Mode II Fracture Analysis of GNP/Epoxy Nanocomposite Film on a Substrate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of GNP/Epoxy Nanocomposite

2.2. SEM Analysis

2.3. Nanoindentation Tests

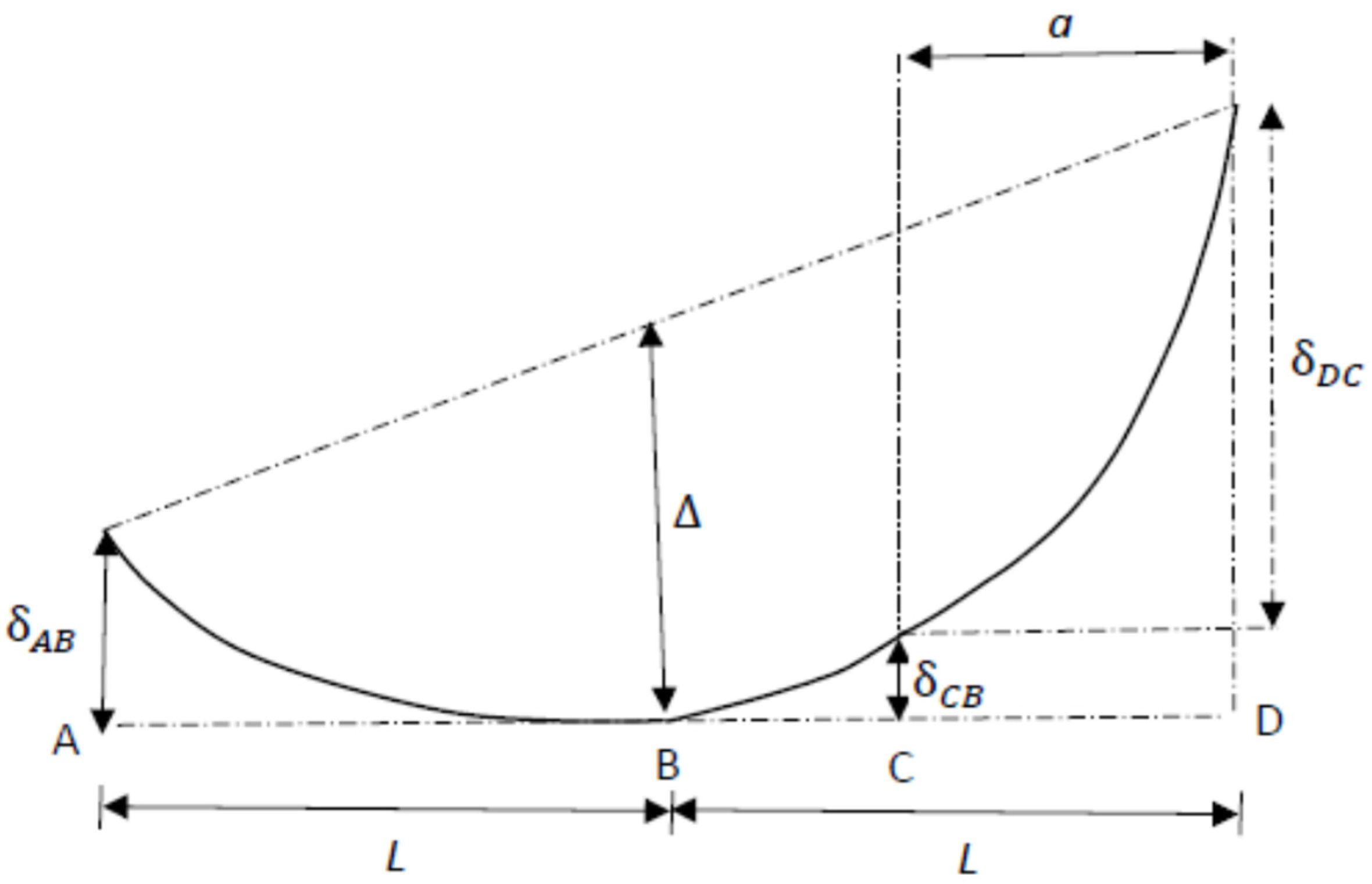

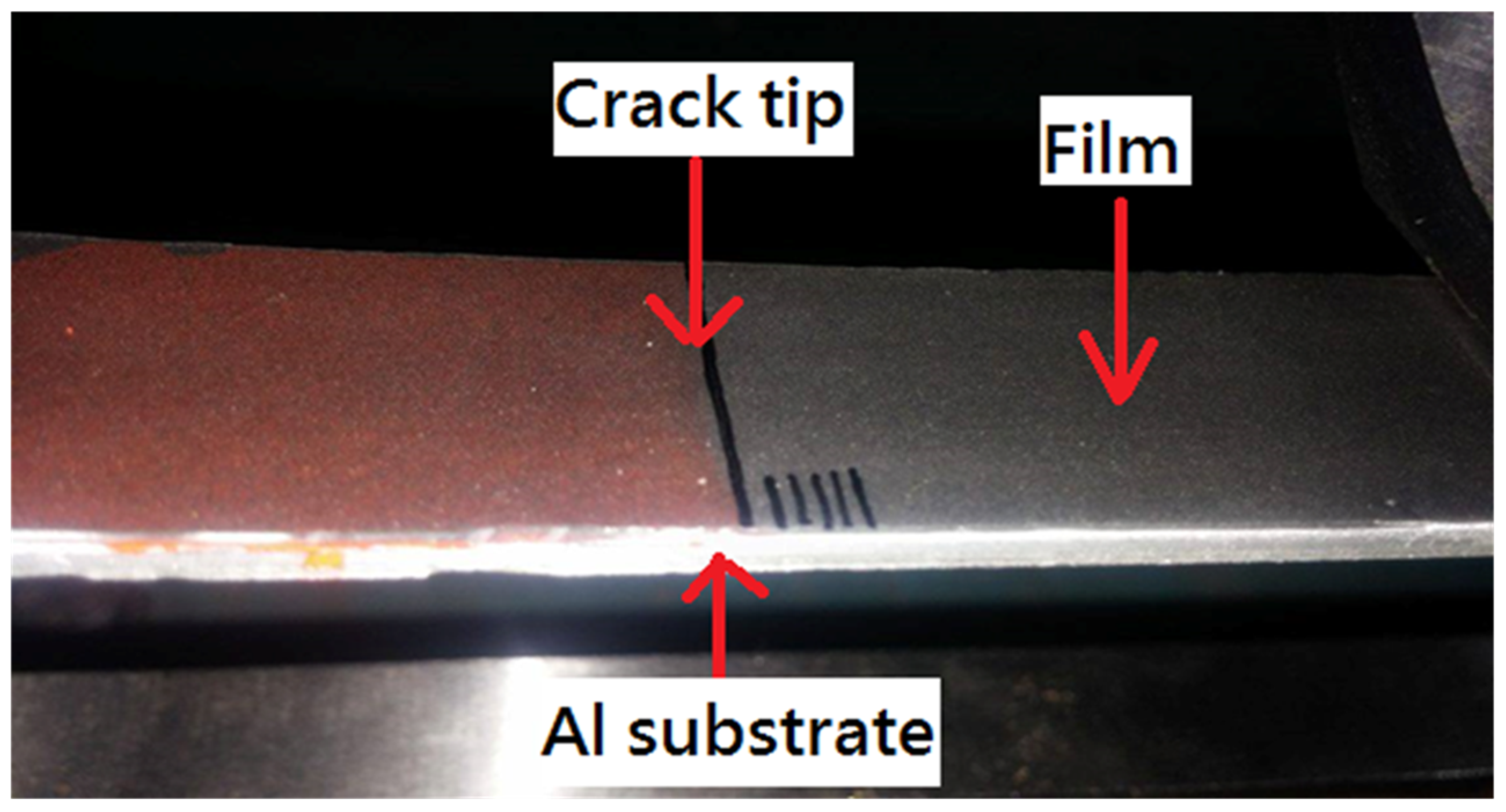

2.4. Mode II Fracture Analysis

3. Results and Discussion

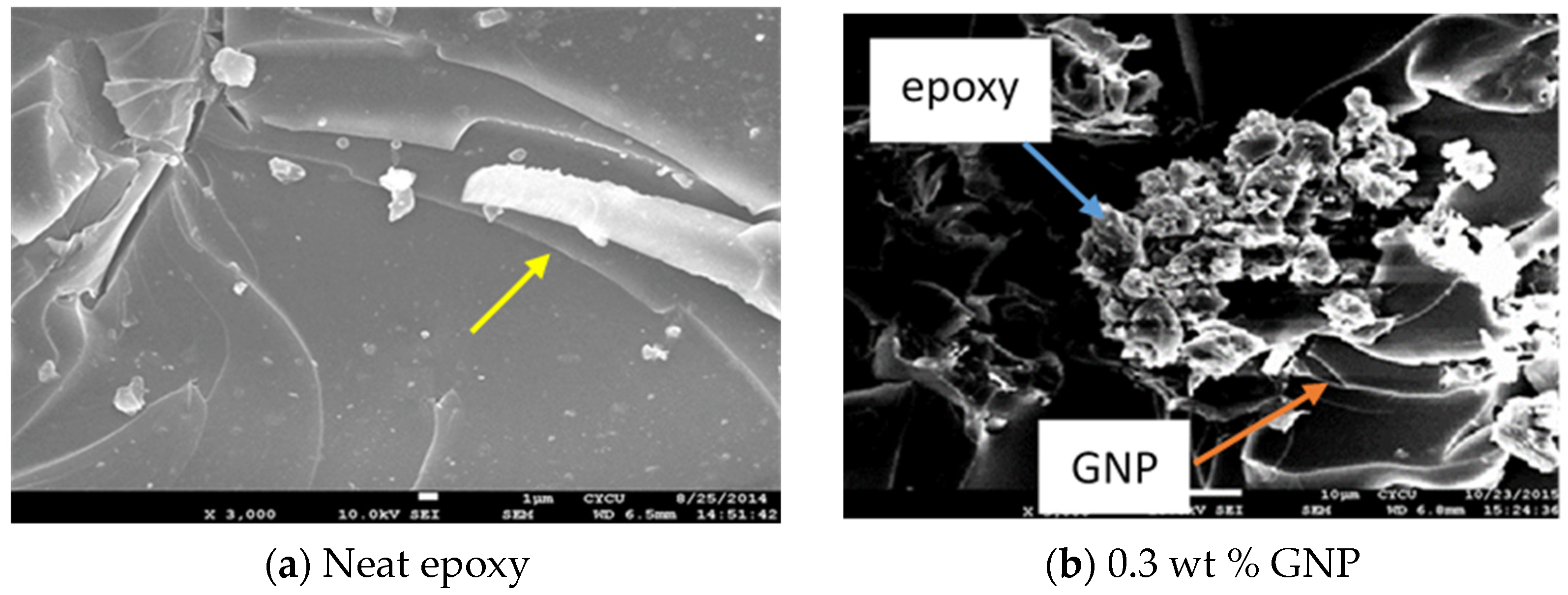

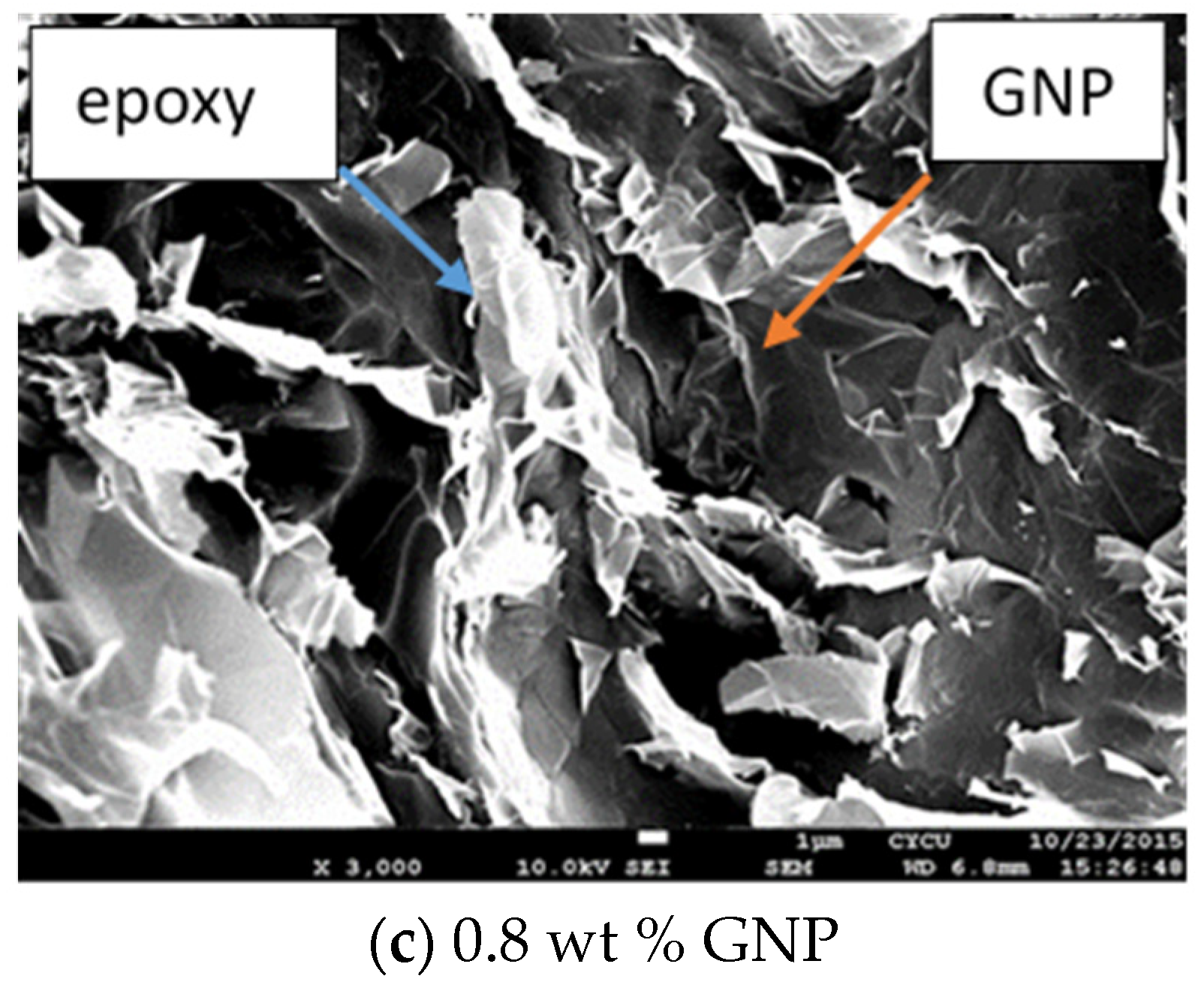

3.1. Surface Morphology

3.2. Hardness and Young’s Modulus

3.3. Mode II Strain Energy Release Rate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| displacement at the middle point of ENF test specimen | |

| displacement at left end of ENF test specimen | |

| displacement at crack tip of ENF test specimen | |

| displacement at right end of ENF test specimen | |

| flexural rigidity of the composite beam | |

| Young’s modulus of the film | |

| Young’s modulus of the substrate | |

| thickness of the film | |

| thickness of the substrate | |

| crack length | |

| mode II strain energy release rate | |

| critical load | |

| critical mode II strain energy release rate |

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigotieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–389. [Google Scholar] [CrossRef]

- Tsoukleri, G.; Parthenios, J.; Papagelis, K.; Jalil, R.; Ferrari, A.C.; Geim, A.K.; Novoselov, K.S.; Galiotis, C. Subjecting a graphene monolayer to tension and compression. Small 2009, 5, 2397–2402. [Google Scholar] [CrossRef] [Green Version]

- Teweldebrhan, D.; Lau, C.N.; Ghosh, S.; Balandin, A.A.; Bao, W.; Calizo, I.; Miao, F. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar]

- Neto, A.H.C.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Thostenson, E.T.; Chou, T.-W. Sensors and actuators based on carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2008, 68, 1227–1249. [Google Scholar] [CrossRef]

- Mirabedini, A.; Ang, A.; Nikzad, M.; Fox, B.; Lau, K.T.; Hameed, N. Evolving strategies for producing multiscale graphene-enhanced fiber-reinforced polymer composites for smart structural applications. Adv. Sci. 2020, 7, 1903501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miculescu, M.; Thakur, V.K.; Miculescu, F.; Voicu, S.I. Graphene-based polymer nanocomposite membranes: A review. Polym. Adv. Technol. 2016, 27, 844–859. [Google Scholar] [CrossRef]

- Anwar, Z.; Kausar, A.; Rafique, I.; Muhammad, B. Advances in epoxy/graphene nanoplatelet composite with enhanced physical properties: A review. Polym. Plast. Technol. Eng. 2016, 55, 643–662. [Google Scholar] [CrossRef]

- Zarasvand, K.A.; Golestanian, H. Investigating the effects of number and distribution of GNP layers on graphene reinforced polymer properties: Physical, numerical and micromechanical methods. Compos. Sci. Technol. 2017, 139, 117–126. [Google Scholar] [CrossRef]

- Cilento, F.; Marton, A.; Carbone, M.G.P.; Galiotis, C.; Giordano, M. Nacre-like GNP/Epoxy composites: Reinforcement efficiency vis-`a-vis graphene content. Compos. Sci. Technol. 2021, 211, 108873. [Google Scholar] [CrossRef]

- Zhang, Y.; Seveyrat, L.; Lebrun, L. Correlation between dielectric, mechanical properties and electromechanical performance of functionalized graphene/polyurethane nanocomposites. Compos. Sci. Technol. 2021, 211, 108843. [Google Scholar] [CrossRef]

- Wang, R.; Aakyiir, M.; Qiu, A.; Oh, J.-A.; Adu, P.; Meng, Q.; Ma, J. Surface-tunable, electrically conductive and inexpensive graphene platelets and their hydrophilic polymer nanocomposites. Polymer 2020, 205, 122851. [Google Scholar] [CrossRef]

- Song, P.; Liang, C.; Wang, L.; Qiu, H.; Gu, H.; Kong, J.; Gu, J. Obviously improved electromagnetic interference shielding performances for epoxy composites via constructing honeycomb structural reduced graphene oxide. Compos. Sci. Technol. 2019, 181, 107698. [Google Scholar] [CrossRef]

- Shadmand, Z.; Shahrouzi, J.R.; Chaboki, H.H. Design and fabrication of a graphene-based microcantilever flow sensor for liquid flow measurement. Sens. Actuators A 2021, 317, 112438. [Google Scholar] [CrossRef]

- Wei, Y.; Hu, X.; Jiang, Q.; Sun, Z.; Wang, P.; Qiu, Y.; Liu, W. Influence of graphene oxide with different oxidation levels on the properties of epoxy composites. Compos. Sci. Technol. 2018, 161, 74–84. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.H.; Vahid, S. Improving the fracture toughness and the strength of epoxy using nanomaterials—A review of the current status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef] [Green Version]

- Johnsen, B.B.; Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Sprenger, S. Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer 2007, 48, 530–541. [Google Scholar] [CrossRef]

- Wang, K.; Chen, L.; Wu, J.S.; Toh, M.L.; He, C.B.; Yee, A.F. Epoxy nanocomposites with highly exfoliated clay: Mechanical properties and fracture mechanisms. Macromolecules 2005, 38, 788–800. [Google Scholar] [CrossRef]

- Cha, J.; Jun, G.H.; Park, J.K.; Kim, J.C.; Ryu, H.J.; Hong, S.H. Improvement of modulus, strength and fracture toughness of CNT/Epoxy nanocomposites through the functionalization of carbon nanotubes. Compos. Part B 2017, 129, 169–179. [Google Scholar] [CrossRef]

- Park, T.T.; Qian, Y.Q.; Chan, C.; Suh, T.; Nejhad, M.G.; Macosko, C.W.; Stein, A. Epoxy toughening with low graphene loading. Adv. Funct. Mater. 2015, 25, 575–585. [Google Scholar] [CrossRef]

- Bortz, D.R.; Heras, E.G.; Martin-Gullon, I. Impressive fatigue life and fracture toughness improvements in graphene oxide/epoxy composites. Macromolecules 2012, 45, 238–245. [Google Scholar] [CrossRef]

- Li, Z.; Wang, R.G.; Young, R.J.; Deng, L.B.; Yang, F.; Hao, L.F.; Jiao, W.C.; Liu, W.B. Control of the functionality of graphene oxide for its in epoxy nanocomposites application. Polymer 2013, 54, 6437–6446. [Google Scholar] [CrossRef]

- Chen, L.; Chai, S.G.; Liu, K.; Ning, N.Y.; Gao, J.; Liu, Q.F.; Chen, F.; Fu, Q. Enhanced epoxy/silica composites mechanical properties by introducing graphene oxide to the interface. ACS Appl. Mater. Interfaces 2012, 4, 4398–4404. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.H.; Zhou, X.F.; Fan, X.Y.; Zhu, C.Y.; Yao, X.Y.; Liu, Z.P. Mechanical and thermal properties of epoxy resin nanocomposites reinforced with graphene oxide. Polym. Plast. Technol. Eng. 2012, 51, 251–256. [Google Scholar] [CrossRef]

- Jiang, T.; Kuila, T.; Kim, N.H.; Ku, B.C.; Lee, J.H. Enhanced mechanical properties of silanized silica nanoparticle attached graphene oxide/epoxy composites. Compos. Sci. Technol. 2013, 79, 115–125. [Google Scholar] [CrossRef]

- Liu, J.; Tang, J.; Gooding, J.J. Strategies for chemical modification of graphene and applications of chemically modified graphene. J. Mater. Chem. 2012, 22, 12435–12452. [Google Scholar] [CrossRef]

- Georgakilas, V.; Otyepka, M.; Bourlinos, A.B.; Chandra, V.; Kim, N.; Kemp, K.C.; Hobza, P.; Zboril, R.; Kim, K.S. Functionalization of graphene: Covalent and non-covalent approaches, derivatives and applications. Chem. Rev. 2012, 112, 6156–6214. [Google Scholar] [CrossRef]

- Wan, Y.-J.; Tang, L.-C.; Yan, D.; Zhao, L.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. Improved dispersion and interface in the graphene/epoxy composites via a facile surfactant-assisted process. Compos. Sci. Technol. 2013, 82, 60–68. [Google Scholar] [CrossRef]

- Tkalya, E.E.; Ghislandi, M.; de With, G.; Koning, C.E. The use of surfactants for dispersing carbon nanotubes and graphene to make conductive nanocomposites. Curr. Opin. Colloid Interface Sci. 2012, 17, 225–232. [Google Scholar] [CrossRef]

- Paramsothy, M. Dispersion, Interface, and Alignment of Carbon Nanotubes in Thermomechanically Stretched Polystyrene Matrix. JOM 2014, 66, 960–969. [Google Scholar] [CrossRef]

- Wang, X.; Jin, J.; Song, M. An investigation of the mechanism of graphene toughening epoxy. Carbon 2013, 65, 324–333. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Song, P.; Zhang, J.; Guo, Q.; Mai, Y.-W. Epoxy nanocomposites simultaneously strengthened and toughened by hybridization with graphene oxide and block ionomer. Compos. Sci. Technol. 2018, 168, 363–370. [Google Scholar] [CrossRef]

- Du, X.; Zhou, H.; Sun, W.; Liu, H.-Y.; Zhou, G.; Zhou, H.; Mai, Y.-W. Graphene/epoxy interleaves for delamination toughening and monitoring of crack damage in carbon fibre/epoxy composite laminate. Compos. Sci. Technol. 2017, 140, 123–133. [Google Scholar] [CrossRef]

- Qiu, J.; Wang, S. Enhancing Polymer Performance Through Graphene Sheet. J. Appl. Polym. Sci. 2011, 119, 3670–3674. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Sato, N.; Tölle, F.; Mülhaupt, R.; Fiedler, B.; Schulte, K. Fracture toughness and failure mechanism of graphene based epoxy composites. Compos. Sci. Technol. 2014, 97, 90–99. [Google Scholar] [CrossRef]

- Ahmadi-Moghadam, B.; Taheri, F. Fracture and toughening mechanisms of GNP-based nanocomposites in modes I and II fracture. Eng. Fract. Mech. 2014, 131, 329–339. [Google Scholar] [CrossRef]

- Srivastava, V.K.; Gries, T.; Veit, D.; Quadflieg, T.; Mohr, B.; Kolloch, M. Effect of nanomaterial on mode I and mode II interlaminar fracture toughness of woven carbon fabric reinforced polymer composites. Eng. Fract. Mech. 2017, 180, 73–86. [Google Scholar] [CrossRef]

- Jia, Z.; Feng, X.; Zou, Y. An investigation on mode II fracture toughness enhancement of epoxy adhesive using graphene nanoplatelets. Compos. Part B Eng. 2018, 155, 452–456. [Google Scholar] [CrossRef]

- Azevedo, J.C.S.; Campilho, R.D.S.G.; da Silva, F.J.G.; Faneco, T.M.S.; Lopes, R.M. Cohesive law estimation of adhesive joints in mode II condition. Theor. Appl. Fract. Mech. 2015, 80, 143–154. [Google Scholar] [CrossRef]

- Geng, Y.; Liu, M.Y.; Li, J.; Shi, X.M.; Kim, J.K. Effects of surfactant treatment on mechanical and electrical properties of CNT/epoxy nanocomposites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1876–1883. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Pharr, G.M.; Oliver, W.C.; Brotzen, F.B. On the generality of the relationship among contact stiffness contact area, and elastic modulus during indentation. J. Mater. Res. 1992, 7, 613–617. [Google Scholar] [CrossRef]

- Zhu, W.; Low, T.; Perebeinos, V.; Bol, A.A.; Zhu, Y.; Yan, H.; Tersoff, J.; Avouris, P. Structure and electronic transport in graphene wrinkles. Nano Lett. 2012, 12, 3431–3436. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seshadri, M.; Saigal, S. Crack bridging in polymer nanocomposites. J. Eng. Mech. 2007, 133, 911–918. [Google Scholar] [CrossRef]

- Chen, X.; Beyerlein, I.J.; Brinson, L.C. Curved-fiber pull-out model for nanocomposites. Part 2: Interfacial debonding and sliding. Mech. Mater. 2009, 41, 293–307. [Google Scholar] [CrossRef]

- Tang, L.C.; Zhang, H.; Sprenger, S.; Ye, L.; Zhang, Z. Fracture mechanisms of epoxy-based ternary composites filled with rigid-soft particles. Compos. Sci. Technol. 2012, 72, 558–565. [Google Scholar] [CrossRef]

- Tang, L.-C.; Wan, Y.-J.; Yan, D.; Pei, Y.-B.; Zhao, L.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon 2013, 60, 16–27. [Google Scholar] [CrossRef]

| GNP Contents | Hardness (GPa) | Young’s Modulus (GPa) |

|---|---|---|

| 0 wt % | 0.32 | 2.61 |

| 0.3 wt % | 0.42 | 2.98 |

| 0.5 wt % | 0.46 | 3.36 |

| 0.8 wt % | 0.49 | 3.55 |

| 1.9 wt % | 0.55 | 4.26 |

| GNP wt % | Specimen 1 | Specimen 2 | Specimen 3 | Average Strain Energy Release Rate (J/m2) | |||

|---|---|---|---|---|---|---|---|

| Critical Load (N) | Strain Energy Release Rate (J/m2) | Critical Load (N) | Strain Energy Release Rate (J/m2) | Critical Load (N) | Strain Energy Release Rate (J/m2) | ||

| 0% | 70.2 | 152.34 | 69.9 | 151.22 | 70 | 152.14 | 151.9 0.68 |

| 0.3% | 78.3 | 162.69 | 78.1 | 162.15 | 78.2 | 162.45 | 162.43 0.28 |

| 0.5% | 83.3 | 173.41 | 83.3 | 173.41 | 83.2 | 173.28 | 173.37 0.08 |

| 0.8% | 86.5 | 196.50 | 86.5 | 196.50 | 86.2 | 195.85 | 196.28 0.43 |

| 1% | 89 | 219.68 | 89 | 219.68 | 88.5 | 218.88 | 219.39 0.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Her, S.-C.; Zhang, K.-C. Mode II Fracture Analysis of GNP/Epoxy Nanocomposite Film on a Substrate. Polymers 2021, 13, 2823. https://doi.org/10.3390/polym13162823

Her S-C, Zhang K-C. Mode II Fracture Analysis of GNP/Epoxy Nanocomposite Film on a Substrate. Polymers. 2021; 13(16):2823. https://doi.org/10.3390/polym13162823

Chicago/Turabian StyleHer, Shiuh-Chuan, and Kai-Chun Zhang. 2021. "Mode II Fracture Analysis of GNP/Epoxy Nanocomposite Film on a Substrate" Polymers 13, no. 16: 2823. https://doi.org/10.3390/polym13162823

APA StyleHer, S.-C., & Zhang, K.-C. (2021). Mode II Fracture Analysis of GNP/Epoxy Nanocomposite Film on a Substrate. Polymers, 13(16), 2823. https://doi.org/10.3390/polym13162823