Current Strategies for the Production of Sustainable Biopolymer Composites

Abstract

1. Introduction

2. Agro-Polymers (Fibers)

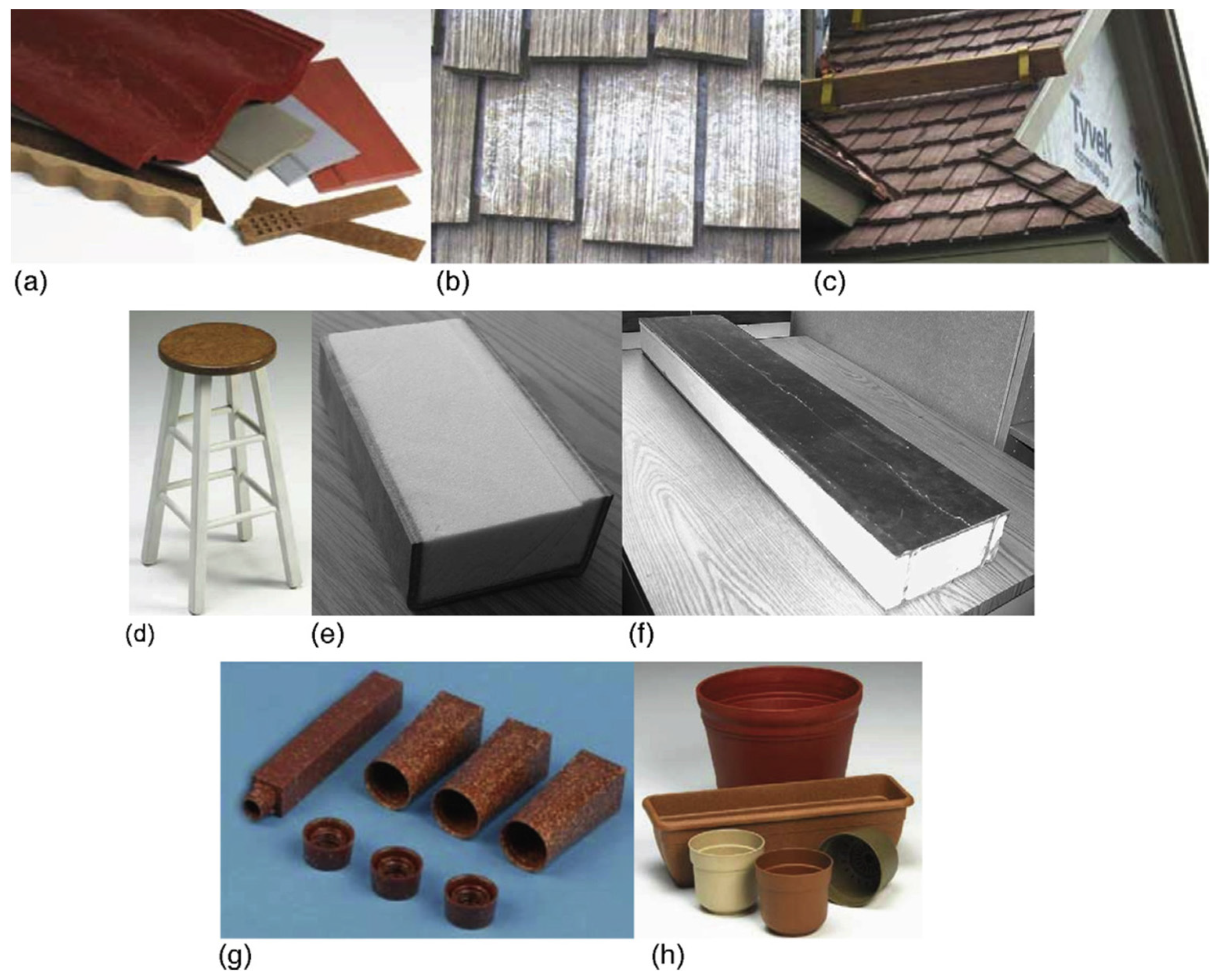

3. Biocomposites

4. Composites Made from Biopolymers

5. Challenges for Degradation of Sustainable Composites

6. Biological Degradation of Sustainable Composites

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Komaragounder, S.; Santhoskumar, A.U.; Palanivelu, K.; Sharma, S.K.; Nayak, S.K. Comparison of Biological Activity Transistion Metal 12 Hydroxy oleate on Photodegradation of Plastics. J. Bioremediation Biodegrad. 2010, 1, 1–8. [Google Scholar] [CrossRef]

- Umapathi, A. A New Synthesis of Nickel 12-Hydroxy Oleate Formulation to Improve Polyolefin’s Degradation. J. Bioremediation Biodegrad. 2010, 1, 108. [Google Scholar] [CrossRef]

- Brigham, C. Biopolymers: Biodegradable alternatives to traditional plastics. In Green Chemistry; Elsevier: Amsterdam, The Netherlands, 2018; pp. 753–770. [Google Scholar]

- Yu, J. Microbial production of bioplastics from renewable resources. In Bioprocessing for Value-Added Products from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2007; pp. 585–610. [Google Scholar]

- Varsha, Y.S.; Varsha, Y. Overview on Polyhydroxyalkanoates: A Promising Biopol. J. Microb. Biochem. Technol. 2011, 3, 59. [Google Scholar] [CrossRef]

- Cyras, V.P.; Manfredi, L.B.; Ton-That, M.T.; Vazquez, A. Physical and mechanical properties of thermoplastic starch/montmorillonite nanocomposite films. Carbohyd. Polym. 2008, 73, 55–63. [Google Scholar] [CrossRef]

- Kumar, M.; Singhal, A.; Verma, P.K.; Thakur, I.S. Production and Characterization of Polyhydroxyalkanoate from Lignin Derivatives by Pandoraea sp. ISTKB. ACS Omega 2017, 2, 9156–9163. [Google Scholar] [CrossRef]

- Avérous, L.; Pollet, E. Green Nano-Biocomposites. In Environmental Silicate Nano-Biocomposites; Avérous, L., Pollet, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1–11. [Google Scholar] [CrossRef]

- Vieira, M.G.A.; da Silva, M.A.; Santos, L.; Beppu, M.M. Natural-based plasticizers and biopolymer films: A review. Eur. Polym. J. 2011, 47, 254–263. [Google Scholar] [CrossRef]

- Patel, J.P.; Parsania, P.H. Characterization, testing, and reinforcing materials of biodegradable composites. In Biodegradable and Biocompatible Polymer Composites; Navinchandra, G.S., Ed.; Woodhead Publishing: Chennai, India, 2018; pp. 55–79. [Google Scholar] [CrossRef]

- Han, J.S.; Rowell, J.S. Chemical composition of fibers. In Paper and Composites from Agro-Based Resources; Rowell, R.A., Young, J.K., Rowell, Eds.; CRC Press: Boca Raton, FL, USA, 1996; pp. 83–134. [Google Scholar]

- Lau, A.K.-T.; Cheung, K.H.Y. Natural fiber-reinforced polymer-based composites. In Natural Fiber-Reinforced Biodegradable and Bioresorbable Polymer Composites; Lau, A.K., Hung, A.P., Eds.; Woodhead Publishing: Chennai, India, 2017; pp. 1–18. [Google Scholar] [CrossRef]

- Mihai, M.; Ton-That, M.-T. Novel polylactide/triticale straw biocomposites: Processing, formulation, and properties. Polym. Eng. Sci. 2013, 54, 446–458. [Google Scholar] [CrossRef]

- Aslan, M.; Tufan, M.; Küçükömeroğlu, T. Tribological and mechanical performance of sisal-filled waste carbon and glass fibre hybrid composites. Compos. Part B Eng. 2018, 140, 241–249. [Google Scholar] [CrossRef]

- Réquilé, S.; Le Duigou, A.; Bourmaud, A.; Baley, C. Peeling experiments for hemp retting characterization targeting biocomposites. Ind. Crop. Prod. 2018, 123, 573–580. [Google Scholar] [CrossRef]

- Martin, N.; Mouret, N.; Davies, P.; Baley, C. Influence of the degree of retting of flax fibers on the tensile properties of single fibers and short fiber/polypropylene composites. Ind. Crop. Prod. 2013, 49, 755–767. [Google Scholar] [CrossRef]

- Väisänen, T.; Batello, P.; Lappalainen, R.; Tomppo, L. Modification of hemp fibers (Cannabis sativa L.) for composite applications. Ind. Crop. Prod. 2018, 111, 422–429. [Google Scholar] [CrossRef]

- Hamidon, M.H.; Sultan, M.T.; Ariffin, A.H.; Shah, A.U. Effects of fibre treatment on mechanical properties of kenaf fibre reinforced composites: A review. J. Mater. Res. Technol. 2019, 8, 3327–3337. [Google Scholar] [CrossRef]

- Atiqah, A.; Maleque, M.; Jawaid, M.; Iqbal, M. Development of kenaf-glass reinforced unsaturated polyester hybrid composite for structural applications. Compos. Part B Eng. 2013, 56, 68–73. [Google Scholar] [CrossRef]

- Kipriotis, E.; Heping, X.; Vafeiadakis, T.; Kiprioti, M.; Alexopoulou, E. Ramie and kenaf as feed crops. Ind. Crop. Prod. 2015, 68, 126–130. [Google Scholar] [CrossRef]

- Chandra, R.; Rustgi, R. Biodegradable polymers. Prog. Polym. Sci. 1998, 23, 1273–1335. [Google Scholar] [CrossRef]

- Quitadamo, A.; Massardier, V.; Valente, M. Eco-Friendly Approach and Potential Biodegradable Polymer Matrix for WPC Composite Materials in Outdoor Application. Int. J. Polym. Sci. 2019, 2019, 3894370. [Google Scholar] [CrossRef]

- Fowler, P.A.; Hughes, J.M.; Elias, R.M. Biocomposites: Technology, environmental, credentials and market forces. J. Sci. Food Agric. 2006, 86, 1781–1789. [Google Scholar] [CrossRef]

- Bhatia, J.K.; Kaith, B.S.; Kalia, S. Recent Developments in Surface Modification of Natural Fibers for Their Use in Biocomposites. In Biodegradable Green Composites; Kalia, S., Ed.; John Wiley and Sons: Hoboken, NJ, USA, 2016; pp. 80–117. [Google Scholar] [CrossRef]

- Akampumuza, O.; Wambua, P.M.; Ahmed, A.; Li, W.; Qin, X.-H. Review of the applications of biocomposites in the automotive industry. Polym. Compos. 2016, 38, 2553–2569. [Google Scholar] [CrossRef]

- Ahmad, F.; Choi, H.S.; Park, M.K. A Review: Natural Fiber Composites Selection in View of Mechanical, Light Weight, and Economic Properties. Macromol. Mater. Eng. 2014, 300, 10–24. [Google Scholar] [CrossRef]

- Shalwan, A.; Yousif, B. In State of Art: Mechanical and tribological behaviour of polymeric composites based on natural fibres. Mater. Des. 2012, 48, 14–24. [Google Scholar] [CrossRef]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Novel sustainable hemp-based composites for application in the building industry: Physical, thermal and mechanical characterization. Energy Build. 2014, 77, 219–226. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on durability of sustainable biobased composites: A review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef]

- Tserki, V.; Matzinos, P.; Zafeiropoulos, N.E.; Panayiotou, C. Development of biodegradable composites with treated and compatibilized lignocellulosic fibers. J. Appl. Polym. Sci. 2006, 100, 4703–4710. [Google Scholar] [CrossRef]

- Koncar, V. Smart Textiles for In Situ Monitoring of Composites; Woodhead Publishing: Chennai, India, 2019. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.O.V. Characterisation of polylactic acid biocomposites made from prepregs composed of woven polylactic acid/hemp–Lyocell hybrid yarn fabrics. Compos. Part A Appl. Sci. Manuf. 2016, 81, 139–144. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable composites based on lignocellulosic fibers—An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- O’Donnell, A.; Dweib, M.; Wool, R. Natural fiber composites with plant oil-based resin. Compos. Sci. Technol. 2004, 64, 1135–1145. [Google Scholar] [CrossRef]

- Dweib, M.; Hu, B.; O’Donnell, A.; Shenton, H.; Wool, R. All natural composite sandwich beams for structural applications. Compos. Struct. 2004, 63, 147–157. [Google Scholar] [CrossRef]

- Hashemi, S. Hybridisation effect on flexural properties of single- and double-gated injection moulded acrylonitrile butadiene styrene (ABS) filled with short glass fibres and glass beads particles. J. Mater. Sci. 2008, 43, 4811–4819. [Google Scholar] [CrossRef]

- Bansal, G.; Singh, V.K.; Patil, P.; Rastogi, S. Water absorption and thickness swelling characterization of chicken feather fiber and extracted fish residue powder filled epoxy based hybrid biocomposite. Int. J. Waste Resour. 2016, 6, 1–6. [Google Scholar] [CrossRef]

- Júnior, C.P.; de Carvalho, L.; Fonseca, V.; Monteiro, S.; D’Almeida, J. Analysis of the tensile strength of polyester/hybrid ramie–cotton fabric composites. Polym. Test. 2004, 23, 131–135. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B. Applications of Natural Fibers and Its Composites: An Overview. Nat. Resour. 2016, 07, 108–114. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Senthamaraikannan, P.; Pradeep, S.; Siengchin, S.; Jawaid, M.; Kathiresan, M. Effect of Various Chemical Treatments of Prosopis juliflora Fibers as Composite Reinforcement: Physicochemical, Thermal, Mechanical, and Morphological Properties. J. Nat. Fibers 2018, 17, 833–844. [Google Scholar] [CrossRef]

- Retuert, J.; Quijada, R.; Arias, V.; Yazdani-Pedram, M. Porous silica derived from chitosan-containing hybrid composites. J. Mater. Res. 2003, 18, 487–494. [Google Scholar] [CrossRef][Green Version]

- Ahmed, K.S.; Vijayarangan, S. Tensile, flexural and interlaminar shear properties of woven jute and jute-glass fabric reinforced polyester composites. J. Mater. Process. Technol. 2008, 207, 330–335. [Google Scholar] [CrossRef]

- Gujjala, R.; Ojha, S.; Acharya, D.K.; Pal, S. Mechanical properties of woven jute–glass hybrid-reinforced epoxy composite. J. Compos. Mater. 2013, 48, 3445–3455. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Mechanical property evaluation of sisal–jute–glass fiber reinforced polyester composites. Compos. Part B Eng. 2013, 48, 1–9. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.-M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef]

- Turku, I.; Keskisaari, A.; Kärki, T.; Puurtinen, A.; Marttila, P. Characterization of wood plastic composites manufactured from recycled plastic blends. Compos. Struct. 2017, 161, 469–476. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Biocomposites from waste derived biochars: Mechanical, thermal, chemical, and morphological properties. Waste Manag. 2016, 49, 560–570. [Google Scholar] [CrossRef]

- Oksman, K. Mechanical Properties of Natural Fibre Mat Reinforced Thermoplastic. Appl. Compos. Mater. 2000, 7, 403–414. [Google Scholar] [CrossRef]

- Rahman, M.M.; Netravali, A.N. Advanced Green composites using liquid crystalline cellulose fibers and waxy maize starch based resin. Compos. Sci. Technol. 2018, 162, 110–116. [Google Scholar] [CrossRef]

- Hosseini, N.; Webster, D.C.; Ulven, C. Advanced biocomposite from highly functional methacrylated epoxidized sucrose soyate (MAESS) resin derived from vegetable oil and fiberglass fabric for composite applications. Eur. Polym. J. 2016, 79, 63–71. [Google Scholar] [CrossRef]

- Bakare, I.; Okieimen, F.; Pavithran, C.; Khalil, H.A.; Brahmakumar, M. Mechanical and thermal properties of sisal fiber-reinforced rubber seed oil-based polyurethane composites. Mater. Des. 2010, 31, 4274–4280. [Google Scholar] [CrossRef]

- Bourmaud, A.; Corre, Y.-M.; Baley, C. Fully biodegradable composites: Use of poly-(butylene-succinate) as a matrix and to plasticize l-poly-(lactide)-flax blends. Ind. Crop. Prod. 2015, 64, 251–257. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.-K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef]

- Alvarez-Chavez, C.R.; Edwards, S.; Moure-Eraso, R.; Geiser, K. Sustainability of bio-based plastics: General comparative analysis and recommendations for improvement. J. Clean. Prod. 2012, 23, 47–56. [Google Scholar] [CrossRef]

- AL-Oqla, F.M.; Omari, M.A. Green Biocomposites. In Manufacturing and Properties; Jawaid, M., Sapuan, S.M., Alothman, O.Y., Eds.; Springer International Publishing: Cham, Germany, 2017; pp. 13–29. [Google Scholar]

- Steinmetz, Z.; Wollmann, C.; Schaefer, M.; Buchmann, C.; David, J.; Troger, J.; Munoz, K.; Fror, O.; Schaumann, G.E. Plastic mulching in agriculture. Trading short-term agronomic benefits for long-term soil degradation? Sci. Total Environ. 2016, 550, 690–705. [Google Scholar] [CrossRef]

- Bari, E.; Morrell, J.J.; Sistani, A. Durability of natural/synthetic/biomass fiberebased polymeric composites: Laboratory and field tests. In Durability and Life Prediction in Biocomposites, Fibre—Reinforced Composites and Hybrid Composites, Woodhead Publishing Series in Composites Science and Engineering; Jawaid, M., Thariq, M., Saba, N., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 15–26. [Google Scholar]

- Beg, M.D.H.; Pickering, K. Accelerated weathering of unbleached and bleached Kraft wood fibre reinforced polypropylene composites. Polym. Degrad. Stab. 2008, 93, 1939–1946. [Google Scholar] [CrossRef]

- Das, R.; Karumbaiah, K.M. Biodegradable polyester-based blends and composites: Manufacturing, properties and applications. In Biodegradable Polyesters; Fakirov, S., Ed.; Wiley-VCH Verlag GmbH & Co.: Weinheim, Germany, 2015; pp. 275–298. [Google Scholar]

- Hidayat, A.; Tachibana, S. Characterization of polylactic acid (PLA)/kenaf composite degradation by immobilized mycelia of Pleurotus ostreatus. Int. Biodeterior. Biodegrad. 2012, 71, 50–54. [Google Scholar] [CrossRef]

- Zhao, Y.-Q.; Cheung, H.-Y.; Lau, K.-T.; Xu, C.-L.; Zhao, D.-D.; Li, H.-L. Silkworm silk/poly(lactic acid) biocomposites: Dynamic mechanical, thermal and biodegradable properties. Polym. Degrad. Stab. 2010, 95, 1978–1987. [Google Scholar] [CrossRef]

- European Standard. 13432:2000 Packaging—Requirements for Packaging Recoverable through Composting and Biodegradation—Test Scheme and Evaluation Criteria for the Final Acceptance of Packaging; European Committee for Standardization: Brussel, Belgium, 2000. [Google Scholar]

- Gurunathan, T.; Mohanty, S.; Nayak, K. A review of the recent developments in biocopmosites based on natural fibres and their application perspectives. Compos. Part A 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Lu, H.; Madbouly, S.A.; Schrader, J.A.; Kessler, M.R.; Grewell, D.; Graves, W.R. Novel bio-based composites of polyhydroxyalkanoate (PHA)/distillers dried grains with solubles (DDGS). RSC Adv. 2014, 4, 39802–39808. [Google Scholar] [CrossRef]

- Cunha, M.; Berthet, M.-A.; Pereira, R.N.; Covas, J.A.; Vicente, A.; Hilliou, L. Development of polyhydroxyalkanoate/beer spent grain fibers composites for film blowing applications. Polym. Compos. 2014, 36, 1859–1865. [Google Scholar] [CrossRef]

- Byrom, D. The synthesis and biodegradation of polyhydroxyalkanoates from bacteria. Int. Biodeterior. Biodegrad. 1993, 31, 199–208. [Google Scholar] [CrossRef]

- Muniyasamy, S.; John, M.J. Biodegradability of Biobased Polymeric Materials in Natural Environments. In Handbook of Composites from Renewable Materials; Thakur, V.K., Thakur, M.K., Kessler, M.R., Eds.; Scrivener Publishing LLC: Beverly, IL, USA, 2017; Volume 5, pp. 625–654. [Google Scholar]

- Shah, A.A.; Hasan, F.; Hameed, A.; Ahmed, S. Biological degradation of plastics: A comprehensive review. Biotechnol. Adv. 2008, 26, 246–265. [Google Scholar] [CrossRef] [PubMed]

- Rutkowska, M.; Heimowska, A.; Krasowska, K.; Janik, H. Biodegradability of Polyethylene Starch Blends in Sea Water. Pol. J. Environ. Stud. 2002, 11, 267–271. [Google Scholar]

- Ruka, D.R.; Sangwan, P.; Garvey, C.J.; Simon, G.P.; Dean, K.M. Biodegradability of poly-3-hydroxybutyrate/bacterial cellulose composites under aerobic conditions—Measured via evolution of carbon dioxide, spectroscopic and diraction methods. Environ. Sci. Technol. 2015, 49, 9979–9986. [Google Scholar] [CrossRef]

- Brebu, M. Environmental Degradation of Plastic Composites with Natural Fillers—A Review. Polymers 2020, 12, 166. [Google Scholar] [CrossRef] [PubMed]

- Taylor, A.; Yadama, V.; Englund, K.R.; Harper, D. Wood Plastic Composites—A Primer; The University of Tennessee: Knoxville, TN, USA, 2009; Available online: https://trace.tennessee.edu/cgi/viewcontent.cgi?article=1037&context=utk_agexfores (accessed on 20 December 2019).

- Chan, C.M.; Vandi, L.-J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Composites of Wood and Biodegradable Thermoplastics: A Review. Polym. Rev. 2017, 58, 444–494. [Google Scholar] [CrossRef]

- Schirp, A.; Wolcott, M.P. Influence of fungal decay and moisture absorption on mechanical properties of extruded wood-plastic composites. Wood Fiber Sci. 2005, 37, 643–652. [Google Scholar]

- Candelier, K.; Atli, A.; Alteyrac, J. Termite and decay resistance of bioplast-spruce green wood-plastic composites. Eur. J. Wood Wood Prod. 2018, 77, 157–169. [Google Scholar] [CrossRef]

- Sahi, S.; Djidjelli, H.; Boukerrou, A. Biodegradation study of bio-corn flour filled low density polyethylene composites assessed by natural soil. J. Polym. Eng. 2016, 36, 245–252. [Google Scholar] [CrossRef]

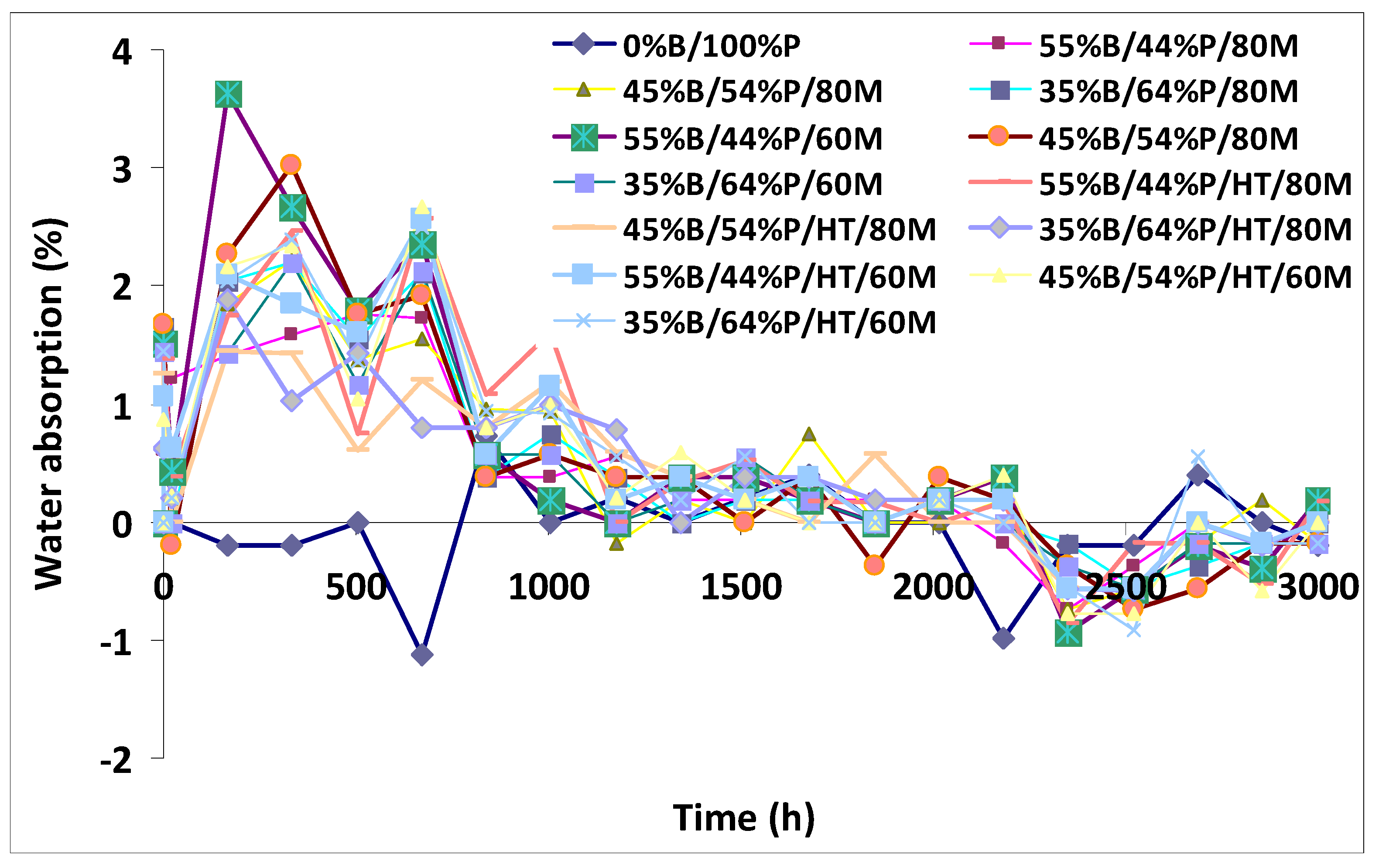

- Dehghan, M. Physical, Mechanical and Biological Resistance of Bamboo Flour-Polylactic Acid (PLA) Biocomposite. Master’s Thesis, Faculty of Natural Resources, University of Tehran, Karaj, Iran, 2018. [Google Scholar]

- Dehghan, M.; Faezipour, M.; Azizi, M.; Hosseinabadi, H.Z.; Bari, E.; Nicholas, D.D. Assessment of physical, mechanical, and biological properties of bamboo plastic composite made with polylactic acid. Maderas Cienc. Tecnol. 2019, 21, 599–610. [Google Scholar] [CrossRef]

- Dehghan, M.; Faezipour, M.; Azizi, M.; Bari, E. Assesement of the Biodegradability of Composites produced from Poly-Lactic Acid and Bamboo Flour. Iran. J. Wood Pap. Ind. 2019, 9, 537–548. [Google Scholar]

- Mastalygina, E.E.; Popov, A.A.; Pantyukhov, P.V. Effect of biobased fillers nature on biodeterioration of hybrid polyethylene composites by mould fungi. IOP Conf. Ser. Mater. Sci. Eng. 2017, 213, 12011. [Google Scholar] [CrossRef]

- Tufan, M.; Akbas, S.; Guleç, T.; Tasçıoglu, C.; Alma, M.H. Mechanical, thermal, morphological properties and decay resistance of filled hazelnut husk polymer composites. Maderas Cienc. Tecnol. 2015, 17, 865–874. [Google Scholar]

- Zhang, J.-F.; Sun, X. Mechanical properties of poly(lactic acid)/starch composites compatibilised by maleicanhydride. Biomacromolecules 2004, 5, 1446–1451. [Google Scholar] [CrossRef]

- Vaidya, U.R.; Battacharya, M. Method of grafting functional groups to synthetic polymers for making biodegradable plastics. J. Appl. Polym. Sci. 1994, 52, 617–628. [Google Scholar] [CrossRef]

- Vasile, C.; Pamfil, D.; Râpa, M.; Darie-Ni¸ta, R.N.; Mitelut, A.C.; Popa, E.E.; Popescu, P.A.; Draghici, M.C.; Popa, M.E. Study of the soil burial degradation of some PLA/CS Biocomposites. Compos. Part B 2018, 142, 251–262. [Google Scholar] [CrossRef]

| Organisms | Compound | Abbreviation | Properties |

|---|---|---|---|

| All plant cells | Cellulose | - | High thermal stability, high ductility, optical transparency [4] |

| All plant cells | Lignin | - | High mechanical properties and high rigidity [5] |

| All higher fungi, arthropods, molluscs, cephalopod beaks, scales of fish and lissamphibians | Chitin | - | Translucent, resilient high ductility [4] |

| Pseudomonas oleovorans, P. putida | Poly(3-hydroxyalkanoate) | PHA | High ductility but brittle [5] |

| Bacillus megaterium, Ralstonia eutropha | Poly(3-hydroxybutyrate) | PHB | Non-transparent, outstanding ductility and toughness, completely biodegradable, moisture-sensitive [5] |

| Laetiporus sulphureus, Laccaria bicolor, Phanerochaete chrysosporium, Bacillus spp., Lactobacillus spp. | Polylactic acid | PLA | Transparent, water-repellent, printable, and breathable [6] |

| Maize, wheat, potatoes, tapioca | Thermoplastic starch | TPS | Soluble in water, poor thermal resistance, low strength [7] |

| Type of Fiber | Cellulose | Lignin | Pentosan | Ash | Silica |

|---|---|---|---|---|---|

| Stalk fiber | 28–48 | ||||

| Rice | 29–51 | 12–16 | 23–28 | 15–20 | 9–14 |

| Wheat | 31–45 | 16–21 | 26–32 | 4.5–9 | 3–7 |

| Barley | 31–48 | 14–15 | 24–29 | 5–7 | 3–6 |

| Qat | 33–50 | 16–19 | 27–38 | 6–8 | 4–6.5 |

| Rye | 16–19 | 27–30 | 2–5 | 0.5–4 | |

| Cane fiber | 32–48 | ||||

| Bagasse | 26–43 | 19–24 | 27–32 | 1.5–5 | 0.7–3.5 |

| Bamboo | 21–31 | 15–26 | 1.7–5 | 0.7 | |

| Grass fiber | 33–38 | ||||

| Esparto | - | 17–19 | 27–32 | 6–8 | - |

| Sabai | 22 | 24 | 6 | - | |

| Red fiber | 44–46 | ||||

| Phragmites communis | 22–24 | 20 | 3 | 2 | |

| Bast fiber | 43–47 | ||||

| Seed flax | 44–57 | 21–23 | 24–26 | 5 | - |

| Kenaf | 45–63 | 15–19 | 22–23 | 2–5 | - |

| Jute | 57–77 | 21.26 | 18.21 | 0.5–2 | - |

| Hemp | 87–91 | 9–13 | 14–17 | 0.8 | - |

| Ramie | - | 5–8 | - | - | |

| Core fiber | 37–49 | ||||

| Kenaf | 41–48 | 15–21 | 18–24 | 2–4 | - |

| Jute | 21–24 | 18–22 | 0.8 | - | |

| Leaf fiber | 56–63 | ||||

| Abaca(Manila) | 47–62 | 7–9 | 15–17 | 3 | - |

| Sisal (agave) | 7–9 | 21–24 | 0.6–1 | - | |

| Seed hull fiber | 85–90 | ||||

| Cotton | 0.7–1.6 | 1–3 | 0.8–2 | - | |

| Wood fiber | 40–45 | ||||

| Coniferous | 48–49 | 26–34 | 7–14 | <1 | - |

| Deciduous | 23–30 | 16–26 | <1 | - |

| Matrix | Reinforcement | Biocomposites | Examples |

|---|---|---|---|

| Polylactic acid | Biofibers (Hemp, Sisal, Jute, etc.) | [Biodegradable] Biofiber-reinforced bio-based-polymer | Sisal/PLA, Biofiber/Starch, Hemp/PBS |

| Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) | Nanocellulose (Plant or Bacteria) | ||

| Poly(butylene succinate)(PBS) | Chitosan | Kenaf/PP, Jute/PE | |

| Thermoplastic starch | Wool/Silk | [Non-Biodegradable] Biofiber-reinforced petro-based polymers Synthetic fibers (glass or carbon fibers)-reinforced bio-based-polymers | |

| Poly(butylene adipate-co-terephthalate) | Biosourced Carbon | CF/PBS, GF/PLA | |

| Polypropylene | Industry Co-product | ||

| Polyethylene | Synthetic fibers (eg. Glass fiber (GF), Carbon fiber (CF)) |

| Fiber | Tensile Strength (MPa) | Youngs Modulus (GPa) | Elongation at Break (%) |

|---|---|---|---|

| OPEFB * | 248 | 3.2 | 2.5 |

| Flax | 88–1500 | 60–80 | 1.2–1.6 |

| Hemp | 550–900 | 70 | 1.6 |

| Jute | 400–800 | 10–30 | 1.8 |

| Ramie | 500 | 44 | 2 |

| Coir | 220 | 6 | 15–25 |

| Sisal | 600–700 | 38 | 2–3 |

| Abaca | 980 | --- | --- |

| Cotton | 400 | 12 | 3–10 |

| Kenaf (bast) | 295 | --- | 2.7–6.9 |

| Kenaf (core) | --- | --- | --- |

| Bagasse | 20–290 | 19.7–27.1 | 1.1 |

| Henequen | 430–580 | --- | 3–4.7 |

| Pineapple | 170–1672 | 82 | 1–3 |

| Banana | 355 | 33.8 | 5.3 |

| Resin | Filler | Impact Strength (kJ/m2) | Tensile Strength(MPa) | Tensile Modulus(GPa) | Comments | Reference |

|---|---|---|---|---|---|---|

| Plastic waste (PE and PP) | Wood flour | 2.9–6.2 Unnotch | 6–13 | 2.3–3.9 | MAPE compatibilization and lubricant utilization | [48] |

| PP | Wood, poultry litter biochar | 8.1 Notch | 27 | 4.3 | Hybrid biocomposites–MAPP compatibilization | [49] |

| PP | Flax fiber | 751 Unnotch | 40 | 6.5 | Needle-punch fiber mat composite | [50] |

| Waxy maize starch | Neat and modified liquid crystalline cellulose, microcrystalline cellulose | - | 505–790 | 22–32 | Starch/cellulose hybrid biocomposites | [51] |

| Epoxy/acrylate | Glass fiber | 237 Notch | 532 | 37 | Methacrylated epoxidized sucrose soyate resin/glass fiber | [52] |

| Bio-polyurethane (Bio-PU) | Sisal fiber | - | 57–119 | 1.2–2.2 | Rubber seed oil polyurethane | [53] |

| PBS/PLA | Flax fiber | 9.1–17.8 Notch | 39–55 | 3.6–7.4 | Fully biodegradable composite | [54] |

| PLA | Carbon fibers, twisted yarns of jute fibers | - | 57–185 | 5.1–19.5 | Continuous fiber reinforcement probed by 3D printing | [55] |

| Treatment | Treatment and Mesh Size | Fungi (Mass Losses %) | ||

|---|---|---|---|---|

| Gloeophyllum Trabeum | Trametes Versicolor | Chaetomium Globosum | ||

| A | 0%B/100%P | 1.34 ± 0.39 | 0.60 ± 0.05 | 0.75 ± 0.63 |

| B | 55%B/44%P/80M | 24.62 ± 0.80 | 3.65 ± 0.96 | 3.29 ± 0.65 |

| C | 45%B/54%P/80M | 25.38 ± 5.49 | 2.65 ± 1.69 | 2.97 ± 0.74 |

| D | 35%B/64%P/80M | 22.80 ± 3.98 | 2.27 ± 0.58 | 10.81 ± 6.49 |

| E | 55%B/44%P/60M | 26.86 ± 2.70 | 2.64 ± 0.47 | 2.60 ± 2.34 |

| F | 45%B/54%P/80M | 18.28 ± 2.26 | 2.28 ± 0.11 | 4.12 ± 3.79 |

| G | 35%B/64%P/60M | 21.97 ± 0.81 | 3.57 ± 0.90 | 3.42 ± 1.79 |

| H | 55%B/44%P/HT/80M | 24.24 ± 1.48 | 2.00 ± 0.19 | 2.37 ± 1.75 |

| I | 45%B/54%P/HT/80M | 23.56 ± 1.96 | 2.20 ± 0.70 | 4.98 ± 2.50 |

| J | 35%B/64%P/HT/80M | 20.12 ± 1.67 | 2.98 ± 0.41 | 5.77 ± 4.38 |

| K | 55%B/44%P/HT/60M | 19.77 ± 2.29 | 2.27 ± 0.58 | 2.64 ± 1.14 |

| L | 45%B/54%P/HT/60M | 22.91 ± 0.33 | 2.44 ± 1.01 | 3.25 ± 2.69 |

| M | 35%B/64%P/HT/60M | 21.98 ± 3.25 | 3.06 ± 0.90 | 2.08 ± 1.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bari, E.; Sistani, A.; Morrell, J.J.; Pizzi, A.; Akbari, M.R.; Ribera, J. Current Strategies for the Production of Sustainable Biopolymer Composites. Polymers 2021, 13, 2878. https://doi.org/10.3390/polym13172878

Bari E, Sistani A, Morrell JJ, Pizzi A, Akbari MR, Ribera J. Current Strategies for the Production of Sustainable Biopolymer Composites. Polymers. 2021; 13(17):2878. https://doi.org/10.3390/polym13172878

Chicago/Turabian StyleBari, Ehsan, Asghar Sistani, Jeffrey J. Morrell, Antonio Pizzi, Mohammad Reza Akbari, and Javier Ribera. 2021. "Current Strategies for the Production of Sustainable Biopolymer Composites" Polymers 13, no. 17: 2878. https://doi.org/10.3390/polym13172878

APA StyleBari, E., Sistani, A., Morrell, J. J., Pizzi, A., Akbari, M. R., & Ribera, J. (2021). Current Strategies for the Production of Sustainable Biopolymer Composites. Polymers, 13(17), 2878. https://doi.org/10.3390/polym13172878