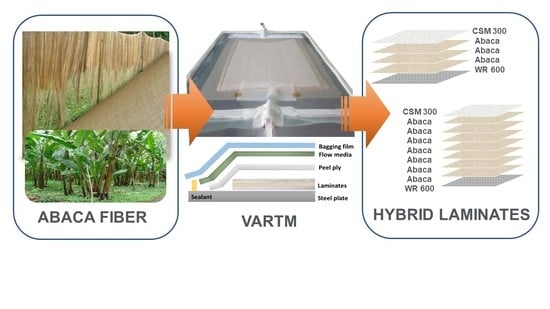

Mechanical Properties of Abaca–Glass Fiber Composites Fabricated by Vacuum-Assisted Resin Transfer Method

Abstract

Share and Cite

Paglicawan, M.A.; Emolaga, C.S.; Sudayon, J.M.B.; Tria, K.B. Mechanical Properties of Abaca–Glass Fiber Composites Fabricated by Vacuum-Assisted Resin Transfer Method. Polymers 2021, 13, 2719. https://doi.org/10.3390/polym13162719

Paglicawan MA, Emolaga CS, Sudayon JMB, Tria KB. Mechanical Properties of Abaca–Glass Fiber Composites Fabricated by Vacuum-Assisted Resin Transfer Method. Polymers. 2021; 13(16):2719. https://doi.org/10.3390/polym13162719

Chicago/Turabian StylePaglicawan, Marissa A., Carlo S. Emolaga, Johanna Marie B. Sudayon, and Kenneth B. Tria. 2021. "Mechanical Properties of Abaca–Glass Fiber Composites Fabricated by Vacuum-Assisted Resin Transfer Method" Polymers 13, no. 16: 2719. https://doi.org/10.3390/polym13162719

APA StylePaglicawan, M. A., Emolaga, C. S., Sudayon, J. M. B., & Tria, K. B. (2021). Mechanical Properties of Abaca–Glass Fiber Composites Fabricated by Vacuum-Assisted Resin Transfer Method. Polymers, 13(16), 2719. https://doi.org/10.3390/polym13162719