Numerical Simulation and Experimental Validation of Hybrid Injection Molded Short and Continuous Fiber-Reinforced Thermoplastic Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Continuous Fiber-Reinforced Thermoplastic Composites

2.1.2. Short Fiber-Reinforced Thermoplastic Composites

2.2. Experimental Work

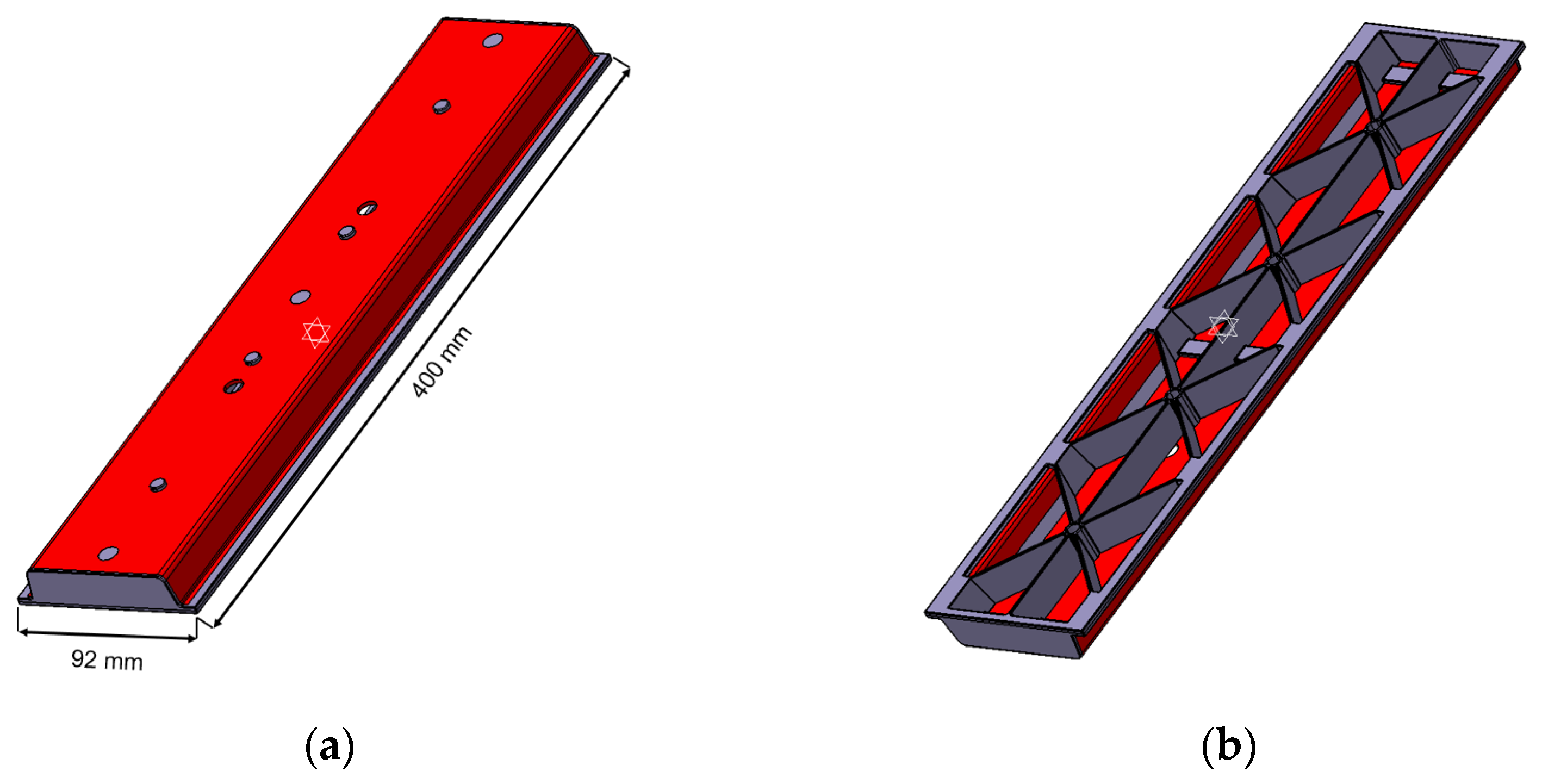

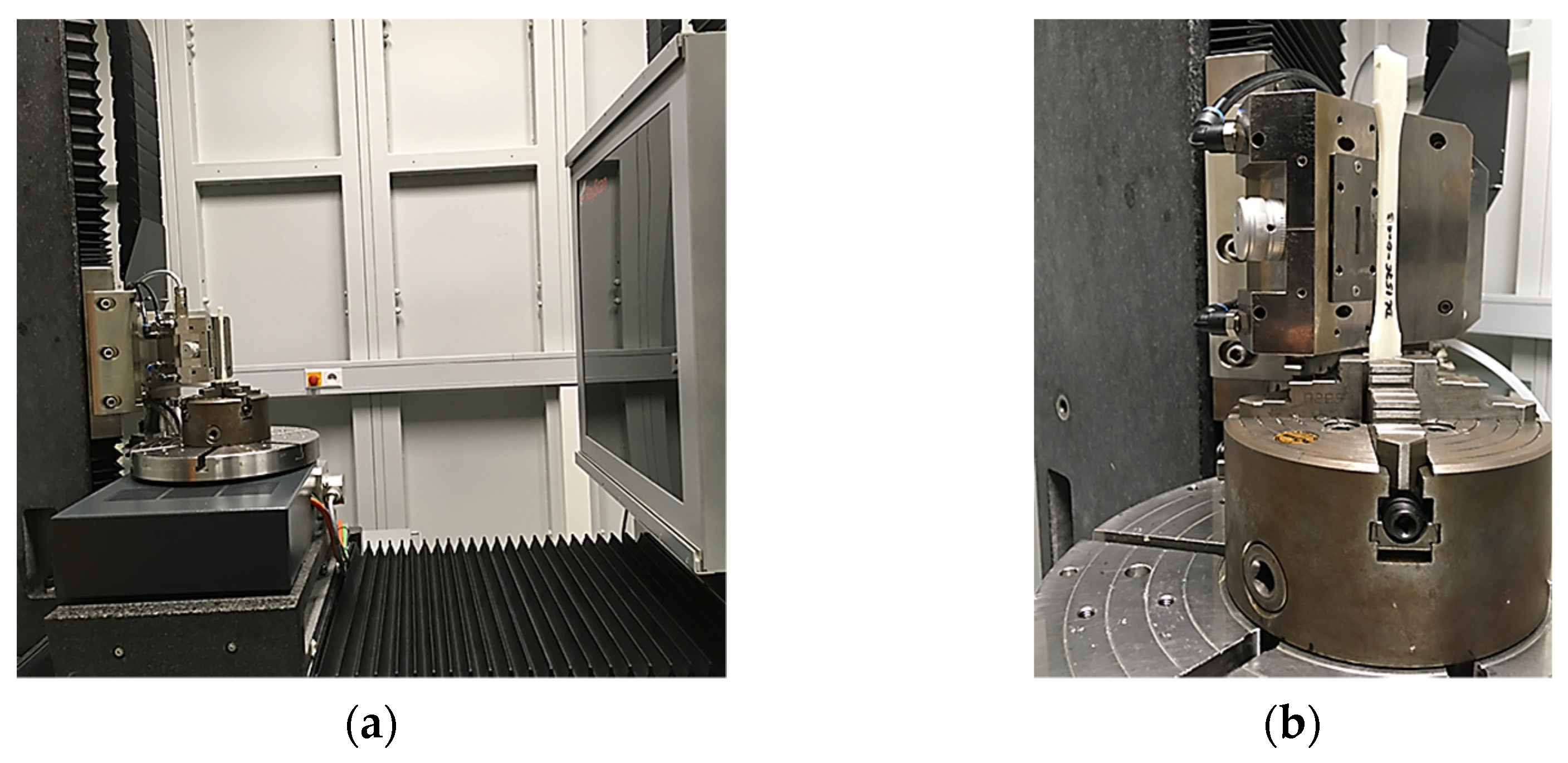

2.2.1. Production of Test Structures

Injection Molding of Short Fiber-Reinforced Thermoplastic Composites

Hybrid Injection Molding of Short and Continuous Fiber-Reinforced Thermoplastic Composites

2.2.2. Morphological Analysis

Fiber Length Analysis of Short Fiber-Reinforced Thermoplastic Composites

Fiber Orientation Analysis of Short Fiber-Reinforced Thermoplastic Composites

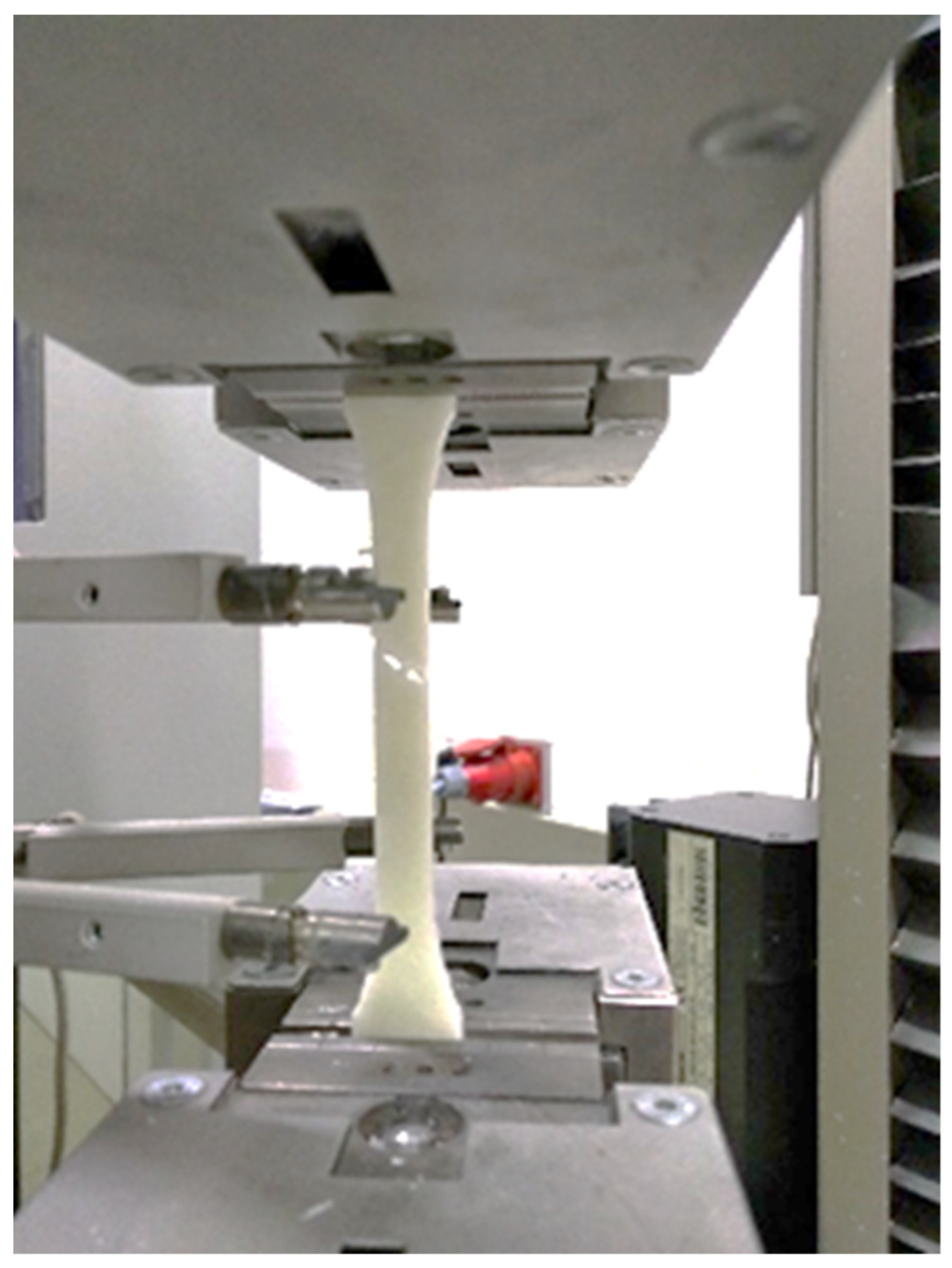

2.2.3. Mechanical Testing

Tensile Test of Short Fiber-Reinforced Thermoplastic Composites

Flexural Test of Hybrid Injection Molded Thermoplastic Composites

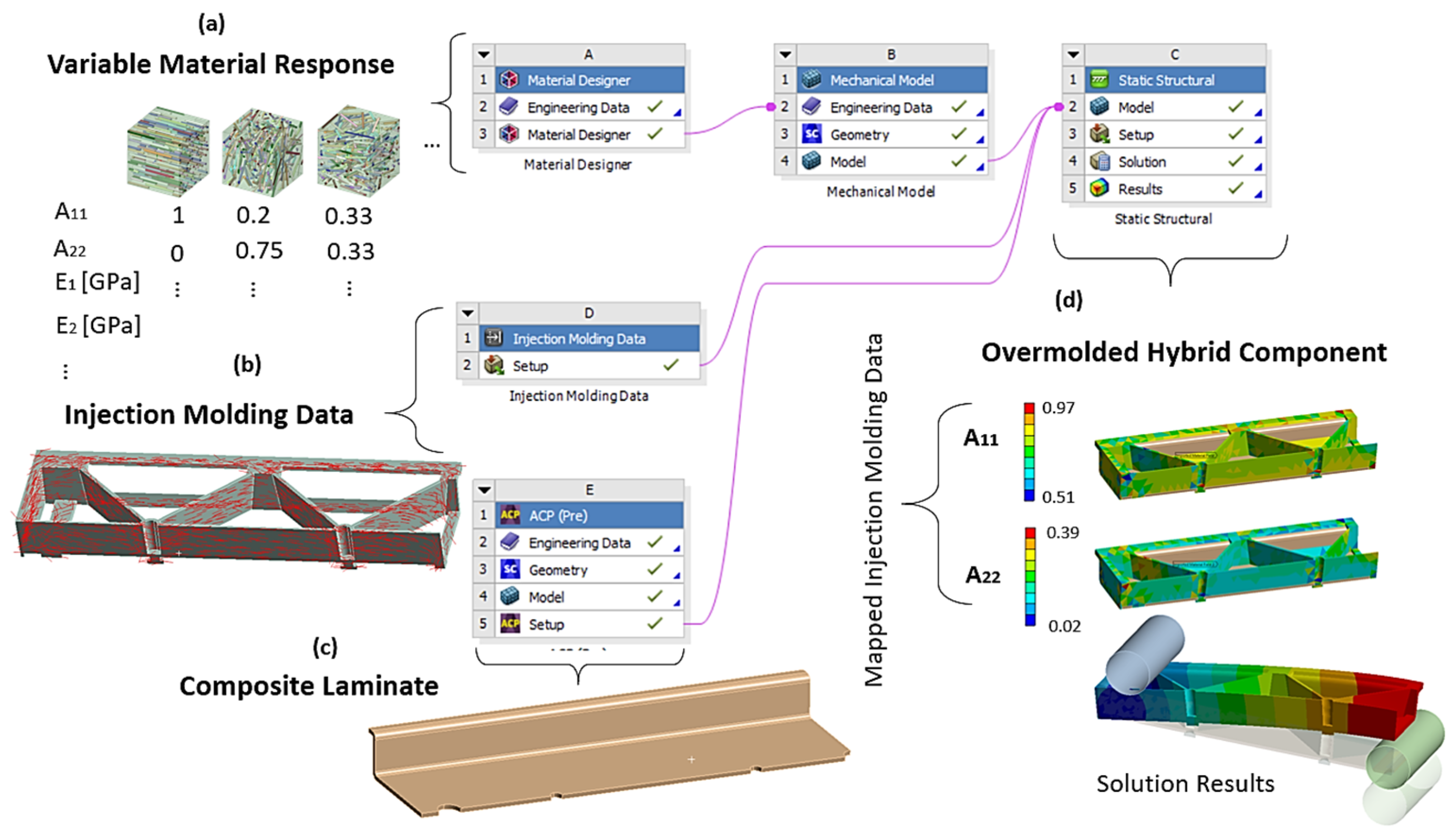

2.3. Numerical Simulations

2.3.1. Theoretical Background

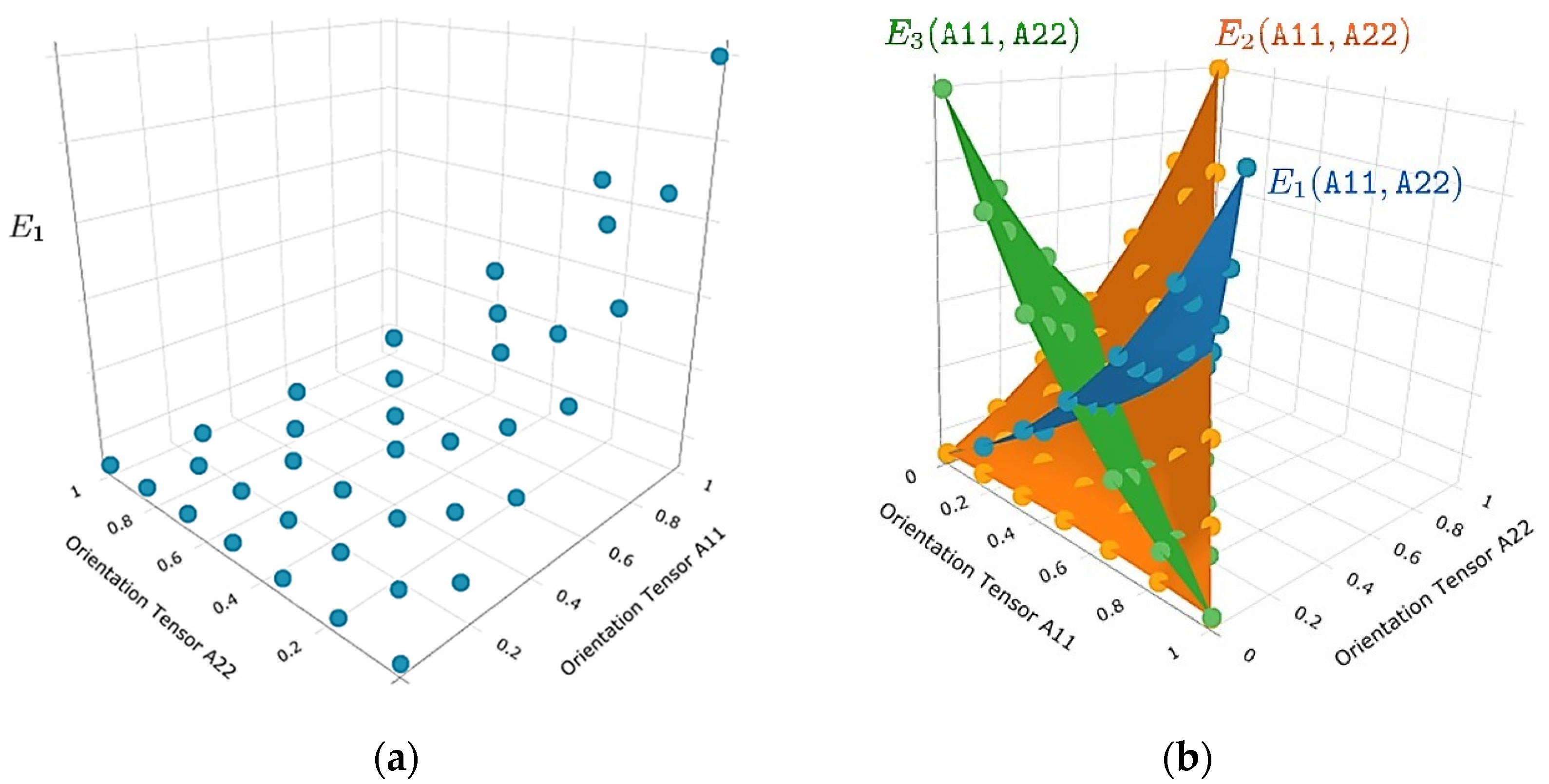

2.3.2. Overview of the Workflow

2.3.3. Numerical Simulation of Injection Molding

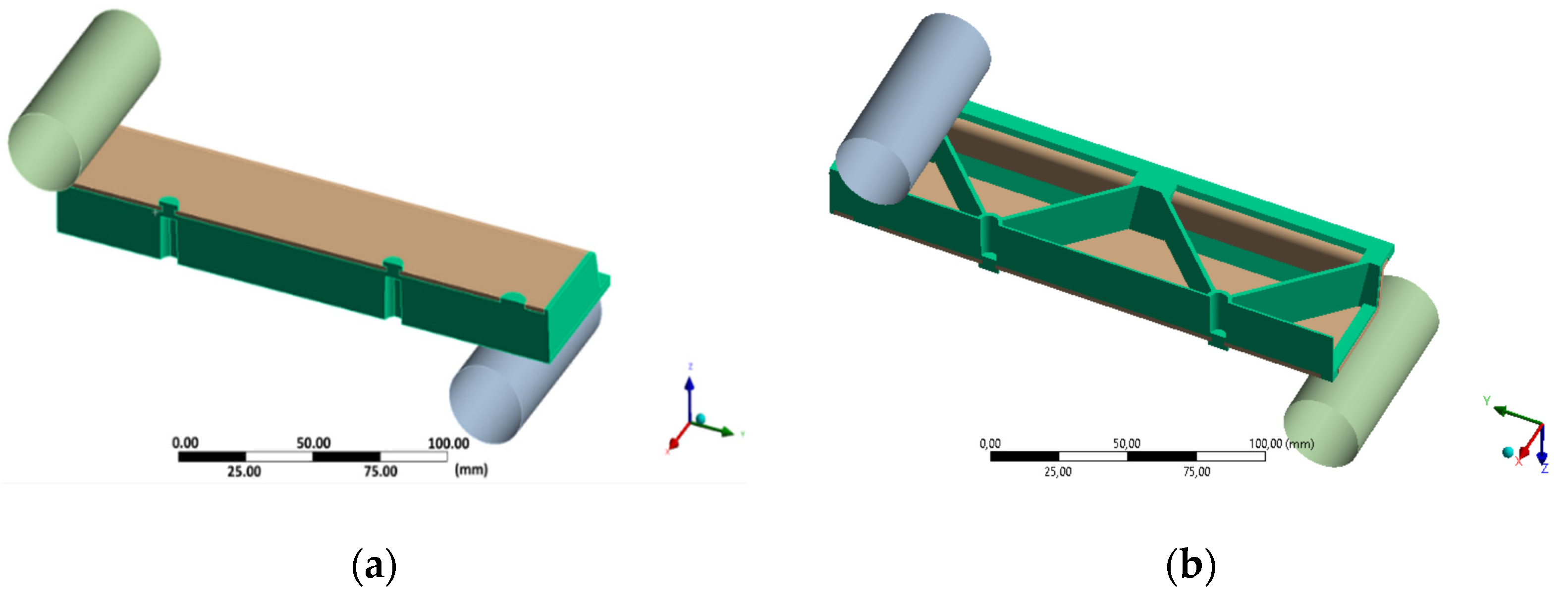

2.3.4. Numerical Simulation of Flexural Test

3. Results and Discussion

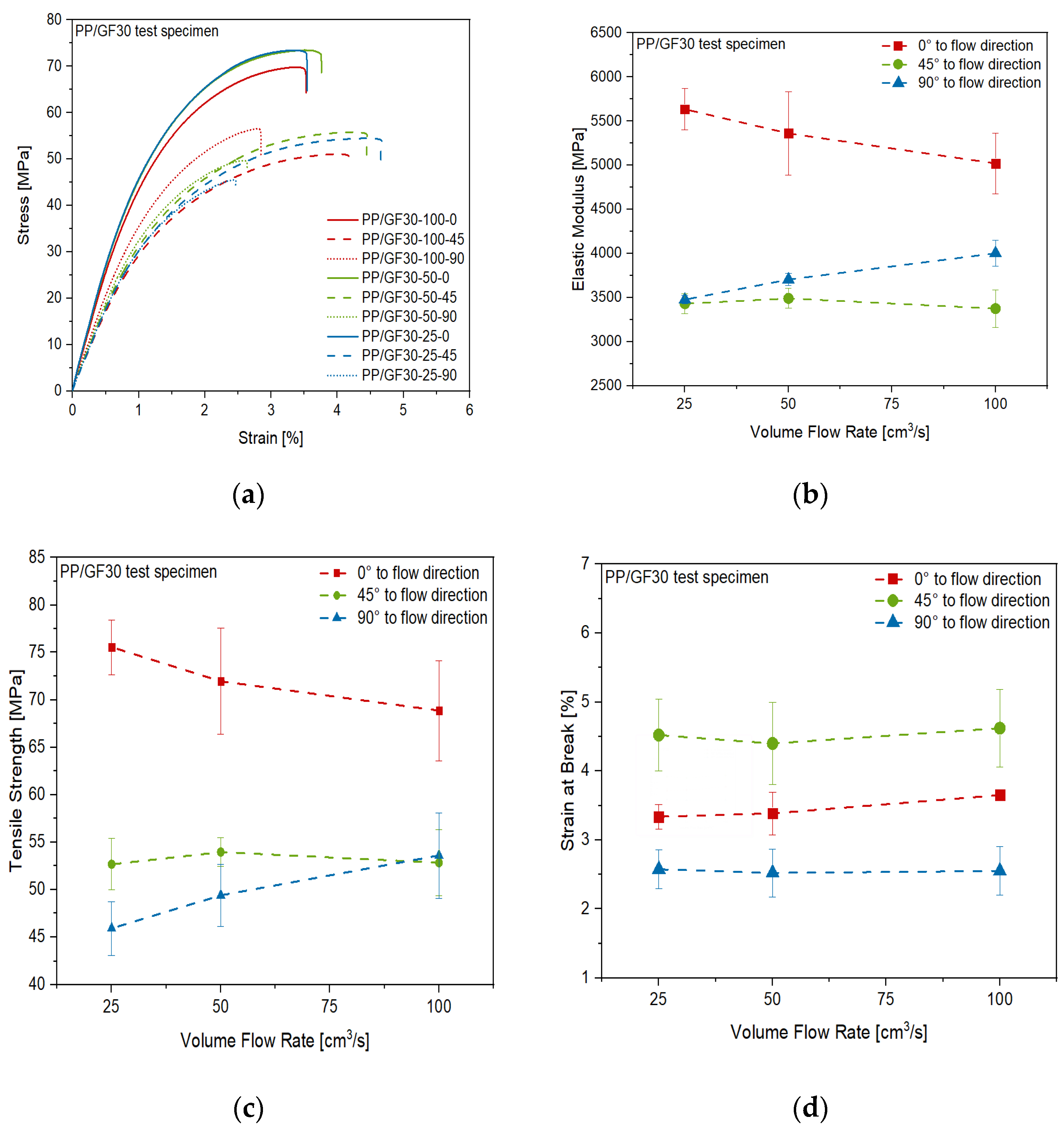

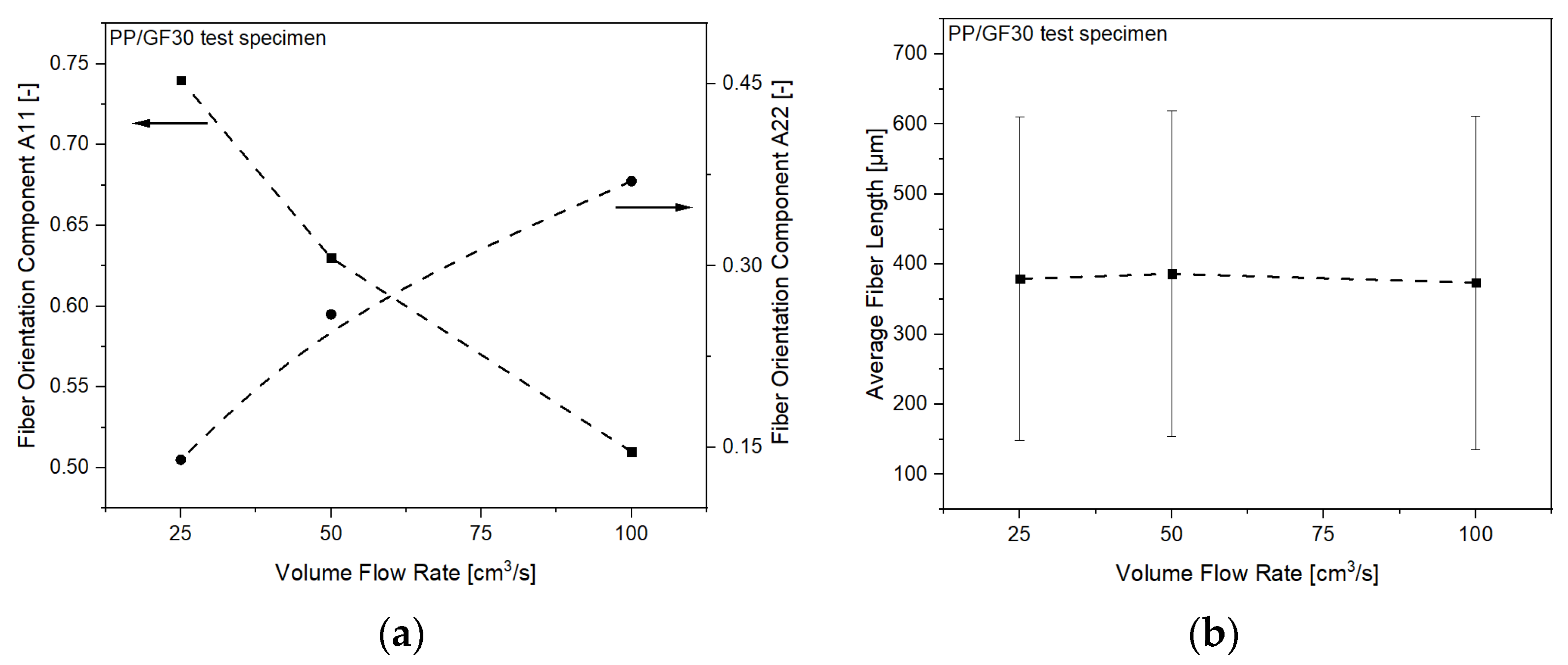

3.1. Anisotropy of Injection Molded Short Fiber-Reinforced Thermoplastic Composites

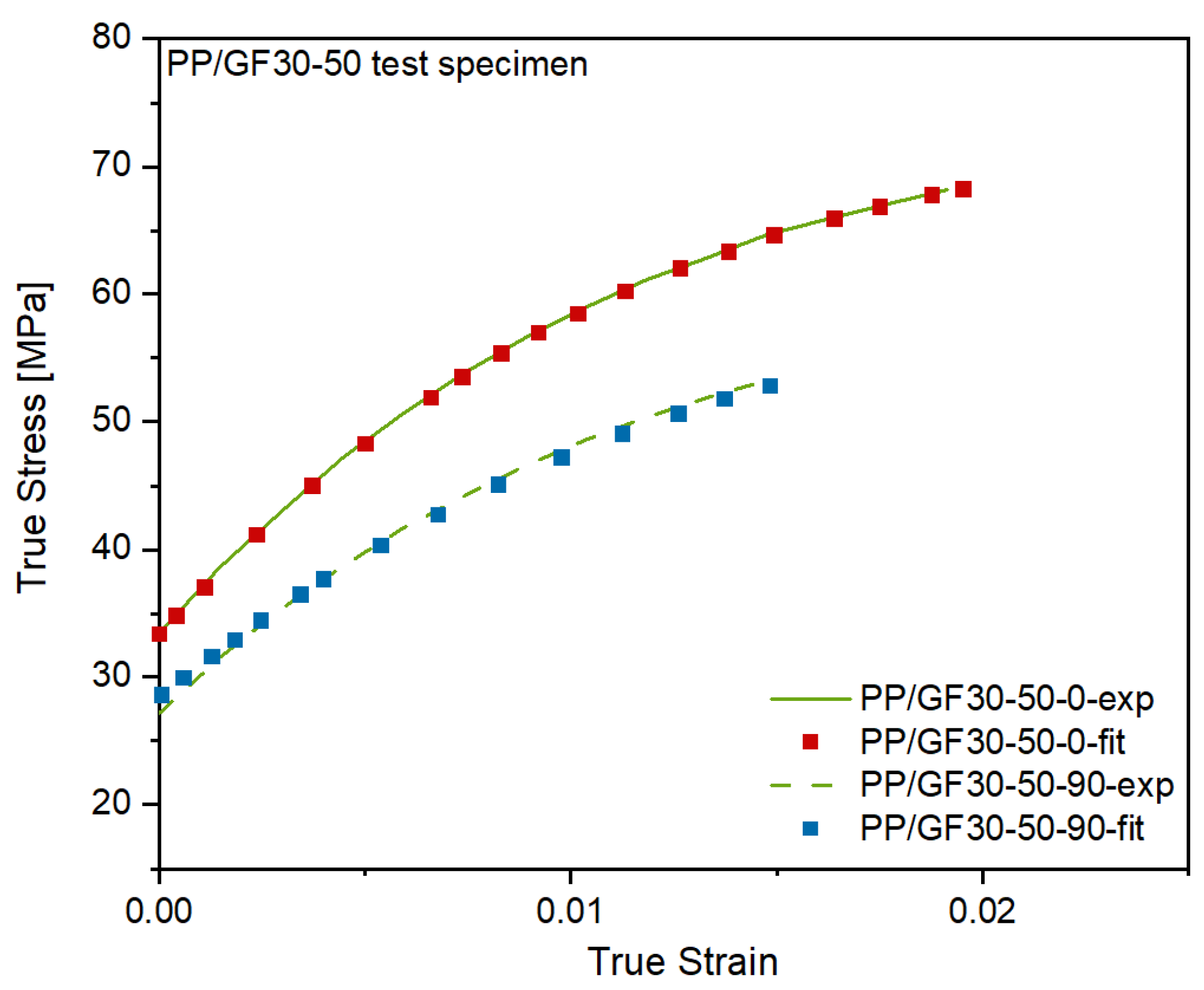

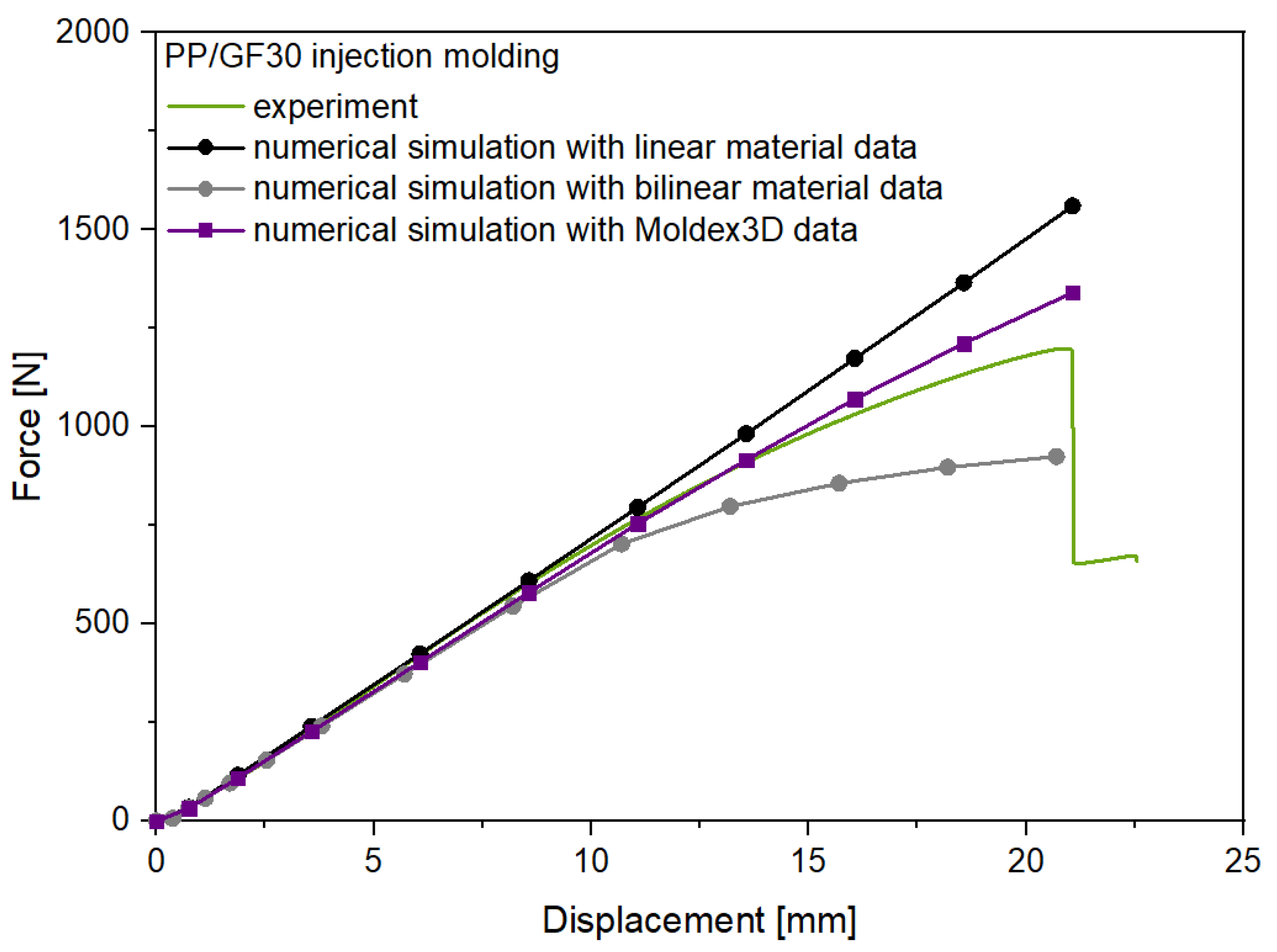

3.2. Numerical Simulation and Experimental Validation of Injection Molding of Short Fiber-Reinforced Thermoplastic Composites

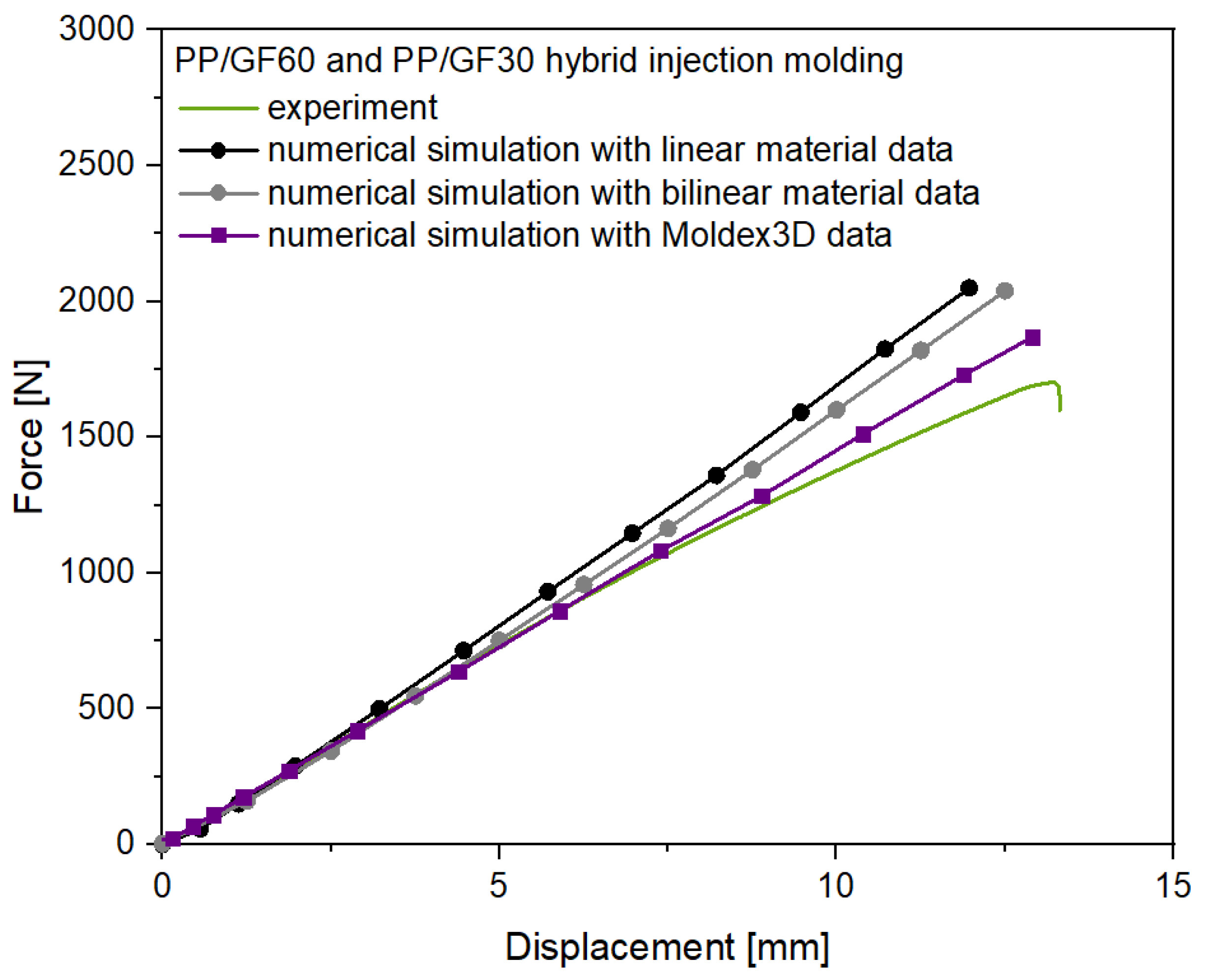

3.3. Numerical Simulation and Experimental Validation of Flexural Test of Hybrid Injection Molded Thermoplastic Composites

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Minchenkov, K.; Vedemikov, A.; Safonov, A.; Akhatov, I. Thermoplastic pultrusion: A review. Polymers 2021, 13, 180. [Google Scholar] [CrossRef]

- Burkhart, A.; Cramer, D. Continuous fibre-reinforced thermoplastic tailored blanks. JEC Compos. Mag. 2006, 43/22, 41–43. [Google Scholar]

- Cao, Z.; Guo, D.; Fu, H.; Han, Z. Mechanical simulation of thermoplastic composite fiber variable-angle laminates. Materials 2020, 13, 3374. [Google Scholar] [CrossRef]

- Carrera, E. Theories and finite elements for multi-layered anisotropic, composites plates and shells. Arch. Comput. Methods Eng. 2002, 9, 87–140. [Google Scholar] [CrossRef]

- Tabiei, A.; Zhang, W. Composite laminate delamination, simulation and experiment: A review of recent development. Appl. Mech. Rev. 2018, 70, 030801. [Google Scholar] [CrossRef]

- Zscheyge, M.; Gude, M.; Boehm, R.; Hufenbach, W. Strain rate dependent deformation and damage behaviour of textile-reinforced thermoplastic composites. In Proceedings of the 17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Kropka, M.; Muehlbacher, M.; Neumeyer, T.; Altstaedt, V. From UD-tape to Final Part—A Comprehensive Approach Towards Thermoplastic Composites. Procedia CIRP 2017, 66, 96–100. [Google Scholar] [CrossRef]

- Bonefeld, D.; Obermann, C. Spriform: A hybrid technique for serial production of 3d parts of continuous fiber reinforced thermoplastics. In Proceedings of the ECCM15-15TH European Conference on Composite Materials, Venice, Italy, 24–28 June 2012. [Google Scholar]

- Cherouat, A.; Borouchaki, H. Present state of the art of composite fabric forming: Geometrical and mechanical approaches. Materials 2009, 2, 1835–1857. [Google Scholar] [CrossRef] [Green Version]

- Kroll, L.; Meyer, M.; Nendel, W.; Schormair, M. Highly rigid assembled composite structures with continuous fiber-reinforced thermoplastics for automotive applications. Procedia Manuf. 2019, 33, 224–231. [Google Scholar] [CrossRef]

- Bussetta, P.; Correia, N. Numerical forming of continuous fibre reinforced composite material: A review. Compos. Part A Appl. Sci. Manuf. 2018, 113, 12–31. [Google Scholar] [CrossRef]

- Müzel, S.D.; Bonhin, E.P.; Guimaraes, N.M.; Guidi, E.S. Application of the finite element method in the analysis of composite materials: A review. Polymers 2020, 12, 818. [Google Scholar] [CrossRef] [Green Version]

- Adam, L.; Assaker, R. Integrated nonlinear multi-scale Material Modelling of Fiber Reinforced Plastics with DIGIMAT: Application to Short and Continuous Fiber Composite. In Proceedings of the 11th World Congress on Computational Mechanics, Barcelona, Spain, 20–25 July 2014. [Google Scholar]

- Reclusado, C.A.T.; Nagasawa, S. Modeling of fiber-reinforced plastics taking into account the manufacturing process. In Proceedings of the ECCOMAS Congress, Crete Island, Greece, 5–10 June 2016. [Google Scholar]

- Chen, L.; Deng, T.; Zhuo, H.; Huang, Z.; Peng, X.; Zhuo, H. A numerical simulation method for the one-step compression-stamping process of continuous fiber reinforced thermoplastic composites. Polymers 2021, 13, 3237. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.; Zhang, M.; Fu, L.; Zhuo, M.; Zhai, Z. Molecular dynamics simulation on the interfacial behavior of over-molded hybrid fiber reinforced thermoplastic composites. Polymers 2020, 12, 1270. [Google Scholar] [CrossRef]

- Matter, M.; Gmür, T.; Cugnoni, J.; Schorderet, A. Numerical-experimental identification of the elastic and damping properties in composite plates. Compos. Struct. 2009, 90, 180–187. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Fatigue behavior and modelling of short fiber reinforced polymer composites: A literature review. Int. J. Fatigue 2015, 70, 297–321. [Google Scholar] [CrossRef]

- Antin, K.-N.; Laukkanen, A.; Andersson, T.; Smyl, D.; Vilaca, P. A multiscale modelling approach for estimating the effect of defects in unidirectional carbon fiber reinforced polymer composites. Materials 2019, 12, 1885. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Andrä, H.; Kabel, M.; Staub, S.; Krizikalla, F.; Schulz, V. Numerische Homogenisierung für viskoelastische Faserverbundwerkstoffe. NAFEMS Online-Mag. 2012, 21, 70–83. [Google Scholar]

- Yvonnet, J.; He, Q.C. The reduced model multiscale method (R3M) for the non-linear homogenization of hyperelastic media at finite strains. J. Comput. Phys. 2007, 223, 341–368. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharjee, S.; Matous, K. A nonlinear manifold-based reduced order model for multiscale analysis of heterogeneous hyperelastic materials. J. Comput. Phys. 2016, 313, 635–653. [Google Scholar] [CrossRef] [Green Version]

- Fritzen, F.; Leuschner, M. Reduced basis hybrid computational homogenization based on a mixed incremental formulation. Comput. Methods Appl. Mech. Eng. 2013, 260, 143–154. [Google Scholar] [CrossRef]

- Temizer, I.; Wriggers, P. An adaptive method for homogenization in orthotropic nonlinear elasticity. Comput. Methods Appl. Mech. Eng. 2007, 35–36, 3409–3423. [Google Scholar] [CrossRef]

- Köbler, J.; Schneider, M.; Ospald, F.; Andrä, H.; Müller, R. Fiber orientation interpolation for the multiscale analysis of short fiber reinforced composite parts. Comput. Mech. 2018, 61, 729–750. [Google Scholar] [CrossRef] [Green Version]

- Furukawa, T.; Yagawa, G. Implicit constitutive modelling for viscoplasticity using neural networks. Int. J. Numer. Methods Eng. 1998, 43, 195–219. [Google Scholar] [CrossRef]

- Hürkamp, A.; Gellrich, S.; Ossowski, T.; Beuscher, J.; Thiede, S.; Herrmann, C.; Dröder, K. Combining simulation and machine learning as digital twin for the manufacturing of overmolded thermoplastic composites. J. Manuf. Mater. Process. 2020, 4, 92. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effects of fiber orientation and anisotropy on tensile strength and elastic modulus of short fiber reinforced polymer composites. Compos. Part B Eng. 2015, 72, 116–129. [Google Scholar] [CrossRef]

- Hartley, W.D.; McCann, J.; Davis, S.; Hocker, T.; Bobba, S.; Verghese, N.; Bajaj, D.; Yu, H.Z.; Dillard, D.A. Fracture characterization of overmold composite adhesion. J. Thermoplast. Compos. Mater. 2020, 33, 1–21. [Google Scholar] [CrossRef]

- Russo, A.; Zarelli, M.; Sellitto, A.; Riccio, A. Fiber bridging induced toughening effects on the delamination behavior of composite stiffened panels under bending loading: A numerical/experimental study. Materials 2019, 12, 2407. [Google Scholar] [CrossRef] [Green Version]

- Lee, D. Local anisotropy analysis based on the Mori-Tanaka model for multiphase composites with fiber length and orientation distributions. Compos. Part B Eng. 2018, 148, 227–234. [Google Scholar] [CrossRef]

- Cintra, J.S.; Tucker, C.L. Orthotropic closure approximations for flow-induced fiber orientation. J. Rheol. 1995, 39, 1095–1122. [Google Scholar] [CrossRef]

- Aretz, H. A simple isotropic-distortional hardening model and its application on elastic-plastic analysis of localized necking in orthotropic sheet metals. Int. J. Plast. 2008, 24, 1457–1480. [Google Scholar] [CrossRef]

- Borges, M.F.; Antunes, F.V.; Prates, P.A.; Branco, R. A numerical study of the effect of isotropic hardening parameters on mode I fatigue crack growth. Metals 2020, 10, 177. [Google Scholar] [CrossRef] [Green Version]

- Bay, R.S.; Tucker, C.L., III. Fiber orientation in simple injection moldings. Part I: Theory and numerical methods. Polym. Compos. 1992, 13, 317–331. [Google Scholar] [CrossRef]

- Bay, R.S.; Tucker, C.L., III. Fiber orientation in simple injection moldings. Part II: Experimental Results. Polym. Compos. 1992, 13, 332–341. [Google Scholar] [CrossRef]

- Oumer, A.N.; Mamat, O. A review of effects of molding methods, mold thickness and other processing parameters on fiber orientation in polymer composites. Asian J. Sci. Res. 2013, 6, 401–410. [Google Scholar] [CrossRef] [Green Version]

- Huang, C.-T.; Lai, C.-H. Investigation on the coupling effects between flow and fibers on Fiber-Reinforced Plastic (FRP) injection parts. Polymers 2020, 12, 2274. [Google Scholar] [CrossRef] [PubMed]

- Foss, P.H.; Tseng, H.-C.; Snawerdt, J.; Chang, Y.-J.; Yang, W.-H.; Hsu, C.-H. Prediction of fiber orientation distribution in injection molded parts using Moldex3D simulation. Polym. Compos. 2014, 35, 671–680. [Google Scholar] [CrossRef]

- Tseng, H.-C.; Chang, R.-Y.; Hsu, C.-H. The use of shear-rate-dependent parameters to improve fiber orientation predictions for injection molded fiber composites. Compos. Part A Appl. Sci. Manuf. 2018, 104, 81–88. [Google Scholar] [CrossRef]

- Kugler, S.K.; Dey, A.P.; Saad, S.; Cruz, C.; Kech, A.; Osswald, T. A flow-dependent fiber orientation model. J. Compos. Sci. 2020, 4, 96. [Google Scholar] [CrossRef]

- Gruber, G.; Wartzack, S. Three-point bending analyses of short fiber reinforced thermoplastics: A comparison between simulation and test results. SAS Technol. J. 2013, 12, 1–8. [Google Scholar]

- Ogierman, W.; Kokot, G. A study on fiber orientation influence on the mechanical response of a short fiber composite structure. Acta Mech. 2016, 227, 173–183. [Google Scholar] [CrossRef]

- Vlach, J.; Steklý, J. Multiscale modeling of short fibre reinforced composites and it’s relationship to modal analysis of machinery parts. Int. Sci. J. Machines. Technol. Mater. 2019, 5, 241–244. [Google Scholar]

- Ding, G.; Zhang, Y.; Zhu, Y. Experimental and numerical investigation of the flexural behavior of CFRP box girders. Adv. Compos. Lett. 2019, 28, 1–13. [Google Scholar] [CrossRef]

- Zscheyge, M.; Böhm, R.; Hornig, A.; Gerritzen, J.; Gude, M. Rate dependent non-linear mechanical behaviour of continuous fibre-reinforced thermoplastic composites—Experimental characterisation and viscoelastic-plastic damage modelling. Mater. Des. 2020, 193, 108827. [Google Scholar] [CrossRef]

- Rizvi, S.J.A. Effect of injection molding parameters on crystallinity and mechanical properties of isotactic polypropylene. Int. J. Plast. Technol. 2017, 21, 404–426. [Google Scholar] [CrossRef]

| Property | Unit | Value |

|---|---|---|

| Glass fiber mass content | wt% | 60 |

| (Ply) thickness | mm | 0.25 |

| Density | g/cm3 | 1.5 |

| Tensile modulus E11 | GPa | 28 |

| Tensile modulus E22 | GPa | 3.2 |

| Tensile strength | MPa | 720 |

| Flexural modulus | GPa | 21 |

| Flexural strength | MPa | 436 |

| Property | Unit | Value |

|---|---|---|

| Glass fiber mass content | wt% | 30 |

| Glass fiber length | mm | 0.5 |

| Density | g/cm3 | 1.14 |

| Tensile modulus | GPa | 6.5 |

| Tensile strength | MPa | 90 |

| Flexural modulus | GPa | 5.5 |

| Flexural strength | MPa | 120 |

| Denomination | Volume Flow Rate [cm3/s] | Orientation Related to Flow Direction [°] |

|---|---|---|

| PP/GF30-100-0 | 100 | 0 |

| PP/GF30-100-45 | 100 | 45 |

| PP/GF30-100-90 | 100 | 90 |

| PP/GF30-50-0 | 50 | 0 |

| PP/GF30-50-45 | 50 | 45 |

| PP/GF30-50-90 | 50 | 90 |

| PP/GF30-25-0 | 25 | 0 |

| PP/GF30-25-45 | 25 | 45 |

| PP/GF30-25-90 | 25 | 90 |

| Property | Unit | Value | Origin |

|---|---|---|---|

| Tensile modulus of matrix (PP) | GPa | 1.4 | supplier |

| Tensile modulus of reinforcing fiber (GF) | GPa | 73 | supplier |

| Fiber volume content | % | 13.5 | pyrolysis |

| Fiber aspect ratio | - | 23.5 | fiber length analysis |

| Fiber orientation component A11 | - | 0.61 | CT analysis |

| Fiber orientation component A22 | - | 0.27 | CT analysis |

| Yield strength σ0 | MPa | 20.9 | ANSYS |

| Hardening law parameter R0 | - | 313.4 | ANSYS |

| Hardening law parameter Rinfty | - | 22.6 | ANSYS |

| Hardening law parameter b | - | 245.2 | ANSYS |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hirsch, P.; John, M.; Leipold, D.; Henkel, A.; Gipser, S.; Schlimper, R.; Zscheyge, M. Numerical Simulation and Experimental Validation of Hybrid Injection Molded Short and Continuous Fiber-Reinforced Thermoplastic Composites. Polymers 2021, 13, 3846. https://doi.org/10.3390/polym13213846

Hirsch P, John M, Leipold D, Henkel A, Gipser S, Schlimper R, Zscheyge M. Numerical Simulation and Experimental Validation of Hybrid Injection Molded Short and Continuous Fiber-Reinforced Thermoplastic Composites. Polymers. 2021; 13(21):3846. https://doi.org/10.3390/polym13213846

Chicago/Turabian StyleHirsch, Patrick, Marianne John, Daniel Leipold, André Henkel, Sylvia Gipser, Ralf Schlimper, and Matthias Zscheyge. 2021. "Numerical Simulation and Experimental Validation of Hybrid Injection Molded Short and Continuous Fiber-Reinforced Thermoplastic Composites" Polymers 13, no. 21: 3846. https://doi.org/10.3390/polym13213846

APA StyleHirsch, P., John, M., Leipold, D., Henkel, A., Gipser, S., Schlimper, R., & Zscheyge, M. (2021). Numerical Simulation and Experimental Validation of Hybrid Injection Molded Short and Continuous Fiber-Reinforced Thermoplastic Composites. Polymers, 13(21), 3846. https://doi.org/10.3390/polym13213846