Electrostrictive and Structural Properties of Poly(Vinylidene Fluoride-Hexafluoropropylene) Composite Nanofibers Filled with Polyaniline (Emeraldine Base)

Abstract

:1. Introduction

2. Materials and Methods

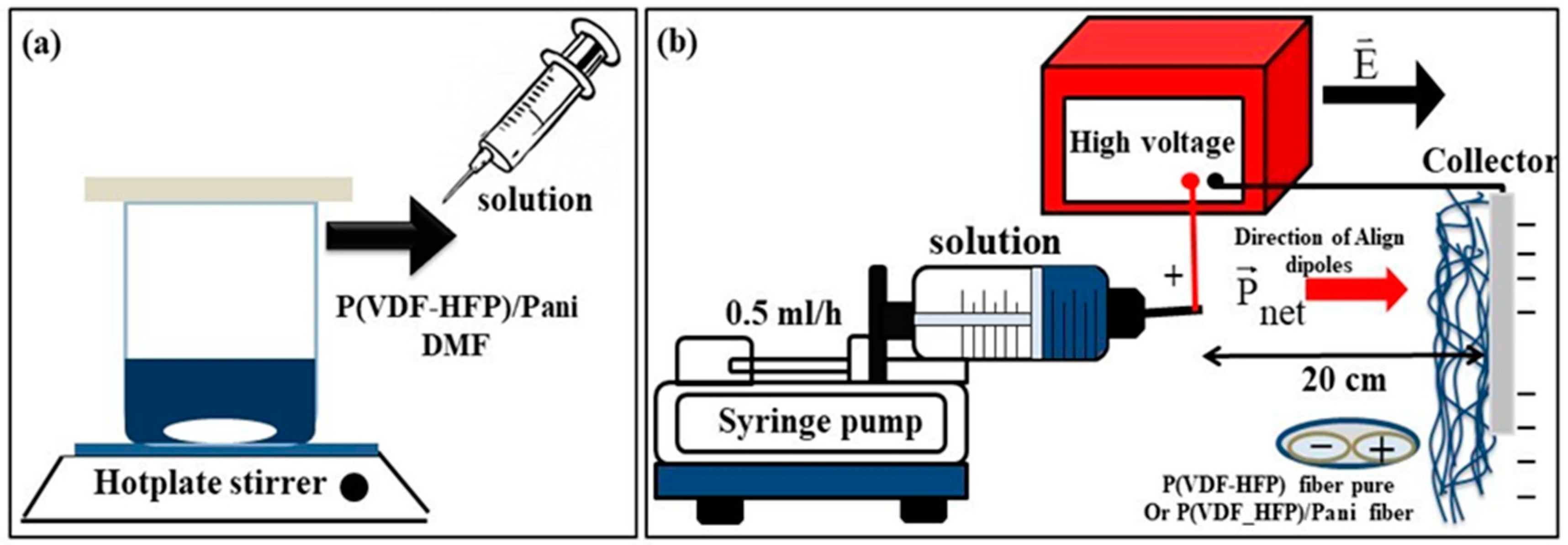

2.1. Materials and Composite Nanofiber Preparation

2.2. Material Characterization

2.2.1. Surface Morphology, Water Contact Angle and Elemental Analyses

2.2.2. Crystalline and Phase Structure Investigations

2.2.3. Dynamic Mechanical and Young’s Modulus Analyses

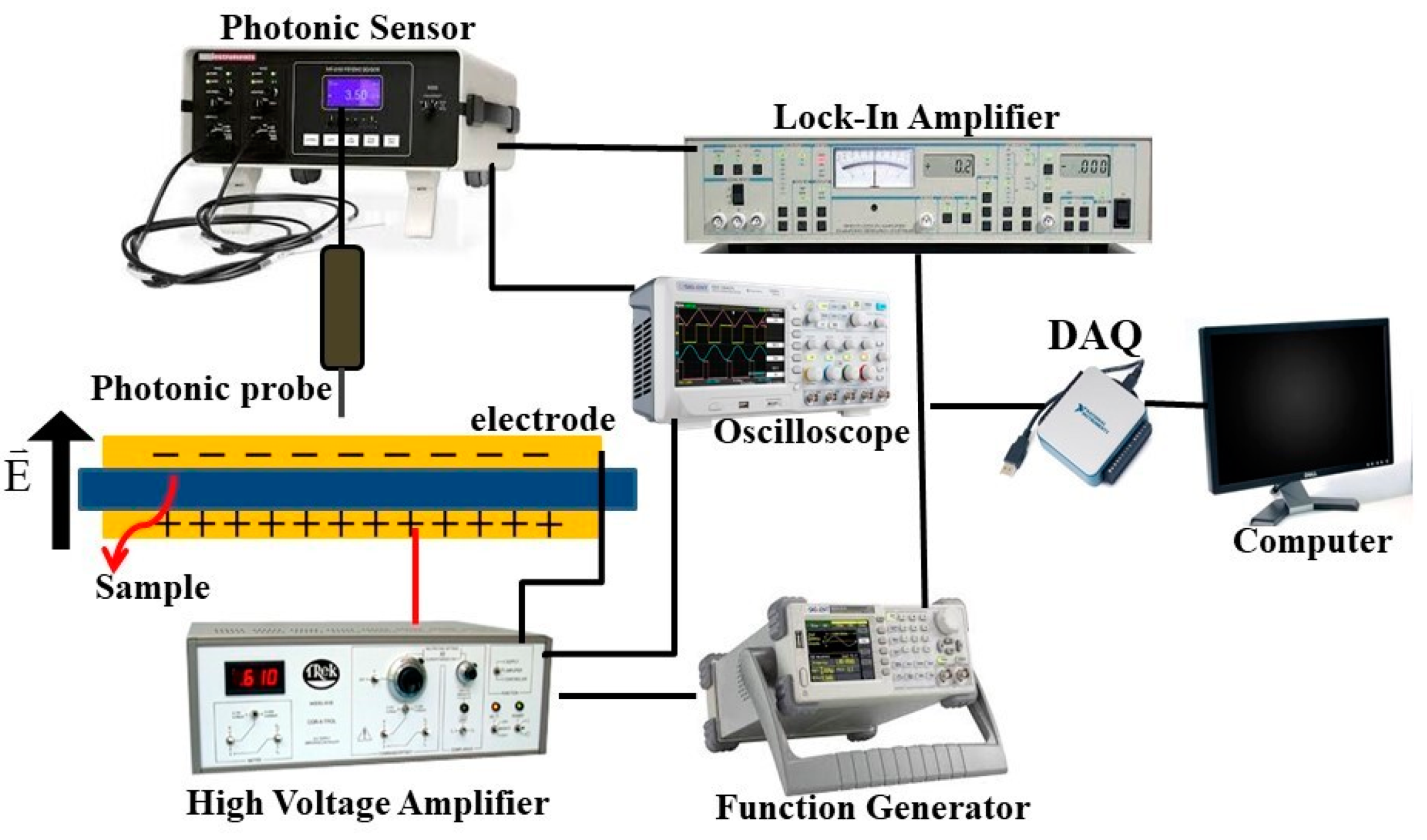

2.2.4. Dielectric Properties and Electrostriction Behavior

3. Results and Discussion

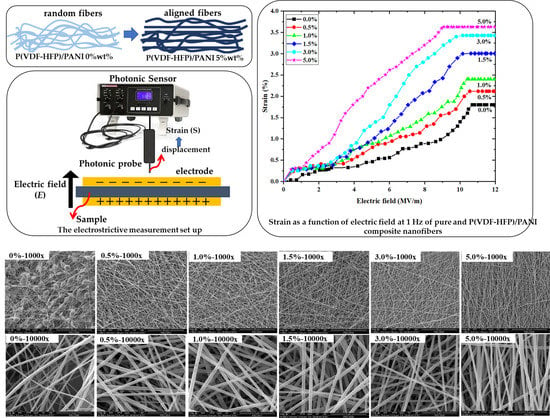

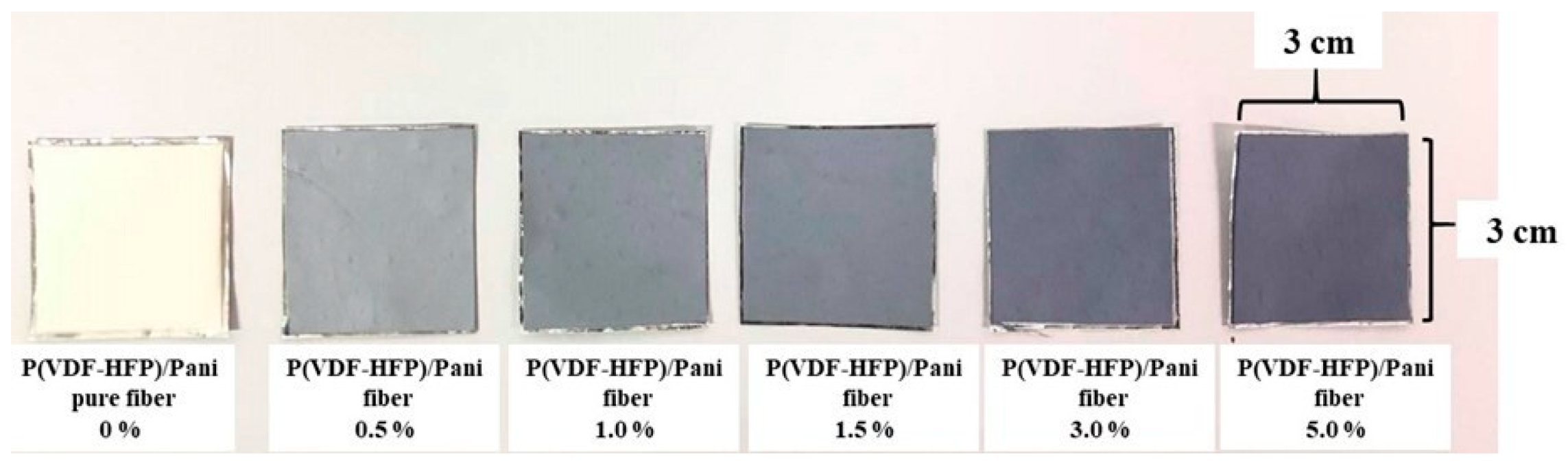

3.1. Surface Morphology

3.2. Crystalline and Phase Structure Analysis

3.3. Mechanical Properties

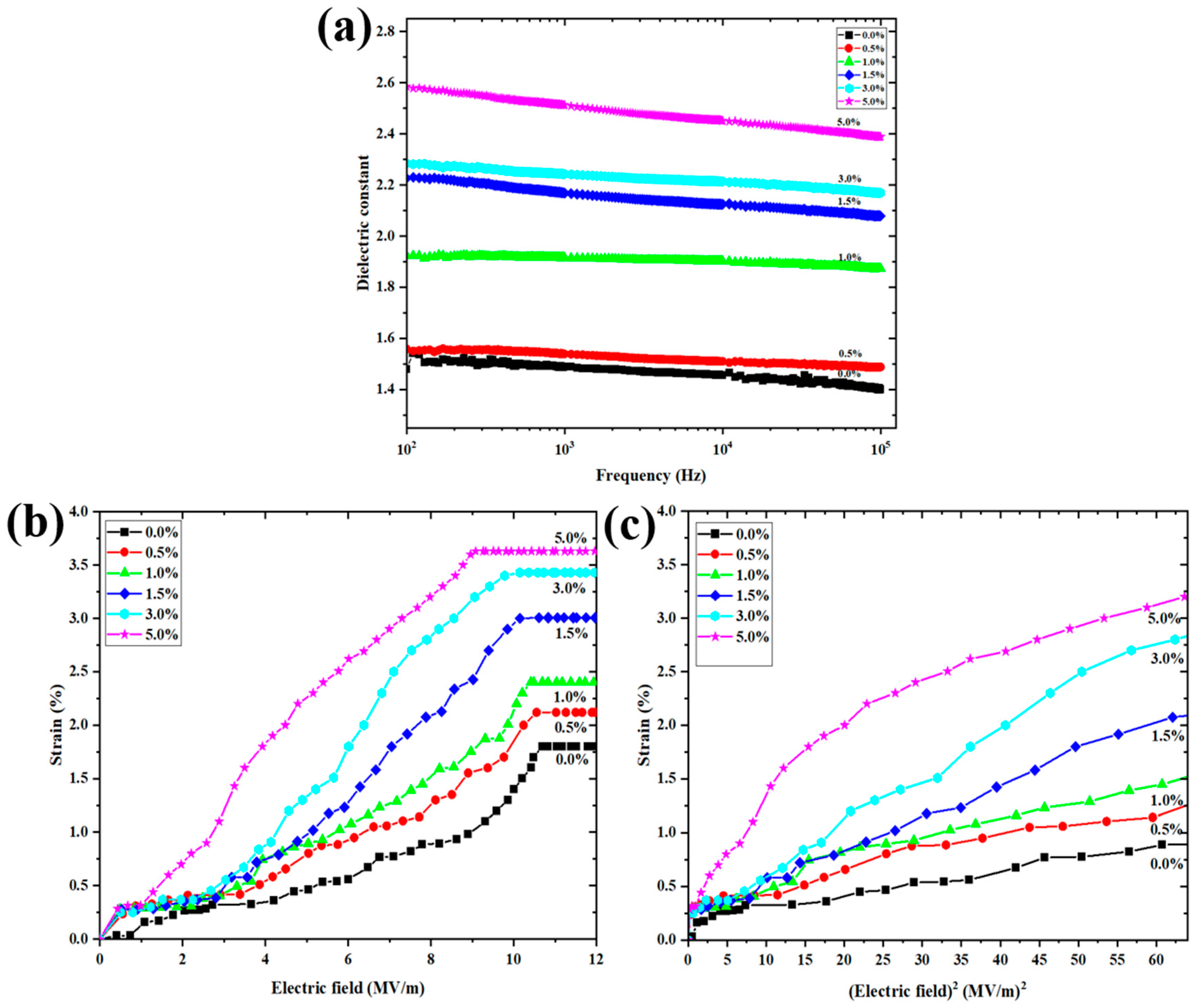

3.4. Dielectric Properties and Electrostrictive Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, F.; Ko, S.Y.; Park, J.O.; Kee, C.D. Electroactive polymer actuator based on pvdf and graphene through electrospinning. Adv. Mat. Res. 2015, 1105, 311–314. [Google Scholar] [CrossRef]

- Bae, J.H.; Chang, S.H. Characterization of an electroactive polymer (PVDF-TrFE) film-type sensor for health monitoring of composite structures. Compos. Struct. 2015, 131, 1090–1098. [Google Scholar] [CrossRef]

- Adhikary, P.; Garain, S.; Mandal, D. The co-operative performance of a hydrated salt assisted sponge like P(VDF-HFP) piezoelectric generator: An effective piezoelectric based energy harvester. Phys. Chem. Chem. Phys. 2015, 17, 7275–7281. [Google Scholar] [CrossRef] [Green Version]

- Martins, P.; Lopes, A.C.; Lanceros-Mendez, S. Electroactive phases of poly(vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Farooqui, U.R.; Ahmad, A.L.; Hamid, N.A. Effect of polyaniline (PANI) on Poly(vinylidene fluoride-co-hexaflouro propylene) (PVDF-co-HFP) polymer electrolyte membrane prepared by breath figure method. Polym. Test. 2017, 60, 124–131. [Google Scholar] [CrossRef]

- Dhakras, D.; Borkar, V.; Ogale, S.; Jog, J. Enhanced piezoresponse of electrospun PVDF mats with a touch of nickel chloride hexahydrate salt. Nanoscale 2012, 4, 752. [Google Scholar] [CrossRef]

- Cai, X.; Huang, X.; Zheng, Z.; Xu, J.; Tang, X.; Lei, T. Effect of Polyaniline (Emeraldine Base) Addition on α to β Phase Transformation in Electrospun PVDF Fibers. J. Macromol. Sci. B 2017, 56, 75–82. [Google Scholar] [CrossRef]

- Acik, G.; Cansoy, C.E.; Kamaci, M. Effect of flow rate on wetting and optical properties of electrospun poly(vinyl acetate) micro-fibers. Colloid Polym. Sci. 2018, 297, 77–83. [Google Scholar] [CrossRef]

- Najjar, R.; Luo, Y.; Jao, D.; Brennan, D.; Xue, Y.; Beachley, V.; Hu, X.; Xue, W. Biocompatible Silk/Polymer Energy Harvesters Using Stretched Poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) Nanofibers. Polymers 2017, 9, 479. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pi, H.; Wang, R.; Ren, B.; Zhang, X.; Wu, J. Facile Fabrication of Multi-Structured SiO2@PVDF-HFP Nanofibrous Membranes for Enhanced Copper Ions Adsorption. Polymers 2018, 10, 1385. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ponnamma, D.; Chamakh, M.M.; Alahzm, A.M.; Salim, N.; Hameed, N.; AlMaadeed, M.A.A. Core-Shell Nanofibers of Polyvinylidene Fluoride-based Nanocomposites as Piezoelectric Nanogenerators. Polymers 2020, 12, 2344. [Google Scholar] [CrossRef] [PubMed]

- Tohluebaji, N.; Thainiramit, P.; Putson, C.; Muensit, N. Phase and Structure Behavior vs. Electromechanical Performance of Electrostrictive P(VDF-HFP)/ZnO Composite Nanofibers. Polymers 2021, 13, 2565. [Google Scholar] [CrossRef] [PubMed]

- Soares, B.G.; Pontes, K.; Marins, J.A.; Calheiros, L.F.; Livi, S.; Barra, G.M.O. Poly(vinylidene fluoride-co-hexafluoropropylene)/polyaniline blends assisted by phosphonium—Based ionic liquid: Dielectric properties and β-phase formation. Eur. Polym. J. 2015, 73, 65–74. [Google Scholar] [CrossRef]

- Karan, S.K.; Mandal, D.; Khatua, B.B. Self-powered flexible Fe-doped RGO/PVDF nanocomposite: An excellent material for a piezoelectric energy harvester. Nanoscale 2015, 48, 10655–10666. [Google Scholar] [CrossRef]

- Sencadas, V.; Gregorio, R.; Lanceros-Méndez, S. α to β phase transformation and microestructural changes of PVDF induced by uniaxial stretch. J. Macromol. Sci. B 2009, 48, 514–525. [Google Scholar] [CrossRef]

- Low, Y.K.A.; Tan, L.Y.; Tan, L.P.; Boey, F.Y.C.; Ng, K.W. Increasing solvent polarity and addition of salts promote β-phase poly(vinylidene fluoride) formation. J. Appl. Polym. Sci. 2013, 128, 2902–2910. [Google Scholar] [CrossRef]

- Uyar, T.; Besenbacher, F. Electrospinning of uniform polystyrene fibers: The effect of solvent conductivity. Polymers 2008, 49, 5336–5343. [Google Scholar] [CrossRef]

- Khalifa, M.; Anandhan, S. PVDF nanofibers with embedded polyaniline-graphitic carbon nitride nanosheet composites for piezoelectric energy conversion. ACS Appl. Nano Mater. 2019, 2, 7328–7339. [Google Scholar] [CrossRef]

- Dognani, G.; Hadi, P.; Ma, H.; Cabrera, F.C.; Job, A.E.; Agostini, D.L.S.; Hsiao, B.S. Effective chromium removal from water by polyaniline-coated electrospun adsorbent membrane. Chem. Eng. J. 2019, 372, 341–351. [Google Scholar] [CrossRef]

- Qiu, B.; Xu, C.; Sun, D.; Yi, H.; Guo, J.; Zhang, X.; Qu, H.; Guerrero, M.; Wang, X.; Noel, N.; et al. Polyaniline coated ethyl cellulose with improved hexavalent chromium removal. ACS Sustain. Chem. Eng. 2014, 2, 2070–2080. [Google Scholar] [CrossRef]

- Hoque, N.A.; Thakur, P.; Roy, S.; Kool, A.; Bagchi, B.; Biswas, P.; Saikh, M.M.; Khatun, F.; Das, S.; Ray, P.P. Er3+/Fe3+ Stimulated electroactive, visible light emitting, and high dielectric flexible pvdf film based piezoelectric nanogenerators: A simple and superior self-powered energy harvester with remarkable power density. ACS Appl. Mater. Interfaces 2017, 9, 23048–23049. [Google Scholar] [CrossRef] [PubMed]

- Tohluebaji, N.; Putson, C.; Muensit, N. Electromechanical deformation based on structural beta-phase content and electrostrictive properties of electrospun poly(vinylidene fluoride- hexafluoropropylene) nanofibers. Polymers 2019, 11, 1817. [Google Scholar] [CrossRef] [Green Version]

- Jana, S.; Garain, S.; Sen, S.; Mandal, D. The influence of hydrogen bonding on the dielectric constant and the piezoelectric energy harvesting performance of hydrated metal salt mediated PVDF films. Phys. Chem. Chem. Phys. 2015, 17, 17429–17436. [Google Scholar] [CrossRef] [PubMed]

- Abd Razak, S.I.; Wahab, I.F.; Fadil, F.; Dahli, F.N.; Md Khudzari, A.Z.; Adeli, H. A review of electrospun conductive polyaniline based nanofiber composites and blends: Processing features, applications, and future directions. Adv. Mater. Sci. Eng. 2015, 2015, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Ke, K.; Wang, Y.; Yang, W.; Xie, B.-H.; Yang, M.-B. Crystallization and reinforcement of poly(vinylidene fluoride) nanocomposites: Role of high molecular weight resin and carbon nanotubes. Polym. Test. 2012, 31, 117–126. [Google Scholar] [CrossRef]

- Komalan, C.; George, K.E.; Kumar, P.A.S.; Varughese, K.T.; Thomas, S. Dynamic mechanical analysis of binary and ternary polymer blends based on nylon copolymer/EPDM rubber and EPM grafted maleic anhydride compatibilizer. Express Polym. Lett. 2007, 1, 641–653. [Google Scholar] [CrossRef]

- Nain, R.; Jassal, M.; Agrawal, A.K. Polymeric nanofiber composites with aligned ZnO nanorods. Compos. Sci. Technol. 2013, 86, 9–17. [Google Scholar] [CrossRef]

- Putson, C.; Jaaoh, D.; Meauma, N.; Muensit, N. Effect of micro- and nano-particle fillers at low percolation threshold on the dielectric and mechanical properties of polyurethane/copper composites. J. Inorg. Organomet. Polym. Mater. 2012, 22, 1300. [Google Scholar] [CrossRef]

- Guiffard, B.; Guyomar, D.; Seveyrat, L.; Chowanek, Y.; Bechelany, M.; Cornu, D.; Miele, P. Enhanced electroactive properties of polyurethane films loaded with carbon-coated SiC nanowires. J. Phys. D Appl. Phys. 2009, 42, 055503. [Google Scholar] [CrossRef]

- Zhang, J.W.; Lebrun, L.; Guiffard, B.; Cottinet, P.J.; Belouadah, R.; Guyomar, D.; Garbuio, L. Influence of corona poling on the electrostrictive behavior of cellular polypropylene films. Sensor. Actuat. A Phys. 2012, 87, 87–93. [Google Scholar] [CrossRef]

- Jaaoh, D.; Putson, C.; Muensit, N. Deformation on segment-structure of electrostrictive polyurethane/polyaniline blends. Polymers 2015, 61, 123–130. [Google Scholar] [CrossRef]

| P(VDF-HFP)/PANI Concentrations | Average Diameter (nm) | Water Contact Angle (Degree) | Element | |

|---|---|---|---|---|

| F (%) | C (%) | |||

| 0.00% | 120.3 ± 20.6 | 139.2 ± 3.2° | 55.5 | 44.5 |

| 0.50% | 265.5 ± 53.1 | 132.6 ± 4.7° | 53.3 | 46.7 |

| 1.00% | 286.3 ± 72.7 | 131.9 ± 5.3° | 54.5 | 45.5 |

| 1.50% | 292.1 ± 50.2 | 130.4 ± 4.4° | 55.9 | 44.1 |

| 3.00% | 293.6 ± 32.9 | 130.2 ± 3.2° | 55.0 | 45.0 |

| 5.00% | 326.5 ± 99.5 | 126.8 ± 2.8° | 51.8 | 48.2 |

| P(VDF-HFP)/PANI Concentrations | Xc (%) | Aβ | Aα | F(β) (%) | %β (%) |

|---|---|---|---|---|---|

| 0.0% | 48.40 | 0.2120 | 0.0605 | 73.53 | 35.59 |

| 0.5% | 52.63 | 0.2477 | 0.0325 | 85.79 | 45.15 |

| 1.0% | 55.58 | 0.2542 | 0.0300 | 87.03 | 48.37 |

| 1.5% | 53.09 | 0.2583 | 0.0237 | 89.64 | 47.59 |

| 3.0% | 55.91 | 0.2113 | 0.0217 | 88.53 | 49.50 |

| 5.0% | 55.49 | 0.2123 | 0.0203 | 89.22 | 49.51 |

| PANI | 46.88 | 0.0582 | 0.0281 | 62.12 | 29.12 |

| P(VDF-HFP)/PANI Concentrations | at 100 Hz | Loss Tangent at 100 Hz | σ at 100 Hz (×10−10 S/m) | Y (MPa) | M33 (×10−14 m2/V2) | |

|---|---|---|---|---|---|---|

| 0.0% | 1.48 | 0.00071 | 1.28 | 5.0 ± 1 | 1.28 | 2.62 × 10−18 |

| 0.5% | 1.56 | 0.00086 | 2.98 | 22.5 ± 3 | 1.30 | 6.14 × 10−19 |

| 1.0% | 1.92 | 0.00175 | 3.34 | 35.0 ± 2 | 1.73 | 4.86 × 10−19 |

| 1.5% | 2.23 | 0.01542 | 4.34 | 40.0 ± 2 | 2.21 | 4.94 × 10−19 |

| 3.0% | 2.28 | 0.01962 | 6.01 | 45.0 ± 3 | 2.42 | 4.49 × 10−19 |

| 5.0% | 2.58 | 0.02403 | 9.18 | 50.0 ± 3 | 2.53 | 4.57 × 10−19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tohluebaji, N.; Putson, C.; Muensit, N.; Yuennan, J. Electrostrictive and Structural Properties of Poly(Vinylidene Fluoride-Hexafluoropropylene) Composite Nanofibers Filled with Polyaniline (Emeraldine Base). Polymers 2021, 13, 3250. https://doi.org/10.3390/polym13193250

Tohluebaji N, Putson C, Muensit N, Yuennan J. Electrostrictive and Structural Properties of Poly(Vinylidene Fluoride-Hexafluoropropylene) Composite Nanofibers Filled with Polyaniline (Emeraldine Base). Polymers. 2021; 13(19):3250. https://doi.org/10.3390/polym13193250

Chicago/Turabian StyleTohluebaji, Nikruesong, Chatchai Putson, Nantakan Muensit, and Jureeporn Yuennan. 2021. "Electrostrictive and Structural Properties of Poly(Vinylidene Fluoride-Hexafluoropropylene) Composite Nanofibers Filled with Polyaniline (Emeraldine Base)" Polymers 13, no. 19: 3250. https://doi.org/10.3390/polym13193250

APA StyleTohluebaji, N., Putson, C., Muensit, N., & Yuennan, J. (2021). Electrostrictive and Structural Properties of Poly(Vinylidene Fluoride-Hexafluoropropylene) Composite Nanofibers Filled with Polyaniline (Emeraldine Base). Polymers, 13(19), 3250. https://doi.org/10.3390/polym13193250