Detection of Barely Visible Impact Damage in Polymeric Laminated Composites Using a Biomimetic Tactile Whisker

Abstract

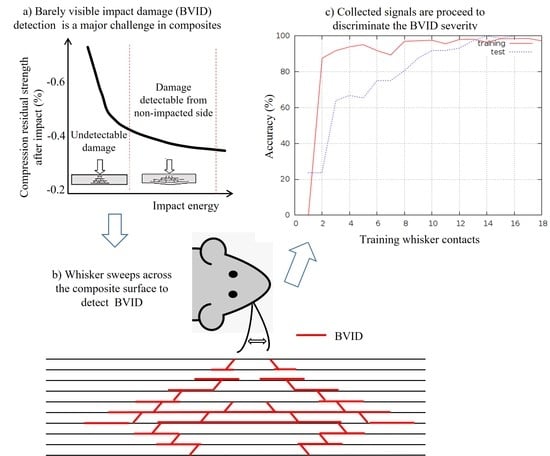

:1. Introduction

- Visual inspection;

- Sonic and ultrasonic (guide wave, laser ultrasonics, tap test, acoustic emission, etc.);

- Optical (digital image correlation, shearography etc.);

- Optical thermography (pulsed phase and line scanning thermography, etc.);

- Non-optical thermography (eddy current and microwave thermography, etc.);

- Electromagnetic (eddy current, inductive, capacitive, microwave, terahertz, etc.);

- Radiographic (X-rays, gamma-rays).

2. Experimental Methods

2.1. Manufacturing and Impact Test

2.2. Set-Up of the Whisker Experiment

2.3. Signal Processing

3. Results and Discussion

3.1. Mechanical Results

3.2. Visual Observations and C-Scan Results

3.3. Results for the Tactile Whisker

3.4. Discussions

3.5. Future Works

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, C.; Curiel-Sosa, J.L.; Duodu, E.A. Finite element analysis of the damage mechanism of 3D braided composites under high-velocity impact. J. Mater. Sci. 2017, 52, 4658–4674. [Google Scholar] [CrossRef]

- Morozov, M.; Jackson, W.; Pierce, S.G. Capacitive imaging of impact damage in composite material. Compos. Part B Eng. 2017, 113, 65–71. [Google Scholar] [CrossRef] [Green Version]

- Damghani, M.; Kennedy, D.; Featherston, C. Critical buckling of delaminated composite plates using exact stiffness analysis. Comput. Struct. 2011, 89, 1286–1294. [Google Scholar] [CrossRef]

- Damghani, M.; Kennedy, D.; Featherston, C. Global buckling of composite plates containing rectangular delaminations using exact stiffness analysis and smearing method. Comput. Struct. 2014, 134, 32–47. [Google Scholar] [CrossRef]

- Cui, X.; Fang, E.; Lua, J. A discrete crack network toolkit for Abaqus for damage and residual strength prediction of laminated composites. J. Compos. Mater. 2017, 51, 1355–1378. [Google Scholar] [CrossRef]

- Shi, Y.; Soutis, C. Modelling low velocity impact induced damage in composite laminates. Mech. Adv. Mater. Mod. Process. 2017, 3, 14. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.C.; Hallet, S.R. Barely visible impact damage in scaled composite laminates: Experiments and numerical simulations. Int. J. Impact Eng. 2017, 109, 178–195. [Google Scholar] [CrossRef] [Green Version]

- Brown, R. Non-Destructive Evaluation (NDE) of Polymer Matrix Composites, Techniques and Applications. Polym. Test. 2013, 32, 1612. [Google Scholar] [CrossRef]

- Yang, R.; He, Y.; Zhang, H. Progress and trends in nondestructive testing and evaluation for wind turbine composite blade. Renew. Sustain. Energy Rev. 2016, 60, 1225–1250. [Google Scholar] [CrossRef]

- Poudel, A.; Shrestha, S.S.; Sandhu, J.S.; Chu, T.P.; Pergantis, C.G. Comparison and analysis of Acoustography with other NDE techniques for foreign object inclusion detection in graphite epoxy composites. Compos. Part B Eng. 2015, 78, 86–94. [Google Scholar] [CrossRef]

- Fotouhi, M.; Suwarta, P.; Jalalvand, M.; Czel, G.; Wisnom, M.R. Detection of fibre fracture and ply fragmentation in thin-ply UD carbon/glass hybrid laminates using acoustic emission. Compos. Part A Appl. Sci. Manuf. 2016, 86. [Google Scholar] [CrossRef] [Green Version]

- Amenabar, I.; Mendikute, A.; López-Arraiza, A.; Lizaranzu, M.; Aurrekoetxea, J. Comparison and analysis of non-destructive testing techniques suitable for delamination inspection in wind turbine blades. Compos. Part B Eng. 2011, 42, 1298–1305. [Google Scholar] [CrossRef]

- Sun, J.G. Analysis of Pulsed Thermography Methods for Defect Depth Prediction. J. Heat Transf. 2006, 128, 329. [Google Scholar] [CrossRef]

- Shepard, S. Flash thermography of aerospace composites. In Proceedings of the IV Conferencia Panamericana de END Buenos Aires, Buenos Aires, Argentina, 22–26 October 2007; NDT.net: Rhineland-Palatinate, Germany, 2007; Volume 7. [Google Scholar] [CrossRef] [Green Version]

- Bui, H.K.; Wasselynck, G.; Trichet, D.; Ramdane, B.; Berthiau, G.; Fouladgar, J. 3-D modeling of thermo inductive non destructive testing method applied to multilayer composite. IEEE Trans. Magn. 2013, 49, 1949–1952. [Google Scholar] [CrossRef]

- Li, Z.; Meng, Z. A review of the radio frequency non-destructive testing for carbon-fibre composites. Meas. Sci. Rev. 2016, 16, 68–76. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Haigh, A.D.; Saleh, M.N.; McCarthy, E.D.; Soutis, C.; Gibson, A.A.P.; Sloan, R. Detection of Impact Damage in Carbon Fiber Composites Using an Electromagnetic Sensor. Res. Nondestruct. Eval. 2016, 29, 123–142. [Google Scholar] [CrossRef] [Green Version]

- Tan, K.T.; Watanabe, N.; Iwahori, Y. X-ray radiography and micro-computed tomography examination of damage characteristics in stitched composites subjected to impact loading. Compos. Part B Eng. 2011. [Google Scholar] [CrossRef]

- Mannella, F.; Maggiore, F.; Baltieri, M.; Pezzulo, G. Active inference through whiskers. Neural Netw. 2021, 144, 428–437. [Google Scholar] [CrossRef]

- Collinson, D.W.; Emnett, H.M.; Ning, J.; Hartmann, M.J.Z.; Brinson, L.C. Tapered polymer whiskers to enable three-dimensional tactile feature extraction. Soft Robot. 2021, 8, 44–58. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Psarras, S.; Loutas, T.; Sotiriadis, G.; Gray, I.; Padiyar, M.J.; Petrunin, I.; Raposo, J.; Fragonara, L.Z.; Tzitzilonis, V.; et al. Autonomous Inspection and Repair of Aircraft Composite Structures. IFAC-PapersOnLine 2018, 51, 554–557. [Google Scholar] [CrossRef]

- Canizo, M.; Onieva, E.; Conde, A.; Charramendieta, S.; Trujillo, S. Real-time predictive maintenance for wind turbines using Big Data frameworks. In Proceedings of the 2017 IEEE International Conference on Prognostics and Health Management, ICPHM, Dallas, TX, USA, 19–21 June 2017. [Google Scholar]

- Khatir, S.; Tiachacht, S.; Le Thanh, C.; Ghandourah, E.; Mirjalili, S.; Abdel Wahab, M. An improved Artificial Neural Network using Arithmetic Optimization Algorithm for damage assessment in FGM composite plates. Compos. Struct. 2021, 273. [Google Scholar] [CrossRef]

- Zenzen, R.; Khatir, S.; Belaidi, I.; Le Thanh, C.; Abdel Wahab, M. A modified transmissibility indicator and Artificial Neural Network for damage identification and quantification in laminated composite structures. Compos. Struct. 2020, 248. [Google Scholar] [CrossRef]

- Azimi, M.; Eslamlou, A.D.; Pekcan, G. Data-driven structural health monitoring and damage detection through deep learning: State-ofthe- art review. Sensors 2020, 20, 2778. [Google Scholar] [CrossRef]

- Von Heimendahl, M.; Itskov, P.M.; Arabzadeh, E.; Diamond, M.E. Neuronal activity in rat barrel cortex underlying texture discrimination. PLoS Biol. 2007, 5, 2696–2708. [Google Scholar] [CrossRef] [Green Version]

- Evans, M.; Fox, C.W.; Pearson, M.J.; Prescott, T.J. Spectral Template Based Classification of Robotic Whisker Sensor Signals in a Floor Texture Discrimination Task. Proc. Towar. Auton. Robot. Syst. 2009, 19–24. [Google Scholar]

- Ibrahim, L.; Wright, E.A. The growth of rats and mice vibrissae under normal and some abnormal conditions. J. Embryol. Exp. Morphol. 1975, 33, 831–844. [Google Scholar] [CrossRef]

- Hires, S.A.; Pammer, L.; Svoboda, K.; Golomb, D. Tapered whiskers are required for active tactile sensation. eLife 2013, 2, e01350. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.E.; Möller, R. Biomimetic whiskers for shape recognition. Rob. Auton. Syst. 2007, 55, 229–243. [Google Scholar] [CrossRef]

- Sullivan, J.C.; Mitchinson, B.; Pearson, M.J.; Evans, M.; Lepora, N.F.; Fox, C.W.; Melhuish, C.; Prescott, T.J. Tactile discrimination using active whisker sensors. IEEE Sens. J. 2012, 12, 350–362. [Google Scholar] [CrossRef]

- ASTM Standard Test Method for Measuring the Fastener Pull-Through Resistance of a Fiber-Reinforced Polymer Matrix Composite 1. Astm 2015, i, 1–12.

- Auger, F.; Flandrin, P.; Gonçalvès, P.; Lemoine, O. Time–Frequency Toolbox. Available online: http://tftb.nongnu.org/tutorial.pdf (accessed on 12 September 2021).

- Shin, Y.S.; Jeon, J.J. Pseudo wigner-ville time-frequency distribution and its application to machinery condition monitoring. Shock Vib. 1993, 1, 65–76. [Google Scholar] [CrossRef]

- Chang, C.C.; Chien, L.J.; Lee, Y.J. A novel framework for multi-class classification via ternary smooth support vector machine. Pattern Recognit. 2011, 44, 1235–1244. [Google Scholar] [CrossRef]

- Davy, M.; Gretton, A.; Doucet, A.; Rayner, P.J.W. Optimized support vector machines for nonstationary signal classification. IEEE Signal Process. Lett. 2002, 9, 442–445. [Google Scholar] [CrossRef]

- Hsu, C.W.; Lin, C.J. A comparison of methods for multiclass support vector machines. IEEE Trans. Neural Netw. 2002, 13, 415–425. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tropis, A.; Thomas, M.; Bounie, J.L.; Lafon, P. Certification of the composite outer wing of the ATR72. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 1995, 209, 327–339. [Google Scholar] [CrossRef]

- Baaran, J. Study on Visual Inspection of Composite Structures; European Aviation Safety Agency: Cologne, Germany, 2009; pp. 1–102. [Google Scholar]

- Deign, J. Fully automated drones could double wind turbine inspection rates. Available online: https://www.reutersevents.com/renewables/wind-energy-update/fully-automated-drones-could-double-wind-turbine-inspection-rates (accessed on 12 September 2021).

- Fotouhi, S.; Pashmforoush, F.; Bodaghi, M.; Fotouhi, M. Autonomous damage recognition in visual inspection of laminated composite structures using deep learning. Compos. Struct. 2021, 268, 113960. [Google Scholar] [CrossRef]

| Prepreg Type | Cured Nominal Thickness | Ply Young Modulus E11 | Fibre Failure Strain |

|---|---|---|---|

| T800 carbon/MTM49-3 epoxy | 0.145 (mm) | 235 (GPa) | 1.70 (%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fotouhi, S.; Khayatzadeh, S.; Pui, W.X.; Damghani, M.; Bodaghi, M.; Fotouhi, M. Detection of Barely Visible Impact Damage in Polymeric Laminated Composites Using a Biomimetic Tactile Whisker. Polymers 2021, 13, 3587. https://doi.org/10.3390/polym13203587

Fotouhi S, Khayatzadeh S, Pui WX, Damghani M, Bodaghi M, Fotouhi M. Detection of Barely Visible Impact Damage in Polymeric Laminated Composites Using a Biomimetic Tactile Whisker. Polymers. 2021; 13(20):3587. https://doi.org/10.3390/polym13203587

Chicago/Turabian StyleFotouhi, Sakineh, Saber Khayatzadeh, Wei Xia Pui, Mahdi Damghani, Mahdi Bodaghi, and Mohamad Fotouhi. 2021. "Detection of Barely Visible Impact Damage in Polymeric Laminated Composites Using a Biomimetic Tactile Whisker" Polymers 13, no. 20: 3587. https://doi.org/10.3390/polym13203587

APA StyleFotouhi, S., Khayatzadeh, S., Pui, W. X., Damghani, M., Bodaghi, M., & Fotouhi, M. (2021). Detection of Barely Visible Impact Damage in Polymeric Laminated Composites Using a Biomimetic Tactile Whisker. Polymers, 13(20), 3587. https://doi.org/10.3390/polym13203587