Effect of Processing Techniques on the Microstructure and Mechanical Performance of High-Density Polyethylene

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Mechanical Testing

2.3. Morphological Analysis

3. Results and Discussion

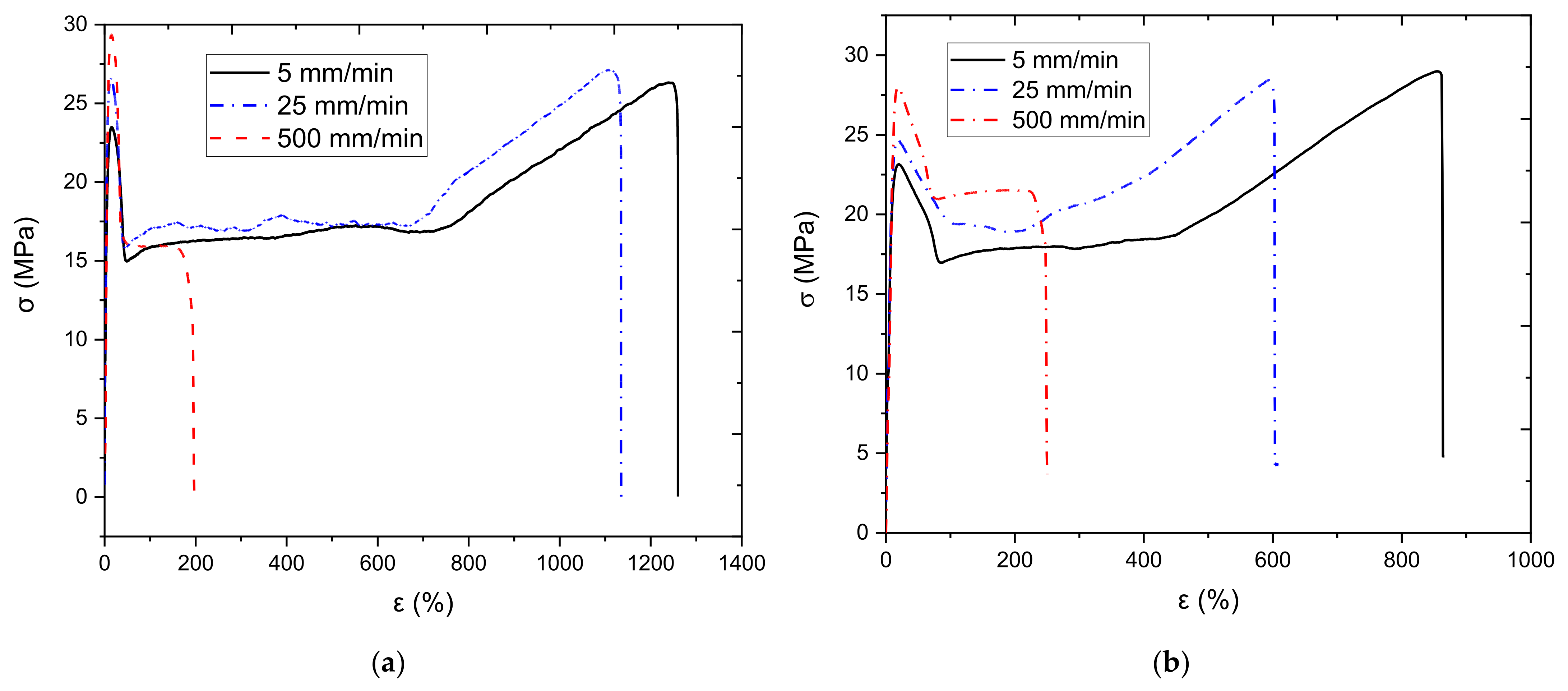

3.1. Strain-Rate Testing

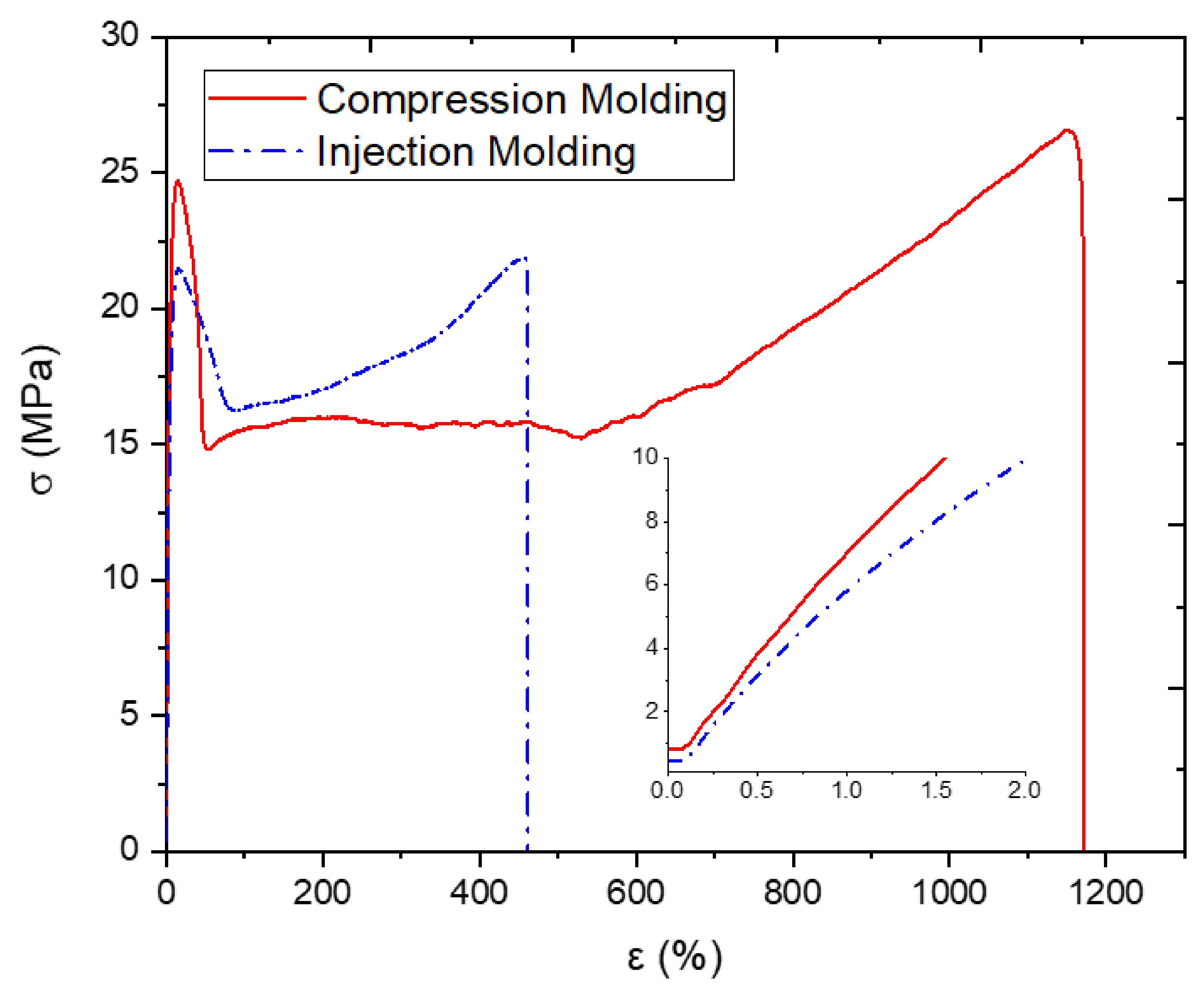

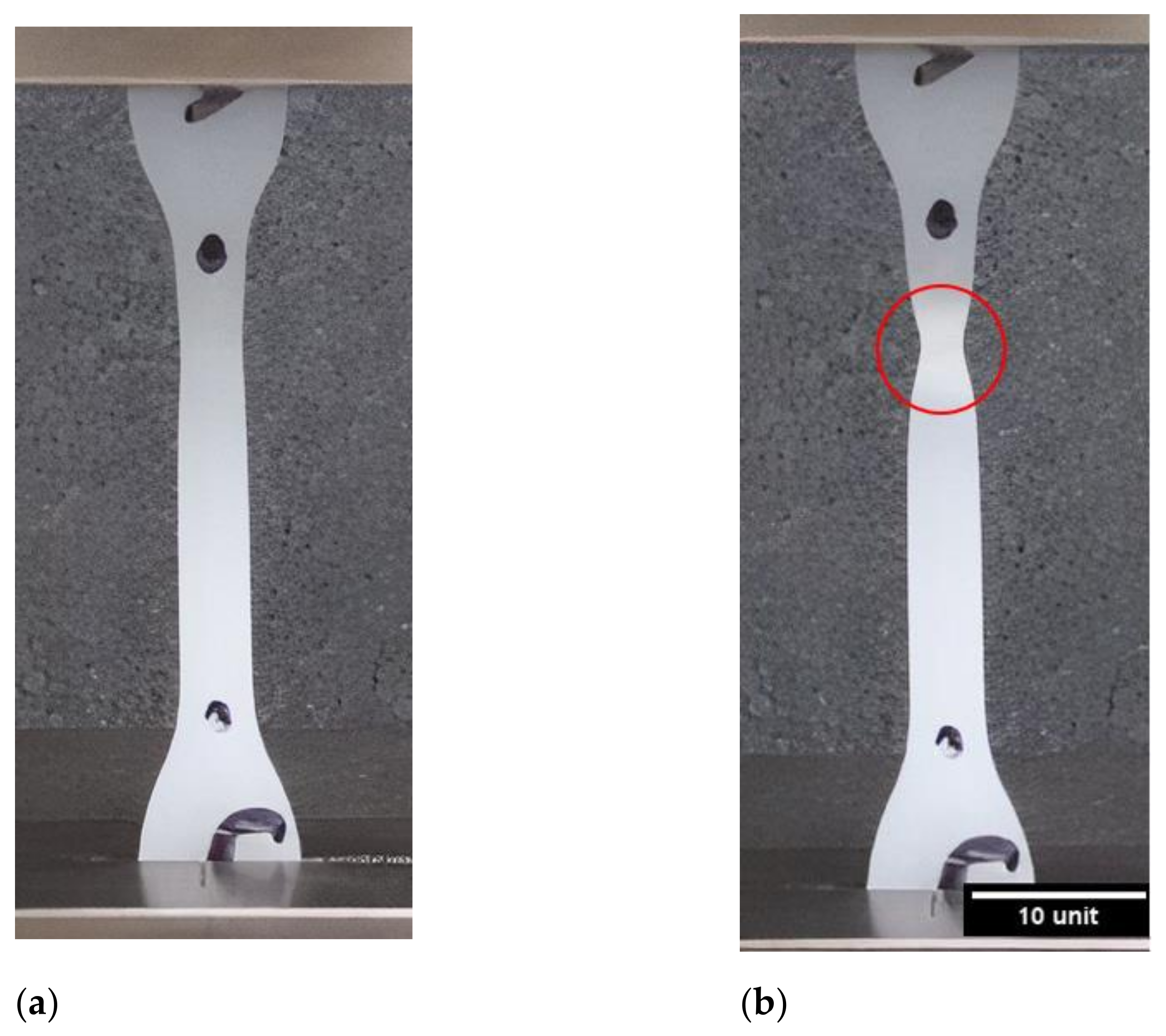

3.2. Tensile Testing

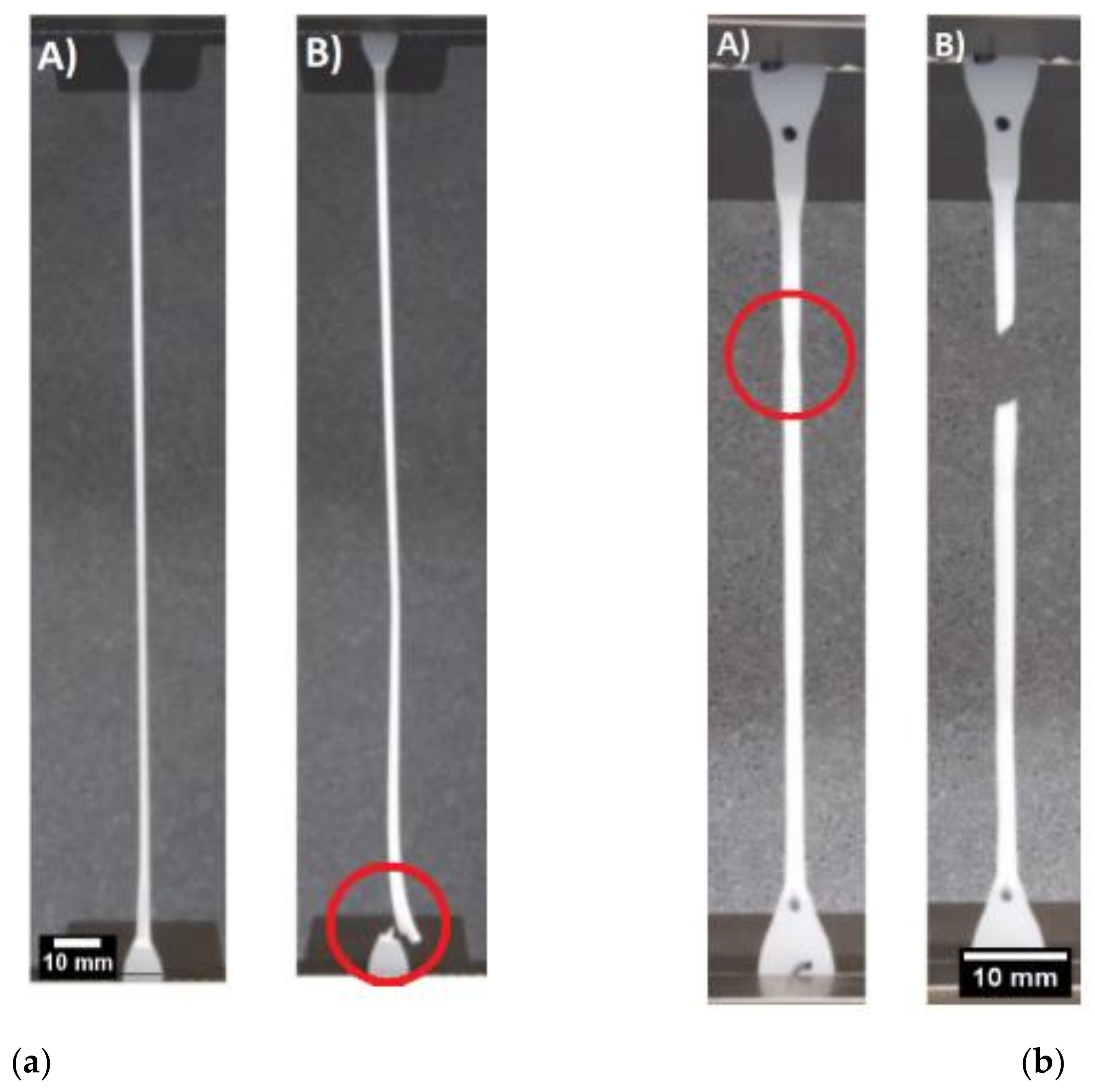

3.3. Morphological Analysis

3.4. Structure–Property Relationship

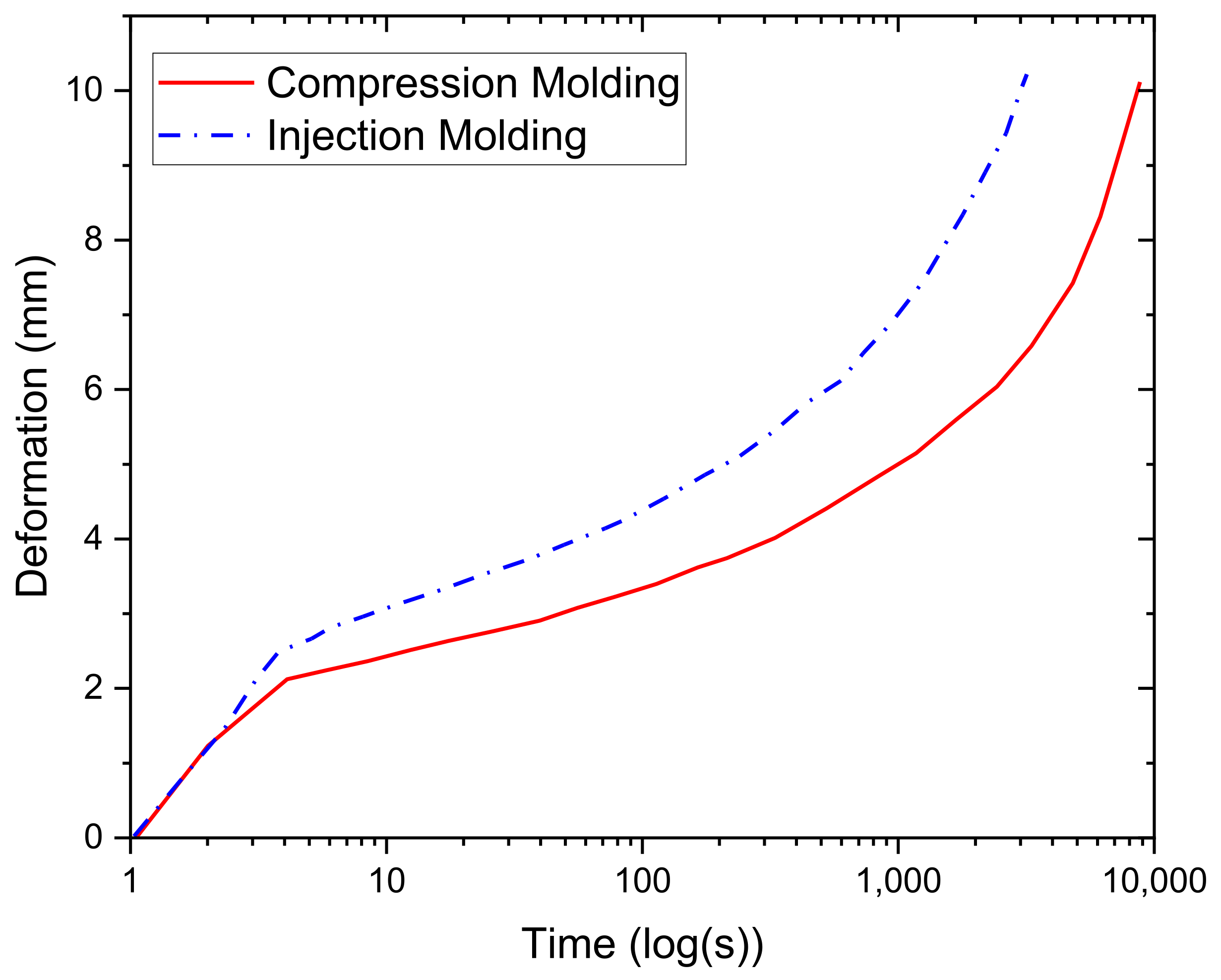

3.5. Creep Testing

4. Conclusions

- The first is that compression-molded samples have superior mechanical properties due to the higher degree of crystallinity and compact packing.

- The premature failure observed in the injection-molded samples are caused by defects that arise due to the flow of the polymer during filling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mourad, A.-H.I.; Dehbi, A. On use of trilayer low density polyethylene greenhouse cover as substitute for monolayer cover. Plast. Rubber Compos. 2014, 43, 111–121. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Akkad, R.O.; Soliman, A.A.; Madkour, T.M. Characterisation of thermally treated and untreated polyethylene–polypropylene blends using DSC, TGA and IR techniques. Plast. Rubber Compos. 2009, 38, 265–278. [Google Scholar] [CrossRef]

- Dehbi, A.; Mourad, A.-H.I.; Bouaza, A. Degradation assessment of LDPE multilayer films used as a greenhouse cover: Natural and artificial aging impacts. J. Appl. Polym. Sci. 2012, 124, 2702–2716. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Elsayed, H.F.; Barton, D.C.; Kenawy, M.; Abdel-Latif, L.A. Ultra high molecular weight polyethylene deformation and fracture behaviour as a function of high strain rate and triaxial state of stress. Int. J. Fract. 2003, 120, 501–515. [Google Scholar] [CrossRef]

- Babaghayou, M.I.; Mourad, A.-H.I.; Lorenzo, V.; de la Orden, M.U.; Urreaga, J.M.; Chabira, S.F.; Sebaa, M. Photodegradation characterization and heterogeneity evaluation of the exposed and unexposed faces of stabilized and unstabilized LDPE films. Mater. Des. 2016, 111, 279–290. [Google Scholar] [CrossRef]

- Nath, S.; Bodhak, S.; Basu, B. HDPE-Al2O3-HAp composites for biomedical applications: Processing and characterizations. J. Biomed. Mater. Res. Part B Appl. Biomater. 2008, 88, 1–11. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Mozumder, M.S.; Mairpady, A.; Pervez, H.; Kannuri, U.M. On the injection molding processing parameters of HDPE-TiO2 nanocomposites. Materials 2017, 10, 85. [Google Scholar] [CrossRef] [Green Version]

- Benabid, F.Z.; Kharchi, N.; Zouai, F.; Mourad, A.-H.I.; Benachour, D. Impact of co-mixing technique and surface modification of ZnO nanoparticles using stearic acid on their dispersion into HDPE to produce HDPE/ZnO nanocomposites. Polym. Compos. 2019, 27, 389–399. [Google Scholar] [CrossRef]

- Mozumder, M.S.; Mourad, A.-H.I.; Mairpady, A.; Pervez, H.; Haque, M.E. Effect of TiO2 nanofiller concentration on the mechanical, thermal and biological properties of HDPE/TiO2 nanocomposites. J. Mater. Eng. Perform. 2018, 27, 2166–2181. [Google Scholar] [CrossRef]

- Mejia, E.B.; Al-Maqdi, S.; Alkaabi, M.; Alhammadi, A.; Alkaabi, M.; Cherupurakal, N.; Mourad, A.-H.I. Upcycling of HDPE waste using additive manufacturing: Feasibility and challenges. In Proceedings of the IEEE 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, UAE, 4 February–9 April 2020; pp. 1–6.

- Pervez, H.; Mozumder, M.S.; Mourad, A.-H.I. Optimization of injection molding parameters for HDPE/TiO2 nanocomposites fabrication with multiple performance characteristics using the Taguchi method and grey relational analysis. Materials 2016, 9, 710. [Google Scholar] [CrossRef] [Green Version]

- Huang, L.; Wang, Z.; Zheng, G.; Guo, J.Z.; Dai, K.; Liu, C. Enhancing oriented crystals in injection-molded HDPE through introduction of pre-shear. Mater. Des. 2015, 78, 12–18. [Google Scholar] [CrossRef]

- Bhatti, M.M.; Abdelsalam, S.I. Thermodynamic entropy of a magnetized Ree-Eyring particle-fluid motion with irreversibility process: A mathematical paradigm. ZAMM 2021, 101, 1–17. [Google Scholar] [CrossRef]

- Raza, R.; Mabood, F.; Naz, R.; Abdelsalam, S.I. Thermal transport of radiative Williamson fluid over stretchable curved surface. Therm. Sci. Eng. Prog. 2021, 23, 100887. [Google Scholar] [CrossRef]

- Eldesoky, I.M.; Abdelsalam, S.I.; El-Askary, W.A.; Ahmed, M.M. The integrated thermal effect in conjunction with slip conditions on peristaltically induced particle-fluid transport in a catheterized pipe. J. Porous Media 2020, 23, 695–713. [Google Scholar] [CrossRef]

- Abdelsalam, S.I.; Velasco-Hernández, J.X.; Zaher, A.Z. Electro-magnetically modulated self-propulsion of swimming sperms via cervical canal. Biomech. Model. Mechanobiol. 2021, 20, 861–878. [Google Scholar] [CrossRef] [PubMed]

- Elkoumy, S.R.; Barakat, E.I.; Abdelsalam, S.I. Hall and transverse magnetic field effects on peristaltic flow of a Maxwell fluid through a porous medium. Glob. J. Pure Appl. Math. 2013, 9, 187–203. [Google Scholar]

- Abdelsalam, S.I.; Zaher, A.Z. Leveraging elasticity to uncover the role of rabinowitsch suspension through a wavelike conduit: Consolidated blood suspension application. Mathematics 2021, 9, 2008. [Google Scholar] [CrossRef]

- Dikobe, D.G.; Luyt, A.S. Thermal and mechanical properties of PP/HDPE/wood powder and MAPP/HDPE/wood powder polymer blend composites. Thermochim. Acta 2017, 654, 40–50. [Google Scholar] [CrossRef] [Green Version]

- Mourad, A.-H.I.; Idrisi, A.H.; Wrage, M.C.; Abdel-Magid, B.M. Long-term durability of thermoset composites in seawater environment. Compos. Part B Eng. 2019, 168, 243–253. [Google Scholar] [CrossRef]

- Dehbi, A.; Mourad, A.-H.I. Durability of mono-layer versus tri-layers LDPE films used as greenhouse cover: Comparative study. Arab. J. Chem. 2016, 9, S282–S289. [Google Scholar] [CrossRef] [Green Version]

- Dehbi, A.; Mourad, A.-H.I.; Bouaza, A. Ageing effect on the properties of tri-layer polyethylene film used as greenhouse roof. Procedia Eng. 2011, 10, 466–471. [Google Scholar] [CrossRef] [Green Version]

- Ferhoum, R.; Aberkane, M.; Hachour, K. Analysis of thermal ageing effect (hold time-crystallinity rate-mechanical property) on high density polyethylene (HDPE). Int. J. Mater. Sci. Appl. 2014, 2, 109. [Google Scholar] [CrossRef] [Green Version]

- LEE, D.-J. Comparison of mechanical properties of compression and injection molded PEEK/Carbon fiber reinforced composites. Key Eng. Mater. 2006, 306–308, 751–756. [Google Scholar] [CrossRef]

- Ghiam, F.; White, J.L. Phase morphology of injection-molded blends of nylon-6 and polyethylene and comparison with compression molding. Polym. Eng. Sci. 1991, 31, 76–83. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Faruk, O. Wood fiber reinforced polypropylene composites: Compression and injection molding process. Polym. Technol. Eng. 2004, 43, 871–888. [Google Scholar] [CrossRef]

- Hedesiu, C.; Demco, D.E.; Kleppinger, R.; Buda, A.A.; Blümich, B.; Remerie, K.; Litvinov, V.M. The effect of temperature and annealing on the phase composition, molecular mobility and the thickness of domains in high-density polyethylene. Polymer 2007, 48, 763–777. [Google Scholar] [CrossRef]

- Kodjie, S.L.; Li, L.; Li, B.; Cai, W.; Li, C.Y.; Keating, M. Morphology and crystallization behavior of HDPE/CNT nanocomposite. J. Macromol. Sci. Part B Phys. 2006, 45, 231–245. [Google Scholar] [CrossRef]

- Bureau, M.N.; El Kadi, H.; Denault, J.; Dickson, J.I. Injection and compression molding of polystyrene/high-density polyethylene blends? Phase morphology and tensile behavior. Polym. Eng. Sci. 1997, 37, 377–390. [Google Scholar] [CrossRef]

- Xie, M.; Chen, J.; Li, H. Morphology and mechanical properties of injection-molded ultrahigh molecular weight polyethylene/polypropylene blends and comparison with compression molding. J. Appl. Polym. Sci. 2009, 111, 890–898. [Google Scholar] [CrossRef]

- Mozumder, M.S.; Mourad, A.-H.I.; Perinpanayagam, H.; Zhu, J. NanoTiO2-Enriched Biocompatible Polymeric Powder Coatings: Adhesion, Thermal and Biological Characterizations. Trans. Tech. Publ. 2014, 995, 113–124. [Google Scholar]

- Zhong, G.-J.; Li, Z.-M. Injection molding-induced morphology of thermoplastic polymer blends. Polym. Eng. Sci. 2005, 45, 1655–1665. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Fouad, H.; Elleithy, R. Impact of some environmental conditions on the tensile, creep-recovery, relaxation, melting and crystallinity behaviour of UHMWPE-GUR 410-medical grade. Mater. Des. 2009, 30, 4112–4119. [Google Scholar] [CrossRef]

- Mourad, A.-H.I. Thermo-mechanical characteristics of thermally aged polyethylene/polypropylene blends. Mater. Des. 2010, 31, 918–929. [Google Scholar] [CrossRef]

- Idrisi, A.H.; Mourad, A.-H.I.; Abdel-Magid, B.M.; Shivamurty, B. Investigation on the durability of E-Glass/Epoxy composite exposed to seawater at elevated temperature. Polymers 2021, 13, 2182. [Google Scholar] [CrossRef]

- Idrisi, A.H.; Mourad, A.-H.I.; Sherif, M.M. Impact of prolonged exposure of eleven years to hot seawater on the degradation of a thermoset composite. Polymers 2021, 13, 2154. [Google Scholar] [CrossRef] [PubMed]

- Mourad, A.-H.I.; Maiti, S.K. Influence of state of stress on mixed mode stable crack growth through D16AT aluminium alloy. Int. J. Fract. 1995, 72, 241–258. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Idrisi, A.H.; Christy, J.V.; Thekkuden, D.T.; Al Jassmi, H.; Ghazal, A.M.; Syam, M.M.; Ali Ahmed Al Qadi, O.D. Mechanical performance assessment of internally-defected materials manufactured using additive manufacturing technology. J. Manuf. Mater. Process. 2019, 3, 74. [Google Scholar]

- Mourad, A.-H.I.; Cherupurakal, N.; Hafeez, F.; Barsoum, I.; Genena, F.A.; Al Mansoori, M.S.; Al Marzooqi, L.A. Impact strengthening of laminated kevlar/epoxy composites by nanoparticle reinforcement. Polymers 2020, 12, 2814. [Google Scholar] [CrossRef] [PubMed]

- Babaghayou, M.I.; Mourad, A.-H.I.; Ochoa, A.; Beltrán, F.; Cherupurakal, N. Study on the thermal stability of stabilized and unstabilized low-density polyethylene films. Polym. Bull. 2020, 78, 5225–5241. [Google Scholar] [CrossRef]

- Wunderlich, B. Macromolecular Physics; Elsevier: Amsterdam, The Netherlands, 1973; ISBN 9780127656014. [Google Scholar]

- Aggarwal, S.L.; Tilley, G.P. Determination of crystallinity in polyethylene by X-ray diffractometer. J. Polym. Sci. 1955, 18, 17–26. [Google Scholar] [CrossRef]

- Jang, B.Z.; Uhlmann, D.R.; Sande, J.B. Vander Ductile–brittle transition in polymers. J. Appl. Polym. Sci. 1984, 29, 3409–3420. [Google Scholar] [CrossRef]

- Li, Z.; Lambros, J. Strain rate effects on the thermomechanical behavior of polymers. Int. J. Solids Struct. 2001, 38, 3549–3562. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Tensile behavior of high-density polyethylene including the effects of processing technique, thickness, temperature, and strain rate. Polymers 2020, 12, 1857. [Google Scholar] [CrossRef] [PubMed]

- Tisserat, B.; Reifschneider, L.; Joshee, N.; Finkenstadt, V.L. Properties of high density polyethylene–Paulownia wood flour composites via injection molding. BioResources 2013, 8, 4440–4458. [Google Scholar] [CrossRef] [Green Version]

- De Morais, J.A.; Gadioli, R.; De Paoli, M.-A. Curaua fiber reinforced high-density polyethylene composites: Effect of impact modifier and fiber loading. Polímeros 2016, 26, 115–122. [Google Scholar] [CrossRef] [Green Version]

- Vijay, A.R.M.; Ratnam, C.T.; Khalid, M.; Appadu, S.; Gupta, T. Effect of radiation on the mechanical, morphological and thermal properties of HDPE/rPTFE blends. Radiat. Phys. Chem. 2020, 177, 109190. [Google Scholar]

- Amoroso, L.; Heeley, E.L.; Ramadas, S.N.; McNally, T. Crystallisation behaviour of composites of HDPE and MWCNTs: The effect of nanotube dispersion, orientation and polymer deformation. Polymer 2020, 201, 122587. [Google Scholar] [CrossRef]

- Sotomayor, M.E.; Krupa, I.; Várez, A.; Levenfeld, B. Thermal and mechanical characterization of injection moulded high density polyethylene/paraffin wax blends as phase change materials. Renew. Energy 2014, 68, 140–145. [Google Scholar] [CrossRef]

- Sakai, T.; Hirai, Y.; Somiya, S. Estimating the creep behavior of glass-fiber-reinforced polyamide considering the effects of crystallinity and fiber volume fraction. Mech. Adv. Mater. Mod. Process. 2018, 4, 1–9. [Google Scholar] [CrossRef] [Green Version]

| Processing | Velocity | Modulus | Yield Stress | Tensile Strength | Failure Strain |

|---|---|---|---|---|---|

| (mm/min) | (MPa) | (MPa) | (MPa) | (%) | |

| Compression-molded | 5 | 524 | 23.49 | 26.32 | 1259.97 |

| 25 | 647 | 26.57 | 27.12 | 1134.96 | |

| 500 | 455 | 29.35 | 15.93 | 197.01 | |

| Injection-molded | 5 | 339.15 | 23.15 | 28.99 | 859.72 |

| 25 | 447.36 | 24.67 | 28.44 | 595.19 | |

| 500 | 322.45 | 28.01 | 21.49 | 249.47 |

| Processing | Modulus | Yield Stress | Tensile Strength | Failure Strain |

|---|---|---|---|---|

| (MPa) | (MPa) | (MPa) | (%) | |

| Compression-molded Current study | 754 | 24.5 | 26.6 | 1170 |

| Injection-molded Current study | 672 | 22.3 | 21.9 | 462 |

| Compression-molded Amjadi and Fatemi [45] | 810 | - | 18 | - |

| Injection-molded Amjadi and Fatemi [45] | 790 | - | 17 | - |

| Injection-molded Tisserat et al. [46] | 339 | 21.5 | - | 105 |

| Injection-molded Morais et al. [47] | 543 | - | 18 | - |

| Processing | Melting Peak | Change in Enthalpy | Degree of Crystallinity |

|---|---|---|---|

| (°C) | (J/g) | (%) | |

| Compression-molded Current study | 123.32 | 232.4 | 80.15 |

| Injection-molded Current study | 128.86 | 217.0 | 74.84 |

| Compression molding Vijay et al. [48] | 132.32 | 216.72 | 78.73 |

| Injection molding Lorena et al. [49] | 134.8 | 221.6 | 75.5 |

| Injection molding Sotomayor et al. [50] | 130.8 | 178.6 | 61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mejia, E.; Cherupurakal, N.; Mourad, A.-H.I.; Al Hassanieh, S.; Rabia, M. Effect of Processing Techniques on the Microstructure and Mechanical Performance of High-Density Polyethylene. Polymers 2021, 13, 3346. https://doi.org/10.3390/polym13193346

Mejia E, Cherupurakal N, Mourad A-HI, Al Hassanieh S, Rabia M. Effect of Processing Techniques on the Microstructure and Mechanical Performance of High-Density Polyethylene. Polymers. 2021; 13(19):3346. https://doi.org/10.3390/polym13193346

Chicago/Turabian StyleMejia, Edgar, Nizamudeen Cherupurakal, Abdel-Hamid I. Mourad, Sultan Al Hassanieh, and Mohamed Rabia. 2021. "Effect of Processing Techniques on the Microstructure and Mechanical Performance of High-Density Polyethylene" Polymers 13, no. 19: 3346. https://doi.org/10.3390/polym13193346

APA StyleMejia, E., Cherupurakal, N., Mourad, A. -H. I., Al Hassanieh, S., & Rabia, M. (2021). Effect of Processing Techniques on the Microstructure and Mechanical Performance of High-Density Polyethylene. Polymers, 13(19), 3346. https://doi.org/10.3390/polym13193346