Synthesis of a Cyclophosphazene Derivative Containing Multiple Cyano Groups for Electron-Beam Irradiated Flame-Retardant Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instruments and Measurements

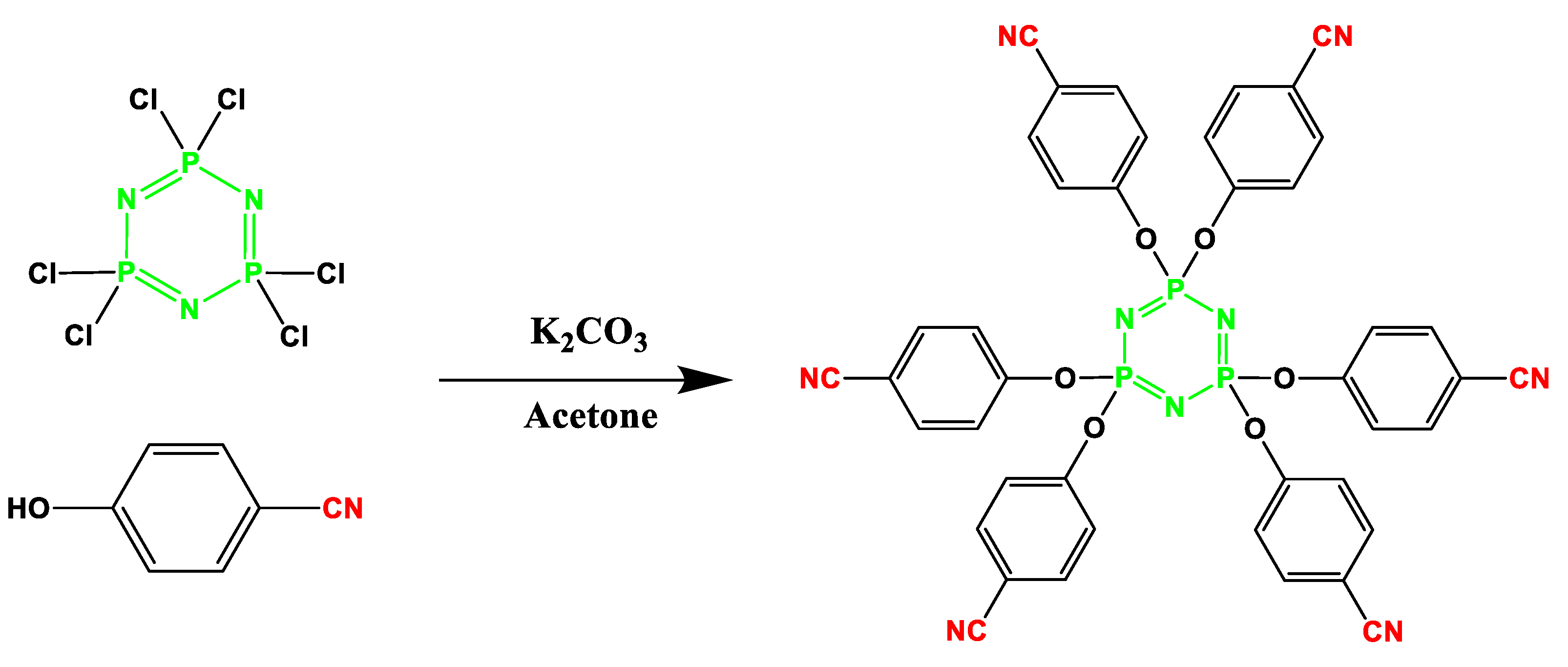

2.3. Synthesis of a Cyano-Functionalized CP

2.4. Preparation of Insulation-Composite Materials Containing Inorganic-Organic Flame Retardants

2.5. Preparation of EB-Irradiated Insulation Materials

3. Results and Discussion

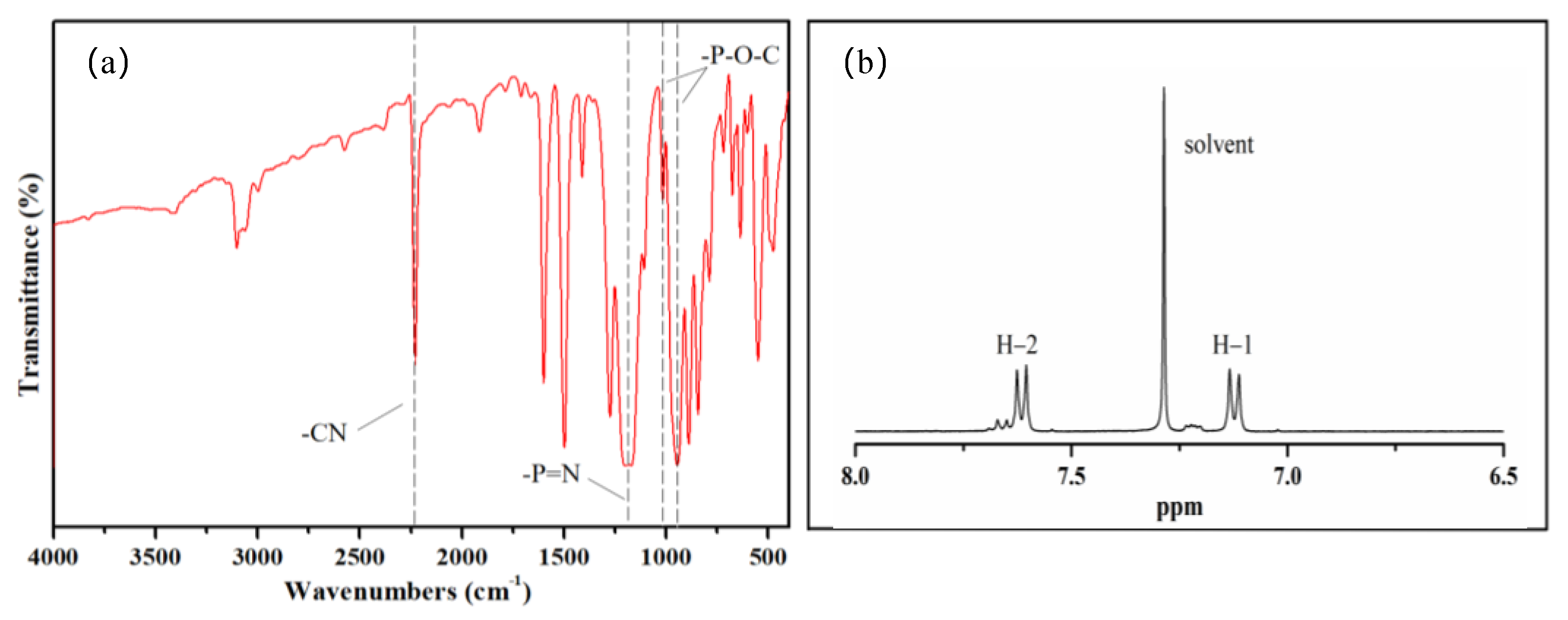

3.1. Synthesis of Multiple Cyano-Containing CP as Organic Flame Retardant

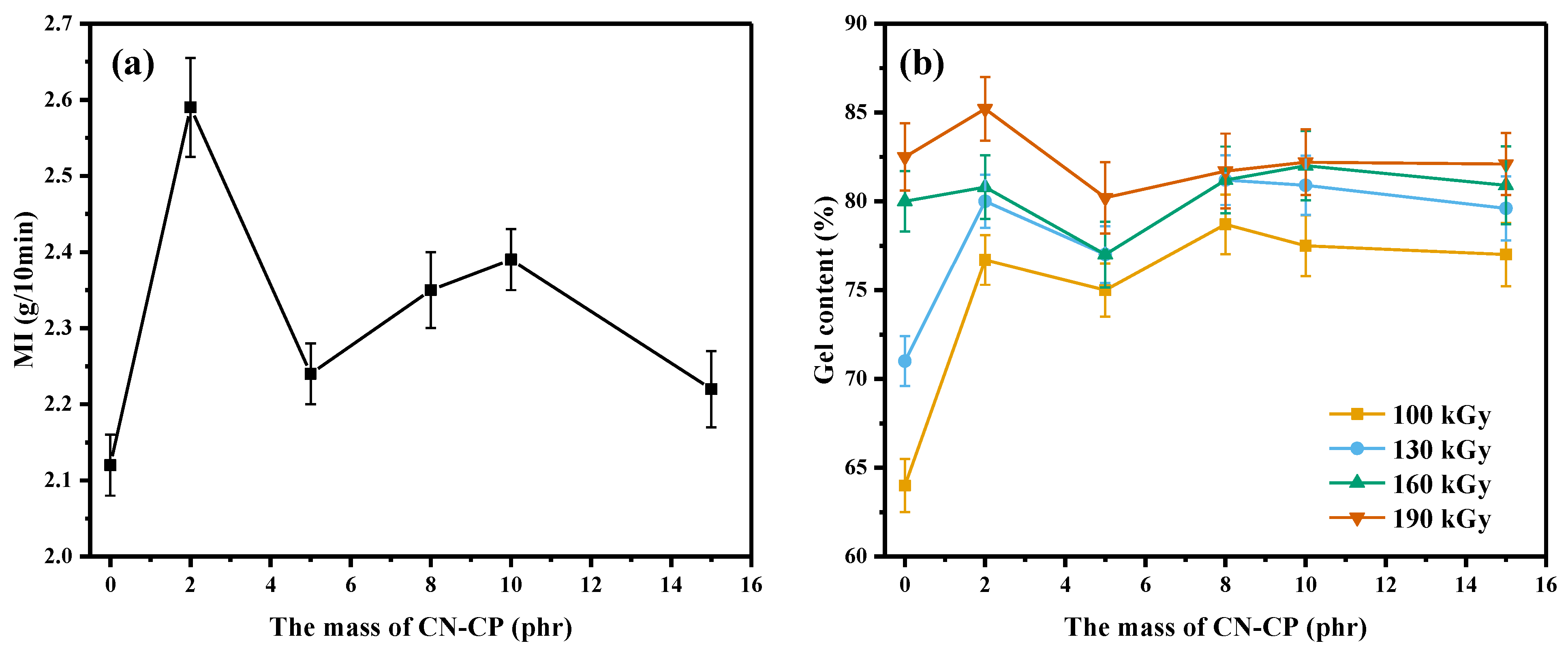

3.2. Preparation of EB-Irradiated LDPE/EVA Composites Containing CN-CP

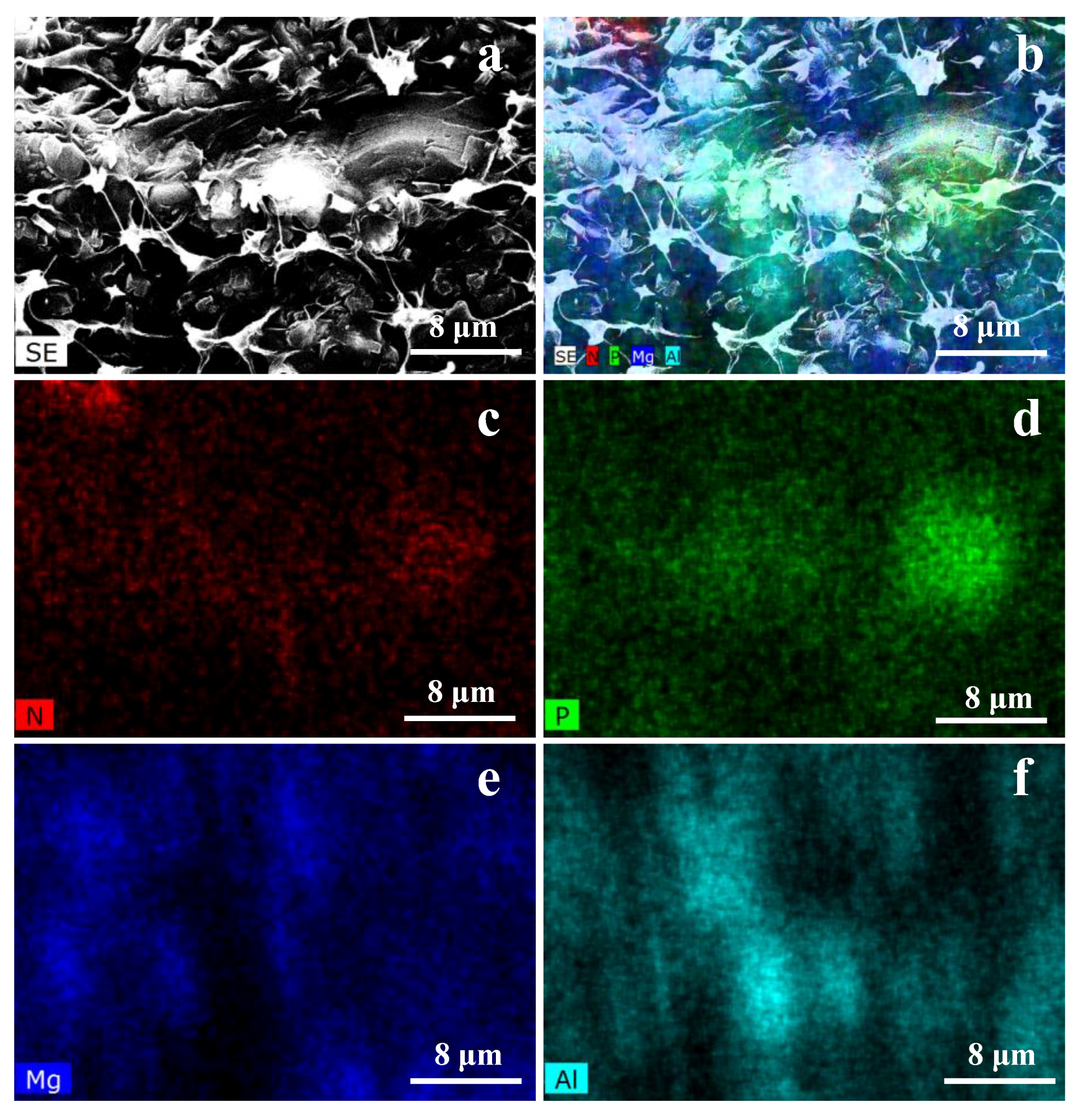

3.3. Morphology of Composites

3.4. Thermal and Mechanical Properties

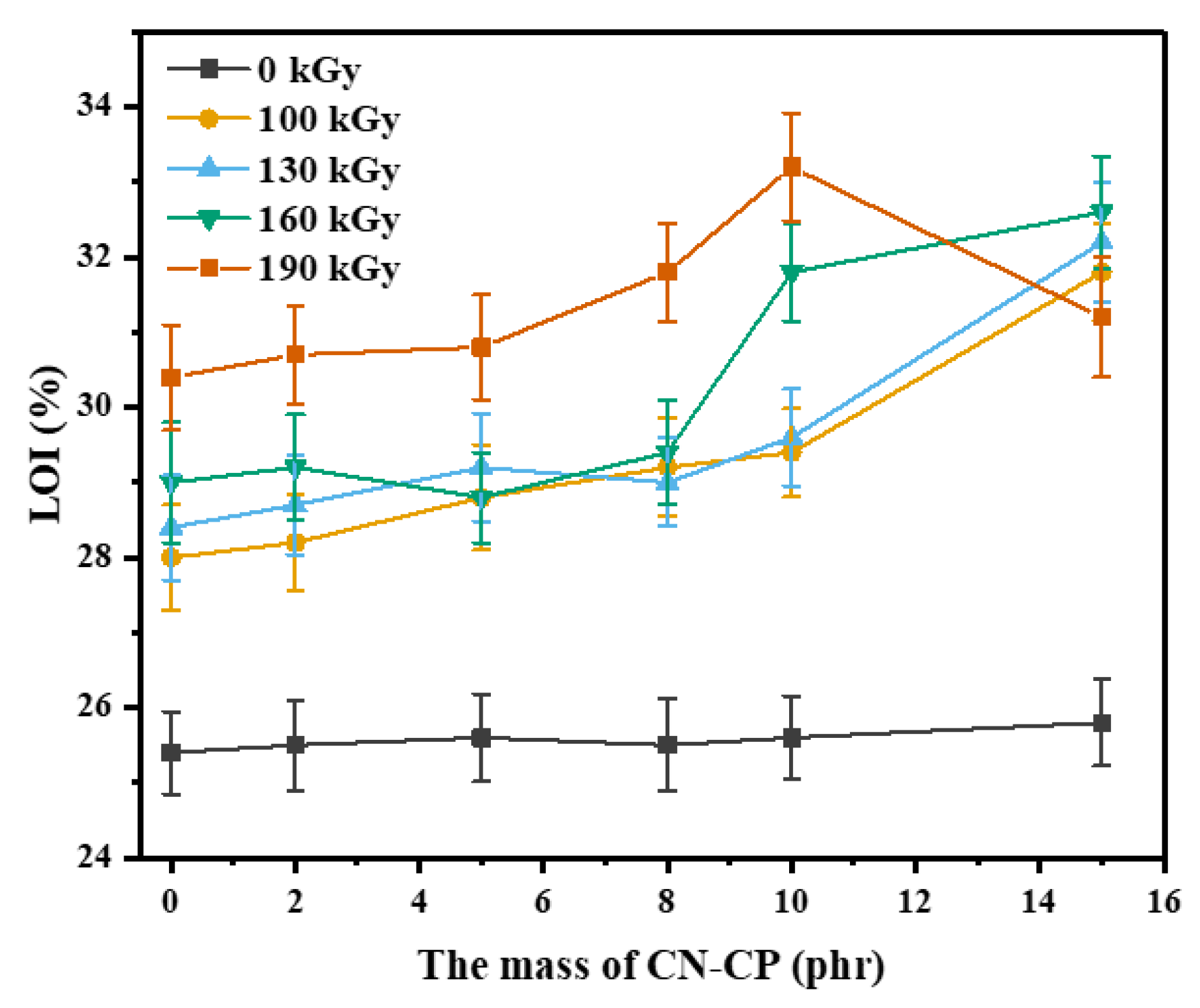

3.5. Flame-Retardancy and Electrical-Insulation Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Spalding, M.A.; Chatterjee, A.M. Handbook of Industrial Polyethylene and Technology: Definitive Guide to Manufacturing, Properties, Processing, Applications and Markets (Part Two); John Wiley & Sons: Hoboken, NJ, USA, 2018; pp. 105–138. [Google Scholar]

- Dadbin, S.; Frounchi, M.; Haji, S.M.; Gangi, F. Molecular structure and physical properties of electron beam-crosslinked low-density polyethylene for wire and cable insulation applications. J. Appl. Polym. Sci. 2002, 86, 1959–1969. [Google Scholar] [CrossRef]

- Haurie, L.; Fernández, A.L.; Velasco, J.C.; Chimenos, J.M.; Lopez-Cuesta, J.M.; Espiell, F. Thermal stability and flame retardancy of LDPE/EVA blends filled with synthetic hydromagnesite/aluminium hydroxide/montmorillonite and magnesium hydroxide/aluminium hydroxide/montmorillonite mixtures. Polym. Degrad. Stabil. 2007, 92, 1082–1087. [Google Scholar] [CrossRef]

- Sabet, M.; Hassan, A.; Ratnam, C.T. Electron beam irradiation of low density polyethylene/ethylene vinyl acetate filled with metal hydroxides for wire and cable applications. Polym. Degrad. Stabil. 2012, 97, 1432–1467. [Google Scholar] [CrossRef]

- Laoutid, F.; Gaudon, P.; Taulemesse, J.M.; Lopez-Cuesta, J.M.; Velasco, J.I.; Piechaczyk, A. Study of hydromagnesite and magnesium hydroxide based fire retardant systems for ethylene vinyl acetate containing organo-modified montmorillonite. Polym. Degrad. Stabil. 2006, 91, 3074–3082. [Google Scholar] [CrossRef]

- Jiao, C.M.; Wang, Z.Z.; Ye, Z.; Hu, Y.; Fan, W.C. Flame Retardation of Ethylene-Vinyl Acetate Copolymer Using Nano Magnesium Hydroxide and Nano Hydrotalcite. J. Fire Sci. 2006, 24, 47–64. [Google Scholar] [CrossRef]

- Bahattab, M.A.; Mosnacek, J.; Basfar, A. Gross-linked poly(ethylene vinyl acetate) (EVA)/low density polyethylene (LDPE)/metal hydroxides composites for wire and cable applications. Polym. Bull. 2010, 64, 569–580. [Google Scholar] [CrossRef]

- Liu, H.; Alkadasi, N.A.; Zhu, Y.; Tong, L.F.; Fang, Z.P.; Wang, Y.C. Electron beam irradiated HDPE/EVA/Mg(OH)2 composites for flame-retardant electric cables. Front. Mater. Sci. China 2008, 2, 426–429. [Google Scholar] [CrossRef]

- Sener, A.A.; Demirhan, E. The investigation of using magnesium hydroxide as a flame retardant in the cable insulation material by cross-linked polyethylene. Mater. Design. 2008, 29, 1376–1379. [Google Scholar] [CrossRef]

- Vahabi, H.; Laoutid, F.; Mehrpouya, M.; RezaSaeb, M.; Dubois, P. Flame retardant polymer materials: An update and the future for 3D printing developments. Mater. Sci. Eng. R. 2021, 144, 100604. [Google Scholar] [CrossRef]

- Dadbin, S.; Frounchi, M.; Sabet, M. Studies on the properties and structure of electron-beam crosslinked low-density polyethylene/poly[ethylene-co-(vinyl acetate)] blends. Polym. Int. 2005, 54, 686–691. [Google Scholar] [CrossRef]

- Shi, C.Y.; Yang, J.Y.; Liu, Y.; Wang, Y.M.; Xu, W.G.; Xu, Y.Q.; Hu, W.; Liu, B.J. Thermally Conductive Study of Polyethylene/Al2O3 Composite Networks Cross-linked by Electron Beam Irradiation. Chem. Res. Chin. Univ. 2020, 36, 940–945. [Google Scholar] [CrossRef]

- Salehi SM, A.; Mirjalili, G.; Amrollahi, J. Effects of high-energy electron beam on low-density polyethylene materials containing EVA. J. Appl. Polym. Sci. 2004, 92, 1049–1052. [Google Scholar] [CrossRef]

- Sharif, J.; Aziz, S.H.S.A.; Hashim, K. Radiation effects on LDPE/EVA blends. Rad. Phys. Chem. 2000, 58, 191–195. [Google Scholar] [CrossRef]

- Zhou, S.; Ning, M.; Wang, X.; Yan, Z.; Guo, D.; He, Q.; Zhang, Y.; She, S.; Hu, Y. The influence of γ-irradiation on the mechanical, thermal degradation, and flame retardant properties of EVA/LDPE/ATH blends. J. Therm. Anal. Calorim. 2015, 119, 167–173. [Google Scholar] [CrossRef]

- Ning, K.; Zhou, L.L.; Zhao, B. A novel aminothiazole-based cyclotriphosphazene derivate towards epoxy resins for high flame retardancy and smoke suppression. Polym. Degrad. Stabil. 2021, 190, 109651. [Google Scholar] [CrossRef]

- Kuan, J.F.; Lin, K.F. Synthesis of hexa-allylamino-cyclotriphosphazene as a reactive fire retardant for unsaturated polyesters. J. Appl. Polym. Sci. 2004, 91, 697–702. [Google Scholar] [CrossRef]

- Mathew, D.; Reghunadhan Nair, C.P.; Ninan, K.N. Phosphazene-triazine cyclomatrix network polymers: Some aspects of synthesis, thermal- and flame-retardant characteristics. Polym. Int. 2000, 49, 48–56. [Google Scholar] [CrossRef]

- Lu, S.Y.; Hamerton, I. Recent developments in the chemistry of halogen-free flame retardant polymers. Prog. Polym. Sci. 2002, 27, 1661–1712. [Google Scholar] [CrossRef]

- Qiu, S.L.; Wang, X.; Yu, B.; Feng, X.M.; Mu, X.W.; Yuen RK, K.; Hu, Y. Flame-retardant-wrapped polyphosphazene nanotubes: A novel strategy for enhancing the flame retardancy and smoke toxicity suppression of epoxy resins. J. Hazard. Mater. 2017, 325, 327–339. [Google Scholar] [CrossRef]

- Gouri, M.E.; Bachiri, A.E.; Hegazi, S.E.; Rafik, M.; Harfi, A.E. Thermal degradation of a reactive flame retardant based on cyclotriphosphazene and its blend with DGEBA epoxy resin. Polym. Degrad. Stabil. 2009, 94, 2101–2106. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.D.; Wu, D.Z. Novel cyclotriphosphazene-based epoxy compound and its application in halogen-free epoxy thermosetting systems: Synthesis, curing behaviors, and flame retardancy. Polym. Degrad. Stabil. 2014, 103, 96–112. [Google Scholar] [CrossRef]

| Sample | PE (phr) | EVA (phr) | Mg(OH)2 (phr) | Al(OH)3 (phr) | HPCTP-CN (phr) |

|---|---|---|---|---|---|

| PE-CN-0 | 100 | 40 | 100 | 100 | 0 |

| PE-CN-1 | 100 | 40 | 100 | 100 | 2 |

| PE-CN-2 | 100 | 40 | 100 | 100 | 5 |

| PE-CN-3 | 100 | 40 | 100 | 100 | 8 |

| PE-CN-4 | 100 | 40 | 100 | 100 | 10 |

| PE-CN-5 | 100 | 40 | 100 | 100 | 15 |

| Sample | UL-94 | Resistance(Ω) | Volume Resistivity(Ω·cm) | Capacitance(pF) | Permittivity |

|---|---|---|---|---|---|

| PE-CN-0 | NR | 2.75 × 1012 | 5.68 × 1014 | 55 | 2.8 |

| PE-CN-1 | V-1 | 1.90 × 1012 | 4.23 × 1014 | 56 | 2.6 |

| PE-CN-2 | V-0 | 2.70 × 1012 | 5.41 × 1014 | 54 | 2.8 |

| PE-CN-3 | V-0 | 2.81 × 1012 | 5.52 × 1014 | 53 | 2.8 |

| PE-CN-4 | V-0 | 3.22 × 1012 | 6.02 × 1014 | 50 | 2.8 |

| PE-CN-5 | V-0 | 2.00 × 1012 | 4.05 × 1014 | 55 | 2.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leng, B.; Yang, J.; Zhu, C.; Wang, Z.; Shi, C.; Liu, Y.; Zhang, H.; Xu, W.; Liu, B. Synthesis of a Cyclophosphazene Derivative Containing Multiple Cyano Groups for Electron-Beam Irradiated Flame-Retardant Materials. Polymers 2021, 13, 3460. https://doi.org/10.3390/polym13203460

Leng B, Yang J, Zhu C, Wang Z, Shi C, Liu Y, Zhang H, Xu W, Liu B. Synthesis of a Cyclophosphazene Derivative Containing Multiple Cyano Groups for Electron-Beam Irradiated Flame-Retardant Materials. Polymers. 2021; 13(20):3460. https://doi.org/10.3390/polym13203460

Chicago/Turabian StyleLeng, Bingbing, Jiayu Yang, Chunhui Zhu, Zhipeng Wang, Chengying Shi, Yang Liu, Hongyan Zhang, Wenge Xu, and Baijun Liu. 2021. "Synthesis of a Cyclophosphazene Derivative Containing Multiple Cyano Groups for Electron-Beam Irradiated Flame-Retardant Materials" Polymers 13, no. 20: 3460. https://doi.org/10.3390/polym13203460

APA StyleLeng, B., Yang, J., Zhu, C., Wang, Z., Shi, C., Liu, Y., Zhang, H., Xu, W., & Liu, B. (2021). Synthesis of a Cyclophosphazene Derivative Containing Multiple Cyano Groups for Electron-Beam Irradiated Flame-Retardant Materials. Polymers, 13(20), 3460. https://doi.org/10.3390/polym13203460