Tuning the 3D Printability and Thermomechanical Properties of Radiation Shields

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Formulation Development and 3D Printing

2.3. Material Characterization Techniques

3. Results and Discussion

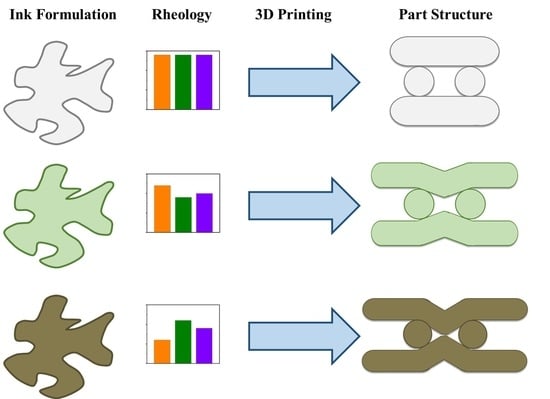

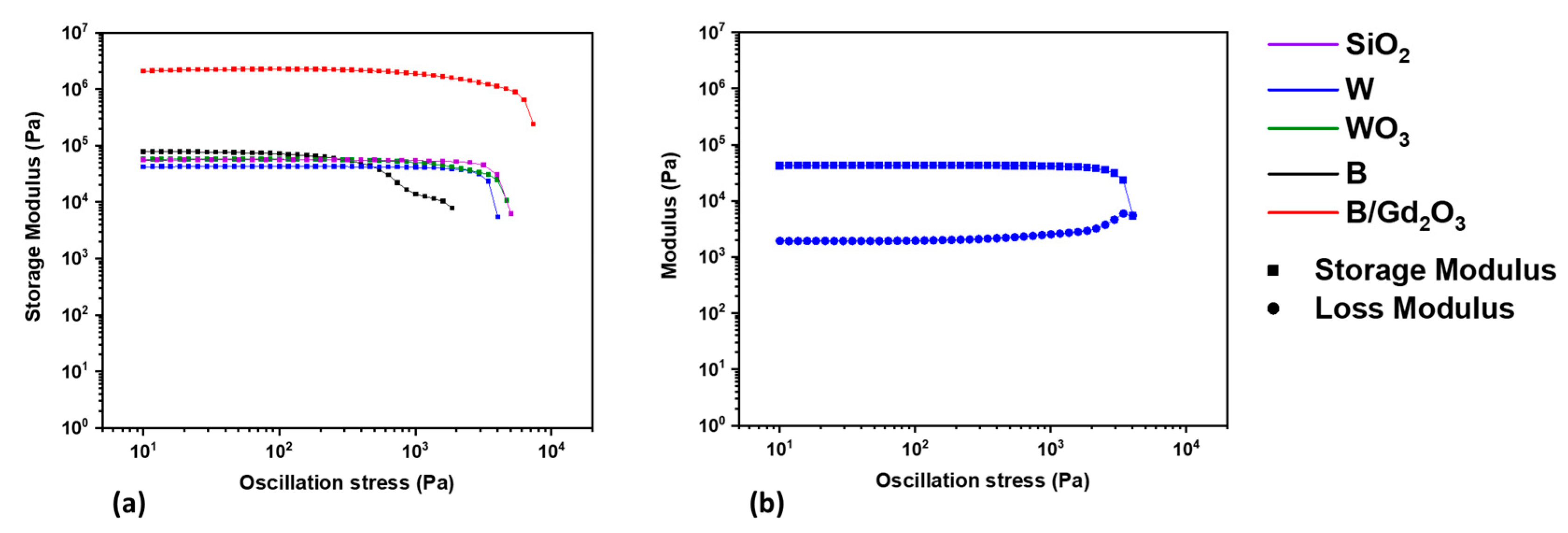

3.1. Rheology

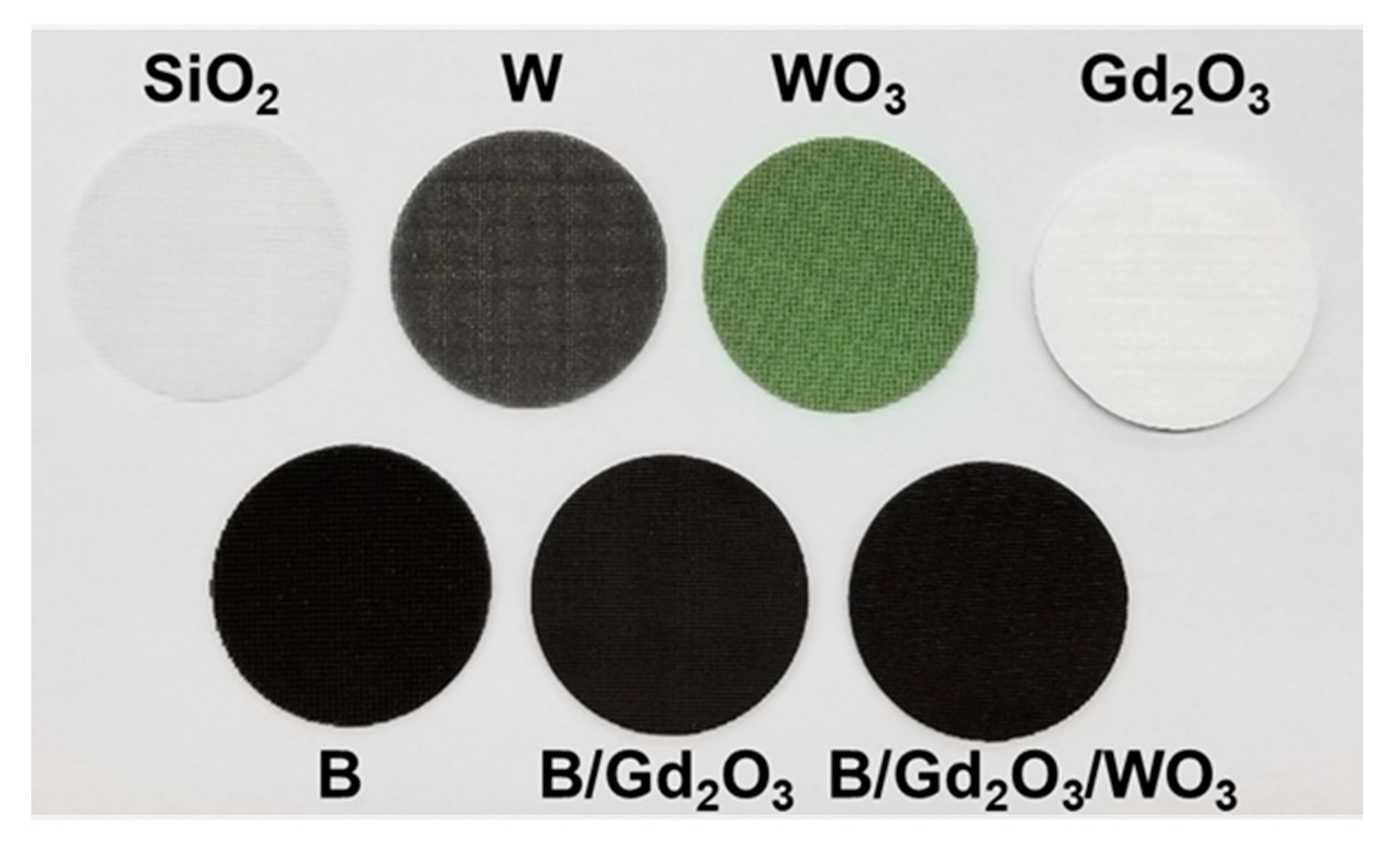

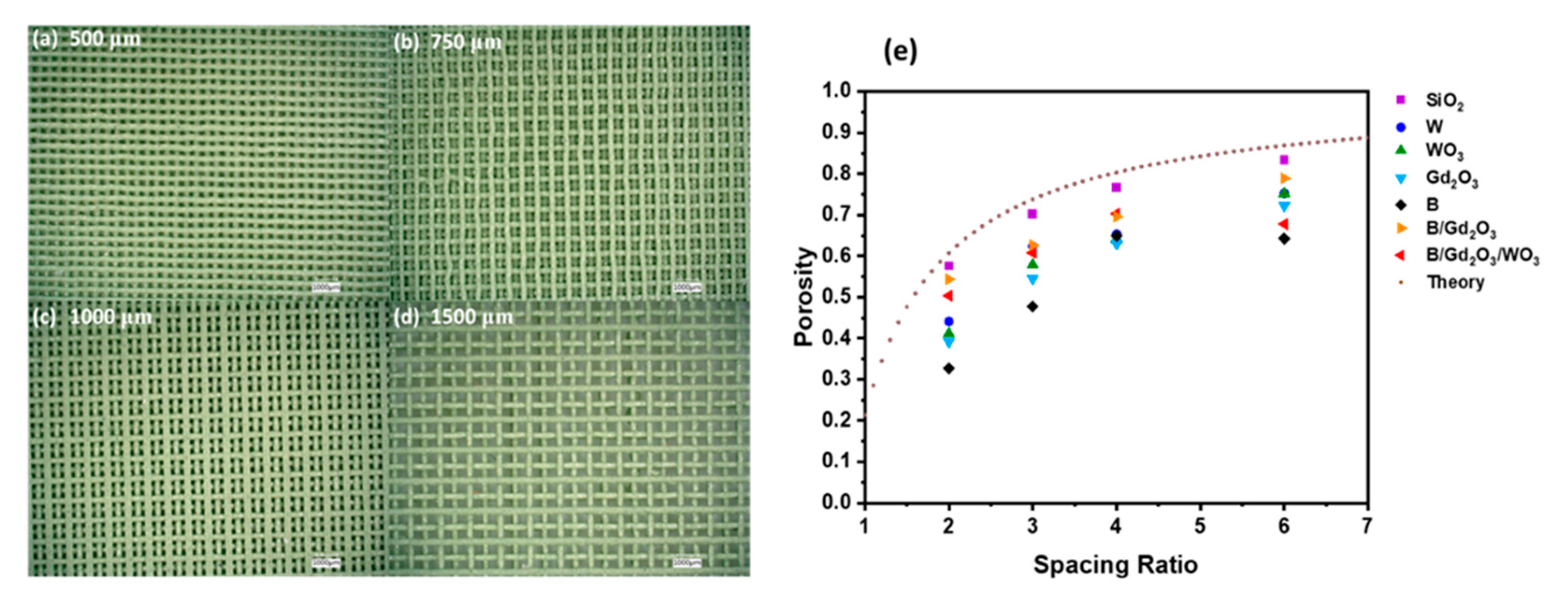

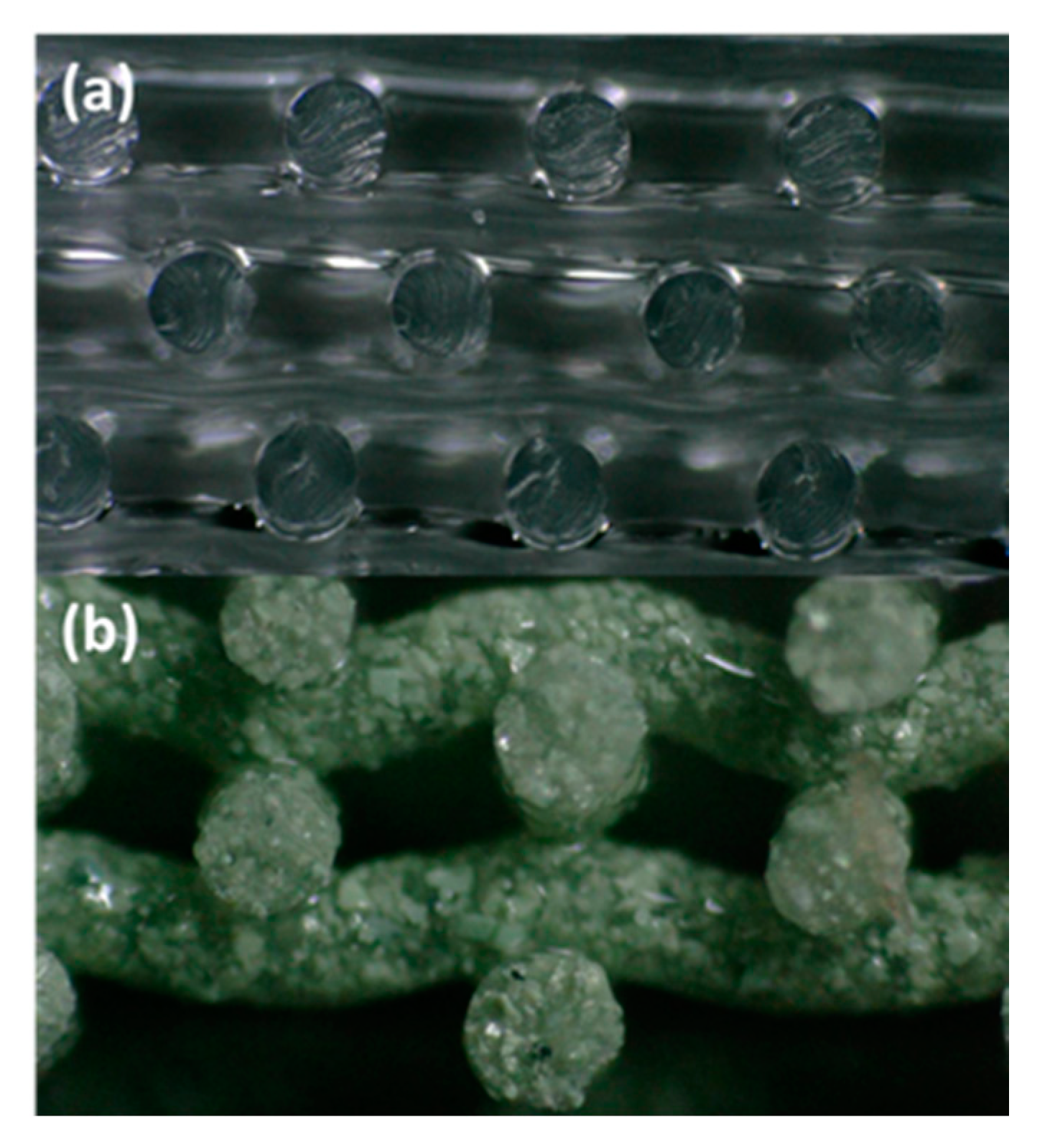

3.2. 3D Printing

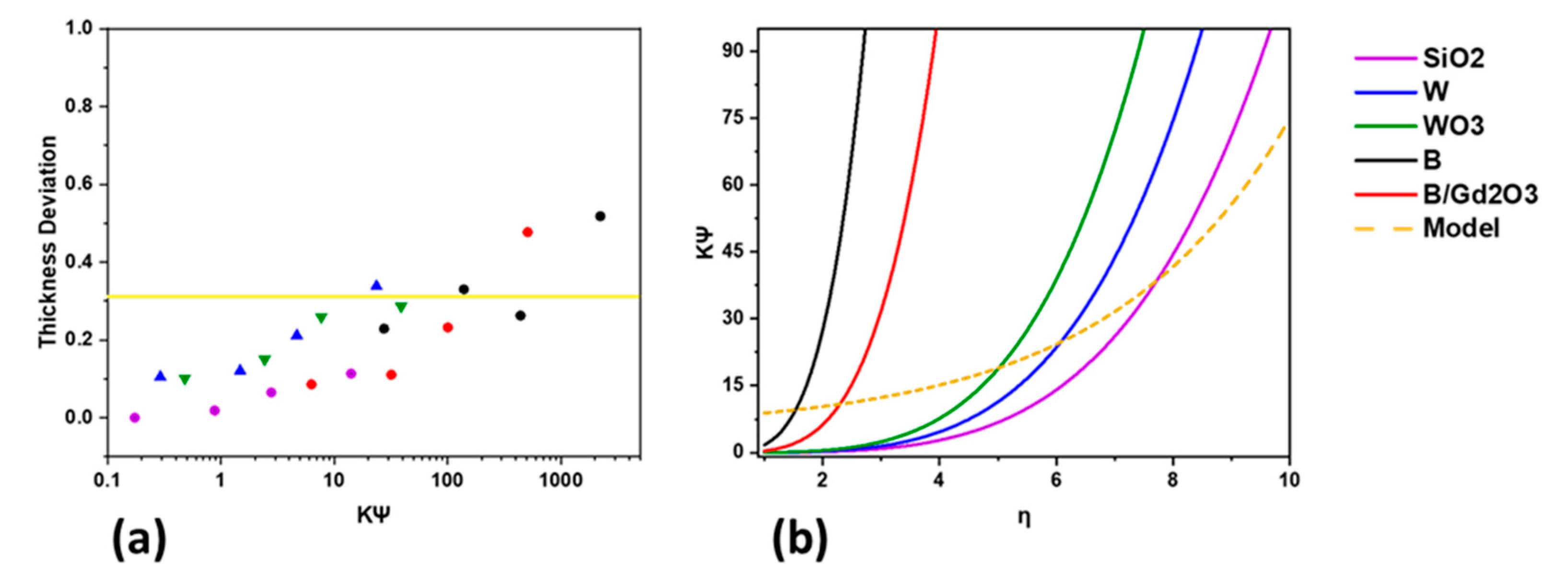

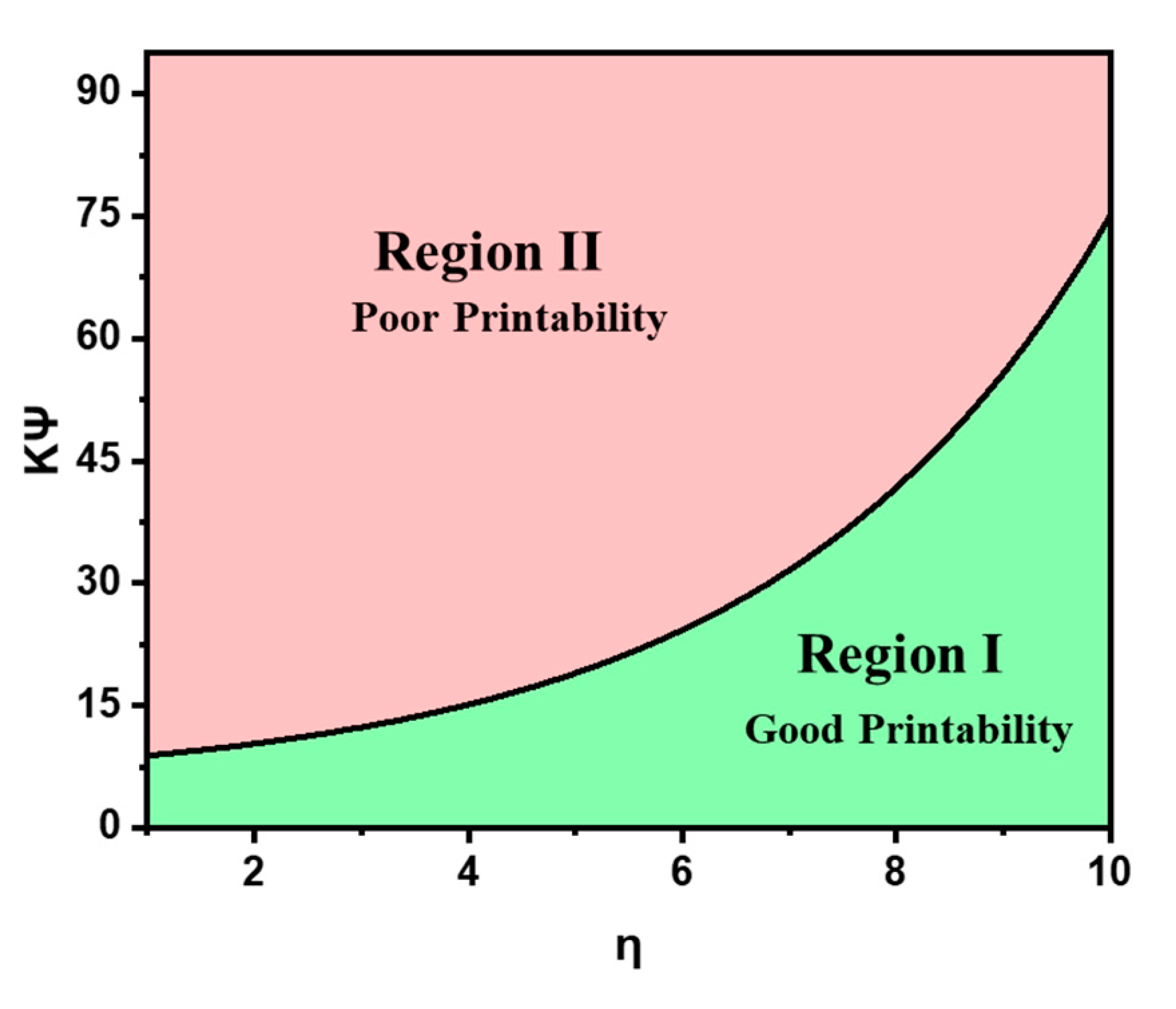

3.3. Rheology–Printability Relationship

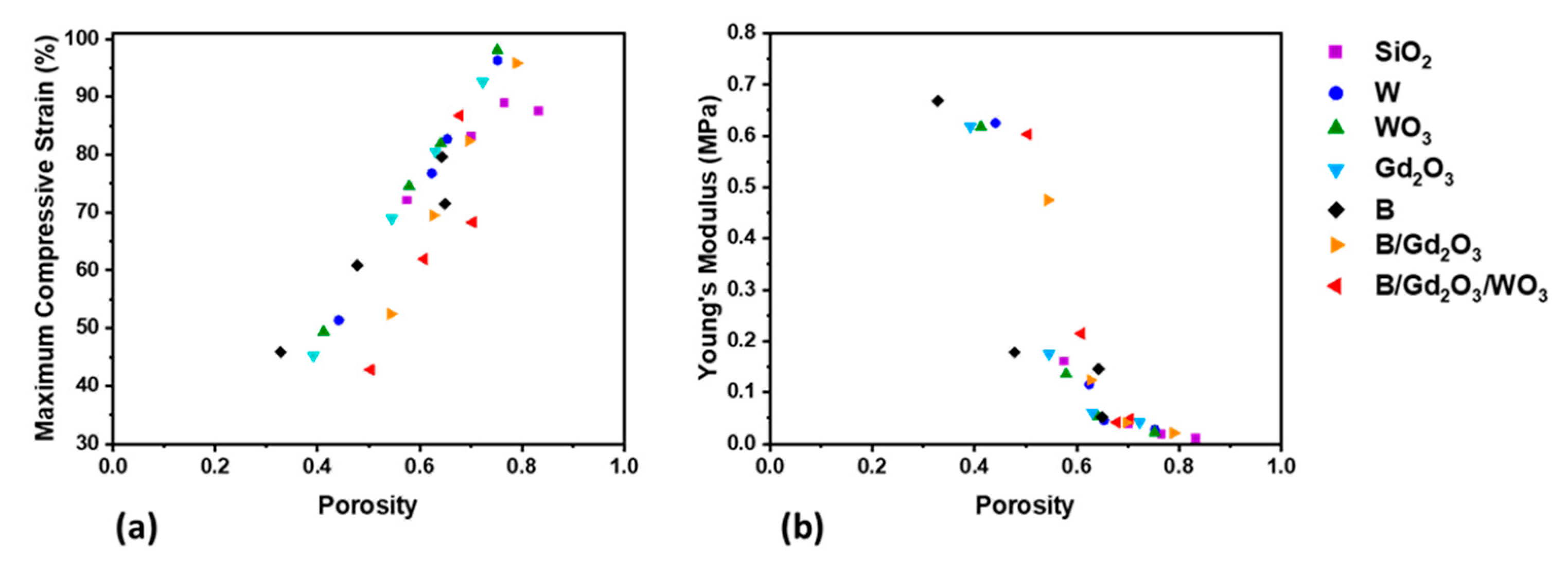

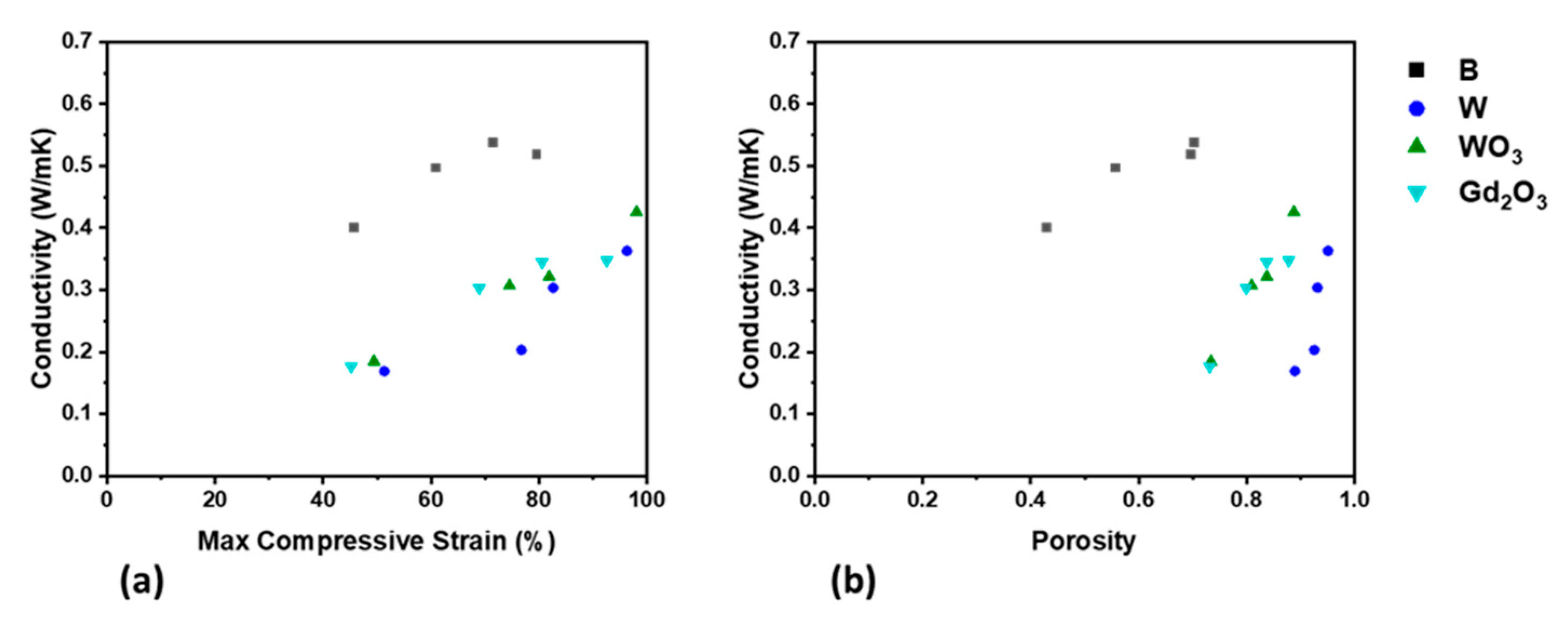

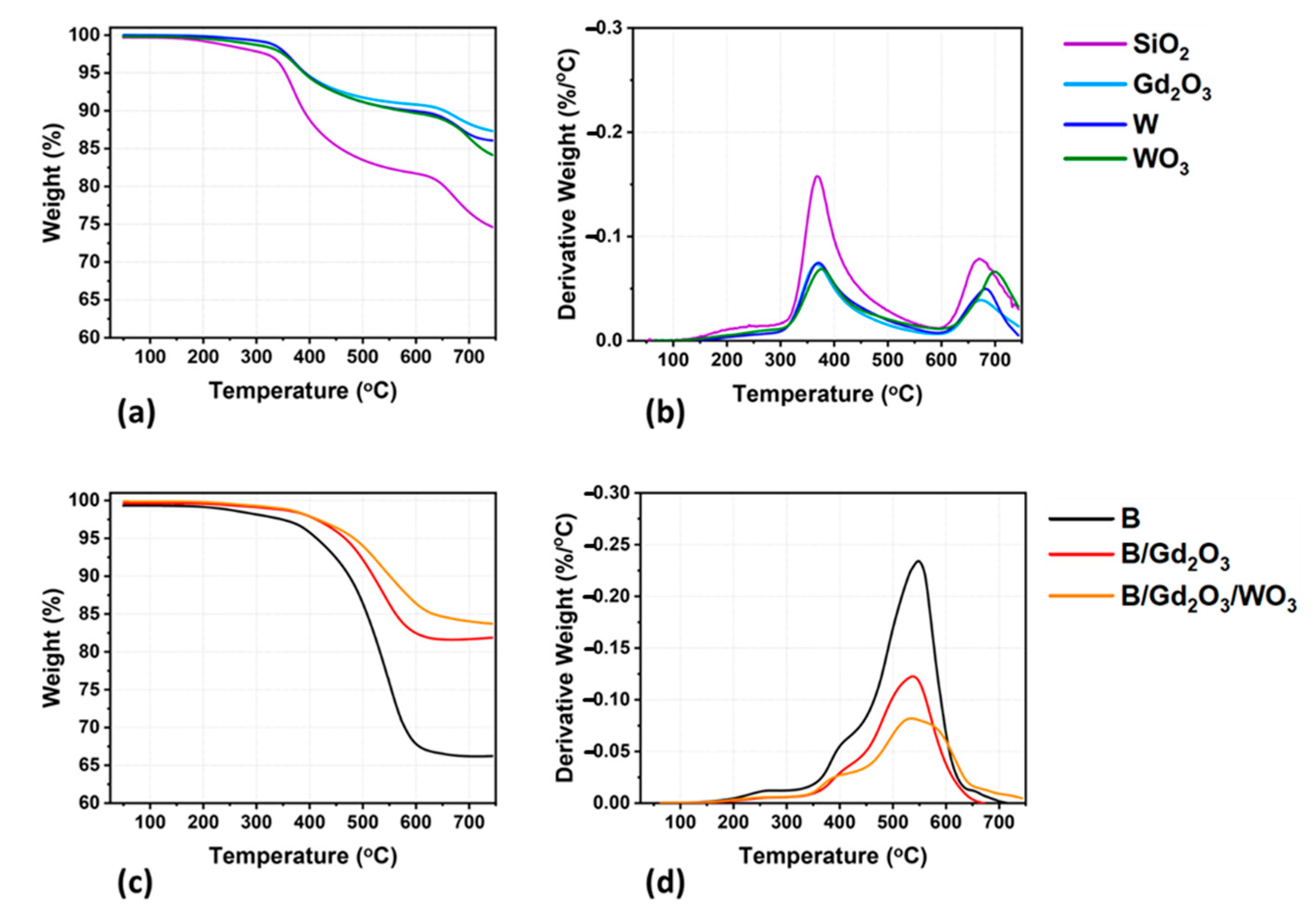

3.4. Thermomechanical Properties

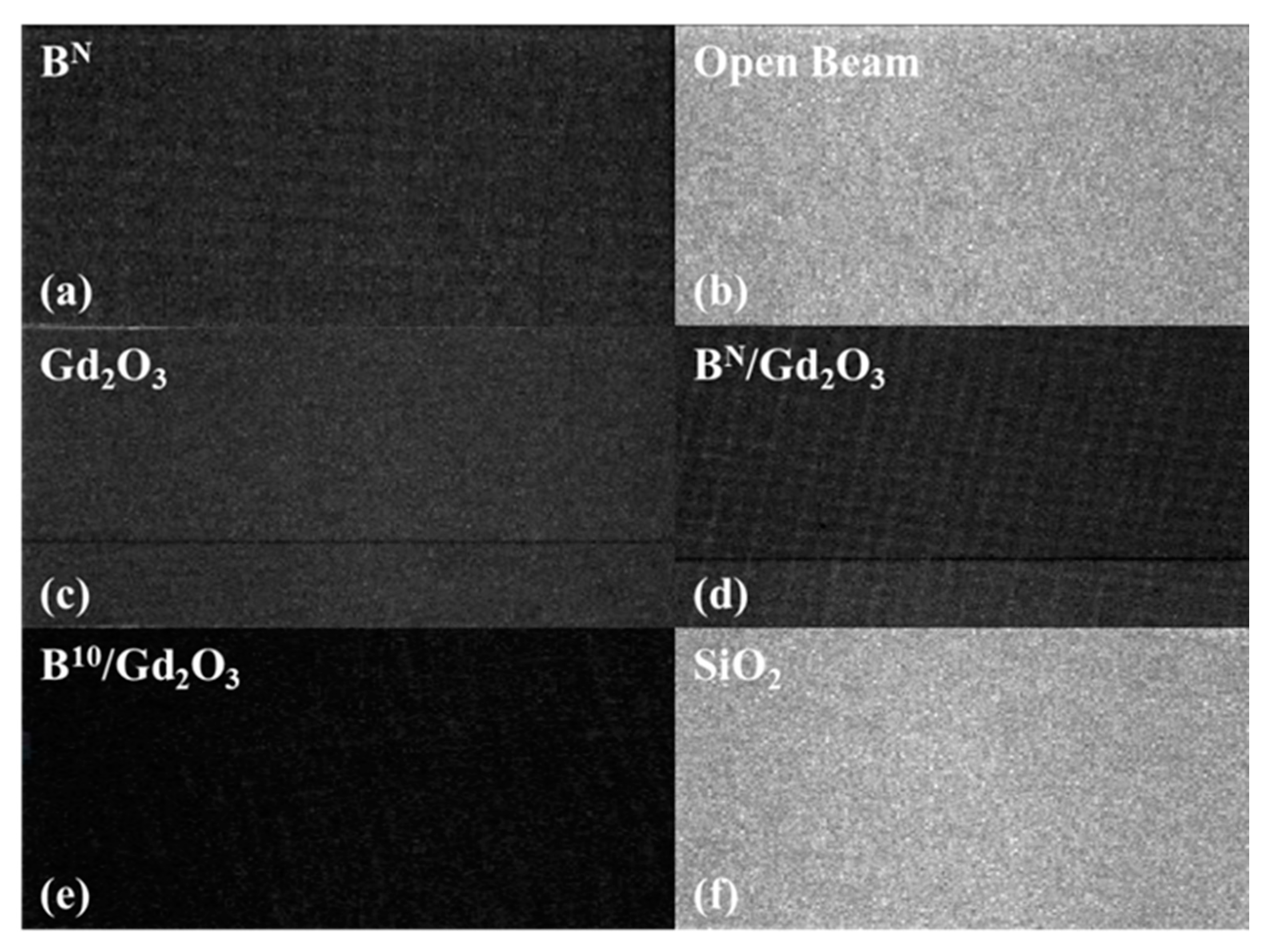

3.5. Attenuation of Ionizing Radiation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davoudinejad, A.; Diaz-Perez, L.C.; Quagliotti, D.; Pedersen, D.B.; Albajez-García, J.A.; Yagüe-Fabra, J.A.; Tosello, G. Additive manufacturing with vat polymerization method for precision polymer micro components production. Procedia CIRP 2018, 75, 98–102. [Google Scholar] [CrossRef]

- Ng, W.L.; Lee, J.M.; Zhou, M.; Chen, Y.-W.; Lee, K.-X.A.; Yeong, W.Y.; Shen, Y.-F. Vat polymerization-based bioprinting—Process, materials, applications and regulatory challenges. Biofabrication 2020, 12, 022001. [Google Scholar] [CrossRef]

- Kruth, J.P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef] [Green Version]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Lewis, J.A.; Smay, J.E.; Stuecker, J.; Cesarano, J. Direct ink writing of three-dimensional ceramic structures. J. Am. Ceram. Soc. 2006, 89, 3599–3609. [Google Scholar] [CrossRef]

- Franchin, G.; Scanferla, P.; Zeffiro, L.; Elsayed, H.; Baliello, A.; Giacomello, G.; Pasetto, M.; Colombo, P. Direct ink writing of geopolymeric inks. J. Eur. Ceram. Soc. 2017, 37, 2481–2489. [Google Scholar] [CrossRef]

- Tagliaferri, S.; Panagiotopoulos, A.; Mattevi, C. Direct ink writing of energy materials. Mater. Adv. 2021, 2, 540–563. [Google Scholar] [CrossRef]

- Calvert, P. Inkjet printing for materials and devices. Chem. Mater. 2001, 13, 3299–3305. [Google Scholar] [CrossRef]

- Minemawari, H.; Yamada, T.; Matsui, H.; Tsutsumi, J.y.; Haas, S.; Chiba, R.; Kumai, R.; Hasegawa, T. Inkjet printing of single-crystal films. Nature 2011, 475, 364–367. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, P.; Chen, G.; Cheng, Y.; Pi, X.; Yu, X.; Yang, D.; Han, L.; Zhang, Y.; Song, Y. Ink engineering of inkjet printing perovskite. ACS Appl. Mater. Interfaces 2020, 12, 39082–39091. [Google Scholar] [CrossRef] [PubMed]

- Kong, S.; Liao, D.-j.; Jia, Y.-m.; An, C.-w.; Li, C.-y.; Ye, B.-y.; Wu, B.-d.; Wang, J.-y.; Guo, H.; Hong, Z.-w. Performances and direct writing of CL-20 based ultraviolet curing explosive ink. Def. Technol. 2020, in press. [Google Scholar] [CrossRef]

- Dimitriou, E.; Michailidis, N.S. Printable conductive inks used for the fabrication of electronics: An overview. Nanotechnology 2021. [Google Scholar] [CrossRef] [PubMed]

- Rodzeń, K.; Sharma, P.K.; McIlhagger, A.; Mokhtari, M.; Dave, F.; Tormey, D.; Sherlock, R.; Meenan, B.J.; Boyd, A. The Direct 3D Printing of Functional PEEK/Hydroxyapatite Composites via a Fused Filament Fabrication Approach. Polymers 2021, 13, 545. [Google Scholar] [CrossRef]

- Brounstein, Z.; Talley, S.; Dumont, J.H.; Zhao, J.; Lee, K.-S.; Labouriau, A. Fused filament fabrication of polymer composites for extreme environments. J. Mater. Res. 2020, 35, 1493–1503. [Google Scholar] [CrossRef]

- Brounstein, Z.; Yeager, C.M.; Labouriau, A. Development of Antimicrobial PLA Composites for Fused Filament Fabrication. Polymers 2021, 13, 580. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Feng, X.; Patil, H.; Tiwari, R.V.; Repka, M.A. Coupling 3D printing with hot-melt extrusion to produce controlled-release tablets. Int. J. Pharm. 2017, 519, 186–197. [Google Scholar] [CrossRef] [PubMed]

- Musazzi, U.M.; Selmin, F.; Ortenzi, M.A.; Mohammed, G.K.; Franzé, S.; Minghetti, P.; Cilurzo, F. Personalized orodispersible films by hot melt ram extrusion 3D printing. Int. J. Pharm. 2018, 551, 52–59. [Google Scholar] [CrossRef]

- Tabard, L.; Garnier, V.; Prud’Homme, E.; Courtial, E.-J.; Meille, S.; Adrien, J.; Jorand, Y.; Gremillard, L. Robocasting of highly porous ceramics scaffolds with hierarchized porosity. Addit. Manuf. 2021, 38, 101776. [Google Scholar]

- Zhang, D.; Jonhson, W.; Herng, T.S.; Ang, Y.Q.; Yang, L.; Tan, S.C.; Peng, E.; He, H.; Ding, J. A 3D-printing method of fabrication for metals, ceramics, and multi-materials using a universal self-curable technique for robocasting. Mater. Horiz. 2020, 7, 1083–1090. [Google Scholar] [CrossRef]

- Liu, D.; Chen, C.; Zhou, Y.; Bao, Y.; Wang, R.; Liu, Y.; He, S.; Huang, H.; Zhang, C.; Foster, B. 3D-Printed, High-Porosity, High-Strength Graphite Aerogel. Small Methods 2021, 2001188. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Yao, B.; Liu, T.; Xiao, W.; Song, Y.; Qian, F.; Zhu, C.; Duoss, E.B.; Spadaccini, C.M.; Li, Y. Direct ink writing of organic and carbon aerogels. Mater. Horiz. 2018, 5, 1166–1175. [Google Scholar] [CrossRef]

- Li, V.C.-F.; Dunn, C.K.; Zhang, Z.; Deng, Y.; Qi, H.J. Direct ink write (DIW) 3D printed cellulose nanocrystal aerogel structures. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef]

- Minas, C.; Carnelli, D.; Tervoort, E.; Studart, A.R. 3D printing of emulsions and foams into hierarchical porous ceramics. Adv. Mater. 2016, 28, 9993–9999. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Han, P.; Vandi, L.-J.; Dehghan-Manshadi, A.; Humphry, J.; Kent, D.; Stefani, I.; Lee, P.; Heitzmann, M.; Cooper-White, J. A biocompatible thermoset polymer binder for Direct Ink Writing of porous titanium scaffolds for bone tissue engineering. Mater. Sci. Eng. C 2019, 95, 160–165. [Google Scholar] [CrossRef] [Green Version]

- Koons, L.G.; Diba, M.; Mikos, A.G. Materials design for bone-tissue engineering. Nat. Rev. Mater. 2020, 5, 584–603. [Google Scholar] [CrossRef]

- Coffigniez, M.; Gremillard, L.; Balvay, S.; Lachambre, J.; Adrien, J.; Boulnat, X. Direct-ink writing of strong and biocompatible titanium scaffolds with bimodal interconnected porosity. Addit. Manuf. 2021, 39, 101859. [Google Scholar]

- Yan, Y.; Chen, H.; Zhang, H.; Guo, C.; Yang, K.; Chen, K.; Cheng, R.; Qian, N.; Sandler, N.; Zhang, Y.S. Vascularized 3D printed scaffolds for promoting bone regeneration. Biomaterials 2019, 190, 97–110. [Google Scholar] [CrossRef]

- Compton, B.G.; Kemp, J.W.; Novikov, T.V.; Pack, R.C.; Nlebedim, C.I.; Duty, C.E.; Rios, O.; Paranthaman, M.P. Direct-write 3D printing of NdFeB bonded magnets. Mater. Manuf. Process. 2018, 33, 109–113. [Google Scholar] [CrossRef]

- Erkoc, P.; Odeh, Y.N.; Alrifai, N.; Zirhli, O.; Gunduz Akdogan, N.; Yildiz, B.; Misirlioglu, I.B.; Akdogan, O. Photocurable pentaerythritol triacrylate/lithium phenyl-2, 4, 6-trimethylbenzoylphosphinate-based ink for extrusion-based 3D printing of magneto-responsive materials. J. Appl. Polym. Sci. 2020, 137, 49043. [Google Scholar] [CrossRef]

- Bastola, A.; Paudel, M.; Li, L. Development of hybrid magnetorheological elastomers by 3D printing. Polymer 2018, 149, 213–228. [Google Scholar] [CrossRef]

- Kharita, M.; Yousef, S.; AlNassar, M. Review on the addition of boron compounds to radiation shielding concrete. Prog. Nucl. Energy 2011, 53, 207–211. [Google Scholar] [CrossRef]

- Tyagi, G.; Singhal, A.; Routroy, S.; Bhunia, D.; Lahoti, M. A review on sustainable utilization of industrial wastes in radiation shielding concrete. Mater. Today Proc. 2020, 32, 746–751. [Google Scholar] [CrossRef]

- McCaffrey, J.; Shen, H.; Downton, B.; Mainegra-Hing, E. Radiation attenuation by lead and nonlead materials used in radiation shielding garments. Med. Phys. 2007, 34, 530–537. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Y.; Liu, Y.; Fang, J.; Luan, W.; Yang, X.; Zhang, W. Preparation and characterization of tungsten/epoxy composites for γ-rays radiation shielding. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 356, 88–93. [Google Scholar] [CrossRef]

- Li, R.; Gu, Y.; Wang, Y.; Yang, Z.; Li, M.; Zhang, Z. Effect of particle size on gamma radiation shielding property of gadolinium oxide dispersed epoxy resin matrix composite. Mater. Res. Express 2017, 4, 035035. [Google Scholar] [CrossRef]

- Kaky, K.M.; Sayyed, M.; Laariedh, F.; Abdalsalam, A.H.; Tekin, H.; Baki, S. Stuctural, optical and radiation shielding properties of zinc boro-tellurite alumina glasses. Appl. Phys. A 2019, 125, 1–12. [Google Scholar] [CrossRef]

- Alshahrani, B.; Olarinoye, I.; Mutuwong, C.; Sriwunkum, C.; Yakout, H.; Tekin, H.; Al-Buriahi, M. Amorphous alloys with high Fe content for radiation shielding applications. Radiat. Phys. Chem. 2021, 183, 109386. [Google Scholar] [CrossRef]

- Kilic, G.; El Agawany, F.; Ilik, B.O.; Mahmoud, K.; Ilik, E.; Rammah, Y. Ta2O5 reinforced Bi2O3–TeO2–ZnO glasses: Fabrication, physical, structural characterization, and radiation shielding efficacy. Opt. Mater. 2021, 112, 110757. [Google Scholar] [CrossRef]

- Talley, S.J.; Robison, T.; Long, A.M.; Lee, S.Y.; Brounstein, Z.; Lee, K.-S.; Geller, D.; Lum, E.; Labouriau, A. Flexible 3D Printed Silicones for Gamma and Neutron Radiation Shielding. Radiat. Phys. Chem. 2021, 188, 109616. [Google Scholar] [CrossRef]

- Ceh, J.; Youd, T.; Mastrovich, Z.; Peterson, C.; Khan, S.; Sasser, T.A.; Sander, I.M.; Doney, J.; Turner, C.; Leevy, W.M. Bismuth Infusion of ABS Enables Additive Manufacturing of Complex Radiological Phantoms and Shielding Equipment. Sensors 2017, 17, 459. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Woosley, S.; Galehdari, N.A.; Kelkar, A.; Aravamudhan, S. Fused deposition modeling 3D printing of boron nitride composites for neutron radiation shielding. J. Mater. Res. 2018, 33, 3657–3664. [Google Scholar] [CrossRef]

- Szentmiklosi, L.; Maroti, B.; Kis, Z.; Janik, J.; Horvath, L.Z. Use of 3D mesh geometries and additive manufacturing in neutron beam experiments. J. Radioanal. Nucl. Chem. 2019, 320, 451–457. [Google Scholar] [CrossRef] [Green Version]

- Chandrasekaran, S.; Lu, R.; Landingham, R.; Cahill, J.T.; Thornley, L.; Du Frane, W.; Worsley, M.A.; Kuntz, J.D. Additive manufacturing of graded B4C-Al cermets with complex shapes. Mater. Des. 2020, 188, 108516. [Google Scholar] [CrossRef]

- Costakis, W.J., Jr.; Rueschhoff, L.M.; Diaz-Cano, A.I.; Youngblood, J.P.; Trice, R.W. Additive manufacturing of boron carbide via continuous filament direct ink writing of aqueous ceramic suspensions. J. Eur. Ceram. Soc. 2016, 36, 3249–3256. [Google Scholar] [CrossRef]

- Al-Hadeethi, Y.; Sayyed, M.; Al-Buriahi, M. Bioactive glasses doped with TiO2 and their potential use in radiation shielding applications. Ceram. Int. 2020, 46, 14721–14732. [Google Scholar] [CrossRef]

- Mirji, R.; Lobo, B. 24. Radiation shielding materials: A brief review on methods, scope and significance. In Proceedings of the National Conference on ‘Advances in VLSI and Microelectronics, PC Jabin Science College, Huballi, India, 27 January 2017. [Google Scholar]

- Levchenko, I.; Bazaka, K.; Belmonte, T.; Keidar, M.; Xu, S. Advanced Materials for Next-Generation Spacecraft. Adv. Mater. 2018, 30, 1802201. [Google Scholar] [CrossRef]

- Al-Ghamdi, H.; Dong, M.; Sayyed, M.I.; Wang, C.; Almuqrin, A.H.; Almasoud, F.I. The Vital Role of La2O3 on the La2O3-CaO-B2O3-SiO2 Glass System for Shielding Some Common Gamma Ray Radioactive Sources. Materials 2021, 14, 4776. [Google Scholar] [CrossRef]

- Chan, S.S.; Sesso, M.L.; Franks, G.V. Direct ink writing of hierarchical porous alumina-stabilized emulsions: Rheology and printability. J. Am. Ceram. Soc. 2020, 103, 5554–5566. [Google Scholar] [CrossRef]

- Smay, J.E.; Cesarano, J.; Lewis, J.A. Colloidal inks for directed assembly of 3-D periodic structures. Langmuir 2002, 18, 5429–5437. [Google Scholar] [CrossRef]

- Talley, S.J.; Branch, B.; Welch, C.F.; Park, C.H.; Watt, J.; Kuettner, L.; Patterson, B.; Dattelbaum, D.M.; Lee, K.-S. Impact of filler composition on mechanical and dynamic response of 3-D printed silicone-based nanocomposite elastomers. Compos. Sci. Technol. 2020, 198, 108258. [Google Scholar] [CrossRef]

- Smay, J.E.; Gratson, G.M.; Shepherd, R.F.; Cesarano III, J.; Lewis, J.A. Directed colloidal assembly of 3D periodic structures. Adv. Mater. 2002, 14, 1279–1283. [Google Scholar] [CrossRef]

- Duoss, E.B.; Weisgraber, T.H.; Hearon, K.; Zhu, C.; Small IV, W.; Metz, T.R.; Vericella, J.J.; Barth, H.D.; Kuntz, J.D.; Maxwell, R.S. Three-dimensional printing of elastomeric, cellular architectures with negative stiffness. Adv. Funct. Mater. 2014, 24, 4905–4913. [Google Scholar] [CrossRef]

- Mora, A.; Verma, P.; Kumar, S. Electrical conductivity of CNT/polymer composites: 3D printing, measurements and modeling. Compos. Part B Eng. 2020, 183, 107600. [Google Scholar] [CrossRef]

- Song, R.; Wang, Y.; Ishutov, S.; Zambrano-Narvaez, G.; Hodder, K.J.; Chalaturnyk, R.J.; Sun, S.; Liu, J.; Gamage, R.P. A comprehensive experimental study on mechanical behavior, microstructure and transport properties of 3D-printed rock analogs. Rock Mech. Rock Eng. 2020, 53, 5745–5765. [Google Scholar] [CrossRef]

- Karande, S.T.; Ong, J.L.; Agrawal, C.M. Diffusion in musculoskeletal tissue engineering scaffolds: Design issues related to porosity, permeability, architecture, and nutrient mixing. Ann. Biomed. Eng. 2004, 32, 1728–1743. [Google Scholar] [CrossRef]

- Zlatanic, A.; Radojcic, D.; Wan, X.; Messman, J.M.; Dvornic, P.R. Suppression of crystallization in polydimethylsiloxanes and chain branching in their phenyl-containing copolymers. Macromolecules 2017, 50, 3532–3543. [Google Scholar] [CrossRef]

- M’barki, A.; Bocquet, L.; Stevenson, A. Linking rheology and printability for dense and strong ceramics by direct ink writing. Sci. Rep. 2017, 7, 1–10. [Google Scholar] [CrossRef]

- Rallini, M.; Torre, L.; Kenny, J.M.; Natali, M. Effect of boron carbide nanoparticles on the thermal stability of carbon/phenolic composites. Polym. Compos. 2017, 38, 1819–1827. [Google Scholar] [CrossRef]

| Weight Percent (w/w)/Volume Percent (v/v) | |||||||

|---|---|---|---|---|---|---|---|

| SiO2 | W | WO3 | Gd2O3 | B | Density (g/cm3) | ||

| Formulation | SiO2 | 10/4.3 | 0/0 | 0/0 | 0/0 | 0/0 | 1.064 |

| W | 4.5/3.6 | 50/5.2 | 0/0 | 0/0 | 0/0 | 2.004 | |

| WO3 | 4.5/3.3 | 0/0 | 50/12.9 | 0/0 | 0/0 | 1.842 | |

| Gd2O3 | 4.5/3.3 | 0/0 | 0/0 | 50/12.4 | 0/0 | 1.850 | |

| B | 1.5/0.9 | 0/0 | 0/0 | 0/0 | 50/30 | 1.424 | |

| B/Gd2O3 | 1.5/1.2 | 0/0 | 0/0 | 30/8.1 | 40/33.7 | 1.998 | |

| B/Gd2O3/WO3 | 1.5/1.2 | 0/0 | 20/5.6 | 10/2.7 | 40/33.7 | 1.995 | |

| Formulation | Flow Point (Pa) | ||

|---|---|---|---|

| SiO2 | 55,470 | 3650 | 4610 |

| W | 42,600 | 3390 | 3900 |

| WO3 | 57,400 | 2940 | 4480 |

| B | 78,720 | 400 | 2270 |

| B/Gd2O3 | 2,277,190 | 5330 | 11,050 |

| Formulation | Κink (m−1) | ηmax (From Equation (7)) |

|---|---|---|

| SiO2 | 4.345 × 10 | 7.7 |

| W | 7.286 × 10 | 6.0 |

| WO3 | 1.200 × 102 | 5.0 |

| B | 6.874 × 103 | 1.5 |

| B/Gd2O3 | 1.571 × 103 | 2.2 |

| Formulation | Td5% (°C) | TdMax (°C) | mf (%) | |

|---|---|---|---|---|

| SiO2 | 355 | 371 | 675 | 75 |

| W | 392 | 373 | 680 | 86 |

| WO3 | 390 | 377 | 701 | 84 |

| Gd2O3 | 392 | 369 | 675 | 87 |

| B | 413 | 548 | 66 | |

| B/Gd2O3 | 467 | 536 | 82 | |

| B/Gd2O3/WO3 | 483 | 537 | 84 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brounstein, Z.; Zhao, J.; Wheat, J.; Labouriau, A. Tuning the 3D Printability and Thermomechanical Properties of Radiation Shields. Polymers 2021, 13, 3284. https://doi.org/10.3390/polym13193284

Brounstein Z, Zhao J, Wheat J, Labouriau A. Tuning the 3D Printability and Thermomechanical Properties of Radiation Shields. Polymers. 2021; 13(19):3284. https://doi.org/10.3390/polym13193284

Chicago/Turabian StyleBrounstein, Zachary, Jianchao Zhao, Jeffrey Wheat, and Andrea Labouriau. 2021. "Tuning the 3D Printability and Thermomechanical Properties of Radiation Shields" Polymers 13, no. 19: 3284. https://doi.org/10.3390/polym13193284

APA StyleBrounstein, Z., Zhao, J., Wheat, J., & Labouriau, A. (2021). Tuning the 3D Printability and Thermomechanical Properties of Radiation Shields. Polymers, 13(19), 3284. https://doi.org/10.3390/polym13193284