Production and Characterization of Polyethylene Terephthalate Nanoparticles

Abstract

:1. Introduction

2. Experimental

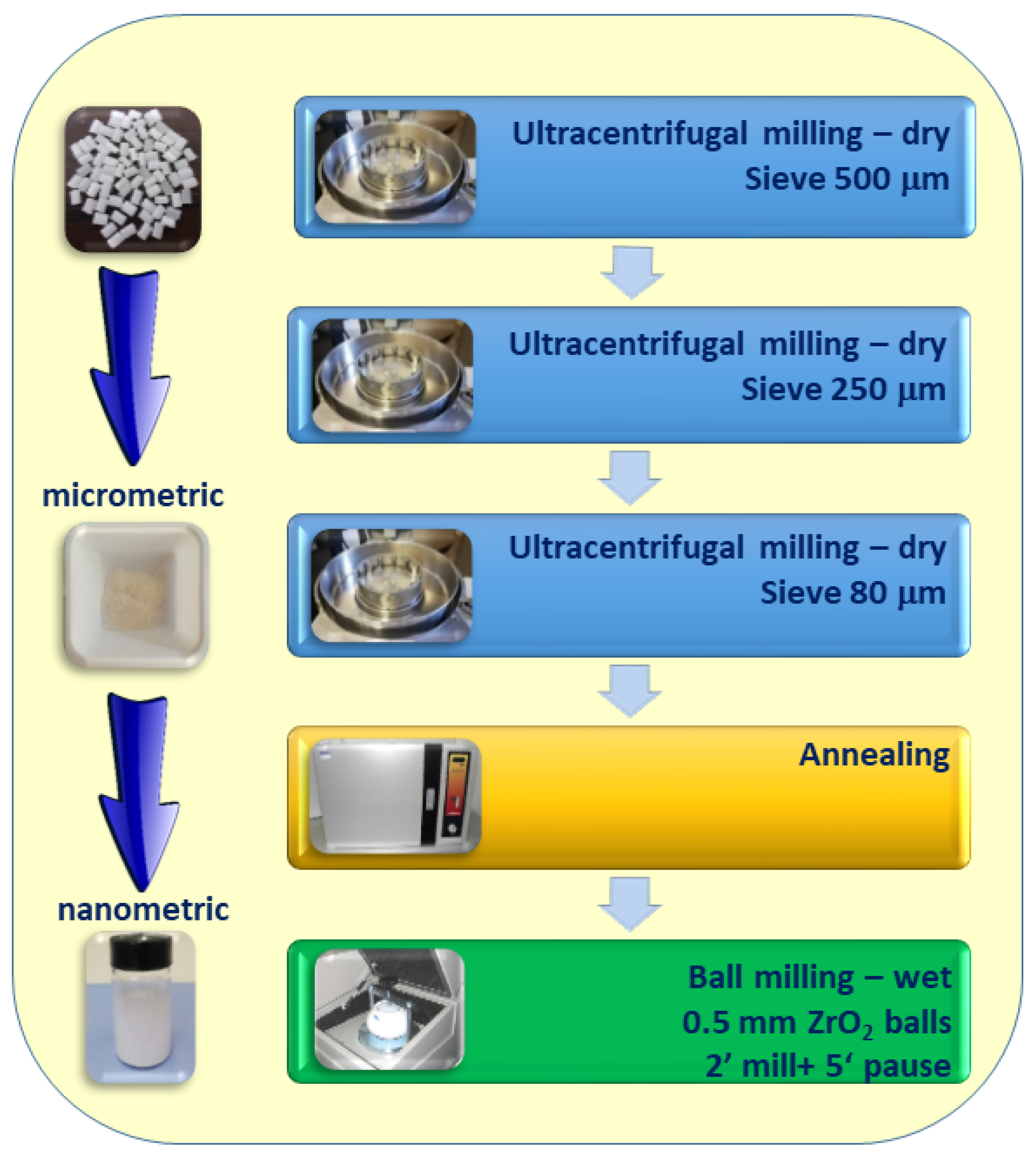

2.1. Preparation of the Aqueous Dispersion of PET Nanoparticles

2.2. Characterization of the Micrometric and Nanometric Particles

3. Results

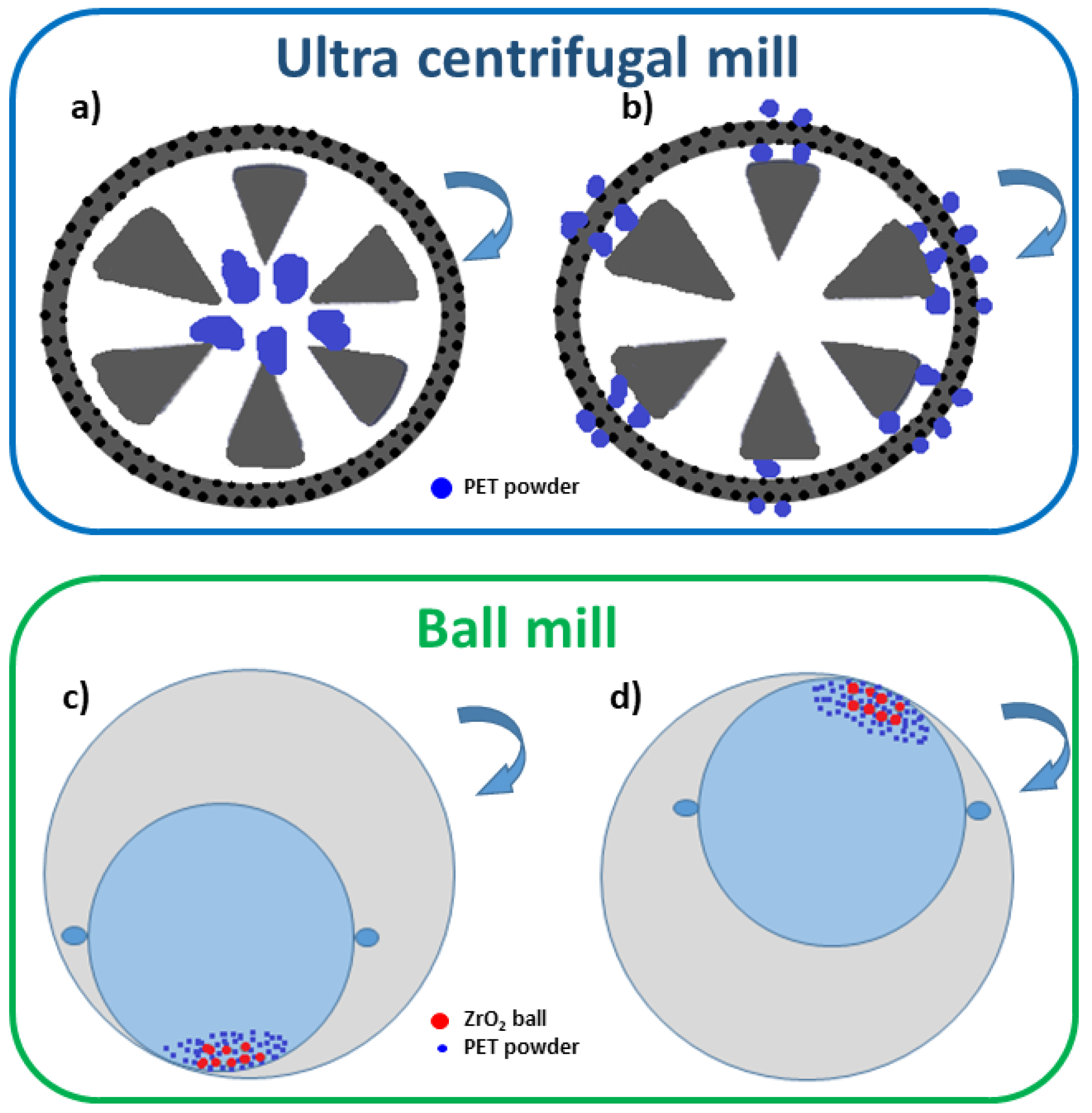

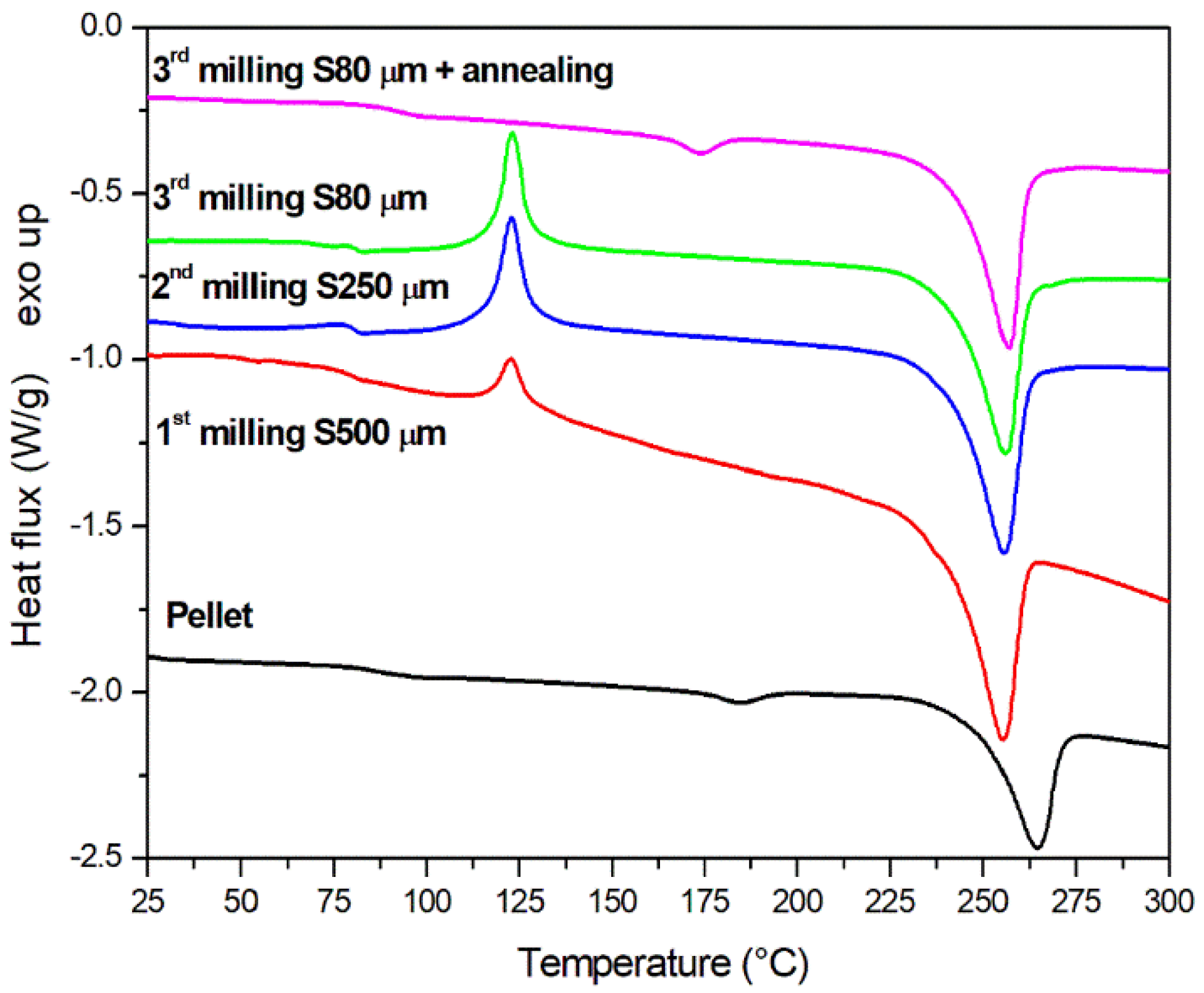

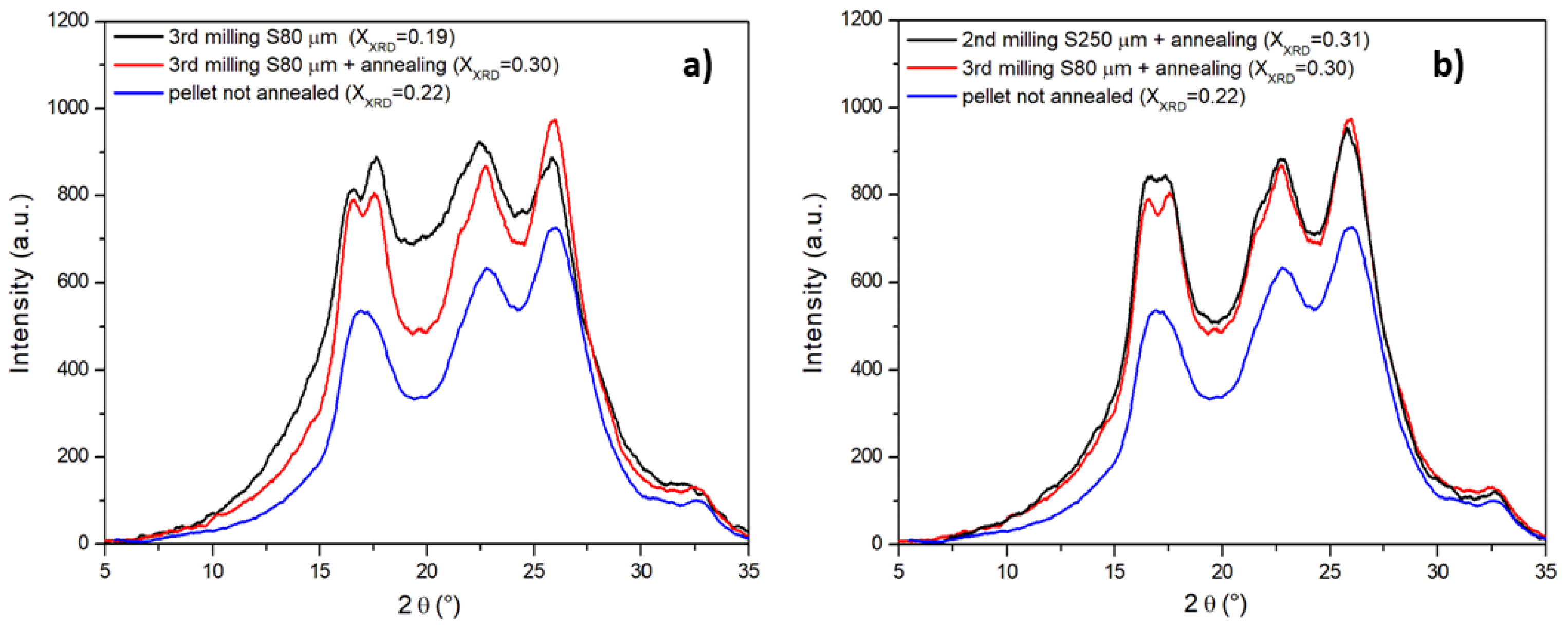

3.1. Analysis of the Structural Changes during Dry Milling in an Ultra Centrifugal Mill

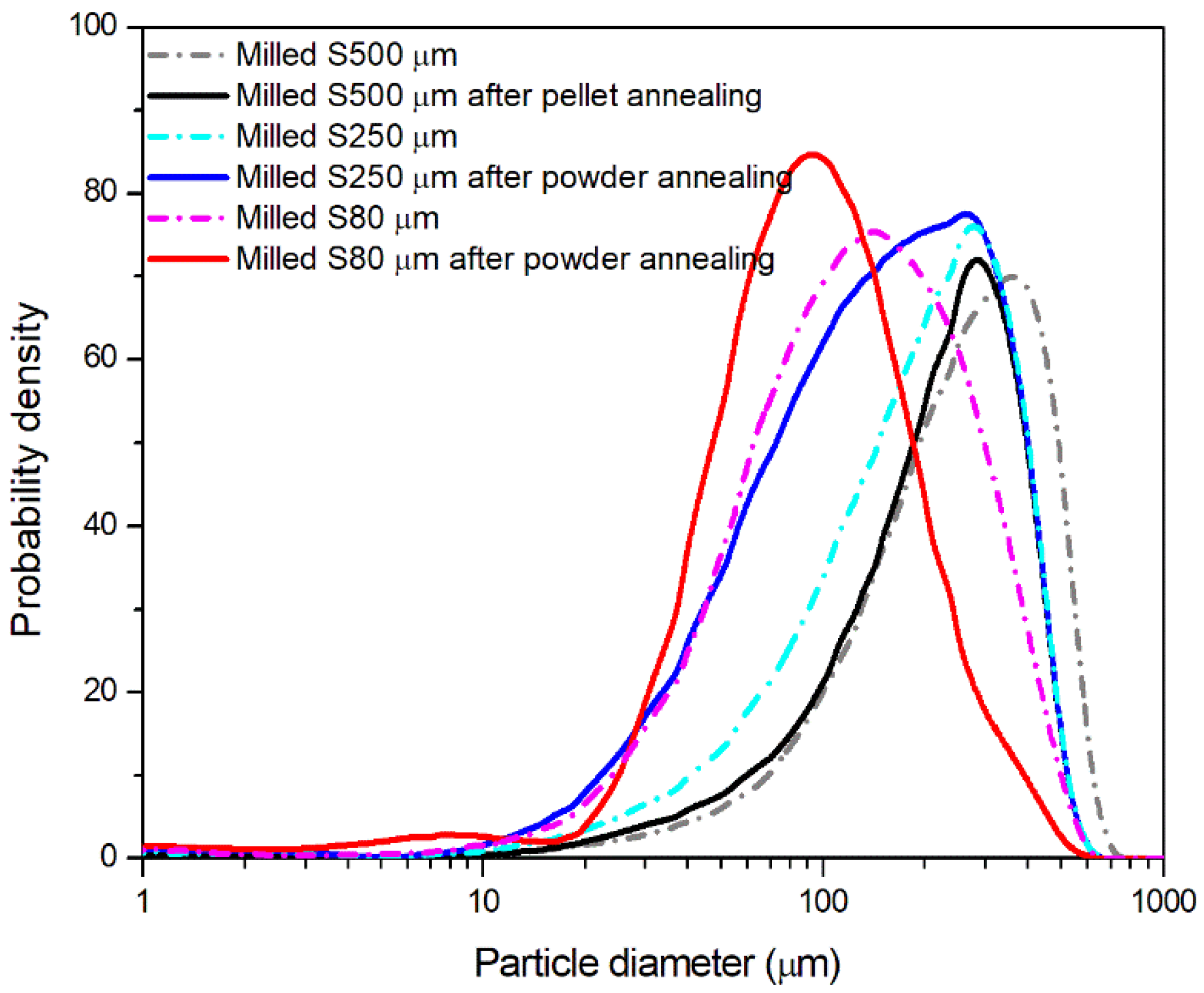

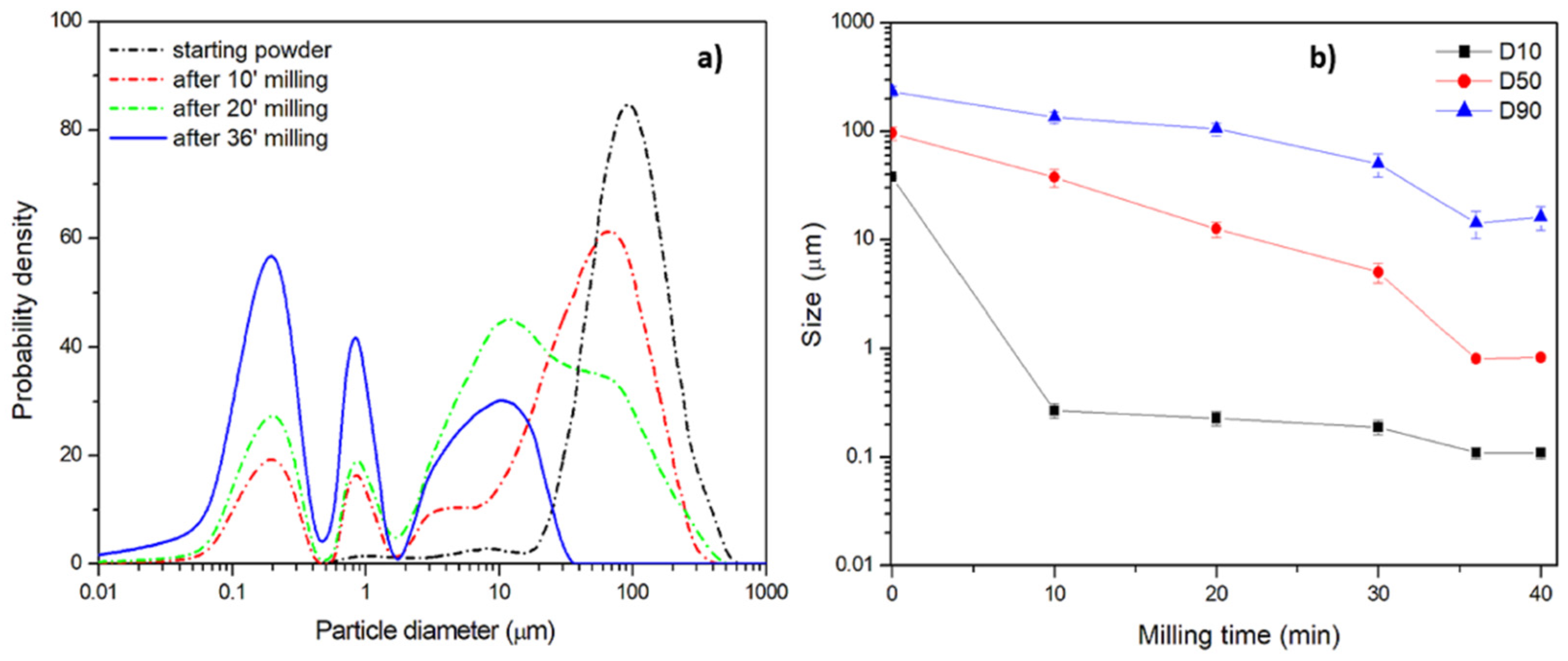

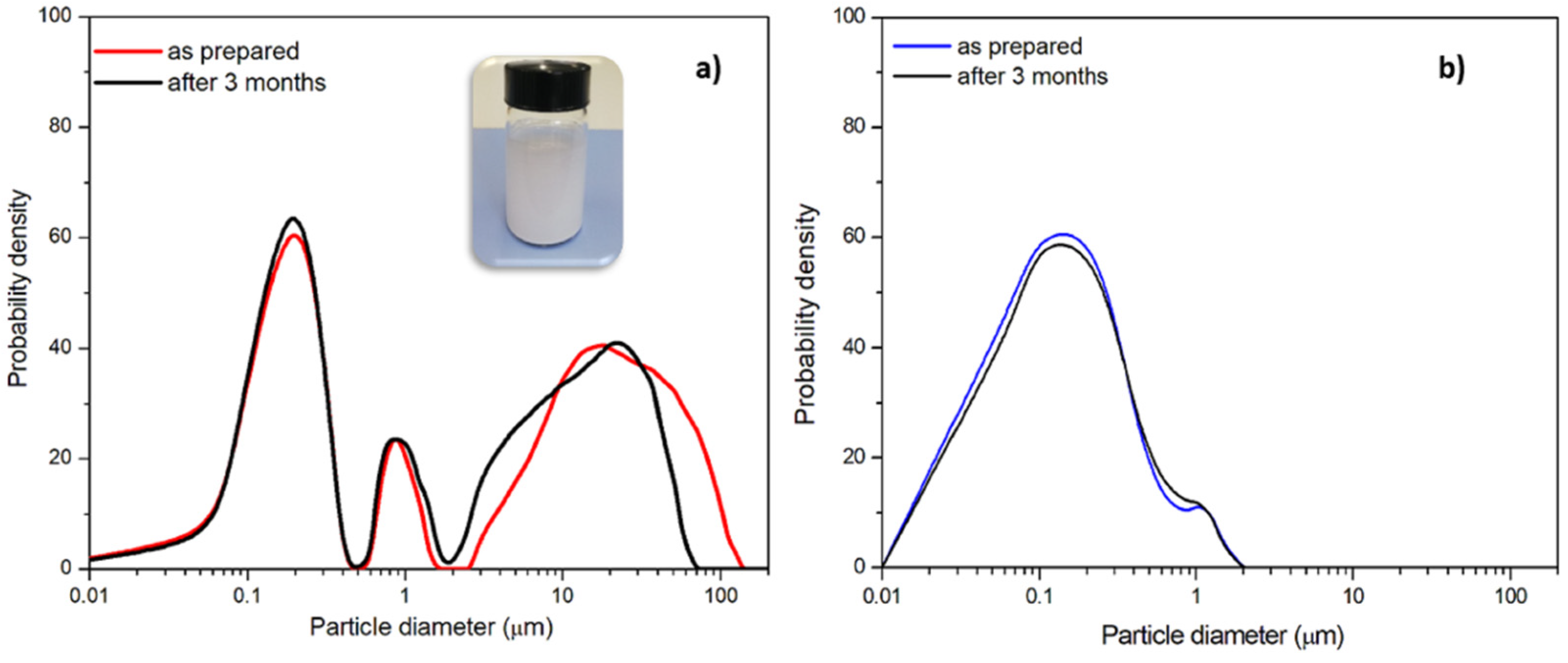

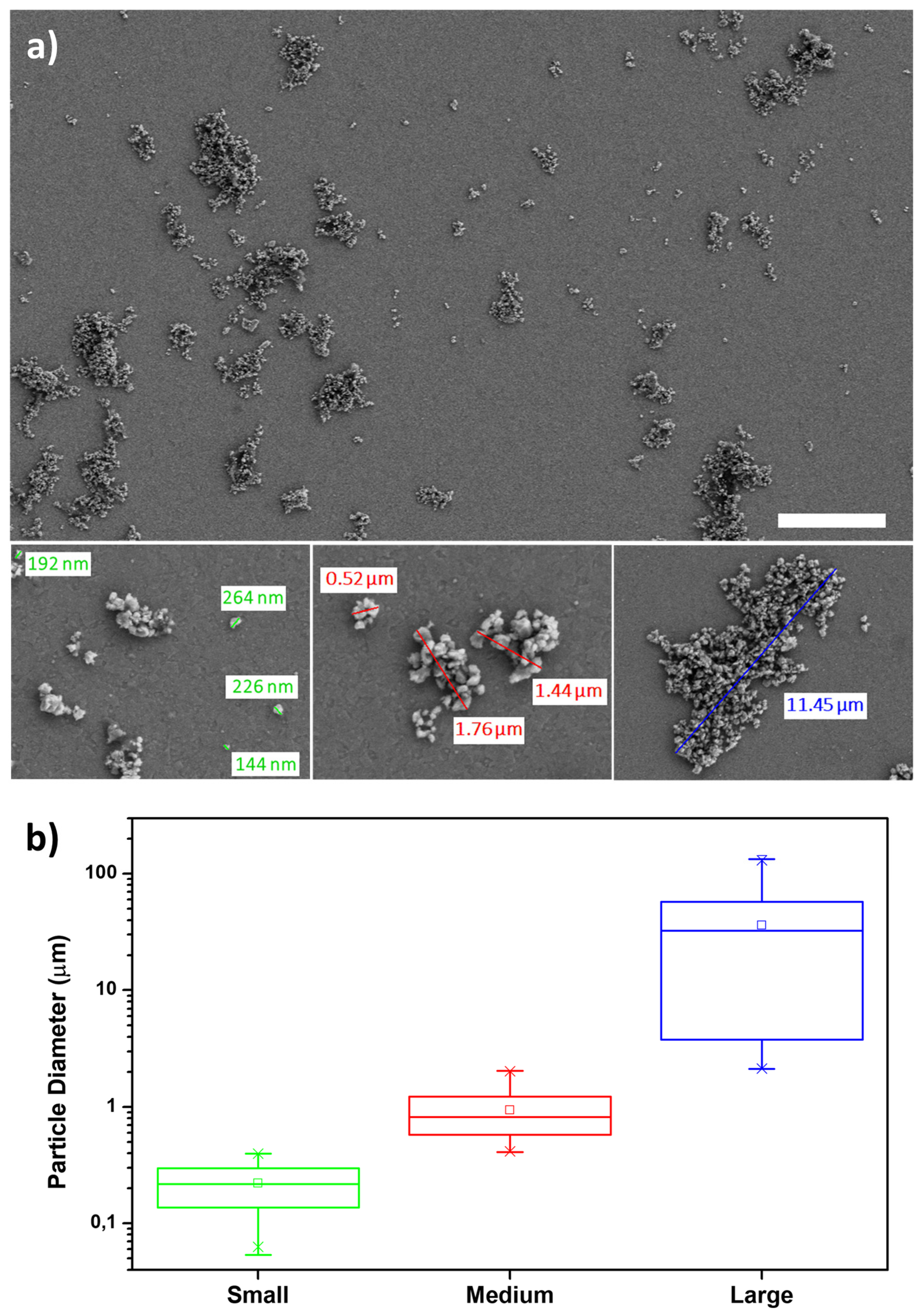

3.2. Optimization of Wet Ball Milling for Producing PET Nanoplastics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Lionetto, F.; Esposito Corcione, C. An Overview of the Sorption Studies of Contaminants on Poly (Ethylene Terephthalate) Microplastics in the Marine Environment. J. Mar. Sci. Eng. 2021, 9, 445. [Google Scholar] [CrossRef]

- Esposito Corcione, C.; Striani, R.; Ferrari, F.; Visconti, P.; Rizzo, D.; Greco, A. An Innovative Method for the Recycling of Waste Carbohydrate-Based Flours. Polymers 2020, 12, 1414. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, F.; Esposito Corcione, C.; Montagna, F.; Maffezzoli, A. 3D Printing of Polymer Waste for Improving People’s Awareness about Marine Litter. Polymers 2020, 12, 1738. [Google Scholar] [CrossRef]

- Valdés, A.; Mellinas, A.C.; Ramos, M.; Garrigós, M.C.; Jiménez, A. Natural additives and agricultural wastes in biopolymer formulations for food packaging. Front. Chem. 2014, 2, 6. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ritchie, H.; Roser, M. Plastic Pollution. Available online: https://ourworldindata.org/plastic-pollution (accessed on 18 March 2021).

- Esposito Corcione, C.; Ferrari, F.; Striani, R.; Visconti, P.; Greco, A. An innovative green process for the stabilization and valorization of organic fraction of municipal solid waste (OFMSW): Optimization of the curing process II part. Appl. Sci. 2019, 9, 3702. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, F.; Striani, R.; Visconti, P.; Esposito Corcione, C.; Greco, A. Durability analysis of formaldehyde/solid urban waste blends. Polymers 2019, 11, 1838. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Plastics —The Facts 2019. Available online: https://www.plasticseurope.org/application/files/9715/7129/9584/FINAL_web_version_Plastics_the_facts2019_14102019.pdf (accessed on 5 December 2020).

- Issifu, I.; Sumaila, U.R. A Review of the Production, Recycling and Management of Marine Plastic Pollution. J. Mar. Sci. Eng. 2020, 8, 945. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef] [PubMed]

- Lionetto, F.; Esposito Corcione, C. Recent applications of biopolymers derived from fish industry waste in food packaging. Polymers 2021, 13, 2337. [Google Scholar] [CrossRef]

- European Commission. Proposal for a Directive on the Reduction of the Impact of Certain Plastic Products on the Environment, COM(2018) 340 Final; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Johnson, L.M.; Mecham, J.B.; Krovi, S.A.; Caffaro, M.M.M.; Aravamudhan, S.; Kovach, A.L.; Fennell, T.R.; Mortensen, N.P. Fabrication of polyethylene terephthalate (PET) nanoparticles with fluorescent tracers for studies in mammalian cells. Nanoscale Adv. 2021, 3, 339–346. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [Green Version]

- Polyethylene Terephthalate (PET): Production, Price, Market and its Properties. Available online: https://www.plasticsinsight.com/resin-intelligence/resin-prices/polyethylene-terephthalate/ (accessed on 7 April 2021).

- Webb, H.K.; Arnott, J.; Crawford, R.J.; Ivanova, E.P. Plastic degradation and its environmental implications with special reference to poly (ethylene terephthalate). Polymers 2013, 5, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Derraik, J.G.B. The pollution of the marine environment by plastic debris: A review. Mar. Pollut. Bull. 2002, 44, 842–852. [Google Scholar] [CrossRef]

- Dutt, K.; Soni, R.K. A review on synthesis of value added products from polyethylene terephthalate (PET) waste. Polym. Sci. Ser. B 2013, 55, 430–452. [Google Scholar] [CrossRef]

- Al-Sabagh, A.M.; Yehia, F.Z.; Eshaq, G.; Rabie, A.M.; ElMetwally, A.E. Greener routes for recycling of polyethylene terephthalate. Egypt. J. Pet. 2016, 25, 53–64. [Google Scholar] [CrossRef] [Green Version]

- Singh, B.; Sharma, N. Mechanistic implications of plastic degradation. Polym. Degrad. Stab. 2008, 93, 561–584. [Google Scholar] [CrossRef]

- Oßmann, B.E.; Sarau, G.; Holtmannspötter, H.; Pischetsrieder, M.; Christiansen, S.H.; Dicke, W. Small-sized microplastics and pigmented particles in bottled mineral water. Water Res. 2018, 141, 307–316. [Google Scholar] [CrossRef]

- Winkler, A.; Santo, N.; Ortenzi, M.A.; Bolzoni, E.; Bacchetta, R.; Tremolada, P. Does mechanical stress cause microplastic release from plastic water bottles? Water Res. 2019, 166, 115082. [Google Scholar] [CrossRef]

- Shruti, V.C.; Pérez-Guevara, F.; Elizalde-Martínez, I.; Kutralam-Muniasamy, G. First study of its kind on the microplastic contamination of soft drinks, cold tea and energy drinks-Future research and environmental considerations. Sci. Total Environ. 2020, 726, 138580. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, E.G.; Li, J.; Chen, Q.; Ma, L.; Zeng, E.Y.; Shi, H. A review of microplastics in table salt, drinking water, and air: Direct human exposure. Environ. Sci. Technol. 2020, 54, 3740–3751. [Google Scholar] [CrossRef]

- David, J.; Steinmetz, Z.; Kučerík, J.; Schaumann, G.E. Quantitative analysis of poly (ethylene terephthalate) microplastics in soil via thermogravimetry–mass spectrometry. Anal. Chem. 2018, 90, 8793–8799. [Google Scholar] [CrossRef]

- Magnusson, K.; Norén, F. Screening of Microplastic Particles in and Down-Stream a Wastewater Treatment Plant; Swedish Environmental Protection Agency: Stockholm, Sweden, 2014.

- Acharya, S.; Rumi, S.S.; Hu, Y.; Abidi, N. Microfibers from synthetic textiles as a major source of microplastics in the environment: A review. Text. Res. J. 2021, 91, 2136–2156. [Google Scholar] [CrossRef]

- Gigault, J.; Pedrono, B.; Maxit, B.; Ter Halle, A. Marine plastic litter: The unanalyzed nano-fraction. Environ. Sci. Nano 2016, 3, 346–350. [Google Scholar] [CrossRef]

- Andrady, A.L. The plastic in microplastics: A review. Mar. Pollut. Bull. 2017, 119, 12–22. [Google Scholar] [CrossRef]

- de Souza Machado, A.A.; Kloas, W.; Zarfl, C.; Hempel, S.; Rillig, M.C. Microplastics as an emerging threat to terrestrial ecosystems. Glob. Chang. Biol. 2018, 24, 1405–1416. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, P.; Wei, S.-S.; Zhang, J.-B.; Ou, Z.; Yang, Y.-Q.; Wang, M.-Y. Occurrence, Composition, and Relationships in Marine Plastic Debris on the First Long Beach Adjacent to the Land-Based Source, South China Sea. J. Mar. Sci. Eng. 2020, 8, 666. [Google Scholar] [CrossRef]

- Lionetto, M.G.; Caricato, R.; Giordano, M.E. Pollution Biomarkers in the Framework of Marine Biodiversity Conservation: State of Art and Perspectives. Water 2021, 13, 1847. [Google Scholar] [CrossRef]

- Kumar, M.; Chen, H.; Sarsaiya, S.; Qin, S.; Liu, H.; Awasthi, M.K.; Kumar, S.; Singh, L.; Zhang, Z.; Bolan, N.S. Current research trends on micro-and nano-plastics as an emerging threat to global environment: A review. J. Hazard. Mater. 2020, 409, 124967. [Google Scholar] [CrossRef]

- Bianco, A.; Sordello, F.; Ehn, M.; Vione, D.; Passananti, M. Degradation of nanoplastics in the environment: Reactivity and impact on atmospheric and surface waters. Sci. Total Environ. 2020, 742, 140413. [Google Scholar] [CrossRef]

- Bianco, A.; Passananti, M. Atmospheric micro and nanoplastics: An enormous microscopic problem. Sustainability 2020, 12, 7327. [Google Scholar] [CrossRef]

- El Hadri, H.; Gigault, J.; Maxit, B.; Grassl, B.; Reynaud, S. Nanoplastic from mechanically degraded primary and secondary microplastics for environmental assessments. NanoImpact 2020, 17, 100206. [Google Scholar] [CrossRef]

- Eitzen, L.; Paul, S.; Braun, U.; Altmann, K.; Jekel, M.; Ruhl, A.S. The challenge in preparing particle suspensions for aquatic microplastic research. Environ. Res. 2019, 168, 490–495. [Google Scholar] [CrossRef]

- Magrì, D.; Sánchez-Moreno, P.; Caputo, G.; Gatto, F.; Veronesi, M.; Bardi, G.; Catelani, T.; Guarnieri, D.; Athanassiou, A.; Pompa, P.P. Laser ablation as a versatile tool to mimic polyethylene terephthalate nanoplastic pollutants: Characterization and toxicology assessment. ACS Nano 2018, 12, 7690–7700. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Hernández, A.G.; Muñoz-Tabares, J.A.; Aguilar-Guzmán, J.C.; Vazquez-Duhalt, R. A novel and simple method for polyethylene terephthalate (PET) nanoparticle production. Environ. Sci. Nano 2019, 6, 2031–2036. [Google Scholar] [CrossRef]

- Piccardo, M.; Provenza, F.; Grazioli, E.; Cavallo, A.; Terlizzi, A.; Renzi, M. PET microplastics toxicity on marine key species is influenced by pH, particle size and food variations. Sci. Total Environ. 2020, 715, 136947. [Google Scholar] [CrossRef] [PubMed]

- Provenza, F.; Piccardo, M.; Terlizzi, A.; Renzi, M. Exposure to pet-made microplastics: Particle size and pH effects on biomolecular responses in mussels. Mar. Pollut. Bull. 2020, 156, 111228. [Google Scholar] [CrossRef] [PubMed]

- Astner, A.F.; Hayes, D.G.; O’Neill, H.; Evans, B.R.; Pingali, S.V.; Urban, V.S.; Young, T.M. Mechanical formation of micro-and nano-plastic materials for environmental studies in agricultural ecosystems. Sci. Total Environ. 2019, 685, 1097–1106. [Google Scholar] [CrossRef] [PubMed]

- Ekvall, M.T.; Lundqvist, M.; Kelpsiene, E.; Šileikis, E.; Gunnarsson, S.B.; Cedervall, T. Nanoplastics formed during the mechanical breakdown of daily-use polystyrene products. Nanoscale Adv. 2019, 1, 1055–1061. [Google Scholar] [CrossRef] [Green Version]

- Kühn, S.; Van Oyen, A.; Booth, A.M.; Meijboom, A.; Van Franeker, J.A. Marine microplastic: Preparation of relevant test materials for laboratory assessment of ecosystem impacts. Chemosphere 2018, 213, 103–113. [Google Scholar] [CrossRef]

- Ji, Y.; Wang, C.; Wang, Y.; Fu, L.; Man, M.; Chen, L. Realistic polyethylene terephthalate nanoplastics and the size-and surface coating-dependent toxicological impacts on zebrafish embryos. Environ. Sci. Nano 2020, 7, 2313–2324. [Google Scholar] [CrossRef]

- Caldwell, J.; Lehner, R.; Balog, S.; Rhême, C.; Gao, X.; Septiadi, D.; Weder, C.; Petri-Fink, A.; Rothen-Rutishauser, B. Fluorescent plastic nanoparticles to track their interaction and fate in physiological environments. Environ. Sci. Nano 2021, 8, 502–513. [Google Scholar] [CrossRef]

- Haq, E.U.; Padmanabhan, S.K.; Licciulli, A. In-situ carbonation of alkali activated fly ash geopolymer. Constr. Build. Mater. 2014, 66, 781–786. [Google Scholar] [CrossRef]

- Licciulli, A.; Notaro, M.; De Santis, S.; Terreni, C.; Padmanabhan, S.K. CO2 capture on amine impregnated mesoporous alumina-silica mixed oxide spheres. Fuel Process. Technol. 2017, 166, 202–208. [Google Scholar] [CrossRef]

- Matuła, I.; Zubko, M.; Dercz, G. Role of Sn as a Process Control Agent on Mechanical Alloying Behavior of Nanocrystalline Titanium Based Powders. Materials 2020, 13, 2110. [Google Scholar] [CrossRef] [PubMed]

- Vergara-Figueroa, J.; Alejandro-Martín, S.; Pesenti, H.; Cerda, F.; Fernández-Pérez, A.; Gacitúa, W. Obtaining nanoparticles of Chilean natural zeolite and its ion exchange with copper salt (Cu2+) for antibacterial applications. Materials 2019, 12, 2202. [Google Scholar] [CrossRef] [Green Version]

- Fu, Q.; Sun, W. Mie theory for light scattering by a spherical particle in an absorbing medium. Appl. Opt. 2001, 40, 1354–1361. [Google Scholar] [CrossRef]

- Lionetto, F.; Pappadà, S.; Buccoliero, G.; Maffezzoli, A. Finite element modeling of continuous induction welding of thermoplastic matrix composites. Mater. Des. 2017, 120, 212–221. [Google Scholar] [CrossRef]

- Wunderlich, B. The ATHAS database on heat capacities of polymers. Pure Appl. Chem. 1995, 67, 1019–1026. [Google Scholar] [CrossRef]

- Androsch, R.; Wunderlich, B. The link between rigid amorphous fraction and crystal perfection in cold-crystallized poly (ethylene terephthalate). Polymer 2005, 46, 12556–12566. [Google Scholar] [CrossRef]

- Bai, C.; Spontak, R.J.; Koch, C.C.; Saw, C.K.; Balik, C.M. Structural changes in poly (ethylene terephthalate) induced by mechanical milling. Polymer 2000, 41, 7147–7157. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Q. Structure changes and thermal behaviors of polymer in PP/BaTiO3 nanocomposites during solid state shear milling. Polym. Plast. Technol. Eng. 2008, 47, 961–968. [Google Scholar] [CrossRef]

- Lionetto, F.; Timo, A.; Frigione, M. Curing kinetics of epoxy-deep eutectic solvent mixtures. Thermochim. Acta 2015, 612, 70–78. [Google Scholar] [CrossRef]

- Lionetto, F.; Timo, A.; Frigione, M. Cold-cured epoxy-based organic–inorganic hybrid resins containing deep eutectic solvents. Polymers 2019, 11, 14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lionetto, F.; Maffezzoli, A. Relaxations during the postcure of unsaturated polyester networks by ultrasonic wave propagation, dynamic mechanical analysis, and dielectric analysis. J. Polym. Sci. Part. B Polym. Phys. 2005, 43, 596–602. [Google Scholar] [CrossRef]

- Gates-Rector, S.D.; Blanton, T.N. XRD JCPDS No. 50-2275; ICDD International Centre for Diffraction Data: Livermore, CA, USA, 2019. [Google Scholar]

- Schrauwen, B.A.G.; Janssen, R.P.M.; Govaert, L.E.; Meijer, H.E.H. Intrinsic deformation behavior of semicrystalline polymers. Macromolecules 2004, 37, 6069–6078. [Google Scholar] [CrossRef] [Green Version]

- Stearne, J.M.; Ward, I.M. The tensile behaviour of polyethylene terephthalate. J. Mater. Sci. 1969, 4, 1088–1096. [Google Scholar] [CrossRef]

| Tg (°C) | Tc (°C) | ΔHc (J/g) | Tm-1 (°C) | ΔHm-1 (J/g) | Tm-2 (°C) | ΔHm-2 (J/g) | |

|---|---|---|---|---|---|---|---|

| Pellet | 84.0 ± 1.0 | - | - | 187.2 ± 5.1 | 2.7 ± 0.1 | 263.4 ± 0.3 | 33.8 ± 0.7 |

| 1st milling S 500 µm | 79.8 ± 0.3 | 125.3 ± 3.0 | 9.6 ± 1.0 | - | - | 253.9 ± 1.1 | 44.8 ± 4.1 |

| 2nd milling S 250 µm | 81.0 ± 0.6 | 123.0 ± 0.2 | 16.3 ± 2.9 | - | - | 255.5 ± 0.5 | 46.9 ± 3.5 |

| 3rd milling S 80 µm | 80.6 ± 0.9 | 122.3 ± 0.4 | 20.9 ± 1.1 | - | - | 256.1 ± 0.3 | 48.5 ± 1.6 |

| 1st milling S 500 µm+ annealing | 93.8 ± 0.4 | - | - | 171.5 ± 0.2 | 1.8 ± 0.2 | 255.6 ± 0.3 | 46.2 ± 1.1 |

| 2nd milling S 250 µm+ annealing | 92.7 ± 0.3 | - | - | 173.9 ± 0.3 | 2.5 ± 0.3 | 256.6 ± 0.2 | 47.1 ± 0.3 |

| 3rd milling S 80 µm+ annealing | 91.5 ± 0.3 | - | - | 173.4 ± 0.3 | 3.2 ± 0.3 | 256.3 ± 0.1 | 44.8 ± 0.2 |

| XXRD (-) | |

|---|---|

| Pellet not annealed | 0.22 |

| S250 not annealed | 0.20 |

| S250 annealed | 0.31 |

| S80 not annealed | 0.19 |

| S80 annealed | 0.30 |

| Procedure | Starting Powder D50 (μm) | ZrO2 Ball (mm) | Milling Conditions * | Milling Time (min) | Overall Time (min) | D10 (µm) | D50 (µm) | D90 (µm) | Nanometric Yield ** (% by Volume) |

|---|---|---|---|---|---|---|---|---|---|

| A | 212 ± 23 | 10 | 5 min (m)–5 min (p) | 147 | 351 | 0.13 ± 0.01 | 8.60 ± 0.71 | 141.10 ± 1.41 | 33.4 ± 7.7 |

| 1 | 3 min (m)–7 min (p) | ||||||||

| 0.5 | 3 min (m)–7 min (p) | ||||||||

| B | 190 ± 21 annealed | 1 | 3 min (m)–6 min (p) | 75 | 252 | 0.13 ± 0.02 | 11.21 ± 0.65 | 142.64 ± 1.69 | 32.7 ± 5.5 |

| 0.5 | 3 min (m)–6 min (p) | ||||||||

| C | 120 ± 18 annealed | 0.5 | 2 min (m) 5 min (p) | 36 | 120 | 0.11 ± 0.01 | 0.81 ± 0.01 | 14.21 ± 1.56 | 36.4 ± 11.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lionetto, F.; Corcione, C.E.; Rizzo, A.; Maffezzoli, A. Production and Characterization of Polyethylene Terephthalate Nanoparticles. Polymers 2021, 13, 3745. https://doi.org/10.3390/polym13213745

Lionetto F, Corcione CE, Rizzo A, Maffezzoli A. Production and Characterization of Polyethylene Terephthalate Nanoparticles. Polymers. 2021; 13(21):3745. https://doi.org/10.3390/polym13213745

Chicago/Turabian StyleLionetto, Francesca, Carola Esposito Corcione, Aurora Rizzo, and Alfonso Maffezzoli. 2021. "Production and Characterization of Polyethylene Terephthalate Nanoparticles" Polymers 13, no. 21: 3745. https://doi.org/10.3390/polym13213745

APA StyleLionetto, F., Corcione, C. E., Rizzo, A., & Maffezzoli, A. (2021). Production and Characterization of Polyethylene Terephthalate Nanoparticles. Polymers, 13(21), 3745. https://doi.org/10.3390/polym13213745