Implementation and Characterization of a Laminate Hybrid Composite Based on Palm Tree and Glass Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

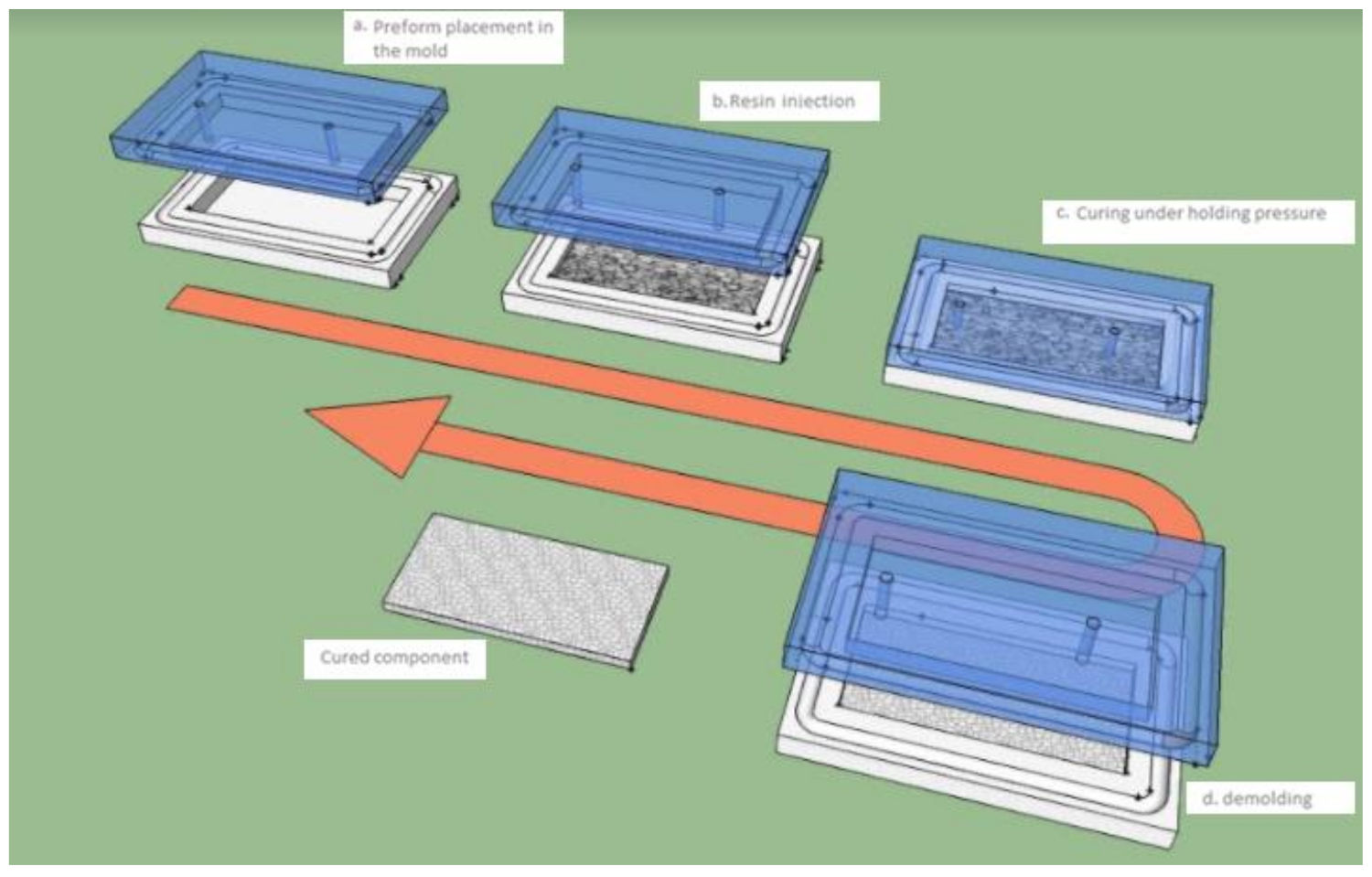

2.2. Preparation of Laminated Composites

3. Characterizations Techniques

3.1. Scanning Electron Microscopy (SEM)

3.2. ATR–FTIR Analysis

3.3. Mechanical Testing

3.3.1. Tensile Test

3.3.2. Flexural Test

3.3.3. Impact Testing

3.3.4. Hardness Test

3.3.5. Micro-Hardness Test

3.3.6. Ultrasonic Measurement Test

3.3.7. Water Uptake Tests

3.3.8. Solar Radiation

4. Results and Discussion

4.1. Structural Characteristics of the Date Palm Fibers

4.2. Mechanical Properties

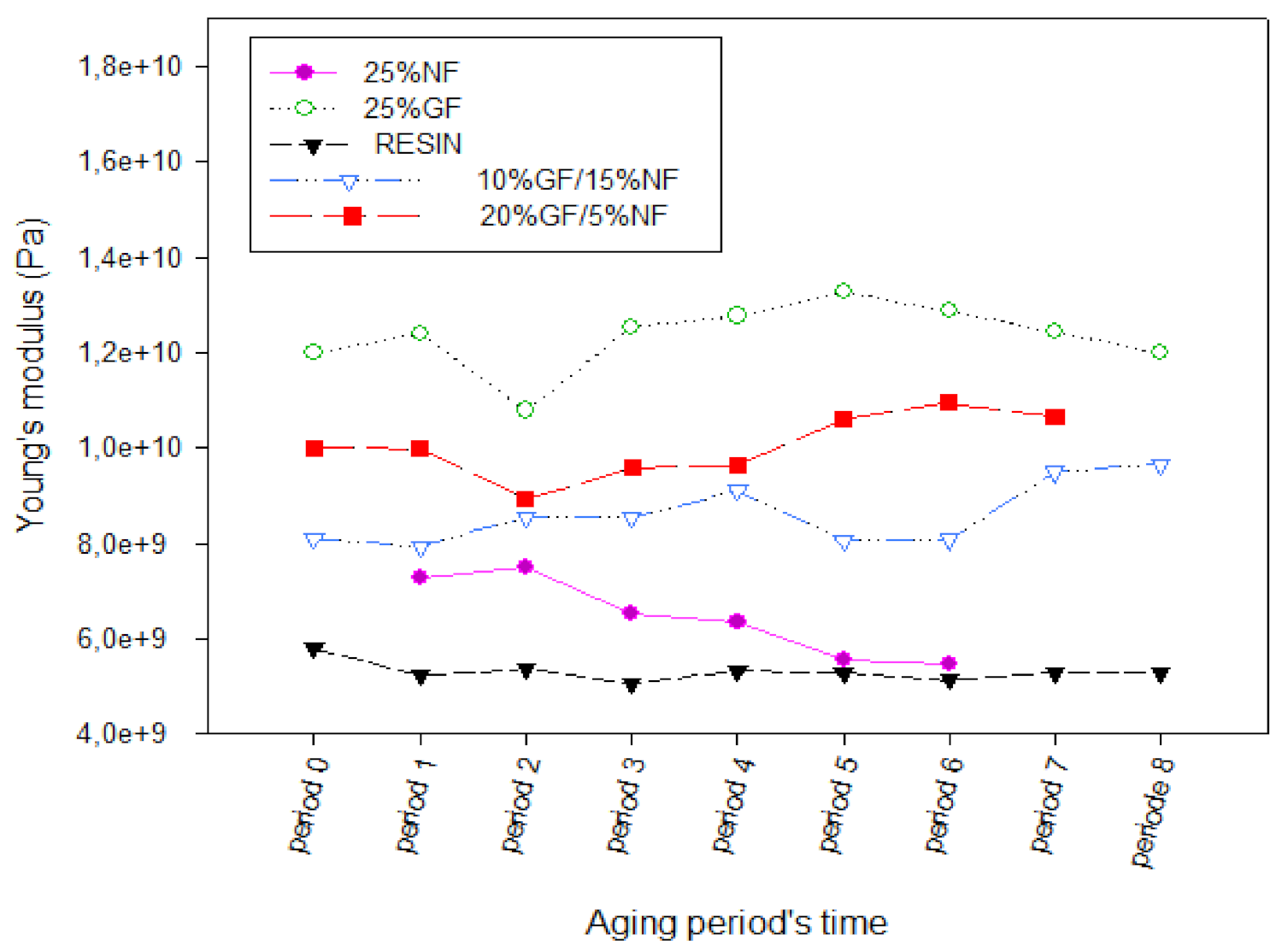

4.2.1. Stiffness of the Composites Obtained from Ultrasonic and Tensile Measurements

4.2.2. Flexural Properties

4.2.3. Impact Properties

4.2.4. Hardness Properties

4.2.5. Water Uptake Properties

4.3. Composite Behavior during Solar Aging

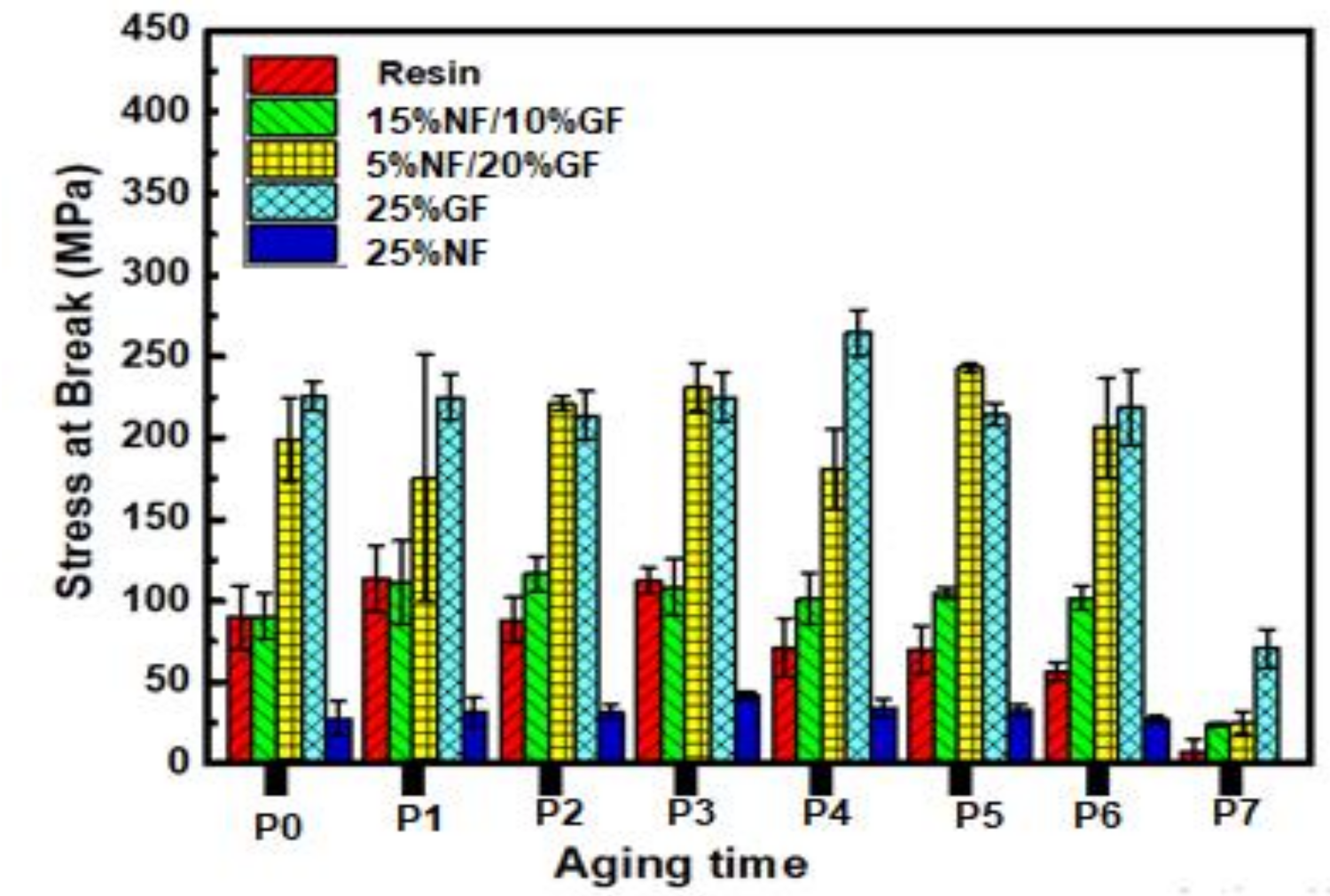

4.3.1. Mechanical Results

4.3.2. Surface Characterization of Materials

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shanmugam, V.; Rajendran, D.J.J.; Babu, K.; Rajendran, S.; Veerasimman, A.; Marimuthu, U.; Singh, S.; Das, O.; Neisiany, R.E.; Hedenqvist, M.S.; et al. The mechanical testing and performance analysis of polymer-fibre composites prepared through the additive manufacturing. Polym. Test 2021, 93, 106925. [Google Scholar] [CrossRef]

- Sbiai, A.; Maazouz, A.; Fleury, E.; Souterneau, H.; Kaddami, H. Short Date Palm Tree Fibers/Polyepoxy Composites Prepared Using Rtm Process: Effect of Tempo Mediated Oxydation of the Fibers. BioResources 2010, 5, 672–689. [Google Scholar]

- Tazi, M.; Erchiqui, F.; Godard, F.; Kaddami, H.; Ajji, A. Characterization of rheological and thermophysical properties of HDPE-wood composite. J. Appl. Polym. Sci. 2014, 131, 40495. [Google Scholar] [CrossRef]

- Tazi, M.; Erchiqui, F.; Kaddami, H. Influence of SOFTWOOD-fillers content on the biodegradability and morphological properties of WOOD-polyethylene composites. Polym. Compos. 2018, 39, 29–37. [Google Scholar] [CrossRef]

- Sbiai, A.; Kaddami, H.; Fleury, E.; Maazouz, A.; Erchiqui, F.; Koubaa, A.; Soucy, J.; Dufresne, A. Effect of the Fiber Size on the Physicochemical and Mechanical Properties of Composites of Epoxy and Date Palm Tree Fibers. Macromol. Mater. Eng. 2008, 293, 684–691. [Google Scholar] [CrossRef]

- Sbiai, A.; Maazouz, A.; Fleury, E.; Sautereau, H.; Kaddami, H. Chapiter 8 “Composites and Their applications”. In TEMPO-Mediated Oxidation of Lignocellulosic Fibers from Date Palm Leaves: Effect of the Oxidation on the Processing by RTM Process and Properties of Epoxy Based Composites; Hu, N., Ed.; Hard cover in subject Composite Materials; InTech: London, UK, 2012; 424p, ISBN 978-953-51 0706-4. [Google Scholar]

- Morampudi, P.; Namala, K.K.; Gajjela, Y.K.; Barath, M.; Prudhvi, G. Review on glass fiber reinforced polymer composites. Mater. Today Proc. 2021, 43, 314–319. [Google Scholar] [CrossRef]

- Sadik, Z.; Ablouh, E.-H.; Benmoussa, K.; Idrissi-Saba, H.; Kaddami, H.; Arrakhiz, F.E. Use of 2D image analysis method for measurement of short fibers orientation in polymer composites. Eng. Solid Mech. 2020, 8, 233–244. [Google Scholar] [CrossRef]

- Chegdani, F.; Takabi, B.; El Mansori, M.; LTai, B.; Bukkapatnam, S.T.S. Effect of flax fiber orientation on machining behavior and surface finish of natural fiber reinforced polymer composites. J. Manuf. Process. 2020, 54, 337–346. [Google Scholar] [CrossRef]

- Karkkainen, R.L.; Sankar, B.; Tzeng, J.T. Strength prediction of multi-layer plain weave textile composites using the direct micromechanics method. Compos. Part B Eng. 2007, 38, 924–932. [Google Scholar] [CrossRef]

- Hammiche, D.; Boukerrou, A.; Guermazi, N.; Arrakhiz, F.E. Effects of types of PVC-g-MA on wettability and dynamical behavior of polyvinyl Chloride/Alfa composites. Mater. Today Proc. 2021, 36, 10–15. [Google Scholar] [CrossRef]

- Arrakhiz, F.; Ben Hamou, K.; Erchiqui, F.; Hammiche, D.; Kaddami, H. Development and characterization of hybrid composite laminate based on luffa and glass fibers. Mater. Today Proc. 2021, 36, 22–28. [Google Scholar] [CrossRef]

- Bledzki, A. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Bouhamed, N.; Souissi, S.; Marechal, P.; Ben Amar, M.; Lenoir, O.; Leger, R.; Bergeret, A. Ultrasound evaluation of the mechanical properties as an investigation tool for the wood-polymer composites including olive wood flour. Mech. Mater. 2020, 148, 103445. [Google Scholar] [CrossRef]

- El-Sabbagh, A.; Steuernage, L.; Ziegmann, G. Characterisation of flax polypropylene composites using ultrasonic longitudinal sound wave technique. Compos. Part B Eng. 2013, 45, 1164–1172. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, J.; Lyu, J.; Cao, J. Orthotropic Viscoelastic Properties of Chinese Fir Wood Saturated with Water in Frozen and Non-frozen States. For. Prod. J. 2021, 71, 77–83. [Google Scholar] [CrossRef]

- ISO 527-3. Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics; iTeh STANDARD: Newark, DE, USA, 2019. [Google Scholar]

- ASTM D790-03. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 10 March 2003. [Google Scholar]

- ASTM D785. Standard Test Method for Rockwell Hardness of Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 1 October 2015. [Google Scholar]

- ASTM E384-99. Standard Test Method for Microindentation Hardness of Materials; ASTM International: West Conshohocken, PA, USA, 15 August 2005; Available online: www.astm.org (accessed on 25 September 2021).

- Bendahou, A.; Habibi, Y.; Kaddami, H.; Dufresne, A. Physico-Chemical Characterization of Palm from Phoenix Dactylifera–L, Preparation of Cellulose Whiskers and Natural Rubber–Based Nanocomposites. J. Biobased Mater. Bioenergy 2009, 3, 81–90. [Google Scholar] [CrossRef]

- Arrakhiz, F.; EL Achaby, M.; Bouhfid, R.; Vaudreuil, S.; Essassi, M.; Qaiss, A.E.K. Mechanical and thermal properties of polypropylene reinforced with Alfa fiber under different chemical treatment. Mater. Des. 2012, 35, 318–322. [Google Scholar] [CrossRef]

- Le Troëdec, M.A. Mechanical properties of hemp-lime reinforced mortars: Influence of the chemical treatment of fibers. J. Compos. Sci. 2011, 45, 2347–2357. [Google Scholar] [CrossRef]

- Neher, B.; Gafur, A.; Al-Mansur, M.A.; Bhuiyan, M.R.; Qadir, R.; Ahmed, F. Investigation of the Surface Morphology and Structural Characterization of Palm Fiber Reinforced Acrylonitrile Butadiene Styrene (PF-ABS) Composites. Mater. Sci. Appl. 2014, 5, 378–386. [Google Scholar] [CrossRef] [Green Version]

- Dan-Asabe, B.; Yaro, S.; Yawas, D. Micro-structural and mechanical characterization of doum-palm leaves particulate reinforced PVC composite as piping materials. Alex. Eng. J. 2018, 57, 2929–2937. [Google Scholar] [CrossRef]

- Montero, C. Caractérisation du Comportement Viscoélastique Asymptotique du Bois; Montpellier 2 University: Montpellier, France, 2011. [Google Scholar]

- Malha, M.; Nekhlaoui, S.; Essabir, H.; Benmoussa, K.; Bensalah, M.-O.; Arrakhiz, F.-E.; Bouhfid, R.; Qaiss, A. Mechanical and thermal properties of compatibilized polypropylene reinforced by woven doum. J. Appl. Polym. Sci. 2013, 130, 4347–4356. [Google Scholar] [CrossRef]

- Castellano, A.; Foti, P.; Fraddosio, A.; Marzano, S.; Piccioni, M.D. A New Ultrasonic Immersion Technique for the Evaluation of Damage Induced Anisotropy in Composite Materials. In Proceedings of the 3rd International Balkans Conference on Challenges of Civil Engineering, 3-BCCCE, Tirana, Albania, 19–21 May 2016. [Google Scholar]

- Hodgkinson, J.M. Mechanical Testing of Advancex Fiber Composites; CRC Press: Boca Raton, FL, USA; Woodhead: Cambridge, UK, 2000. [Google Scholar]

- Arrakhiz, F.; Malha, M.; Bouhfid, R.; Benmoussa, K.; Qaiss, A.E.K. Tensile, flexural and torsional properties of chemically treated alfa, coir and bagasse reinforced polypropylene. Compos. Part B Eng. 2013, 47, 35–41. [Google Scholar] [CrossRef]

- Hallonet, A.; Michel, L.; Ferrier, E. Comportement Mécanique D’un Polymère Époxy Renforcé par Fibres de lin Longues Stratifié au Contact Pour le Renforcement Externe de Structures en Béton Armé; Rencontres Universitaires de Génie Civil: Bayonne, France, May 2015; Available online: https://hal.archives-ouvertes/hal-01167600 (accessed on 28 September 2021).

- Bachchan, A.A.; Das, P.P.; Chaudhary, V. Effect of moisture absorption on the properties of natural fiber reinforced polymer composites: A review. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Halip, J.A.; Hua, L.S.; Ashaari, Z.; Tahir, P.M.; Chen, L.W.; Uyup, M.K.A. Effect of treatment on water absorption behavior of natural fiber–Reinforced polymer composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 141–156. [Google Scholar]

- Mohanty, A.k.; Manjusri, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites, 1st ed.; Mohanty, A.K., Manjusri, M., Drzal, L.T., Eds.; Taylor & Francis: Boca Raton, FL, USA, 2005; p. 852. [Google Scholar]

- Sanjay, M.R.; Arpitha, G.R.; LaxmanaNaik, L.; Gopalakrishna, K.; Yogesha, B. Studies on Mechanical Properties of Banana/E-Glass Fabrics Reinforced Polyester Hybrid Composites. J. Mater. Environ. Sci. 2016, 7, 3179–3192. [Google Scholar]

| 0% NF/ 25% GF | 25% NF/ 0% GF | 15% NF/ 10% GF | 5% NF/ 20% GF |

|---|---|---|---|

|  |  |  |

| |||

| Wave Number (cm−1) | Characteristic Group | Component |

|---|---|---|

| 3327 | -O-H [23] | Alcohol and water |

| 2911 | -C-H [24] | Polysaccharide |

| 1724 | C=O [23] | Xylan (hemicellulose) |

| 1623 | -O-H [23] | Alcohol and water |

| 1506 | C=C [23] | Lignin |

| 1424 | CH2 [23,25] | Polysaccharides |

| 1245 | C-C plus O-C plus C=O [23] | Cellulose |

| 1046 | C-C, C-OH, C-H [23] | Cellulose, hemicellulose |

| 895 | COC, CCO, and CCH [23] | Polysaccharide |

| Tensile Test Results | Ultrasonic Test Measurements | |||

|---|---|---|---|---|

| Young’s Modulus (GPa) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Poisson’s Ratio | |

| Resin matrix | 3 | 47.4 | 4.96 | 0.338804046 |

| 0% NF/25% GF | 4.22 | 20.1 | 4.68 | 0.289017097 |

| 25% GF/0% NF | 7.00 | 184 | 7.10 | 0.354185644 |

| 20% GF/5% NF | 6.02 | 142 | 6.73 | 0.309382566 |

| 10% GF/15% NF | 5.35 | 82.5 | 6.55 | 0.303627805 |

| Volume Fraction of Fibers Layers | Flexural Stress (MPa) | Flexural Modulus (MPa) |

|---|---|---|

| 0% GF/25% NF | 36 ± 2 | 2156 ± 148 |

| 10% GF/15% NF | 75 ± 1 | 3823 ± 179 |

| 20% GF/5% NF | 170 ± 17 | 6583 ± 207 |

| 25% GF/0% NF | 232 ± 14 | 8472 ± 302 |

| Resin | 75 ± 15 | 2000 ± 58 |

| Fiber Volume Fraction | Loss Energy, Eloss (J) | Impact Energy (J) (EAb + Eloss) | Absorption Energy, EAb (J) |

|---|---|---|---|

| Resin | 4.36 | 0.14 | −4.22 |

| 25% GF | 4.36 | 0.73 | −3.63 |

| 25%NF | 4.36 | 0.28 | −4.08 |

| 10% GF/15% NF | 4.36 | 0.38 | −3.98 |

| 20% GF/5% NF | 4.36 | 0.5 | −3.86 |

| Fiber Volume Fraction | Resin | 25% GF/0% NF | 0% GF/25% NF | 10% GF/15% NF | 20% GF/5% NF |

|---|---|---|---|---|---|

| RH | 83 | 96.91 | 89.16 | 92.75 | 92 |

| Aging | ||||

|---|---|---|---|---|

| P0 | P3 | P5 | P7 | |

| Resin | 30.8 HV | 30.5 HV | 30.6 HV | 30.5 HV |

| 0% GF/25% NF | 32.2 HV | 31.2 HV | 30.6 HV | 30.7 HV |

| 25% GF/0% NF | 34.6 HV | 30.7 HV | 30.5 HV | 30.5 HV |

| 20% GF/5% NF | 32.7 HV | 30.9 HV | 30.6 HV | 30.6 HV |

| 10% GF/15% NF | 31.9 HV | 31 HV | 30.7 HV | 29.1 HV |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaddami, H.; Arrakhiz, F.-e.; Hafs, O.; Assimi, T.E.; Boulafrouh, L.; Ablouh, E.-H.; Mansori, M.; Banouni, H.; Bouzit, S.; Erchiqui, F.; et al. Implementation and Characterization of a Laminate Hybrid Composite Based on Palm Tree and Glass Fibers. Polymers 2021, 13, 3444. https://doi.org/10.3390/polym13193444

Kaddami H, Arrakhiz F-e, Hafs O, Assimi TE, Boulafrouh L, Ablouh E-H, Mansori M, Banouni H, Bouzit S, Erchiqui F, et al. Implementation and Characterization of a Laminate Hybrid Composite Based on Palm Tree and Glass Fibers. Polymers. 2021; 13(19):3444. https://doi.org/10.3390/polym13193444

Chicago/Turabian StyleKaddami, Hamid, Fatima-ezzahra Arrakhiz, Oumaima Hafs, Taha EL Assimi, Lamia Boulafrouh, El-Houssaine Ablouh, Mohamed Mansori, Hicham Banouni, Said Bouzit, Fouad Erchiqui, and et al. 2021. "Implementation and Characterization of a Laminate Hybrid Composite Based on Palm Tree and Glass Fibers" Polymers 13, no. 19: 3444. https://doi.org/10.3390/polym13193444

APA StyleKaddami, H., Arrakhiz, F. -e., Hafs, O., Assimi, T. E., Boulafrouh, L., Ablouh, E. -H., Mansori, M., Banouni, H., Bouzit, S., Erchiqui, F., & Benmoussa, K. (2021). Implementation and Characterization of a Laminate Hybrid Composite Based on Palm Tree and Glass Fibers. Polymers, 13(19), 3444. https://doi.org/10.3390/polym13193444