Material Modeling of PMMA Film for Hot Embossing Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Proposed Modeling Method

2.2. Modeling of Initial Yield Stress

2.3. Modeling of Work Hardening

2.4. Modeling of Softening

3. Results and Discussion

3.1. Verification of the Proposed Constitutive Model

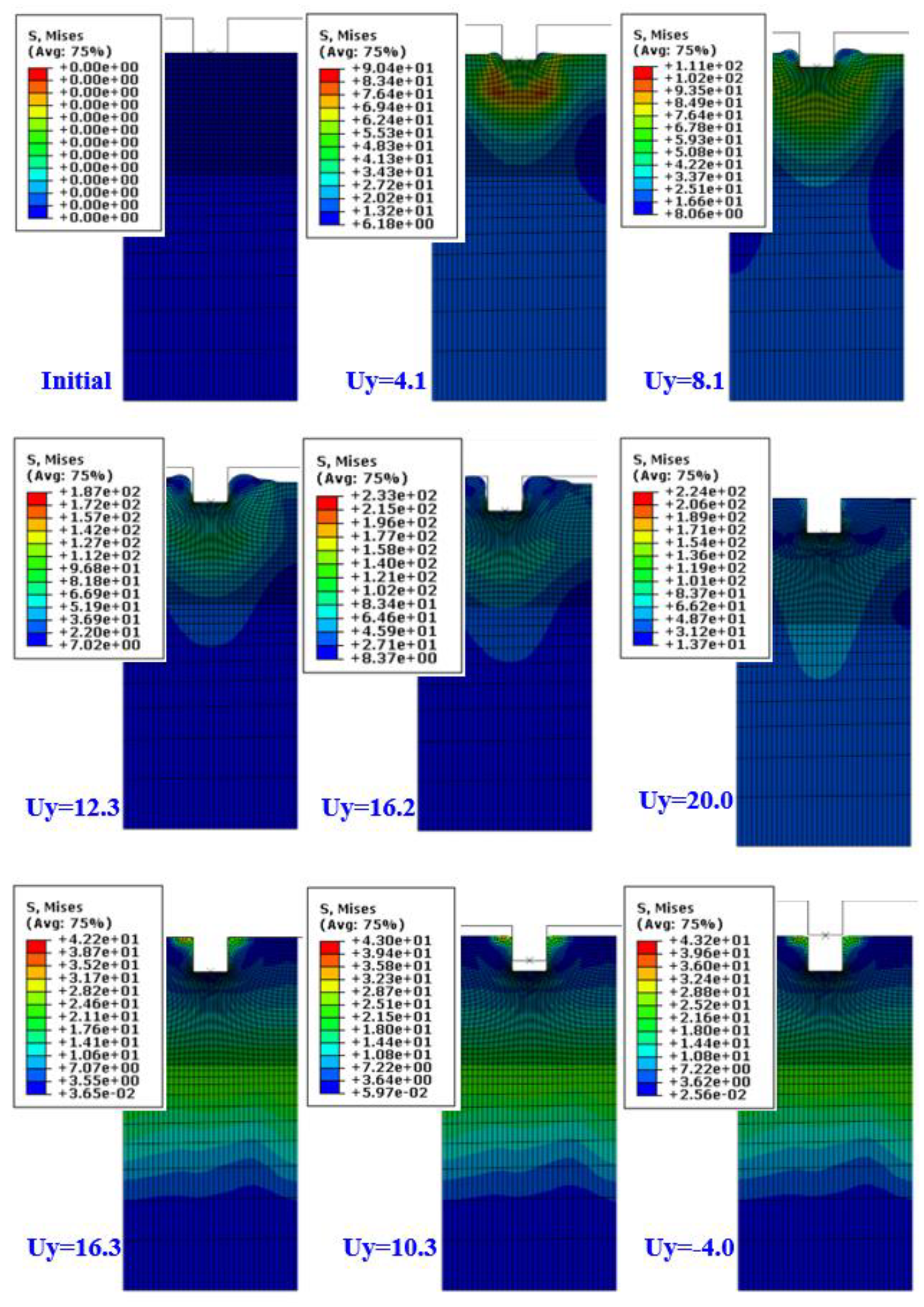

3.2. Finite Element (FE) Modeling and Case Study

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ALE: | arbitrary Lagrangian–Eulerian |

| : | Strain |

| : | Strain rate |

| FEM: | Finite element method |

| FEP: | Fluorinated ethylene propylene |

| H: | Hardness |

| LIGA: | Lithographie, Galvanoformung, Abformung |

| NIL: | Nano Imprint Lithography |

| NIMP: | Nanoimprinting by melt processing |

| PMMA: | Poly methyl methacrylate |

| S: | Softness |

| T: | Temperature |

References

- Gerlach, A.; Knebel, G.; Guber, A.; Heckele, M.; Herrmann, D.; Muslija, A.; Sshaller, T. Microfabrication of single-use plastic microfluidic devices for high-throughput screening and DNA analysis. Microsyst. Technol. 2002, 7, 265–268. [Google Scholar] [CrossRef]

- Ahn, S.H.; Guo, L.J. High-Speed Roll-to-Roll Nanoimprint Lithography on Flexible Plastic Substrates. Adv. Mater. 2008, 20, 2044–2049. [Google Scholar] [CrossRef] [Green Version]

- Thomas, J.; Gangopadhyay, P.; Araci, E.; Norwood, R.A.; Peyghambarian, N. Nanoimprinting by Melt Processing: An Easy Technique to Fabricate Versatile Nanostructures. Adv. Mater. 2011, 23, 4782–4787. [Google Scholar] [CrossRef] [PubMed]

- Truckenmüller, R.; Giselbrecht, S.; Rivron, N.; Gottwald, E.; Saile, V.; van den Berg, A.; Wessling, M.; van Blitterswijk, C. Thermoforming of Film-Based Biomedical Microdevices. Adv. Mater. 2011, 23, 1311–1329. [Google Scholar] [CrossRef] [PubMed]

- Boesel, L.F.; Greiner, C.; Arzt, E.; del Campo, A. Gecko-Inspired Surfaces: A Path to Strong and Reversible Dry Adhesives. Adv. Mater. 2010, 22, 2125–2137. [Google Scholar] [CrossRef] [PubMed]

- Lan, S.; Lee, H.-J.; Kim, E.; Ni, J.; Lee, S.-H.; Lai, X.; Song, J.-H.; Lee, N.K.; Lee, M.G. A parameter study on the micro hot-embossing process of glassy polymer for pattern replication. Microelectron. Eng. 2009, 86, 2369–2374. [Google Scholar] [CrossRef]

- Haponow, L.; Kettle, J.; Allsop, J. Optimization of a continuous hot embossing process for fabrication of micropyramid structures in thermoplastic sheets. J. Vac. Sci. Technol. B 2021, 39, 012203. [Google Scholar] [CrossRef]

- Juang, Y.-J.; Lee, L.J.; Koelling, K.W. Hot embossing in microfabrication. Part II: Rheological characterization and process analysis. Polym. Eng. Sci. 2002, 42, 551–566. [Google Scholar] [CrossRef]

- Sun, J.; Wu, D.; Liu, Y.; Dai, L.; Jiang, C. Numerical simulation and experimental study of filling process of micro prism by isothermal hot embossing in solid-like state. Adv. Polym. Technol. 2018, 37, 1581–1591. [Google Scholar] [CrossRef]

- Gomez, J.A.; Conner, G.T.; Chun, D.H.; Kim, Y.-J.; Song, I.-H.; You, B.H. Mold filling analysis of an alignment structure in micro hot embossing. Fibers Polym. 2014, 15, 1197–1201. [Google Scholar] [CrossRef]

- Worgull, M.; Heckele, M. New aspects of simulation in hot embossing. Microsyst. Technol. 2004, 10, 432–437. [Google Scholar] [CrossRef]

- Kiew, C.M.; Lin, W.-J.; Teo, T.J.; Tan, J.L.; Lin, W.; Yang, G. (Eds.) Finite element analysis of PMMA pattern formation during hot embossing process. In Proceedings of the 2009 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Singapore, 14–17 July 2009; IEEE: Singapore, 2009; pp. 2813–2823. Available online: https://ieeexplore.ieee.org/abstract/document/5229996 (accessed on 30 July 2021).

- Lei, K.F.; Li, W.J.; Yam, Y. Effects of contact-stress on hot-embossed PMMA microchannel wall profile. Microsyst. Technol. 2005, 11, 353–357. [Google Scholar] [CrossRef]

- Liu, C.; Li, J.; Liu, J.; Wang, L. Deformation behavior of solid polymer during hot embossing process. Microelectron. Eng. 2010, 87, 200–207. [Google Scholar] [CrossRef]

- Wang, X.; Li, W.; Chen, T. Simulation and Experimental Validation of the Hot Embossing Process of Poly(lactic-co-glycolic acid) Microstructures. Int. J. Polym. Sci. 2015, 2015, 520512. [Google Scholar] [CrossRef] [Green Version]

- Baselmans, H.; Meijer, H.; Govaert, L.; Klompen, I.E. A New Modelling Approach of Rate Dependent Softening in Glassy Polymers. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2002. [Google Scholar]

- Ghatak, A.; Dupaix, R.B. Material characterization and continuum modeling of poly (methyl methacrylate)(PMMA) above the glass transition. Int. J. Struct. Chang. Solids 2010, 2, 53–63. [Google Scholar]

- Roetling, J.A. Yield stress behabior of Polymethylmethacrylate. Polymer 1965, 6, 311–317. [Google Scholar] [CrossRef]

- Dassault Systèmes, Abaqus, Analysis User’s Guide, Vers. 6.14. Simulia. 2013. Available online: http://132.235.17.20:2080/v6.14/books/usb/default.htm?startat=pt08ch35s03aus132.html (accessed on 30 July 2021).

- Overview of materials for Acrylonitrile Butadiene Styrene (ABS)/Nylon Blend, Glass Reinforced. Available online: http://www.matweb.com/search/DataSheet.aspx?MatGUID=225de9228732470dba61f96f0df4a369 (accessed on 30 July 2021).

- PLEXIGLAS® XT Basic grades 20070 and 29070. Available online: http://www-eng.lbl.gov/~shuman/NEXT/MATERIALS&COMPONENTS/WLS_materials/PLEXIGLAS-XT-Basic-grades.pdf (accessed on 30 July 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, D.; Kim, J.-B. Material Modeling of PMMA Film for Hot Embossing Process. Polymers 2021, 13, 3398. https://doi.org/10.3390/polym13193398

Yun D, Kim J-B. Material Modeling of PMMA Film for Hot Embossing Process. Polymers. 2021; 13(19):3398. https://doi.org/10.3390/polym13193398

Chicago/Turabian StyleYun, Dongwon, and Jong-Bong Kim. 2021. "Material Modeling of PMMA Film for Hot Embossing Process" Polymers 13, no. 19: 3398. https://doi.org/10.3390/polym13193398

APA StyleYun, D., & Kim, J.-B. (2021). Material Modeling of PMMA Film for Hot Embossing Process. Polymers, 13(19), 3398. https://doi.org/10.3390/polym13193398