Dry Fibre Placement: The Influence of Process Parameters on Mechanical Laminate Properties and Infusion Behaviour

Abstract

:1. Introduction

1.1. Fibre Placement State of the Art

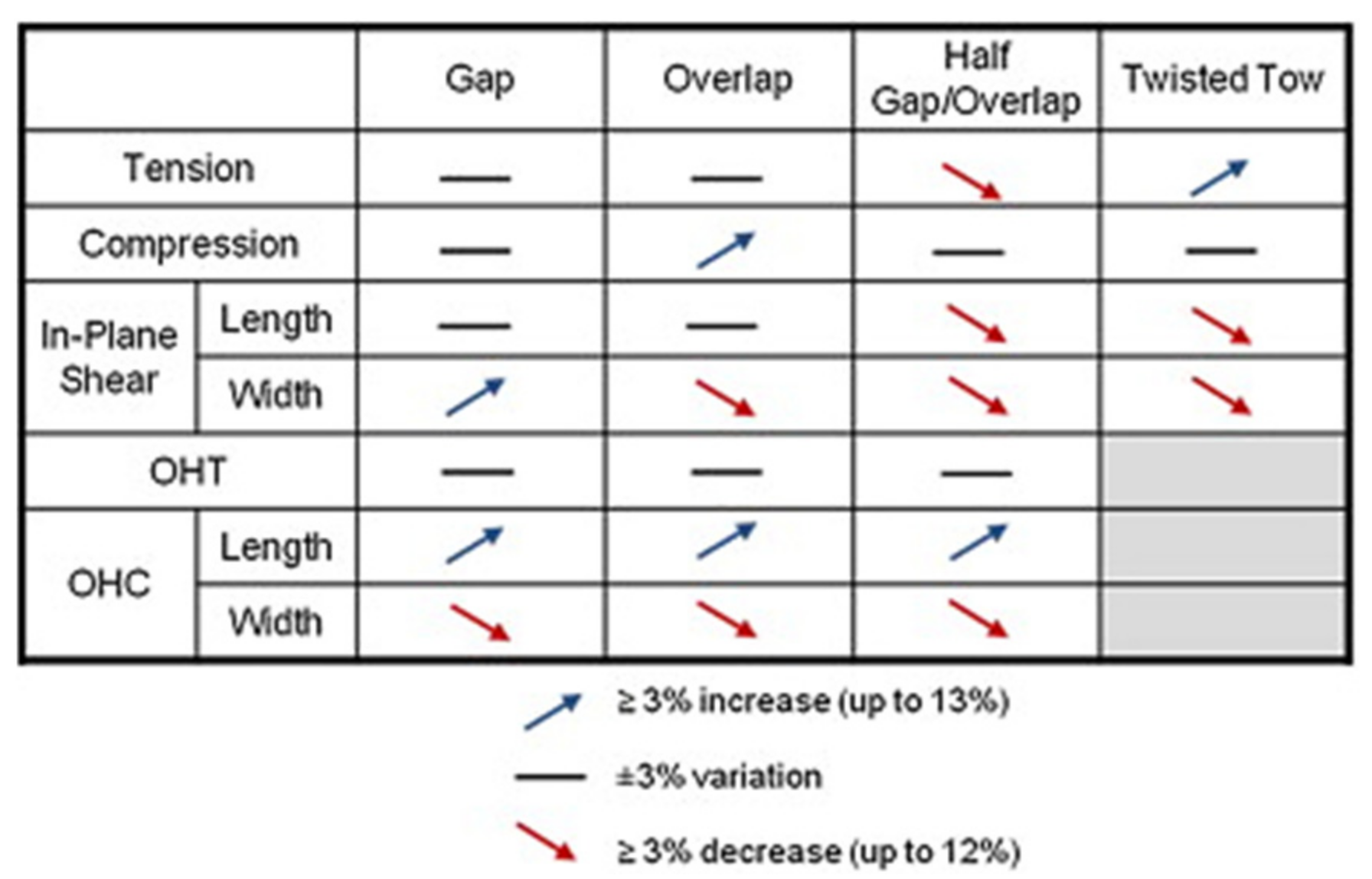

1.2. Impact of Preform Defects on Mechanical Properties

- Gaps.

- Overlaps.

- Fibre undulation/waviness.

- Wrinkles.

- Fuzz balls/fibre fluff.

- Binder residue.

- Loose fibre (surface/tow edges).

- Fibre folding.

- Twisted tows.

1.3. Influencing of the Permeability of a DFP Preform

- Laying of gaps.

- Adaption of the ply structure/fibre orientation.

- Needling/tufting.

- Application of binder/binder yarns on the ply structure.

- Wettability of the fibre surface.

1.4. Scope

2. Materials and Methods

2.1. Materials Used for Sample Plates

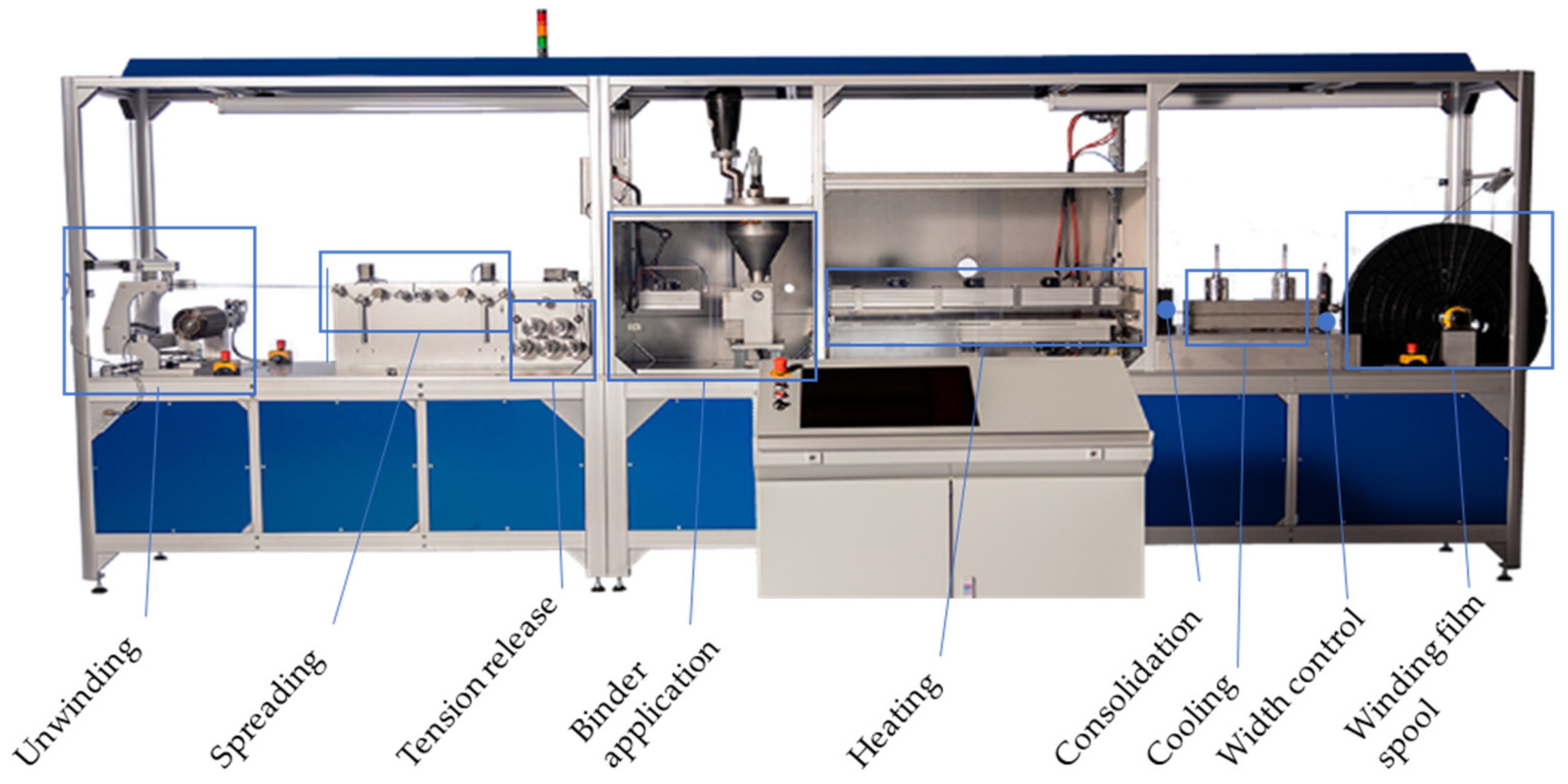

2.2. Manufacturing of Fixed Tow

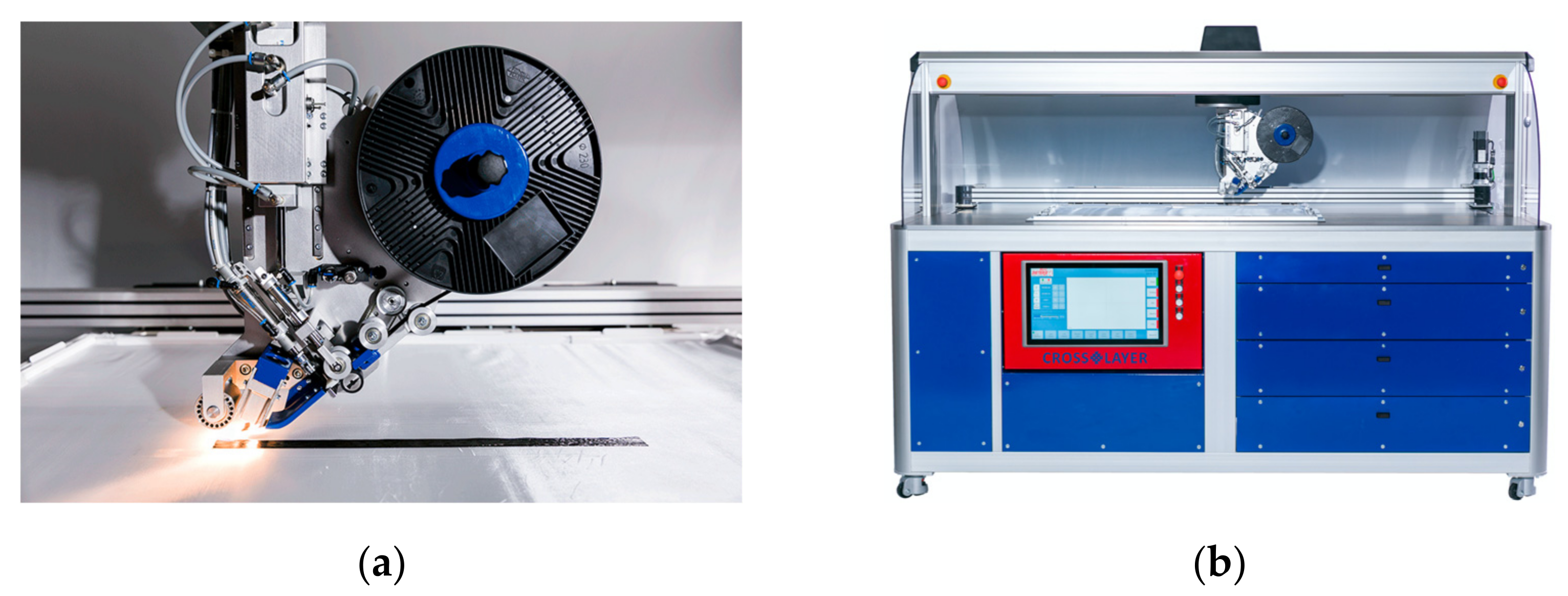

2.3. Production of Preforms by DFP

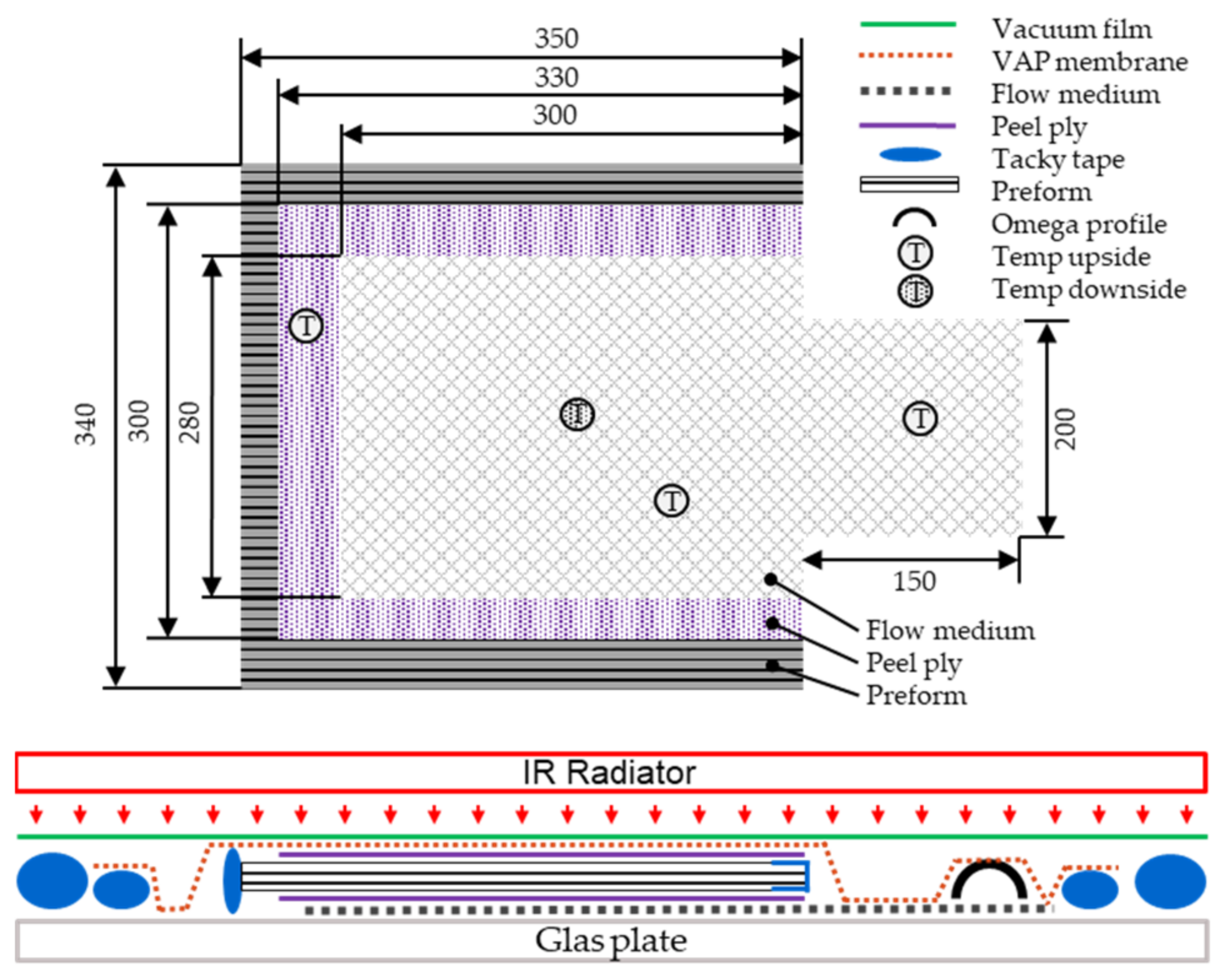

2.4. Liquid Resin Infusion by the Vacuum-Assisted Process (VAP)

2.5. Relation between Laminate Thickness and Infusion Time B-Factor

2.6. Measurement of Infiltration Time in the z-Direction

2.7. Ply Configuration of Sample Plates

2.8. Testing Methods

2.9. Determination of the Fibre Volume Fraction

3. Results

3.1. Mechanical Values of Unidirectional Reference Laminate “No Gaps” and “No 90° Plies”

3.2. Mechanical Bending and Tensile Characteristics: Influence of the 2 mm Gaps and the Number of 90° Plies

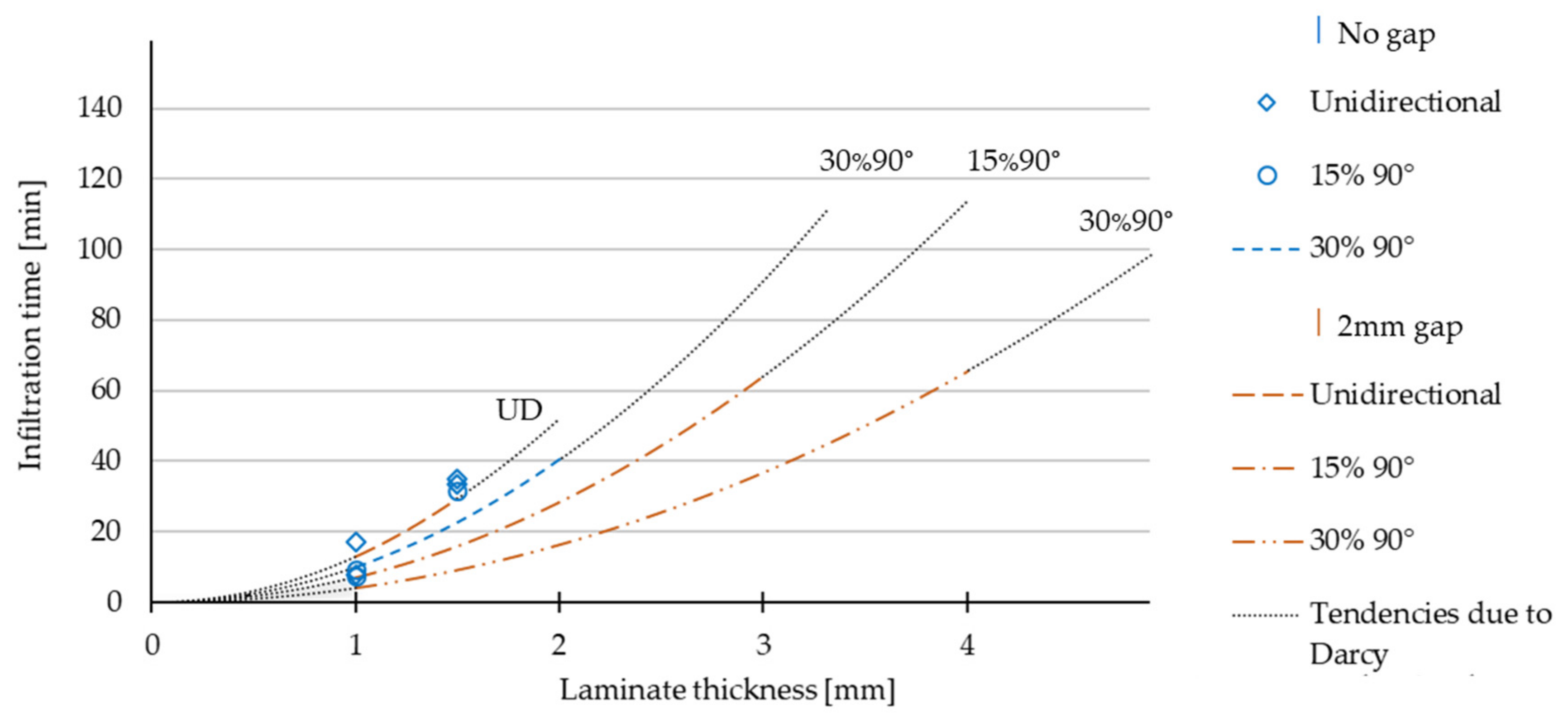

3.3. Infiltration Time

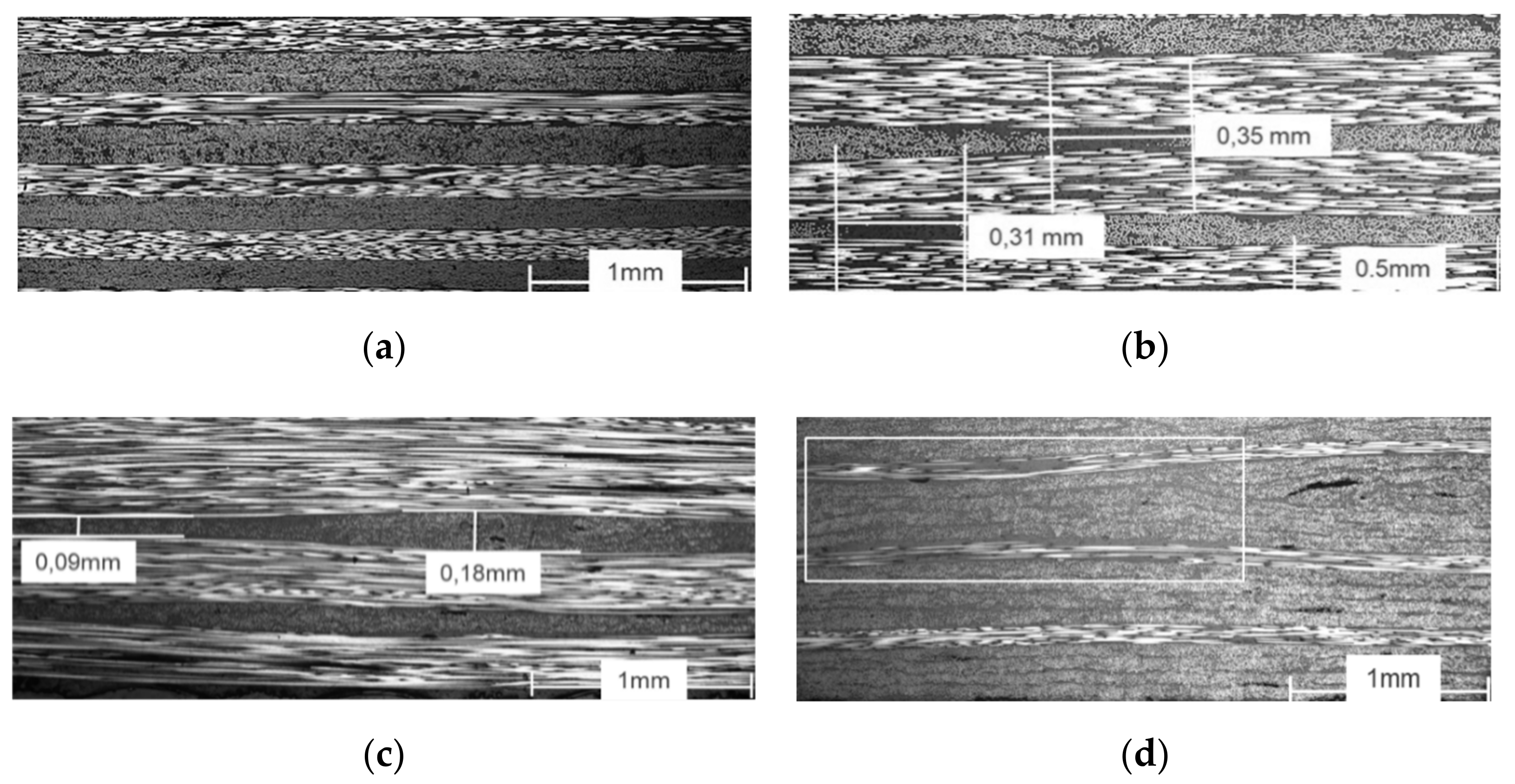

3.4. Laminate Quality and Cross-Sections

4. Discussion

4.1. Bending Characteristics: Influence of the 2 mm Gaps and the Number of 90° Plies

- First, 2-mm-wide gaps had no influence on the flexural modulus.

- The flexural strength was reduced by 3% if 2-mm-wide gaps were introduced.

- The flexural strength was reduced by 8% when 90° plies were inserted (ratio: 30%).

4.2. Tensile Characteristics: Influence of the 2 mm Gaps and the Number of 90° Plies

- The tensile modulus was reduced by 2.6% when 2-mm-wide gaps were introduced.

- The tensile strength was reduced by 7% when 2-mm-wide gaps were introduced.

- The reduction in tensile strength and modulus correlated to the same extent with the percentage of 90° plies

4.3. Influence of the Ply Configuration and Laminate Thickness on the Infiltration Time

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Property | Unit | Value |

|---|---|---|

| Filament Count | [-] | 24,000 |

| Tex | [tex] | 1600 |

| Density | [g/cm3] | 1.79 |

| Tensile strength | [GPa] | 5.0 |

| Tensile modulus | [GPa] | 270 |

| Strain max | [%] | 1.9 |

| Sizing | Epoxy | |

| Sizing content | [m-%] | 1.0 |

| Property | Unit | Value |

|---|---|---|

| Density | [g/cm3] | 1.19 |

| Bending strength | [MPa] | 110 |

| Bending Modulus | [GPa] | 2.95 |

| Tensile strength | [MPa] | 67.5 |

| Compression strength | [MPa] | 85 |

| Strain max | [%] | 7.5 |

| Pot Life (35 °C) | [min] | 120 |

| Viscosity (35 °C) | [mPas] | 180 |

| Property | Unit | Value |

|---|---|---|

| Bulk density | [g/cm3] | 0.40 |

| Particle size > 90 µm | [%] | 5–20 |

| Softening point | [°C] | 100 ± 15 |

| B-time at 150 °C | [s] | 50–100 |

| Reversible forming (90–110 °C) | [min] | 0.1–3.0 |

| Crosslinking irreversible (120 °C) | [min] | 6 |

References

- Helber, F.; Schrick, B.; Carosella, S.; Middendorf, P. Tailored preform production with customizable UD materials for hybrid material design. In Proceedings of the SAMPE Europe Conference, Stuttgart, Germany, 14–16 November 2017; p. 5. [Google Scholar]

- Rimmel, O.; Becker, D.; Mitschang, P. Impact of Stitching on Permeability and Mechanical Properties of Preforms Manufactured by Dry Fiber Placement. Polym. Compos. 2018, 40, 1631–1642. [Google Scholar] [CrossRef]

- Gardiner, G. The spread of spread tow. CW Compos. World Mag. 2018, 4, 30–32. [Google Scholar]

- Lukaszewicz, D.H.-J.A.; Ward, C.; Potter, K.D. The engineering aspects of automated prepreg layup: History, present and future. Compos. Part B 2012, 43, 997–1009. [Google Scholar] [CrossRef]

- Szcesny, M.; Heieck, F.; Carosella, S.; Middendorf, P.; Sehrschön, H.; Schneiderbauer, M. The advanced ply placement process—An innovative direct 3D placement technology for plies and tapes. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 2–9. [Google Scholar] [CrossRef] [Green Version]

- Kim, B.C.; Potter, K.; Weaver, P.M. Continuous tow shearing for manufacturing variable angle tow composites. Compos. Part A 2012, 43, 1347–1356. [Google Scholar] [CrossRef]

- Helber, F.; Carosella, S.; Middendorf, P. Multi-robotic composite production of complex and large-scaled components for the automotive industry. In Proceedings of the SCAP 2020—Stuttgart Conference on the Automotive Production, Stuttgart, Germany, 9–10 November 2020. [Google Scholar]

- Croft, K.; Lessard, L.; Pasini, D.; Hojjati, M.; Chen, J.; Yousefpour, A. Experimental study of the effect of automated fiber placement induced defects on performance of composite laminates. Compos. Part A 2011, 42, 484–491. [Google Scholar] [CrossRef] [Green Version]

- Hsiao, M.; Daniel, I.M. Effect of fiber waviness on stiffness and strength reduction of unidirectional composites under compressive loading. Compos. Sci. Technol. 1996, 56, 581–593. [Google Scholar] [CrossRef]

- Thor, M.; Sause, M.G.R.; Hinterhölzl, R.M. Mechanisms of Origin and Classification of Out-of-Plane Fiber Waviness in Composite Materials—A Review. J. Compos. Sci. 2020, 4, 130. [Google Scholar] [CrossRef]

- Aziz, A.R.; Ali, M.A.; Zeng, X.; Umer, R.; Schubel, P.; Cantwell, W.J. Transverse permeability of dry fiber preforms manufactured by automated fiber placement. Compos. Sci. Technol. 2017, 152, 57–67. [Google Scholar] [CrossRef]

- Rimmel, O.; Becker, D.; Mitschang, P. Maximizing the out-of-plane-permeability of preforms manufactured by dry fiber placement. Adv. Manuf. Polym. Compos. Sci. 2016, 2, 93–102. [Google Scholar] [CrossRef] [Green Version]

- Sirtautas, J. Coupled Fabric Deformation and Infusion Process Simulation. Available online: https://elib.uni-stuttgart.de/bitstream/11682/9766/1/Sirtautas_ifb_2017.pdf (accessed on 15 October 2021).

- Hammond, V.H.; Loos, A.C. The Effects of Fluid Type and Viscosity on the Steady-State and Advancing Front Permeability Behaviour of Textile Preforms. J. Reinf. Plast. Compos. 1997, 16, 50–72. [Google Scholar] [CrossRef]

- George, A. Optimization of Resin Infusion Processing for Composite Materials: Simulation and Characterization Strategies. Available online: http://dx.doi.org/10.18419/opus-3857 (accessed on 15 October 2021).

- Yong, A.X.H.; Aktas, A.; May, D.; Endruweit, A.; Advani, S.; Hubert, P.; Abaimov, S.G.; Abliz, D.; Akhatov, I.; Ali, M.A.; et al. Out-of-plane permeability measurement for reinforcement textiles: A benchmark exercise. Compos. Part A 2021, 148, 106480. [Google Scholar] [CrossRef]

- Darcy, H. Les Fontaines Publiques de la Ville de Dijon (The Public Fountains of the City of Dijon); Libraire des Corps Imperiaux des Ponts et Chausses et des Mines: Paris, France, 1856; Available online: https://books.google.co.jp/books?hl=en&lr=&id=DOwbgyt_MzQC&oi=fnd&pg=PA1&dq=Les+Fontaines+Publiques+de+la+ville+de+Dijon+&ots=sUwYc2RA37&sig=jZJp2mLuOMuUQPbWWynTMUA1WPM&redir_esc=y#v=onepage&q=Les%20Fontaines%20Publiques%20de%20la%20ville%20de%20Dijon&f=false (accessed on 15 October 2021).

- Long, A.C. Design and Manufacture of Textile Composites. 2005, pp. 292–299. Available online: https://books.google.co.jp/books?hl=en&lr=&id=gKkILDvGYMAC&oi=fnd&pg=PR9&dq=Design+and+manufacture+of+textile+composites&ots=suoQv7Uy9v&sig=I7IDLTyp8ai1l9AnTWlPZ2uxlpU&redir_esc=y#v=onepage&q=Design%20and%20manufacture%20of%20textile%20composites&f=false (accessed on 15 October 2021).

| Material | Description |

|---|---|

| Fibre | SGL SIGRAFIL®C T24-5.0/270-E100 |

| Binder | Hexion Epikote Resin TRAC 06720 |

| Matrix | Hexion RIMR135/RIMH137 |

| Substrate | Hexcel, HexForce 02116 1260 TF970, 105 g/m2, plain weave |

| Fixed Tow | Unit | Value |

|---|---|---|

| Width | [mm] | 20 |

| Binder, one sided | [mass-%] | 8 |

| Tex fibre | [tex] | 2400 |

| Aerial weight, including binder | [g/m2] | 89 |

| Parameter | Unit | Value |

|---|---|---|

| Temperature infusion | [°C] | 35 |

| Vacuum pressure, absolute | [mbar] | 50 |

| Temperature curing | [°C] | 50 |

| Curing time | [h] | 16 |

| Type of Value | Norm | Geometry (l × b × t) | Testing Length | Testing Speed | Strain Measurement |

|---|---|---|---|---|---|

| [mm] | [mm] | [mm/min] | |||

| Tensile | DIN-EN ISO 527-5 | 250 × 15 × 1 | 150 | 2 | VE |

| Bending (4-point) | DIN-EN ISO 14125B | 100 × 15 × 2 | 81 | 2 | VE |

| Type of Value | Unit | Value (Std Dev.) | Norm |

|---|---|---|---|

| 0° Tensile strength | [MPa] | 2079 (±133) | DIN-EN ISO 527-5 |

| 0° Tensile modulus | [GPa] | 117 (±4) | DIN-EN ISO 527-5 |

| 0° Bending strength | [MPa] | 1088 (±39) | DIN-EN ISO 14125B |

| 0° Bending modulus | [GPa] | 96 (±3) | DIN-EN ISO 14125B |

| No Gap | 2 mm Gap | ||||||

|---|---|---|---|---|---|---|---|

| Type of Value | Unit | UD | 15% 90° | 30% 90° | UD | 15% 90° | 30% 90° |

| 0° Tensile strength | [MPa] | 2079 (±133) | 1937 (±79) | 1589 (±26) | 1944 (±121) | 1773 (±92) | 1514 (±47) |

| 0° Tensile modulus | [GPa] | 117 (±4) | 105 (±3) | 88 (±1) | 117 (±5) | 98 (±4) | 86 (±2) |

| 0° Bending strength | [MPa] | 1088 (±39) | 1010 (±84) | 977 (±37) | 1032 (±53) | 972 (±33) | 956 (±55) |

| 0° Bending modulus | [GPa] | 96 (±3) | 91 (±8) | 70 (±2) | 98 (±6) | 88 (±2) | 70 (±2) |

| No Gap | 2 mm Gap | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | UD | B | 15% 90° | B | 30% 90° | B | UD | B | 15% 90° | B | 30% 90° | B |

| [mm] | [min] | [min] | [min] | [min] | [min] | [min] | ||||||

| 1 | 17.0 | 17.0 | 9.5 | 9.5 | 11.0 | 11.0 | 15.5 | 15.5 | 5.0 | 5.0 | 3.5 | 3.5 |

| 1 | 8.0 | 8.0 | 7.5 | 7.5 | --- | 7.5 | 7.5 | --- | --- | |||

| 1.5 | 79.0 | 35.1 | 71.0 | 31.6 | 24.0 | 10.7 | 36.0 | 16.0 | --- | --- | ||

| 1.5 | 75.0 | 33.3 | N/I | --- | --- | --- | --- | |||||

| 2 | N/I | 35.0 | 8.8 | N/I | 40.0 | 10.0 | 14.0 | 3.5 | ||||

| 2 | N/I | --- | 27.0 | 6.8 | ||||||||

| 3 | 57.0 | 6.3 | 27.0 | 3.0 | ||||||||

| 4 | N/I | 59.0 | 3.7 | |||||||||

| Mean value | 23.4 | 16.2 | 10.1 | 13.0 | 7.1 | 4.1 | ||||||

| Std. dev. | 11.3 | 10.9 | 1.0 | 3.9 | 2.1 | 1.4 | ||||||

| No Gap | 2 Mm Gap | ||||||

|---|---|---|---|---|---|---|---|

| Fibre Volume Fraction | Unit | UD | 15% 90° | 30% 90° | UD | 15% 90° | 30% 90° |

| 1 mm plates tensile | [vol.-%] | 53.0 (±0.2) | 51.4 (±0.4) | 50.4 (±0.2) | 53.3 (±1.3) | 51.4 (±0.6) | 50.0 (±0.6) |

| 2 mm plates bending | [vol.-%] | 53.2 (±0.2) | 50.8 (±0.3) | 51.4 (±0.9) | 53.2 (±1.2) | 50.6 (±1.9) | 51.0 (±0.7) |

| No Gaps | 2 mm Gap | |||||

|---|---|---|---|---|---|---|

| Unidirectional | Unit | Measured | Process Loss | CLT | Measured | Process Loss |

| 0° Tensile strength | [MPa] | 2079 | 25% | 2787 | 1944 | 30% |

| 0° Tensile modulus | [GPa] | 117 | 22% | 150 | 117 | 22% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grisin, B.; Carosella, S.; Middendorf, P. Dry Fibre Placement: The Influence of Process Parameters on Mechanical Laminate Properties and Infusion Behaviour. Polymers 2021, 13, 3853. https://doi.org/10.3390/polym13213853

Grisin B, Carosella S, Middendorf P. Dry Fibre Placement: The Influence of Process Parameters on Mechanical Laminate Properties and Infusion Behaviour. Polymers. 2021; 13(21):3853. https://doi.org/10.3390/polym13213853

Chicago/Turabian StyleGrisin, Benjamin, Stefan Carosella, and Peter Middendorf. 2021. "Dry Fibre Placement: The Influence of Process Parameters on Mechanical Laminate Properties and Infusion Behaviour" Polymers 13, no. 21: 3853. https://doi.org/10.3390/polym13213853

APA StyleGrisin, B., Carosella, S., & Middendorf, P. (2021). Dry Fibre Placement: The Influence of Process Parameters on Mechanical Laminate Properties and Infusion Behaviour. Polymers, 13(21), 3853. https://doi.org/10.3390/polym13213853