Investigation of the Release Mechanism and Mould Resistance of Citral-Loaded Bamboo Strips

Abstract

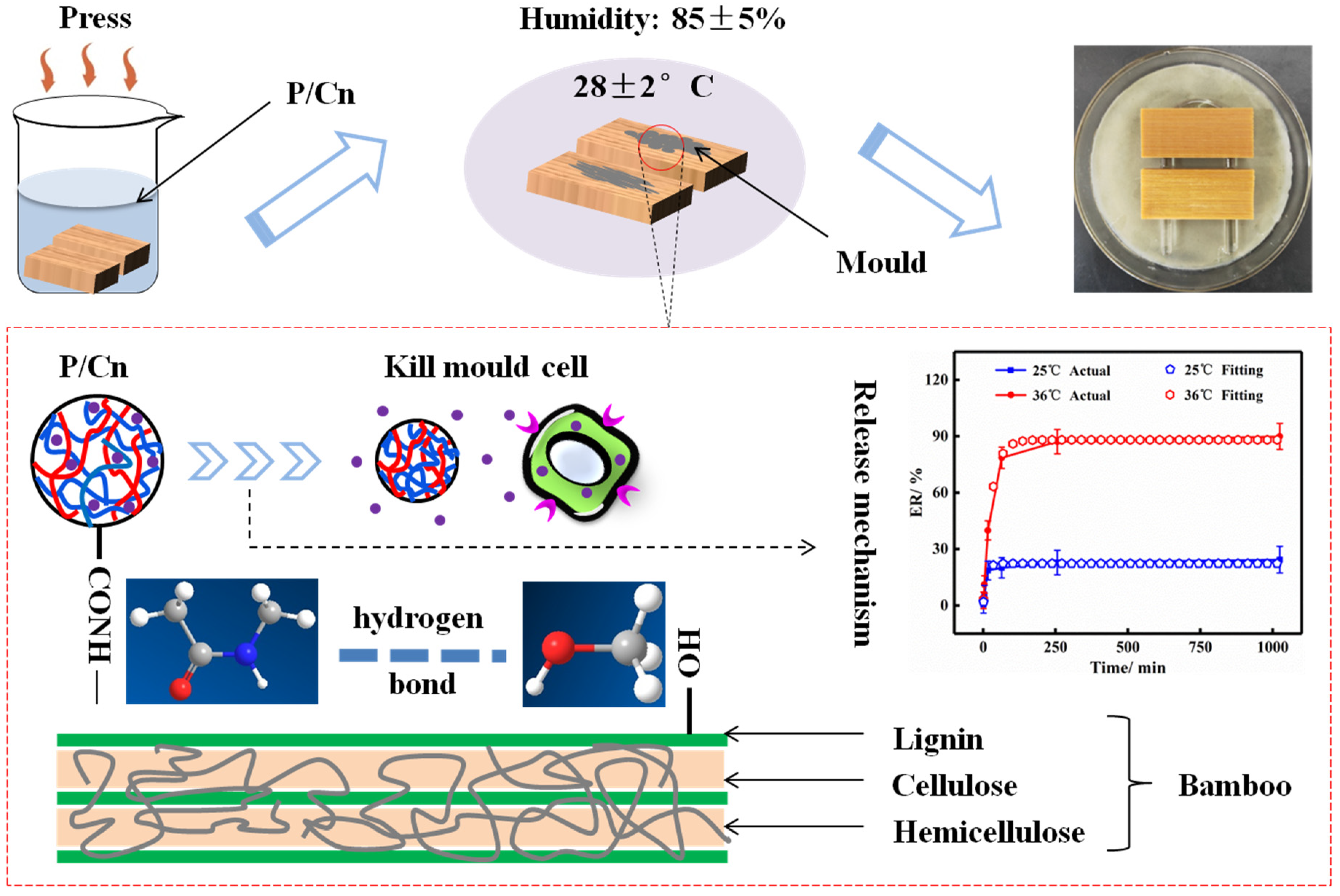

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Phosphate-Buffered Saline

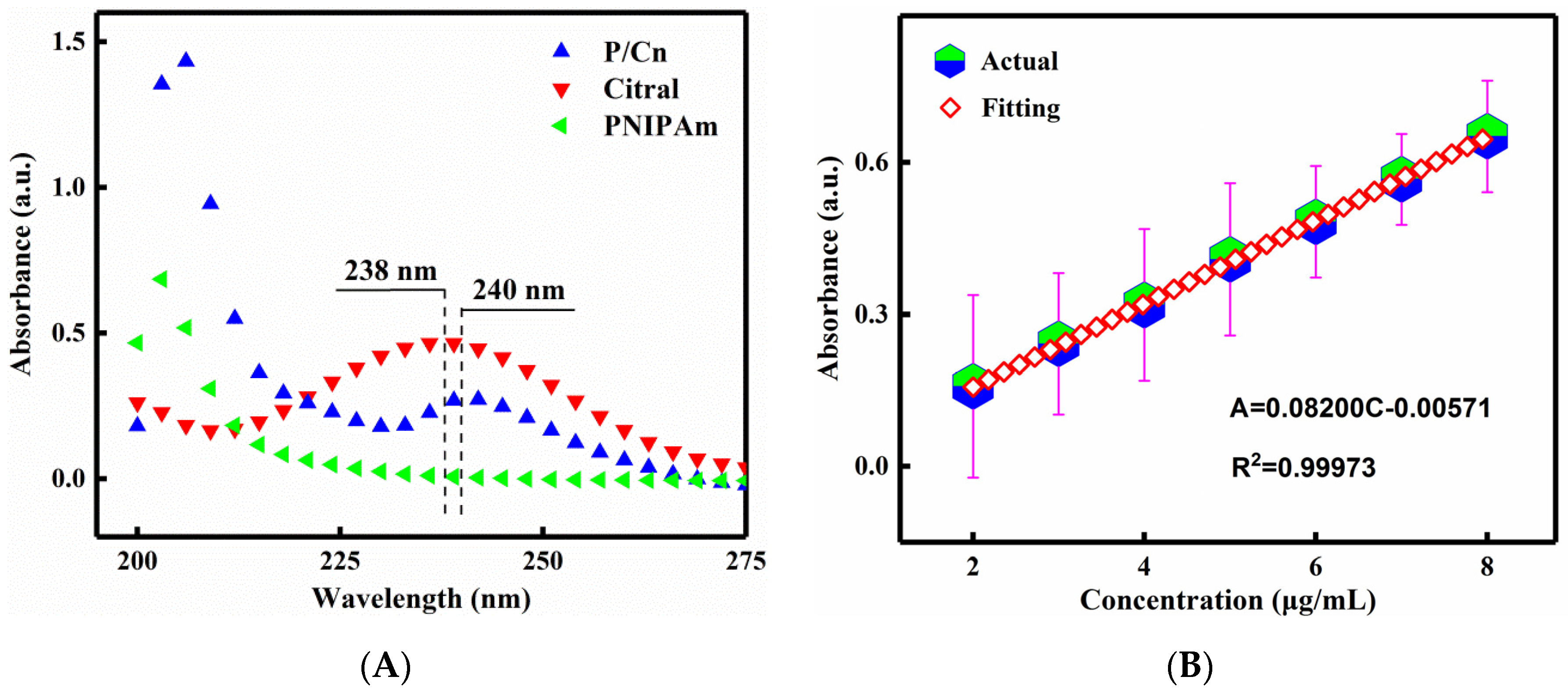

2.3. The Standard Curve

2.4. Release and Detection of Citral

2.5. Optimisation of Release Parameters

2.6. Sustained-Release Kinetics

2.7. Impregnation of Bamboo Strips

2.8. Optimisation of the Impregnation Process

2.9. Fourier-Transformed Infrared Spectroscopy

2.10. Anti-Mould Property

3. Results and Discussion

3.1. Draw the Standard Curve

3.2. Orthogonal Test

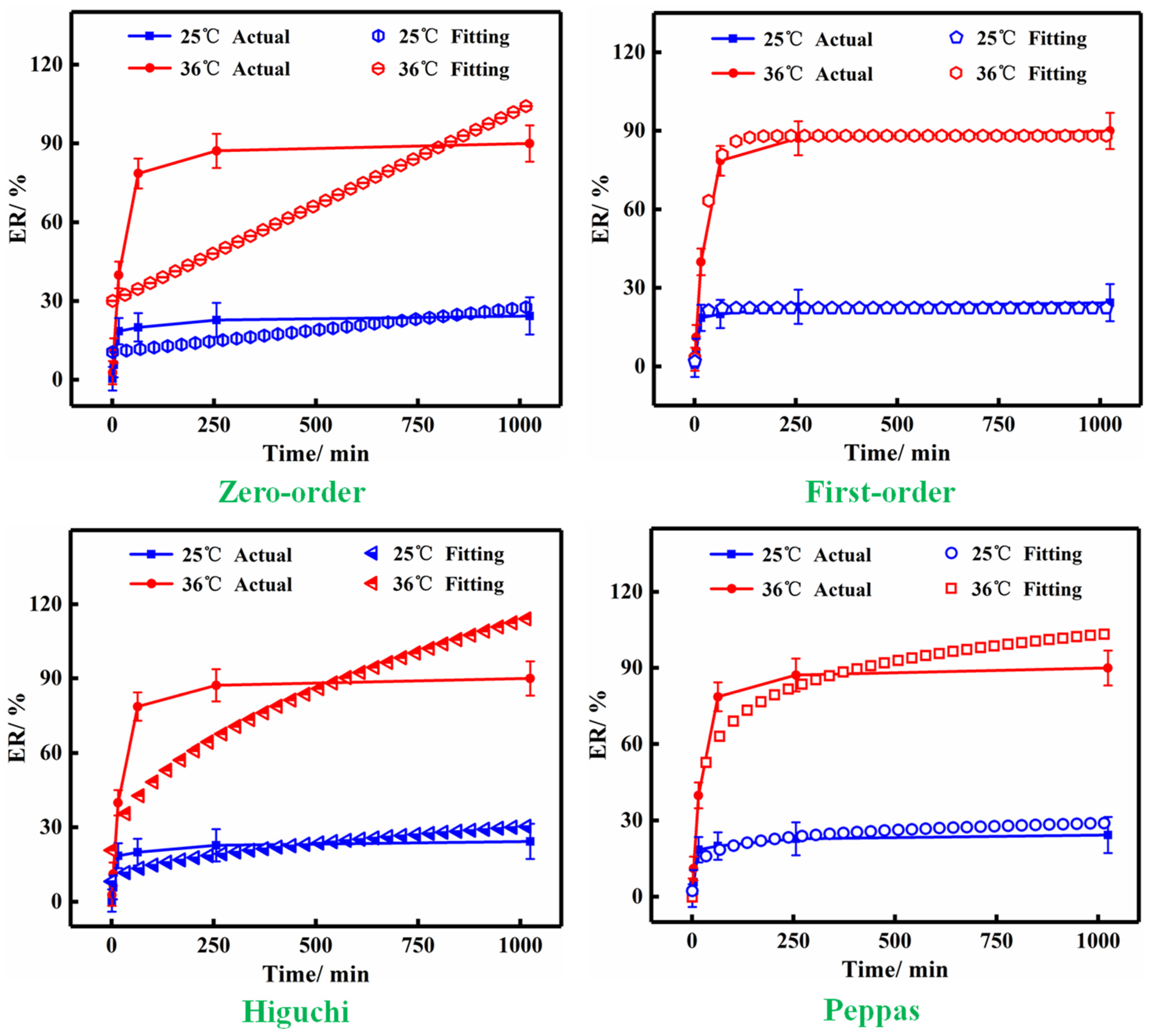

3.3. Release Kinetics Analysis

3.4. Effect of Pressure

3.5. Effect of Impregnation Time

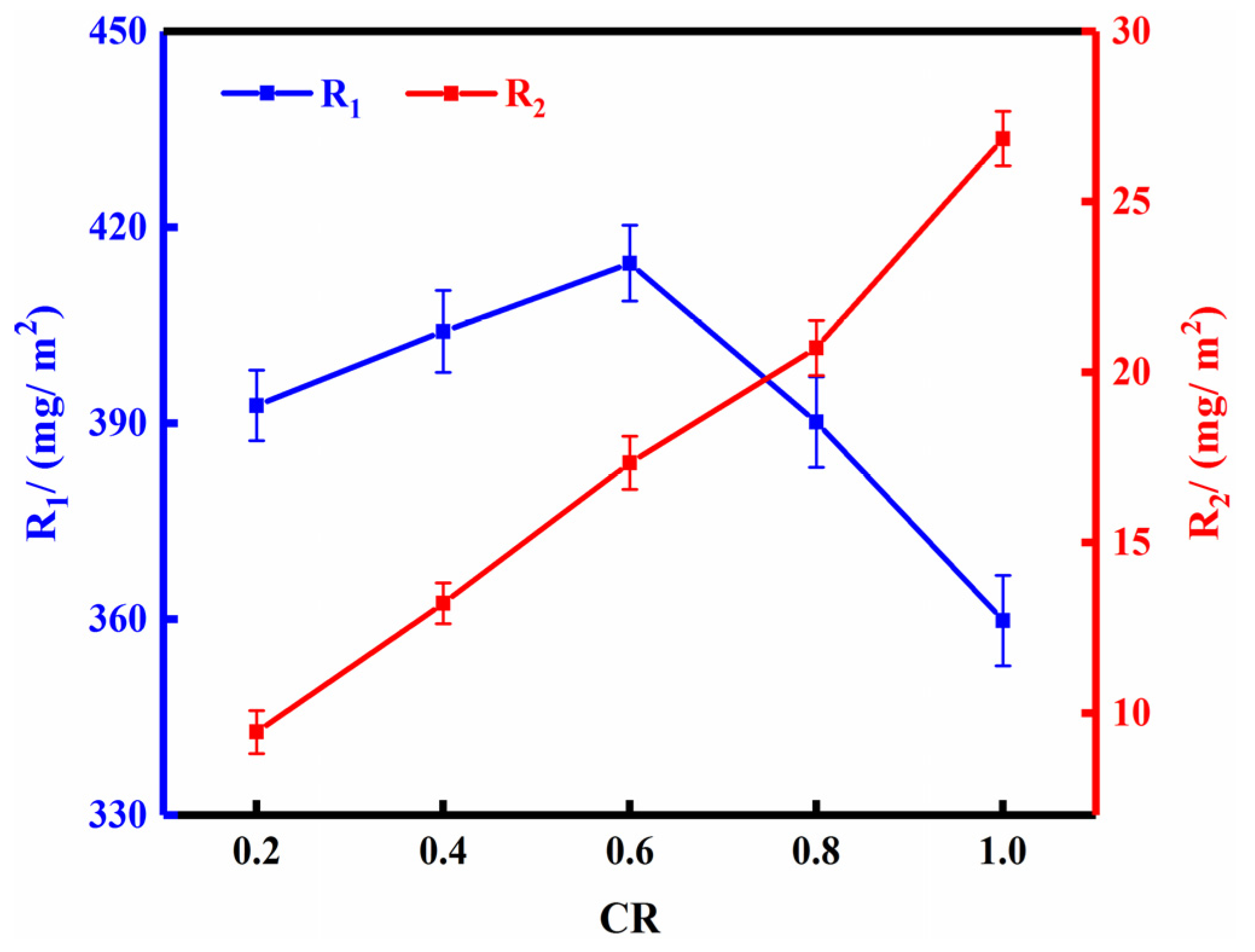

3.6. Effect of CR

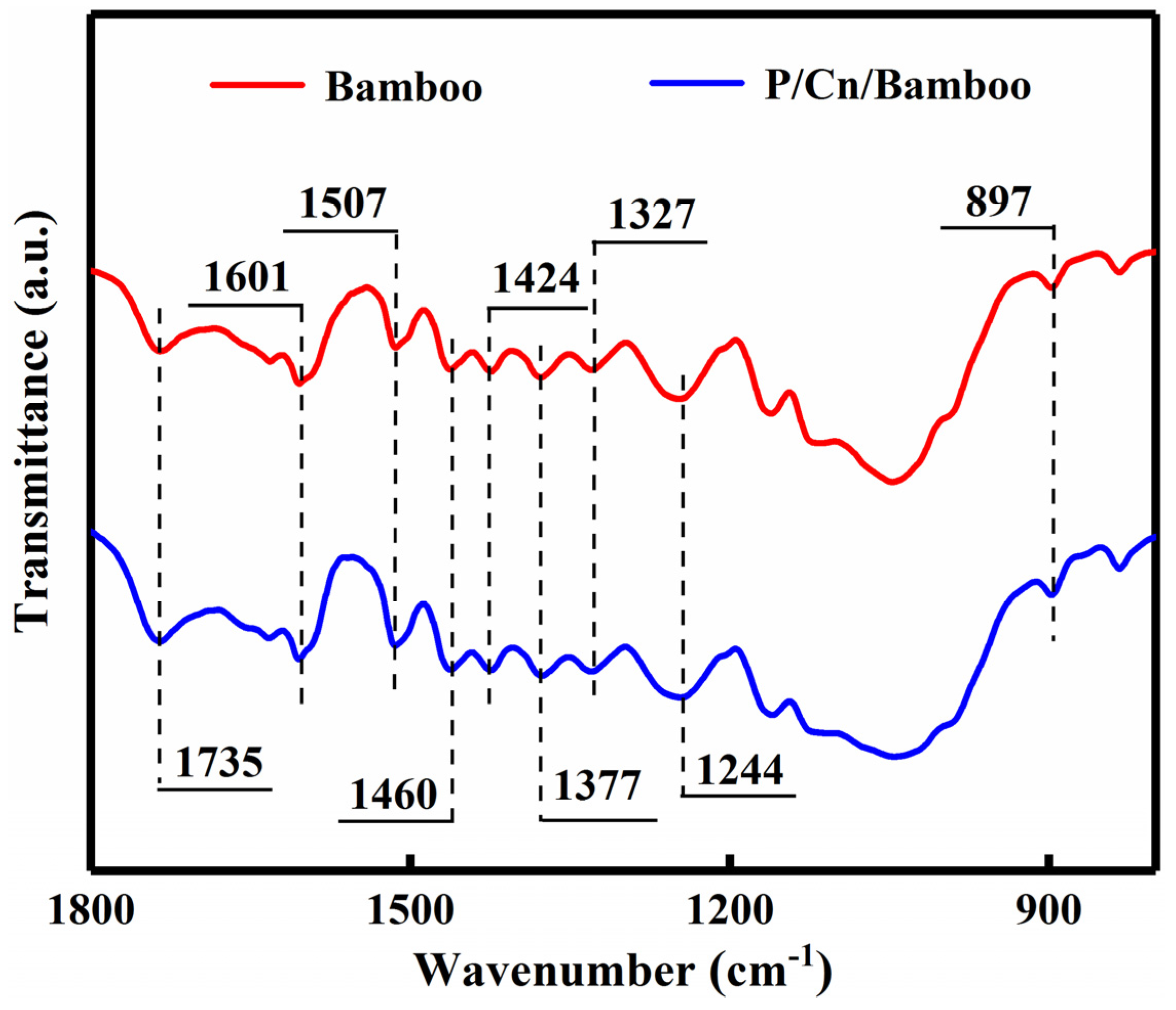

3.7. FT-IR Analysis

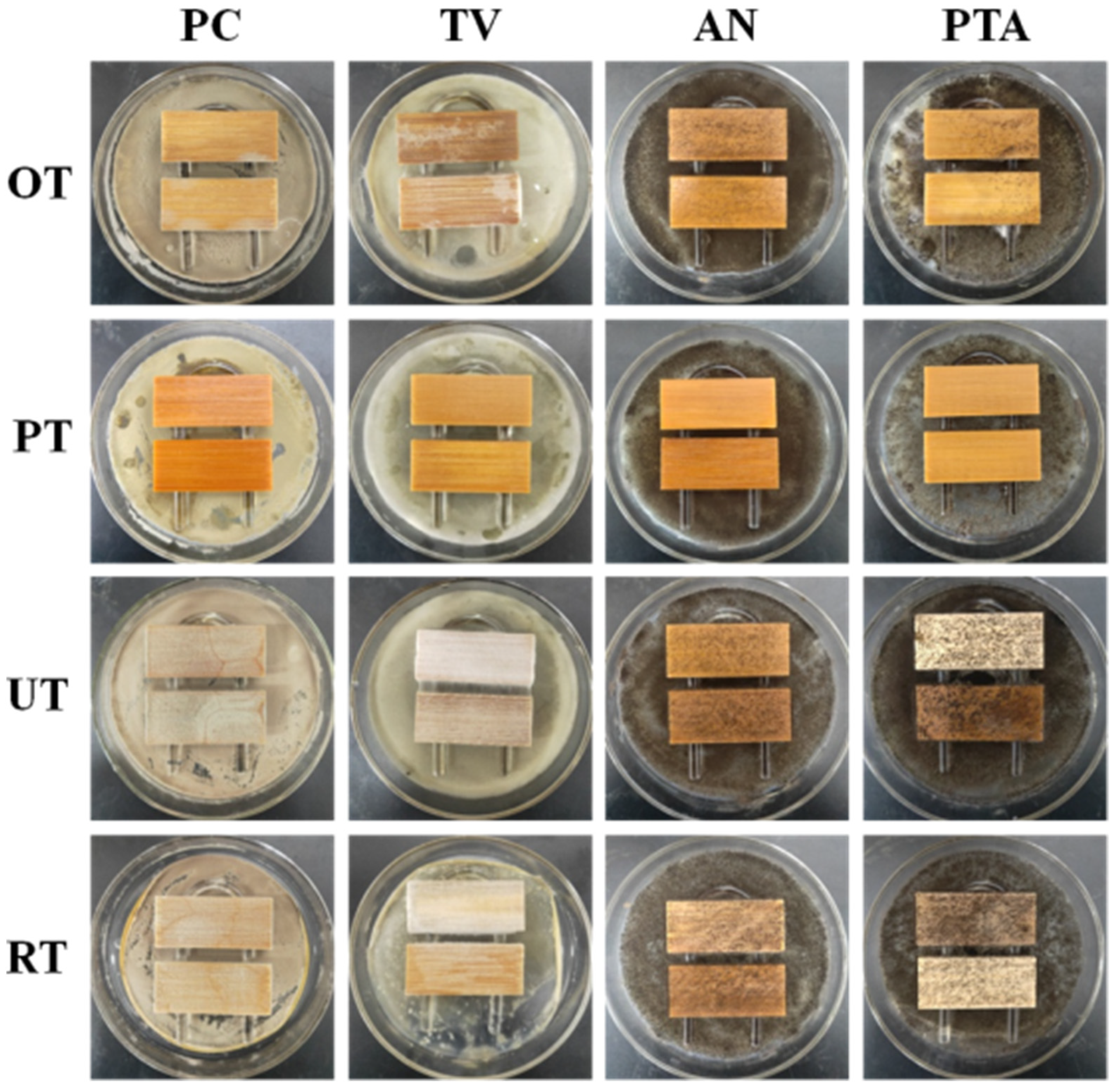

3.8. Analysis of Mould Resistance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Gielen, D.; Boshell, F.; Saygin, D. Climate and energy challenges for materials science. Nat. Mater. 2016, 15, 117–120. [Google Scholar] [CrossRef]

- Brunet-Navarro, P.; Jochheim, H.; Cardellini, G.; Richter, K.; Muys, B. Climate mitigation by energy and material substitution of wood products has an expiry date. J. Clean. Prod. 2021, 303, 127026. [Google Scholar] [CrossRef]

- Peng, R.; Yu, H.; Du, C.; Zhang, J.; Hu, A.; Li, Q.; Hua, Y.; Liu, H.; Chu, S. Preparation of uniformly dispersed N-isopropylacryl-amide/Acrylic acid/nanosilver composite hydrogel and its anti-mold properties. BioResources 2020, 16, 441–454. [Google Scholar] [CrossRef]

- Li, Z.; Chen, C.; Mi, R.; Gan, W.; Dai, J.; Jiao, M.; Xie, H.; Yao, Y.; Xiao, S.; Hu, L. A strong, tough, and scalable structural material from fast-growing bamboo. Adv. Mater. 2020, 32, 1906308. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Li, Z.; Mi, R.; Dai, J.; Xie, H.; Pei, Y.; Li, J.; Qiao, H.; Tang, H.; Yang, B.; et al. Rapid processing of whole bamboo with exposed, aligned nanofibrils toward a high-performance structural material. ACS Nano 2020, 14, 5194–5202. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wu, Z.; Bao, Y.; Chen, Y.; Huang, C.; Li, N.; He, S.; Chen, Z. Wet chemical synthesis of ZnO nanocoating on the surface of bamboo timber with improved mould-resistance. J. Saudi Chem. Soc. 2017, 21, 920–928. [Google Scholar] [CrossRef]

- Chen, J.; Ma, Y.; Lin, H.; Zheng, Q.; Zhang, X.; Yang, W.; Li, R. Fabrication of hydrophobic ZnO/PMHS coatings on bamboo surfaces: The synergistic effect of ZnO and PMHS on anti-mildew properties. Coatings 2018, 9, 15. [Google Scholar] [CrossRef] [Green Version]

- Ren, D.; Li, J.; Bao, Y.; Wu, Z.; He, S.; Wang, A.; Guo, F.; Chen, Y. Low-temperature synthesis of flower-like ZnO microstructures supported on TiO2 thin films as efficient antifungal coatings for bamboo protection under dark conditions. Colloids Surf. A Physicochem. Eng. Asp. 2018, 555, 381–388. [Google Scholar] [CrossRef]

- Sharma, B.; Gatoo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Li, J.; Yu, H.; Wu, Z.; Wang, J.; He, S.; Ji, J.; Li, N.; Bao, Y.; Huang, C.; Chen, Z.; et al. Room temperature synthesis of crystalline anatase TiO2 on bamboo timber surface and their short-term antifungal capability under natural weather conditions. Colloids Surf. A Physicochem. Eng. Asp. 2016, 508, 117–123. [Google Scholar] [CrossRef]

- Zhang, J.; Du, C.; Li, Q.; Hu, A.; Peng, R.; Sun, F.; Zhang, W. Inhibition mechanism and antibacterial activity of natural antibacterial agent citral on bamboo mould and its anti-mildew effect on bamboo. R. Soc. Open Sci. 2021, 8, 202244. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Ku, K.H.; Kim, M.; Shin, J.M.; Han, J.; Park, C.H.; Yi, G.-R.; Jang, S.G.; Kim, B.J. Nanostructured particles: Stimuli-responsive, shape-transforming nanostructured particles. Adv. Mater. 2017, 29, 1700608. [Google Scholar] [CrossRef]

- Sultana, T.; Van Hai, H.; Park, M.; Lee, S.Y.; Lee, B.T. Controlled release of Mitomycin C from modified cellulose based thermo-gel prevents post-operative de novo peritoneal adhesion. Carbohydr. Polym. 2020, 229, 115552. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Lu, Z.; Zhu, X.; Du, X.; Hu, J.; Chang, S.; Li, X.; Liu, Y. Facile in-situ growth of Ag/TiO2 nanoparticles on polydopamine modified bamboo with excellent mildew-proofing. Sci. Rep. 2019, 9, 16496. [Google Scholar] [CrossRef] [PubMed]

- Almeida, K.B.; Ramos, A.S.; Nunes, J.B.B.; Silva, B.O.; Ferraz, E.R.A.; Fernandes, A.S.; Felzenszwalb, I.; Amaral, A.C.F.; Roullin, V.G.; Falcão, D.Q. PLGA nanoparticles optimized by Box-Behnken for efficient encapsulation of therapeutic Cymbopogon citratus essential oil. Colloids Surf. B Biointerfaces 2019, 181, 935–942. [Google Scholar] [CrossRef]

- Zhang, R.; Li, Y.; He, Y.; Qin, D. Preparation of iodopropynyl butycarbamate loaded halloysite and its anti-mildew activity. J. Mater. Res. Technol. 2020, 9, 10148–10156. [Google Scholar] [CrossRef]

- Johnson, T.J.; Gupta, K.M.; Fabian, J.; Albright, T.H.; Kiser, P.F. Segmented polyurethane intravaginal rings for the sustained combined delivery of antiretroviral agents dapivirine and tenofovir. Eur. J. Pharm. Sci. 2010, 39, 203–212. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Shi, Y.; Pena, D.A.; Peng, L.; Yu, G. Thermally responsive hydrogel blends: A general drug carrier model for controlled drug release. Angew. Chem. 2015, 127, 7484–7488. [Google Scholar] [CrossRef]

- Elashnikov, R.; Slepička, P.; Rimpelova, S.; Ulbrich, P.; Švorčík, V.; Lyutakov, O. Temperature-responsive PLLA/PNIPAM nanofibers for switchable release. Mater. Sci. Eng. C 2017, 72, 293–300. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wu, J.; Zhao, P.; Dai, N.; Zhai, Z.; Ai, T. Improving cracking resistance of cement mortar by thermo-sensitive poly N-isopropyl acrylamide (PNIPAM) gels. J. Clean. Prod. 2018, 176, 1292–1303. [Google Scholar] [CrossRef]

- Rikhtegar, F.; Athanasiou, L.; Edelman, E. Endovascular drug-delivery and drug-elution systems. In Biomechanics of Coronary Atherosclerotic Plaque; Academic Press: Cambridge, MA, USA, 2021; pp. 595–631. [Google Scholar] [CrossRef]

- Bode, C.; Kranz, H.; Fivez, A.; Siepmann, F.; Siepmann, J. Often neglected: PLGA/PLA swelling orchestrates drug release: HME implants. J. Control. Release 2019, 306, 97–107. [Google Scholar] [CrossRef]

- Abbasnezhad, N.; Zirak, N.; Shirinbayan, M.; Kouidri, S.; Salahinejad, E.; Tcharkhtchi, A.; Bakir, F. Controlled release from polyurethane films: Drug release mechanisms. J. Appl. Polym. Sci. 2020, 138, 50083. [Google Scholar] [CrossRef]

- Abdel-Mottaleb, M.M.A.; Lamprecht, A. Standardized in vitro drug release test for colloidal drug carriers using modified USP dissolution apparatus I. Drug Dev. Ind. Pharm. 2011, 37, 178–184. [Google Scholar] [CrossRef] [PubMed]

- Zambito, Y.; Pedreschi, E.; Di Colo, G. Is dialysis a reliable method for studying drug release from nanoparticulate systems?—A case study. Int. J. Pharm. 2012, 434, 28–34. [Google Scholar] [CrossRef] [PubMed]

- Aldawsari, H.M.; Badr-Eldin, S.M.; Labib, G.S.; El-Kamel, A.H. Design and formulation of a topical hydrogel integrating lemongrass-loaded nanosponges with an enhanced antifungal effect: In vitro/in vivo evaluation. Int. J. Nanomed. 2015, 10, 893–902. [Google Scholar] [CrossRef] [Green Version]

- Almeida, K.B.; Araujo, J.L.; Cavalcanti, J.F.; Romanos, M.T.V.; Mourão, S.C.; Amaral, A.C.F.; Falcão, D.Q. In vitro release and anti-herpetic activity of Cymbopogon citratus volatile oil-loaded nanogel. Rev. Bras. Farmacogn. 2018, 28, 495–502. [Google Scholar] [CrossRef]

- Test Method for Anti-Mildew Agents in Controlling Wood Mould and Stain Fungi. GB/T 18261-2013. 2013. Available online: http://www.nssi.org.cn/nssi/front/83564233.html (accessed on 10 September 2021).

- Nisha, C.K.; Dhara, D.; Chatterji, P.R. Superabsorbency and volume phase transition in crosslinked poly[[3-(methacryloylamino)propyl]-trimethylammonium chloride] hydrogels. J. Macromol. Sci. Part. A 2000, 37, 1447–1460. [Google Scholar] [CrossRef]

- Natrajan, D.; Srinivasan, S.; Sundar, K.; Ravindran, A. Formulation of essential oil-loaded chitosan–alginate nanocapsules. J. Food Drug Anal. 2015, 23, 560–568. [Google Scholar] [CrossRef] [Green Version]

- Jovanović, J.; Krnjajić, S.; Ćirković, J.; Radojković, A.; Popović, T.; Branković, G.; Branković, Z. Effect of encapsulated lemongrass (Cymbopogon citratus L.) essential oil against potato tuber moth Phthorimaea operculella. Crop. Prot. 2020, 132, 105109. [Google Scholar] [CrossRef]

- Jiang, Y.; Yan, R.; Pang, B.; Mi, J.; Zhang, Y.; Liu, H.; Xin, J.; Zhang, Y.; Li, N.; Zhao, Y.; et al. A novel temperature-dependent hydrogel emulsion with Sol/Gel reversible phase transition behavior based on Polystyrene-co-poly(N-isopropylacrylamide)/Poly(N-isopropylacrylamide) core–shell nanoparticle. Macromol. Rapid Commun. 2021, 42, 2000507. [Google Scholar] [CrossRef]

- Cao-Luu, N.-H.; Pham, Q.-T.; Yao, Z.-H.; Wang, F.-M.; Chern, C.-S. Synthesis and characterization of poly(N-isopropylacrylamide-co-acrylamide) mesoglobule core–silica shell nanoparticles. J. Colloid Interface Sci. 2019, 536, 536–547. [Google Scholar] [CrossRef] [PubMed]

- Rocky, B.; Thompson, A. Analyses of the chemical compositions and structures of four bamboo species and their natural fibers by infrared, laser, and x-ray spectroscopies. Fibers Polym. 2021, 22, 916–927. [Google Scholar] [CrossRef]

- Sirisomboon, P.; Funke, A.; Posom, J. Improvement of proximate data and calorific value assessment of bamboo through near infrared wood chips acquisition. Renew. Energy 2020, 147, 1921–1931. [Google Scholar] [CrossRef]

- Haiyee, Z.A.; Saim, N.; Said, M.; Illias, R.M.; Mustapha, W.A.W.; Hassan, O. Characterization of cyclodextrin complexes with turmeric oleoresin. Food Chem. 2009, 114, 459–465. [Google Scholar] [CrossRef]

| Test No. | Factor | L2 (mg) | ER (%) | ||

|---|---|---|---|---|---|

| A (mg) | B (h) | C (°C) | |||

| 1 | 1 | 1 | 1 | 5.099 | 81.919 |

| 2 | 1 | 2 | 2 | 5.628 | 85.675 |

| 3 | 1 | 3 | 3 | 4.942 | 81.919 |

| 4 | 2 | 1 | 2 | 19.820 | 82.893 |

| 5 | 2 | 2 | 3 | 19.748 | 82.197 |

| 6 | 2 | 3 | 1 | 22.515 | 90.542 |

| 7 | 3 | 1 | 3 | 27.132 | 85.953 |

| 8 | 3 | 2 | 1 | 33.469 | 89.986 |

| 9 | 3 | 3 | 2 | 31.093 | 95.828 |

| k1 (L3) | 5.223 | 17.35 | 20.361 | ||

| k2 (L3) | 20.694 | 19.615 | 18.847 | ||

| k3 (L3) | 30.565 | 19.517 | 17.274 | ||

| k1 (ER) | 83.171 | 83.588 | 87.482 | ||

| k2 (ER) | 85.211 | 85.953 | 88.132 | ||

| k3 (ER) | 90.589 | 89.43 | 83.356 | ||

| R (L3) | 25.342 | 2.265 | 3.087 | ||

| R (ER) | 7.418 | 5.842 | 4.776 | ||

| Source | DEVSQ | F | F0.01 | F0.1 | Significance | |||

|---|---|---|---|---|---|---|---|---|

| L2 | ER | L2 | ER | L2 | ER | L2 | ER | |

| A | 978.986 | 88.113 | 610.721 | 9.245 | 99 | 9 | * | * |

| B | 9.831 | 51.801 | 6.133 | 5.435 | 99 | 9 | ||

| C | 14.296 | 40.253 | 8.918 | 4.223 | 99 | 9 | ||

| Error | 1.600 | 9.530 | ||||||

| Total | 1004.713 | 189.697 | ||||||

| Equation | 25 °C | 36 °C | ||

|---|---|---|---|---|

| Fitted Equation | R2 | Fitted Equation | R2 | |

| Zero-order | Q = 0.017t + 10.586 | 0.11427 | Q = 0.073t + 30.049 | 0.24557 |

| First-order | Q = 22.295 × (1 − e−0.091t) | 0.96479 | Q = 88.143 × (1 − e−0.036t) | 0.99905 |

| Higuchi | Q = 0.719t1/2 + 7.528 | 0.38481 | Q = 3.025t1/2+17.720 | 0.55642 |

| Peppas | Q = 44,021.197t0.00088 − 44,018.933 | 0.80165 | Q = 55,938.699t0.00027 − 55,938.810 | 0.88923 |

| Moulds | Day 7 | Day 14 | Day 21 | Day 28 | Group |

|---|---|---|---|---|---|

| PC | 0.1 | 0.6 | 0.9 | 1.2 | OT |

| 0 | 0 | 0 | 0 | PT | |

| 1.2 | 2.2 | 3.5 | 4.0 | UT | |

| 1.0 | 2.0 | 3.0 | 4.0 | RT | |

| TV | 0.7 | 1.3 | 1.9 | 2.1 | OT |

| 0 | 0 | 0 | 0 | PT | |

| 1.5 | 2.5 | 3.6 | 4.0 | UT | |

| 1.1 | 2.3 | 3.2 | 4.0 | RT | |

| AN | 1.3 | 2.1 | 2.6 | 3.2 | OT |

| 0 | 0 | 0 | 0 | PT | |

| 2.0 | 3.5 | 4.0 | 4.0 | UT | |

| 1.8 | 3.1 | 3.9 | 4.0 | RT | |

| PTA | 1.4 | 2.2 | 2.6 | 3.0 | OT |

| 0 | 0 | 0 | 0 | PT | |

| 2.1 | 3.6 | 4 | 4 | UT | |

| 1.9 | 3.6 | 3.9 | 4 | RT |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, R.; Zhang, J.; Du, C.; Li, Q.; Hu, A.; Liu, C.; Chen, S.; Shan, Y.; Yin, W. Investigation of the Release Mechanism and Mould Resistance of Citral-Loaded Bamboo Strips. Polymers 2021, 13, 3314. https://doi.org/10.3390/polym13193314

Peng R, Zhang J, Du C, Li Q, Hu A, Liu C, Chen S, Shan Y, Yin W. Investigation of the Release Mechanism and Mould Resistance of Citral-Loaded Bamboo Strips. Polymers. 2021; 13(19):3314. https://doi.org/10.3390/polym13193314

Chicago/Turabian StylePeng, Rui, Jingjing Zhang, Chungui Du, Qi Li, Ailian Hu, Chunlin Liu, Shiqin Chen, Yingying Shan, and Wenxiu Yin. 2021. "Investigation of the Release Mechanism and Mould Resistance of Citral-Loaded Bamboo Strips" Polymers 13, no. 19: 3314. https://doi.org/10.3390/polym13193314

APA StylePeng, R., Zhang, J., Du, C., Li, Q., Hu, A., Liu, C., Chen, S., Shan, Y., & Yin, W. (2021). Investigation of the Release Mechanism and Mould Resistance of Citral-Loaded Bamboo Strips. Polymers, 13(19), 3314. https://doi.org/10.3390/polym13193314