Plasticized Poly(vinyl chloride) Modified with Developed Fire Retardant System Based on Nanoclay and L-histidinium Dihydrogen Phosphate-Phosphoric Acid

Abstract

:1. Introduction

2. Materials and Methods

3. Results

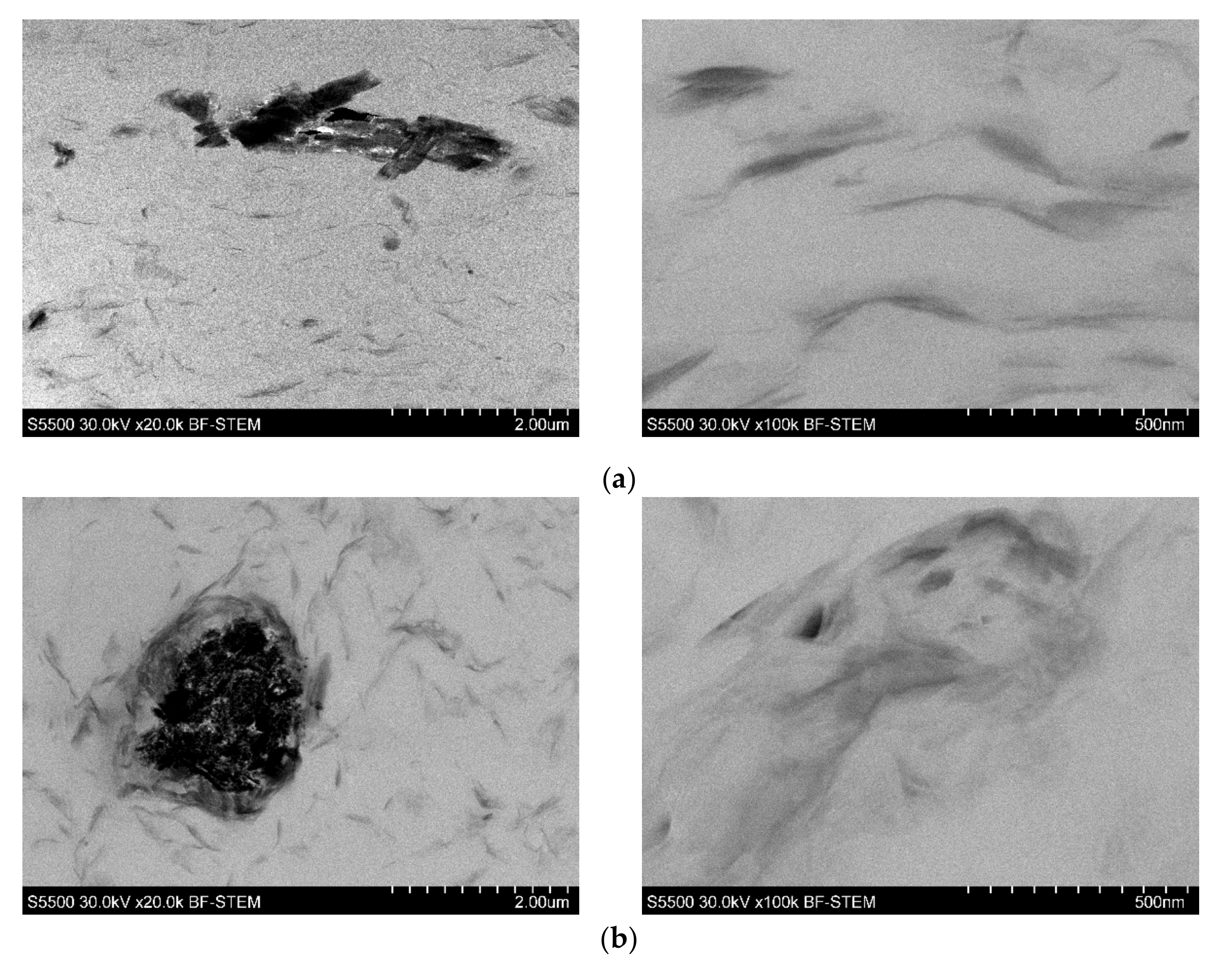

3.1. Microstructure Analysis

3.2. Mechanical Performance

3.3. Thermal Stability

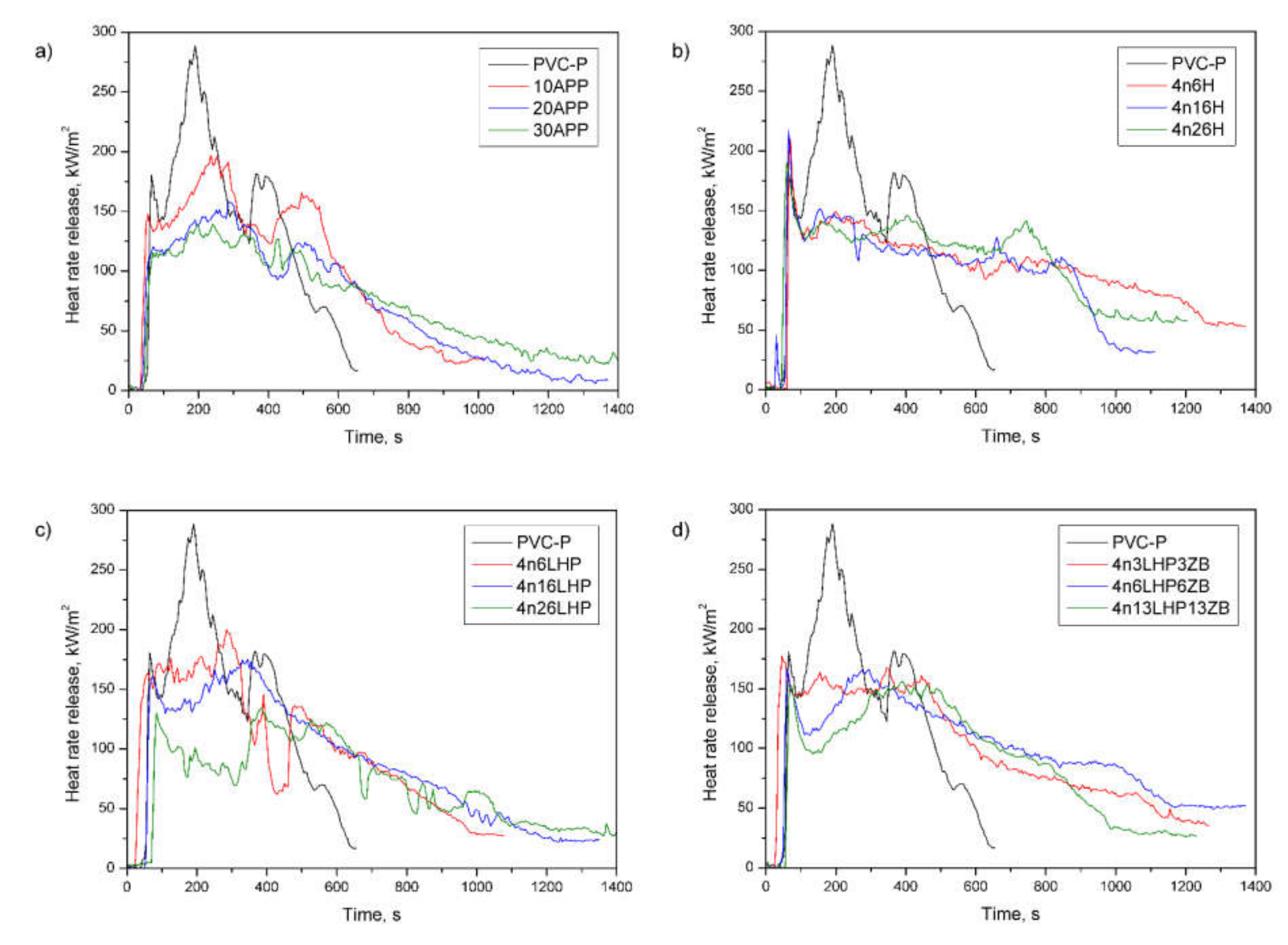

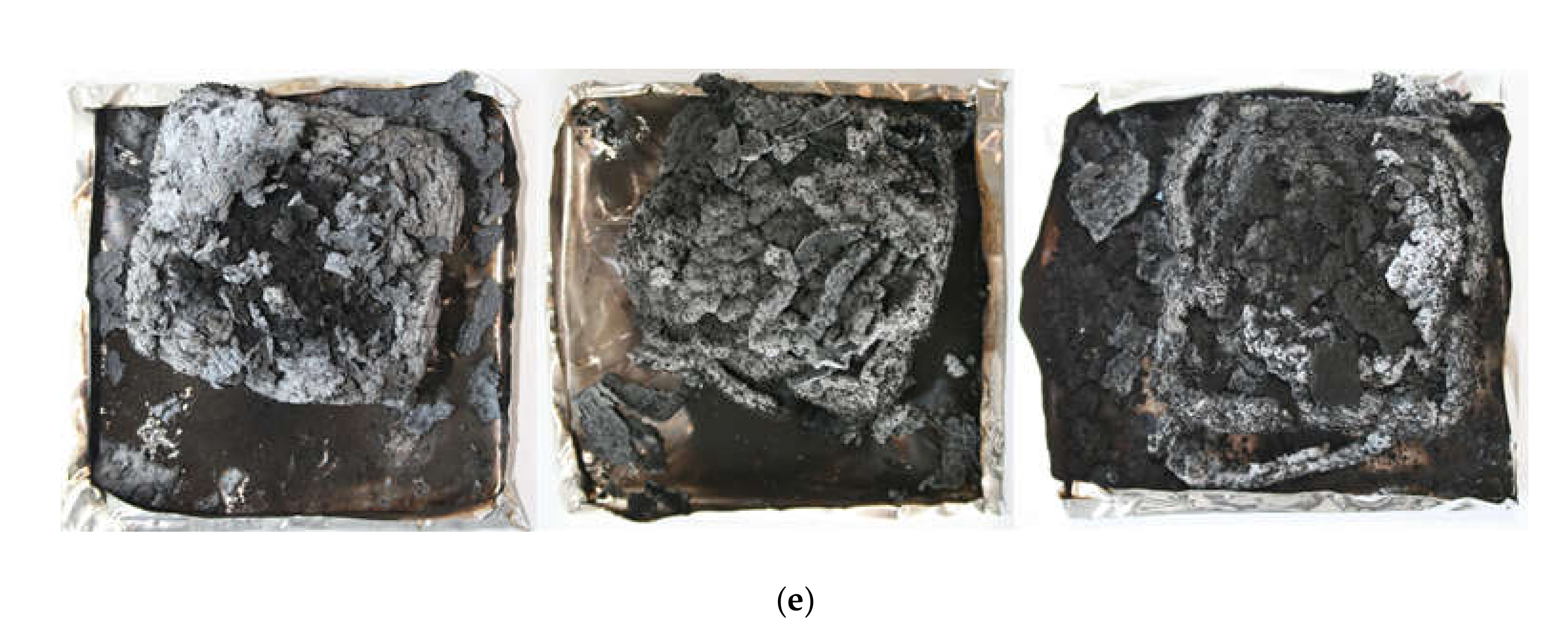

3.4. Forced Flaming Fire Behavior (Cone Calorimeter)

3.5. Smoke Emission

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Available online: https://firesafeeurope.eu/european-fire-safety-strategy-needed/ (accessed on 23 March 2020).

- Giebułtowicz, J.; Rużycka, M.; Wroczyński, P.; Purser, D.A.; Stec, A.A. Analysis of fire deaths in Poland and influence of smoke toxicity. Forensic Sci. Int. 2017, 277, 77–87. [Google Scholar] [CrossRef]

- Available online: https://dane.gov.pl/dataset/1783,statystyki-zdarzen-systemu-wspomagania-decyzji-panstwowej-strazy-pozarnej-swd-psp-za-rok-2019?page=1&per_page=20&q=&sort=-data_date (accessed on 23 March 2020).

- Wiatr, J. Cables and Wires (LV, MV, HV) The Impact of the Fire Temperature on the Voltage Supplying Electrical Devices and the Effectiveness of Protection Against Electric Shock for Devices that must Function during a Fire. European Copper Institute: Brussels, Belgium, 2013. [Google Scholar]

- Sawicki, T. Plastics and fire hazard. Work. Saf. 2003, 7–8, 43–45. [Google Scholar]

- Available online: https://marketpublishers.com/lists/23819/news.html (accessed on 10 May 2020).

- Obłój-Muzaj, M.; Świerz-Motysia, B.; Szabłowska, B. Polyvinyl Chloride; Scientific and Technical Publishing House: Warsaw, Poland, 1997. [Google Scholar]

- Thornton, J. Impacts of Polyvinyl Chloride Buildings Materials; Healthy Buiding Network: Washington, DC, USA, 2002. [Google Scholar]

- Janowska, G.; Przygocki, W.; Włochowicz, A. Flammability of Polymers and Polymeric Materials; Scientific and Technical Publishing House: Warsaw, Poland, 2007. [Google Scholar]

- Tai, Q.; Yuen, R.K.K.; Yang, W.; Qiao, Z.; Song, L.; Hu, Y. Iron-montmorillonite and zinc borate as synergistic agents in flame-retardant glass fiber reinforced polyamide 6 composites in combination with melamine polyphosphate. Compos. Part A 2012, 43, 415–422. [Google Scholar] [CrossRef]

- Salasinska, K.; Celiński, M.; Mizera, K.; Kozikowski, P.; Leszczyński, M.K.; Gajek, A. Synergistic effect between histidinephosphate complex and hazelnut shell for flammability reduction of low-smoke emission epoxy resin. Polym. Degrad. Stab. 2020, 181, 109292. [Google Scholar] [CrossRef]

- Salasinska, K.; Celiński, M.; Mizera, K.; Barczewski, M.; Kozikowski, P.; Leszczyński, M.K.; Domańska, A. Moisture Resistance, Thermal Stability and Fire Behavior of Unsaturated Polyester Resin Modified with L-histidiniumDihydrogen Phosphate-Phosphoric Acid. Molecules 2021, 26, 932. [Google Scholar] [CrossRef] [PubMed]

- Salasinska, K.; Mizera, K.; Celiński, M.; Kozikowski, P.; Mirowski, J.; Gajek, A. Thermal properties and fire behavior of a flexible poly(vinyl chloride) modified with complex of 3-aminotriazole with zinc phosphate. Fire Saf. J. 2021, 122, 103326. [Google Scholar] [CrossRef]

- Lewandowski, K.; Skórczewska, K.; Piszczek, K.; Manikowski, M.; Mirowski, J. Modification of rigid poly(vinyl chloride) for application in three-layer feed pipes. Polimery-W 2020, 65, 304–310. [Google Scholar] [CrossRef]

- Vahabi, H.; Kandola, B.K.; Reza, S.M. Flame Retardancy Index for Thermoplastic Composites. Polymers 2019, 11, 407. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hajibeygi, M.; Maleki, M.; Shabanian, M.; Bucos, F.; Vahabi, H. New polyvinyl chloride (PVC) nanocomposite consisting of aromatic polyamide and chitosan modified ZnO nanoparticles with enhanced thermal stability, low heat release rate an improved mechanical properties. Appl. Surf. Sci. 2018, 439, 1163–1179. [Google Scholar] [CrossRef]

- Allahbakhsh, A. PVC/Rice Straw/SDBS-Modified Graphene Oxide Sustainable Nanocomposites: Melt Mixing Process and Electrical Insulation Characteristics. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105902. [Google Scholar] [CrossRef]

- Crespo, J.E.; Sánchez, L.; García, D.; López, J. Study of the Mechanical and Morphological Properties of Plasticized PVC Composites Containing Rice Husk Fillers. J. Reinf. Plast. Compos. 2008, 27, 229–243. [Google Scholar] [CrossRef]

- Mirowski, J.; Oliwa, R.; Oleksy, M.; Tomaszewska, J.; Ryszkowska, J.; Budzik, G. Poly(vinyl chloride) Composites with Raspberry Pomace Filler. Polymers 2021, 13, 1079. [Google Scholar] [CrossRef] [PubMed]

- Daniels, P.H.; Cabrera, A. Plasticizer compatibility testing: Dynamic mechanical analysis and glass transition temperatures. J. Vinyl Addit. Technol. 2015, 21, 7–11. [Google Scholar] [CrossRef]

- Fisch, M.; Bacaloglu, R. Study of additive compatibility with poly(vinyl chloride) (PVC). 2: Dynamic mechanical analysis of PVC lubrication by stearic acid and its derivatives. J. Vinyl Addit. Technol. 1998, 4, 4–11. [Google Scholar] [CrossRef]

- Yue, X.; Chen, F.; Zhou, X. Improved interfacial bonding of PVC/wood-flour composites by lignin amine modification. BioResources 2011, 6, 2022–2034. [Google Scholar] [CrossRef]

- Noguchi, T.; Nagai, T.; Seto, J. Melt viscosity and electrical conductivity of carbon black-PVC composite. J. Appl. Polym. Sci. 1986, 31, 1913–1924. [Google Scholar] [CrossRef]

- Namhata, S.P.; Santolini, L.; Locati, G. Rationalisation of Vicat softening point measurements. Polym. Test. 1990, 9, 75–89. [Google Scholar] [CrossRef]

- Aouachria, K.; Belhaneche-Bensemra, N. Miscibility of PVC/PMMA blends by vicat softening temperature, viscometry, DSC and FTIR analysis. Polym. Test. 2006, 25, 1101–1108. [Google Scholar] [CrossRef]

- Bastida, S.; Eguiazábal, J.I.; Nazábal, J. The Vicat softening temperature as a method to assess the phase behaviour of amorphous polymer blends. Polym. Test. 1993, 12, 233–242. [Google Scholar] [CrossRef]

- Chen, N.; Wan, C.; Zhang, Y.; Zhang, Y. Effect of nano-CaCO3 on mechanical properties of PVC and PVC/Blendex blend. Polym. Test. 2004, 23, 169–174. [Google Scholar] [CrossRef]

- Petersen, H.; Jakubowicz, I.; Enebro, J.; Yarahmadi, N. Development of nanocomposites based on organically modified montmorillonite and plasticized PVC with improved barrier properties. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Çetin, A.; Erzengin, S.G.; Alp, F.B. Various Combinations of Flame Retardants for Poly (vinyl chloride). Open Chem. 2019, 17, 980–987. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; Hu, Y.; Tai, Q.; Lu, H.; Song, L.; Yuen, R.K.K. Fire and mechanical performance of nanoclay reinforced glass-fiber/PBT composites containing aluminum hypophosphite particles. Compos. Part A Appl. Sci. Manuf. 2011, 42, 794–800. [Google Scholar] [CrossRef]

- Liu, S.-T.; Zhang, P.-P.; Yan, K.-K.; Zhang, Y.-H.; Ye, Y.; Chen, X.-G. Sb-intercalated layered double hydroxides–poly(vinyl chloride) nanocomposites: Preparation, characterization, and thermal stability. J. Appl. Polym. Sci. 2015, 132, 42524. [Google Scholar] [CrossRef]

- Xue, X.; Zhang, H.; Zhang, S. Preparation of MgAl LDHs Intercalated with Amines and Effect on Thermal Behavior for Poly(vinyl chloride). Adv. Mater. Phys. Chem. 2014, 4, 258–266. [Google Scholar] [CrossRef] [Green Version]

- Salasinska, K.; Leszczyńska, M.; Celiński, M.; Kozikowski, P.; Kowiorski, K.; Lipińska, L. Moisture Resistance, Burning Behaviour of Rigid Polyurethane Foams with Histidine and Modified Graphene Oxide. Materials 2021, 14, 1184. [Google Scholar] [CrossRef] [PubMed]

- Schartel, B.; Perret, B.; Dittrich, B.; Ciesielski, M.; Krämer, J.; Müller, P. Flame retardancy of polymers: The role of specific reactions in the condensed phase. Macromol. Mater. Eng. 2016, 301, 9–35. [Google Scholar] [CrossRef]

- Schartel, B.; Hull, T.R. Development of fire-retarded materials–interpretation of cone calorimeter data. Fire Mater. 2007, 31, 327–354. [Google Scholar] [CrossRef]

- Battig, A.; Abdou-Rahaman Fadul, N.; Frasca, D.; Schulze, D.; Schartel, B. Multifunctional graphene nanofiller in flame retarded polybutadiene/ chloroprene/carbon black composites. E-Polymers 2021, 21, 244–262. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, Q.; Zhang, X.; Pan, H.; Lu, Y. Graphene oxide-filled multilayer coating to improve flame-retardant and smoke suppression properties of flexible polyurethane foam. J. Mater. Sci. 2016, 51, 10361–10374. [Google Scholar] [CrossRef]

| Samples | Components, wt% | |||||

|---|---|---|---|---|---|---|

| PVC-P | APP | H | LHP | ZB | n | |

| PVC-P | 100 | |||||

| 10APP | 90 | 10 | ||||

| 20APP | 80 | 20 | ||||

| 30APP | 70 | 30 | ||||

| 4n6H | 90 | 6 | 4 | |||

| 4n16H | 80 | 16 | 4 | |||

| 4n26H | 70 | 26 | 4 | |||

| 4n6LHP | 90 | 6 | 4 | |||

| 4n16LHP | 80 | 16 | 4 | |||

| 4n26LHP | 70 | 26 | 4 | |||

| 4n3LHP3ZB | 90 | 3 | 3 | 4 | ||

| 4n8LHP8ZB | 80 | 8 | 8 | 4 | ||

| 4n13LHP13ZB | 70 | 13 | 13 | 4 | ||

| Samples | G′−40 °C | G′25 °C | G′80 °C | T at G′′ Max | tanδ Peak | Tg at tanδ | VST |

|---|---|---|---|---|---|---|---|

| 109 Pa | 108 Pa | 106 Pa | °C | - | °C | °C | |

| PVC-P | 1.72 | 1.70 | 1.79 | −13.7 | 0.324 | 45.4 | 51.5 ± 0.7 |

| 10APP | 1.92 | 1.83 | 2.25 | −14.7 | 0.321 | 43.0 | 58.8 ± 0.6 |

| 20APP | 2.18 | 2.40 | 2.92 | −13.2 | 0.322 | 44.8 | 61.6 ± 0.6 |

| 30APP | 1.80 | 1.74 | 2.18 | −13.7 | 0.321 | 42.4 | 67.4 ± 1.2 |

| 4n6H | 1.87 | 2.55 | 3.97 | −14.5 | 0.300 | 48.7 | 61.7 ± 1.0 |

| 4n16H | 2.25 | 3.60 | 6.69 | −13.9 | 0.282 | 49.9 | 65.5 ± 0.8 |

| 4n26H | 2.66 | 5.07 | 11.1 | −10.8 | 0.278 | 52.3 | 69.2 ± 0.7 |

| 4n6LHP | 1.93 | 2.16 | 3.43 | −16.4 | 0.303 | 46.5 | 59.3 ± 0.5 |

| 4n16LHP | 2.12 | 2.52 | 4.62 | −15.5 | 0.296 | 46.4 | 60.4 ± 0.9 |

| 4n26LHP | 2.25 | 3.31 | 6.83 | −15.2 | 0.283 | 49.2 | 63.1 ± 0.6 |

| 4n3LHP3ZB | 2.11 | 2.47 | 3.80 | −16.2 | 0.299 | 49.1 | 61.0 ± 1.2 |

| 4n8LHP8ZB | 2.21 | 3.03 | 4.99 | −13.5 | 0.300 | 49.3 | 62.2 ± 0.6 |

| 4n13LHP13ZB | 1.80 | 2.22 | 3.62 | −13.5 | 0.284 | 46.5 | 65.7 ± 0.6 |

| Samples | T5% | 1st DTG Peak | 2nd DTG Peak | Residual Mass |

|---|---|---|---|---|

| °C | °C; %/min | % | ||

| PVC-P | 247 | 297; −9.02 | 454; −3.61 | 8.7 |

| 10APP | 255 | 300; −17.29 | 450; −3.72 | 11.3 |

| 20APP | 257 | 300; −14.39 | 447; −3.50 | 14.5 |

| 30APP | 258 | 302; −12.17 | 454; −3.21 | 20.4 |

| 4n6H | 247 | 273; −10.60 | 449; −3.06 | 12.8 |

| 4n16H | 246 | 263; −10.54 | 452; −2.69 | 17.4 |

| 4n26H | 244 | 253; −11.33 | 454; −2.59 | 19.9 |

| 4n6LHP | 242 | 294; −8.67 | 445 −3.00 | 14.1 |

| 4n16LHP | 237 | 278; −7.48 | 451; −2.86 | 17.6 |

| 4n26LHP | 233 | 228; −6.87 | 451; −2.35 | 22.0 |

| 4n3LHP3ZB | 223 | 269; −10.46 | 459; −2.58 | 19.3 |

| 4n8LHP8ZB | 219 | 249; −9.39 | 456; −2.16 | 24.0 |

| 4n13LHP13ZB | 223 | 267; −10.69 | 456; −2.53 | 18.8 |

| Samples | TTI, s | pHRR, kW/m2 | MARHE, kW/m2 | FRI, - | THR, MJ/m2 | EHC, MJ/kg | Mass Loss, % |

|---|---|---|---|---|---|---|---|

| PVC-P | 60 ± 20 | 282 ± 10 | 163 ± 5 | - | 90 ± 5 | 12.4 ± 1 | 87 ± 3 |

| 10APP | 40 ± 10 | 206 ± 9 | 141 ± 2 | 0.8 | 108 ± 5 | 14.0 ± 1 | 86 ± 1 |

| 20APP | 56 ± 7 | 161 ± 7 | 113 ± 4 | 1.5 | 97 ± 10 | 14.0 ± 2 | 79 ± 1 |

| 30APP | 47 ± 2 | 144 ± 8 | 109 ± 7 | 1.3 | 142 ± 31 | 15.6 ± 1 | 70 ± 1 |

| 4n6H | 60 ± 2 | 204 ± 11 | 118 ± 8 | 0.9 | 114 ± 7 | 18.2 ± 4 | 88 ± 1 |

| 4n16H | 51 ± 19 | 179 ± 35 | 117 ± 8 | 1.1 | 122 ± 4 | 15.3 ± 1 | 84 ± 1 |

| 4n26H | 47 ± 17 | 166 ± 22 | 122 ± 4 | 1.0 | 112 ± 4 | 16.7 ± 1 | 79 ± 1 |

| 4n6LHP | 30 ± 2 | 185 ± 21 | 147 ± 10 | 0.6 | 112 ± 8 | 14.2 ± 1 | 88 ± 1 |

| 4n16LHP | 50 ± 10 | 170 ± 6 | 122 ± 7 | 1.1 | 101 ± 9 | 14.6 ± 1 | 83 ± 0 |

| 4n26LHP | 71 ± 5 | 138 ± 3 | 89 ± 8 | 2.2 | 120 ± 6 | 14.1 ± 1 | 76 ± 0 |

| 4n3LHP3ZB | 34 ± 2 | 181 ± 24 | 136 ± 6 | 0.7 | 142 ± 30 | 15.8 ± 1 | 84 ± 1 |

| 4n8LHP8ZB | 50 ± 15 | 171 ± 15 | 124 ± 10 | 0.9 | 109 ± 1 | 19.3 ± 4 | 78 ± 2 |

| 4n13LHP13ZB | 60 ± 3 | 163 ± 10 | 122 ± 6 | 1.4 | 142 ± 31 | 15.8 ± 0 | 72 ± 0 |

| Samples | TSR, m2/ m2 | SEA, m2/kg | Dsmax | VOF4 |

|---|---|---|---|---|

| PVC-P | 5034 ± 150 | 680 ± 13 | 1209 ± 134 | 434 ± 31 |

| 10APP | 7481 ± 273 | 965 ± 32 | 1028 ± 3 | 375 ± 50 |

| 20APP | 6160 ± 205 | 850 ± 13 | 954 ± 31 | 239 ± 38 |

| 30APP | 4613 ± 128 | 684 ± 7 | 918 ± 0 | 291 ± 42 |

| 4n6H | 4704 ± 302 | 592 ± 27 | 906 ± 65 | 462 ± 106 |

| 4n16H | 4899 ± 13 | 646 ± 18 | 851 ± 38 | 296 ± 68 |

| 4n26H | 4289 ± 156 | 578 ± 22 | 889 ± 38 | 295 ± 15 |

| 4n6LHP | 4417 ± 140 | 558 ± 12 | 961 ± 32 | 609 ± 72 |

| 4n16LHP | 3878 ± 291 | 499 ± 33 | 878 ± 59 | 474 ± 58 |

| 4n26LHP | 2674 ± 140 | 351 ± 23 | 776 ± 33 | 373 ± 79 |

| 4n3LHP3ZB | 4336 ± 273 | 569 ± 28 | 924 ± 33 | 533 ± 118 |

| 4n8LHP8ZB | 3573 ± 285 | 469 ± 42 | 717 ± 40 | 265 ± 330 |

| 4n13LHP13ZB | 2999 ± 169 | 411 ± 25 | 678 ± 2 | 480 ± 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sałasińska, K.; Barczewski, M.; Celiński, M.; Kozikowski, P.; Kozera, R.; Sodo, A.; Mirowski, J.; Zajchowski, S.; Tomaszewska, J. Plasticized Poly(vinyl chloride) Modified with Developed Fire Retardant System Based on Nanoclay and L-histidinium Dihydrogen Phosphate-Phosphoric Acid. Polymers 2021, 13, 2909. https://doi.org/10.3390/polym13172909

Sałasińska K, Barczewski M, Celiński M, Kozikowski P, Kozera R, Sodo A, Mirowski J, Zajchowski S, Tomaszewska J. Plasticized Poly(vinyl chloride) Modified with Developed Fire Retardant System Based on Nanoclay and L-histidinium Dihydrogen Phosphate-Phosphoric Acid. Polymers. 2021; 13(17):2909. https://doi.org/10.3390/polym13172909

Chicago/Turabian StyleSałasińska, Kamila, Mateusz Barczewski, Maciej Celiński, Paweł Kozikowski, Rafał Kozera, Aleksandra Sodo, Jacek Mirowski, Stanisław Zajchowski, and Jolanta Tomaszewska. 2021. "Plasticized Poly(vinyl chloride) Modified with Developed Fire Retardant System Based on Nanoclay and L-histidinium Dihydrogen Phosphate-Phosphoric Acid" Polymers 13, no. 17: 2909. https://doi.org/10.3390/polym13172909

APA StyleSałasińska, K., Barczewski, M., Celiński, M., Kozikowski, P., Kozera, R., Sodo, A., Mirowski, J., Zajchowski, S., & Tomaszewska, J. (2021). Plasticized Poly(vinyl chloride) Modified with Developed Fire Retardant System Based on Nanoclay and L-histidinium Dihydrogen Phosphate-Phosphoric Acid. Polymers, 13(17), 2909. https://doi.org/10.3390/polym13172909