Contribution of Polymers to Electronic Memory Devices and Applications

Abstract

:1. Introduction

2. Polymer-Based Memory Devices

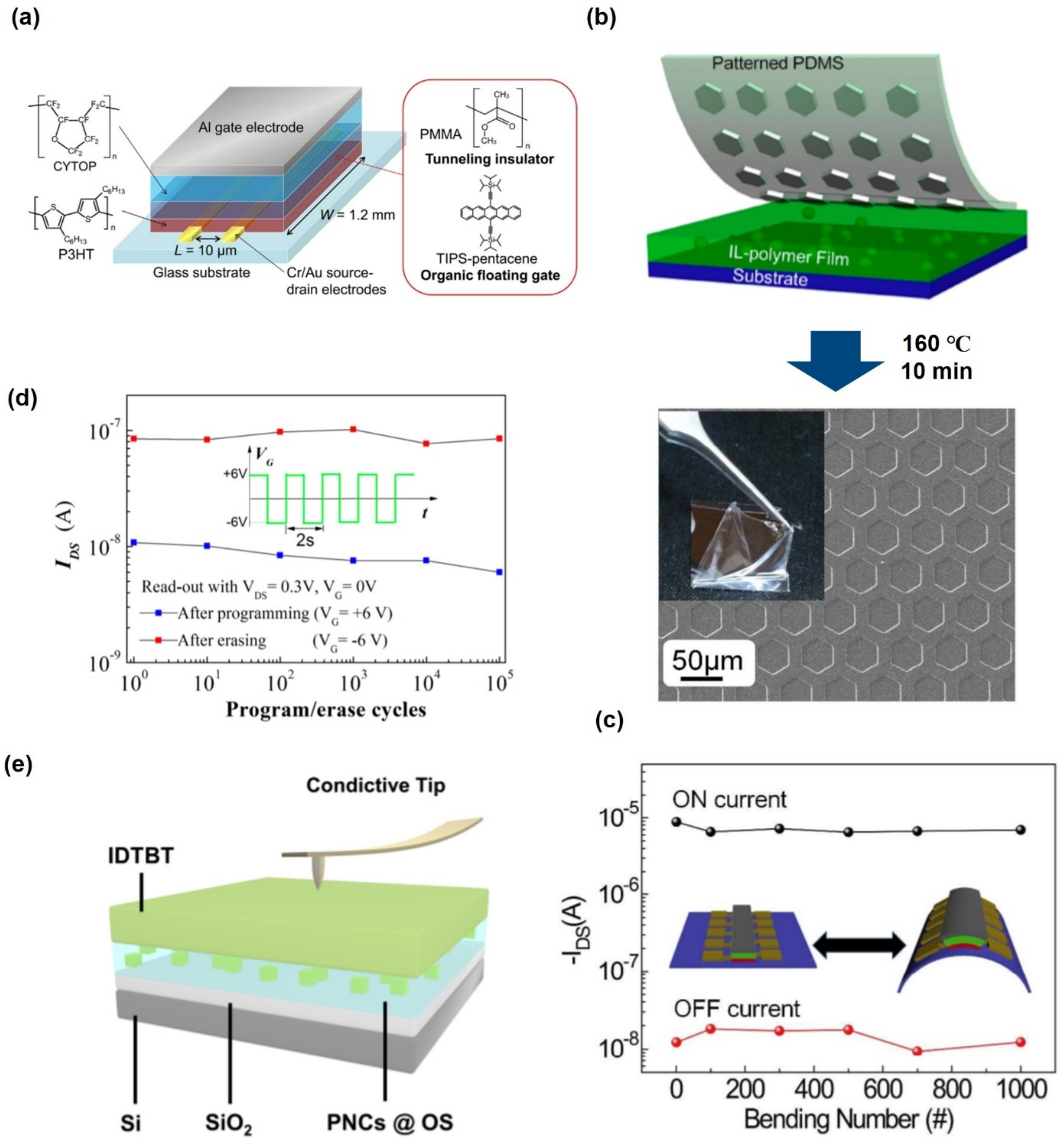

2.1. Floating-Gate Memory

| Polymer | Thickness (nm) | On/Off Switching Ratio | Memory Window (V) | Retention Time (s) | Mobility (cm2 V−1 s−1) | [Ref] | |

|---|---|---|---|---|---|---|---|

| Floating gate | cPVP/F8T2 | 22 | >104 | 30 | a few hours | 0.02 | [29] |

| FBC3SH | 3.67 | <102 | 18.7 | 105 | 0.05 | [37] | |

| PCBM/CsPbBr3/PS | 62 | 102 | 12.5 | 104 | N/A | [39] | |

| TIPS Pentacene | 45 | 102 | >25 | 5000 | 0.065 | [42] | |

| PFO/PS | 3.48 | 104 | 21 | 104 | 0.0074 | [43] | |

| CH3NH3PbBr3/poly(2-vinylpyridine) | 60 | <104 | 14 | >104 | N/A | [44] | |

| PCBM/PMMA | 9.90 | >102 | 22.1 | 1.2 × 104 | N/A | [46] | |

| PVN/C60 | 0.3 | 105–106 | 10.31 | 104 | 0.26 | [47] | |

| F8BT/Polystyrene | 50 | 106 | 5, 17 (at each level state) | 2 × 104 | 1 | [50] | |

| Tunneling layer | PVP | 16 | 1500 | N/A | 200 | 0.02 | [16] |

| Pentacene | 10–20 | >105 | 18.7 | 104 | 0.53 | [30] | |

| PMMA | 8–10 | 104 | 20 | N/A | N/A | [36] | |

| PMMA | 100 | 102 | 20 | 103 | 0.15 | [41] | |

| Electrode | PEDOT:PSS | 10 | >104 | 10 | 107 | 0.08 | [31] |

| Semiconductor | DPP-DTT | 80 | 103 | 20 | 108 | 0.3 | [42] |

2.2. Polymer Electret Memory

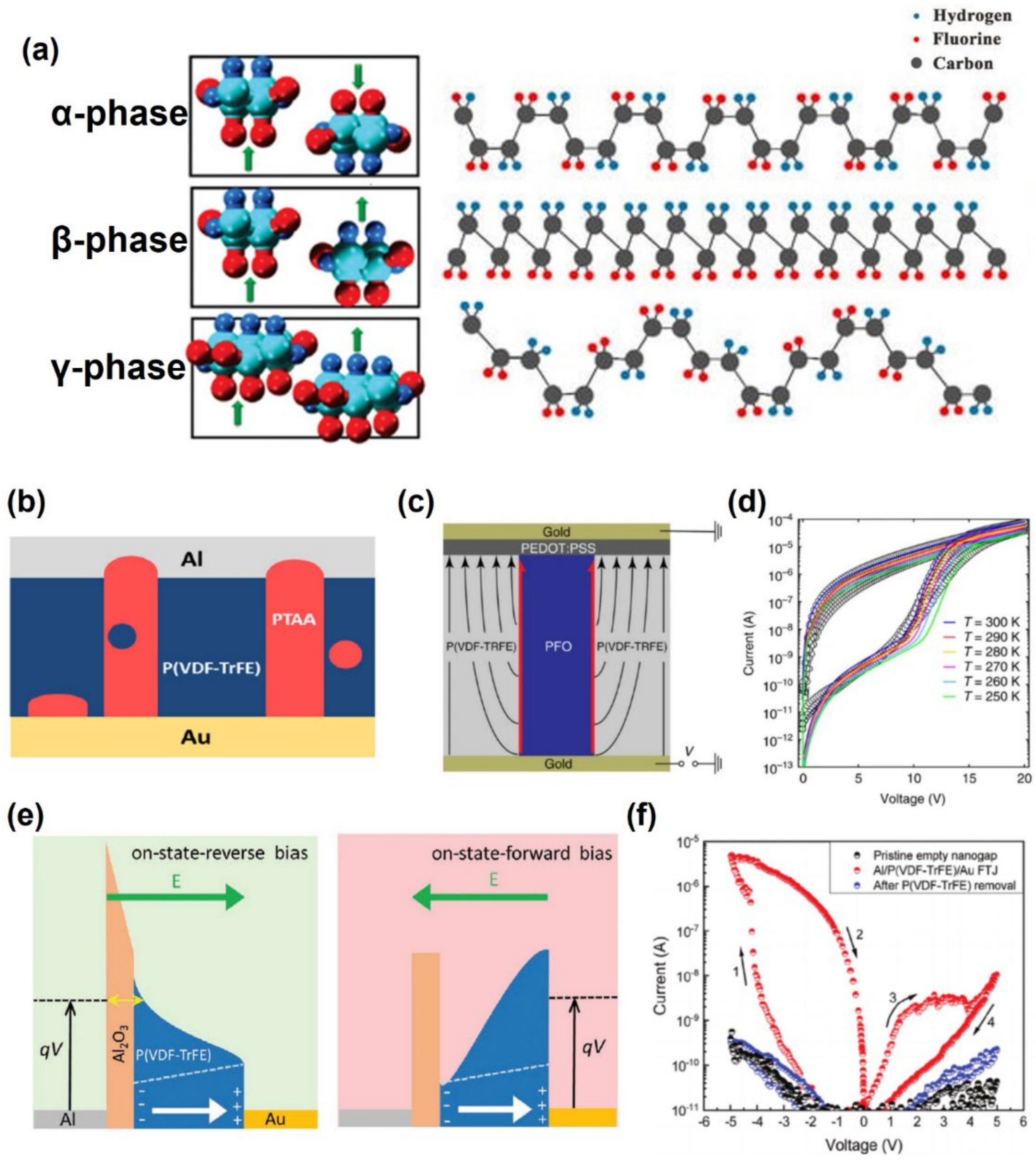

2.3. Ferroelectric Memory

2.3.1. Two-Terminal Ferroelectric Memory

2.3.2. Three-Terminal Ferroelectric Memory

| Ferroelectric Polymer | Thickness (nm) | On/Off Switching Ratio | Memory Window (V) | Retention Time (s) | Mobility (cm2 V−1 s−1) | [Ref] | |

|---|---|---|---|---|---|---|---|

| 2terminal ferroelectric layer (Switching layer) | P(VDF-TrFE)_ ZnO NPs blends | 300 | 2 × 107 | N/A | 104 | N/A | [77] |

| P(VDF-TrFE) | 300 | 103 | N/A | 104 | N/A | [78] | |

| P(VDF-TrFE) | 250 ± 54 | 102 | N/A | 8.7 × 104 | N/A | [74] | |

| P(VDF-TrFE) | 265 ± 10 | 105 | N/A | N/A | N/A | [75] | |

| P(VDF-TrFE) | 6 | 102–104 | N/A | 109 | N/A | [73] | |

| P(VDF-TrFE) | 300 | 105 | N/A | N/A | N/A | [76] | |

| 3terminal ferroelectric layer (Gate insulator) | P(VDF-TrFE) | 900 | 104 | N/A | 5 × 103 | 0.072–0.12 | [82] |

| P(VDF-TrFE-CTFE) | 60 | 102 | 13.3 | 8 × 104 | 1.7–3.3 | [84] | |

| P(VDF-TrFE-CTFE) | 650 | 103–104 | 12.4 | 6 × 103 | 0.5 | [85] | |

| P(VDF-TrFE) | 300 | 106 | 12 ± 2 | 106 | 5.6 | [86] | |

| P(VDF-TrFE) | 800–1500 | 2.4 | N/A | N/A | 400 | [90] | |

| P(VDF-TrFE) | 220 | 103 | 15 | 4 × 102 | 1159 | [88] | |

| P(VDF-TrFE) | 300 | 107 | 16.9 | 3 × 103 | 588 | [89] | |

| P(VDF-TrFE)_ PMMA blends | N/A | 104 | N/A | 103 | N/A | [93] |

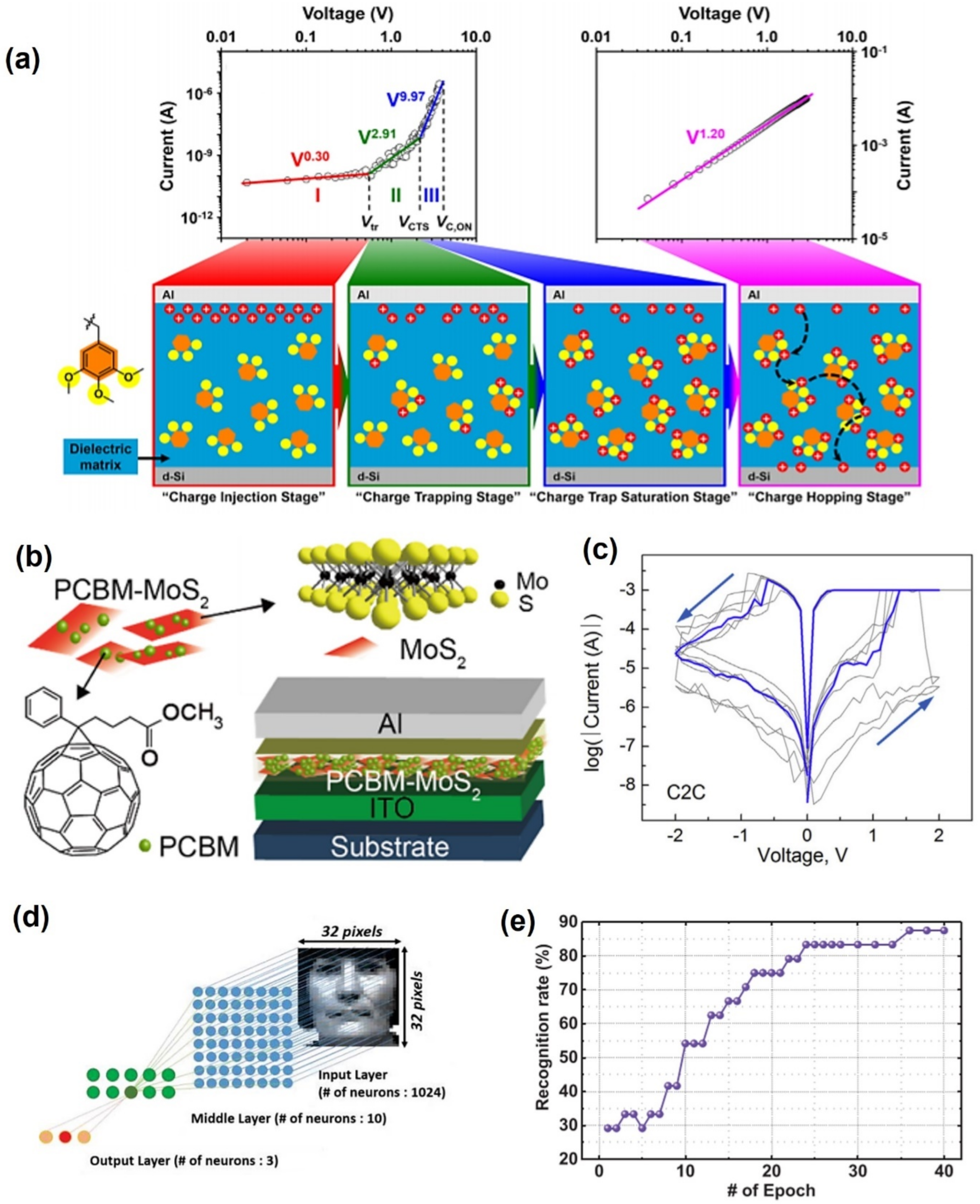

2.4. Memristor

| Polymer | Thickness (nm) | On/Off Switching Ratio | Memory Window (V) | Retention Time (s) | Mobility (cm2 V−1 s−1) | [Ref] | |

|---|---|---|---|---|---|---|---|

| Switching Layer | PEM-BzOMe3 | 35.6 | 108 | 4 | 4 × 104 | N/A | [95] |

| PCBM-MoS2 | 50 | 3 × 102 | 4.5 | >104 | N/A | [97] | |

| Parylene dimer(2,2-para-cycloophane) | 100 | 103 | 4 | >104 | N/A | [98] | |

| Parylene | 40 | 105 | 2.5 | 104 | N/A | [100] | |

| pV3D3 | 13.5 | 105 | <1 | >103 | N/A | [99] |

3. New Applications

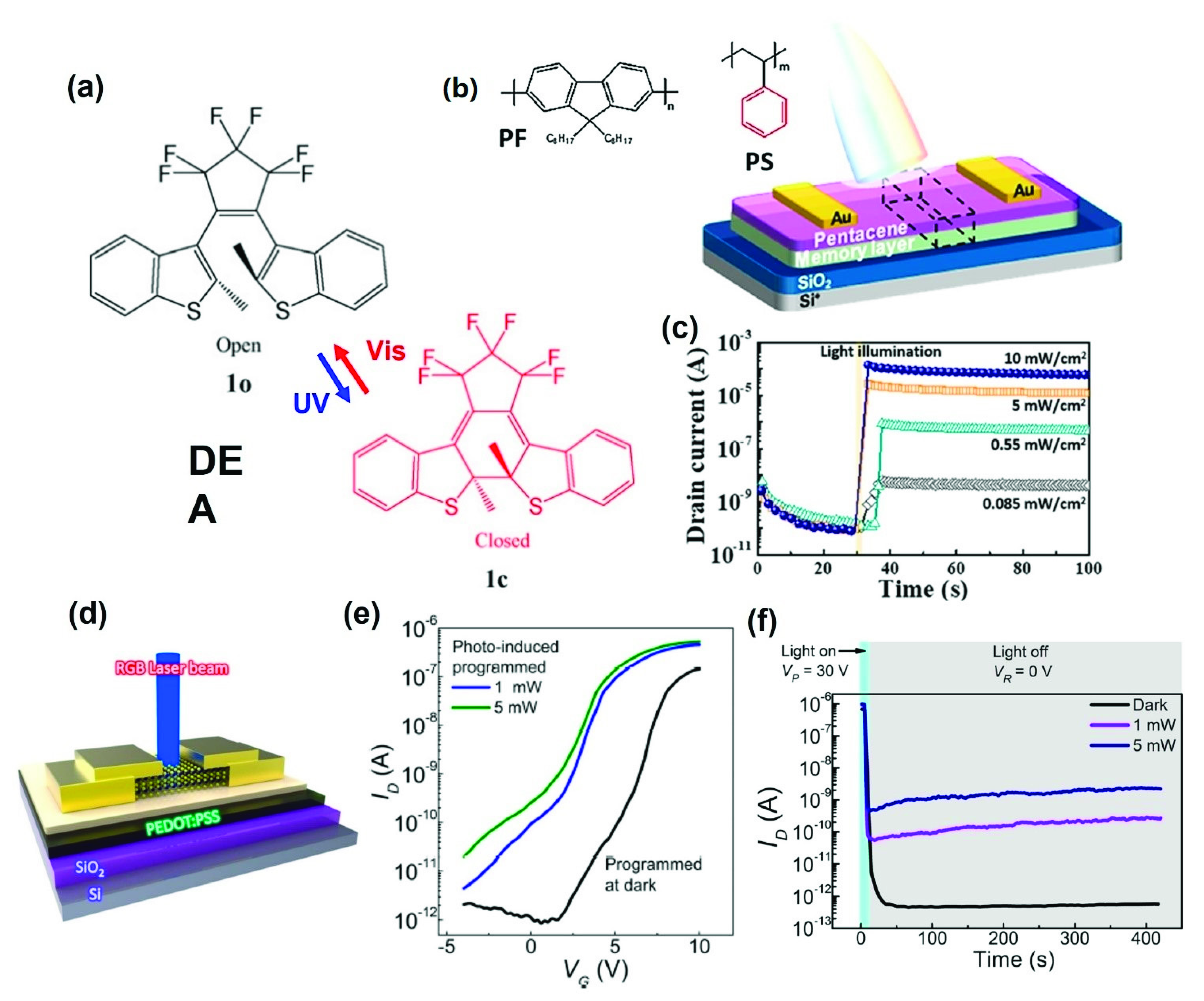

3.1. Optoelectrical Memory

| Photoreaction Polymers | Wavelength (nm) | Thickness (nm) | On/Off Switching Ratio | Memory Window (V) | Retention Time (s) | Mobility (cm2 V−1 s−1) | [Ref] |

|---|---|---|---|---|---|---|---|

| P3HT-DAE-Me | 313, 546 | N/A | 105 | N/A | 107 | 0.01 | [101] |

| PVK | 400~700 | 20 | 104 | 70 | 104 | 0.072 | [107] |

| PF/PS blend | 405, 450, 520 | 50–60 | 106 | 18 | 105 | 0.87 | [105] |

| CH3NH3PbBr3 | 450, 530 | 50 | 105 | N/A | N/A | N/A | [108] |

| PEDOT:PSS | 405, 532, 638 | N/A | 2.3 × 107 | 62 | 2 × 103 | N/A | [106] |

3.2. Neuromorphic Device

3.3. Flexible Devices

3.4. Biodegradable Memory Devices

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bi, S.; Li, Y.; He, Z.; Ouyang, Z.; Guo, Q.; Jiang, C. Self-assembly diketopyrrolopyrrole-based materials and polymer blend with enhanced crystal alignment and property for organic field-effect transistors. Org. Electron. 2019, 65, 96–99. [Google Scholar] [CrossRef]

- Hendsbee, A.D.; Li, Y. Performance comparisons of polymer semiconductors synthesized by direct (hetero) arylation polymerization (dhap) and conventional methods for organic thin film transistors and organic photovoltaics. Molecules 2018, 23, 1255. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, J.; Yu, P.; Qiu, S.; Zhao, Q.; Feng, L.; Ogier, S.; Tang, W.; Fan, J.; Liu, W.; Liu, Y. Universal compact model for thin-film transistors and circuit simulation for low-cost flexible large area electronics. IEEE Trans. Electron Devices 2017, 64, 2030–2037. [Google Scholar] [CrossRef]

- Zhang, C.; Sun, H.; Zhu, Q. Study on Flexible Large-Area Poly (Vinylidene Fluoride)-Based Piezoelectric Films Prepared by Extrusion-Casting Process for Sensors and Microactuators. Mater. Chem. Phys. 2022, 275, 125221. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Zhao, W.; Zhang, M.; Qin, H.; Xie, Y. Flexible, stretchable sensors for wearable health monitoring: Sensing mechanisms, materials, fabrication strategies and features. Sensors 2018, 18, 645. [Google Scholar] [CrossRef] [Green Version]

- Guo, L.; Zhu, X.; Sun, S.; Cong, C.; Zhou, Q.; Sun, X.; Liu, Y. Flexible semi-transparent organic transistors and circuits based on easily prepared polyphenyleneoxide dielectric. Org. Electron. 2019, 69, 308–312. [Google Scholar] [CrossRef]

- Mizukami, M.; Cho, S.-I.; Watanabe, K.; Abiko, M.; Suzuri, Y.; Tokito, S.; Kido, J. Flexible organic light-emitting diode displays driven by inkjet-printed high-mobility organic thin-film transistors. IEEE Electron Device Lett. 2017, 39, 39–42. [Google Scholar] [CrossRef]

- Gao, M.; Li, L.; Song, Y. Inkjet printing wearable electronic devices. J. Mater. Chem. C 2017, 5, 2971–2993. [Google Scholar] [CrossRef]

- Hong, A.J.; Song, E.B.; Yu, H.S.; Allen, M.J.; Kim, J.; Fowler, J.D.; Wassei, J.K.; Park, Y.; Wang, Y.; Zou, J. Graphene flash memory. ACS Nano 2011, 5, 7812–7817. [Google Scholar] [CrossRef]

- Xiang, J.; Li, X.; Ma, Y.; Zhao, Q.; Ho, C.-L.; Wong, W.-Y. Efficient flash memory devices based on non-conjugated ferrocene-containing copolymers. J. Mater. Chem. C 2018, 6, 11348–11355. [Google Scholar] [CrossRef]

- Kim, M.; Ha, J.; Kwon, I.; Han, J.H.; Cho, S.; Cho, I.H. A novel one-transistor dynamic random-access memory (1T DRAM) featuring partially inserted wide-bandgap double barriers for high-temperature applications. Micromachines 2018, 9, 581. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ling, Q.-D.; Chang, F.-C.; Song, Y.; Zhu, C.-X.; Liaw, D.-J.; Chan, D.S.-H.; Kang, E.-T.; Neoh, K.-G. Synthesis, dynamic random access memory behavior of a functional polyimide. J. Am. Chem. Soc. 2006, 128, 8732–8733. [Google Scholar] [CrossRef] [PubMed]

- Geier, M.L.; McMorrow, J.J.; Xu, W.; Zhu, J.; Kim, C.H.; Marks, T.J.; Hersam, M.C. Solution-processed carbon nanotube thin-film complementary static random access memory. Nat. Nanotechnol. 2015, 10, 944–948. [Google Scholar] [CrossRef]

- Avila-Niño, J.; Patchett, E.; Taylor, D.; Assender, H.; Yeates, S.; Ding, Z.; Morrison, J. Stable organic static random access memory from a roll-to-roll compatible vacuum evaporation process. Org. Electron. 2016, 31, 77–81. [Google Scholar] [CrossRef] [Green Version]

- Kim, E.K.; Kim, J.-H.; Lee, D.U.; Kim, G.H.; Kim, Y.-H. Characterization of nano-floating gate memory with zno nanoparticles embedded in polymeric matrix. Jpn. J. Appl. Phys. 2006, 45, 7209. [Google Scholar] [CrossRef]

- Liu, Z.; Xue, F.; Su, Y.; Lvov, Y.M.; Varahramyan, K. Memory effect of a polymer thin-film transistor with self-assembled gold nanoparticles in the gate dielectric. IEEE Trans. Nanotechnol. 2006, 5, 379–384. [Google Scholar]

- Reece, T.J.; Ducharme, S.; Sorokin, A.; Poulsen, M. Nonvolatile memory element based on a ferroelectric polymer langmuir–blodgett film. Appl. Phys. Lett. 2003, 82, 142–144. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; McCreery, R.L. Solid-state electrochemistry in molecule/tio2 molecular heterojunctions as the basis of the tio2 “memristor”. J. Electrochem. Soc. 2008, 156, P29. [Google Scholar] [CrossRef] [Green Version]

- Ha, H.; Kim, O. Bipolar switching characteristics of nonvolatile memory devices based on poly (3, 4-ethylenedioxythiophene): Poly (styrenesulfonate) thin film. Appl. Phys. Lett. 2008, 93, 265. [Google Scholar] [CrossRef] [Green Version]

- Casalbore-Miceli, G.; Camaioni, N.; Geri, A.; Ridolfi, G.; Zanelli, A.; Gallazzi, M.C.; Maggini, M.; Benincori, T. “Solid state charge trapping”: Examples of polymer systems showing memory effect. J. Electroanal. Chem. 2007, 603, 227–234. [Google Scholar] [CrossRef] [Green Version]

- Yu, A.D.; Tung, W.Y.; Chiu, Y.C.; Chueh, C.C.; Liou, G.S.; Chen, W.C. Multilevel nonvolatile flexible organic field-effect transistor memories employing polyimide electrets with different charge-transfer effects. Macromol. Rapid Commun. 2014, 35, 1039–1045. [Google Scholar] [CrossRef]

- Koliopoulou, S.; Dimitrakis, P.; Goustouridis, D.; Normand, P.; Pearson, C.; Petty, M.; Radamson, H.; Tsoukalas, D. Metal nano-floating gate memory devices fabricated at low temperature. Microelectron. Eng. 2006, 83, 1563–1566. [Google Scholar] [CrossRef]

- Paul, S.; Pearson, C.; Molloy, A.; Cousins, M.; Green, M.; Kolliopoulou, S.; Dimitrakis, P.; Normand, P.; Tsoukalas, D.; Petty, M. Langmuir—blodgett film deposition of metallic nanoparticles, their application to electronic memory structures. Nano Lett. 2003, 3, 533–536. [Google Scholar] [CrossRef]

- Leong, W.L.; Lee, P.S.; Lohani, A.; Lam, Y.M.; Chen, T.; Zhang, S.; Dodabalapur, A.; Mhaisalkar, S.G. Non-volatile organic memory applications enabled by in situ synthesis of gold nanoparticles in a self-assembled block copolymer. Adv. Mater. 2008, 20, 2325–2331. [Google Scholar] [CrossRef]

- Chen, C.-C.; Chiu, M.-Y.; Sheu, J.-T.; Wei, K.-H. Photoresponses, memory effects in organic thin film transistors incorporating poly (3-hexylthiophene)/cdse quantum dots. Appl. Phys. Lett. 2008, 92, 143105. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.-M.; Lee, D.-H.; Jeun, J.-H.; Lee, H.H.; Ko, S.S.; Yeon, I.-J.; Kim, Y.-S. Organic thin film transistor memory based on cdse nanoparticle/pmma blend as a tunneling layer. Memory 2004, 29, 833–837. [Google Scholar]

- Kim, S.S.; Cho, W.-J.; Ahn, C.-G.; Im, K.; Yang, J.-H.; Baek, I.-B.; Lee, S.; Lim, K.S. Fabrication of fin field-effect transistor silicon nanocrystal floating gate memory using photochemical vapor deposition. Appl. Phys. Lett. 2006, 88, 223502. [Google Scholar] [CrossRef] [Green Version]

- Guarini, K.W.; Black, C.T.; Zhang, Y.; Babich, I.V.; Sikorski, E.M.; Gignac, L.M. Low voltage, scalable nanocrystal FLASH memory fabricated by templated self assembly. In Proceedings of the IEEE International Electron Devices Meeting 2003, Washington, DC, USA, 8–10 December 2003; IEEE: Piscataway, NJ, USA, 2003. [Google Scholar]

- Baeg, K.J.; Noh, Y.Y.; Sirringhaus, H.; Kim, D.Y. Controllable shifts in threshold voltage of top-gate polymer field-effect transistors for applications in organic nano floating gate memory. Adv. Funct. Mater. 2010, 20, 224–230. [Google Scholar] [CrossRef]

- Zhang, J.-Y.; Liu, L.-M.; Su, Y.-J.; Gao, X.; Liu, C.-H.; Liu, J.; Dong, B.; Wang, S.-D. Synergistic effect in organic field-effect transistor nonvolatile memory utilizing bimetal nanoparticles as nano-floating-gate. Org. Electron. 2015, 25, 324–328. [Google Scholar] [CrossRef]

- Kim, C.; Song, J.-M.; Lee, J.-S.; Lee, M.J. All-solution-processed nonvolatile flexible nano-floating gate memory devices. Nanotechnology 2013, 25, 014016. [Google Scholar] [CrossRef]

- Shiono, F.; Abe, H.; Nagase, T.; Kobayashi, T.; Naito, H. Optical memory characteristics of solution-processed organic transistors with self-organized organic floating gates for printable multi-level storage devices. Org. Electron. 2019, 67, 109–115. [Google Scholar] [CrossRef]

- Hwang, S.K.; Park, T.J.; Kim, K.L.; Cho, S.M.; Jeong, B.J.; Park, C. Organic one-transistor-type nonvolatile memory gated with thin ionic liquid-polymer film for low voltage operation. ACS Appl. Mater. Interfaces 2014, 6, 20179–20187. [Google Scholar] [CrossRef]

- Li, J.; Yan, F. Solution-processable low-voltage, flexible floating-gate memories based on an n-type polymer semiconductor, high-k polymer gate dielectrics. ACS Appl. Mater. Interfaces 2014, 6, 12815–12820. [Google Scholar] [CrossRef]

- Lin, W.; Chen, G.; Li, E.; He, L.; Yu, W.; Peng, G.; Chen, H.; Guo, T. Nonvolatile multilevel photomemory based on lead-free double perovskite Cs2AgBiBr6 nanocrystals wrapped within SiO2 as a charge trapping layer. ACS Appl. Mater. Interfaces 2020, 12, 43967–43975. [Google Scholar] [CrossRef] [PubMed]

- Artemyev, M.; Woggon, U.; Jaschinski, H.; Gurinovich, L.; Gaponenko, S. Spectroscopic study of electronic states in an ensemble of close-packed cdse nanocrystals. J. Phys. Chem. B 2000, 104, 11617–11621. [Google Scholar] [CrossRef]

- Kim, C.; Kim, J.Y.; Lee, K.; Jung, S.Y.; Yun, D.-J.; An, T.K.; Lee, H.S.; Jeong, Y.J.; Lee, J. Surface-modified quantum-dot floating layer using novel thiol with large dipole moment for improved feasibility of light-erasable organic transistor memory applications. J. Ind. Eng. Chem. 2020, 85, 111–117. [Google Scholar] [CrossRef]

- Samanta, S.K.; Singh, P.K.; Yoo, W.J.; Samudra, G.; Yeo, Y.C.; Bera, L.K.; Balasubramanian, N. Enhancement of memory window in short channel non-volatile memory devices using double layer tungsten nanocrystals. In Proceedings of the IEEE InternationalElectron Devices Meeting, 2005. IEDM Technical Digest, Washington, DC, USA, 5–7 December 2005; IEEE: Piscataway, NJ, USA, 2005. [Google Scholar]

- Li, Q.; Li, T.; Zhang, Y.; Zhao, H.; Li, J.; Yao, J. Dual-functional optoelectronic memories based on ternary hybrid floating gate layers. Nanoscale 2021, 13, 3295–3303. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Zhang, S. Nanoparticle floating-gate transistor memory based on solution-processed ambipolar organic semiconductor. In E3S Web of Conferences; EDP Sciences: Ulis, France, 2020. [Google Scholar]

- Higashinakaya, M.; Nagase, T.; Abe, H.; Hattori, R.; Tazuhara, S.; Kobayashi, T.; Naito, H. Electrically programmable multilevel nonvolatile memories based on solution-processed organic floating-gate transistors. Appl. Phys. Lett. 2021, 118, 103301. [Google Scholar] [CrossRef]

- Wu, C.; Wang, W.; Song, J. Molecular floating-gate organic nonvolatile memory with a fully solution processed core architecture. Appl. Phys. Lett. 2016, 109, 223301. [Google Scholar] [CrossRef]

- Chen, Y.-C.; Lin, Y.-C.; Hsieh, H.-C.; Hsu, L.-C.; Yang, W.-C.; Isono, T.; Satoh, T.; Chen, W.-C. Improving the performance of photonic transistor memory devices using conjugated block copolymers as a floating gate. J. Mater. Chem. C 2021, 9, 1259–1268. [Google Scholar] [CrossRef]

- Yang, W.-C.; Lin, Y.-C.; Liao, M.-Y.; Hsu, L.-C.; Lam, J.-Y.; Chuang, T.-H.; Li, G.-S.; Yang, Y.-F.; Chueh, C.-C.; Chen, W.-C. Comprehensive non-volatile photo-programming transistor memory via a dual-functional perovskite-based floating gate. ACS Appl. Mater. Interfaces 2021, 13, 20417–22026. [Google Scholar] [CrossRef] [PubMed]

- Lan, S.; Zhong, J.; Li, E.; Yan, Y.; Wu, X.; Chen, Q.; Lin, W.; Chen, H.; Guo, T. High-performance nonvolatile organic photoelectronic transistor memory based on bulk heterojunction structure. ACS Appl. Mater. Interfaces 2020, 12, 31716–33124. [Google Scholar] [CrossRef]

- Li, Q.; Li, T.; Zhang, Y.; Chen, Z.; Li, Y.; Jin, L.; Zhao, H.; Li, J.; Yao, J. Photoerasable organic field-effect transistor memory based on a one-step solution-processed hybrid floating gate layer. J. Phys. Chem. C 2020, 124, 23343–23351. [Google Scholar] [CrossRef]

- Jeong, Y.J.; Yun, D.-J.; Kim, S.H.; Jang, J.; Park, C.E. Photoinduced recovery of organic transistor memories with photoactive floating-gate interlayers. ACS Appl. Mater. Interfaces 2017, 9, 11759–11769. [Google Scholar] [CrossRef] [PubMed]

- Jin, R.; Wang, J.; Shi, K.; Qiu, B.; Ma, L.; Huang, S.; Li, Z. Multilevel storage, photoinduced-reset memory by an inorganic perovskite quantum-dot/polystyrene floating-gate organic transistor. RSC Adv. 2020, 10, 43225–43232. [Google Scholar] [CrossRef]

- Zhou, Y.; Han, S.-T.; Sonar, P.; Roy, V. Nonvolatile multilevel data storage memory device from controlled ambipolar charge trapping mechanism. Sci. Rep. 2013, 3, 2319. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, T.; Guo, S.; Qi, W.; Li, S.; Xu, M.; Wang, W. Organic transistor nonvolatile memory with three-level information storage, optical detection functions. ACS Appl. Mater. Interfaces 2020, 12, 21952–21960. [Google Scholar] [CrossRef]

- Sun, Q.; Ho, D.H.; Choi, Y.; Pan, C.; Kim, D.H.; Wang, Z.L.; Cho, J.H. Piezopotential-programmed multilevel nonvolatile memory as triggered by mechanical stimuli. ACS Nano 2016, 10, 11037–11043. [Google Scholar] [CrossRef]

- Jeong, Y.J.; Yun, D.-J.; Noh, S.H.; Park, C.E.; Jang, J. Surface modification of cdse quantum-dot floating gates for advancing light-erasable organic field-effect transistor memories. ACS Nano 2018, 12, 7701–7709. [Google Scholar] [CrossRef]

- Scharnberg, M.; Rehders, S.; Adiyaman, Ö.; Schröder, S.; Strunskus, T.; Faupel, F. Evaporated electret films with superior charge stability based on teflon af 2400. Org. Electron. 2019, 70, 167–171. [Google Scholar] [CrossRef]

- Bodurov, I.; Viraneva, A.; Yovcheva, T. Electret, dielectric properties of lyophilized polymer films. J. Phys. Conf. Ser. 2019, 1186, 012013. [Google Scholar] [CrossRef]

- Baeg, K.J.; Noh, Y.Y.; Ghim, J.; Lim, B.; Kim, D.Y. Polarity effects of polymer gate electrets on non-volatile organic field-effect transistor memory. Adv. Funct. Mater. 2008, 18, 3678–3685. [Google Scholar] [CrossRef]

- Kim, J.; Ho, D.; Kim, I.S.; Kim, M.-G.; Baeg, K.-J.; Kim, C. Solution-processed flexible nonvolatile organic field-effect transistor memory using polymer electret. Org. Electron. 2021, 99, 106331. [Google Scholar] [CrossRef]

- Cheng, S.-W.; Chien, Y.-H.C.; Huang, T.-Y.; Liu, C.-L.; Liou, G.-S. Linkage effects of triphenylamine-based aromatic polymer electrets on electrical memory performance. Polymer 2018, 148, 382–389. [Google Scholar] [CrossRef]

- He, W.; Xu, W.; He, H.; Jing, X.; Liu, C.; Feng, J.; Luo, C.; Fan, Z.; Wu, S.; Gao, J. From unipolar, worm-type to ambipolar, bistable organic electret memory device by controlling minority lateral transport. Adv. Electron. Mater. 2020, 6, 1901320. [Google Scholar] [CrossRef]

- Chang, M.-F.; Lee, P.-T.; McAlister, S.; Chin, A. A flexible organic pentacene nonvolatile memory based on high-κ dielectric layers. Appl. Phys. Lett. 2008, 93, 439. [Google Scholar] [CrossRef]

- Lu, G.; Koch, N.; Neher, D. In-situ tuning threshold voltage of field-effect transistors based on blends of poly (3-hexylthiophene) with an insulator electret. Appl. Phys. Lett. 2015, 107, 063301. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Barrett, B.; Lee, T.; Mukhopadhyaya, T.; Lu, C.; Plunkett, E.C.; Kale, T.; Chi, C.; Livi, K.J.; McGuiggan, P. Maximized hole trapping in a polystyrene transistor dielectric from a highly branched iminobis (aminoarene) side chain. ACS Appl. Mater. Interfaces 2021, 13, 34584–34596. [Google Scholar] [CrossRef]

- Yang, S.M.; Yoon, J.-G.; Noh, T.W. Nanoscale studies of defect-mediated polarization switching dynamics in ferroelectric thin film capacitors. Curr. Appl. Phys. 2011, 11, 1111–1125. [Google Scholar] [CrossRef]

- Nelson, C.T.; Gao, P.; Jokisaari, J.R.; Heikes, C.; Adamo, C.; Melville, A.; Baek, S.-H.; Folkman, C.M.; Winchester, B.; Gu, Y. Domain dynamics during ferroelectric switching. Science 2011, 334, 968–971. [Google Scholar] [CrossRef] [Green Version]

- Fitsilis, M.; Kohlstedt, H.; Waser, R.; Ullmann, M. A new concept for using ferroelectric transistors in nonvolatile memories. Integr. Ferroelectr. 2004, 60, 45–58. [Google Scholar] [CrossRef]

- Aizawa, K.; Park, B.-E.; Kawashima, Y.; Takahashi, K.; Ishiwara, H. Impact of hfo 2 buffer layers on data retention characteristics of ferroelectric-gate field-effect transistors. Appl. Phys. Lett. 2004, 85, 3199–3201. [Google Scholar] [CrossRef]

- Eshita, T.; Wang, W.; Nomura, K.; Nakamura, K.; Saito, H.; Yamaguchi, H.; Mihara, S.; Hikosaka, Y.; Kataoka, Y.; Kojima, M. Development of highly reliable ferroelectric random access memory, its internet of things applications. Jpn. J. Appl. Phys. 2018, 57, 11UA01. [Google Scholar] [CrossRef]

- Khanna, S.; Jung, M.; Zwerg, M.; Bartling, S. Ferro-Electric RAM Based Microcontrollers: Ultra-Low Power Intelligence for the Internet of Things. In Enabling the Internet of Things; Springer: Cham, Switzerland, 2017; pp. 503–520. [Google Scholar]

- Zhu, L.; Wang, Q. Novel ferroelectric polymers for high energy density, low loss dielectrics. Macromolecules 2012, 45, 2937–2954. [Google Scholar] [CrossRef]

- Wu, T.; Jin, H.; Dong, S.; Xuan, W.; Xu, H.; Lu, L.; Fang, Z.; Huang, S.; Tao, X.; Shi, L. A flexible film bulk acoustic resonator based on β-phase polyvinylidene fluoride polymer. Sensors 2020, 20, 1346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Furukawa, T. Ferroelectric properties of vinylidene fluoride copolymers. Phase Transit. Multinatl. J. 1989, 18, 143–211. [Google Scholar] [CrossRef]

- Carroli, M.; Dixon, A.G.; Herder, M.; Pavlica, E.; Hecht, S.; Bratina, G.; Orgiu, E.; Samorì, P. Multiresponsive nonvolatile memories based on optically switchable ferroelectric organic field-effect transistors. Adv. Mater. 2021, 33, 2007965. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, X.; Wan, B.; Yang, Z.; Li, F.; Lu, J.; Hu, G.; Pan, C.; Wang, Z.L. In2O3 nanowire field-effect transistors with sub-60 mv/dec subthreshold swing stemming from negative capacitance, their logic applications. ACS Nano 2018, 12, 9608–9616. [Google Scholar] [CrossRef]

- Majumdar, S. Ultrafast Switching and Linear Conductance Modulation in Ferroelectric Tunnel Junctions via P (VDF-TrFE) Morphology Control. Nanoscale 2021, 13, 11270–11278. [Google Scholar] [CrossRef] [PubMed]

- Ghittorelli, M.; Lenz, T.; Dehsari, H.S.; Zhao, D.; Asadi, K.; Blom, P.W.; Kovács-Vajna, Z.M.; de Leeuw, D.M.; Torricelli, F. Quantum tunnelling, charge accumulation in organic ferroelectric memory diodes. Nat. Commun. 2017, 8, 15741. [Google Scholar]

- Kumar, M.; Dehsari, H.S.; Anwar, S.; Asadi, K. Air-stable memory array of bistable rectifying diodes based on ferroelectric-semiconductor polymer blends. Appl. Phys. Lett. 2018, 112, 123302. [Google Scholar] [CrossRef]

- Kumar, M.; Georgiadou, D.G.; Seitkhan, A.; Loganathan, K.; Yengel, E.; Faber, H.; Naphade, D.; Basu, A.; Anthopoulos, T.D.; Asadi, K. Colossal tunneling electroresistance in co-planar polymer ferroelectric tunnel junctions. Adv. Electron. Mater. 2020, 6, 1901091. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.Y.; Anoop, G.; Son, Y.J.; Kim, S.H.; Lee, E.; Jo, J.Y. Ferroelectric-mediated filamentary resistive switching in P (vdf-trfe)/zno nanocomposite films. Phys. Chem. Chem. Phys. 2018, 20, 16176–16183. [Google Scholar] [CrossRef] [PubMed]

- Lenz, T.; Ghittorelli, M.; Benneckendorf, F.S.; Asadi, K.; Kasparek, C.; Glasser, G.; Blom, P.W.; Torricelli, F.; de Leeuw, D.M. Downscaling, charge transport in nanostructured ferroelectric memory diodes fabricated by solution micromolding. Adv. Funct. Mater. 2016, 26, 5111–5119. [Google Scholar] [CrossRef]

- Kim, D.; Lu, H.; Ryu, S.; Bark, C.-W.; Eom, C.-B.; Tsymbal, E.; Gruverman, A. Ferroelectric tunnel memristor. Nano Lett. 2012, 12, 5697–5702. [Google Scholar] [CrossRef] [PubMed]

- Kanaparthi, S.; Badhulika, S. Solvent-free fabrication of a biodegradable all-carbon paper based field effect transistor for human motion detection through strain sensing. Green Chem. 2016, 18, 3640–3646. [Google Scholar] [CrossRef] [Green Version]

- Chang, J.; Shin, C.H.; Park, Y.J.; Kang, S.J.; Jeong, H.J.; Kim, K.J.; Hawker, C.J.; Russell, T.P.; Ryu, D.Y.; Park, C. Polymeric gate dielectric interlayer of cross-linkable poly (styrene-r-methylmethacrylate) copolymer for ferroelectric pvdf-trfe field effect transistor memory. Org. Electron. 2009, 10, 849–856. [Google Scholar] [CrossRef]

- Nguyen, C.; Mhaisalkar, S.; Ma, J.; Lee, P. Enhanced organic ferroelectric field effect transistor characteristics with strained poly (vinylidene fluoride-trifluoroethylene) dielectric. Org. Electron. 2008, 9, 1087–1092. [Google Scholar] [CrossRef]

- Kang, S.J.; Bae, I.; Park, Y.J.; Park, T.H.; Sung, J.; Yoon, S.C.; Kim, K.H.; Choi, D.H.; Park, C. Non-volatile ferroelectric poly (vinylidene fluoride-co-trifluoroethylene) memory based on a single-crystalline tri-isopropylsilylethynyl pentacene field-effect transistor. Adv. Funct. Mater. 2009, 19, 1609–1616. [Google Scholar] [CrossRef]

- Xu, T.; Xiang, L.; Xu, M.; Xie, W.; Wang, W. Excellent low-voltage operating flexible ferroelectric organic transistor nonvolatile memory with a sandwiching ultrathin ferroelectric film. Sci. Rep. 2017, 7, 8890. [Google Scholar] [CrossRef] [Green Version]

- Xu, M.; Guo, S.; Xu, T.; Xie, W.; Wang, W. Low-voltage programmable/erasable high performance flexible organic transistor nonvolatile memory based on a tetratetracontane passivated ferroelectric terpolymer. Org. Electron. 2019, 64, 62–70. [Google Scholar] [CrossRef]

- Song, L.; Wang, Y.; Gao, Q.; Guo, Y.; Wang, Q.; Qian, J.; Jiang, S.; Wu, B.; Wang, X.; Shi, Y. Speed up ferroelectric organic transistor memories by using two-dimensional molecular crystalline semiconductors. ACS Appl. Mater. Interfaces 2017, 9, 18127–18133. [Google Scholar] [CrossRef]

- Kim, K.L.; Lee, W.; Hwang, S.K.; Joo, S.H.; Cho, S.M.; Song, G.; Cho, S.H.; Jeong, B.; Hwang, I.; Ahn, J.-H. Epitaxial growth of thin ferroelectric polymer films on graphene layer for fully transparent, flexible nonvolatile memory. Nano Lett. 2016, 16, 334–340. [Google Scholar] [CrossRef]

- Lee, Y.T.; Kwon, H.; Kim, J.S.; Kim, H.-H.; Lee, Y.J.; Lim, J.A.; Song, Y.-W.; Yi, Y.; Choi, W.-K.; Hwang, D.K. Nonvolatile ferroelectric memory circuit using black phosphorus nanosheet-based field-effect transistors with P (vdf-trfe) polymer. ACS Nano 2015, 9, 10394–10401. [Google Scholar] [CrossRef]

- Tian, H.; Wang, X.; Zhu, Y.; Liao, L.; Wang, X.; Wang, J.; Hu, W. High performance top-gated ferroelectric field effect transistors based on two-dimensional zno nanosheets. Appl. Phys. Lett. 2017, 110, 043505. [Google Scholar] [CrossRef]

- Hassanpour Amiri, M.; Heidler, J.; Müllen, K.; Asadi, K. Design rules for memories based on graphene ferroelectric field-effect transistors. ACS Appl. Electron. Mater. 2019, 2, 2–8. [Google Scholar] [CrossRef] [Green Version]

- Das, S.; Demarteau, M.; Roelofs, A. Ambipolar phosphorene field effect transistor. ACS Nano 2014, 8, 11730–11738. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, J.; Xu, R.; Wang, F.; Li, W.; Ghufran, M.; Zhang, Y.-W.; Yu, Z.; Zhang, G.; Qin, Q. Extraordinary photoluminescence, strong temperature/angle-dependent raman responses in few-layer phosphorene. ACS Nano 2014, 8, 9590–9596. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, J.-R.; Boampong, A.A.; Choi, Y.; Kim, M.-H. Ferroelectric-dielectric mixed buffer layer for enhanced electrical performance of organic ferroelectric memory transistors. J. Nanosci. Nanotechnol. 2019, 19, 4651–4656. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.J.; Pickett, M.D.; Li, X.; Ohlberg, D.A.; Stewart, D.R.; Williams, R.S. Memristive switching mechanism for metal/oxide/metal nanodevices. Nat. Nanotechnol. 2008, 3, 429–433. [Google Scholar] [CrossRef]

- Ree, B.J.; Isono, T.; Satoh, T. Chemically controlled volatile, nonvolatile resistive memory characteristics of novel oxygen-based polymers. ACS Appl. Mater. Interfaces 2020, 12, 28435–28445. [Google Scholar] [CrossRef] [PubMed]

- Liao, K.; Lei, P.; Tu, M.; Luo, S.; Jiang, T.; Jie, W.; Hao, J. Memristor based on inorganic, organic two-dimensional materials: Mechanisms, performance, synaptic applications. ACS Appl. Mater. Interfaces 2021, 13, 32606–32623. [Google Scholar] [CrossRef] [PubMed]

- Lv, W.; Wang, H.; Jia, L.; Tang, X.; Lin, C.; Yuwen, L.; Wang, L.; Huang, W.; Chen, R. Tunable nonvolatile memory behaviors of pcbm–mos2 2d nanocomposites through surface deposition ratio control. ACS Appl. Mater. Interfaces 2018, 10, 6552–6559. [Google Scholar] [CrossRef]

- Minnekhanov, A.A.; Shvetsov, B.S.; Martyshov, M.M.; Nikiruy, K.E.; Kukueva, E.V.; Presnyakov, M.Y.; Forsh, P.A.; Rylkov, V.V.; Erokhin, V.V.; Demin, V.A. On the resistive switching mechanism of parylene-based memristive devices. Org. Electron. 2019, 74, 89–95. [Google Scholar] [CrossRef]

- Jang, B.C.; Kim, S.; Yang, S.Y.; Park, J.; Cha, J.-H.; Oh, J.; Choi, J.; Im, S.G.; Dravid, V.P.; Choi, S.-Y. Polymer analog memristive synapse with atomic-scale conductive filament for flexible neuromorphic computing system. Nano Lett. 2019, 19, 839–849. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Lin, M.; Wang, Z.; Zhao, X.; Cai, Y.; Liu, Q.; Fang, Y.; Yang, Y.; He, M.; Huang, R. Low power parylene-based memristors with a graphene barrier layer for flexible electronics applications. Adv. Electron. Mater. 2019, 5, 1800852. [Google Scholar] [CrossRef]

- Leydecker, T.; Herder, M.; Pavlica, E.; Bratina, G.; Hecht, S.; Orgiu, E.; Samorì, P. Flexible non-volatile optical memory thin-film transistor device with over 256 distinct levels based on an organic bicomponent blend. Nat. Nanotechnol. 2016, 11, 769–775. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, H.; Cheng, N.; Ma, W.; Li, M.; Hu, S.; Gu, L.; Meng, S.; Guo, X. Design of a photoactive hybrid bilayer dielectric for flexible nonvolatile organic memory transistors. ACS Nano 2016, 10, 436–445. [Google Scholar] [CrossRef]

- Perrier, A.; Maurel, F.; Jacquemin, D. Single molecule multiphotochromism with diarylethenes. Acc. Chem. Res. 2012, 45, 1173–1182. [Google Scholar] [CrossRef] [PubMed]

- Yun, C.; You, J.; Kim, J.; Huh, J.; Kim, E. Photochromic fluorescence switching from diarylethenes, its applications. J. Photochem. Photobiol. C Photochem. Rev. 2009, 10, 111–129. [Google Scholar] [CrossRef]

- Shih, C.-C.; Chiang, Y.-C.; Hsieh, H.-C.; Lin, Y.-C.; Chen, W.-C. Multilevel photonic transistor memory devices using conjugated/insulated polymer blend electrets. ACS Appl. Mater. Interfaces 2019, 11, 42429–44237. [Google Scholar] [CrossRef]

- Hong, S.; Park, J.; Lee, J.J.; Lee, S.; Yun, K.; Yoo, H.; Kim, S. Multifunctional molybdenum disulfide flash memory using a pedot: Pss floating gate. NPG Asia Mater. 2021, 13, 38. [Google Scholar] [CrossRef]

- Yi, M.; Xie, M.; Shao, Y.; Li, W.; Ling, H.; Xie, L.; Yang, T.; Fan, Q.; Zhu, J.; Huang, W. Light programmable/erasable organic field-effect transistor ambipolar memory devices based on the pentacene/pvk active layer. J. Mater. Chem. C 2015, 3, 5220–5225. [Google Scholar] [CrossRef]

- Ercan, E.; Chen, J.-Y.; Shih, C.-C.; Chueh, C.-C.; Chen, W.-C. Influence of polymeric electrets on the performance of derived hybrid perovskite-based photo-memory devices. Nanoscale 2018, 10, 18869–18877. [Google Scholar] [CrossRef]

- Jung, R.; Brauer, E.J.; Abbas, J.J. Real-time interaction between a neuromorphic electronic circuit, the spinal cord. IEEE Trans. Neural Syst. Rehabil. Eng. 2001, 9, 319–326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Melianas, A.; Quill, T.; LeCroy, G.; Tuchman, Y.; Loo, H.v.; Keene, S.; Giovannitti, A.; Lee, H.; Maria, I.; McCulloch, I. Temperature-resilient solid-state organic artificial synapses for neuromorphic computing. Sci. Adv. 2020, 6, eabb2958. [Google Scholar] [CrossRef]

- Kong, L.-a.; Sun, J.; Qian, C.; Gou, G.; He, Y.; Yang, J.; Gao, Y. Ion-gel gated field-effect transistors with solution-processed oxide semiconductors for bioinspired artificial synapses. Org. Electron. 2016, 39, 64–70. [Google Scholar] [CrossRef]

- Park, Y.; Kim, M.-K.; Lee, J.-S. Artificial synaptic transistors based on schottky barrier height modulation using reduced graphene oxides. Carbon 2020, 165, 455–460. [Google Scholar] [CrossRef]

- Go, G.-T.; Lee, Y.; Seo, D.-G.; Pei, M.; Lee, W.; Yang, H.; Lee, T.-W. Achieving microstructure-controlled synaptic plasticity, long-term retention in ion-gel-gated organic synaptic transistors. Adv. Intell. Syst. 2020, 2, 2000012. [Google Scholar] [CrossRef]

- Sun, H.; Luo, Z.; Zhao, L.; Liu, C.; Ma, C.; Lin, Y.; Gao, G.; Chen, Z.; Bao, Z.; Jin, X. Bifeo3-based flexible ferroelectric memristors for neuromorphic pattern recognition. ACS Appl. Electron. Mater. 2020, 2, 1081–1089. [Google Scholar] [CrossRef]

- Albano, L.G.; Vello, T.P.; de Camargo, D.H.; da Silva, R.M.; Padilha, A.C.; Fazzio, A.; Bufon, C.C. Ambipolar resistive switching in an ultrathin surface-supported metal–organic framework vertical heterojunction. Nano Lett. 2020, 20, 1080–1088. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Q.; Ni, Z.; Li, Q.; Liu, H.; Yang, Y.; Wang, L.; Ran, Y.; Guo, Y.; Hu, W. A ferroelectric/electrochemical modulated organic synapse for ultraflexible, artificial visual-perception system. Adv. Mater. 2018, 30, 1803961. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Heo, K.; Lee, S.; Seo, S.; Kim, H.; Cho, J.; Lee, H.; Lee, K.-B.; Park, J.-H. Ferroelectric polymer-based artificial synapse for neuromorphic computing. Nanoscale Horiz. 2021, 6, 139–147. [Google Scholar] [CrossRef]

- Yu, T.-F.; Chen, H.-Y.; Liao, M.-Y.; Tien, H.-C.; Chang, T.-T.; Chueh, C.-C.; Lee, W.-Y. Solution-processable anion-doped conjugated polymer for nonvolatile organic transistor memory with synaptic behaviors. ACS Appl. Mater. Interfaces 2020, 12, 33968–33978. [Google Scholar] [CrossRef] [PubMed]

- Jang, B.C.; Yang, S.Y.; Seong, H.; Kim, S.K.; Choi, J.; Im, S.G.; Choi, S.-Y. Zero-static-power nonvolatile logic-in-memory circuits for flexible electronics. Nano Res. 2017, 10, 2459–2470. [Google Scholar] [CrossRef]

- Choi, C.; Leem, J.; Kim, M.S.; Taqieddin, A.; Cho, C.; Cho, K.W.; Lee, G.J.; Seung, H.; Bae, H.J.; Song, Y.M. Curved neuromorphic image sensor array using a mos 2-organic heterostructure inspired by the human visual recognition system. Nat. Commun. 2020, 11, 5934. [Google Scholar] [CrossRef]

- Jiao, F.; Di, C.-a.; Sun, Y.; Sheng, P.; Xu, W.; Zhu, D. Inkjet-printed flexible organic thin-film thermoelectric devices based on p-and n-type poly (metal 1, 1, 2, 2-ethenetetrathiolate) s/polymer composites through ball-milling. Philos. Trans. Royal Soc. 2014, 372, 20130008. [Google Scholar] [CrossRef] [Green Version]

- Punetha, D.; Kar, M.; Pandey, S.K. A new type low-cost, flexible, wearable tertiary nanocomposite sensor for room temperature hydrogen gas sensing. Sci. Rep. 2020, 10, 2151. [Google Scholar] [CrossRef]

- Münzenrieder, N.; Petti, L.; Zysset, C.; Kinkeldei, T.; Salvatore, G.A.; Tröster, G. Flexible self-aligned amorphous ingazno thin-film transistors with submicrometer channel length, a transit frequency of 135 mhz. IEEE Trans. Electron Devices 2013, 60, 2815–2820. [Google Scholar] [CrossRef]

- Lee, S.; Seong, H.; Im, S.G.; Moon, H.; Yoo, S. Organic flash memory on various flexible substrates for foldable, disposable electronics. Nat. Commun. 2017, 8, 725. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jung, S.-W.; BonáKoo, J.; Woo Park, C.; Soon Na, B.; Park, N.-M.; Oh, J.-Y.; Gyeong Moon, Y.; Lee, S.S.; Koo, K.-W. Non-volatile organic ferroelectric memory transistors fabricated using rigid polyimide islands on an elastomer substrate. J. Mater. Chem. C 2016, 4, 4485–4490. [Google Scholar]

- Kang, B.; Park, N.; Min, H.; Lee, J.; Jeong, H.; Baek, S.; Cho, K.; Lee, H.S. Fully drawn all-organic flexible transistors prepared by capillary pen printing on flexible planar, curvilinear substrates. Adv. Electron. Mater. 2015, 1, 1500301. [Google Scholar] [CrossRef]

- Jiang, T.; Meng, X.; Zhou, Z.; Wu, Y.; Tian, Z.; Liu, Z.; Lu, G.; Eginlidil, M.; Yu, H.-D.; Liu, J. Highly flexible, degradable memory electronics comprised of all-biocompatible materials. Nanoscale 2021, 13, 724–729. [Google Scholar] [CrossRef]

- Wang, W.; Hwang, S.K.; Kim, K.L.; Lee, J.H.; Cho, S.M.; Park, C. Highly reliable top-gated thin-film transistor memory with semiconducting, tunneling, charge-trapping, blocking layers all of flexible polymers. ACS Appl. Mater. Interfaces 2015, 7, 10957–10965. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Guo, F.; Ling, H.; Zhang, P.; Yi, M.; Wang, L.; Wu, D.; Xie, L.; Huang, W. High-performance nonvolatile organic field-effect transistor memory based on organic semiconductor heterostructures of pentacene/p13/pentacene as both charge transport, trapping layers. Adv. Sci. 2017, 4, 1700007. [Google Scholar] [CrossRef]

- Kang, M.; Lee, S.-A.; Jang, S.; Hwang, S.; Lee, S.-K.; Bae, S.; Hong, J.-M.; Lee, S.H.; Jeong, K.-U.; Lim, J.A. Low-voltage organic transistor memory fiber with a nanograined organic ferroelectric film. ACS Appl. Mater. Interfaces 2019, 11, 22575–22582. [Google Scholar] [CrossRef]

- Zhou, Y.; Ding, G. Polymer Nanocomposite Materials: Applications in Integrated Electronic Devices; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Wu, W.; Han, S.-T.; Venkatesh, S.; Sun, Q.; Peng, H.; Zhou, Y.; Yeung, C.; Li, R.K.; Roy, V. Biodegradable skin-inspired nonvolatile resistive switching memory based on gold nanoparticles embedded alkali lignin. Org. Electron. 2018, 59, 382–388. [Google Scholar] [CrossRef]

- Huang, W.-Y.; Chang, Y.-C.; Sie, Y.-F.; Yu, C.-R.; Wu, C.-Y.; Hsu, Y.-L. Bio-Cellulose Substrate for Fabricating Fully Biodegradable Resistive Random Access Devices. ACS Appl. Polym. Mater. 2021, 3, 4478–4484. [Google Scholar] [CrossRef]

- Ji, X.; Song, L.; Zhong, S.; Jiang, Y.; Lim, K.G.; Wang, C.; Zhao, R. Biodegradable, flexible resistive memory for transient electronics. J. Phys. Chem. C 2018, 122, 16909–16915. [Google Scholar] [CrossRef]

| Polymer Electret (Gate insulator) | Thickness (nm) | On/Off Switching Ratio | Memory Window (V) | Retention Time (s) | Mobility (cm2 V−1 s−1) | [Ref] |

|---|---|---|---|---|---|---|

| PS | 30–35 | 106 | 22.1 ± 2.8 | 5.2 × 105 | 0.26 × 0.23 | [55] |

| PaMS | 30–35 | 106 | 26.0 ± 2.7 | 2.2 × 105 | 0.35 × 0.15 | |

| P4MS | 30–35 | 105 | 24.1 ± 1.2 | 2.1 × 105 | 0.25 × 0.07 | |

| PVP | 30–35 | 105 | 17.0 ± 1.1 | 0.24 × 105 | 0.21 × 0.05 | |

| PVPyr | 30–35 | 105 | 21.0 ± 1.7 | 0.42 × 105 | 0.12 × 0.13 | |

| PVN | 30–35 | 106 | 27.8 ± 1.8 | 3.4 × 105 | 0.61 × 0.05 | |

| PVA | 30–35 | 105 | Negligible | N/A | 0.07 × 0.06 | |

| PaMS | N/A | 105 | 24 V | 104 | 5.3 × 102 | [58] |

| PS-brush | N/A | 104 | 30 V | 108 | 0.01 | [56] |

| TPA-PIS | ~50 | 105–106 | 32.4 ± 1.2 | 104 | 0.27 ± 0.05 | [57] |

| TPA-PES | ~50 | 105–106 | 43.2 ± 4.7 | 104 | 0.22 ± 0.01 | |

| TPA-PETS | ~50 | 103–104 | 21.7 ± 1.0 | 104 | 0.10 ± 0.04 | |

| PITE(BMI-BMMD) | ~50 | 9.0 × 105 | 64.39 | N/A | 5.7 × 10−3 | [21] |

| PI(APS-ODPA) | ~50 | 9.3 × 104 | 61.22 | N/A | 1.3 × 10−3 | |

| PI(APS-BPA) | ~50 | 4.6 × 104 | 81.49 | N/A | 6.0 × 10−4 |

| Flexible Substrate | Banding Radius | On/Off Switching Ratio | Memory Window (V) | Retention Time (s) | Mobility (cm2 V−1 s−1) | [Ref] |

|---|---|---|---|---|---|---|

| PES | 5.8 mm | 2 × 104 | 15.4 | 108 | 3.8 × 10−2 | [128] |

| PET | 10 mm | 102 | 30 | 104 | 0.23 | [129] |

| Mylar™ films | 300 μm | 106 | 5.5 | 3.2 × 108 | N/A | [124] |

| Ag wires | 1.1 mm | 103 | 5.6 | 5 × 104 | 9 × 10−3 | [130] |

| PDMS, PI | Stretchable | 105 | 11 | N/A | 4 × 10−2 | [125] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Kim, S.; Yoo, H. Contribution of Polymers to Electronic Memory Devices and Applications. Polymers 2021, 13, 3774. https://doi.org/10.3390/polym13213774

Lee S, Kim S, Yoo H. Contribution of Polymers to Electronic Memory Devices and Applications. Polymers. 2021; 13(21):3774. https://doi.org/10.3390/polym13213774

Chicago/Turabian StyleLee, Subin, Somi Kim, and Hocheon Yoo. 2021. "Contribution of Polymers to Electronic Memory Devices and Applications" Polymers 13, no. 21: 3774. https://doi.org/10.3390/polym13213774

APA StyleLee, S., Kim, S., & Yoo, H. (2021). Contribution of Polymers to Electronic Memory Devices and Applications. Polymers, 13(21), 3774. https://doi.org/10.3390/polym13213774