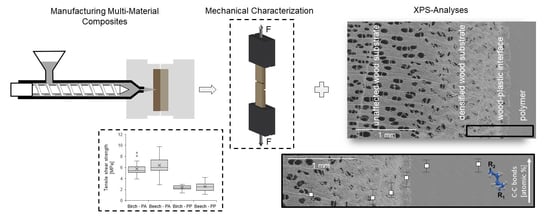

Interfacial Adhesion and Mechanical Properties of Wood-Polymer Hybrid Composites Prepared by Injection Molding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

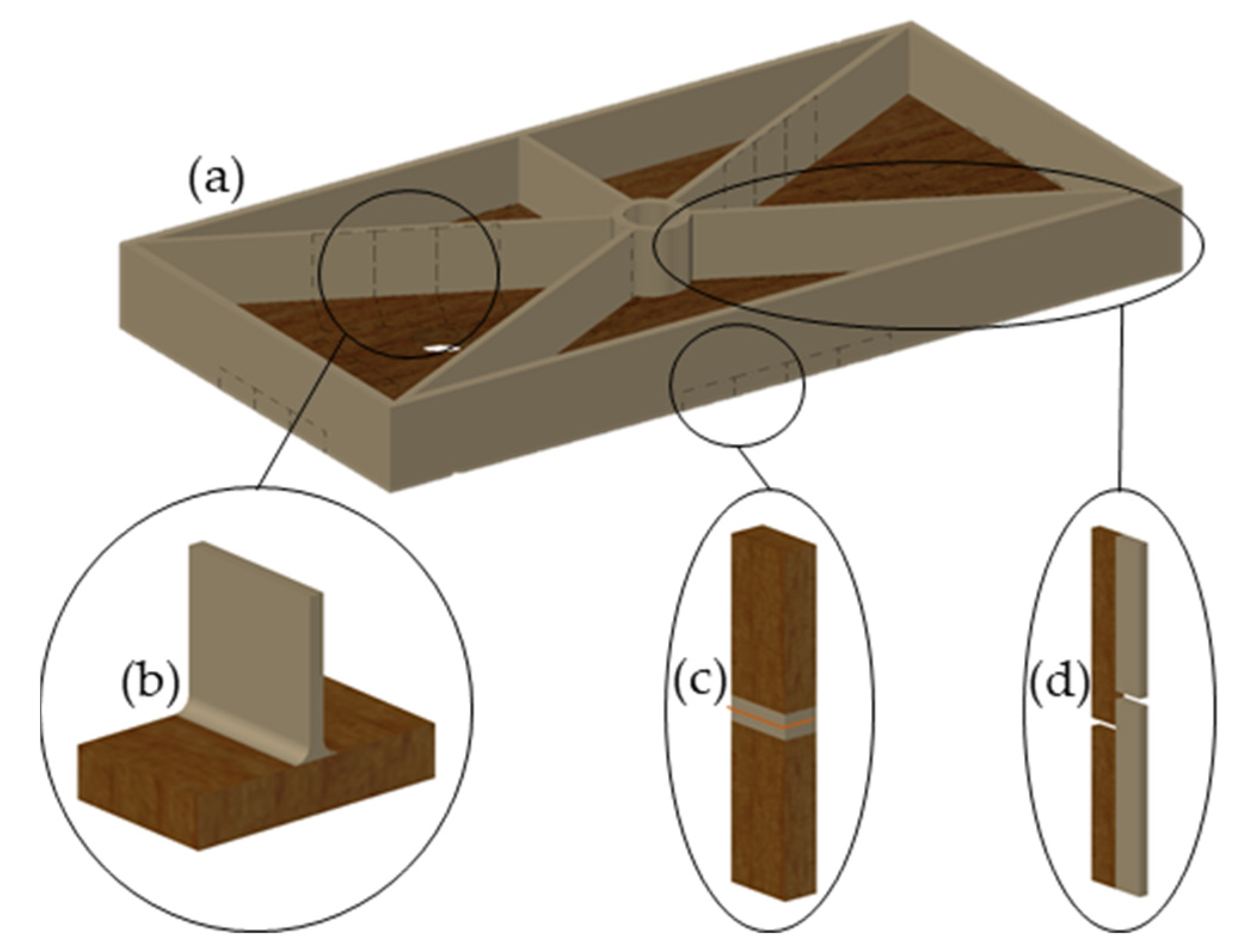

2.2. Plywood Composites

2.3. Solid Wood Composites

2.4. Mechanical Properties of Wood-Polymer Composites

2.5. Scanning Electron Microscopy (SEM) and X-ray Photoelectron Spectroscopy (XPS)

2.6. Statistics

3. Results and Discussion

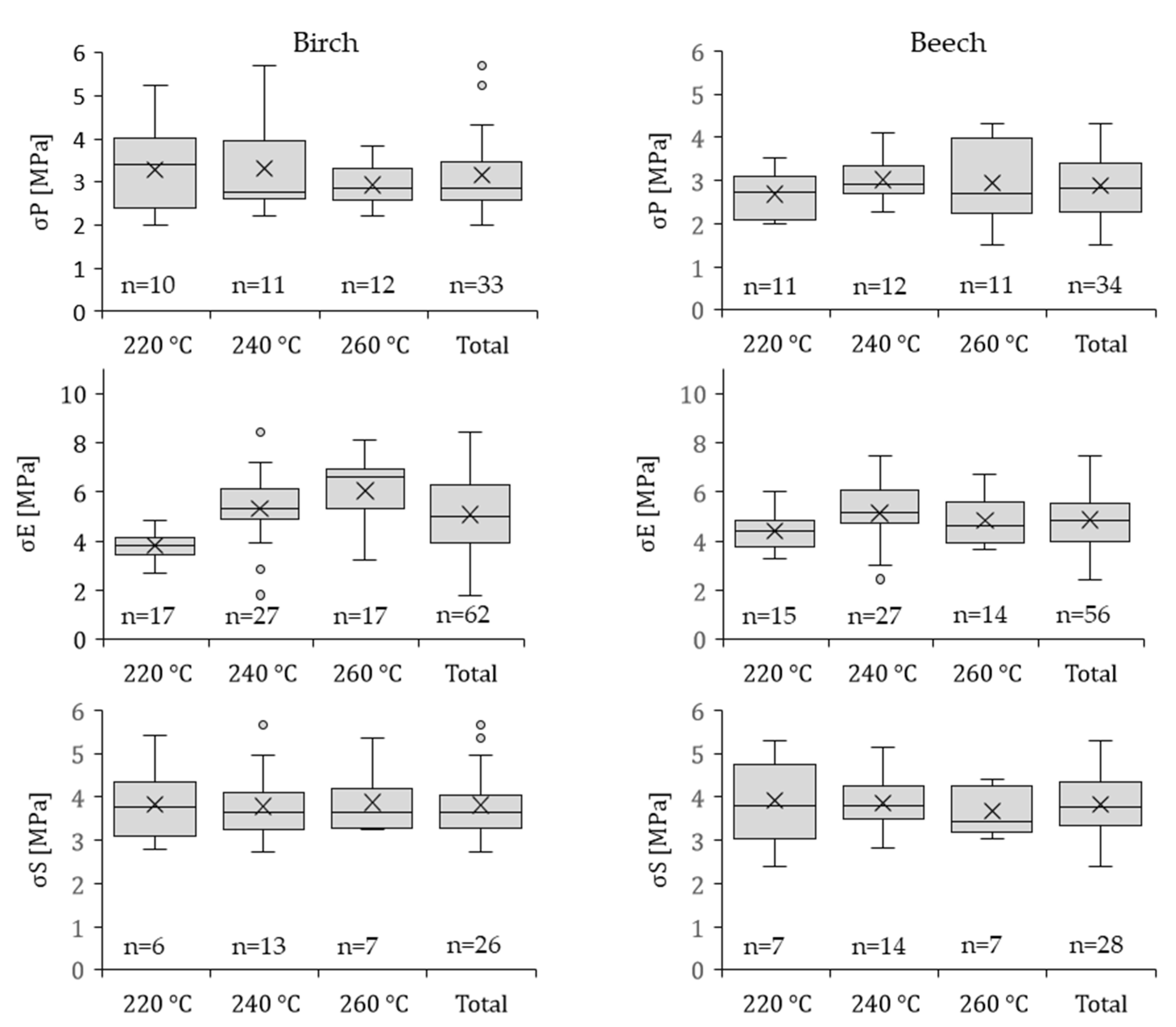

3.1. Mechanical Properties of Wood-Polymer Composites

3.1.1. Plywood-Polymer Composites

3.1.2. Solid Wood-Polymer Composites

3.2. Wood-Polymer Interfaces

3.2.1. Morphology of Wood Polymer Composites by SEM

3.2.2. Elemental Composition and Chemistry of the Interface in Wood-Polymer Composites

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Leitgeb, W.; Kerschbichler, S.; Jost, T.; Mayrhofer, P.; Wagner, W.; Müller, U. Holz im strukturellen Fahrzeugbau. In IHD, Konferenzproceedings—2; Interdisziplinäres Fahrzeugkolloquium: Dresden, Germany, 2016; pp. 1–118. [Google Scholar]

- Statistisches Bundesamt. Available online: https://www.destatis.de/Europa/DE/Thema/Umwelt-Energie/CO2_Strassenverkehr.html (accessed on 16 August 2021).

- Mair-Bauernfeind, C.; Zimek, M.; Asada, R.; Bauernfeind, D.; Baumgartner, R.J.; Stern, T. Prospective sustainability assessment: The case of wood in automotive applications. Int. J. Life Cycle Assess. 2020, 25, 2027–2049. [Google Scholar] [CrossRef]

- Franzini, F.; Berghäll, S.; Toppinen, A.; Toivonen, R. Comparing wood versus concrete: An explorative study of municipal civil servants’ beliefs about multistory building materials in Finland. For. Prod. J. 2021, 71, 65–76. [Google Scholar] [CrossRef]

- Asada, R.; Cardellini, G.; Mair-Bauernfeind, C.; Wenger, J.; Haas, V.; Holzer, D.; Stern, T. Effective bioeconomy? A MRIO-based socioeconomic and environmental impact assessment of generic sectoral innovations. Technol. Forecast. Soc. Change 2020, 153, 119946. [Google Scholar] [CrossRef]

- Mair, C.; Zimek, M.; Stern, T.; Baumgartner, R.J. Sustainability performance of wood-based materials: A systemic assessment of lightweight materials for the mobility sector. In Proceedings of the 24th Annual ISDRS Conference, Messina, Italy, 13–15 June 2018. [Google Scholar]

- Kohl, D.; Link, P.; Böhm, S. Wood as a Technical Material for Structural Vehicle Components. Procedia CIRP 2016, 40, 557–561. [Google Scholar] [CrossRef] [Green Version]

- Müller, U.; Feist, F.; Jost, T. Wood composites in the automotive industry of the future? Assumed crash tests and simulation of wood materials. Holztechnologie 2019, 5–15. Available online: https://www.woodcar.eu/wa_files/04_jost%20et%20al.%202018_final.pdf (accessed on 20 August 2021).

- Boland, C.S.; De Kleine, R.; Keoleian, G.A.; Lee, E.C.; Kim, H.C.; Wallington, T.J. Life cycle impacts of natural fiber composites for automotive applications: Effects of renewable energy content and lightweighting. J. Ind. Ecol. 2016, 20, 179–189. [Google Scholar] [CrossRef]

- De Melo, R.R.; Del Menezzi, C.H.S. Influence of veneer thickness on the properties of LVL from Paricá (Schizolobium amazonicum) plantation trees. Eur. J. Wood Wood Prod. 2014, 72, 191–198. [Google Scholar] [CrossRef]

- Dunky, M.; Niemz, P. Holzwerkstoffe und Leime; Springer: Berlin/Heidelberg, Germany, 2002; ISBN 9783642624759. [Google Scholar]

- Friedrich, H.E. Leichtbau in der Fahrzeugtechnik; Springer: Stuttgart, Germany, 2017; ISBN 3658122951. [Google Scholar]

- Luckeneder, G.; Autengruber, R.; Stellnberger, K.-H.; Kurz, J.F.T. Corrosion Protection of Galvanized Press-Hardening Steel: Main Influencing Factors and Mechanisms. In Proceedings of the Galvatech 2015 Conference Proceedings, Toronto, ON, Canada, 31 May–4 June 2015; pp. 868–875. [Google Scholar]

- Pritchard, G. Reinforced Plastics Durability; CRC Press: Cambridge, UK, 1999; ISBN 0849305470. [Google Scholar]

- Stadlmann, A.; Pramreiter, M.; Stingl, R.; Kurzböck, C.; Jost, T.; Müller, U. Durability of wood exposed to alternating climate test and natural weathering. Forests 2020, 11, 953. [Google Scholar] [CrossRef]

- Stadlmann, A.; Veigel, S.; Dornik, F.; Pramreiter, M.; Steiner, G.; Müller, U. Bond strength of different wood-plastic hybrid components prepared through back injection moulding. BioResources 2020, 15, 1050–1061. [Google Scholar] [CrossRef]

- Teaca, C.A.; Tanasa, F.; Zanoaga, M. Multi-component Polymer Systems Comprising Wood as Bio-based Component and Thermoplastic Polymer Matrices—An Overview. BioResources 2018, 13, 4728–4769. [Google Scholar] [CrossRef] [Green Version]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Gacitua, E.W.; Wolcott, M.P. Morphology of Wood Species Affecting Wood-Plastic Interaction: Mechanical Interlocking and Mechanical Properties. In Proceedings of the 9th International Conference on Wood and Biofiber Plastic Composites, Madison, WI, USA, 21–23 May 2007. [Google Scholar]

- Gacitua, W.; Wolcott, M. Morphology of wood species affecting wood-thermoplastic interaction: Microstructure and mechanical adhesion. Maderas. Cienc. Tecnol. 2009, 11, 217–231. [Google Scholar] [CrossRef]

- Sretenovic, A.; Müller, U.; Gindl, W. Mechanism of stress transfer in a single wood fibre-LDPE composite by means of electronic laser speckle interferometry. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1406–1412. [Google Scholar] [CrossRef]

- Keener, T.J.; Stuart, R.K.; Brown, T.K. Maleated coupling agents for natural fibre composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 357–362. [Google Scholar] [CrossRef]

- Correa, C.A.; Razzino, C.A.; Hage, E. Role of maleated coupling agents on the interface adhesion of polypropylene-wood composites. J. Thermoplast. Compos. Mater. 2007, 20, 323–339. [Google Scholar] [CrossRef]

- Fang, L.; Chang, L.; Guo, W.J.; Ren, Y.P.; Wang, Z. Preparation and characterization of wood-plastic plywood bonded with high density polyethylene film. Eur. J. Wood Wood Prod. 2013, 71, 739–746. [Google Scholar] [CrossRef]

- Chang, L.; Tang, Q.; Gao, L.; Fang, L.; Wang, Z.; Guo, W. Fabrication and characterization of HDPE resins as adhesives in plywood. Eur. J. Wood Wood Prod. 2018, 76, 325–335. [Google Scholar] [CrossRef]

- Fang, L.; Chang, L.; Guo, W.J.; Chen, Y.; Wang, Z. Influence of silane surface modification of veneer on interfacial adhesion of wood-plastic plywood. Appl. Surf. Sci. 2014, 288, 682–689. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, L.; Wang, W.; Sun, Y.; Wang, H. Modifying wood veneer with silane coupling agent for decorating wood fiber/high-density polyethylene composite. Constr. Build. Mater. 2019, 224, 691–699. [Google Scholar] [CrossRef]

- Bekhta, P.; Müller, M.; Hunko, I. Properties of thermoplastic-bonded plywood: Effects of the wood species and types of the thermoplastic films. Polymers 2020, 12, 2582. [Google Scholar] [CrossRef]

- Solt, P.; Konnerth, J.; Gindl-Altmutter, W.; Kantner, W.; Moser, J.; Mitter, R.; van Herwijnen, H.W.G. Technological performance of formaldehyde-free adhesive alternatives for particleboard industry. Int. J. Adhes. Adhes. 2019, 94, 99–131. [Google Scholar] [CrossRef]

- Stoeckel, F.; Konnerth, J.; Gindl-Altmutter, W. Mechanical properties of adhesives for bonding wood—A review. Int. J. Adhes. Adhes. 2013, 45, 32–41. [Google Scholar] [CrossRef]

- Konnerth, J.; Gindl, W.; Harm, M.; Müller, U. Comparing dry bond strength of spruce and beech wood glued with different adhesives by means of scarf- and lap joint testing method. Holz Roh Werkst. 2006, 64, 269–271. [Google Scholar] [CrossRef]

- Konnerth, J.; Kluge, M.; Schweizer, G.; Miljković, M.; Gindl-Altmutter, W. Survey of selected adhesive bonding properties of nine European softwood and hardwood species. Eur. J. Wood Wood Prod. 2016, 74, 809–819. [Google Scholar] [CrossRef] [Green Version]

- Wolcott, M.P.; Englund, K. A technology review of WPC. In Proceedings of the 33rd International Particleboard/Composite Materials Symposium, Washingtonm DC, USA, 13–15 April 1999; pp. 103–111. [Google Scholar]

- ÖNORM EN 302-1. Klebstoffe für tragende Holzbauteile—Prüfverfahren—Teil 1: Bestimmung der Längszugscherfestigkeit; Austrian Standards International: Vienna, Austria, 2013. [Google Scholar]

- ISO 554. Normalklimate für die Konditionierung und/oder Prüfung: Anforderungen International Organization of Standardization; ISO: Geneva, Switzerland, 1976. [Google Scholar]

- ÖNORM EN 319:1993. Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board; Austrian Standards International: Vienna, Austria, 2003. [Google Scholar]

- DIN 52188. Prüfung von Holz—Bestimmung der Zugfestigkeit Paralell zur Faser; German Institute for Standardization: Berlin, Germany, 1979. [Google Scholar]

- Liu, Y.; Sun, Y.; Hao, J.; Wang, W.; Song, Y.; Zhou, Z. Interface Bonding Properties and Mechanism of Poplar Board-Veneered Wood Fiber/Polypropylene Composites with Chlorinated Polypropylene Films as an Intermediate Layer. Langmuir 2019, 35, 13934–13941. [Google Scholar] [CrossRef] [PubMed]

- Wagenführ, R.; Scheiber, C. Holzatlas; Fachbuchverlag Leibzig im Carl Hanser Verlag: Leibzig, Germany, 2007; ISBN 3446406492. [Google Scholar]

- Adriaensens, P.; Pollaris, A.; Carleer, R.; Vanderzande, D.; Gelan, J.; Litvinov, V.M.; Tijssen, J. Quantitative magnetic resonance imaging study of water uptake by polyamide 4,6. Polymer 2001, 42, 7943–7952. [Google Scholar] [CrossRef]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Hoboken, NJ, USA, 2006; Volume 5, ISBN 9780470021729. [Google Scholar]

- Burmester, A. Zur Dimensionsstabilisierung von Holz. Holz Roh Werkst. 1975, 33, 333–335. [Google Scholar] [CrossRef]

- Follrich, J.; Müller, U.; Gindl, W.; Mundigler, N. Effects of long-term storage on the mechanical characteristics of wood plastic composites produced from thermally modified wood fibers. J. Thermoplast. Compos. Mater. 2010, 23, 845–853. [Google Scholar] [CrossRef]

- Mattheck, C.H.K. Wood—The Internal Optimization of Trees; Springer: Berlin/Heidelberg, Germany, 1997; ISBN 9783540620198. [Google Scholar]

- Smith, M.J.; Dai, H.; Ramani, K. Wood–thermoplastic adhesive interface—Method of characterization and results. Int. J. Adhes. Adhes. 2002, 22, 197–204. [Google Scholar] [CrossRef]

- Gupta, B.S.; Reiniati, I.; Laborie, M.P.G. Surface properties and adhesion of wood fiber reinforced thermoplastic composites. Colloids Surfaces A Physicochem. Eng. Asp. 2007, 302, 388–395. [Google Scholar] [CrossRef]

- Müller, U.; Gindl, W.; Teischinger, A. Effects of cell anatomy on the plastic and elastic behaviour of different wood species loaded perpendicular to grain. IAWA J. 2003, 24, 117–128. [Google Scholar] [CrossRef]

- Vorreiter, L. Holztechnologisches Handbuch; Verlag Georg Fromme und Co: Wien, Austria, 1949. [Google Scholar]

- Bosshard, H.H. Holzkunde. Band 1, Mikroskopie und Makroskopie des Holzes; Birkhäuser Verlag: Basel, Switzerland, 1982; ISBN 978-3-0348-5323-1. [Google Scholar]

- Popescu, C.M.; Tibirna, C.M.; Vasile, C. XPS characterization of naturally aged wood. Appl. Surf. Sci. 2009, 256, 1355–1360. [Google Scholar] [CrossRef]

- Nzokou, P.; Kamdem, D.P. X-ray photoelectron spectroscopy study of red oak- (Quercus rubra), black cherry- (Prunus serotina) and red pine- (Pinus resinosa) extracted wood surfaces. Surf. Interface Anal. 2005, 37, 689–694. [Google Scholar] [CrossRef]

- Oliveira, F.R.; Zille, A.; Souto, A.P. Dyeing mechanism and optimization of polyamide 6,6 functionalized with double barrier discharge (DBD) plasma in air. Appl. Surf. Sci. 2014, 293, 177–186. [Google Scholar] [CrossRef] [Green Version]

- Morent, R.; De Geyter, N.; Leys, C.; Gengembre, L.; Payen, E. Comparison between XPS- And FTIR-analysis of plasma-treated polypropylene film surfaces. Surf. Interface Anal. 2008, 40, 597–600. [Google Scholar] [CrossRef]

- Kashani Rahimi, S.; Otaigbe, J.U. The role of particle surface functionality and microstructure development in isothermal and non-isothermal crystallization behavior of polyamide 6/cellulose nanocrystals nanocomposites. Polymer 2016, 107, 316–331. [Google Scholar] [CrossRef] [Green Version]

| Composite | Elemental | Wood Substrate | −2 | −1 | 0 | 1 | Polymer |

|---|---|---|---|---|---|---|---|

| Birch-PA 6 | C at [%] | 81.85 | 86.37 | 87.65 | 87.74 | 91.11 | 90.00 |

| N at [%] | 0.19 | 0.14 | 0.15 | 2.05 | 4.28 | 5.02 | |

| O at [%] | 17.95 | 13.50 | 12.21 | 10.22 | 4.61 | 4.98 | |

| O/C | 0.219 | 0.156 | 0.139 | 0.116 | 0.051 | 0.055 | |

| N/C | 0.002 | 0.002 | 0.002 | 0.023 | 0.047 | 0.056 | |

| Beech-PA 6 | C at [%] | 67.77 | 67.76 | 67.37 | 73.07 | 89.24 | 87.74 |

| N at [%] | 0.38 | 0.34 | 0.29 | 1.52 | 5.82 | 5.56 | |

| O at [%] | 31.85 | 31.90 | 32.34 | 25.41 | 4.95 | 6.71 | |

| O/C | 0.470 | 0.471 | 0.480 | 0.348 | 0.055 | 0.076 | |

| N/C | 0.006 | 0.005 | 0.004 | 0.021 | 0.065 | 0.063 | |

| Birch-PP | C at [%] | 72.61 | 71.46 | 70.40 | 85.30 | 98.68 | 98.32 |

| N at [%] | 0.45 | 0.27 | 0.33 | 0.35 | 0.41 | 0.40 | |

| O at [%] | 26.95 | 28.27 | 29.27 | 14.35 | 0.92 | 1.29 | |

| O/C | 0.371 | 0.396 | 0.416 | 0.168 | 0.009 | 0.013 | |

| Beech-PP | C at [%] | 66.66 | 65.70 | 65.96 | 83.45 | 99.29 | 99.11 |

| N at [%] | 0.32 | 0.28 | 0.24 | 0.38 | 0.30 | 0.31 | |

| O at [%] | 33.02 | 34.03 | 33.81 | 16.17 | 0.42 | 0.59 | |

| O/C | 0.495 | 0.518 | 0.513 | 0.194 | 0.004 | 0.006 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stadlmann, A.; Mautner, A.; Pramreiter, M.; Bismarck, A.; Müller, U. Interfacial Adhesion and Mechanical Properties of Wood-Polymer Hybrid Composites Prepared by Injection Molding. Polymers 2021, 13, 2849. https://doi.org/10.3390/polym13172849

Stadlmann A, Mautner A, Pramreiter M, Bismarck A, Müller U. Interfacial Adhesion and Mechanical Properties of Wood-Polymer Hybrid Composites Prepared by Injection Molding. Polymers. 2021; 13(17):2849. https://doi.org/10.3390/polym13172849

Chicago/Turabian StyleStadlmann, Alexander, Andreas Mautner, Maximilian Pramreiter, Alexander Bismarck, and Ulrich Müller. 2021. "Interfacial Adhesion and Mechanical Properties of Wood-Polymer Hybrid Composites Prepared by Injection Molding" Polymers 13, no. 17: 2849. https://doi.org/10.3390/polym13172849

APA StyleStadlmann, A., Mautner, A., Pramreiter, M., Bismarck, A., & Müller, U. (2021). Interfacial Adhesion and Mechanical Properties of Wood-Polymer Hybrid Composites Prepared by Injection Molding. Polymers, 13(17), 2849. https://doi.org/10.3390/polym13172849