1, 2 January 2001. [Google Scholar]

- Pipper, G. Process for the Production of Linear Polyamides. U.S. Patent 0455066 A1, 19 April 1991. [Google Scholar]

- Lang, J.J. Low Temperature Manufacturing Process for Nylon. W.O. Patent 96/16108, 30 June 1996. [Google Scholar]

- Papaspyrides, C.D.; Vouyiouka, S.; Georgousopoulou, I.N.; Marinkovic, S.; Estrine, B.; Joly, C.; Dole, P. Feasibility of Solid-state post polymerization on fossil- and bio-based poly (butylene succinate) including polymer upcycling routes. Ind. Eng. Chem. Res. 2016, 55, 5832–5842. [Google Scholar] [CrossRef]

- Flory, P. Principles of Polymer Chemistry; Cornell University Press: Ithaca, NY, USA, 1975; pp. 75–83, 317–325. [Google Scholar]

- Van Laarhoven, B.; Stoelwinder, C.J.C.; Helmsing, M. Process for Preparing a Polyamide, a Nylon Salt to Be Used Therein and a Process for Making the Salt. U.S. Patent 0210850 A1, 27 June 2017. [Google Scholar]

- Rulkens, R.; Grolman, E.; Poel Vanden, G.; Kierkels, R.; Cuypers, T.; Papaspyrides, C.; Porfyris, A. Process for Producing a Semi-Aromatic Semi-Crystalline Polyamide. W.O. Patent 2014/202506 A1, 24 December 2014. [Google Scholar]

- Kuehn, F.; Rulkens, R. Process for the Preparation of Polyamide Granules. W.O. Patent 0,056,803A1, 28 September 2000. [Google Scholar]

| TDSSP (°C) | t (h) | N2 Flow (mL min−1) | |

|---|---|---|---|

| Micro Scale DSSP | |||

| TGA_160_24_25 | 160 | 24 | 25 |

| TGA_165_6_25 | 165 | 6 | 25 |

| TGA_168_5_25 | 168 | 5 | 25 |

| TGA_170_5_25 | 170 | 5 | 25 |

| Laboratory Scale DSSP | |||

| Effect of Reactor Design: Scouting Experiments | |||

| R1_165_6_20 | 165 | 6 | 20 |

| R2_165_6_20 | 165 | 6 | 20 |

| Evaluation of Time-Temperature Profiles Tested | |||

| R2_160_24_20 | 160 | 24 | 20 |

| R2_165_6_20 | 165 | 6 | 20 |

| R2_168_5_20 | 168 | 5 | 20 |

| Effect of Nitrogen Flow Rate | |||

| R2_165_6_20 | 165 | 6 | 20 |

| R2_165_6_0 | 165 | 6 | 0 |

| Demonstration of a Feasible Two-Step DSSP | |||

| R2_165_6_0 | 165 | 6 | 0 |

| Post_SSP_170_4_0 | 170 | 4 | 0 |

| [NH3+]theor = [COO−]theοr (meq kg−1) | [COO−] (meq kg−1) | [NH3+] (meq kg−1) | D = [COO−] − [NH3+] (meq kg−1) | |

|---|---|---|---|---|

| Fossil-based PA 612 salt | 5772 | 5740 ±110 | 5680 ± 90 | 60 |

| Partly biobased PA 612 salt | 5772 | 5790 ± 100 | 5670 ± 22 | 120 |

| Boussia et al. PA612 salt [25] | 5772 | 5580 ± 100 | 5720 ± 60 | −140 |

| Commercial PA 66 salt | 7620 | 8170 ± 170 | 7650 ± 170 | 520 |

| Tm (°C) | ΔHm (J g−1) | Tstep1 (°C) | Tstep2 (°C) | mstep_1 (%) | |

|---|---|---|---|---|---|

| Fossil-based PA 612 salt | 189 | 167 | 199 | 449 | 84 |

| Bio-based PA 612 salt | 189 | 175 | 197 | 461 | 83 |

| Salt Grade | TDSSP (°C) | mloss (%) | t1/2 (h) |

|---|---|---|---|

| Fossil-based PA 612 salt | 160 | 12.7 | 3.1 |

| 165 | 11.9 | 1.8 | |

| 168 | 11.7 | 1.4 | |

| 170 | 11.9 | 1.2 | |

| Bio-based PA 612 salt | 160 | 11.6 | 5.3 |

| 165 | 10.6 | 3.1 | |

| 168 | 11.3 | 1.0 | |

| 170 | 11.8 | 1.1 |

| [η] (dL g−1) | (kg mol−1) * | D = [COOH] − [NH2] (meq kg−1) | ||||

|---|---|---|---|---|---|---|

| fossil | bio | fossil | bio | fossil | bio | |

| R1_165_6_20 | 0.713 ± 0.010 | 0.684 ± 0.021 | 5400 | 5800 | 143 | 267 |

| R2_165_6_20 | 0.251 ± 0.020 | 0.387 ± 0.021 | 1300 | 2700 | 217 | 402 |

| Tm (°C) | ΔHm (J g−1) | Xc (%) | Td (°C) | Td,5% (°C) | Residue (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| fossil | bio | fossil | bio | fossil | bio | fossil | bio | fossil | bio | fossil | bio | |

| R1_165_6_20 | 216 | 213 | 53 | 69 | 20 | 27 | 460 | 475 | 378 | 378 | 3 | 3 |

| R2_165_6_20 | 217 | 217 | 48 | 58 | 18 | 22 | 457 | 454 | 378 | 379 | 3 | 3 |

| [η] (dL g−1) | (kg mol−1) * | D = [COOH] − [NH2] (meq kg−1) | ||||

|---|---|---|---|---|---|---|

| fossil | bio | fossil | bio | fossil | bio | |

| R2_160_24_20 | 0.480 ± 0.002 | 0.610 ± 0.006 | 4800 | 5350 | 296 | 303 |

| R2_165_6_20 | 0.251 ± 0.020 | 0.387 ± 0.021 | 1300 | 2700 | 217 | 402 |

| R2_168_5_20 | 0.410 ± 0.035 | 0.475 ± 0.016 | 4550 | 3950 | 358 | 372 |

| Tm (°C) | ΔHm (J g−1) | Xc (%) | Td (°C) | Td,5% (°C) | Residue (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| fossil | bio | fossil | bio | fossil | bio | fossil | bio | fossil | bio | fossil | bio | |

| R2_160_24_20 | 220 | 217 | 50 | 69 | 19 | 27 | 455 | 448 | 374 | 378 | 3 | 3 |

| R2_165_6_20 | 217 | 217 | 48 | 58 | 18 | 22 | 457 | 454 | 378 | 379 | 3 | 3 |

| R2_168_5_20 | 209 | 218 | 58 | 48 | 22 | 19 | 453 | 448 | 376 | 380 | 2 | 3 |

| [η] (dL g−1) | (kg mol−1) * | D = [COOH] − [NH2] (meq kg−1) | ||||

|---|---|---|---|---|---|---|

| fossil | bio | fossil | bio | fossil | bio | |

| R2_165_6_20 | 0.251 ± 0.020 | 0.387 ± 0.021 | 1300 | 2700 | 217 | 402 |

| R2_165_6_0 | 0.448 ± 0.020 | 0.433 ± 0.085 | 2150 | 2050 | 208 | 320 |

| [η] (dL g−1) | (kg mol−1) * | D = [COOH] − [NH2] (meq kg−1) | |

|---|---|---|---|

| Fossil—based | |||

| R2_165_6_0 | 0.448 ± 0.020 | 2100 | 208 |

| Post_SSP_R2_170_4_0 | 0.522 ± 0.015 | 6350 | 87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mytara, A.D.; Porfyris, A.D.; Vouyiouka, S.N.; Papaspyrides, C.D. New Aspects on the Direct Solid State Polycondensation (DSSP) of Aliphatic Nylon Salts: The Case of Hexamethylene Diammonium Dodecanoate. Polymers 2021, 13, 2625. https://doi.org/10.3390/polym13162625

Mytara AD, Porfyris AD, Vouyiouka SN, Papaspyrides CD. New Aspects on the Direct Solid State Polycondensation (DSSP) of Aliphatic Nylon Salts: The Case of Hexamethylene Diammonium Dodecanoate. Polymers. 2021; 13(16):2625. https://doi.org/10.3390/polym13162625

Chicago/Turabian StyleMytara, Angeliki D., Athanasios D. Porfyris, Stamatina N. Vouyiouka, and Constantine D. Papaspyrides. 2021. "New Aspects on the Direct Solid State Polycondensation (DSSP) of Aliphatic Nylon Salts: The Case of Hexamethylene Diammonium Dodecanoate" Polymers 13, no. 16: 2625. https://doi.org/10.3390/polym13162625

APA StyleMytara, A. D., Porfyris, A. D., Vouyiouka, S. N., & Papaspyrides, C. D. (2021). New Aspects on the Direct Solid State Polycondensation (DSSP) of Aliphatic Nylon Salts: The Case of Hexamethylene Diammonium Dodecanoate. Polymers, 13(16), 2625. https://doi.org/10.3390/polym13162625