Influence of Tire Rubber Particles Addition in Different Branching Degrees Polyethylene Matrix Composites on Physical and Structural Behavior

Abstract

:1. Introduction

2. Methods and Materials

Sample Manufacturing

3. Results and Discussion

3.1. Internal Structure—Micrographs Analysis

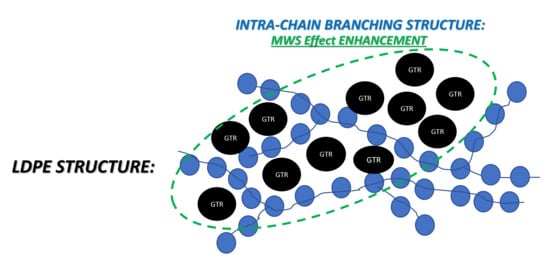

3.2. Conductivity Analysis

3.3. Permittivity Analysis

3.4. Electrical Modulus

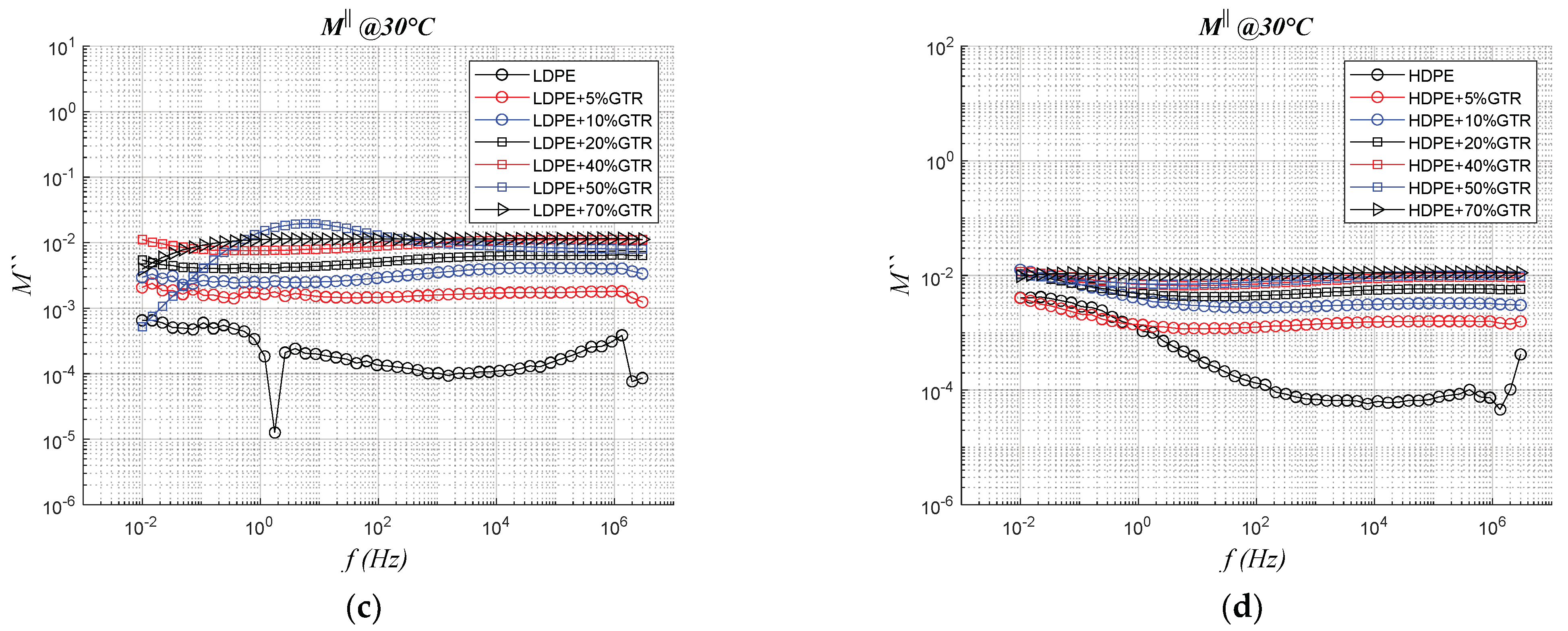

3.5. Argand Diagrams

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fazli, A.; Rodrigue, D. Recycling Waste Tires into Ground Tire Rubber (GTR)/Rubber Compounds: A Review. J. Compos. Sci. 2020, 4, 103. [Google Scholar] [CrossRef]

- Presti, D.L. Recycled tyre rubber modified bitumens for road asphalt mixtures: A literature review. Constr Build Mater 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Forrest, M.J. 3. Overview of the world rubber recycling market. In Recycling and Re-Use of Waste Rubber; De Gruyter: Berlin, Germany; Boston, MA, USA, 2019; pp. 13–20. [Google Scholar] [CrossRef]

- Nuzaimah, M.; Sapuan, S.M.; Nadlene, R.; Jawaid, M. Recycling of waste rubber as fillers: A review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 012016. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Marín-Genescà, M.; García-Amorós, J.; Mujal-Rosas, R.; Vidal, L.M.; Arroyo, J.B.; Fajula, X.C. Ground Tire Rubber Recycling in Applications as Insulators in Polymeric Compounds. Accord. Span. UNE Standards. Recycl. 2020, 5, 16. [Google Scholar] [CrossRef]

- Marín-Genescà, M.; Mujal-Rosas, R.; García-Amorós, J.; Mudarra, M.; Ramis Juan, X.; Colom Fajula, X. Study Analysis of Thermal, Dielectric, and Functional Characteristics of an Ethylene Polyethylene Diene Monomer Blended with End-of-Life Tire Microparticles Amounts. Polymers 2021, 13, 509. [Google Scholar] [CrossRef]

- Marín-Genescà, M.; García-Amorós, J.; Mujal-Rosas, R.; Salueña Berna, X.; Massagués Vidal, L. Comparison of Mechanical and Electrical Characteristics of Various Polymers Blended with Ground Tire Rubber (GTR) and Applications. Appl. Sci. 2019, 9, 1564. [Google Scholar] [CrossRef] [Green Version]

- Laurence, W. McKeen, Chapter 1—Introduction to Plastics and Polymers. In Plastics Design Library, Film Properties of Plastics and Elastomers, 3rd ed.; William Andrew Publishing: Norwich, NY, USA, 2012; pp. 1–18. ISBN 9781455725519. [Google Scholar] [CrossRef]

- Adamec, V.; Calderwood, J.H. On the determination of electrical conductivity in polyethylene. J. Phys. D: Appl. Phys. 1981, 14, 1487. [Google Scholar] [CrossRef]

- Bässler, H. Hopping conduction in polymers. Int. J. Mod. Phys. B 1994. [Google Scholar] [CrossRef]

- Psarras, G.C. Hopping conductivity in polymer matrix–metal particles composites. Compos. Part A: Appl. Sci. Manuf. 2006, 37, 1545–1553. [Google Scholar] [CrossRef]

- Das-Gupta, D. Conduction mechanisms and high-field effects in synthetic insulating polymers. IEEE Trans. Dielectr. Electr. Insul. 1997, 4, 149–156. [Google Scholar] [CrossRef]

- Röhl, P. Electronic hopping transport mechanism in polyethylene. In Proceedings of the 1984 IEEE International Conference on Eletrical Insulation, Montreal, QC, Canada, 11–13 June 1984; pp. 186–189. [Google Scholar] [CrossRef]

- Rubel, O.; Baranovskii, S.D.; Thomas, P.; Yamasaki, S. Concentration dependence of the hopping mobility in disordered organic solids. Phys. Rev. B 2004, 69, 014206. [Google Scholar] [CrossRef]

- Shklovskii, B.I.; Efros, A.L. Variable-Range Hopping Conduction. In Electronic Properties of Doped Semiconductors. Springer Series in Solid-State Sciences; Springer: Berlin/Heidelberg, Germany, 1984; Volume 45. [Google Scholar] [CrossRef]

- William, T. Coffey, Dielectric relaxation: An overview. J. Mol. Liq. 2004, 114, 5–25. [Google Scholar] [CrossRef]

- Debye, P. Verh. Dtsch. Phys. Ges 1913, 15, 777. [Google Scholar]

- Debye, P. Polar Molecules; Chemical Catalog: New York, NY, USA, 1929; reprinted by Dover, NY, USA, 1954. [Google Scholar]

- Jonscher, A.K. Dielectric relaxation in solids. J. Phys. D Appl. Phys. 1999, 32, R57. [Google Scholar] [CrossRef]

- Jonscher, A. The ‘universal’ dielectric response. Nature 1977, 267, 673–679. [Google Scholar] [CrossRef]

- Orrit-Prat, J.; Mujal-Rosas, R.; Rahhali, A.; Marin-Genesca, M.; Colom-Fajula, X.; Belana-Punseti, J. Dielectric, and mechanical characterization of PVC composites with ground tire rubber. J. Compos. Mater. 2011, 45, 1233–1243. [Google Scholar] [CrossRef]

- Almond, D.P.; Hunter, C.C.; West, A.R. The extraction of ionic conductivities and hopping rates from a.c. conductivity data. J Mater Sci. 1984, 19, 3236–3248. [Google Scholar] [CrossRef]

- Sim, A. Unified Model of Charge Transport in Insulating Polymeric Materials. 2013. All Graduate Theses and Dissertations. 2044. Available online: https://digitalcommons.usu.edu/etd/2044/ (accessed on 12 May 2021).

- Hammami, H.; Arous, M.; Lagache, M.; Kallel, A. Study of the interfacial MWS relaxation by dielectric spectroscopy in unidirectional PZT fibres/epoxy resin composites. J. Alloy. Compd. 2007, 430, 1–8. [Google Scholar] [CrossRef]

- Perrier, G.; Bergeret, A. Maxwell–Wagner–Sillars relaxations in polystyrene–glass-bead composites. J. Appl. Phys. 1995, 77, 2651–2658. [Google Scholar] [CrossRef]

- Mujal-Rosas, R.; Orrit-Prat, J.; Ramis-Juan, X.; Marin-Genesca, M.; Ahmed, R. Dielectric Properties of Various Polymers (PVC, EVA, HDPE, and PP) Reinforced with Disused Tires (GTR) —Afinidad, 2011—raco.cat. Available online: https://raco.cat/index.php/afinidad/article/view/268106/355687 (accessed on 10 May 2021).

- Pollak, M. A percolation treatment of dc hopping conduction. J. Non-Cryst. Solids 1972, 11, 1–24. [Google Scholar] [CrossRef]

- Capaccioli, S.; Lucchesi, M.; Rolla, P.A.; Ruggeri, G. Dielectric response analysis of a conducting polymer dominated by the hopping charge transport. J. Phys. Condens. Matter 1998, 10, 5595. [Google Scholar] [CrossRef]

- Marín-Genescà, M.; García-Amorós, J.; Mujal-Rosas, R.; Massagués, L.; Colom, X. Study and Characterization of the Dielectric Behavior of Low Linear Density Polyethylene Composites Mixed with Ground Tire Rubber Particles. Polymers 2020, 12, 1075. [Google Scholar] [CrossRef]

- Mujal-Rosas, R.; Orrit-Prat, J.; Ramis-Juan, X.; Marin-Genesca, M.; Rahhali, A. Study on Dielectric, Mechanical and Thermal Properties of Polypropylene (PP) Composites with Ground Tyre Rubber (GTR). Polym. Polym. Compos. 2012, 20, 797–808. [Google Scholar] [CrossRef]

- Coelho, R. On the Relaxation of a Space-Charge. Rev. Phys. Appl. 1983, 18, 137. [Google Scholar] [CrossRef]

- Marin, M.; Mujal, R. Ethylene vinyl acetate compound (EVA) reinforced with end-of-life tires (GTR) dielectric, mechanical and thermal properties. Afinidad: Rev. De Química Teórica Y Apl. 2014, 71, 101–111. Available online: https://upcommons.upc.edu/handle/2117/24172 (accessed on 26 May 2021).

- Scaife, B.K.P. Principles of Dielectrics, 2nd ed.; Oxford University Press: London, UK, 1998. [Google Scholar]

- Cole, K.S.; Cole, R.H. Dispersion and Absorption in Dielectrics I. Alternating Current Characteristics. J. Chem. Phys. 1941, 9, 341. [Google Scholar] [CrossRef] [Green Version]

- Kalmykov, Y.P.; Coffey, W.T.; Crothers, D.S.F.; Titov, S.V. Microscopic models for dielectric relaxation in disordered systems. Phys. Rev. E 2004, 70, 041103. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marín-Genescà, M.; García-Amorós, J.; Mujal-Rosas, R.; Massagués Vidal, L.; Colom Fajula, X. Application Properties Analysis as a Dielectric Capacitor of End-of-Life Tire-Reinforced HDPE. Polymers 2020, 12, 2675. [Google Scholar] [CrossRef]

| Feature | LDPE | HDPE |

|---|---|---|

| Density, g/cm3 | 0.92–0.93 | 0.95–0.96 |

| Tensile strength × 1000 PSI | 8 | 5.4 |

| Elongation at break, % | 720 | 700 |

| Crystallinity, % | 65 | 95 |

| Maximum use temperature, °C | 82–100 | 80–120 |

| Flow index g/10 min | 1 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marín-Genescà, M.; Mujal Rosas, R.; García Amorós, J.; Massagues Vidal, L.; Colom Fajula, X. Influence of Tire Rubber Particles Addition in Different Branching Degrees Polyethylene Matrix Composites on Physical and Structural Behavior. Polymers 2021, 13, 3213. https://doi.org/10.3390/polym13193213

Marín-Genescà M, Mujal Rosas R, García Amorós J, Massagues Vidal L, Colom Fajula X. Influence of Tire Rubber Particles Addition in Different Branching Degrees Polyethylene Matrix Composites on Physical and Structural Behavior. Polymers. 2021; 13(19):3213. https://doi.org/10.3390/polym13193213

Chicago/Turabian StyleMarín-Genescà, Marc, Ramon Mujal Rosas, Jordi García Amorós, Lluis Massagues Vidal, and Xavier Colom Fajula. 2021. "Influence of Tire Rubber Particles Addition in Different Branching Degrees Polyethylene Matrix Composites on Physical and Structural Behavior" Polymers 13, no. 19: 3213. https://doi.org/10.3390/polym13193213

APA StyleMarín-Genescà, M., Mujal Rosas, R., García Amorós, J., Massagues Vidal, L., & Colom Fajula, X. (2021). Influence of Tire Rubber Particles Addition in Different Branching Degrees Polyethylene Matrix Composites on Physical and Structural Behavior. Polymers, 13(19), 3213. https://doi.org/10.3390/polym13193213