Compressive Properties and Constitutive Model of Semicrystalline Polyethylene

Abstract

:1. Introduction

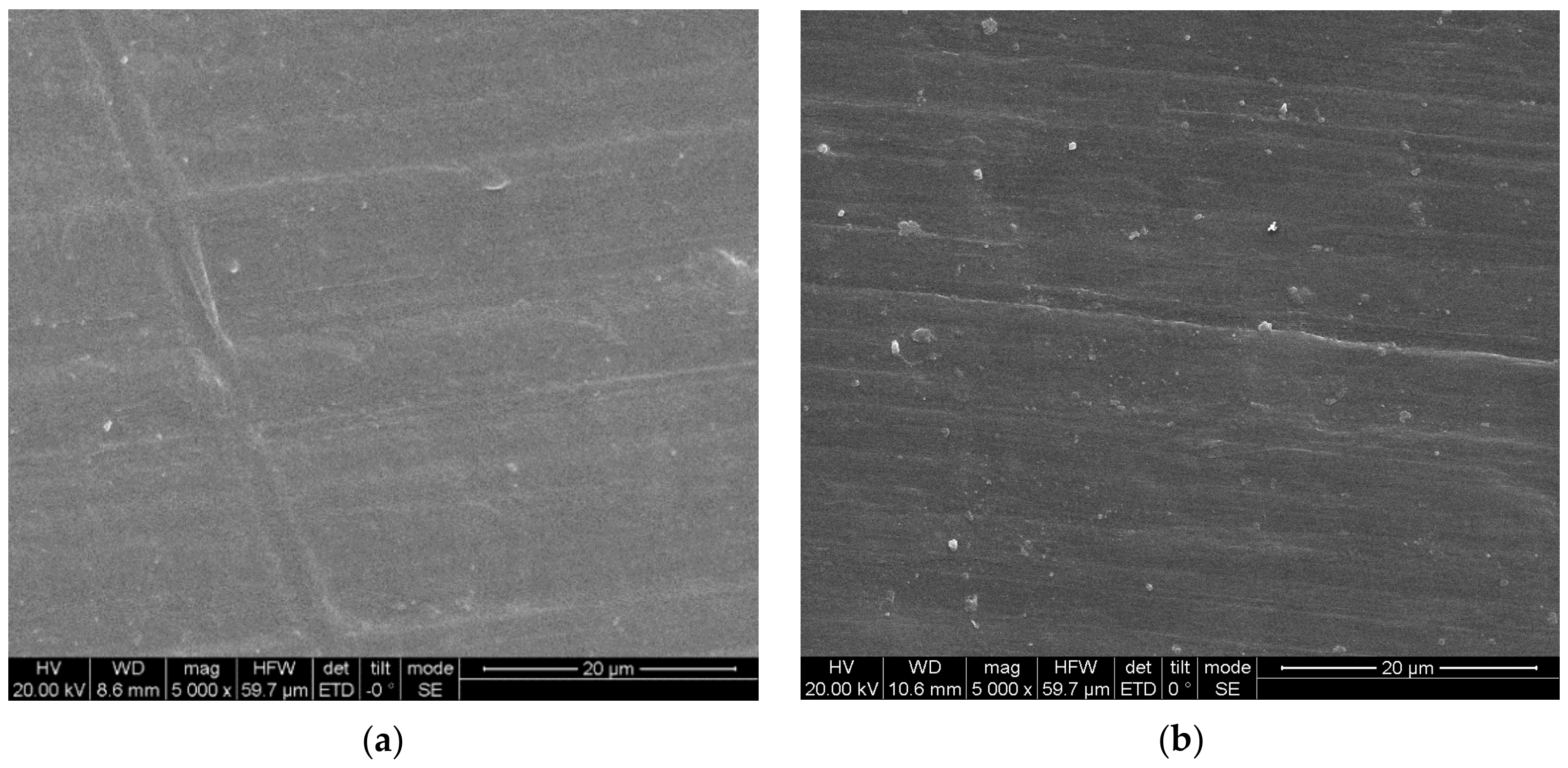

2. Materials

2.1. Sample Preparation

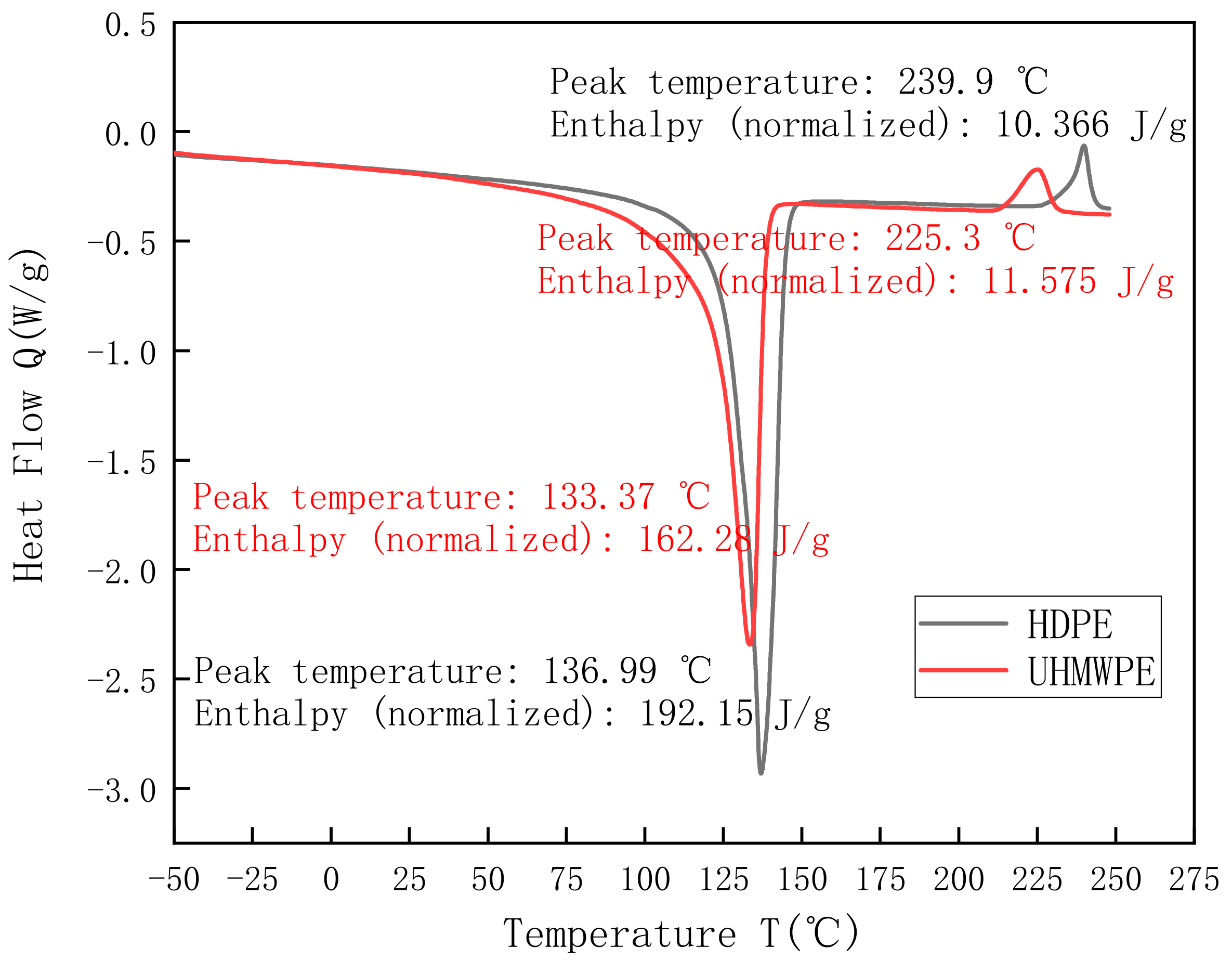

2.2. Differential Scanning Calorimetry Test

3. Test Method

3.1. Quasi-Static Testing

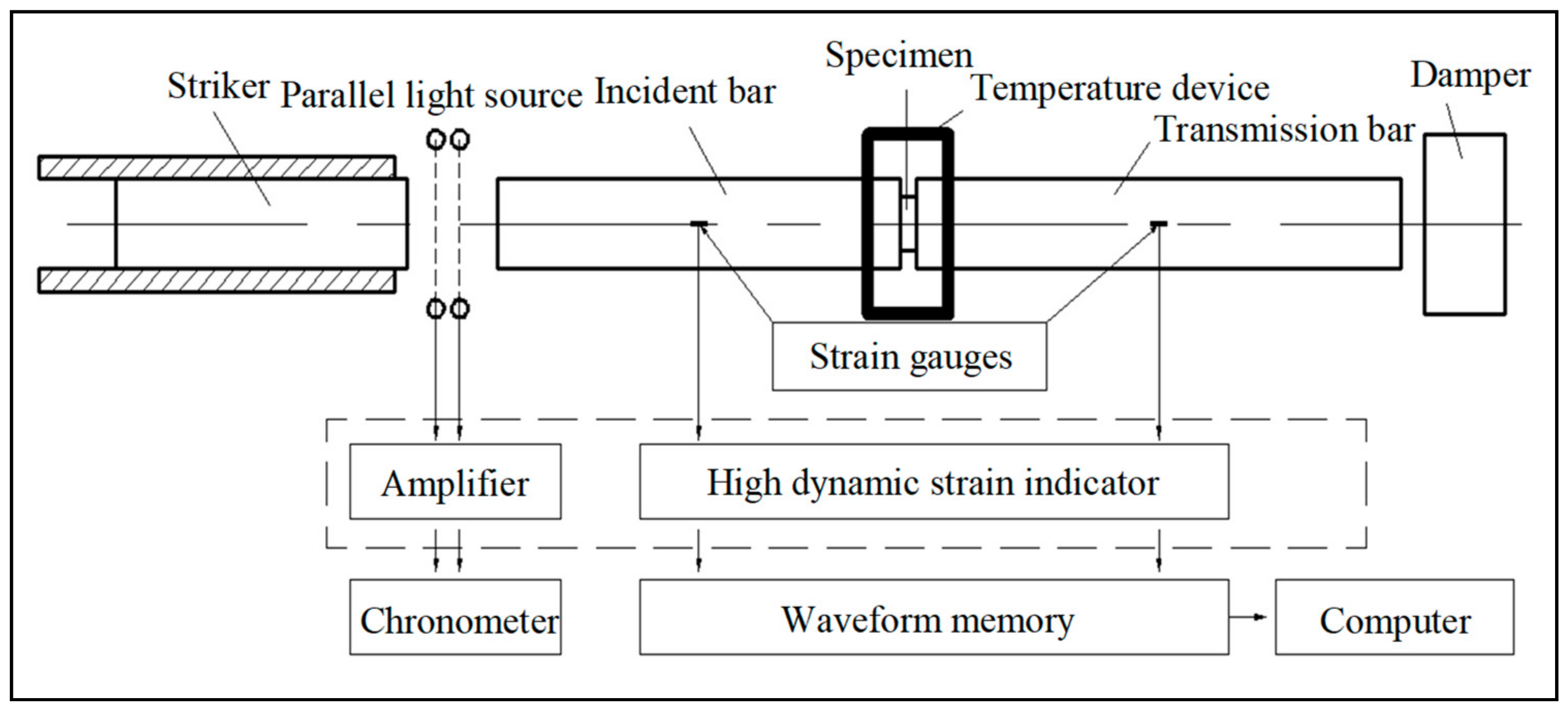

3.2. Dynamic Testing

4. Results and Discussion

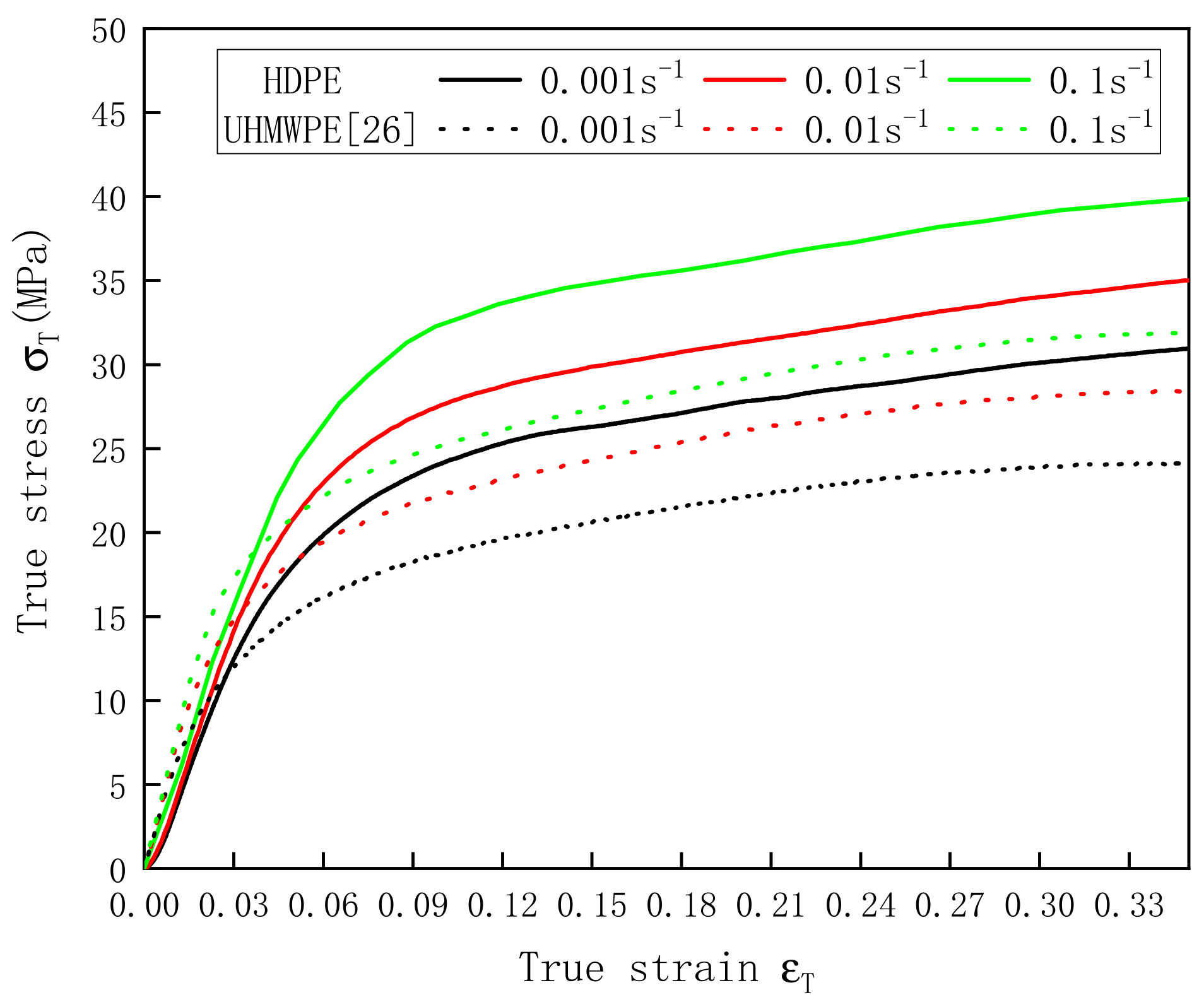

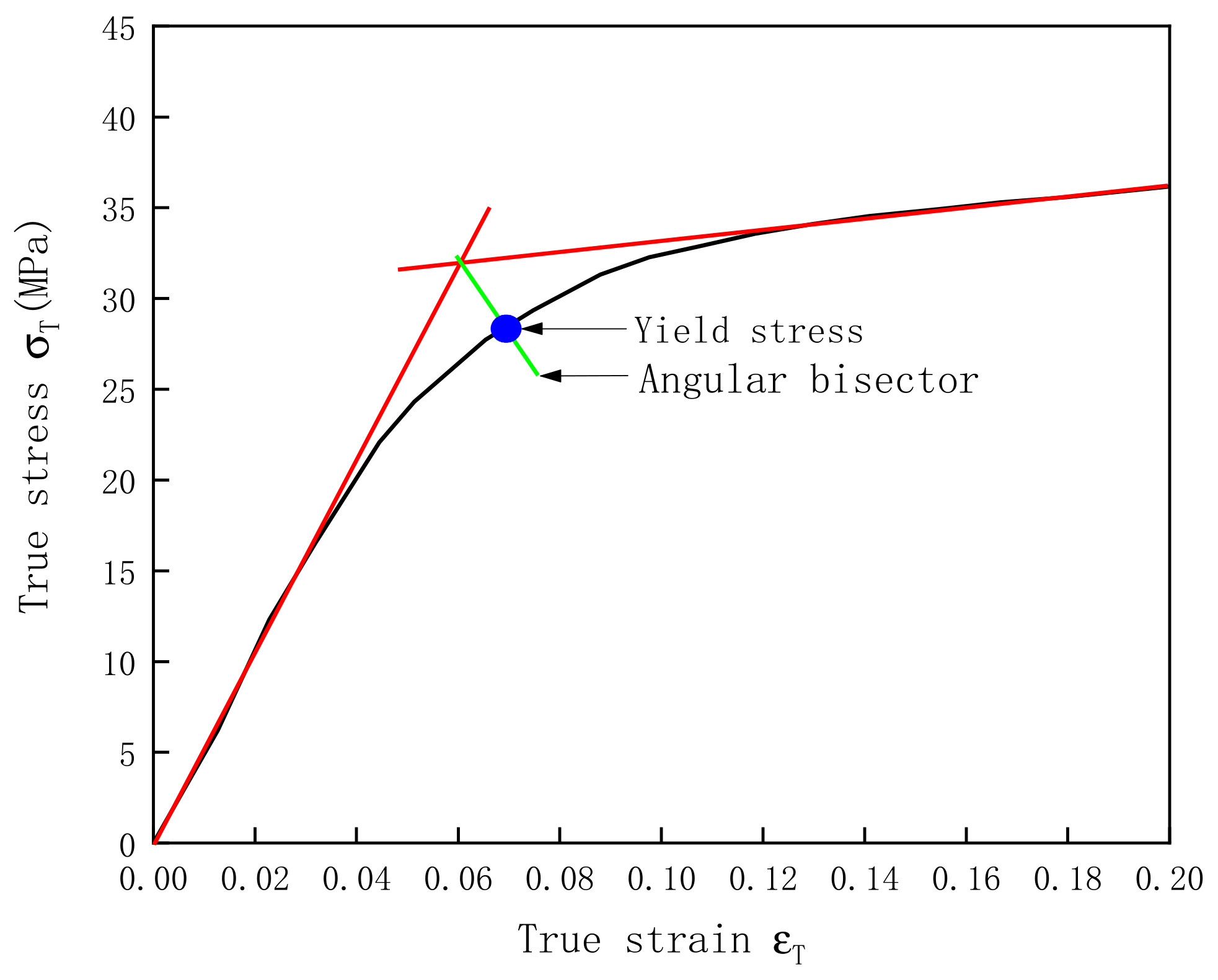

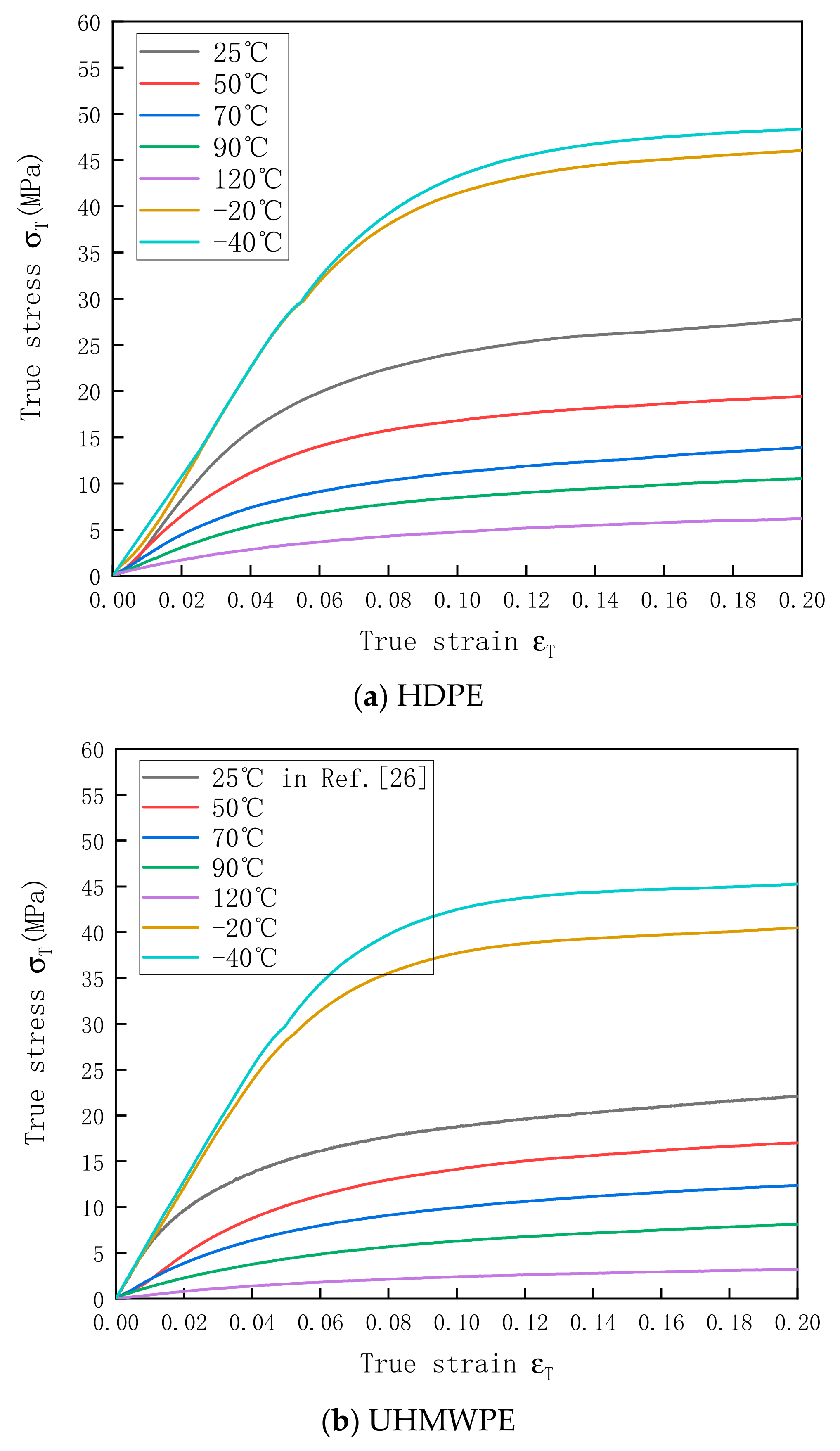

4.1. Quasi-Static Test

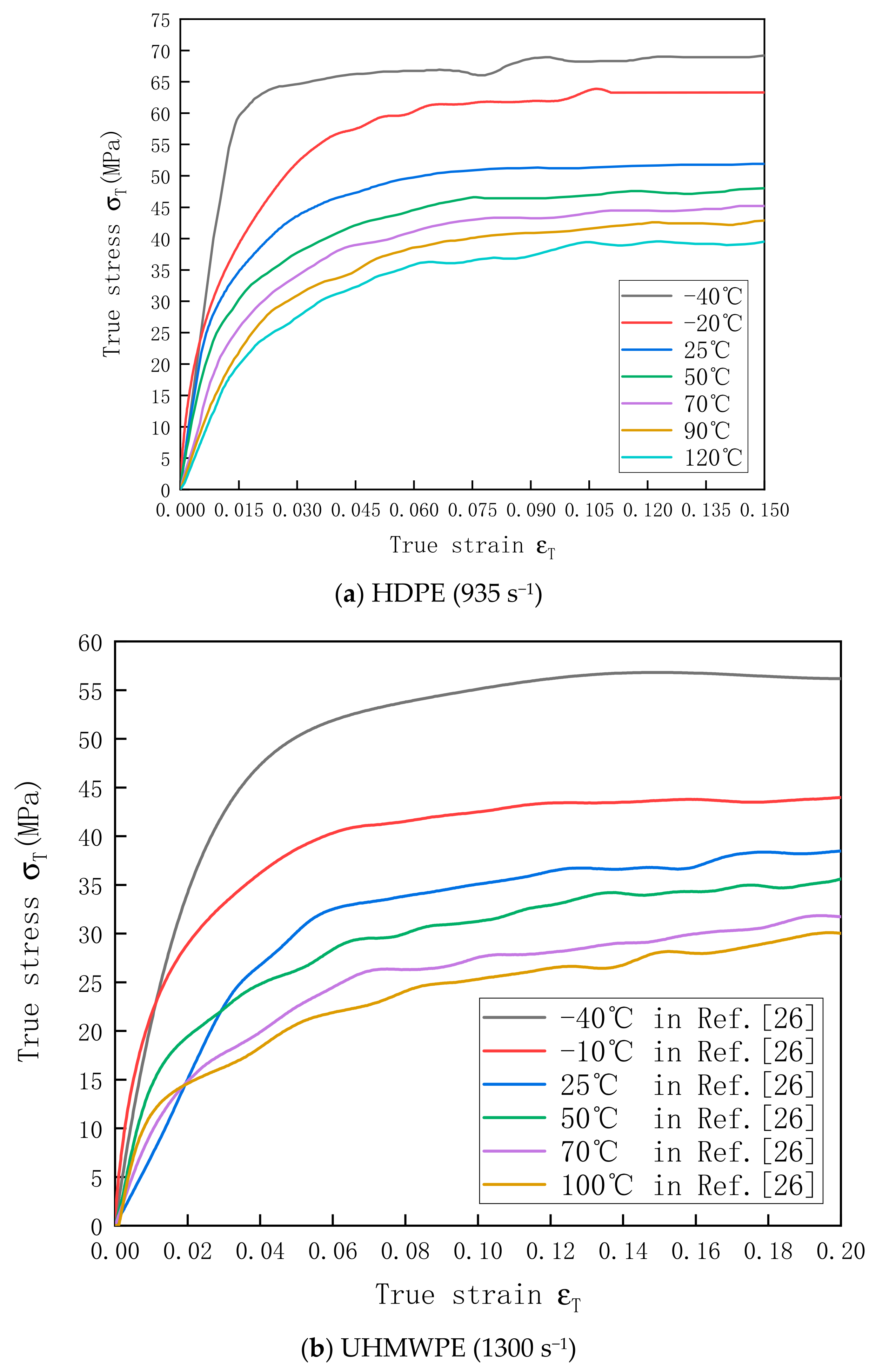

4.2. Dynamic Test

4.3. Constitutive Model

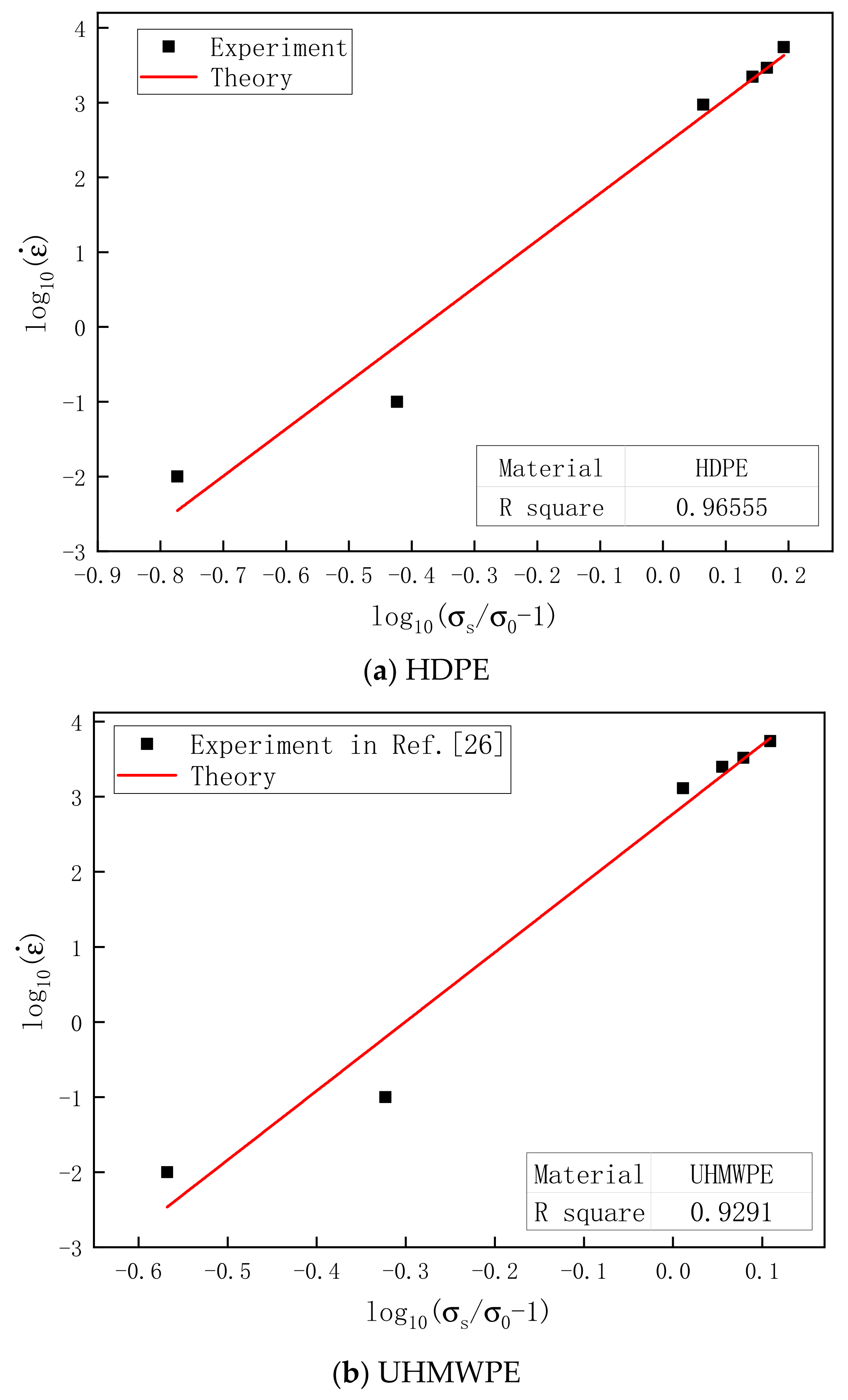

4.3.1. Strain Rate Effect

4.3.2. Temperature Effect

4.4. Constitutive Model and Validation

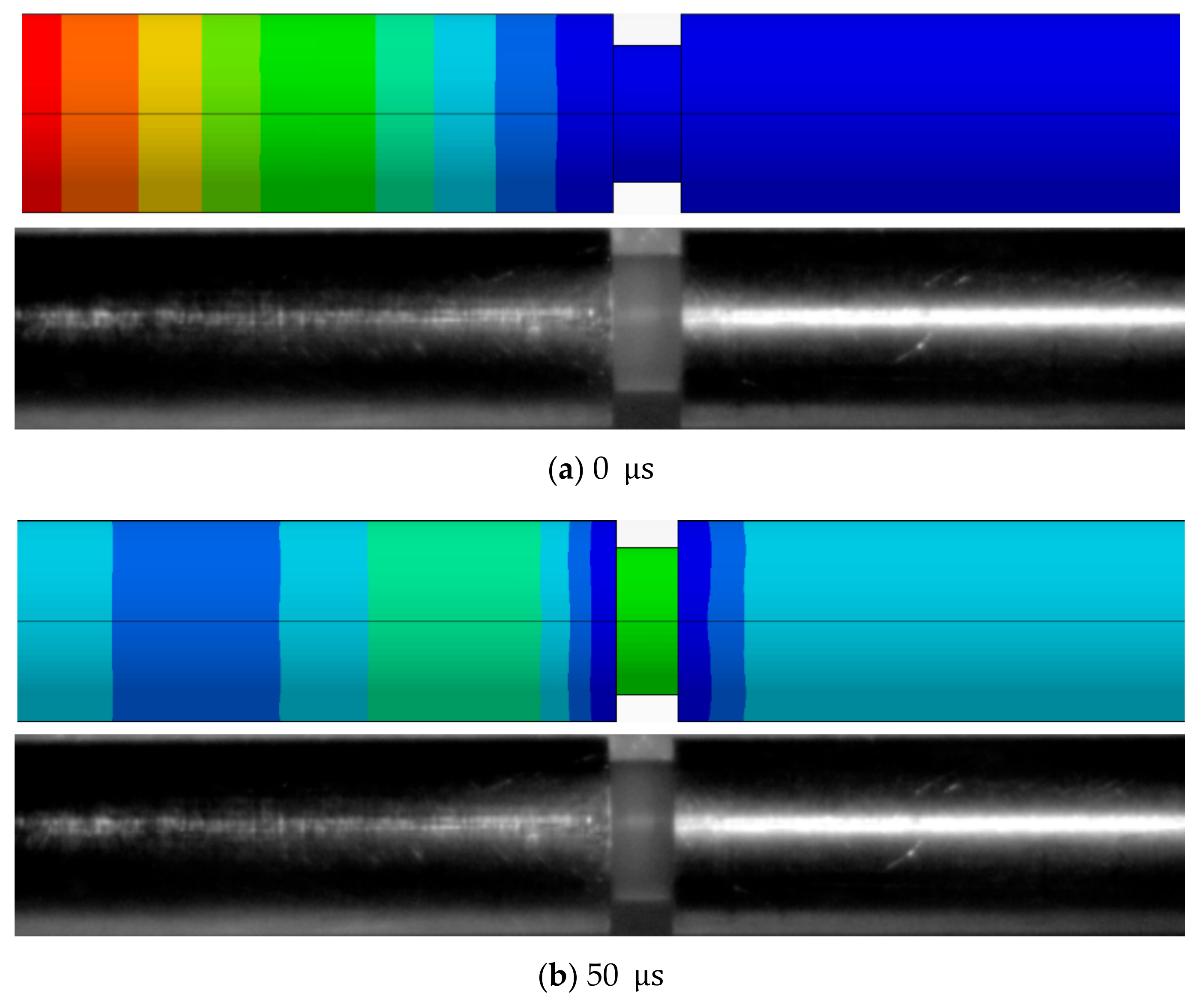

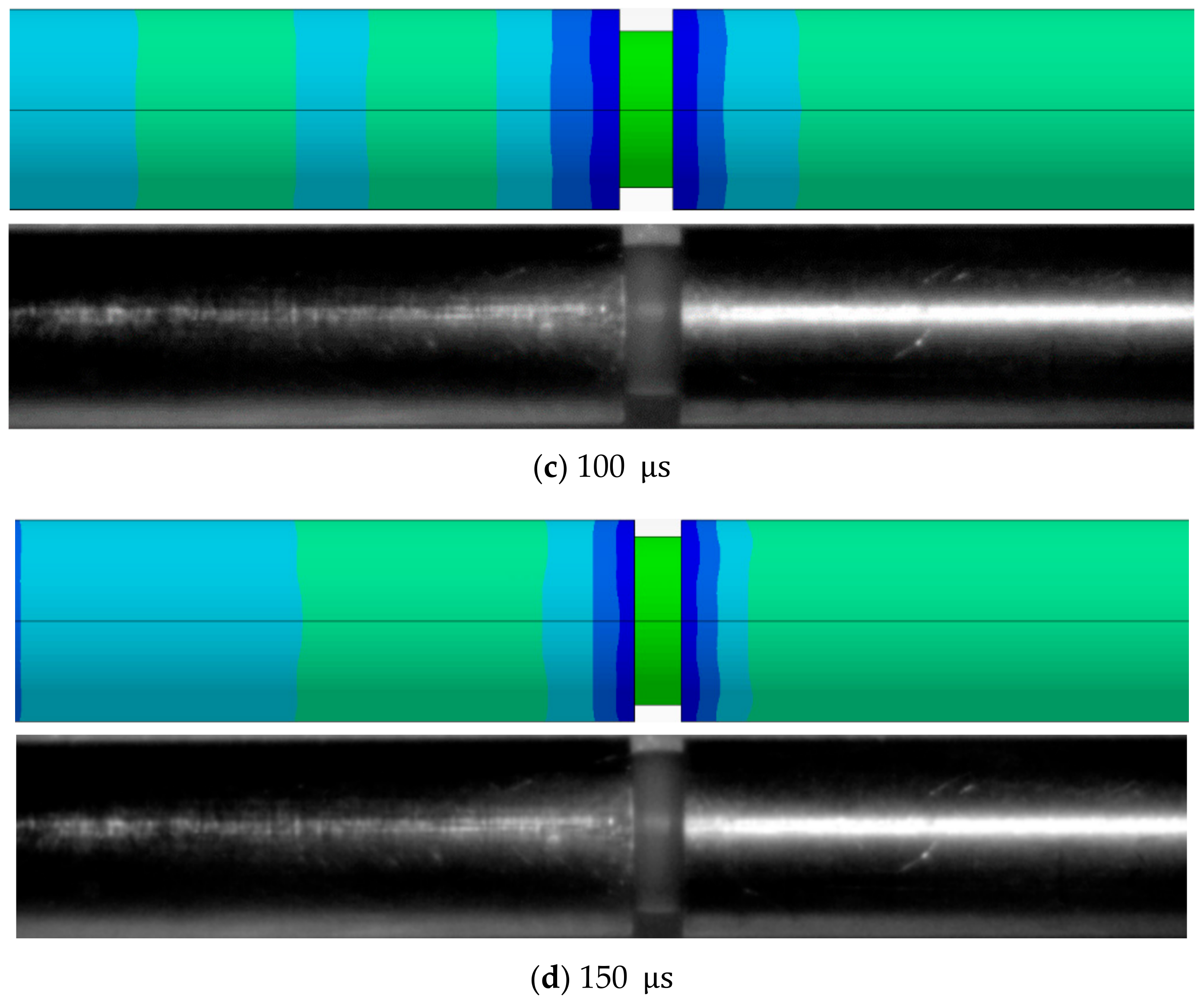

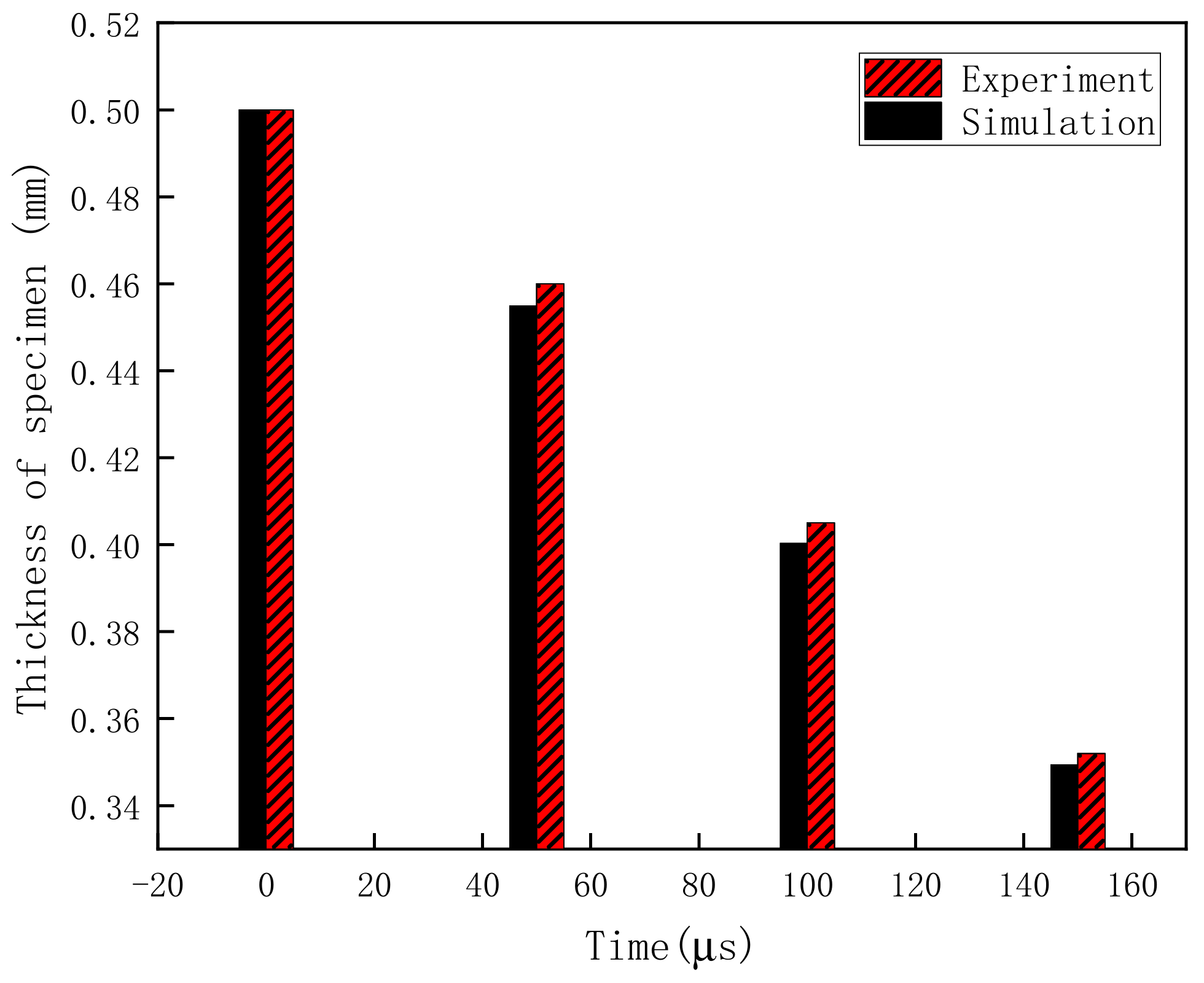

4.5. Simulation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liang, B.; Qian, L.; Niu, G. Preliminary analysis on thermal mitigation technology of conventional ammunition. In Proceedings of the 2014 (6th) Symposium on Energetic Materials and Insensitive Ammunition Technology, Chengdu, China, 20–23 November 2019; p. 6. [Google Scholar]

- Qian, L.; Liang, B.; Niu, G. Safety requirements and design technology of insensitive ammunition. In Proceedings of the 2014 (6th) Symposium on Energetic Materials and Insensitive Ammunition Technology, Chengdu, China, 20–23 November 2019; p. 5. [Google Scholar]

- Chen, K.; Huang, H.; Lu, Z.; Jiang, Z. Design method and experimental study of a kind of shell exhaust slow release structure. J. Missile Guid. 2015, 35, 15–18. [Google Scholar]

- Yan, L.; Wang, Y.; Wen, Q. New development of foreign insensitive ammunition technology. Winged Missile 2017, 8, 43–51. [Google Scholar]

- Chen, H.; Jiang, Z.; Chen, K.; Lu, Z. Study on formation conditions of sustained release exhaust channel. J. Sichuan Ordnance Ind. 2015, 36, 145–148. [Google Scholar]

- He, J.; Xue, P.; He, Y. Properties and Applications of UHMWPE. Eng. Plast. Appl. 1996, 5, 55–59. [Google Scholar]

- Chen, Z.; Wang, J.; Qin, D. Properties and Application of UHMWPE in Machinery. Mech. Eng. Mater. 2001, 8, 1–3. [Google Scholar]

- Zhang, K.; Li, W.; Zheng, Y.; Yao, W.; Zhao, C. Dynamic Constitutive Model of Ultra-High Molecular Weight Polyethylene (UHMWPE): Considering the Temperature and Strain Rate Effects. Polymers 2020, 12, 1561. [Google Scholar] [CrossRef] [PubMed]

- Daniel, F.; Solveig, H.; Johnny, M.; Diego, M.; Andreas, E.; Gary, C.C. 3D Printable Filaments Made of Biobased Polyethylene Biocomposites. Polymers 2018, 10, 314. [Google Scholar]

- Rousakis, T.C. Reusable and recyclable nonbonded composite tapes and ropes for concrete columns confinement. Compos. Part B Eng. 2016, 103, 15–22. [Google Scholar] [CrossRef]

- Li, W.; Liu, X.; Feng, M.; Yang, J. Bamboo-like ultra-high molecular weight polyethylene fibers and their epoxy composites. Compos. Sci. Technol. 2019, 182, 107716. [Google Scholar] [CrossRef]

- Singh, I.; Singh, T.; Goyal, N.; Dubey, M. Preparation and Investigating Mechanical Properties of Rice Husk Fiber Reinforced High Density Polyethylene Matrix Composites. Polymers 2018, 10, 286. [Google Scholar]

- Sphsa, B.; Hmj, B.; Naf, A. Load transfer within the bolted joint of a laminate made from ultra-high molecular weight polyethylene fibres. Int. J. Solids Struct. 2020, 185–186, 182–190. [Google Scholar]

- Lozano-Sánchez, L.M.; Bagudanch, I.; Sustaita, A.O.; Iturbe-Ek, J.; Elizalde, L.E.; Garcia-Romeu, M.L.; Elías-Zúñiga, A. Single-Point Incremental Forming of Two Biocompatible Polymers: An Insight into Their Thermal and Structural Properties. Polymers 2018, 10, 391. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, J.; Liu, R.; Guo, R.; Qiu, H.; Liu, M. Study on surface temperature field of high speed spinning projectile. Acta Armamentarii 2013, 34, 425–430. [Google Scholar]

- Xu, M.; Huang, G.; Feng, S.; McShane, G.J.; Stronge, W.J. Static and Dynamic Properties of Semi-Crystalline Polyethylene. Polymers 2016, 8, 77. [Google Scholar] [CrossRef]

- Sedighiamiri, A.; Govaert, L.E.; Dommelen, J. Micromechanical Modeling of the Deformation Kinetics of Semicrystalline Polymers. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1297–1310. [Google Scholar] [CrossRef] [Green Version]

- Drozdov, A.D. Modelling nonlinear viscoelasticity and damage in amorphous glassy polymers. Math. Comput. Model. 2001, 33, 883–893. [Google Scholar] [CrossRef]

- Bergström, J.S.; Kurtz, S.M.; Rimnac, C.M.; Edidin, A.A. Constitutive modeling of ultra-high molecular weight polyethylene under large-deformation and cyclic loading conditions. Biomaterials 2002, 23, 2329–2343. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Pruitt, L.; Jewett, C.W.; Crawford, R.P.; Crane, D.J.; Edidin, A.A. The yielding, plastic flow, and fracture behavior of ultra-high molecular weight polyethylene used in total joint replacements. Biomaterials 1998, 19, 1989. [Google Scholar] [CrossRef]

- Hossain, M.; Steinmann, P. Modelling and simulation of the curing process of polymers by a modified formulation of the Arruda--Boyce model. Arch. Mech. 2011, 63, 621–633. [Google Scholar]

- Cioroianu, A.R.; Spiesz, E.M.; Storm, C. An Improved Non-Affine Arruda-Boyce Type Constitutive Model for Collagen Networks. Biophys. J. 2013, 104, 511a. [Google Scholar] [CrossRef] [Green Version]

- Cho, H.; Rinaldi, R.G.; Boyce, M.C. Constitutive modeling of the rate-dependent resilient and dissipative large deformation behavior of a segmented copolymer polyurea. Soft Matter. 2013, 9, 6319–6330. [Google Scholar] [CrossRef]

- Dal, H.; Kaliske, M. Bergström–Boyce model for nonlinear finite rubber viscoelasticity: Theoretical aspects and algorithmic treatment for the FE method. Comput. Mech. 2009, 44, 809–823. [Google Scholar] [CrossRef]

- Xu, L.; Gao, G.; Zhao, Z.; Wang, J.; Chen, C. Compressive mechanical properties of polyethylene at different strain rates. Explos. Shock Waves 2019, 39, 8. [Google Scholar]

- Zhang, K.; Li, W.; Wang, X.; Yao, W.; Song, P.; Zhao, C. A constitutive model of the compressive mechanical properties of ultra high molecular weight polyethylene (UHMWPE) at different temperatures and different strain rates. Mater. Res. Express 2020, 6, 1–13. [Google Scholar] [CrossRef]

- Hallquist, J.O. LS-Dyna Keyword User’s Manual; Livermore Software Technology Corporation: San Francisco, CA, USA, 2007. [Google Scholar]

- Tang, Z. Optimum size of specimens in dynamic mechanical properties test of transversely isotropic materials. Explos. Impact 1985, 2. [Google Scholar]

- Li, Q.; Liu, Z.; Zhang, D.; Guo, X. Effect of crystal morphology on impact properties of UHMWPE. Appl. Mod. Plast. Process. 2000, 1, 10–13. [Google Scholar]

- Zhang, Q. Determination of Crystallinity of Polyethylene and Study on Its Crystallization Mechanism. Master’s Thesis, Northwest University of Technology, Xi’an, China, 2003. [Google Scholar]

- Mu, L. Study on Strain Rate Dependent Constitutive Model of Typical Polymer Materials. Master’s Thesis, Southwest University of Science and Technology, Mianyang, China, 2017. [Google Scholar]

- Richeton, J.; Ahzi, S.; Daridon, L.; Rémond, Y. A formulation of the cooperative model for the yield stress of amorphous polymers for a wide range of strain rates and temperatures. Polymer 2005, 46, 6035–6043. [Google Scholar] [CrossRef]

- Al-Mousawi, M.M.; Reid, S.R.; Deans, W.F. The use of the split Hopkinson pressure bar techniques in high strain rate materials testing. Arch. Proc. Inst. Mech. Eng. Part C 1997, 211, 273–292. [Google Scholar] [CrossRef]

- Hughes, F.; Prudom, A.; Swallowe, G. The high strain-rate behaviour of three molecular weights ofpolyethylene examined with a magnesium alloy split-Hopkinson pressure bar. Polym. Test. 2013, 32, 827–834. [Google Scholar] [CrossRef] [Green Version]

- Xuetao, Z. Dynamic Mechanical Properties of TB6 Titanium Alloy and Impact Resistance of Its Typical Structure. Master’s Thesis, South China University of Technology, Guangzhou, China, 2019. [Google Scholar]

- Xiaohu, Y.; Huilan, R.; Rong, L.; Xiaoqing, Z. Study on dynamic mechanical properties and energy absorption of polymeric foams. Chin. J. High Press. Phys. 2012, 26, 531–536. [Google Scholar]

- Bauwens-Crowet, C.; Bauwens, J.C.; Homes, G. The temperature dependence of yield of polycarbonate in uniaxial compression and tensile tests. J. Mater. Sci. 1972, 7, 176–183. [Google Scholar] [CrossRef]

- Bauwens-Crowet, C. The compression yield behaviour of polymethyl methacrylate over a wide range of temperatures and strain-rates. J. Mater. Sci. 1973, 8, 968–979. [Google Scholar] [CrossRef]

- Bergstrom, J.S.; Bischoff, J.E. An advanced thermomechanical constitutive model for UHMWPE. Int. J. Struct. Chang. Solids 2010, 2, 31–39. [Google Scholar]

| (g/cm3) | E (MPa) | ||||

|---|---|---|---|---|---|

| HDPE | 0.95 | 388 | 0.46 | 0.04–0.7 million | 270.03 |

| UHMWPE | 0.98 | 597.28 | 0.46 | 6 million | 288.42 |

| E0 (GPa) | Elastic Wave Velocity C0 (m/s) | Bar Diameter (mm) | Striker Length (mm) | Incident Bar Length (mm) | Transmission Bar Length (mm) |

|---|---|---|---|---|---|

| 70 | 4991 | 14.5 | 400 | 1500 | 2000 |

| Strain Rate (s−1) | Temperature (°C) | Yield Stress of HDPE (MPa) | Yield Stress of UHMWPE (MPa) |

|---|---|---|---|

| 0.1 | 25 | ||

| 0.01 | 25 | ||

| 0.001 | 25 | ||

| 0.001 | 50 | ||

| 0.001 | 70 | ||

| 0.001 | 90 | ||

| 0.001 | 120 | ||

| 0.001 | −20 | ||

| 0.001 | −40 |

| HDPE | 20.35 | 374.44 | 5.58 | −3.98288 | 2.44658 | |

| −1.36692 | 0.67368 | |||||

| UHMWPE | 14.64 | 1038.84 | 6.35 | −5.18376 | 7.0655 | |

| −2.25395 | 2.18186 |

| MAT_PLASTIC_KINEMATIC | ||

|---|---|---|

| (g/cm3) | ||

| 2810 | 370 | 0.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Li, W.; Zheng, Y.; Yao, W.; Zhao, C. Compressive Properties and Constitutive Model of Semicrystalline Polyethylene. Polymers 2021, 13, 2895. https://doi.org/10.3390/polym13172895

Zhang K, Li W, Zheng Y, Yao W, Zhao C. Compressive Properties and Constitutive Model of Semicrystalline Polyethylene. Polymers. 2021; 13(17):2895. https://doi.org/10.3390/polym13172895

Chicago/Turabian StyleZhang, Kebin, Wenbin Li, Yu Zheng, Wenjin Yao, and Changfang Zhao. 2021. "Compressive Properties and Constitutive Model of Semicrystalline Polyethylene" Polymers 13, no. 17: 2895. https://doi.org/10.3390/polym13172895

APA StyleZhang, K., Li, W., Zheng, Y., Yao, W., & Zhao, C. (2021). Compressive Properties and Constitutive Model of Semicrystalline Polyethylene. Polymers, 13(17), 2895. https://doi.org/10.3390/polym13172895