Life-Cycle Assessment of Polypropylene Production in the Gulf Cooperation Council (GCC) Region

Abstract

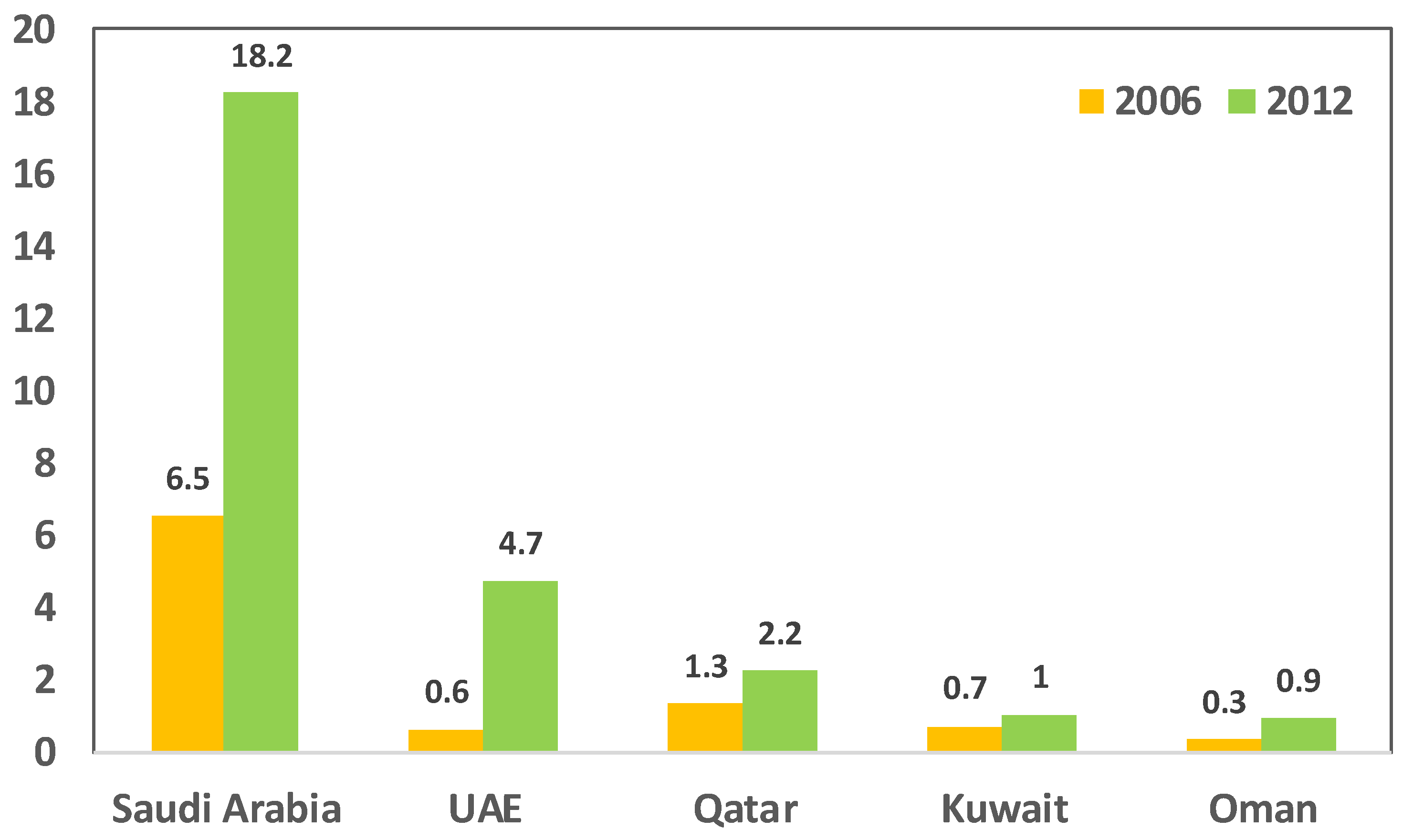

:1. Introduction

2. Literature Review

3. Methods

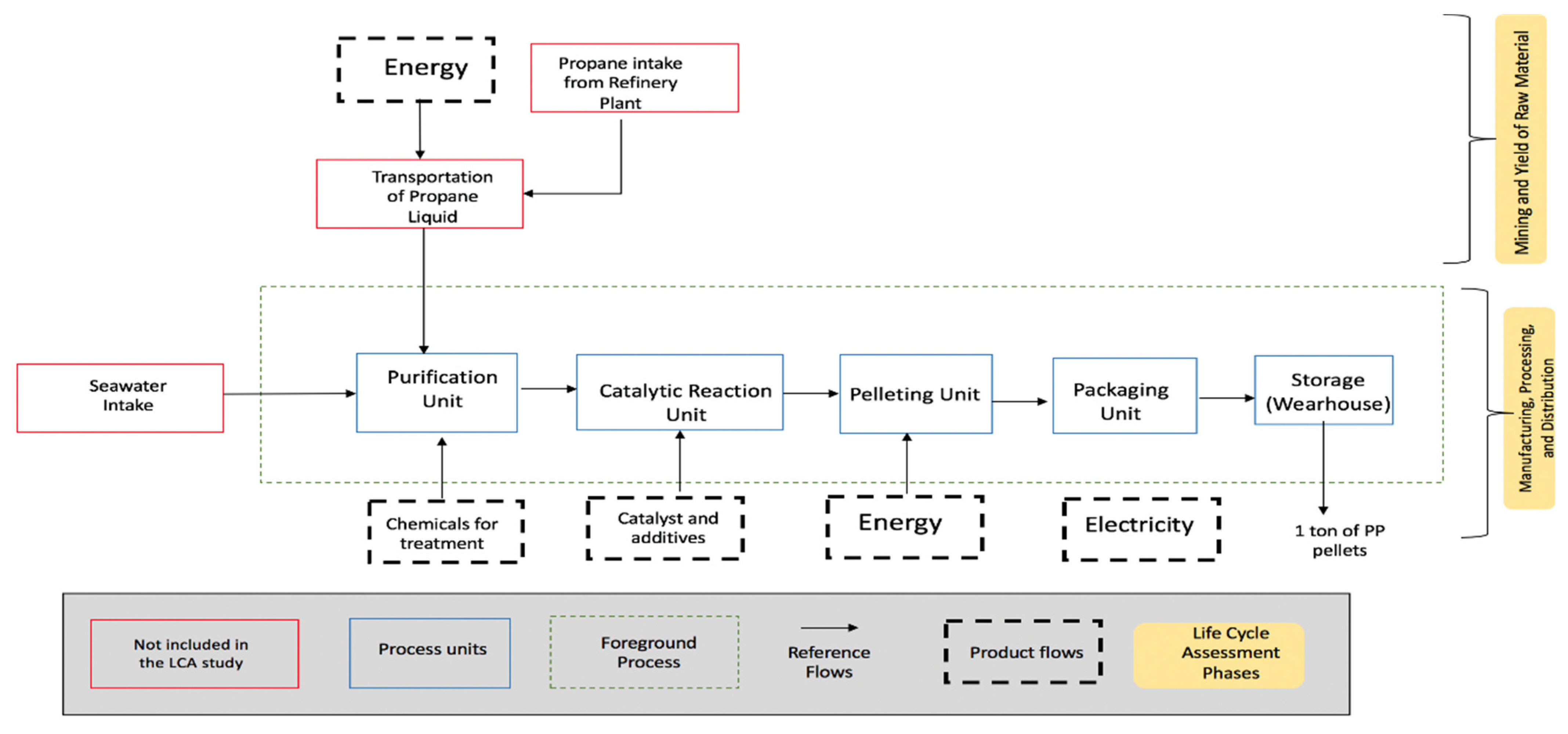

3.1. Description of the Analyzed PP Plant

3.2. LCA Framework

3.2.1. Goal and Scope of the LCA

3.2.2. Life Cycle Inventory Analysis

3.2.3. Life Cycle Impact Assessment

3.2.4. LCA Interpretation

4. Results and Discussion

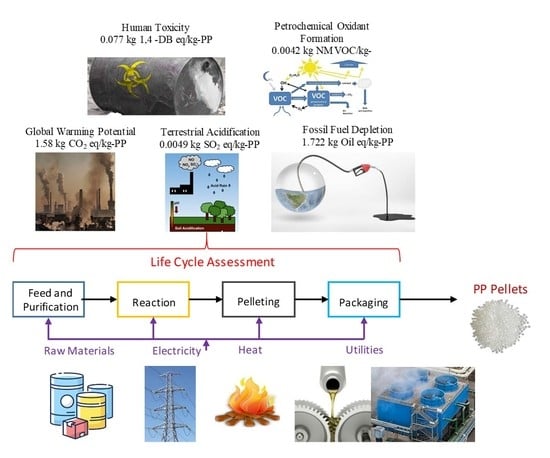

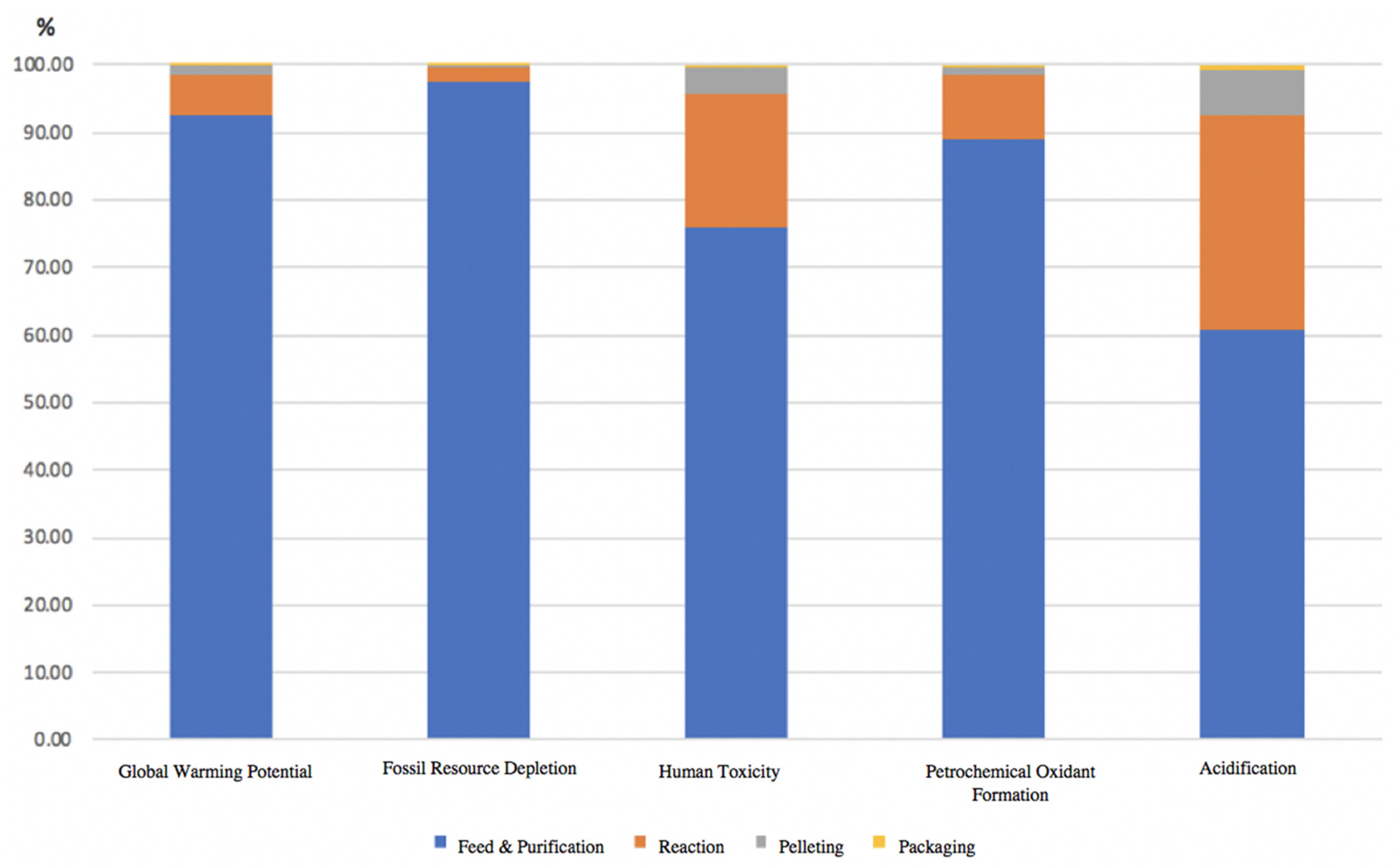

4.1. LCA Results

4.2. Results Comparison with Previous LCA Studies

4.3. Data and Results Quality and Uncertainty

- The data that was collected from the existing PP plant, and is confidential (such as energy mix, details of the processes, name of the plant cannot be furnished in this work).

- Other data not provided from the PP plant were instead obtained from GaBi software and applied to other regions.

5. Conclusions and Outlook

- The results indicate 1.58 kg of carbon emissions and 1.72 kg of oil depletion for each kilogram of PP pellet production.

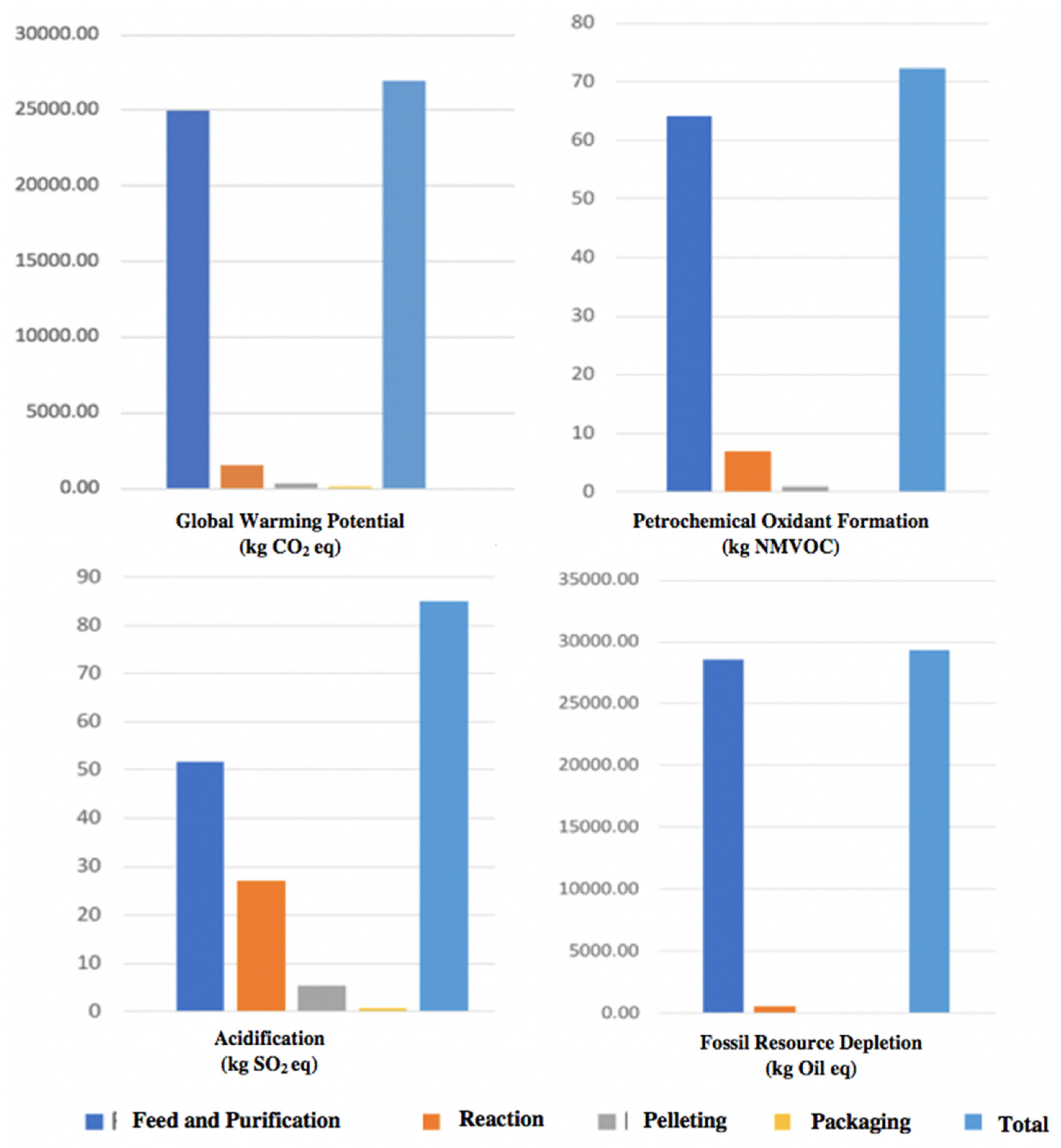

- The feed and purification phase has the highest contribution environmental impacts followed by reaction process. Furthermore, the pelleting and packaging processes have negligible contributions in GWP, POF, and FD compared to the total environmental impacts of the PP plant. However, pelleting and packaging processes have a smaller impact on terrestrial acidification.

- The GPCA study showed 1.95 kg of equivalent carbon emissions for the production of 1 kg of PP pellets. This value represents the averaging of PP manufacturing plants in the GCC region and is more than the present study. The variation is mainly due to the difference in data sets used as the study by GPCA was based on data sets collected from seven petrochemical plants located in different GCC countries. The fuel type, energy mix, production capacity, plant age, energy and process efficiency, and process type may differ from plant to plant, increasing the average carbon emissions values

- The GWP in this work is compared with values available in the literature, and it is found that the present work aligns within the range available in the literature. These results guide the petrochemical industrial sector to shift the production technology, especially the feed purification and reaction phases since they have the highest impact results to overcome undesired environmental impacts such as greenhouse gas emissions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Husain, R.; Assavapokee, T.; Khumawala, B. Supply Chain Management in the Petroleum Industry: Challenges and Opportunities Supply Chain Management in the Petroleum Industry. Int. J. Glob. Logist. Supply Chain Manag. 2006, 1, 90–97. [Google Scholar]

- Thakre, A.R.; Baxi, R.N.; Walke, P.V. Polypropylene Alloys and Composites—A Review; Kolhe, M., Labhasetwar, P., Suryawanshi, H., Eds.; Smart Technologies for Energy, Environment and Sustainable Development. Lecture Notes on Multidisciplinary Industrial Engineering; Springer: Singapore, 2019; pp. 53–61. [Google Scholar]

- Ramesh, P.; Vinodh, S. State of art review on Life Cycle Assessment of polymers. Int. J. Sustain. Eng. 2020, 13, 411–422. [Google Scholar] [CrossRef]

- Shubhra, Q.T.; Alam, A.; Quaiyyum, M. Mechanical properties of polypropylene composites. J. Thermoplast. Compos. Mater. 2013, 26, 362–391. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a Promising Plastic: A Review Polypropylene as a Promising Plastic: A Review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Brown, G.; Diaz-Chavez, R.A. Book Review: “Life Cycle Assessment. Principles, Practice and Prospects” Horne R, Grant T, Verghese, K.J. Environ. Assess. Policy Manag. 2010, 12, 355–356. [Google Scholar] [CrossRef]

- Alsabri, A.; Al-Ghamdi, S.G. Carbon footprint and embodied energy of PVC, PE, and PP piping: Perspective on environmental performance. Energy Rep. 2020, 6, 364–370. [Google Scholar] [CrossRef]

- Samruk Kazyna Global Polypropylene Market Outlook. 2015. Available online: https://www.sk.kz/upload/iblock/713/713c4a54b6fdb2183807bba0dc84cbb3.pdf (accessed on 15 July 2021).

- Tidey, A. A Breaking the Cycle? Cost Efficiency in Upstream Oil and Gas. 2015. Available online: https://www.woodmac.com/news/opinion/cost-efficiency-upstream-oil-gas/ (accessed on 15 July 2021).

- Gulf Petrochemicals &Chemicals Association. GCC Plastic Industry Indicators; GPCA: Dubai, United Arab Emirates, 2016; Available online: https://gpca.org.ae/wp-content/uploads/2018/03/GCC-Plastics-Industry-Indicators-2016.pdf (accessed on 15 July 2021).

- Eveloy, V.; Rodgers, P.; Diana, A. Performance investigation of thermally enhanced polymer composite materials for microelectronics cooling. Microelectron. J. 2015, 46, 1216–1224. [Google Scholar] [CrossRef]

- Tahir, F.; Mabrouk, A.; Al-Ghamdi, S.G.; Krupa, I.; Sedlacek, T.; Abdala, A.; Koc, M. Sustainability Assessment and Techno-Economic Analysis of Thermally Enhanced Polymer Tube for Multi-Effect Distillation (MED) Technology. Polymers 2021, 13, 681. [Google Scholar] [CrossRef] [PubMed]

- Panda, A.K.; Singh, R.K.; Mishra, D.K. Thermolysis of waste plastics to liquid fuel. A suitable method for plastic waste management and manufacture of value added products-A world prospective. Renew. Sustain. Energy Rev. 2010, 14, 233–248. [Google Scholar] [CrossRef]

- Harding, K.G.; Dennis, J.S.; von Blottnitz, H.; Harrison, S.T.L. Environmental analysis of plastic production processes: Comparing petroleum-based polypropylene and polyethylene with biologically-based poly-β-hydroxybutyric acid using life cycle analysis. J. Biotechnol. 2007, 130, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Bledzki, A.K.; Mamun, A.A.; Jaszkiewicz, A.; Erdmann, K. Polypropylene composites with enzyme modified abaca fibre. Compos. Sci. Technol. 2010, 70, 854–860. [Google Scholar] [CrossRef]

- Ayalon, O.; Goldrath, T.; Rosenthal, G.; Grossman, M. Reduction of plastic carrier bag use: An analysis of alternatives in Israel. Waste Manag. 2009, 29, 2025–2032. [Google Scholar] [CrossRef]

- Grünberg, T. A review of improvement methods in manufacturing operations. Work Study 2003, 52, 89–93. [Google Scholar] [CrossRef]

- Deif, A.M. A system model for green manufacturing. J. Clean. Prod. 2011, 19, 1553–1559. [Google Scholar] [CrossRef] [Green Version]

- Fediuk, R.S.; Yevdokimova, Y.G.; Smoliakov, A.K.; Stoyushko, N.Y.; Lesovik, V.S. Use of geonics scientific positions for designing of building composites for protective (fortification) structures. IOP Conf. Ser. Mater. Sci. Eng. 2017, 221, 12011. [Google Scholar] [CrossRef]

- Elistratkin, M.Y.; Lesovik, V.S.; Zagorodnjuk, L.H.; Pospelova, E.A.; Shatalova, S.V. New point of view on materials development. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 32020. [Google Scholar] [CrossRef] [Green Version]

- Mannheim, V.; Simenfalvi, Z. Total Life Cycle of Polypropylene Products: Reducing Environmental Impacts in the Manufacturing Phase. Polymers 2020, 12, 1901. [Google Scholar] [CrossRef] [PubMed]

- Ruban, A. Life Cycle Assessment of Plastic Bag Production Life Cycle Assessment of Plastic Bag Production Anna Ruban; Uppsala University: Uppsala, Sweden, 2012. [Google Scholar]

- Al-Khori, K.; Al-Ghamdi, S.G.; Boulfrad, S.; Koç, M. Life Cycle Assessment for Integration of Solid Oxide Fuel Cells into Gas Processing Operations. Energies 2021, 14, 4668. [Google Scholar] [CrossRef]

- Jelti, F.; Allouhi, A.; Al-Ghamdi, S.G.; Saadani, R.; Jamil, A.; Rahmoune, M. Environmental life cycle assessment of alternative fuels for city buses: A case study in Oujda city, Morocco. Int. J. Hydrogen Energy 2021, 46, 25308–25319. [Google Scholar] [CrossRef]

- Greene, J. Life Cycle Assessment of Reusable and Single—Use Plastic Bags in California; Institute for Sustainable Development, California State University: Long Beach, CA, USA, 2011; pp. 1–26. [Google Scholar]

- Ingarao, G.; Licata, S.; Sciortino, M.; Planeta, D.; Di Lorenzo, R.; Fratini, L. Life cycle energy and CO2 emissions analysis of food packaging: An insight into the methodology from an Italian perspective. Int. J. Sustain. Eng. 2017, 10, 31–43. [Google Scholar] [CrossRef]

- Gulf Petrochemicals and Chemicals Association. Eco-Profile of Polyolefins (HDPE and PP) in the GCC; GPCA: Dubai, United Arab Emirates, 2018; Available online: https://www.ifeu.de/en/project/oekoprofil-von-polyolefinen-aus-laendern-des-mittleren-ostens/ (accessed on 15 July 2021).

- Narita, N.; Sagisaka, M.; Inaba, A. Life cycle inventory analysis of CO2 emissions: Manufacturing commodity plastics in Japan. Int. J. Life Cycle Assess. 2002, 7, 277–282. [Google Scholar] [CrossRef]

- ISO 14040. Environmental Management—Life Cycle Assessment: Requirements and Guidelines; International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- ISO 14044. Environmental Management—Life Cycle Assessment: Principles and Framework; International Organization for Standardization (ISO): Geneva, Switzerland, 1997. [Google Scholar]

- Thinkstep GaBi [Computer Software], Thinkstep, Sphera Solutions; Sphera: Leinfelden-Echterdingen, Germany, 2020.

- Mannan, M.; Alhaj, M.; Mabrouk, A.N.; Al-Ghamdi, S.G. Examining the life-cycle environmental impacts of desalination: A case study in the State of Qatar. Desalination 2019, 452, 238–246. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008 A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level First Edition Report I: Characterisation Mark Huijbregts 3; Ruemte en Milieu: Haarlem, The Netherlands, 2009; Available online: https://www.researchgate.net/publication/302559709_ReCiPE_2008_A_life_cycle_impact_assessment_method_which_comprises_harmonised_category_indicators_at_the_midpoint_and_the_endpoint_level (accessed on 15 July 2021).

- Qadir, S.A.; Al-Motairi, H.; Tahir, F.; Al-Fagih, L. Incentives and strategies for financing the renewable energy transition: A review. Energy Rep. 2021, 7, 3590–3606. [Google Scholar] [CrossRef]

- Imteyaz, B.; Lawal, D.U.; Tahir, F.; Rehman, S. Prospects of large--scale photovoltaic--based power plants in the Kingdom of Saudi Arabia. Eng. Rep. 2021, 3, e12398. [Google Scholar]

- Imteyaz, B.; Qadir, S.A.; Tahir, F. Prospects of CO2 Utilization after Carbon Capture Process. In Proceedings of the 12th International Exergy, Energy and Environment Symposium (IEEES-12), Doha, Qatar, 20–24 December 2020. [Google Scholar]

| Impact Categories | Abbreviations | Units | Scale |

|---|---|---|---|

| Terrestrial Acidification | TA | kg SO2 eq. | Regional |

| Petrochemical Oxidant formation | POF | kg NMVOC | Local |

| Human Toxicity | HT | kg 1,4-DB eq. | Local |

| Fossil Resource Depletion | FD | kg oil eq. | Regional |

| Global Warming Potential | GWP | kg CO2 eq. | Global |

| Impact Categories | Units | Emissions per Annual Production (146,880 Tons of PP Pellets/yr) | Emissions per 1 ton of PP Pellets | Emissions per 1 kg of PP Pellets |

|---|---|---|---|---|

| TA | kg SO2 eq. | 84.92 | 4.99 | 0.0049 |

| GWP | kg CO2 eq. | 26,968.80 | 1586.35 | 1.5863 |

| POF | kg NMVOC | 72.20 | 4.24 | 0.0042 |

| FD | kg Oil eq. | 29,289.40 | 1722.90 | 1.7222 |

| HT | kg 1,4-DB eq. | 1309.16 | 77.00 | 0.0770 |

| GWP | Feed & Purification | Reaction | Pelleting | Packaging | Total (kg CO2 eq.) |

|---|---|---|---|---|---|

| For Annual Production | 25,000.000 | 1600.000 | 326.000 | 42.800 | 26,968.800 |

| For 1 ton of PP pellets | 1470.588 | 94.118 | 19.176 | 2.518 | 1586.400 |

| For 1 kg of PP pellets | 1.471 | 0.094 | 0.019 | 0.003 | 1.586 |

| Resource | Location | Equivalent CO2 Emission per 1 kg of PP |

|---|---|---|

| Life cycle inventory analysis of CO2 emissions: Manufacturing commodity plastics in Japan [28] | Japan | 1.4 kg CO2 eq. |

| This LCA study | One of the GCC countries | 1.58 kg CO2 eq. |

| GPCA study [27] | The entire GCC region | 1.95 kg CO2 eq. |

| LCA of single use and reusable plastics bags [25] | California, US | 1.34 kg CO2 eq. |

| Gabi database [31] | US | 2.41 kg CO2 eq. |

| Gabi database [31] | Germany | 1.64 kg CO2 eq. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsabri, A.; Tahir, F.; Al-Ghamdi, S.G. Life-Cycle Assessment of Polypropylene Production in the Gulf Cooperation Council (GCC) Region. Polymers 2021, 13, 3793. https://doi.org/10.3390/polym13213793

Alsabri A, Tahir F, Al-Ghamdi SG. Life-Cycle Assessment of Polypropylene Production in the Gulf Cooperation Council (GCC) Region. Polymers. 2021; 13(21):3793. https://doi.org/10.3390/polym13213793

Chicago/Turabian StyleAlsabri, Amzan, Furqan Tahir, and Sami G. Al-Ghamdi. 2021. "Life-Cycle Assessment of Polypropylene Production in the Gulf Cooperation Council (GCC) Region" Polymers 13, no. 21: 3793. https://doi.org/10.3390/polym13213793

APA StyleAlsabri, A., Tahir, F., & Al-Ghamdi, S. G. (2021). Life-Cycle Assessment of Polypropylene Production in the Gulf Cooperation Council (GCC) Region. Polymers, 13(21), 3793. https://doi.org/10.3390/polym13213793