Organic Dye-Doped PMMA Lasing

Abstract

:1. Introduction

2. Results

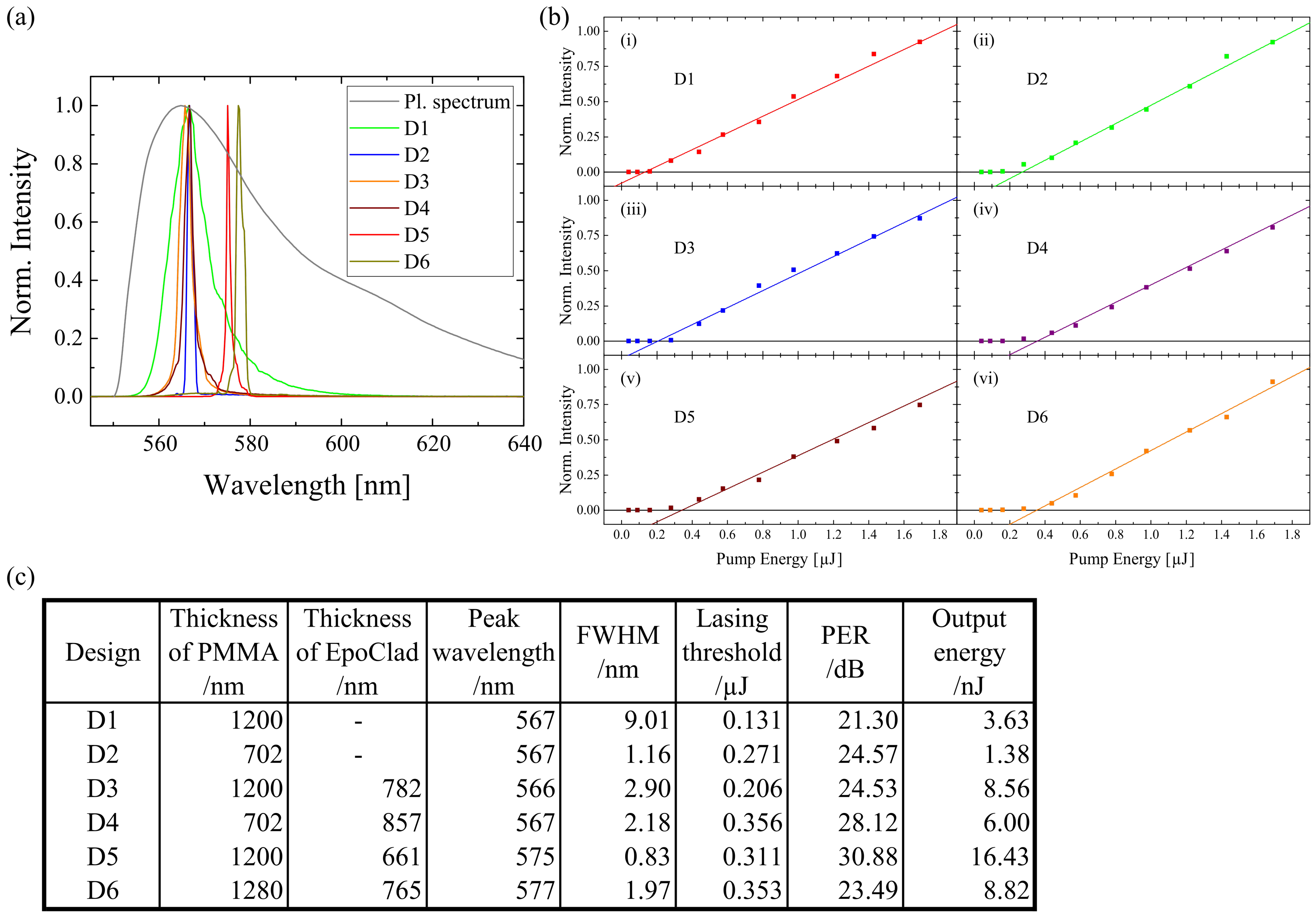

2.1. Design Variation

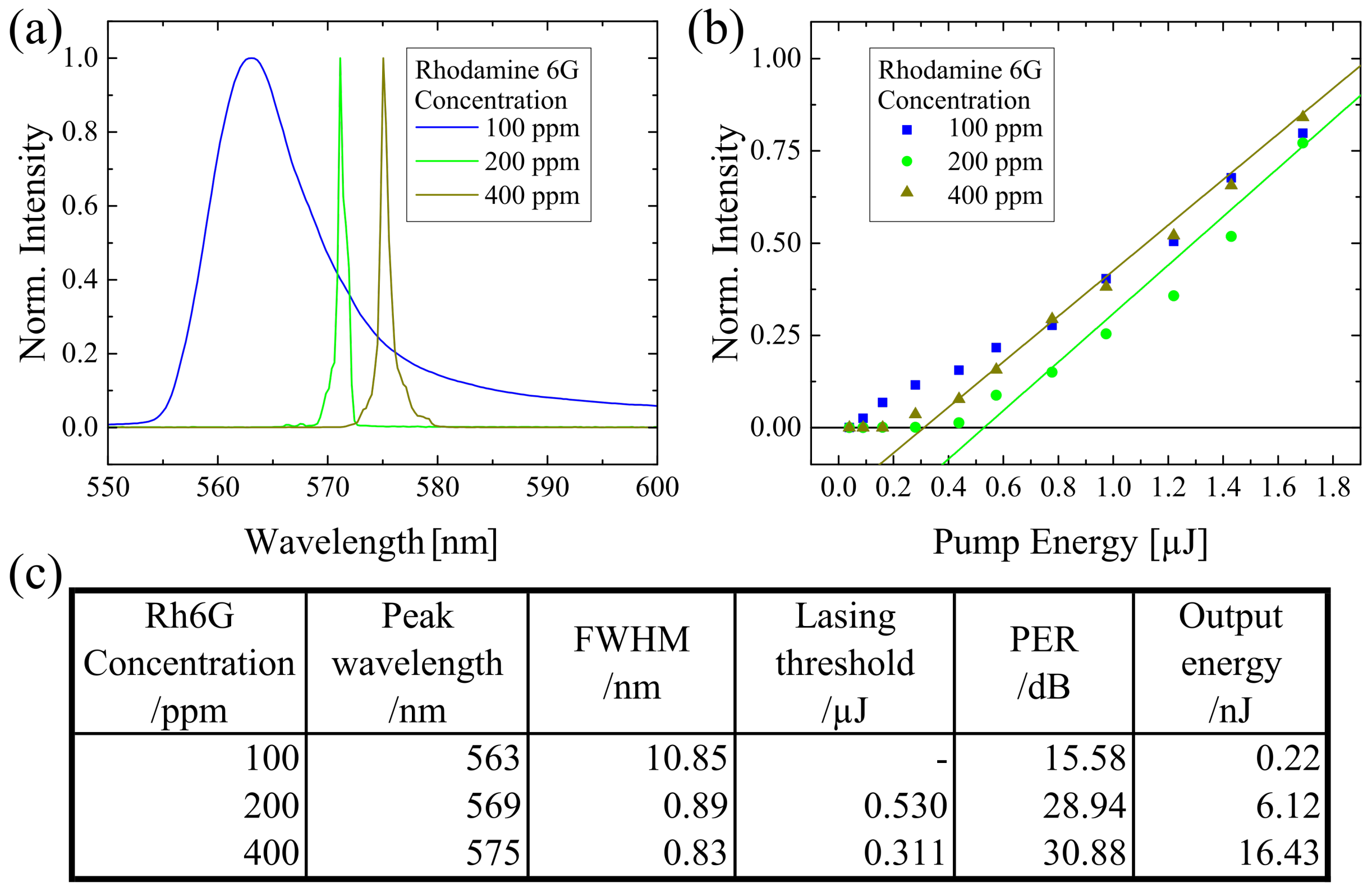

2.2. Concentration Variation

2.3. Grating Variation

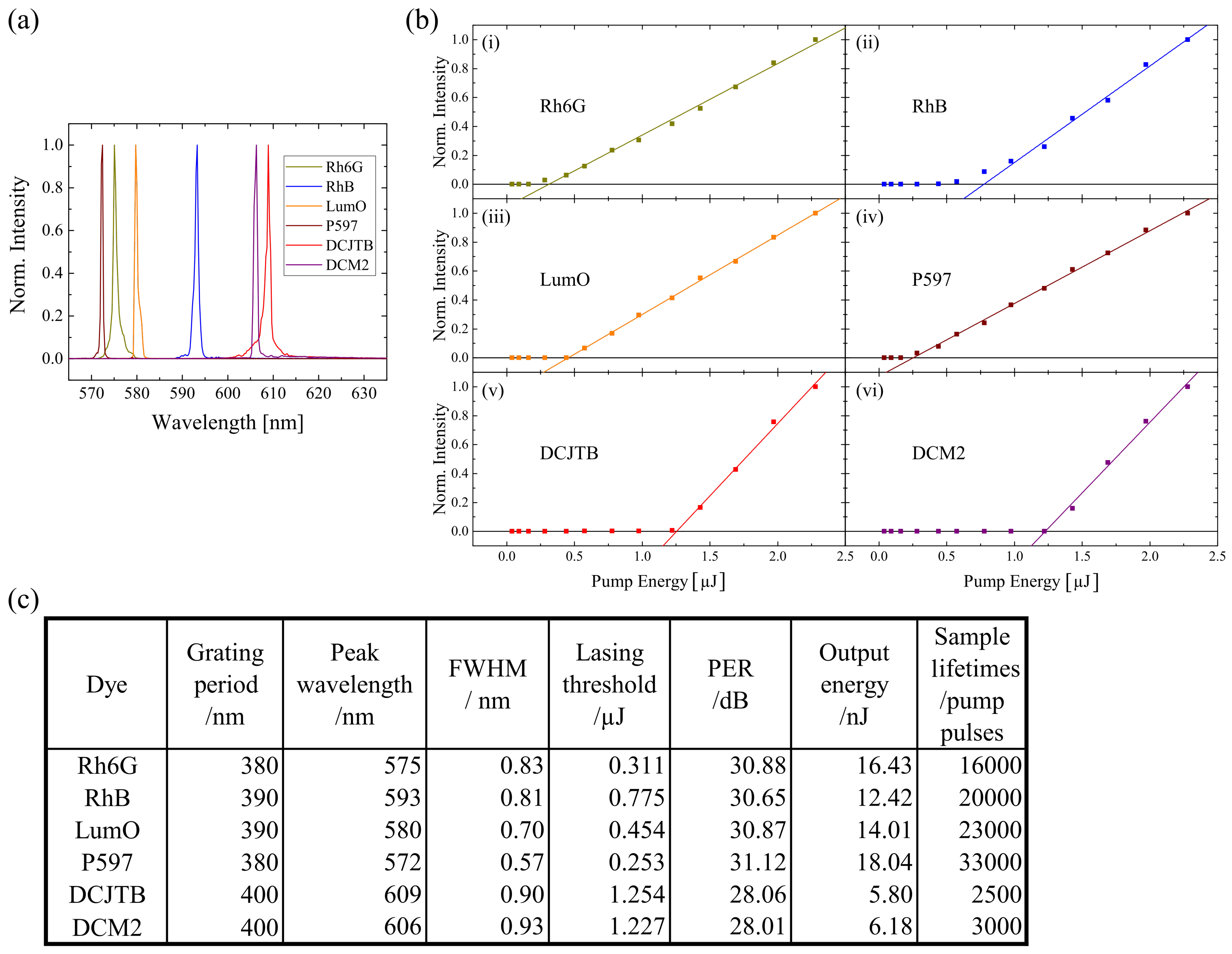

2.4. Dyes Variation

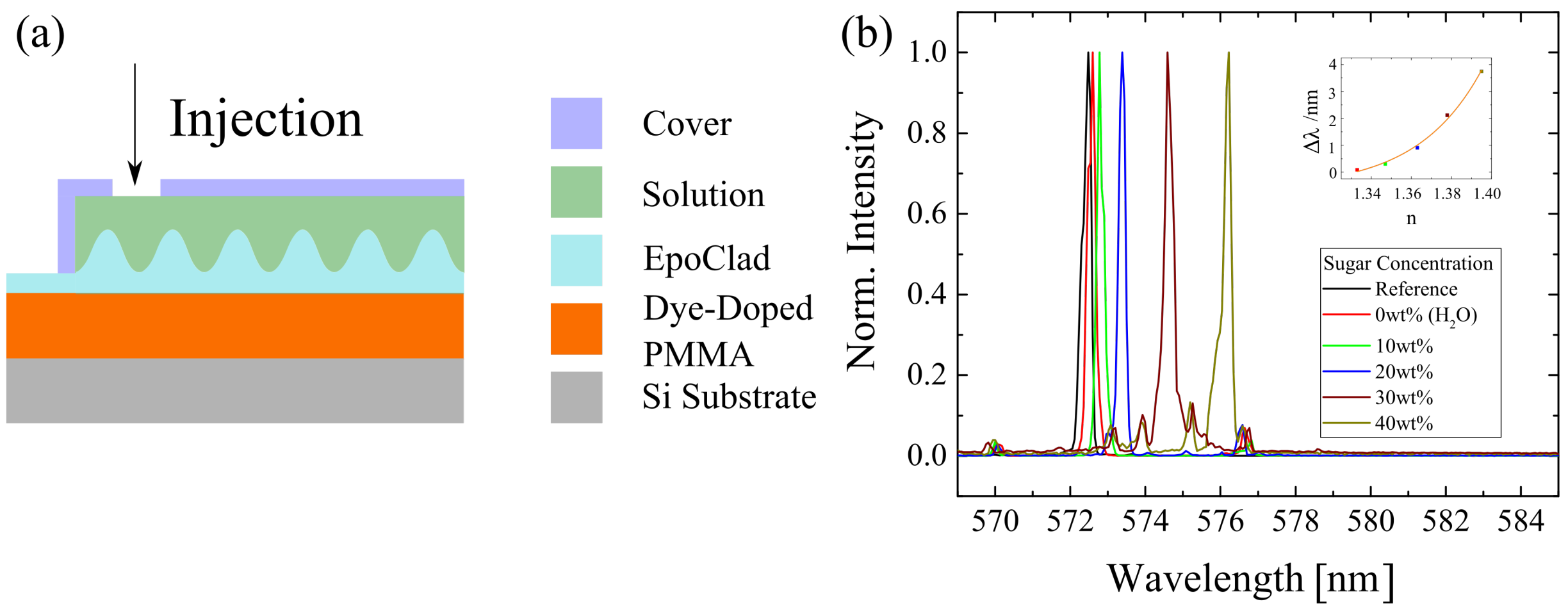

2.5. Application Potential

3. Conclusions

4. Methods and Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Vannahme, C.; Klinkhammer, S.; Lemmer, U.; Mappes, T. Plastic lab-on-a-chip for fluorescence excitation with integrated organic semiconductor lasers. Opt. Express 2011, 19, 8179–8186. [Google Scholar] [CrossRef] [PubMed]

- Clark, J.; Lanzani, G. Organic photonics for communications. Nat. Photon. 2010, 4, 438–446. [Google Scholar] [CrossRef]

- Morales-Vidal, M.; Boj, P.G.; Quintana, J.A.; Villalvilla, J.M.; Retolaza, A.; Merino, S.; Díaz-García, M.A. Distributed feedback lasers based on perylenediimide dyes for label-free refractive index sensing. Sens. Actuators B Chem. 2015, 220, 1368–1375. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Morawska, P.O.; Kanibolotsky, A.L.; Skabara, P.J.; Turnbull, G.A.; Samuel, I.D. LED pumped polymer laser sensor for explosives. Laser Photon. Rev. 2013, 7, L71–L76. [Google Scholar] [CrossRef] [Green Version]

- Oki, Y.; Miyamoto, S.; Maeda, M.; Vasa, N.J. Multiwavelength distributed-feedback dye laser array and its application to spectroscopy. Opt. Lett. 2002, 27, 1220–1222. [Google Scholar] [CrossRef] [PubMed]

- Woggon, T.; Klinkhammer, S.; Lemmer, U. Compact spectroscopy system based on tunable organic semiconductor lasers. Appl. Phys. B 2010, 99, 47–51. [Google Scholar] [CrossRef]

- Ramírez, M.G.; Villalvilla, J.M.; Quintana, J.A.; Boj, P.G.; Díaz-García, M.A. Distributed feedback lasers based on dichromated poly (vinyl alcohol) reusable surface-relief gratings. Opt. Mater. Express 2014, 4, 733–738. [Google Scholar] [CrossRef] [Green Version]

- Nilsson, D.; Nielsen, T.; Kristensen, A. Solid state microcavity dye lasers fabricated by nanoimprint lithography. Rev. Sci. Instrum. 2004, 75, 4481–4486. [Google Scholar] [CrossRef] [Green Version]

- Gaal, M.; Gadermaier, C.; Plank, H.; Moderegger, E.; Pogantsch, A.; Leising, G.; List, E.J. Imprinted conjugated polymer laser. Adv. Mater. 2003, 15, 1165–1167. [Google Scholar] [CrossRef]

- Wenger, B.; Tétreault, N.; Welland, M.E.; Friend, R.H. Mechanically tunable conjugated polymer distributed feedback lasers. Appl. Phys. Lett. 2010, 97, 237. [Google Scholar] [CrossRef]

- Namdas, E.B.; Tong, M.; Ledochowitsch, P.; Mednick, S.R.; Yuen, J.D.; Moses, D.; Heeger, A.J. Low thresholds in polymer lasers on conductive substrates by distributed feedback nanoimprinting: Progress toward electrically pumped plastic lasers. Adv. Mater. 2009, 21, 799–802. [Google Scholar] [CrossRef]

- Klinkhammer, S.; Woggon, T.; Geyer, U.; Vannahme, C.; Dehm, S.; Mappes, T.; Lemmer, U. A continuously tunable low-threshold organic semiconductor distributed feedback laser fabricated by rotating shadow mask evaporation. Appl. Phys. B 2009, 97, 787. [Google Scholar] [CrossRef]

- Tsiminis, G.; Wang, Y.; Kanibolotsky, A.L.; Inigo, A.R.; Skabara, P.J.; Samuel, I.D.; Turnbull, G.A. Nanoimprinted organic semiconductor laser pumped by a light-emitting diode. Adv. Mater. 2013, 25, 2826–2830. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schauer, S.; Liu, X.; Worgull, M.; Lemmer, U.; Hölscher, H. Shape-memory polymers as flexible resonator substrates for continuously tunable organic DFB lasers. Opt. Mater. Express 2015, 5, 576–584. [Google Scholar] [CrossRef]

- Ge, C.; Lu, M.; Jian, X.; Tan, Y.; Cunningham, B.T. Large-area organic distributed feedback laser fabricated by nanoreplica molding and horizontal dipping. Opt. Express 2010, 18, 12980–12991. [Google Scholar] [CrossRef] [PubMed]

- Herrnsdorf, J.; Guilhabert, B.; Chen, Y.; Kanibolotsky, A.L.; Mackintosh, A.; Pethrick, R.; Skabara, P.; Gu, E.; Laurand, N.; Dawson, M. Flexible blue-emitting encapsulated organic semiconductor DFB laser. Opt. Express 2010, 18, 25535–25545. [Google Scholar] [CrossRef] [PubMed]

- Xia, R.; Heliotis, G.; Stavrinou, P.; Bradley, D. Polyfluorene distributed feedback lasers operating in the green-yellow spectral region. Appl. Phys. Lett. 2005, 87, 031104. [Google Scholar] [CrossRef]

- Heliotis, G.; Xia, R.; Turnbull, G.A.; Andrew, P.; Barnes, W.L.; Samuel, I.D.W.; Bradley, D.D. Emission characteristics and performance comparison of polyfluorene lasers with one-and two-dimensional distributed feedback. Adv. Funct. Mater. 2004, 14, 91–97. [Google Scholar] [CrossRef]

- Camposeo, A.; Del Carro, P.; Persano, L.; Pisignano, D. Electrically tunable organic distributed feedback lasers embedding nonlinear optical molecules. Adv. Mater. 2012, 24, OP221–OP225. [Google Scholar] [CrossRef]

- Voss, T.; Scheel, D.; Schade, W. A microchip-laser-pumped DFB-polymer-dye laser. Appl. Phys. B 2001, 73, 105–109. [Google Scholar] [CrossRef]

- Boj, P.G.; Morales-Vidal, M.; Villalvilla, J.M.; Quintana, J.A.; Marcilla, A.; Díaz-García, M.A. Organic distributed feedback laser to monitor solvent extraction upon thermal annealing in solution-processed polymer films. Sens. Actuators B Chem. 2016, 232, 605–610. [Google Scholar] [CrossRef] [Green Version]

- Quintana, J.A.; Villalvilla, J.M.; Morales-Vidal, M.; Boj, P.G.; Zhu, X.; Ruangsupapichat, N.; Tsuji, H.; Nakamura, E.; Díaz-García, M.A. An Efficient and Color-Tunable Solution-Processed Organic Thin-Film Laser with a Polymeric Top-Layer Resonator. Adv. Opt. Mater. 2017, 5, 1700238. [Google Scholar] [CrossRef]

- Görrn, P.; Lehnhardt, M.; Kowalsky, W.; Riedl, T.; Wagner, S. Elastically Tunable Self-Organized Organic Lasers. Adv. Mater. 2011, 23, 869–872. [Google Scholar] [CrossRef]

- Döring, S.; Kollosche, M.; Rabe, T.; Stumpe, J.; Kofod, G. Electrically tunable polymer DFB laser. Adv. Mater. 2011, 23, 4265–4269. [Google Scholar] [CrossRef]

- Klinkhammer, S.; Liu, X.; Huska, K.; Shen, Y.; Vanderheiden, S.; Valouch, S.; Vannahme, C.; Bräse, S.; Mappes, T.; Lemmer, U. Continuously tunable solution-processed organic semiconductor DFB lasers pumped by laser diode. Opt. Express 2012, 20, 6357–6364. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Weimann, T.; Hinze, P.; Ade, G.; Schneider, D.; Rabe, T.; Riedl, T.; Kowalsky, W. A continuously tunable organic DFB laser. Microelectr. Eng. 2005, 78, 364–368. [Google Scholar] [CrossRef]

- Čehovski, M.; Becker, J.; Charfi, O.; Johannes, H.H.; Müller, C.; Kowalsky, W. Single-Mode Polymer Ridge Waveguide Integration of Organic Thin-Film Laser. Appl. Sci. 2020, 10, 2805. [Google Scholar] [CrossRef] [Green Version]

- Ozaki, R.; Shinpo, T.; Yoshino, K.; Ozaki, M.; Moritake, H. Tunable liquid crystal laser using distributed feedback cavity fabricated by nanoimprint lithography. Appl. Phys. Express 2008, 1, 012003. [Google Scholar] [CrossRef]

- Klinkhammer, S.; Heussner, N.; Huska, K.; Bocksrocker, T.; Geislhöringer, F.; Vannahme, C.; Mappes, T.; Lemmer, U. Voltage-controlled tuning of an organic semiconductor distributed feedback laser using liquid crystals. Appl. Phys. Lett. 2011, 99, 137. [Google Scholar] [CrossRef]

- Schäfer, F.P.; Schmidt, W.; Volze, J. Organic dye solution laser. Appl. Phys. Lett. 1966, 9, 306–309. [Google Scholar] [CrossRef]

- Zhai, T.; Zhang, X.; Pang, Z. Polymer laser based on active waveguide grating structures. Opt. Express 2011, 19, 6487–6492. [Google Scholar] [CrossRef]

- McGehee, M.D.; Gupta, R.; Veenstra, S.; Miller, E.K.; Diaz-Garcia, M.A.; Heeger, A.J. Amplified spontaneous emission from photopumped films of a conjugated polymer. Phys. Rev. B 1998, 58, 7035. [Google Scholar] [CrossRef]

- Van den Berg, S.; den Bezemer, R.v.S.; Schoo, H.; Eliel, E. From amplified spontaneous emission to laser oscillation: Dynamics in a short-cavity polymer laser. Opt. Lett. 1999, 24, 1847–1849. [Google Scholar] [CrossRef] [PubMed]

- Bonal, V.; Muñoz-Mármol, R.; Gámez, F.G.; Morales-Vidal, M.; Villalvilla, J.M.; Boj, P.G.; Quintana, J.A.; Gu, Y.; Wu, J.; Casado, J. Solution-processed nanographene distributed feedback lasers. Nat. Commun. 2019, 10, 3327. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bonal, V.; Quintana, J.A.; Villalvilla, J.M.; Boj, P.G.; Díaz-García, M.A. Controlling the emission properties of solution-processed organic distributed feedback lasers through resonator design. Sci. Rep. 2019, 9, 11159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Simović, A.; Drljača, B.; Savović, S.; Djordjevich, A.; Min, R. Investigation of bandwidth in multimode graded-index plastic optical fibers. Opt. Express 2021, 29, 29587–29594. [Google Scholar] [CrossRef]

- Peters, K. Polymer optical fiber sensors—A review. Smart Mater. Struct. 2010, 20, 013002. [Google Scholar] [CrossRef]

- Savović, S.; Drljača, B.; Kovačević, M.S.; Djordjevich, A.; Bajić, J.S.; Stupar, D.Z.; Stepniak, G. Frequency response and bandwidth in low-numerical-aperture step-index plastic optical fibers. Appl. Opt. 2014, 53, 6999–7003. [Google Scholar] [CrossRef]

- He, J.; Chan, W.K.; Cheng, X.; Tse, M.L.; Lu, C.; Wai, P.K.; Savovic, S.; Tam, H.Y. Experimental and theoretical investigation of the polymer optical fiber random laser with resonant feedback. Adv. Opt. Mater. 2018, 6, 1701187. [Google Scholar] [CrossRef]

- Kuriki, K.; Kobayashi, T.; Imai, N.; Tamura, T.; Koike, Y.; Okamoto, Y. Organic dye-doped polymer optical fiber laser. Polym. Adv. Technol. 2000, 11, 612–616. [Google Scholar] [CrossRef]

- Yuyama, S.; Nakajima, T.; Yamashita, K.; Oe, K. Solid state organic laser emission at 970 nm from dye-doped fluorinated-polyimide planar waveguides. Appl. Phys. Lett. 2008, 93, 252. [Google Scholar] [CrossRef]

- Mhibik, O.; Leang, T.; Siove, A.; Forget, S.; Chénais, S. Broadly tunable (440–670 nm) solid-state organic laser with disposable capsules. Appl. Phys. Lett. 2013, 102, 041112. [Google Scholar] [CrossRef] [Green Version]

- Arrue, J.; Jiménez, F.; Ayesta, I.; Illarramendi, M.A.; Zubia, J. Polymer-optical-fiber lasers and amplifiers doped with organic dyes. Polymers 2011, 3, 1162–1180. [Google Scholar] [CrossRef]

- Spelthann, S.; Unland, S.; Thiem, J.; Jakobs, F.; Kielhorn, J.; Ang, P.Y.; Johannes, H.H.; Kracht, D.; Neumann, J.; Ruehl, A. Towards Highly Efficient Polymer Fiber Laser Sources for Integrated Photonic Sensors. Sensors 2020, 20, 4086. [Google Scholar] [CrossRef]

- Kuriki, K.; Kobayashi, T.; Imai, N.; Tamura, T.; Nishihara, S.; Nishizawa, Y.; Tagaya, A.; Koike, Y.; Okamoto, Y. High-efficiency organic dye-doped polymer optical fiber lasers. Appl. Phys. Lett. 2000, 77, 331–333. [Google Scholar] [CrossRef]

- Samuel, I.D.; Namdas, E.B.; Turnbull, G.A. How to recognize lasing. Nat. Photon. 2009, 3, 546–549. [Google Scholar] [CrossRef]

- Lemmer, U. Stimulated emission and lasing in conjugated polymers. Polym. Adv. Technol. 1998, 9, 476–487. [Google Scholar] [CrossRef]

- Miniscalco, W.J.; Thompson, B.A.; Dakss, M.L.; Zemon, S.A.; Andrews, L.J. Measurement and analysis of cross sections for rare-earth-doped glasses. In Fiber Laser Sources and Amplifiers III; International Society for Optics and Photonics: Bellingham, WA, USA, 1992; Volume 1581, pp. 80–90. [Google Scholar]

- Malinin, A.; Zanishevskaja, A.; Tuchin, V.; Skibina, Y.S.; Silokhin, I.Y. Photonic crystal fibers for food quality analysis. In Photonic Solutions for Better Health Care III; International Society for Optics and Photonics: Bellingham, WA, USA, 2012; Volume 8427, p. 842746. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ang, P.Y.; Čehovski, M.; Lompa, F.; Hänisch, C.; Samigullina, D.; Reineke, S.; Kowalsky, W.; Johannes, H.-H. Organic Dye-Doped PMMA Lasing. Polymers 2021, 13, 3566. https://doi.org/10.3390/polym13203566

Ang PY, Čehovski M, Lompa F, Hänisch C, Samigullina D, Reineke S, Kowalsky W, Johannes H-H. Organic Dye-Doped PMMA Lasing. Polymers. 2021; 13(20):3566. https://doi.org/10.3390/polym13203566

Chicago/Turabian StyleAng, Pen Yiao, Marko Čehovski, Frederike Lompa, Christian Hänisch, Dinara Samigullina, Sebastian Reineke, Wolfgang Kowalsky, and Hans-Hermann Johannes. 2021. "Organic Dye-Doped PMMA Lasing" Polymers 13, no. 20: 3566. https://doi.org/10.3390/polym13203566