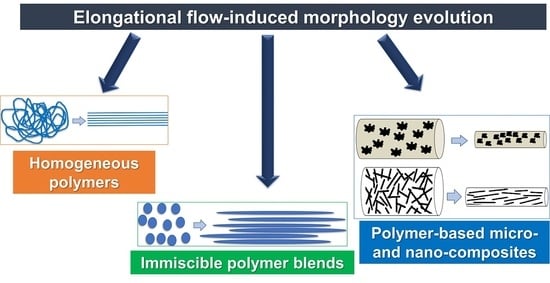

Effect of the Elongational Flow on the Morphology and Properties of Polymer Systems: A Brief Review

Abstract

:1. Introduction

2. Main Features of the Elongational Flow

3. Rheological Properties in Elongational Flow

3.1. Rheological Properties in Isothermal Elongational Flow

3.2. Rheological Properties in Non-Isothermal Elongational Flow

4. Effect of Elongational Flow in Modifying Morphology and Mechanical Properties of Homogeneous Polymers

5. Morphology Evolution of Polymer-Based Blends under Elongational Flow

6. Morphology Evolution of Polymer-Based Composites and Nanocomposites under Elongational Flow

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Denn, M.M. Polymer Melt Processing—Foundations in Fluid Mechanics and Heat Transfer; Cambridge University Press: New York, NY, USA, 2014. [Google Scholar]

- Wu, H.; Lv, S.; He, Y.; Qu, J.P. The study of the thermomechanical degradation and mechanical properties of PET recycled by industrial-scale elongational processing. Polym. Test. 2019, 77, 105882. [Google Scholar] [CrossRef]

- Mistretta, M.C.; Botta, L.; Arrigo, R.; Leto, F.; Malucelli, G.; La Mantia, F.P. Bionanocomposite blown films: Insights on the rheological and mechanical behavior. Polymers 2021, 13, 1167. [Google Scholar] [CrossRef]

- Sentmanat, M.L. Miniature universal testing platform: From extensional melt rheology to solid-state deformation behavior. Rheol. Acta 2004, 43, 657–669. [Google Scholar] [CrossRef]

- Stary, Z.; Papp, M.; Burghelea, T. Deformation regimes, failure and rupture of a low density polyethylene (LDPE) melt undergoing uniaxial extension. J. Non Newtonian Fluid Mech. 2015, 219, 35–49. [Google Scholar] [CrossRef]

- López Cabarcos, E.; Bayer, R.K.; Zachmann, H.G.; Baltá Calleja, F.J.; Meins, W. Properties of elongational flow injection-molded polyethylene part 2: Influence of processing parameters. Polym. Eng. Sci. 1989, 29, 193–201. [Google Scholar] [CrossRef]

- Tadmor, Z. Molecular orientation in injection molding. J. Appl. Polym. Sci. 1974, 18, 1753–1772. [Google Scholar] [CrossRef]

- Pandey, V.; Chen, H.; Ma, J.; Maia, J.M. Extension-dominated improved dispersive mixing in single-screw extrusion. Part 2: Comparative analysis with twin-screw extruder. J. Appl. Polym. Sci. 2021, 138, 49765. [Google Scholar] [CrossRef]

- Chen, H.; Pandey, V.; Carson, S.; Maia, J.M. Enhanced dispersive mixing in twin-screw extrusion via extension-dominated static mixing elements of varying contraction ratios. Int. Polym. Process. 2020, 35, 37–49. [Google Scholar] [CrossRef]

- Yuan, Z.; Chen, X.; Yu, D. Recent advances in elongational flow dominated polymer processing technologies. Polymers 2021, 13, 1792. [Google Scholar] [CrossRef] [PubMed]

- Bourry, D.; Godbille, F.; Khayat, R.E.; Luciani, A.; Picot, J.; Utracki, L.A. Extensional flow of polymeric dispersions. Polym. Eng. Sci. 1999, 39, 1072–1086. [Google Scholar] [CrossRef]

- Tokihisa, M.; Yakemoto, K.; Sakai, T.; Utracki, L.A.; Sepehr, M.; Li, J.; Simard, Y. Extensional flow mixer for polymer nanocomposites. Polym. Eng. Sci. 2006, 46, 1040–1050. [Google Scholar] [CrossRef]

- Utracki, L.A.; Luciani, A.; Bourry, D.J.J. Extensional Flow Mixer. Canada Patent No. 2 304 668, 30 March 2004. [Google Scholar]

- Nazari, B.; Nazockdast, H.; Katbab, A.A. The role of flow-induced microstructure in rheological behavior and nonisothermal crystallization kinetics of polyethylene/organoclay nanocomposites. Polym. Eng. Sci. 2014, 54, 1839–1847. [Google Scholar] [CrossRef]

- White, J.L.; Ide, Y. Instabilities and failure in elongational flow and melt spinning of fibers. J. Appl. Polym. Sci. 1978, 22, 3057–3074. [Google Scholar] [CrossRef]

- Macosko, C.W. Rheology Principles, Measurements, and Applications; Wiley-VCH: New York, NY, USA, 1994. [Google Scholar]

- Petrie, C.J.S. Extensional viscosity: A critical discussion. J. Non Newtonian Fluid Mech. 2006, 137, 15–23. [Google Scholar] [CrossRef] [Green Version]

- Münstedt, H. Dependence of the elongational behavior of polystyrene melts on molecular weight and molecular weight distribution. J. Rheol. 1980, 24, 847–867. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Piccarolo, S.; Valenza, A.; Acierno, D. Constant stretching rate experiments on low density polyethylene. Polym. Bull. 1985, 13, 271–276. [Google Scholar] [CrossRef]

- Yaoita, T.; Isaki, T.; Masubuchi, Y.; Watanabe, H.; Ianniruberto, G.; Marrucci, G. Primitive chain network simulation of elongational flows of entangled linear chains: Stretch/orientation-induced reduction of monomeric friction. Macromolecules 2012, 45, 2773–2782. [Google Scholar] [CrossRef]

- Koyama, K.; Ishizuka, O. Birefringence of polyethylene melt in transient elongational flow at constant strain rate. J. Polym. Sci. Part B Polym. Phys. 1989, 27, 297–306. [Google Scholar] [CrossRef]

- Ward, I.M. Mechanical properties of oriented polymers. Polymer 1974, 15, 286–379. [Google Scholar] [CrossRef]

- Li, L.; Masuda, T. Elongational flow behavior of ABS polymer melts. J. Rheol. 1990, 34, 103–116. [Google Scholar] [CrossRef]

- Battisti, M.; Perko, L.; Arunachalam, S.; Stieger, S.; Friesenbichler, W. Influence of elongational flow generating nozzles on material properties of polypropylene nanocomposites. Polym. Eng. Sci. 2018, 58, 3–12. [Google Scholar] [CrossRef]

- Okamoto, M.; Kubo, H.; Kotaka, T. Elongational flow-induced crystallization and structure development in supercooled poly (ethylene naphthalate). Macromolecules 1998, 31, 4223–4231. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Biopolymer blends based on poly (lactic acid): Shear and elongation rheology/structure/blowing process relationships. Polymers 2015, 7, 939–962. [Google Scholar] [CrossRef]

- Oosterlinck, F.; Mours, M.; Laun, H.M.; Moldenaers, P. Morphology development of a polystyrene/polymethylmethacrylate blend during startup of uniaxial elongational flow. J. Rheol. 2005, 49, 897–918. [Google Scholar] [CrossRef]

- Stary, Z. Morphology development in polymer blends under uniaxial elongation. AIP Conf. Proc. 2009, 1152, 228. [Google Scholar]

- Park, J.H.; Joo, Y.L. Tailoring nanorod alignment in a polymer matrix by elongational flow under confinement: Simulation, experiments, and surface enhanced Raman scattering application. Soft Matter 2014, 10, 3494–3505. [Google Scholar] [CrossRef] [PubMed]

- Dintcheva, N.T.; Arrigo, R.; Nasillo, G.; Caponetti, E.; La Mantia, F.P. On the role of extensional flow in morphology and property modifications of MWCNT/polyamide-based fibers. Macromol. Mater. Eng. 2011, 296, 645–657. [Google Scholar] [CrossRef]

- Eriksson, M.; Goossens, H.; Peijs, T. Influence of the solidification process on the mechanical properties of solid-state drawn pcl/sepiolite nanocomposite tapes. Fibers 2020, 8, 70. [Google Scholar] [CrossRef]

- Yang, S.; Luo, C.; Lin, H.; Xu, P.P.; Xu, L.; Lei, J.; Zhong, G.J.; Li, Z.M. Robust propylene-ethylene copolymer/polypropylene films: Extensional stress-induced orientation realized at low temperature processing. Polymer 2020, 206, 122848. [Google Scholar] [CrossRef]

- Jia, S.; Qu, J.; Wu, C.; Liu, W.; Chen, R.; Zhai, S.; Huang, Z.; Chen, F. Novel dynamic elongational flow procedure for reinforcing strong, tough, thermally stable polypropylene/thermoplastic polyurethane blends. Langmuir 2013, 29, 13509–13517. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Fontana, P.; Morreale, M.; Mistretta, M.C. Orientation induced brittle-ductile transition in a polyethylene/polyamide 6 blend. Polym. Test. 2014, 36, 20–23. [Google Scholar] [CrossRef]

- Mistretta, M.C.; Morreale, M.; Botta, L.; Ceraulo, M.; Fontana, P.; La Mantia, F.P. “Compatibilization” through elongational flow processing of LDPE/PA6 blends. Materials 2018, 11, 2375. [Google Scholar] [CrossRef] [Green Version]

- Russo, P.; Acierno, D.; Marletta, G.; Li Destri, G. Tensile properties, thermal and morphological analysis of thermoplastic polyurethane films reinforced with multiwalled carbon nanotubes. Europ. Polym. J. 2013, 49, 3155–3164. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, S.Y.; Youn, J.R. Rheological behavior and theoretical modeling of uniaxial elongational flow properties of polypropylene/layered silicate nanocomposites. Polym. Compos. 2009, 30, 1426–1436. [Google Scholar] [CrossRef]

- Agassant, J.F.; Avenas, P.; Carreau, P.J.; Vergnes, B.; Vincent, M. Polymer Processing—Principles and Modeling, 2nd ed.; Hanser Publishers: Cincinnati, OH, USA, 2017. [Google Scholar]

- Morrison, F.A. Understanding Rheology; Oxford University Press: Cary, NC, USA, 2001. [Google Scholar]

- Marrucci, G. Limiting concepts in extensional flow. Polym. Eng. Sci. 1975, 15, 229–233. [Google Scholar] [CrossRef]

- Münstedt, H. Extensional rheology and processing of polymeric materials. Intern. Polym. Process. 2018, 33, 594–618. [Google Scholar] [CrossRef]

- Sarkar, D.; Gupta, M. Further investigation on the effect of elongational viscosity on entrance flow. J. Reinf. Plast. Compos. 2001, 20, 1473–1484. [Google Scholar] [CrossRef]

- Münstedt, H. Recoverable extensional flow of polymer melts and its relevance for processing. Polymers 2020, 12, 1512. [Google Scholar] [CrossRef]

- Münstedt, H.; Schwarzl, F.R. Deformation and Flow of Polymeric Materials; Springer: Heidelberg, Germany, 2014. [Google Scholar]

- Meissner, J.; Hostettler, A. A new elongational rheometer for polymer melts and other highly viscoelastic liquids. Rheol. Acta 1994, 33, 1–21. [Google Scholar] [CrossRef]

- Laun, H.M.; Münstedt, H. Comparison of the elongational behaviour of a polyethylene melt at constant stress and constant strain rate. Rheol. Acta 1976, 15, 517–524. [Google Scholar] [CrossRef]

- Wagner, M.H.; Rolon-Garrido, V.H. Constant force elongational flow of polymer melts: Experiment and modeling. J. Rheol. 2012, 56, 1279–1297. [Google Scholar] [CrossRef]

- Münstedt, H.; Stary, Z. Steady states in extensional flow of strain hardening polymer melts and the uncertainties of their determination. J. Rheol. 2013, 57, 1065–1077. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Arinstein, A.; Kulichikhin, V.G. Polymer extension flows and instabilities. Progr. Polym. Sci. 2014, 39, 959–978. [Google Scholar] [CrossRef]

- Meissner, J. Development of a universal extensional rheometer for the uniaxial extension of polymer melts. Trans. Soc. Rheol. 1972, 16, 405. [Google Scholar] [CrossRef]

- Chatraei, S.; Macosko, C.W. Lubricated squeezing flow: A new biaxial extensional rheometer. J. Rheol. 1981, 25, 433–443. [Google Scholar] [CrossRef]

- Hachmann, P.; Meissner, J. Rheometer for equibiaxial and planar elongations of polymer melts. J. Rheol. 2003, 47, 989–1010. [Google Scholar] [CrossRef]

- Meissner, J. Polymer melt elongation-methods, results, and recent developments. Polym. Eng. Sci. 1987, 27, 537–546. [Google Scholar] [CrossRef]

- Cogswell, F.N. Converging flow of polymer melts in extrusion dies. Polym. Eng. Sci. 1972, 12, 64–73. [Google Scholar] [CrossRef]

- Cogswell, F.N. Measuring the extensional rheology of polymer melts. Trans. Soc. Rheol. 1972, 16, 383–403. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Acierno, D.; Curto, D. Extensional flow of HDPE/LDPE blends. Rheol. Acta 1982, 21, 452–455. [Google Scholar] [CrossRef]

- Kwag, C.; Vlachopoulos, J. An assessment of cog swell’s method for measurement of extensional viscosity. Polym. Eng. Sci. 1991, 31, 1015–1021. [Google Scholar] [CrossRef]

- White, J.L.; Spruiell, J.E. The specification of orientation and its development in polymer processing. Polym. Eng. Sci. 1983, 23, 247–256. [Google Scholar] [CrossRef]

- Samon, J.M.; Schultz, J.M.; Hsiao, B.S. Structure development in the early stages of crystallization during melt spinning. Polymer 2002, 43, 1873–1875. [Google Scholar] [CrossRef]

- Doufas, A.K.; McHugh, A.J.; Miller, C. Simulation of melt spinning including flow-induced crystallization: Part I. Model development and predictions. J. Non Newtonian Fluid Mech. 2000, 92, 27–66. [Google Scholar] [CrossRef]

- Nakamura, K.; Watanabe, T.; Amano, T.; Katayama, K. Some aspects of nonisothermal crystallization of polymers. III. Crystallization during melt spinning. J. Appl. Polym. Sci. 1974, 18, 615–623. [Google Scholar]

- Wagner, M.H.; Bernnat, A.; Schulze, V. The rheology of the rheotens test. J. Rheol. 1998, 42, 917–928. [Google Scholar] [CrossRef]

- Härth, M.; Dörnhöfer, A. Film blowing of linear and long-chain branched poly(ethylene terephthalate). Polymers 2020, 12, 1605. [Google Scholar] [CrossRef]

- Wagner, M.H.; Collignon, B.; Verbeke, J. Rheotens-mastercurves and elongational viscosity of polymer melts. Rheol. Acta 1996, 25, 117–126. [Google Scholar] [CrossRef]

- Doufas, A.K. Analysis of the rheotens experiment with viscoelastic constitutive equations for probing extensional rheology of polymer melts. J. Rheol. 2006, 50, 749–769. [Google Scholar] [CrossRef]

- Wagner, M.H.; Schulze, V.; Gottfert, A. Rheotens-mastercurves and drawability of polymer melts. Polym. Eng. Sci. 1996, 36, 925–935. [Google Scholar] [CrossRef]

- Acierno, D.; Brancaccio, A.; Curto, D.; La Mantia, F.P.; Valenza, A. Molecular weight dependency of rheological characteristics of linear low density polyethylene. J. Rheol. 1985, 29, 323–334. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Valenza, A.; Acierno, D. Influence of the structure of linear density polyethylene on the rheological and mechanical properties of blends with low density polyethylene. Eur. Polym. J. 1986, 22, 647–652. [Google Scholar] [CrossRef]

- Gotsis, A.D.; Zeevenhoven, B.L.F.; Hogt, A.H. The effect of long chain branching on the processability of polypropylene in thermoforming. Polym. Eng. Sci. 2004, 44, 973–982. [Google Scholar] [CrossRef]

- Wolff, F.; Resch, J.A.; Kaschta, J.; Münstedt, H. Comparison of viscous and elastic properties of polyolefin melts in shear and elongation. Rheol. Acta 2010, 49, 95–103. [Google Scholar] [CrossRef]

- Münstedt, H.; Kurzbeck, S.; Egersdorfer, L. Influence of molecular structure on rheological properties of polyethylenes. Part II. Elongational behavior. Rheol. Acta 1998, 37, 21–29. [Google Scholar] [CrossRef]

- Minoshima, W.; White, J.L. A comparative experimental study of the isothermal shear and maximal elongational rheological properties of low density, high density, and linear low density polyethylenes. J. Non Newtonian Fluid Mech. 1986, 19, 251–274. [Google Scholar] [CrossRef]

- Münstedt, H.; Steffl, T.; Malmberg, A. Correlation between rheological behaviour in uniaxial elongation and film blowing properties of various polyethylenes. Rheol. Acta 2005, 45, 14–22. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Valenza, A.; Acierno, D. Elongational behavior of low density/linear low density polyethylenes. Polym. Eng. Sci. 1988, 28, 90–95. [Google Scholar] [CrossRef]

- Münstedt, H.; Laun, H.M. Elongational properties and molecular structure of polyethylene melts. Rheol. Acta 1981, 20, 211–221. [Google Scholar] [CrossRef]

- Stadler, F.J.; Kaschta, J.; Münstedt, H.; Becker, F.; Buback, M. Influence of molar mass distribution and long-chain branching on strain hardening of low density polyethylene. Rheol. Acta 2009, 48, 479–490. [Google Scholar] [CrossRef]

- Stange, J.; Münstedt, H. Effect of long-chain branching on the foaming of polypropylene with azodicarbonamide. J. Cell. Plast. 2006, 42, 445–467. [Google Scholar] [CrossRef] [Green Version]

- Lau, H.C.; Bhattacharya, S.N.; Field, G.J. Melt strength of polypropylene: Its relevance to thermoforming. Polym. Eng. Sci. 1998, 38, 1915–1923. [Google Scholar] [CrossRef]

- Cao, K.; Li, Y.; Lu, Z.Q.; Wu, S.L.; Chen, Z.H.; Yao, Z.; Huang, Z.M. Preparation and characterization of high melt strength polypropylene with long chain branched structure by the reactive extrusion process. J. Appl. Polym. Sci. 2011, 121, 3384–3392. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Valenza, A.; Scargiali, F. Nonisothermal elongational behavior of blends with liquid crystalline polymers. Polym. Eng. Sci. 1994, 34, 799–803. [Google Scholar] [CrossRef]

- Ho, K.; Kale, L.; Montgomery, S. Melt strength of linear low-density polyethylene/low-density polyethylene blends. J. Appl. Poly. Sci. 2002, 85, 1408–1418. [Google Scholar] [CrossRef]

- Fisher, R.J.; Denn, M.M. Mechanics of nonisothermal polymer melt spinning. AIChE J. 1977, 23, 23–27. [Google Scholar] [CrossRef]

- Denn, M.M. Fibre Spinning. Computational Analysis of Polymer Processing; Pearson, J.R.A., Richardson, S.M., Eds.; Springer: Dordrecht, The Netherlands, 1983; pp. 179–216. [Google Scholar]

- Denn, M.M. Continuous drawing of liquids to form fibers. Annu. Rev. Fluid Mech. 1980, 12, 365–387. [Google Scholar] [CrossRef]

- Denn, M.M.; Marrucci, G. Effect of a relaxation time spectrum on mechanics of polymer melt spinning. J. Non Newtonian Fluid Mech. 1977, 2, 159–167. [Google Scholar] [CrossRef]

- Muke, S.; Ivanov, I.; Kao, N.; Bhattacharya, S.N. Extensional rheology of polypropylene melts from the Rheotens test. J. Non Newtonian Fluid Mech. 2001, 101, 77–93. [Google Scholar] [CrossRef]

- Liang, J.Z. Melt strength and drawability of HDPE, LDPE and HDPE/LDPE blends. Polym. Test. 2019, 73, 433–438. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Acierno, D. Influence of the molecular structure on the melt strength and extensibility of polyethylenes. Polym. Eng. Sci. 1985, 25, 279–283. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Gupta, R.K.; Jollands, M.; Bhattacharya, S.N. Foaming behavior of high-melt strength polypropylene/clay nanocomposites. Polym. Eng. Sci. 2009, 49, 2071–2084. [Google Scholar] [CrossRef]

- Wang, K.; Xu, M.; Choi, Y.; Chung, I.J. Effect of aspect ratio of clay on melt extensional process of maleated polyethylene/clay nanocomposites. Polym. Bull. 2001, 46, 499–505. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Dintcheva, N.T. Eva copolymer-based nanocomposites: Rheological behavior under shear and isothermal and non-isothermal elongational flow. Polym. Test. 2006, 25, 701–708. [Google Scholar] [CrossRef]

- Su, F.H.; Yan, J.H.; Huang, H.X. Structure and melt rheology of long-chain branching polypropylene/clay nanocomposites. J. Appl. Polym. Sci. 2010, 119, 1230–1232. [Google Scholar] [CrossRef]

- McInerney, L.F.; Kao, N.; Bhattacharya, S.N. Melt strength and extensibility of talc-filled polypropylene. Polym. Eng. Sci. 2003, 43, 1821–1829. [Google Scholar] [CrossRef]

- Rudolf, A.; Sfiligoj-Smole, M. Structure–properties relations of the drawn poly(ethylene terephthalate) filament sewing thread. J. Appl. Polym. Sci. 2008, 110, 2641–2648. [Google Scholar] [CrossRef]

- Doufas, A.K. A microstructural flow-induced crystallization model for film blowing: Validation with experimental data. Rheol. Acta 2014, 53, 269–293. [Google Scholar] [CrossRef]

- Nitta, K. On the orientation-induced crystallization of polymers. Polymers 2016, 8, 229. [Google Scholar] [CrossRef] [Green Version]

- Alcock, B.; Cabrera, N.O.; Barkoula, N.M.; Peijs, T. The effect of processing conditions on the mechanical properties and thermal stability of highly oriented PP tapes. Europ. Polym. J. 2009, 45, 2878–2894. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Bekheet, N.; El-Butch, A.; Abdel-Latif, L.; Nafee, D.; Barton, D.C. The effects of process parameters on the mechanical properties of die drawn polypropylene. Polym. Test. 2005, 24, 169–180. [Google Scholar] [CrossRef]

- Peterlin, A. Drawing and extrusion of semi-crystalline polymers. Coll. Polym. Sci. 1987, 265, 357–382. [Google Scholar] [CrossRef]

- Irvine, P.A.; Smith, P. Development of the axial Young’s modulus with draw ratio of flexible-chain polymers. Macromolecules 1986, 19, 240–242. [Google Scholar] [CrossRef]

- Taheri, H.; Nóbrega, J.M.; Samyn, P.; Covas, J.A. The effect of temperature and drawing ratio on the mechanical properties of polypropylene monofilaments. AIP Conf. Proc. 2014, 1593, 80–85. [Google Scholar]

- Foster, R.J.; Hine, P.J.; Ward, J.M. The effect of draw ratio on the mechanical properties and crystalline structure of single polymer polypropylene composites. Polymer 2016, 91, 156–161. [Google Scholar] [CrossRef] [Green Version]

- La Mantia, F.P.; D’Amico, R.; Acierno, D. Uniaxial hot stretching of polystyrene and mechanical properties of the oriented samples. Acta Polym. 1979, 30, 685–688. [Google Scholar] [CrossRef]

- Mai, F.; Tu, W.; Bilotti, E.; Peijs, T. The Influence of solid-state drawing on mechanical properties and hydrolytic degradation of melt-spun poly(Lactic Acid) (PLA) tapes. Fibers 2015, 3, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Troisi, E.M.; van Drongelen, M.; Caelers, H.J.M.; Portale, G.; Peters, G.W.M. Structure evolution during film blowing: An experimental study using in-situ small angle X-ray scattering. Europ. Polym. J. 2016, 74, 190–208. [Google Scholar] [CrossRef] [Green Version]

- Schimanski, T.; Peijs, T.; Lemstra, P.J.; Loos, J. Influence of postdrawing temperature on mechanical properties of melt-spun isotactic polypropylene. Macromolecules 2004, 37, 1810–1815. [Google Scholar] [CrossRef]

- He, Y.; Xu, W.H.; Zhang, H.; Qu, J.P. Constructing bone-mimicking high-performance structured poly(lactic acid) by an elongational flow field and facile annealing process. ACS Appl. Mater. Interfaces 2020, 12, 13411–13420. [Google Scholar] [CrossRef]

- Lu, J.; Sue, H.J.; Rieker, T.P. Dual crystalline texture in HDPE blown films and its implication on mechanical properties. Polymer 2001, 42, 4635–4646. [Google Scholar] [CrossRef]

- Fambri, L.; Dabrowska, I.; Ceccato, R.; Pegoretti, A. Effects of Fumed silica and draw ratio on nanocomposite polypropylene fibers. Polymers 2017, 9, 41. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gururajan, G.; Ogale, A.O. Real-time crystalline orientation measurements during low-density polyethylene blown film extrusion using wide-angle X-ray diffraction. Polym. Eng. Sci. 2012, 52, 1532–1536. [Google Scholar] [CrossRef]

- Gururajan, G.; Ogale, A.O. Molecular orientation evolution during low-density polyethylene blown film extrusion using real-time Raman spectroscopy. J. Raman Spectrosc. 2009, 40, 212–217. [Google Scholar] [CrossRef]

- Hadinata, C.; Boos, D.; Gabriel, C.; Wassner, E.; Rüllmann, M.; Kao, N.; Laun, M. Elongation-induced crystallization of a high molecular weight isotactic polybutene-1 melt compared to shear-induced crystallization. J. Rheol. 2007, 51, 195–215. [Google Scholar] [CrossRef]

- Spruiell, J.E.; White, J.L. Structure development during polymer processing: Studies of the melt spinning of polyethylene and polypropylene fibers. Polym. Eng. Sci. 1975, 15, 660–667. [Google Scholar] [CrossRef]

- Nadella, H.P.; Spruiell, J.E.; White, J.L. Drawing and annealing of polypropylene fibers: Structural changes and mechanical properties. J. Appl. Polym. Sci. 1978, 22, 3121–3133. [Google Scholar] [CrossRef]

- Di Maio, L.; Scarfato, P.; Incarnato, L.; Acierno, D. Biaxial orientation of polyamide films: Processability and properties. Macromol. Symp. 2002, 180, 1–8. [Google Scholar] [CrossRef]

- Kwack, T.H.; Han, C.D. Development of crystalline structure during tubular film blowing of low-density polyethylene. J. Appl. Polym. Sci. 1988, 35, 363–389. [Google Scholar] [CrossRef]

- Bafna, A.; Beaucage, G.; Mirabella, F.; Skillas, G.; Sukumaran, S. Optical properties and orientation in polyethylene blown films. J. Polym. Sci. Part B 2001, 39, 2923–2936. [Google Scholar] [CrossRef] [Green Version]

- Elmoumni, A.; Winter, H.H.; Waddon, A.J.; Fruitwala, H. Correlation of material and processing time scales with structure development in isotactic polypropylene crystallization. Macromolecules 2003, 36, 6453–6461. [Google Scholar] [CrossRef]

- van Drongelen, M.; Cavallo, D.; Balzano, L.; Portale, G.; Vittorias, I.; Bras, W.; Alfonso, G.C.; Peters, G.W.M. Structure development of low-density polyethylenes during film blowing: A real-time wide-angle X-ray diffraction study. Macromol. Mater. Eng. 2014, 299, 1494–1512. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Chen, W.; Zhao, H.; Ji, Y.; Meng, L.; Wang, D.; Li, L. In-situ tracking polymer crystallization during film blowing by synchrotron radiation X-ray scattering: The critical role of network. Polymer 2020, 198, 122492. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Turng, L.S.; Shen, C.Y. Morphological evolution and orientation development of stretched iPP films: Influence of draw ratio. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 1223–1234. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Wang, Y.; Shen, C.; Liu, C.; Wang, Z. Melt extension-induced shish-kebabs with heterogeneous spatial distribution of crystalline polymorphs in lightly crosslinked poly(lactic acid). Polymer 2020, 208, 122875. [Google Scholar] [CrossRef]

- Zhang, X.M.; Elkoun, S.; Ajji, A.; Huneault, M.A. Oriented structure and anisotropy properties of polymer blown films: HDPE, LLDPE and LDPE. Polymer 2004, 45, 217–229. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, Q.; Xia, Z.; Yang, E.; Zhang, M.; Wang, Y.; Ji, Y.; Chen, W.; Wang, D.; Meng, L.; et al. Elucidation of the relationships of structure-process-property for different ethylene/α-olefin copolymers during film blowing: An in-situ synchrotron radiation X-ray scattering study. Polym. Test. 2020, 85, 106439. [Google Scholar] [CrossRef]

- Čermák, R.; Obadal, M.; Habrová, V.; Stoklasa, K.; Verney, V.; Commereuc, S.; Fraïsse, F. Self-reinforcement of polymers as a consequence of elongational flow. Rheol. Acta 2006, 45, 366–373. [Google Scholar] [CrossRef]

- Furuhashi, Y.; Kimura, Y.; Yoshie, N.; Yamane, H. Higher-order structures and mechanical properties of stereocomplex-type poly(lactic acid) melt spun fibers. Polymer 2006, 47, 5965–5972. [Google Scholar] [CrossRef]

- Tanabe, Y.; Kanetsuma, H. Mechanism for thermal shrinkage of oriented polystyrene monofilaments. Polymer 1979, 20, 1121–1128. [Google Scholar] [CrossRef]

- Matsumoto, K.; Fellers, J.F.; White, J.L. Uniaxial and biaxial orientation development and mechanical properties of polystyrene films. J. Appl. Polym. Sci. 1981, 26, 85–96. [Google Scholar] [CrossRef]

- Zhang, X.; Ajji, A. Biaxial orientation behavior of polystyrene: Orientation and properties. J. Appl. Polym. Sci. 2003, 89, 487–496. [Google Scholar] [CrossRef]

- Zartman, G.D.; Cheng, S.; Li, X.; Lin, F.; Becker, M.L.; Wang, S.Q. How melt-stretching affects mechanical behavior of polymer glasses. Macromolecules 2012, 45, 6719–6732. [Google Scholar] [CrossRef]

- Yan, Q.; Xu, T.; Zhang, W.; Lv, C.; Guo, H.; Tian, F.; Chen, W.; Li, L. Abnormal brittle-ductile transition for glassy polymers after free and constrained melt stretching: The role of molecular alignment. Polymer 2021, 233, 124199. [Google Scholar] [CrossRef]

- Tanabe, Y.; Kanetsuna, H. Structure of oriented polystyrene monofilaments and its relationship to brittle-to-ductile transition. J. Appl. Polym. Sci. 1978, 22, 1619–1630. [Google Scholar] [CrossRef]

- Utracki, L.A. On the viscosity-concentration dependence of immiscible polymer blends. J. Rheol. 1991, 35, 1615–1637. [Google Scholar] [CrossRef]

- Pötschke, P.; Paul, D.R. Formation of co-continuous structures in melt mixed immiscible polymer blends. J. Macromol. Sci. Part C 2003, 43, 87–141. [Google Scholar] [CrossRef]

- Utracki, L.A.; Shi, Z.H. Development of polymer blend morphology during compounding in a twin-screw extruder. Part I: Droplet dispersion and coalescence—A review. Polym. Eng. Sci. 1992, 32, 1824–1833. [Google Scholar] [CrossRef]

- Carfagna, C.; Amendola, E.; Nicolais, L.; Acierno, D.; Francescangeli, O.; Yang, B.; Rustichelli, F. Blends of a polyetherimide and a liquid crystalline polymer: Fiber orientation and mechanical properties. J. Appl. Polym. Sci. 1991, 43, 839–844. [Google Scholar] [CrossRef]

- Janssen, J.M.H. Emulsions: The dynamics of liquid–liquid mixing. Part II. Structure development during processing. In Materials Science and Technology; Wiley-VCH Verlag GmbH & Co: Weinheim, Germany, 2006; pp. 113–188. [Google Scholar]

- Harrats, C.; Thomas, S.; Groeninckx, G. Micro- and Nanostructured Multiphase Polymer Blend Systems. Phase Morphology and Interfaces; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2006. [Google Scholar]

- Macosko, C.W. Morphology development and control in immiscible polymer blends. Macromol. Symp. 2000, 149, 171–184. [Google Scholar] [CrossRef]

- Gonzalez-Nunez, R.; Favis, B.D.; Cafweau, P.J.; Lavallée, C. Factors influencing the formation of elongated morphologies in immiscible polymer blends during melt processing. Polym. Eng. Sci. 1993, 33, 851–859. [Google Scholar] [CrossRef]

- Delaby, I.; Ernst, B.; Germain, Y.; Muller, R. Droplet deformation in polymer blends during uniaxial elongational flow: Influence of viscosity ratio for large capillary numbers. J. Rheol. 1994, 38, 1705–1720. [Google Scholar] [CrossRef]

- Grace, H.P. Dispersion phenomena in high viscosity immiscible fluid systems and application of static mixers as dispersion devices in such systems. Chem. Eng. Commun. 1982, 14, 225–277. [Google Scholar] [CrossRef]

- García-Masabet, V.; Santana Pérez, O.; Cailloux, J.; Abt, T.; Sánchez-Soto, M.; Carrasco, F.; Maspoch, M.L. PLA/PA bio-blends: Induced morphology by extrusion. Polymers 2020, 12, 10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heindl, M.; Sommer, M.K.; Münstedt, H. Morphology development in polystyrene/polyethylene blends during uniaxial elongational flow. Rheol. Acta 2004, 44, 55–70. [Google Scholar] [CrossRef]

- Kirchberger, A.; Münstedt, H. Droplet deformation under extensional flow in immiscible and partially miscible polymer blends based on poly(styrene-coacrylonitrile). J. Rheol. 2010, 54, 687–704. [Google Scholar] [CrossRef]

- Utracki, L.A.; Sammut, P. On the uniaxial elongational flow of PS/PE blends. Polym. Eng. Sci. 1990, 30, 1019–1026. [Google Scholar] [CrossRef]

- Lacroix, C.; Grmela, M.; Carreau, P.J. Morphological evolution of immiscible polymer blends in simple shear and elongational flows. J. Non Newtonian Fluid Mech. 1999, 86, 37–59. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, X.; Qu, J.P. Microstructure evolution and mechanism of PLA/PVDF hybrid dielectrics fabricated under elongational flow. Polymer 2021, 224, 123719. [Google Scholar] [CrossRef]

- Oosterlinck, F.; Vinckier, I.; Mours, M.; Laun, H.M.; Moldenaers, P. Morphology development of a PS/PMMA polymer blend during flow in dies. Rheol. Acta 2005, 44, 631–643. [Google Scholar] [CrossRef]

- Pan, D.; Chen, L.; He, H.; Deng, K.; Qin, Z. Deformation of dispersed polystyrene droplets in immiscible polypropylene/polystyrene blend fibers under uniaxial elongational flow. Fibers Polym. 2016, 17, 1343–1351. [Google Scholar] [CrossRef]

- Chapleau, N.; Favis, B.D. Droplet/fibre transitions in immiscible polymer blends generated during melt processing. J. Mater. Sci. 1995, 30, 142–150. [Google Scholar] [CrossRef]

- Delaby, I.; Ernst, B.; Muller, R. Drop deformation during elongational flow in blends of viscoelastic fluids. Small deformation theory and comparison with experimental results. Rheol. Acta 1995, 34, 525–533. [Google Scholar]

- Delaby, I.; Ernst, B.; Froelich, D.; Muller, R. Droplet deformation in immiscible polymer blends during transient uniaxial elongational flow. Polym. Eng. Sci. 1996, 36, 1627–1635. [Google Scholar] [CrossRef]

- Delaby, I.; Froelich, D.; Muller, R. Drop deformation in polymer blends during uniaxial elongational flow. Macromolec. Symp. 1995, 100, 131–135. [Google Scholar] [CrossRef]

- Delaby, I.; Ernst, B.; Muller, R. Drop deformation in polymer blends during elongational flow. J. Macromol. Sci. Part B 1996, 35, 547–561. [Google Scholar] [CrossRef]

- Gramespacher, H.; Meissner, J. Melt elongation and recovery of polymer blends: Morphology and influence of interfacial tension. J. Rheol. 1997, 41, 27–44. [Google Scholar] [CrossRef]

- Mechbal, N.; Bousmina, M. Uniaxial deformation and relaxation of polymer blends: Relationship between flow and morphology development. Rheol. Acta 2004, 43, 119–126. [Google Scholar] [CrossRef]

- Yu, W.; Bousmina, M.; Zhou, C.X.; Tucker, C.L. Theory for drop deformation in viscoelastic systems. J. Rheol. 2004, 48, 417–438. [Google Scholar] [CrossRef]

- Fortelny, I.; Zivny, A. Extensional flow induced coalescence in polymer blends. Rheol. Acta 2003, 42, 454–461. [Google Scholar] [CrossRef]

- Yang, J.; White, J.L.; Jiang, Q. Phase morphology development in a low interfacial tension immiscible polyolefin blend during die extrusion and melt spinning. Polym. Eng. Sci. 2010, 50, 1969–1977. [Google Scholar] [CrossRef]

- Chen, L.; Pan, D.; He, H. Morphology development of polymer blend fibers along spinning line. Fibers 2019, 7, 35. [Google Scholar] [CrossRef] [Green Version]

- He, H.; Chen, L.; Zhang, Y.; Hong, S.; Zhou, Y.; Zhu, M. Studies on melt spinning of sea-island fibers. I. morphology evolution of polypropylene/polystyrene blend fibers. Fibers Polym. 2014, 15, 1941–1949. [Google Scholar] [CrossRef]

- Cakmak, M.; Teitge, A.; Zachmann, H.G.; White, J.L. On-line small-angle and wide-angle X-ray scattering studies on melt-spinning poly(vinylidene fluoride) tape using synchrotron radiation. J. Polym. Sci. Part B Polym. Phys. 1993, 31, 371–381. [Google Scholar] [CrossRef]

- Dees, J.R.; Spruiell, J.E. Structure development during melt spinning of linear polyethylene fibers. J. Appl. Polym. Sci. 1974, 18, 1053–1078. [Google Scholar] [CrossRef]

- Liang, B.; Pan, L.; He, X. Structure and properties of blend fibers from poly(ethylene terephthalate) and liquid crystalline polymer. J. Appl. Polym. Sci. 1997, 66, 217–224. [Google Scholar] [CrossRef]

- Dae Han, C.; Lamonte, R.R. Studies on melt spinning. I. Effect of molecular structure and molecular weight distribution on elongational viscosity. Trans. Soc. Rheol. 1972, 16, 447–472. [Google Scholar]

- Tran, N.H.A.; Brünig, H.; Boldt, R.; Heinrich, G. Morphology development from rod-like to nanofibrillar structures of dispersed poly (lactic acid) phase in a binary blend with poly (vinyl alcohol) matrix along the spinline. Polymer 2014, 55, 6354–6363. [Google Scholar] [CrossRef]

- Lu, J.; Sue, H.J. Morphology and mechanical properties of blown films of a low-density polyethylene/linear low-density polyethylene blend. J. Polym. Sci. Part B Polym. Phys. 2002, 40, 507–518. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Saiu, L.M.; Valenza, A.; Paci, L.M.; Magagnini, P.L. Relationships between mechanical properties and structure for blends of nylon-6 with a liquid crystal polymer. Eur. Polym. J. 1990, 26, 323–327. [Google Scholar] [CrossRef]

- López-Barrón, C.R.; Robledo-Ortiz, J.R.; Rodrigue, D.; González-Núñez, R. Film Processability, morphology, and properties of polyamide-6/low density polyethylene blends. J. Plast. Film Sheeting 2007, 23, 149–169. [Google Scholar] [CrossRef]

- Morawiec, J.; Krasnikova, N.P.; Galeski, A.; Pracella, M. Oriented films from recycled poly(ethylene terephthalate)/recycled high-density polyethylene compatibilized blends. J. Appl. Polym. Sci. 2002, 86, 1486–1496. [Google Scholar] [CrossRef]

- Li, Z.M.; Yang, M.B.; Xie, B.H.; Feng, J.M.; Huang, R. In-situ microfiber reinforced composite based on PET and PE via slit die extrusion and hot stretching: Influences of hot stretching ratio on morphology and tensile properties at a fixed composition. Polym. Eng. Sci. 2003, 43, 615–628. [Google Scholar] [CrossRef]

- Dadouche, T.; Yousfi, M.; Samuel, C.; Lacrampe, M.F.; Soulestin, J. (Nano)Fibrillar morphology development in biobased poly(butylene succinate-co-adipate)/poly(amide-11) blown films. Polym. Eng. Sci. 2021, 61, 1324–1337. [Google Scholar] [CrossRef]

- Li, Z.M.; Yang, M.B.; Feng, J.M.; Yang, W.; Huang, R. Morphology of in situ poly(ethylene terephthalate)/polyethylene microfiber reinforced composite formed via slit-die extrusion and hot-stretching. Mater. Res. Bull. 2002, 37, 2185–2197. [Google Scholar] [CrossRef]

- Xie, L.; Xu, H.; Niu, B.; Ji, X.; Chen, J.; Li, Z.M.; Hsiao, B.S.; Zhong, G.J. Unprecedented access to strong and ductile poly(lactic acid) by introducing in situ nanofibrillar poly(butylene succinate) for green packaging. Biomacromolecules 2014, 15, 4054–4064. [Google Scholar] [CrossRef]

- Anstey, A.; Chang, E.; Kim, E.S.; Rizvi, A.; Kakroodi, A.R.; Park, C.B.; Lee, P.C. Nanofibrillated polymer systems: Design, application, and current state of the art. Progr. Polym. Sci. 2021, 113, 101346. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Kazemi, Y.; Ding, W.; Ameli, A.; Park, C.B. Poly(lactic acid)-based in situ microfibrillar composites with enhanced crystallization kinetics, mechanical properties, rheological behavior, and foaming ability. Biomacromolecules 2015, 16, 3925–3935. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Kazemi, Y.; Nofar, M.; Park, C.B. Tailoring poly(lactic acid) for packaging applications via the production of fully bio-based in situ microfibrillar composite films. Chem. Eng. J. 2017, 308, 772–782. [Google Scholar] [CrossRef]

- Yousfi, M.; Dadouche, T.; Chomat, D.; Samuel, C.; Soulestin, J.; Lacrampe, M.F.; Krawczak, P. Development of nanofibrillar morphologies in poly(L-lactide)/poly(amide) blends: Role of the matrix elasticity and identification of the critical shear rate for the nodular/fibrillar transition. RSC Adv. 2018, 8, 22023. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.T.; Yang, J.X.; Fan, J.H.; Feng, Y.H.; Huang, Z.X. Preparation of super-toughened Poly(L-lactide) composites under elongational flow: A strategy for balancing stiffness and ductility. Compos. Sci. Technol. 2021, 208, 108758. [Google Scholar] [CrossRef]

- Jašo, V.; Rodić, M.V.; Petrović, Z.S. Biocompatible fibers from thermoplastic polyurethane reinforced with polylactic acid microfibers. Europ. Polym. J. 2015, 63, 20–28. [Google Scholar] [CrossRef]

- Wu, T.; He, Y.; Qu, J.P. Effect of continuous elongational flow on structure and properties of poly(l-lactic acid)/poly(ethylene glycol) blend and its organo-modified montmorillonite nanocomposites. Polym. Compos. 2019, 40, E617–E628. [Google Scholar] [CrossRef]

- Shah, R.K.; Krishnaswamy, R.K.; Takahashi, S.; Paul, D.R. Blown films of nanocomposites prepared from low density polyethylene and a sodium ionomer of poly(ethylene-co-methacrylic acid). Polymer 2006, 47, 6187–6201. [Google Scholar] [CrossRef]

- Marini, J.; Branciforti, M.C.; Vercelino Alves, R.M.; Bretas, R.E.S. Effect of EVA as compatibilizer on the mechanical properties, permeability characteristics, lamellae orientation, and long period of blown films of HDPE/Clay nanocomposites. J. Appl. Polym. Sci. 2010, 118, 2240–3350. [Google Scholar] [CrossRef]

- Gao, W.; Dong, H.; Hou, H.; Zhang, H. Effects of clays with various hydrophilicities on properties of starch–clay nanocomposites by film blowing. Carbohydr. Polym. 2012, 88, 321–328. [Google Scholar] [CrossRef]

- Botta, L.; La Mantia, F.P.; Mistretta, M.C.; Oliveri, A.; Arrigo, R.; Malucelli, G. Structure–Property Relationships in Bionanocomposites for Pipe Extrusion Applications. Polymers 2021, 13, 782. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Huang, Z.; Wang, D.; Qu, J. Effect of continuous elongational flow on structure and properties of short glass fiber reinforced polyamide 6 composites. Adv. Ind. Eng. Polym. Res. 2019, 2, 93–101. [Google Scholar] [CrossRef]

- Hendrix, J.W.; Szeto, R.; Nosker, T.; Lynch-Branzoi, J.; Emge, T.J. Evaluation of exfoliated graphite to graphene in polyamide 66 using novel high shear elongational flow. Polymers 2018, 10, 1399. [Google Scholar] [CrossRef] [Green Version]

- Oxfall, H.; Rondin, J.; Bouquey, M.; Muller, R.; Rigdahl, M.; Rychwalski, R.W. Elongational flow mixing for manufacturing of graphite nanoplatelet/polystyrene composites. J. Appl. Polym. Sci. 2013, 128, 2679–2686. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Ceraulo, M.; Mistretta, M.C.; Botta, L. Effect of the elongational flow on morphology and properties of polypropylene/graphene nanoplatelets nanocomposites. Polym. Test. 2018, 71, 10–17. [Google Scholar] [CrossRef]

- Ibarra-Gomez, R.; Muller, R.; Bouquey, M.; Rondin, J.; Serra, C.A.; Hassouna, F.; El Mouedden, Y.; Toniazzo, V.; Ruch, D. Processing of nanocomposites PLA/graphite using a novel elongational mixing device. Polym. Eng. Sci. 2015, 55, 214–222. [Google Scholar] [CrossRef]

- Singh, V.P.; Vimal, K.K.; Kapur, G.S.; Sharma, S.; Choudhary, V. High-density polyethylene/halloysite nanocomposites: Morphology and rheological behaviour under extensional and shear flow. J. Polym. Res. 2016, 23, 43. [Google Scholar] [CrossRef]

- Kutlu, B.; Meinl, J.; Leuteritz, A.; Brünig, H.; Heinrich, G. Melt-spinning of LDH/HDPE nanocomposites. Polymer 2013, 54, 5712–5718. [Google Scholar] [CrossRef]

- Kutlu, B.; Meinl, J.; Leuteritz, A.; Brunig, A.; Wiebner, S.; Heinrich, G. Up-scaling of melt-spun LDH/HDPE nanocomposites. Macromol. Mater. Eng. 2014, 299, 825–833. [Google Scholar] [CrossRef]

- Chen, S.; Schueneman, G.; Pipes, B.; Youngblood, J.; Moon, R.J. Effects of crystal orientation on cellulose nanocrystals−cellulose acetate nanocomposite fibers prepared by dry spinning. Biomacromolecules 2014, 15, 3827–3835. [Google Scholar] [CrossRef]

- Feng, Y.; Yuan, Z.; Sun, H.; He, H.; Zhang, G. Toughening and reinforcing wood flour/polypropylene composites with high molecular weight polyethylene under elongation flow. Compos. Sci. Technol. 2020, 200, 108395. [Google Scholar] [CrossRef]

- Nilsson, E.; Oxfall, H.; Wandelt, W.; Rychwalski, R.; Hagstrom, B. Melt spinning of conductive textile fibers with hybridized graphite nanoplatelets and carbon black filler. J. Appl. Polym. Sci. 2013, 130, 2579–2587. [Google Scholar] [CrossRef]

- Handge, U.A.; Pötschke, P. Deformation and orientation during shear and elongation of a polycarbonate/carbon nanotubes composite in the melt. Rheol. Acta 2007, 46, 889–898. [Google Scholar] [CrossRef] [Green Version]

- Duc, B.N.; Son, Y. Enhanced dispersion of multi walled carbon nanotubes by an extensional batch mixer in polymer/MWCNT nanocomposites. Compos. Comm. 2020, 21, 100420. [Google Scholar] [CrossRef]

- Abbasi, S.; Carreau, P.J.; Derdouri, A. Flow induced orientation of multiwalled carbon nanotubes in polycarbonate nanocomposites: Rheology, conductivity and mechanical properties. Polymer 2010, 51, 922–935. [Google Scholar] [CrossRef] [Green Version]

- de Goes, M.A.; Woicichowski, L.A.; da Rosa, R.V.V.; Santos, J.P.F.; Carvalho, B.M. Improving the dispersion of MWCNT and MMT in PVDF melts employing controlled extensional flows. J. Appl. Polym. Sci. 2021, 138, 50274. [Google Scholar] [CrossRef]

- Che, J.; Jing, M.; Liu, D.; Wang, K.; Fu, Q. Largely enhanced thermal conductivity of HDPE/boron nitride/carbon nanotubes ternary composites via filler network-network synergy and orientation. Compos. Part A 2018, 112, 32–39. [Google Scholar] [CrossRef]

- Dintcheva, N.T.; Arrigo, R.; Nasillo, G.; Caponetti, E.; La Mantia, F.P. Effect of the Nanotube Aspect Ratio and Surface Functionalization on the Morphology and Properties of Multiwalled Carbon Nanotube Polyamide-Based Fibers. J. Appl. Polym. Sci. 2013, 129, 2479–2489. [Google Scholar] [CrossRef]

- Vad, T.; Wulfhorst, J.; Pan, T.T.; Steinmann, W.; Dabringhaus, S.; Beckers, M.; Seide, G.; Gries, T.; Sager, W.F.C.; Heidelmann, M.; et al. Orientation of well-dispersed multiwalled carbon nanotubes in melt-spun polymer fibers and its impact on the formation of the semicrystalline polymer structure: A combined wide-angle X-ray scattering and electron tomography study. Macromolecules 2013, 46, 5604–5613. [Google Scholar] [CrossRef]

- Russo, P.; Lavorgna, M.; Piscitelli, F.; Acierno, D.; Di Maio, L. Thermoplastic polyurethane films reinforced with carbon nanotubes: The effect of processing on the structure and mechanical properties. Europ. Polym. J. 2013, 49, 379–388. [Google Scholar] [CrossRef]

- Haggenmueller, R.; Gommans, H.H.; Rinzler, A.G.; Fischer, J.E.; Winey, K.I. Aligned single-wall carbon nanotubes in composites by melt processing methods. Chem. Phys. Lett. 2000, 330, 219–225. [Google Scholar] [CrossRef]

- Hou, Z.; Wang, K.; Zhao, P.; Zhang, Q.; Yang, C.; Chen, D.; Du, R.; Fu, Q. Structural orientation and tensile behavior in the extrusion-stretched sheets of polypropylene/multi-walled carbon nanotubes’ composite. Polymer 2008, 49, 3582–3589. [Google Scholar] [CrossRef]

- Sulong, A.B.; Park, J.; Azhari, C.H.; Jusoff, K. Process optimization of melt spinning and mechanical strength enhancement of functionalized multi-walled carbon nanotubes reinforcing polyethylene fibers. Compos. Part B 2011, 42, 11–17. [Google Scholar] [CrossRef]

- Arras, M.M.L.; Schillai, C.; Keller, T.F.; Schulze, R.; Jandt, K.D. Alignment of multi-wall carbon nanotubes by disentanglement in ultra-thin melt-drawn polymer films. Carbon 2013, 60, 366–378. [Google Scholar] [CrossRef]

- Li, C.; Guo, J.; Jiang, T.; Zhang, X.; Xia, L.; Wu, H.; Guo, S.; Zhang, X. Extensional flow-induced hybrid crystalline fibrils (shish) in CNT/PLA nanocomposite. Carbon 2018, 129, 720–729. [Google Scholar] [CrossRef]

- Liu, Y.; Kumar, S. Polymer/carbon nanotube nano composite fibers−a review. ACS Appl. Mater. Interfaces 2014, 6, 6069–6087. [Google Scholar] [CrossRef] [PubMed]

- Bautista-Quijano, J.R.; Pötschke, P.; Brünig, H.; Heinrich, G. Strain sensing, electrical and mechanical properties of polycarbonate/multiwall carbon nanotube monofilament fibers fabricated by melt spinning. Polymer 2016, 82, 181–189. [Google Scholar] [CrossRef]

- Pötschke, P.; Brunig, H.; Janke, A.; Fischer, D.; Jehnichen, D. Orientation of multiwalled carbon nanotubes in composites with polycarbonate by melt spinning. Polymer 2005, 46, 10355–10363. [Google Scholar] [CrossRef]

- Litchfield, D.W.; Baird, D.G. The role of nanoclay in the generation of poly(ethylene terephthalate) fibers with improved modulus and tenacity. Polymer 2008, 49, 5027–5036. [Google Scholar] [CrossRef]

- Okamoto, M.; Nam, P.H.; Maiti, P.; Kotaka, T.; Hasegawa, N.; Usuki, A. A house of cards structure in polypropylene/clay nanocomposites under elongational flow. Nano Lett. 2001, 6, 295–298. [Google Scholar] [CrossRef]

- Pasanovic-Zujo, V.; Gupta, R.K.; Bhattacharya, S.N. Effect of vinyl acetate content and silicate loading on EVA nanocomposites under shear and extensional flow. Rheol. Acta 2004, 43, 99–108. [Google Scholar] [CrossRef]

- Gupta, R.K.; Pasanovic-Zujo, V.; Bhattacharya, S.N. Shear and extensional rheology of EVA/layered silicate-nanocomposites. J. Non Newtonian Fluid Mech. 2005, 128, 116–125. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Dintcheva, N.T.; Scaffaro, R.; Marino, R. Morphology and properties of polyethylene/clay nanocomposite drawn fibers. Macomol. Mater. Eng. 2008, 14, 83–91. [Google Scholar] [CrossRef]

- Bafna, A.; Beaucage, G.; Mirabella, F.; Meht, S. 3D Hierarchical orientation in polymer–clay nanocomposite films. Polymer 2003, 44, 1103–1115. [Google Scholar] [CrossRef]

- Golebiewski, J.; Rozanski, A.; Dzwonkowski, J.; Galeski, A. Low density polyethylene–montmorillonite nanocomposites for film blowing. Europ. Polym. J. 2008, 44, 270–286. [Google Scholar] [CrossRef]

- Huang, Z.X.; Meng, C.; Zhang, G.; Qu, J.P. Manufacturing polymer/clay nanocomposites through elongational flow technique, Mater. Manuf. Process. 2017, 32, 1409–1415. [Google Scholar] [CrossRef]

- Murima, D.; Pfukwa, H.; Tiggelman, I.; Hartmann, P.C.; Pasch, H. Novel Polymer Clay-Based Nanocomposites: Films with remarkable optical and water vapor barrier properties. Macromol. Mater. Eng. 2016, 301, 836–845. [Google Scholar] [CrossRef]

- Xu, B.; Leisen, J.; Beckham, H.W.; Abu-Zurayk, R.; Harkin-Jones, E.; McNally, T. Evolution of clay morphology in polypropylene/montmorillonite nanocomposites upon equibiaxial stretching: A solid-state nmr and tem approach. Macromolecules 2009, 42, 8959–8968. [Google Scholar] [CrossRef]

- Coppola, B.; Scarfato, P.; Incarnato, L.; Di Maio, L. Morphology development and mechanical properties variation during cold-drawing of polyethylene-clay nanocomposite fibers. Polymers 2017, 9, 235. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garofalo, E.; Russo, G.M.; Scarfato, P.; Incarnato, L. Nanostructural modifications of polyamide/MMT hybrids under isothermal and nonisothermal elongational flow. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 981–993. [Google Scholar] [CrossRef]

- Tong, Y.; Huang, Q.; He, G.; Cao, X.; Yang, Z.; Yin, X. Phase transformation and dielectric properties of polyvinylidene fluoride/organic-montmorillonite nanocomposites fabricated under elongational flow field. J. Appl. Polym. Sci. 2021, 138, 50409. [Google Scholar] [CrossRef]

- Ren, W.; Jayaraman, K. Blown films with balanced in-plane properties from polypropylene-clay nanocomposites though silane coupling. J. Plast. Film Sheeting 2021, 37, 93–110. [Google Scholar] [CrossRef]

- Min, K.; Kim, M.; Choi, K.Y.; Lee, J.H.; Lee, S.G. Effect of layered silicates on the crystallinity and mechanical properties of HDPE/MMT nanocomposite blown films. Polym. Bull. 2006, 57, 101–108. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Marino, R.; Dintcheva, N.T. Morphology modification of polyethylene/clay nanocomposite samples under convergent flow. Macromol. Mater. Eng. 2009, 294, 575–581. [Google Scholar] [CrossRef]

- Garofalo, E.; Fariello, M.L.; Di Maio, L.; Incarnato, L. Effect of biaxial drawing on morphology and properties of copolyimide nanocomposites produced by film blowing. Europ. Polym. J. 2013, 49, 80–89. [Google Scholar] [CrossRef]

- Pavliková, S.; Thomann, R.; Reichert, P.; Mülhaupt, R.; Marcinčin, A.; Borsig, E. Fiber spinning from poly(propylene)–organoclay nanocomposite. J. Appl. Polym. Sci. 2003, 89, 604–611. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Ceraulo, M.; Mistretta, M.C.; Sutera, F.; Ascione, L.; Nasillo, G. Effect of elongational flow and polarity of organomodified clay on morphology and mechanical properties of a PLA based nanobiocomposite. Int. Polym. Process. 2016, 5, 541–547. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arrigo, R.; Malucelli, G.; Mantia, F.P.L. Effect of the Elongational Flow on the Morphology and Properties of Polymer Systems: A Brief Review. Polymers 2021, 13, 3529. https://doi.org/10.3390/polym13203529

Arrigo R, Malucelli G, Mantia FPL. Effect of the Elongational Flow on the Morphology and Properties of Polymer Systems: A Brief Review. Polymers. 2021; 13(20):3529. https://doi.org/10.3390/polym13203529

Chicago/Turabian StyleArrigo, Rossella, Giulio Malucelli, and Francesco Paolo La Mantia. 2021. "Effect of the Elongational Flow on the Morphology and Properties of Polymer Systems: A Brief Review" Polymers 13, no. 20: 3529. https://doi.org/10.3390/polym13203529

APA StyleArrigo, R., Malucelli, G., & Mantia, F. P. L. (2021). Effect of the Elongational Flow on the Morphology and Properties of Polymer Systems: A Brief Review. Polymers, 13(20), 3529. https://doi.org/10.3390/polym13203529