The Out-of-Plane Compression Response of Woven Thermoplastic Composites: Effects of Strain Rates and Temperature

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials

2.2. Experiments

3. Results and Discussion

3.1. Dynamic Compressive Behavior

3.1.1. Effect of Strain Rate on Out-of-Plane Dynamic Compressive Response

3.1.2. Effect of Temperature on Out-of-Plane Dynamic Compressive Response

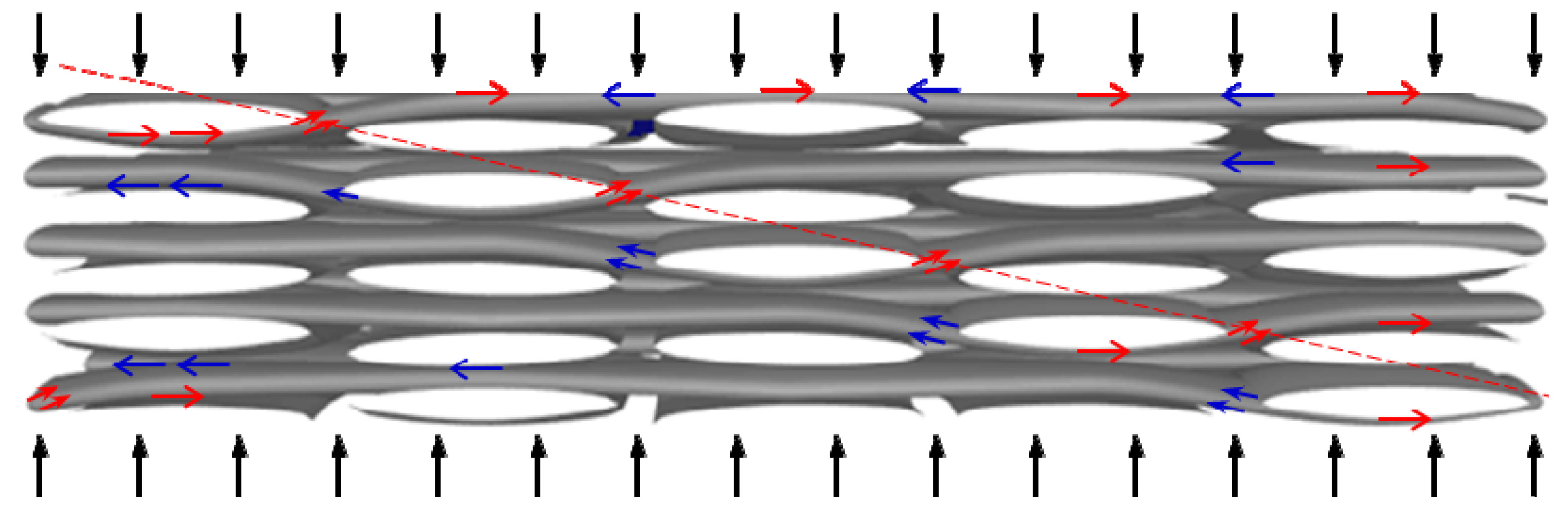

3.2. Fracture Morphologies and Failure Mechanisms of Thermoplastic Composite under Out-of-Plane Dynamic Compression

3.2.1. Effect of Strain Rates on Failure Mechanisms

3.2.2. Effect of Temperature on Failure Mechanisms

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yao, S.S.; Jin, F.L.; Rhee, K.Y.; Hui, D.; Park, S.J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Naik, A.K.; Chouhan, H.; Bhatnagar, N. High strain rate compression testing of intra-ply and inter-ply hybrid thermoplastic composites reinforced with Kevlar/basalt fibers. Polym. Test. 2020, 84, 106407. [Google Scholar]

- Russo, P.; Langella, A.; Papa, I.; Simeoli, G.; Lopresto, V. Thermoplastic polyurethane/glass fabric composite laminates: Low velocity impact behavior under extreme temperature conditions. Compos. Struct. 2017, 166, 146–152. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Fang, G.; Zhang, J.; Zhou, Z.; Wang, S. Influence of temperature on the impact behavior of woven-ply carbon fiber reinforced thermoplastic composites. Compos. Struct. 2018, 185, 435–445. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Omidi, M.J. Compressive response of glass–fiber reinforced polymeric composites to increasing compressive strain rates. Compos. Struct. 2009, 89, 517–523. [Google Scholar] [CrossRef]

- Qian, X.; Wang, H.; Zhang, D.; Wen, G. High strain rate out-of-plane compression properties of aramid fabric reinforced polyamide composite. Polym. Test. 2016, 53, 314–322. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Mittal, V.K.; Chouhan, H.; Asija, N.; Bhatnagar, N.; Ahmad, S. Characterization of 3D angle-interlock thermoplastic composites under high strain rate compression loadings. Polym. Test. 2017, 62, 355–365. [Google Scholar] [CrossRef]

- Vieille, B.; Aucher, J.; Taleb, L. Influence of temperature on the behavior of carbon fiber fabrics reinforced PPS laminates. Mater. Sci. Eng. A 2009, 517, 51–60. [Google Scholar] [CrossRef]

- Woo, S.C.; Kim, T.W. High-strain-rate impact in Kevlar-woven composites and fracture analysis using acoustic emission. Compos. Part B Eng. 2014, 60, 125–136. [Google Scholar] [CrossRef]

- Wang, S.; Wen, L.; Xiao, J.; Lei, M.; Liang, J. Influence of strain rate and temperature on mechanical properties of carbon woven-ply PPS thermoplastic laminates under dynamic compression. Polym. Test. 2020, 89, 106725. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Choukri, S.; Nême, A. Effect of fiber orientation on mechanical properties of the laminated polymer composites subjected to out-of-plane high strain rate compressive loadings. Compos. Sci. Technol. 2008, 68, 477–485. [Google Scholar] [CrossRef] [Green Version]

- Kara, A.; Tasdemirci, A.; Guden, M. Modeling quasi-static and high strain rate deformation and failure behavior of a (±45) symmetric e-glass/polyester composite under compressive loading. Mater. Des. 2013, 49, 566–574. [Google Scholar] [CrossRef] [Green Version]

- Hosur, M.V.; Alexander, J.; Vaidya, U.K.; Jeelani, S. High strain rate compression response of carbon/epoxy laminate composites. Compos. Struct. 2001, 52, 405–417. [Google Scholar] [CrossRef]

- Song, Z.H.; Wang, Z.H.; Ma, H.W.; Xuan, H.J. Mechanical behavior and failure mode of woven carbon/epoxy laminate composites under dynamic compressive loading. Compos. Part B Eng. 2014, 60, 531–536. [Google Scholar] [CrossRef]

- Woldesenbet, E.; Vinson, J.R. Specimen geometry effects on high-strain-rate testing of graphite/epoxy composites. AIAA J. 1999, 37, 1102–1106. [Google Scholar] [CrossRef]

- Montes, C.R.; Reis, V.L.; Opelt, C.V.; Santiago, R.C.; Rezende, M.C.; Tiburcio, C.G.; Donadon, M. High strain-rate behavior of fiber reinforced thermoplastic composites under compressive loadings. COBEM-2017-1122. In Proceedings of the 24th ABCM International Congress of Mechanical Engineering, Curitiba, Brazil, 3–8 December 2017. [Google Scholar]

- Brown, K.A.; Brooks, R.; Warrior, N.A. The static and high strain rate behavior of a commingled E-glass/polypropylene woven fabric composite. Compos. Sci. Technol. 2010, 70, 272–283. [Google Scholar] [CrossRef]

- Massaq, A.; Rusinek, A.; Klosak, M.; Bahi, S.; Arias, A. Strain rate effect on the mechanical behavior of polyamide composites under compression loading. Compos. Struct. 2019, 214, 114–122. [Google Scholar] [CrossRef]

- Vieille, B.; Albouy, W.; Chevalier, L.; Taleb, L. About the influence of stamping on thermoplastic-based composites for aeronautical applications. Compos. Part B Eng. 2013, 45, 821–834. [Google Scholar] [CrossRef]

- Zhao, T.; Rans, C.; Villegas, I.F.; Benedictus, R. On sequential ultrasonic spot welding as an alternative to mechanical fastening in thermoplastic composite assemblies: A study on single-column multi-row single-lap shear joints. Compos. Part A Appl. Sci. Manuf. 2019, 120, 1–11. [Google Scholar] [CrossRef]

- Russo, P.; Acierno, D.; Simeoli, G.; Iannace, S.; Sorrentino, L. Flexural and impact response of woven glass fiber fabric/polypropylene composites. Compos. Part B Eng. 2013, 54, 415–421. [Google Scholar] [CrossRef]

- Kumar, K.V.; Safiulla, M.; Ahmed, A.N.K. An experimental evaluation of fiber reinforced polypropylene thermoplastics for aerospace applications. J. Mech. Eng. 2013, 43, 92–97. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Zhou, Z.; Zhang, J.; Fang, G.; Wang, Y. Effect of temperature on bending behavior of woven fabric-reinforced PPS-based composites. J. Mater. Sci. 2017, 52, 13966–13976. [Google Scholar] [CrossRef]

- Chabchoub, M.; Vieille, B.; Beyaoui, M.; Taktak, M.; Haddar, M.; Taleb, L. Determination of J-R curves by load separation criterion in highly ductile TP-based composites under high temperature conditions. Compos. Struct. 2017, 182, 391–401. [Google Scholar] [CrossRef]

- Gabrion, X.; Placet, V.; Trivaudey, F.; Boubakar, L. About the thermomechanical behaviour of a carbon fibre reinforced high-temperature thermoplastic composite. Compos. Part B Eng. 2016, 95, 386–394. [Google Scholar] [CrossRef] [Green Version]

- Chabchoub, M.; Bouscarrat, D.; Vieille, B.; Gautrelet, C.; Beyaoui, M.; Taktak, M.; Haddar, M.; Taleb, L. Investigations on the mode I translaminar failure and determination of fracture toughness in woven-ply carbon fibers thermoplastic composites at high temperatures. Appl. Acoust. 2017, 128, 55–63. [Google Scholar] [CrossRef]

- Dai, G.; Zhan, L.; Guan, C.; Huang, M. The effect of moulding process parameters on interlaminar properties of CF/PEEK composite laminates. High Perform. Polym. 2020, 32, 835–841. [Google Scholar] [CrossRef]

- Carpier, Y.; Vieille, B.; Coppalle, A.; Barbe, F. About the tensile mechanical behaviour of carbon fibers fabrics reinforced thermoplastic composites under very high temperature conditions. Compos. Part B Eng. 2020, 181, 107586. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J.; Zhou, Z.; Fang, G.; Wang, Y. Compressive and flexural behavior of carbon fiber-reinforced PPS composites at elevated temperature. Mech. Adv. Mater. Struct. 2018, 27, 286–294. [Google Scholar] [CrossRef]

- Liu, A.; Wang, B.; Li, F. High performance thermoplastic polymer for the compressive behavior of carbon fiber reinforced composites. Pigment Resin Technol. 2020. [Google Scholar] [CrossRef]

- Schoßig, M.; Bierögel, C.; Grellmann, W.; Mecklenburg, T. Mechanical behavior of glass-fiber reinforced thermoplastic materials under high strain rates. Polym. Test. 2008, 27, 893–900. [Google Scholar] [CrossRef]

- Barba, D.; Arias, A.; Garcia-Gonzalez, D. Temperature and strain rate dependences on hardening and softening behaviours in semi-crystalline polymers: Application to PEEK. Int. J. Solids Struct. 2020, 182, 205–217. [Google Scholar] [CrossRef]

- Zou, H.; Yin, W.; Cai, C.; Wang, B.; Liu, A.; Yang, Z.; Li, Y.; He, X. The Out-of-Plane Compression Behavior of Cross-Ply AS4/PEEK Thermoplastic Composite Laminates at High Strain Rates. Materials 2018, 11, 2312. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miao, Y.-G.; Li, Y.; Liu, H.; Deng, Q.; Shen, L.; Mai, Y.-W.; Guo, Y.; Suo, T.; Hu, H.-T.; Xie, F.-Q.; et al. Determination of dynamic elastic modulus of polymeric materials using vertical split Hopkinson pressure bar. Int. J. Mech. Sci. 2016, 108, 188–196. [Google Scholar] [CrossRef]

- Alves, M.; Karagiozova, D.; Micheli, G.B.; Calle, M.A.G. Limiting the influence of friction on the split Hopkinson pressure bar tests by using a ring specimen. Int. J. Impact Eng. 2012, 49, 130–141. [Google Scholar] [CrossRef]

- Meng, H.; Li, Q. Correlation between the accuracy of a SHPB test and the stress uniformity based on numerical experiments. Int. J. Impact Eng. 2003, 28, 537–555. [Google Scholar] [CrossRef]

- Yang, L.M.; Shim, V.P.W. An analysis of stress uniformity in split Hopkinson bar test specimens. Int. J. Impact Eng. 2005, 31, 129–150. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Neme, A.; Choukri, S. Damage Kinetics of Glass/Epoxy Composite Materials Under Dynamic Compression. J. Compos. Mater. 2009, 43, 1137–1154. [Google Scholar] [CrossRef]

- Arbaoui, J.; Tarfaoui, M.; Alaoui, A.E.M. Mechanical behavior and damage kinetics of woven E-glass/vinylester laminate composites under high strain rate dynamic compressive loading: Experimental and numerical investigation. Int. J. Impact Eng. 2016, 87, 44–54. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, M.; Miao, Y.; Wang, H.; Chen, T.; Fan, X.; Chang, H. Dynamic Mechanical Response and Damage Mechanism of HTPB Propellant under Impact Loading. Materials 2020, 13, 3031. [Google Scholar] [CrossRef]

- Naik, N.K.; Kavala, V.R. High strain rate behavior of woven fabric composites under compressive loading. Mater. Sci. Eng. A 2008, 474, 301–311. [Google Scholar] [CrossRef]

- Khan, A.S.; Colak, O.U.; Centala, P. Compressive failure strengths and modes of woven S2-glass reinforced polyester due to quasi-static and dynamic loading. Int. J. Plast. 2002, 18, 1337–1357. [Google Scholar] [CrossRef]

| GF/PPS Composite | CF/PPS Composite | ||||||

|---|---|---|---|---|---|---|---|

| Strain Rate (s-1) | Strength (MPa) | Modulus (GPa) | Failure Strain (%) | Strain Rate (s-1) | Strength (MPa) | Modulus (GPa) | Failure Strain (%) |

| 573 | 414.87 | 12.94 | 3.94 | 717 | 354.96 | 11.17 | 3.52 |

| 1434 | 598.38 | 13.83 | 7.04 | 1408 | 441.05 | 11.67 | 4.48 |

| 1980 | 653.77 | 14.49 | 8.19 | 1934 | 494.75 | 11.99 | 5.34 |

| 2476 | 664.16 | 14.77 | 8.11 | 2433 | 539.33 | 12.34 | 6.21 |

| 3520 | 685.57 | 15.33 | 8.03 | 3414 | 625.27 | 12.85 | 7.94 |

| Specimen | ||||||

|---|---|---|---|---|---|---|

| m | m | m | ||||

| GF/PPS | 40.18 | 0.369 | 8.31 | 0.087 | 0.11 | 0.567 |

| CF/PPS | 30.37 | 0.367 | 6.38 | 0.088 | 0.075 | 0.569 |

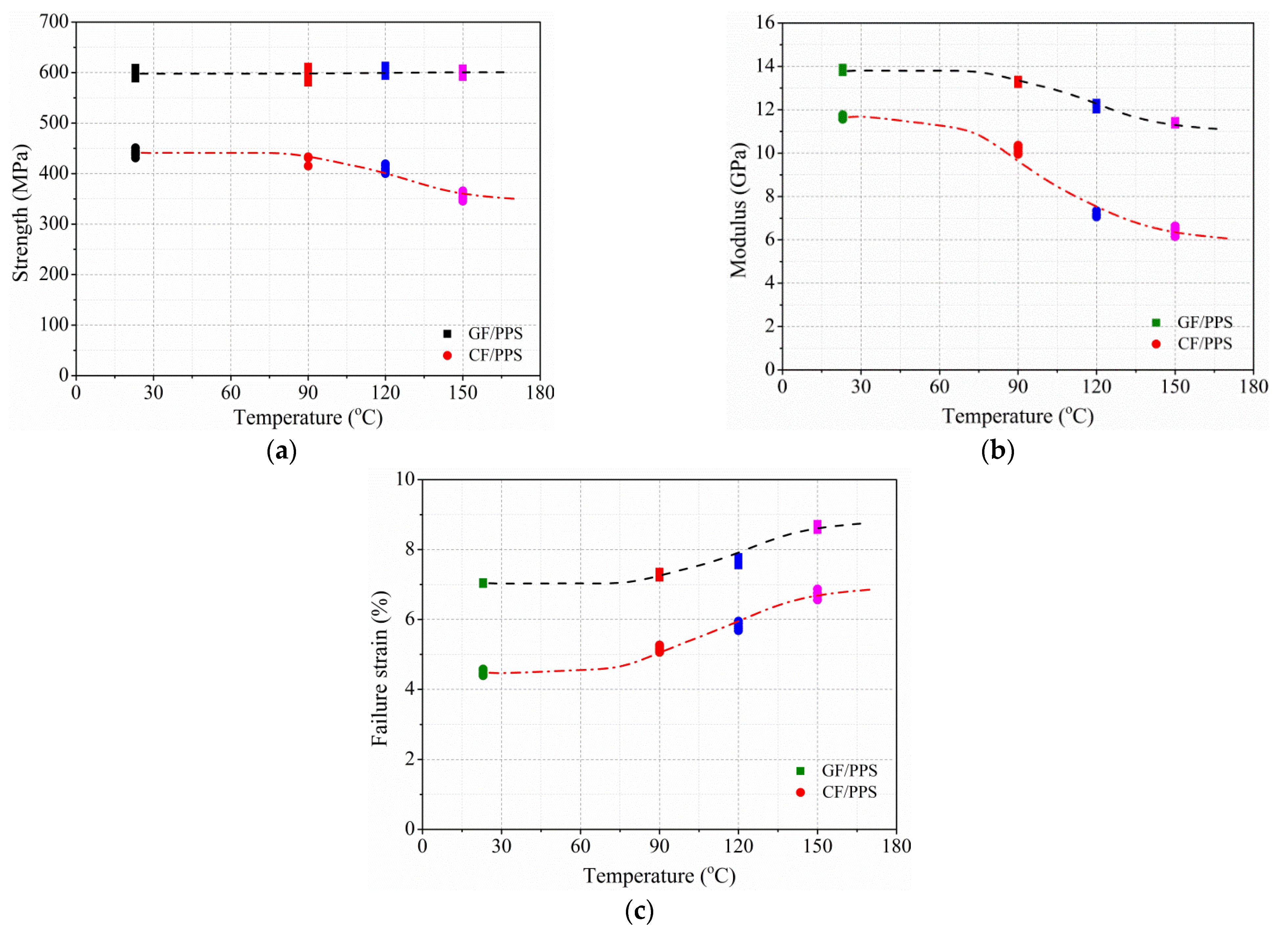

| Temperature (°C) | GF/PPS Composite | CF/PPS Composite | ||||

|---|---|---|---|---|---|---|

| Strength (MPa) | Modulus (GPa) | Failure Strain (%) | Strength (MPa) | Modulus (GPa) | Failure Strain (%) | |

| 23 | 598.38 | 13.82 | 7.04 | 441.05 | 11.67 | 4.48 |

| 90 | 596.51 | 13.28 | 7.27 | 425.11 | 10.18 | 5.17 |

| 120 | 603.43 | 12.17 | 7.67 | 410.18 | 7.16 | 5.81 |

| 150 | 601.09 | 11.41 | 8.65 | 355.72 | 6.41 | 6.73 |

| Materials | Strength (%) | Modulus (%) | Failure Strain (%) |

|---|---|---|---|

| GF/PPS | 1.49 | 0.78 | 1.17 |

| CF/PPS | 1.95 | 2.46 | 1.76 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wen, L.; Xiao, J.; Lei, M.; Hou, X.; Liang, J. The Out-of-Plane Compression Response of Woven Thermoplastic Composites: Effects of Strain Rates and Temperature. Polymers 2021, 13, 264. https://doi.org/10.3390/polym13020264

Wang S, Wen L, Xiao J, Lei M, Hou X, Liang J. The Out-of-Plane Compression Response of Woven Thermoplastic Composites: Effects of Strain Rates and Temperature. Polymers. 2021; 13(2):264. https://doi.org/10.3390/polym13020264

Chicago/Turabian StyleWang, Shiyu, Lihua Wen, Jinyou Xiao, Ming Lei, Xiao Hou, and Jun Liang. 2021. "The Out-of-Plane Compression Response of Woven Thermoplastic Composites: Effects of Strain Rates and Temperature" Polymers 13, no. 2: 264. https://doi.org/10.3390/polym13020264

APA StyleWang, S., Wen, L., Xiao, J., Lei, M., Hou, X., & Liang, J. (2021). The Out-of-Plane Compression Response of Woven Thermoplastic Composites: Effects of Strain Rates and Temperature. Polymers, 13(2), 264. https://doi.org/10.3390/polym13020264