Effect of Mould Orientation on the Field-Dependent Properties of MR Elastomers under Shear Deformation

Abstract

:1. Introduction

2. Materials, Fabrications, and Methods

2.1. Materials

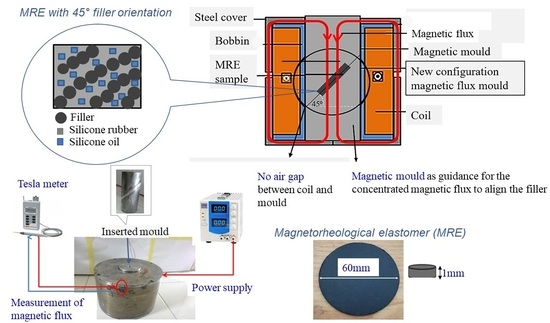

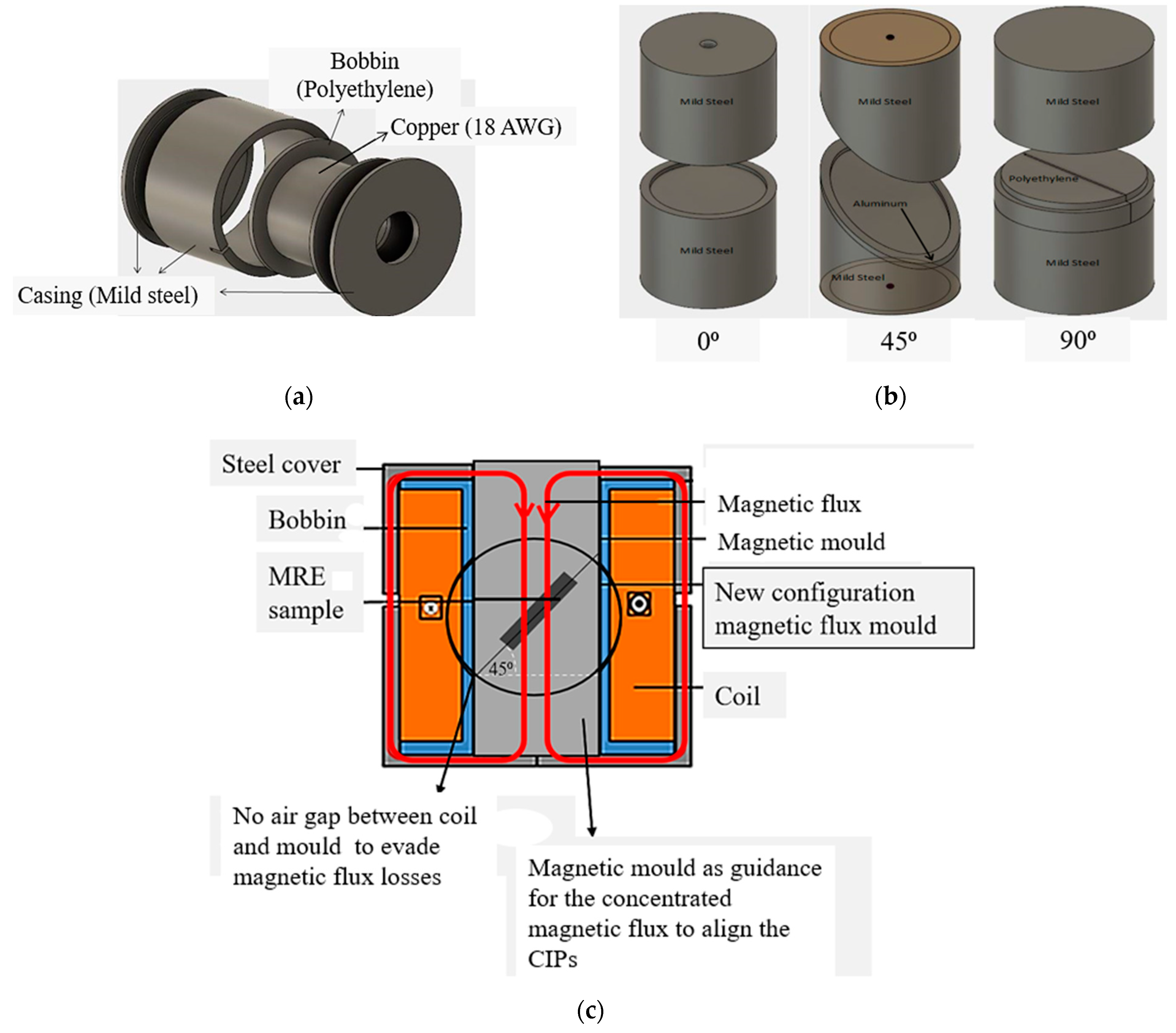

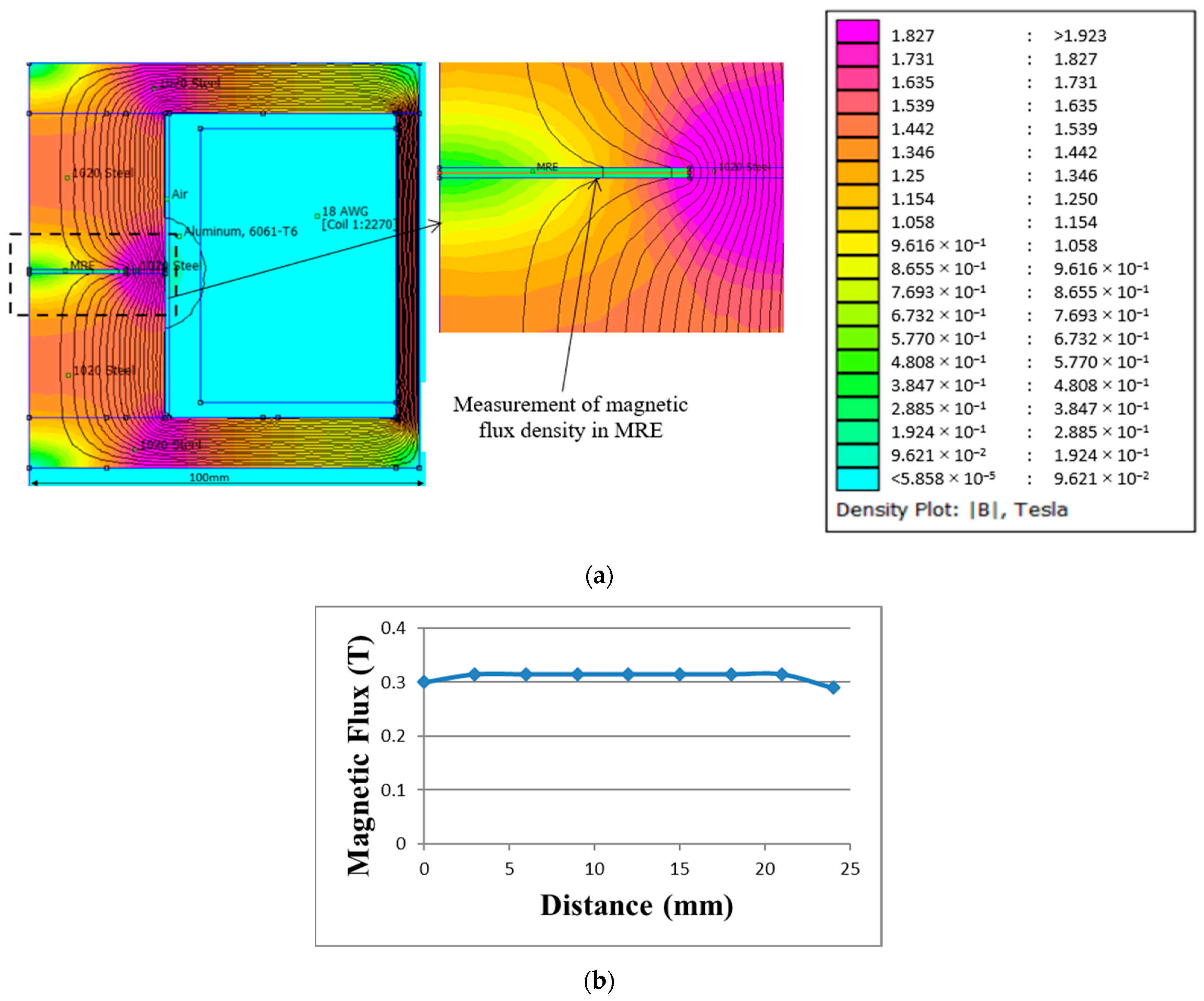

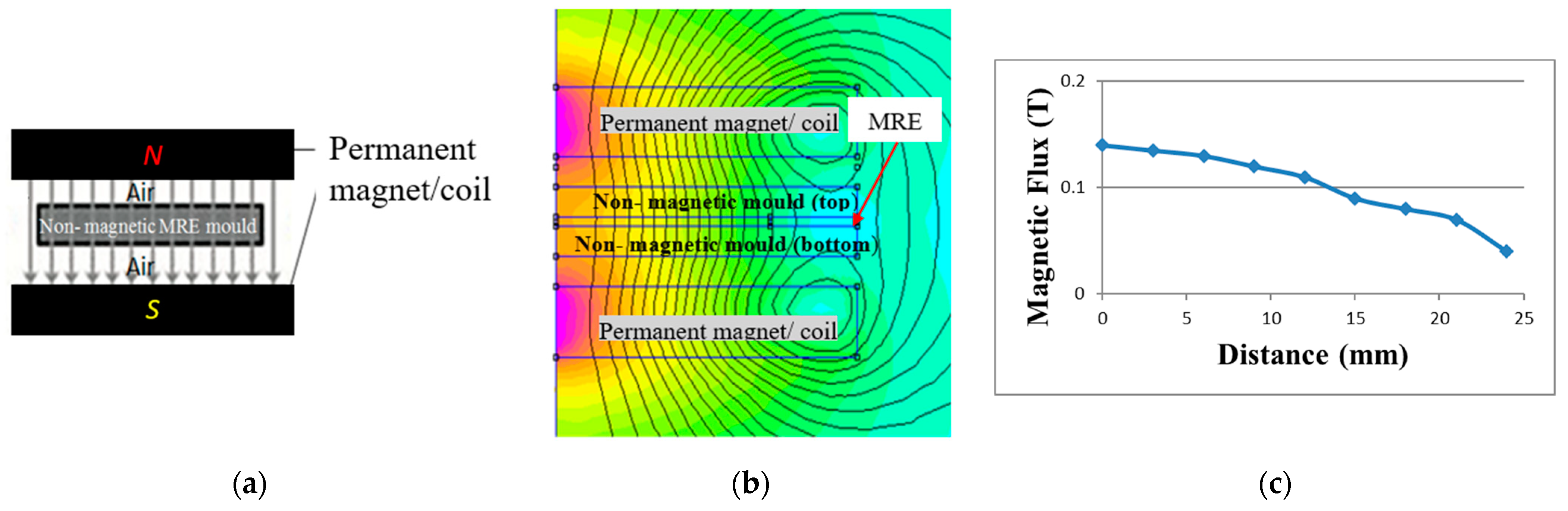

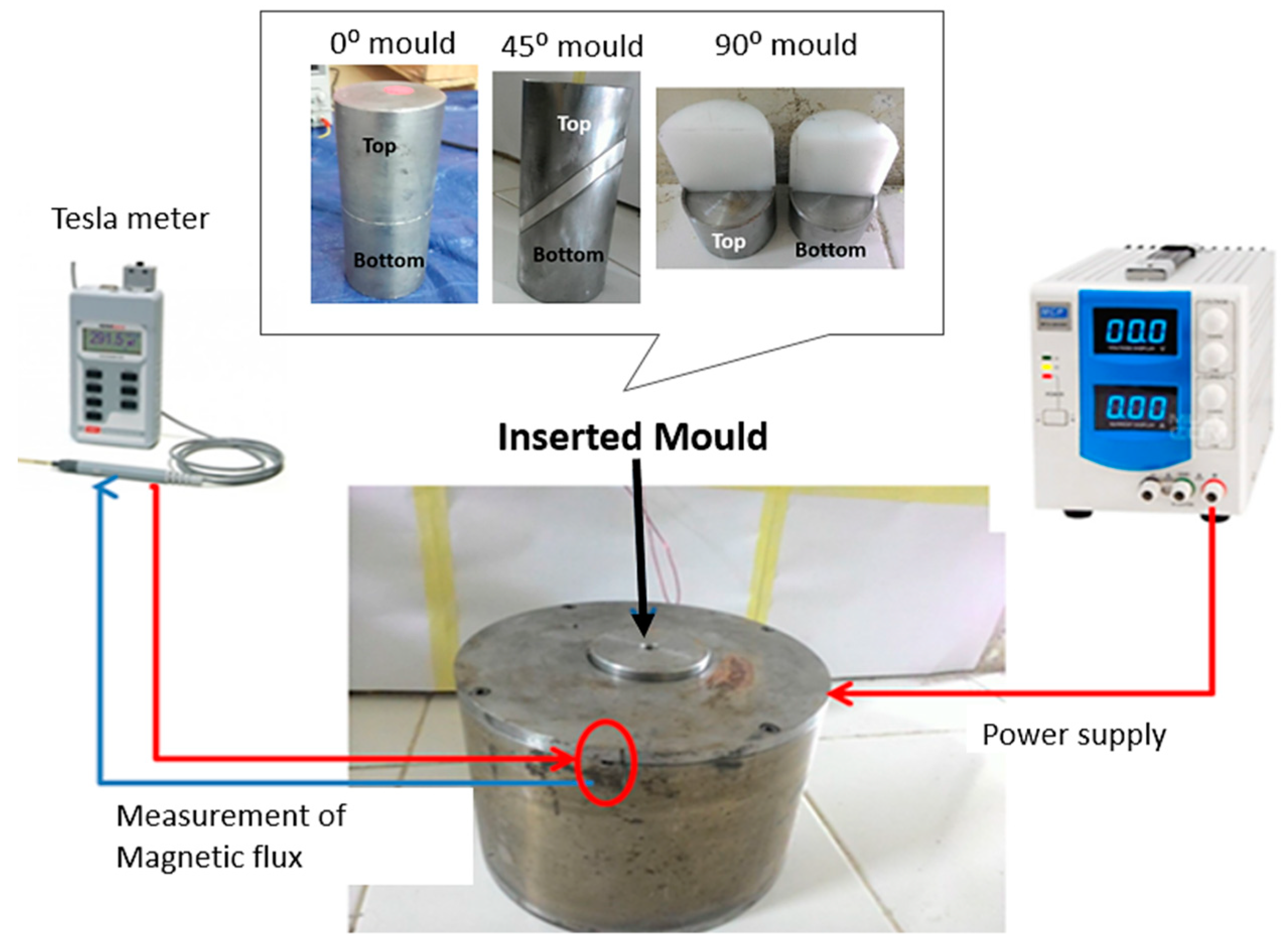

2.2. Curing Device and Simulation of Magnetic Flux

2.3. Magnetic Properties Measurement and Morphological Observation

2.4. Rheological Properties Test

3. Results and Discussions

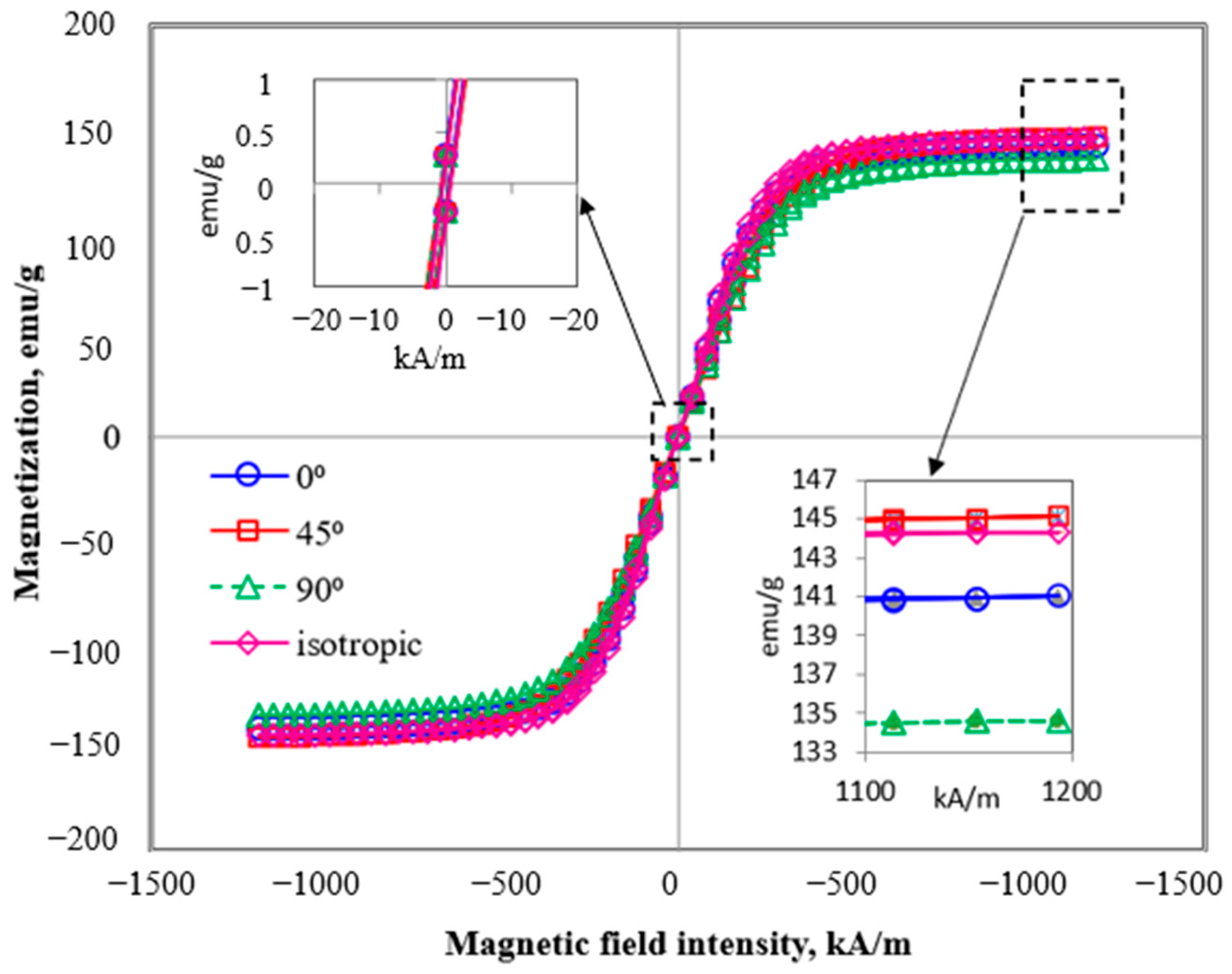

3.1. Magnetic Properties

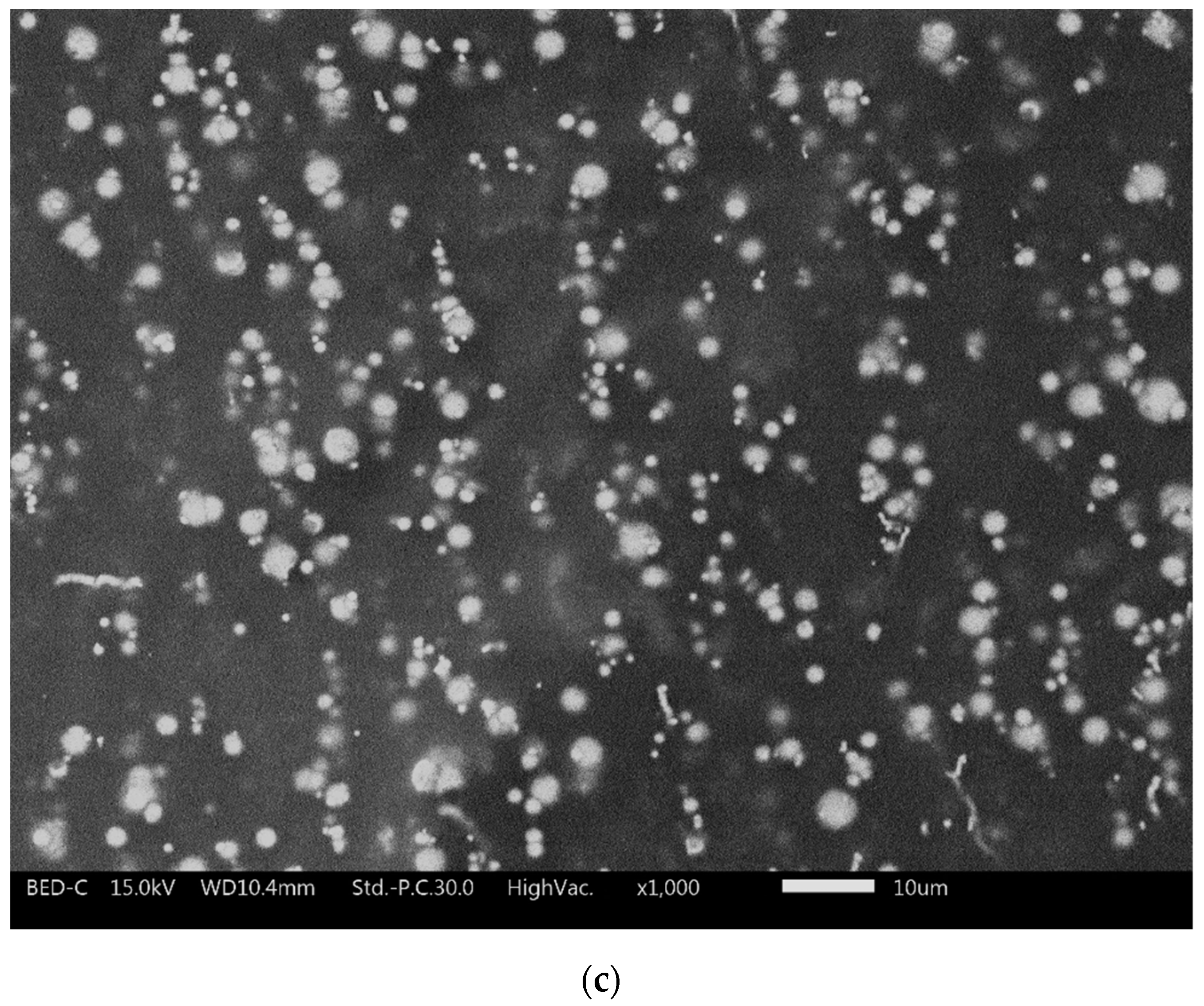

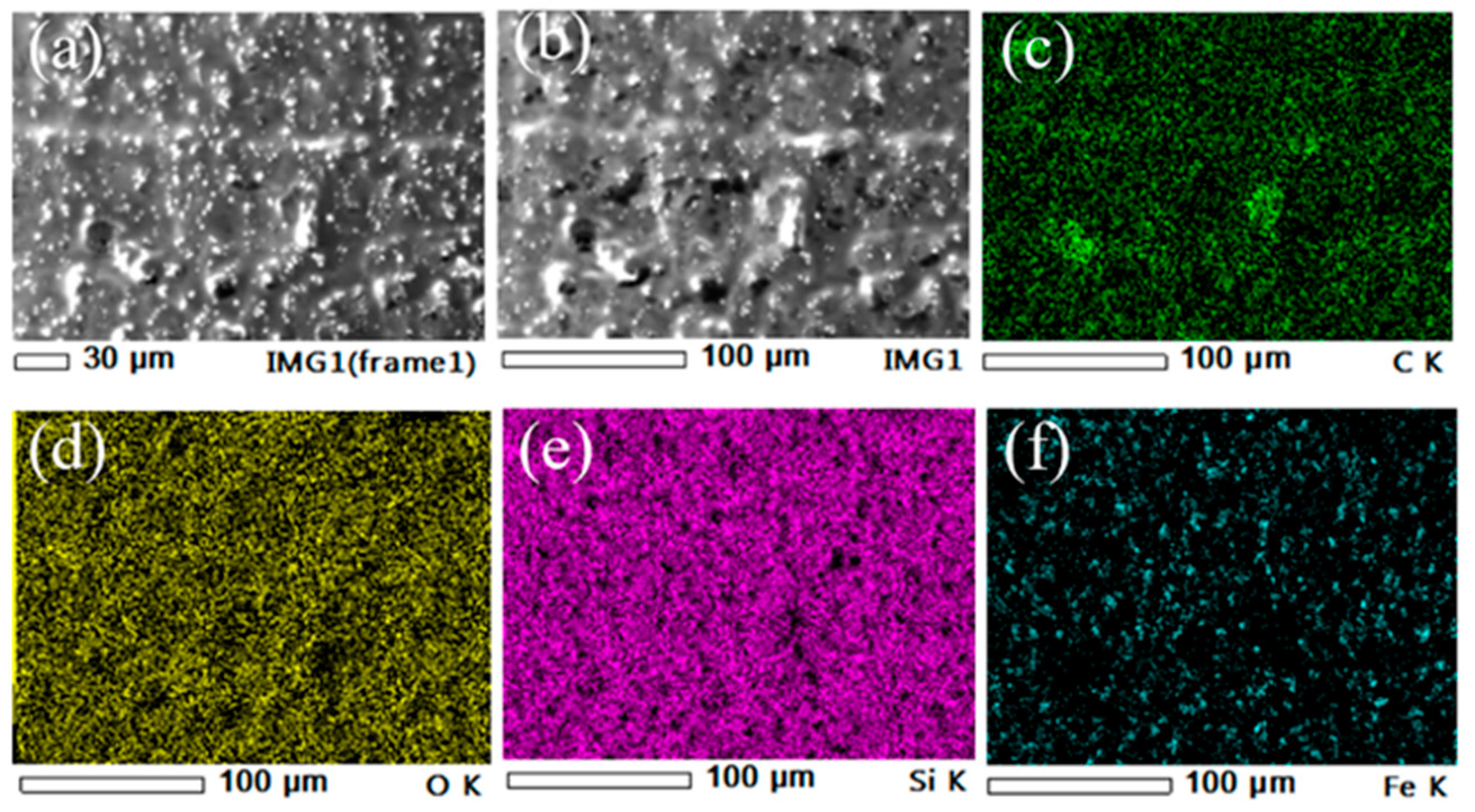

3.2. Morphology of the MRE

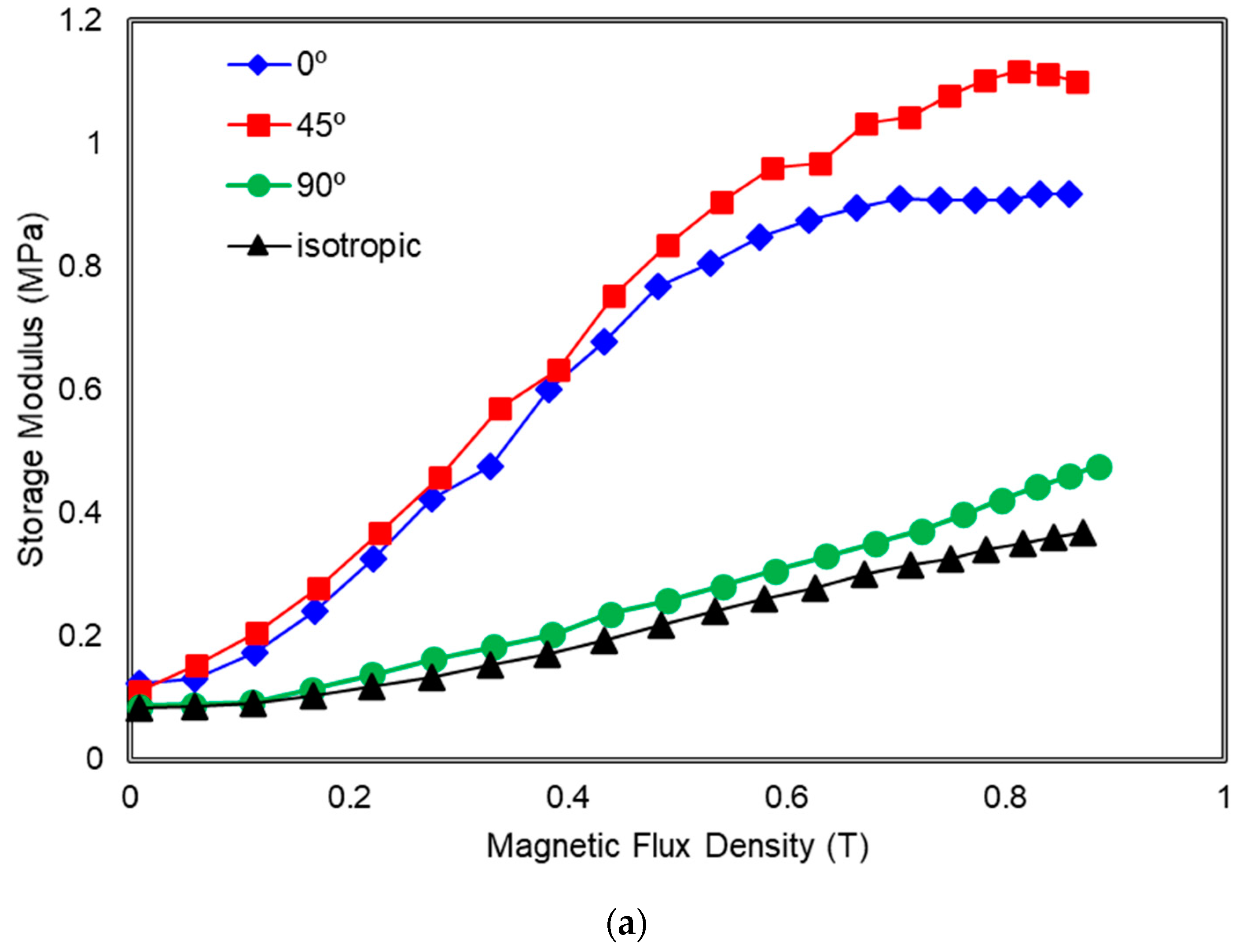

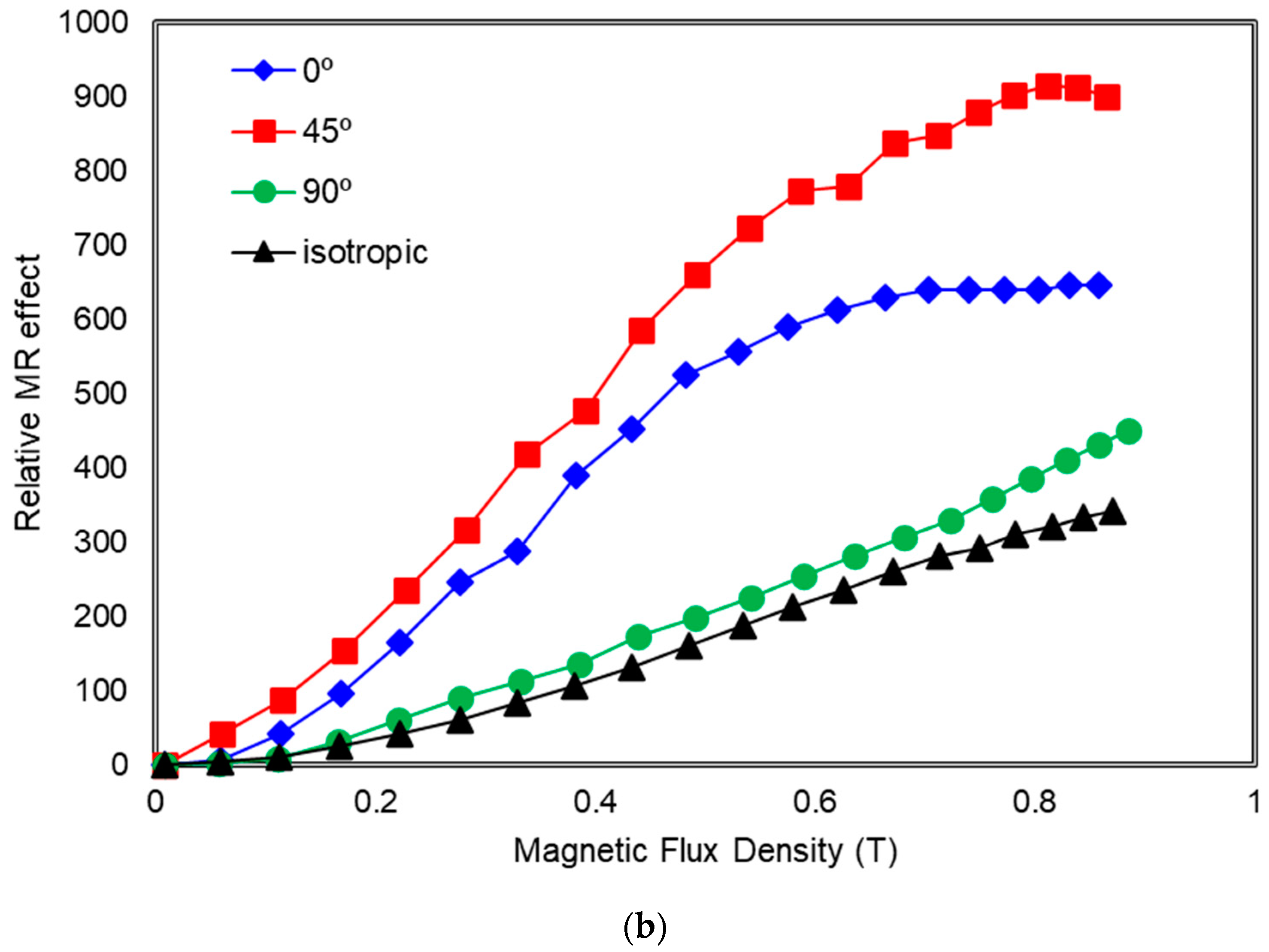

3.3. Rheological Properties: Effect of Mold Orientation

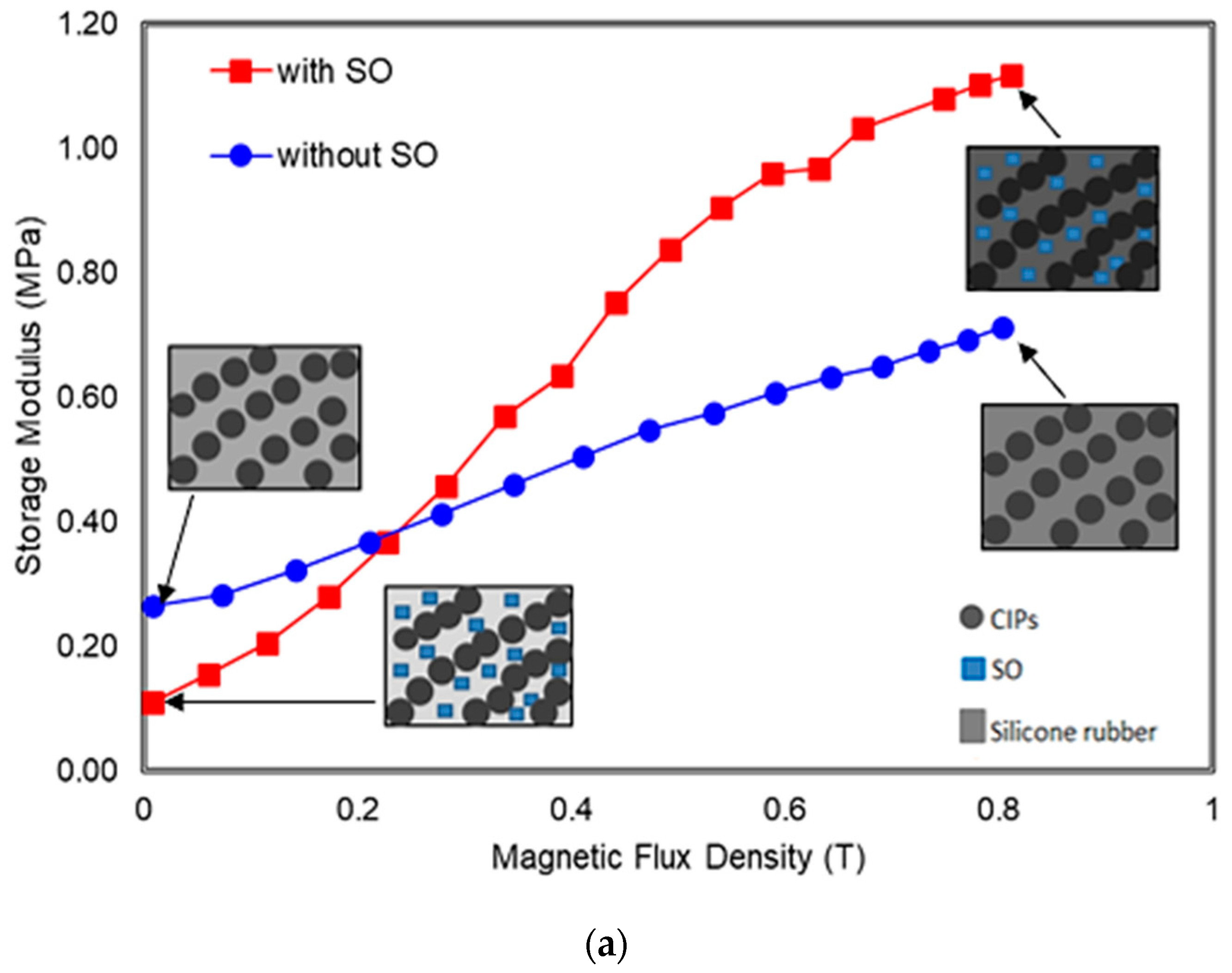

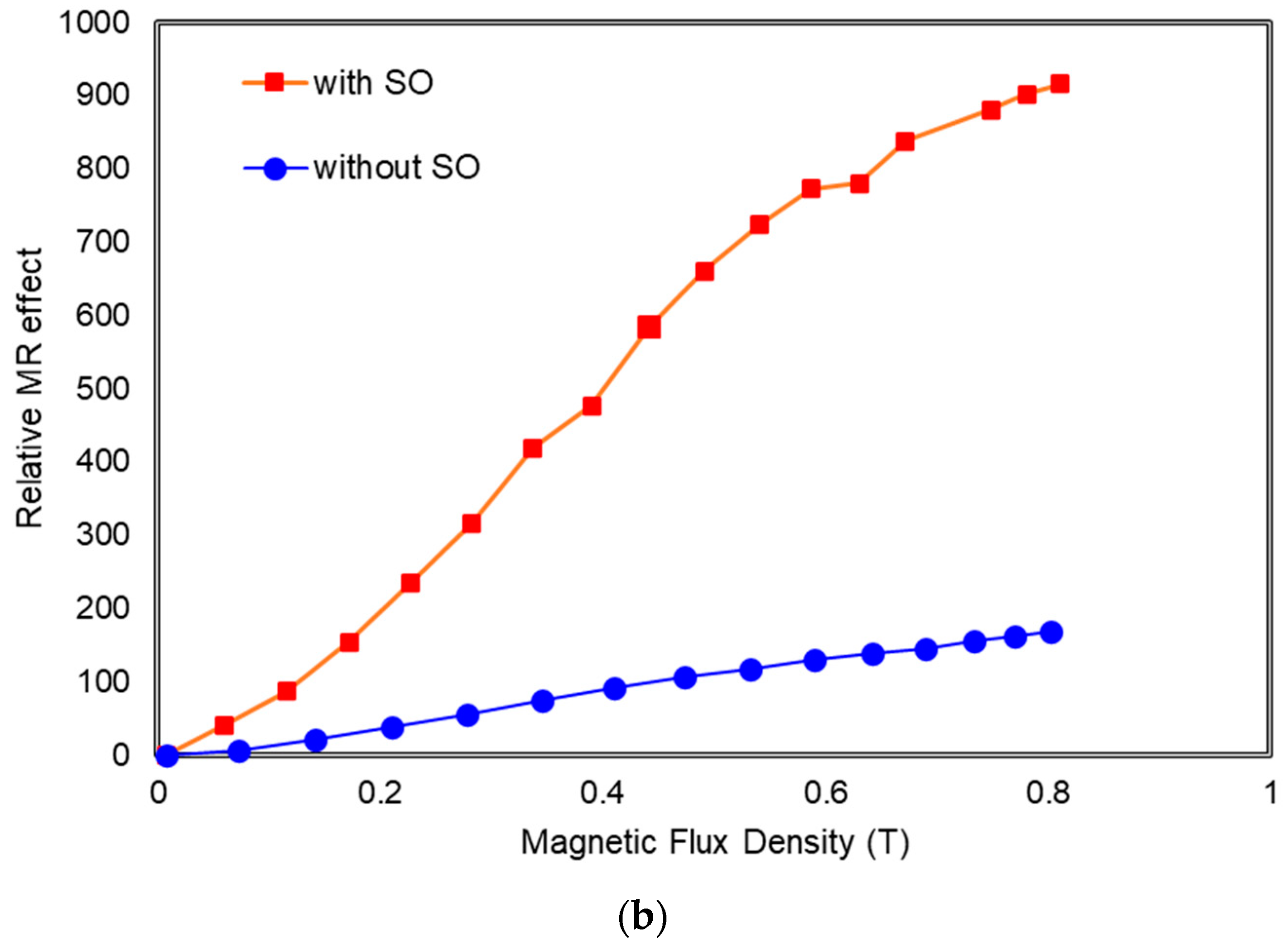

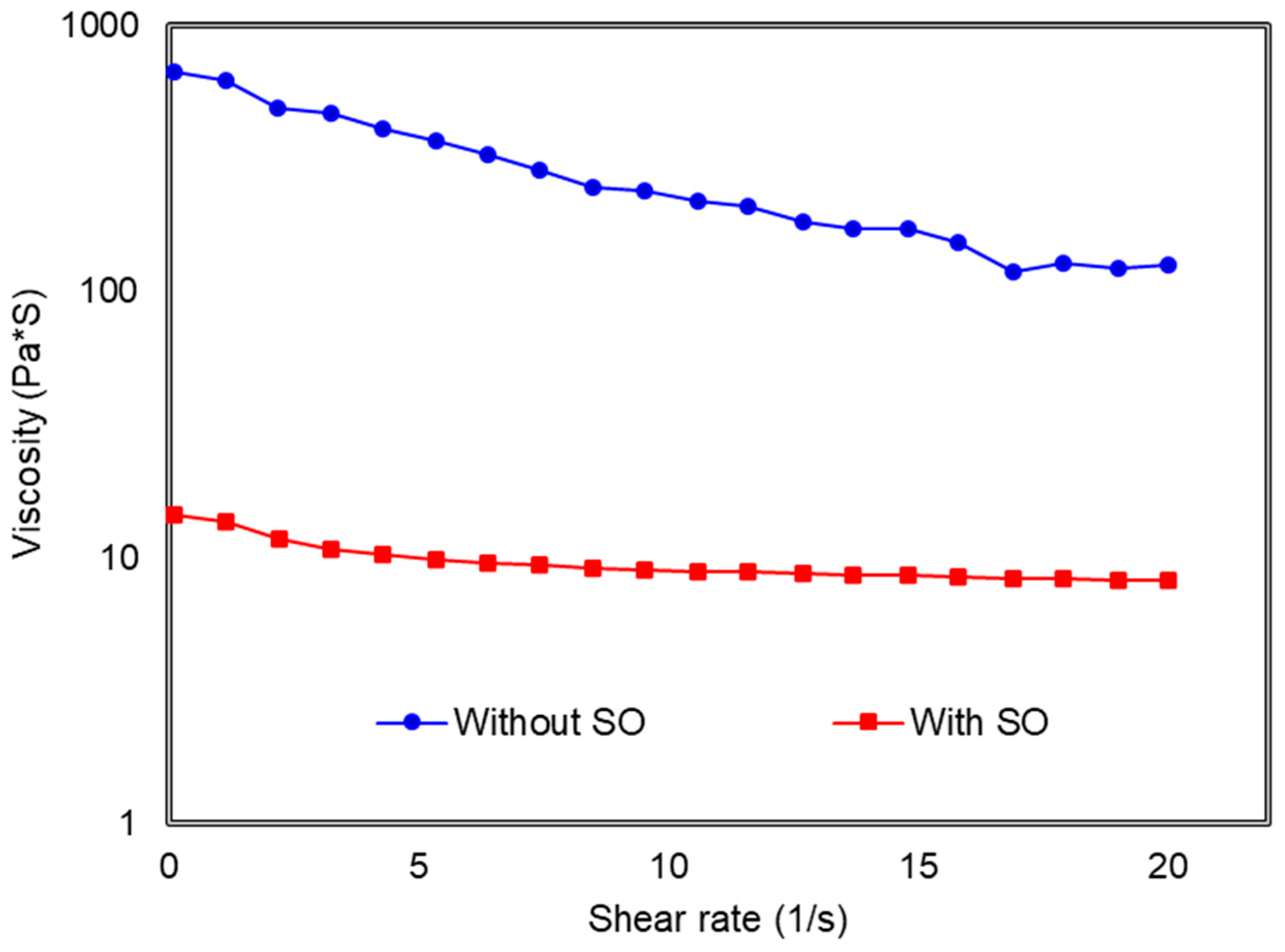

3.4. Rheological Properties: Effect of SO

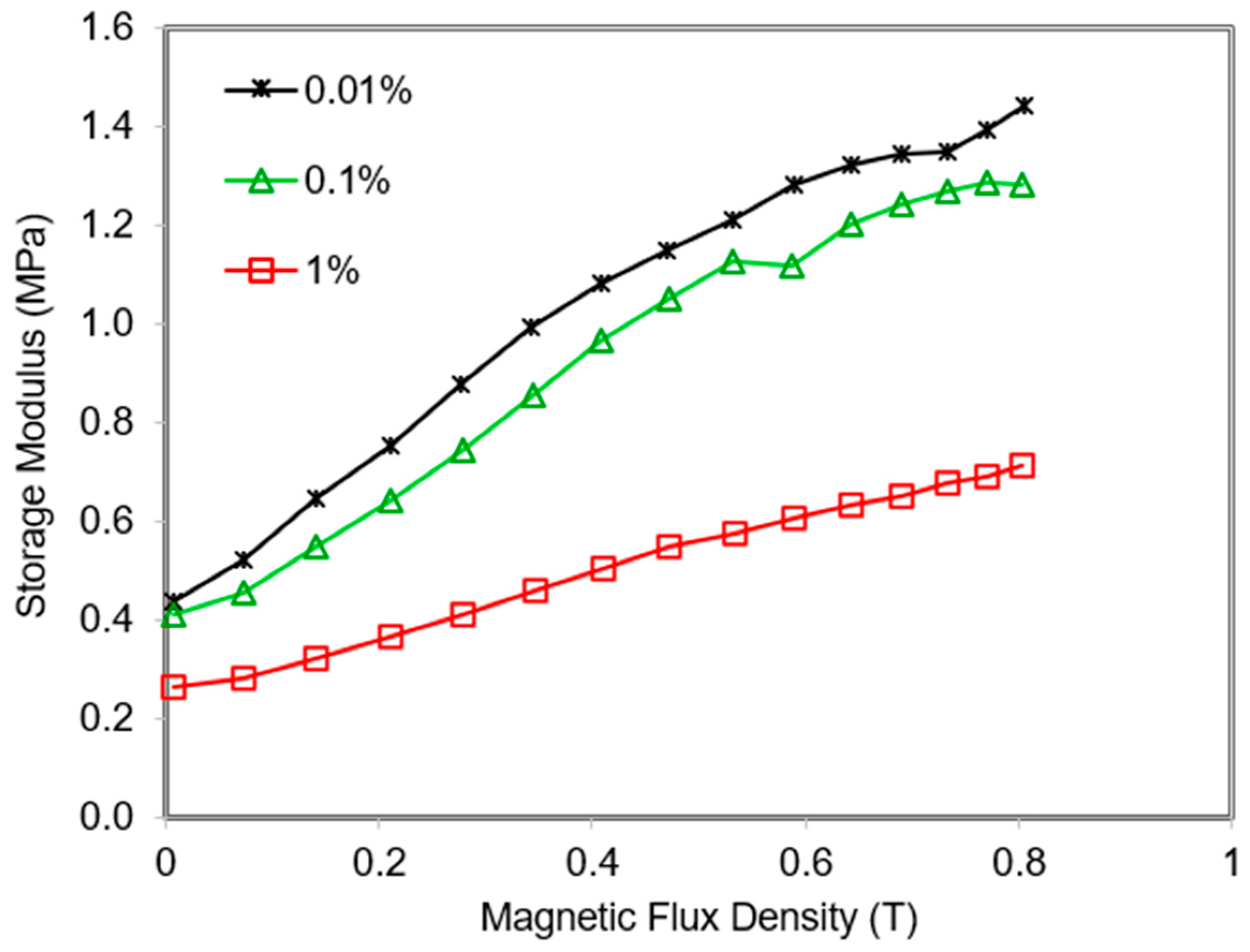

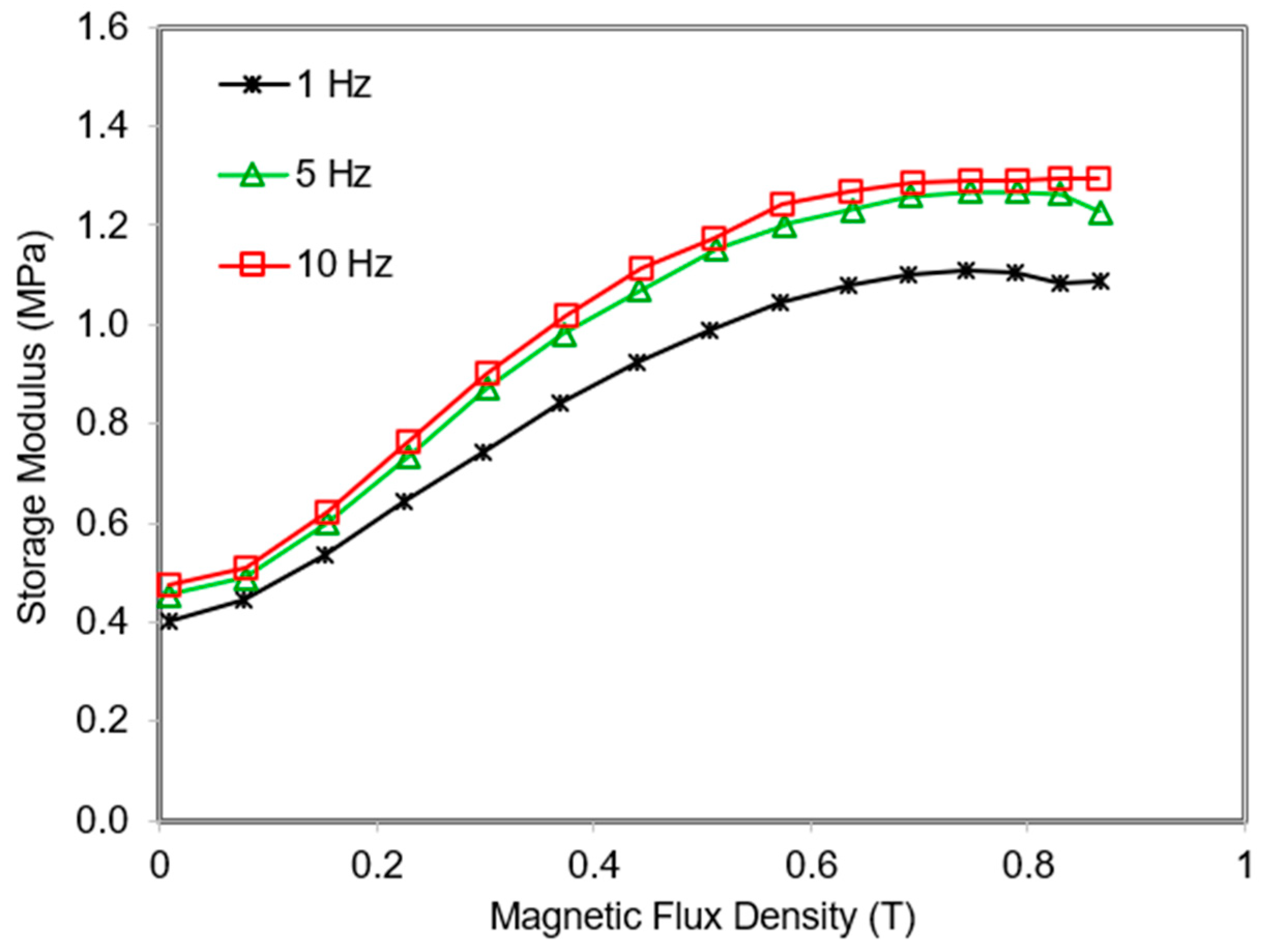

3.5. Rheological Properties: Effect of Strain Amplitude and Frequency

4. Conclusions

- (a)

- The new configuration of magnetic flux mold for curing device produces 0.315 T through simulation with uniform distribution of magnetic flux flow across the MRE sample.

- (b)

- The magnetic mold was inserted in the magnetic coil without an air gap to evade magnetic flux losses. The magnetic molds have functioned as guidance for the concentrated magnetic flux to flow parallelly from top to bottom parts that passing through the MRE sample, which was sandwiched between the mold’s parts for enhancing the alignment of CIPs in the MRE.

- (c)

- The orientation of mold does alter the MR effect of MRE with the order of the storage modulus or MR effect versus orientations is 45° > 0° > 90° with 45° orientation achieved the highest relative MR effect of 909% and 1.01 MPa for magneto-induced modulus. It is interesting to note that the finding exceeds the result from the literature that obtained 0.6 MPa magneto-induced modulus based on 70 wt.% CIPs.

- (d)

- Relative MR effect for MRE for mold orientation at 0°, 90° and isotropic distribution exhibited of 646%, 433% and 343%, respectively.

- (e)

- Plasticization is an effective method to improve the MR effect. Without the SO, the relative MR effect obtained was only 173% with 0.45 MPa magneto-induced modulus for MRE 45°. Meanwhile, the relative MR effect is dependent on the test frequency and strain.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hapipi, N.; Aziz, S.A.A.; Mazlan, S.A.; Ubaidillah; Choi, S.B.; Mohamad, N.; Khairi, M.H.A.; Fatah, A.Y.A. The field-dependent rheological properties of plate-like carbonyl iron particle-based magnetorheological elastomers. Results Phys. 2019, 12, 2146–2154. [Google Scholar] [CrossRef]

- Gan, R.; Li, Y.; Qi, S.; Zhu, M.; Yu, M. Study on the effect of particles size on viscoelastic properties of magnetorheological Elastomers. Curr. Smart Mater. 2019, 4, 59–67. [Google Scholar] [CrossRef]

- Yunus, N.; Mazlan, S.; Ubaidillah; Abdul Aziz, S.; Tan Shilan, S.; Abdul Wahab, N. Thermal stability and rheological properties of epoxidized natural rubber-based magnetorheological Elastomer. Int. J. Mol. Sci. 2019, 20, 746. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bastola, A.; Hossain, M. Enhanced performance of core-shell hybrid magnetorheological elastomer with nanofillers. Mater. Lett. 2021, 297, 129944. [Google Scholar] [CrossRef]

- Li, W.; Qi, S.; Zhu, M.; Xia, D.; Fu, J.; Yu, M. Improving transient magnetorheological response of magnetorheological elastomer by incorporating CIP@FeNi particles. Smart Mater. Struct. 2021, 30, 024002. [Google Scholar] [CrossRef]

- Xia, L.; Hu, Z.; Sun, L. Micromechanics-based simulation of anisotropic magneto-mechanical properties of magnetorheological elastomers with chained microstructures. Smart Mater. Struct. 2021, 30, 2021. [Google Scholar] [CrossRef]

- Khairi, M.H.A.; Mazlan, S.A.; Ubaidillah; Choi, S.; Aziz, S.A.A.; Mohamad, N.; Hapipi, N.M.; Nordin, N. Role of additives in enhancing the rheological properties of magnetorheological solids: A review. Adv. Eng. Mater. 2019, 21, 1800696. [Google Scholar] [CrossRef]

- Samal, S.; Škodová, M.; Abate, O.; Blanco, I. Magneto-rheological elastomer composites. A review. Appl. Sci. 2017, 10, 124–134. [Google Scholar]

- Vatandoost, H.; Norouzi, M.; Alehashem, S.M.S.; Smoukov, S.K. A novel phenomenological model for dynamic behavior of magnetorheological elastomers in tension-compression mode. Smart Mater. Struct. 2017, 26. [Google Scholar] [CrossRef] [Green Version]

- Samal, S.; Škodová, M.; Blanco, I. Effects of filler distribution on magnetorheological silicon-based composites. Materials 2019, 12, 3017. [Google Scholar] [CrossRef] [Green Version]

- An, J.S.; Kwon, S.H.; Choi, H.J.; Jung, J.H.; Kim, Y.G. Modified silane-coated carbonyl iron/natural rubber composite elastomer and its magnetorheological performance. Compos. Struct. 2017, 160, 1020–1026. [Google Scholar] [CrossRef]

- Aziz, S.A.A.; Mazlan, S.A.; Ubaidillah, U.; Shabdin, M.K.; Yunus, N.A.; Nordin, N.A.; Choi, S.B.; Rosnan, R.M. Enhancement of viscoelastic and electrical properties of magnetorheological elastomers with nanosized Ni-Mg cobalt-ferrites as fillers. Materials 2019, 12, 3531. [Google Scholar]

- Zhao, D.; Cui, J.; Dai, X.; Liu, S.; Dong, L. Magneto-piezoresistive characteristics of graphene/room temperature vulcanized silicon rubber-silicon rubber magnetorheological elastomer. J. Appl. Polym. Sci. 2021, 138, 1–13. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, M.; Zhang, J.; Qiao, Y.; Zhai, P. Experimental investigation on the effect of graphene oxide additive on the steady-state and dynamic shear properties of PDMS-based magnetorheological elastomer. Polymers 2021, 13, 1777. [Google Scholar]

- Gong, X.L.; Chen, L.; Li, J.F. Study of utilizable magnetorheological elastomers. Int. J. Mod. Physic B 2007, 21, 4875–4882. [Google Scholar] [CrossRef]

- Lokander, M.; Stenberg, B. Improving the magnetorheological effect in isotropic magnetorheological rubber materials. Polym. Test. 2003, 22, 677–680. [Google Scholar] [CrossRef]

- Chen, L.; Gong, X.L.; Jiang, W.Q.; Yao, J.J.; Deng, H.X.; Li, W.H. Investigation on magnetorheological elastomers based on natural rubber. J. Mater. Sci. 2007, 42, 5483–5489. [Google Scholar] [CrossRef] [Green Version]

- Boczkowska, A.; Awietjan, S.F.; Pietrzko, S.; Kurzydłowski, K.J. Mechanical properties of magnetorheological elastomers under shear deformation. Compos. Part B Eng. 2012, 43, 636–640. [Google Scholar] [CrossRef]

- Yao, J.; Yang, W.; Gao, Y.; Scarpa, F.; Li, Y. Magnetorheological elastomers with particle chain orientation: Modelling and experiments. Smart Mater. Struct. 2019, 28, 095008. [Google Scholar] [CrossRef]

- Kimura, Y.; Kanauchi, S.; Kawai, M.; Mitsumata, T.; Tamesue, S.; Yamauchi, T. Effect of plasticizer on the magnetoelastic behavior for magnetic polyurethane elastomers. Chem. Lett. 2015, 44, 177–178. [Google Scholar] [CrossRef]

- Wu, J.; Gong, X.; Fan, Y.; Xia, H. Improving the magnetorheological properties of polyurethane magnetorheological elastomer through plasticization. J. Appl. Polym. Sci. 2012, 123, 2476–2484. [Google Scholar] [CrossRef]

- Immergut, E.H.; Mark, H.F. Principles of Plasticization. In Plasticization and Plasticizer Processes; ACS Publications: Washington, DC, USA, 1965; Volume 48, pp. 1–26. ISBN 9780841200494. [Google Scholar]

- Awagon, A. Introduction to Rubber Elasticity; Society of Rubber Science and Technology: Tokyo, Japan, 1996; Volume 69, ISBN 1859571506. [Google Scholar]

- Kallio, M.; Lindroos, T.; Aalto, S.; Järvinen, E.; Kärnä, T.; Meinander, T. Dynamic compression testing of a tunable spring element consisting of a magnetorheological elastomer. Smart Mater. Struct. 2007, 16, 506–514. [Google Scholar] [CrossRef]

- Tian, T.; Nakano, M. Fabrication and characterisation of anisotropic magnetorheological elastomer with 45° iron particle alignment at various silicone oil concentrations. J. Intell. Mater. Syst. Struct. 2018, 29, 151–159. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Li, W.; Du, H. A state-of-the-art review on magnetorheological elastomer devices. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Samal, S.; Kolinova, M.; Blanco, I. The magneto-mechanical behavior of active components in iron-elastomer composite. J. Compos. Sci. 2018, 2, 54. [Google Scholar] [CrossRef] [Green Version]

- Nayak, B.; Dwivedy, S.K.; Murthy, K.S.R.K. Fabrication and characterization of magnetorheological elastomer with carbon black. J. Intell. Mater. Syst. Struct. 2015, 26, 830–839. [Google Scholar] [CrossRef]

- Suo, S.; Xu, Z.; Xu, F. A model of magnetorheological elastomer based on chi-square distribution. J. Funct. Mater. 2016, 47, 9063–9067. [Google Scholar]

- Davis, L.C. Model of magnetorheological elastomers. J. Appl. Phys. 1999, 85, 3348–3351. [Google Scholar] [CrossRef]

- Samal, S.; Kolinova, M.; Blanco, I.; Poggetto, G.D.; Catauro, M. Magnetorheological Elastomer Composites: The Influence of Iron Particle Distribution on the Surface Morphology. Macromol. Symp. 2020, 389, 2–5. [Google Scholar] [CrossRef]

- Szymczyk, W.; Boczkowska, A.; Niezgoda, T.; Zubko, K. Experimental Validation of Numerical Methods of MRE Simulations. Solid State Phenom. 2009, 154, 113–120. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Oh, J.; Chung, K. Fabrication and properties of magnetorheological elastomers based on CR/ENR self-crosslinking blends. Smart Mater. Struct. 2015, 24, 95006. [Google Scholar] [CrossRef]

- Ge, L.; Gong, X.L.; Fan, Y.; Xuan, S. Preparation and mechanical properties of the magnetorheological elastomer based on natural rubber/rosin glycerin hybrid matrix. Smart Mater. Struct. 2013, 22, 115029. [Google Scholar] [CrossRef] [Green Version]

- Fan, Y.; Gong, X.L.; Xuan, S.; Qin, L.; Li, X. Effect of cross-link density of the matrix on the damping properties of magnetorheological elastomers. Ind. Eng. Chem. Res. 2013, 52, 771–778. [Google Scholar] [CrossRef]

- Ubaidillah; Imaduddin, F.; Li, Y.; Mazlan, S.A.; Sutrisno, J.; Koga, T.; Yahya, I.; Choi, S.B. A new class of magnetorheological elastomers based on waste tire rubber and the characterization of their properties. Smart Mater. Struct. 2016, 25, 1–15. [Google Scholar] [CrossRef]

| Component Name | Material |

|---|---|

| Mould (0°, 45° and 90°) | Mild steel |

| Steel Cover | Mild steel |

| Electromagnetic Coil | Copper (18 AWG (2270 turns)) |

| Casing | Mild Steel |

| Bobbin | Mild Steel |

| Separator for 45° and 90° mold | Non-magnetic |

| MRE sample | Magnetic and Non-magnetic |

| MRE Orientation (°) | Hc [Oe] | Ms [emu/g] | Mr [emu/g] |

|---|---|---|---|

| 0 | 8.00 | 141 | 0.27 |

| 45 | 8.30 | 145 | 0.29 |

| 90 | 7.52 | 135 | 0.26 |

| isotropic | 7.32 | 144 | 0.28 |

| Sample | G0 (MPa) | Gmax (MPa) | ΔG (MPa) | Relative MR Effect (%) |

|---|---|---|---|---|

| 0° | 0.12 | 0.92 | 0.79 | 646 |

| 45° | 0.11 | 1.12 | 1.01 | 918 |

| 90° | 0.09 | 0.48 | 0.39 | 433 |

| isotropic | 0.08 | 0.37 | 0.29 | 343 |

| Sample | G0 (MPa) | Gmax (MPa) | ΔG (MPa) | Relative MR Effect (%) |

|---|---|---|---|---|

| Without plasticizer | 0.26 | 0.71 | 0.45 | 173 |

| With plasticizer | 0.11 | 1.12 | 1.01 | 918 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad Khairi, M.H.; Mazlan, S.A.; Ubaidillah; Nordin, N.A.; Aziz, S.A.A.; Nazmi, N. Effect of Mould Orientation on the Field-Dependent Properties of MR Elastomers under Shear Deformation. Polymers 2021, 13, 3273. https://doi.org/10.3390/polym13193273

Ahmad Khairi MH, Mazlan SA, Ubaidillah, Nordin NA, Aziz SAA, Nazmi N. Effect of Mould Orientation on the Field-Dependent Properties of MR Elastomers under Shear Deformation. Polymers. 2021; 13(19):3273. https://doi.org/10.3390/polym13193273

Chicago/Turabian StyleAhmad Khairi, Muntaz Hana, Saiful Amri Mazlan, Ubaidillah, Nur Azmah Nordin, Siti Aishah Abdul Aziz, and Nurhazimah Nazmi. 2021. "Effect of Mould Orientation on the Field-Dependent Properties of MR Elastomers under Shear Deformation" Polymers 13, no. 19: 3273. https://doi.org/10.3390/polym13193273

APA StyleAhmad Khairi, M. H., Mazlan, S. A., Ubaidillah, Nordin, N. A., Aziz, S. A. A., & Nazmi, N. (2021). Effect of Mould Orientation on the Field-Dependent Properties of MR Elastomers under Shear Deformation. Polymers, 13(19), 3273. https://doi.org/10.3390/polym13193273