A Review of Structural Adhesive Joints in Hybrid Joining Processes

Abstract

:1. Introduction

1.1. Epoxy Adhesives

1.2. Polyurethane Adhesives

1.3. Acrylic and Cyanoacrylate Adhesives

1.4. Anaerobic Adhesives

1.5. High-Temperature Adhesives (HTAs)

- Introduction of the main class of adhesives, subdivided by their chemical nature considering epoxy, polyurethane, acrylic and cyanoacrylate, anaerobic and high-temperature adhesives;

- Description of the most commonly used HJ techniques (mechanical fastening and adhesive bonding, welding processes and adhesive bonding);

- Recent advances on the application of structural adhesive joints in hybrid joining processes.

2. Hybrid Joining Processes

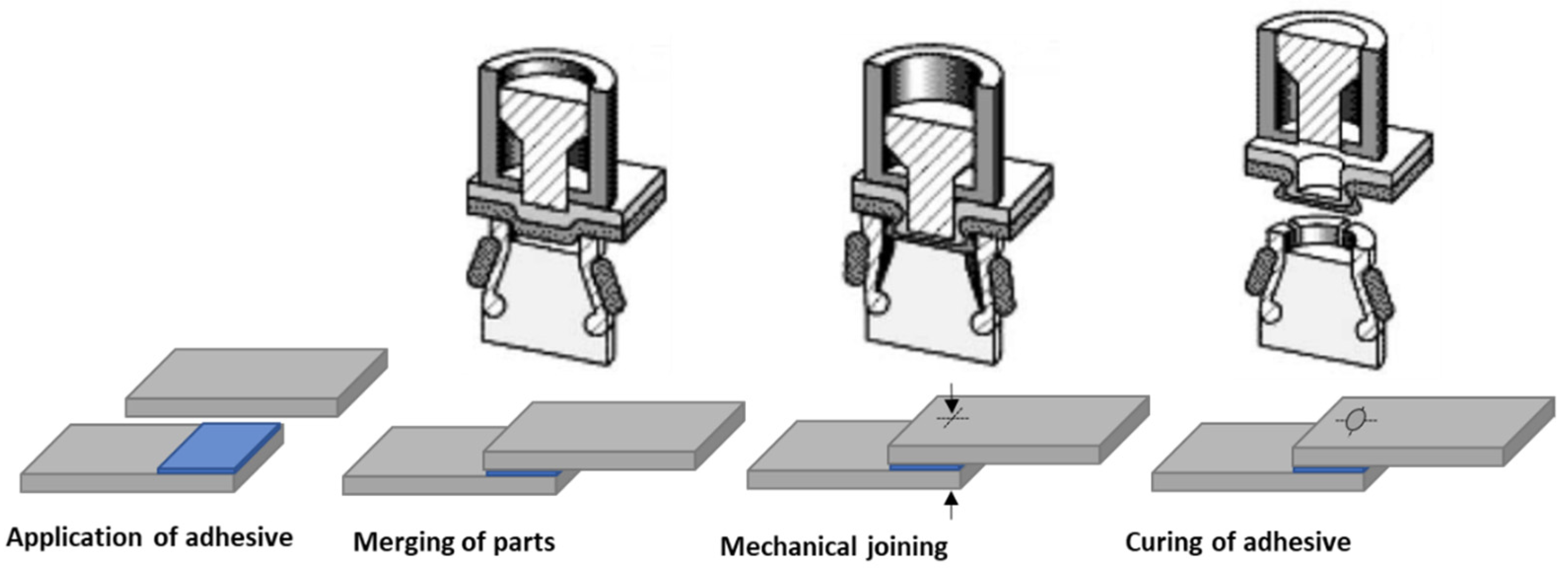

2.1. Advanced Fastening and Bonding Processes

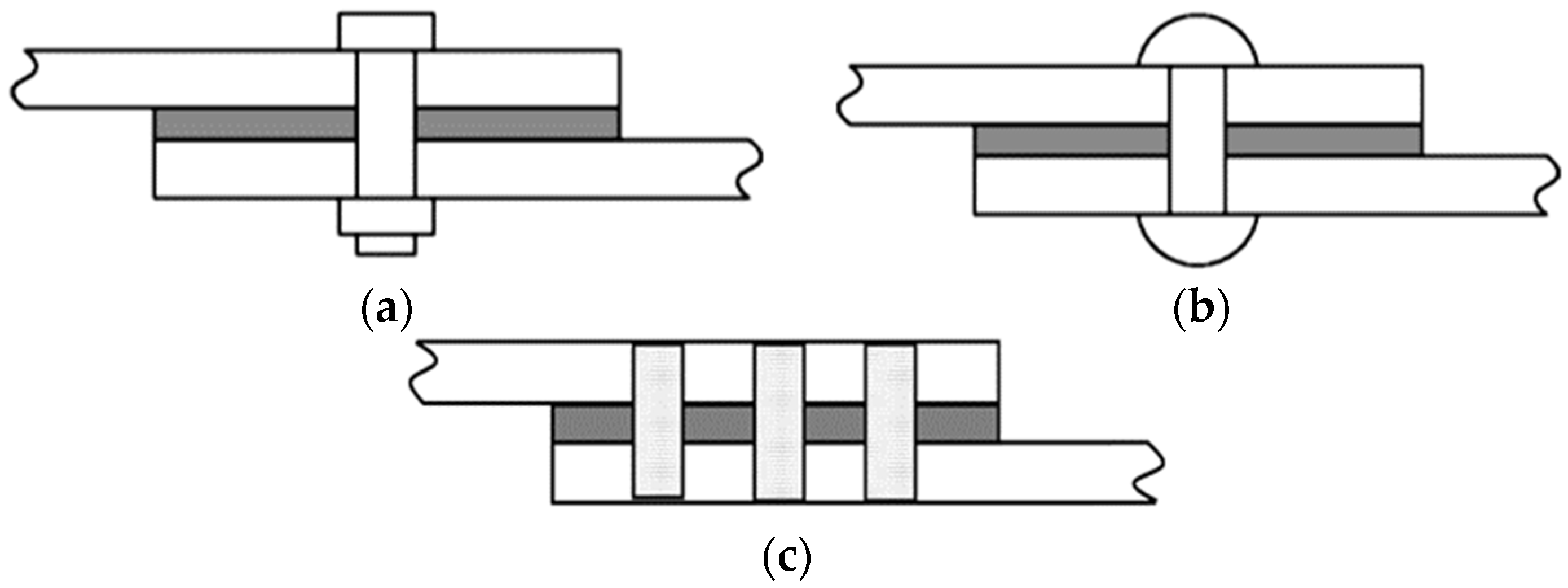

2.1.1. Hybrid-Bonded Fastened Joints

2.1.2. Clinch Bonding

2.2. Welding Processes and Adhesive Bonding

2.2.1. Resistance Spot Welding and Adhesive Bonding (RSW-AB)

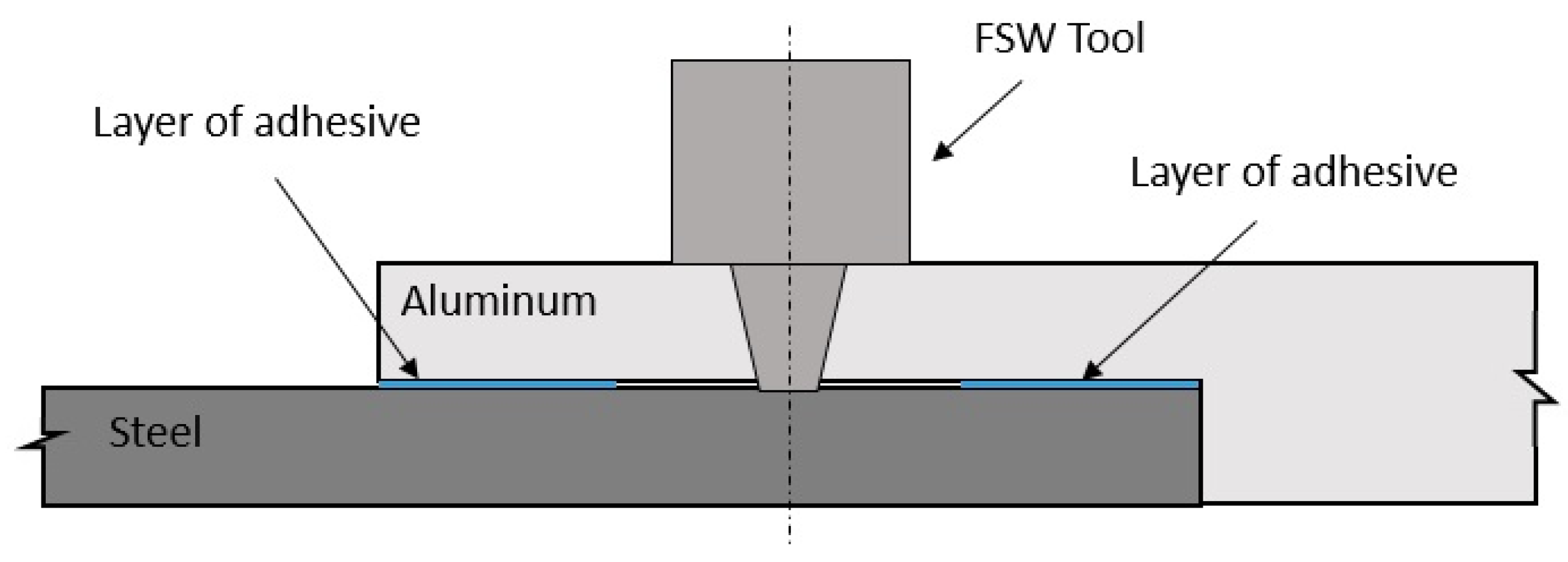

2.2.2. Friction Stir Welding and Adhesive Bonding (FSW-AB)

- The process’ temperature range is between 300 and 470 °C [41];

- The chemical nature of the polymeric adhesives used is relevant, in particular with reference to their thermal resistance (during the process) and chemical resistance (during the use in corrosion environment);

- The avoidance as much as possible of solvents, or nonenvironmentally friendly additives, in order to reduce the environmental impact of the process.

3. Application of Structural Adhesive Joints in Hybrid Joining Processes

3.1. Fasteners and Adhesive Joint

3.1.1. Hybrid Bonded Fastened Joints

3.1.2. Clinch Bonding

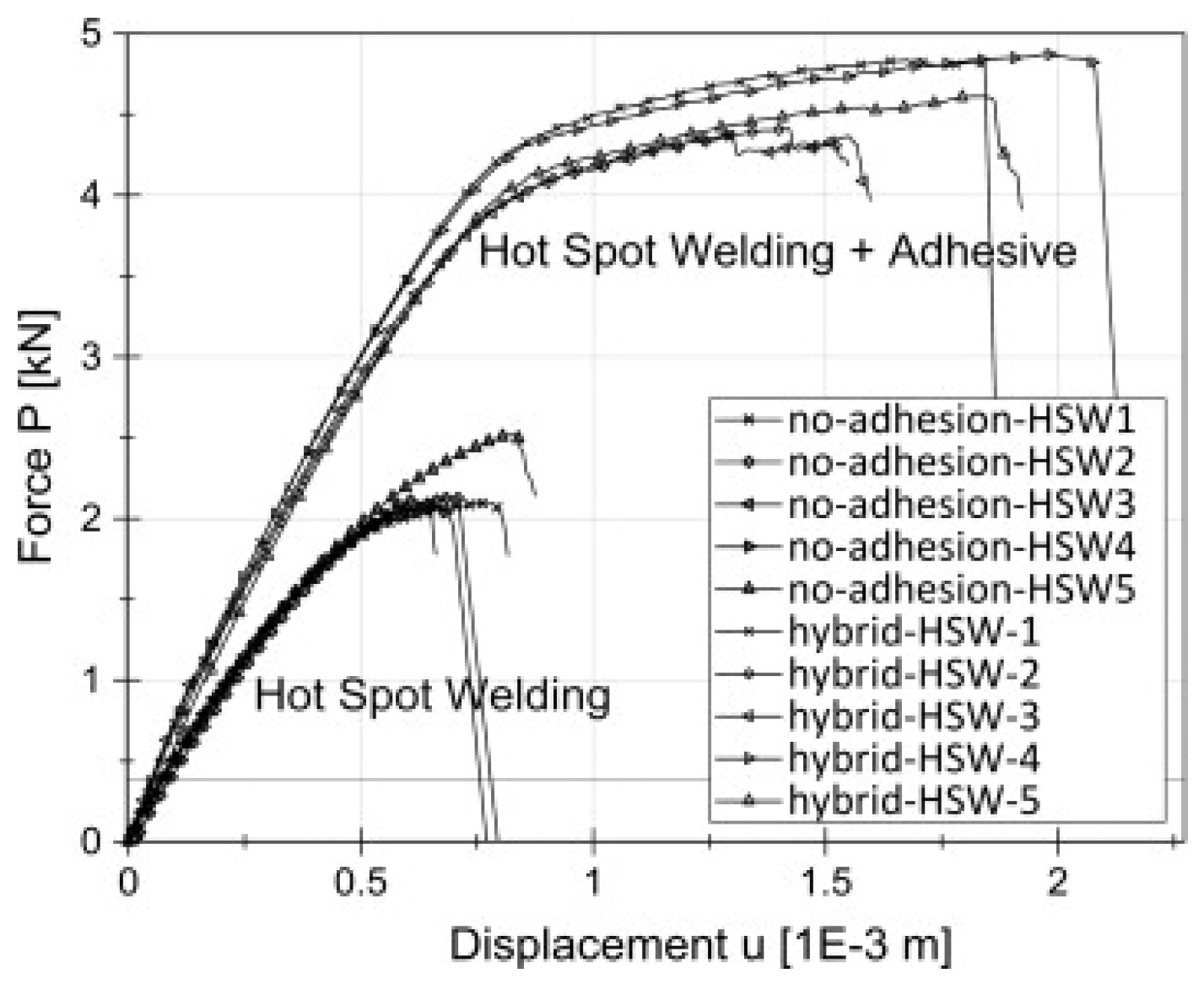

3.2. Welding Processes and Adhesive Bonding

3.2.1. Resistance Spot Welding and Adhesive Bonding (RSW-AB)

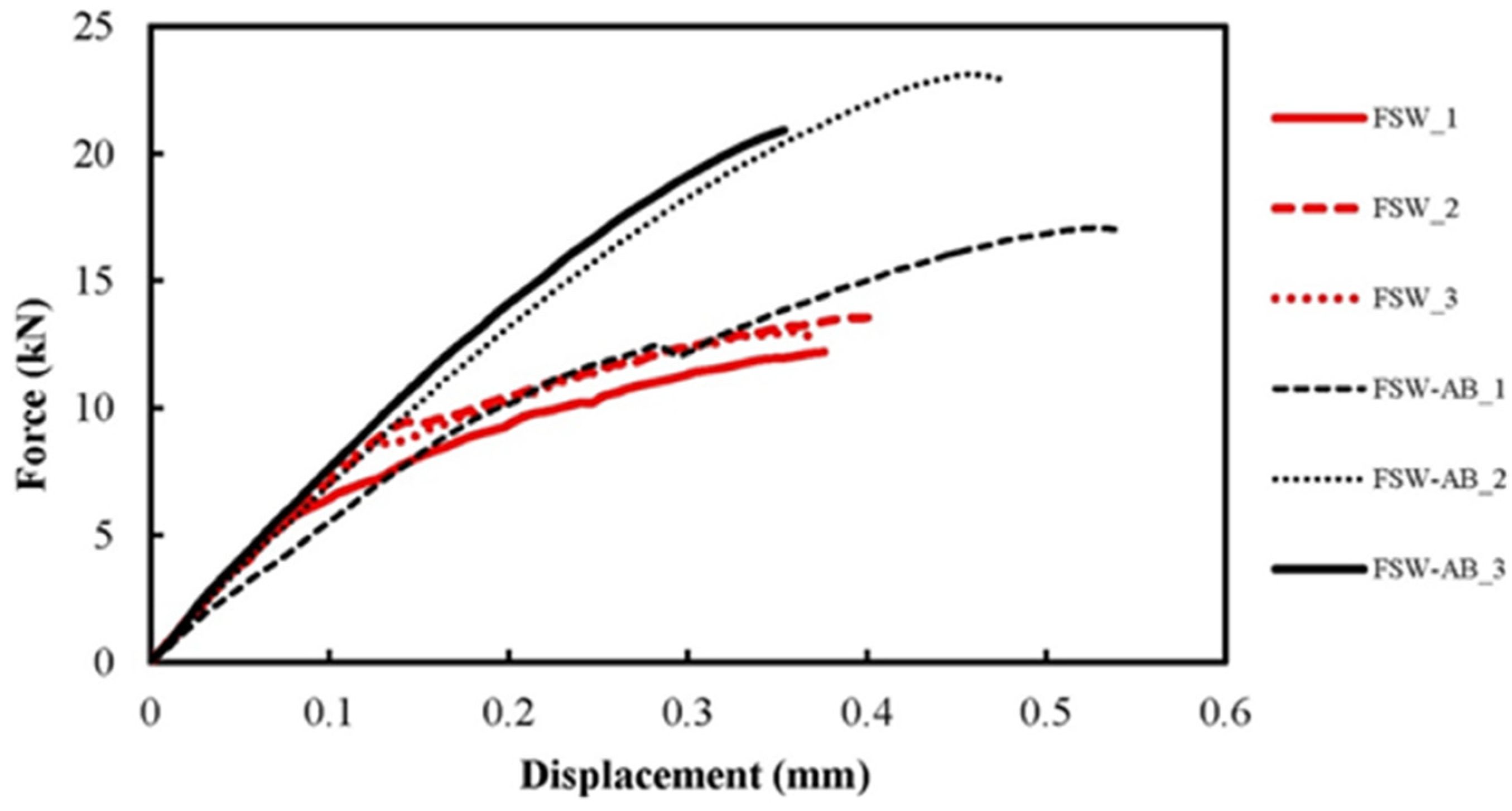

3.2.2. Friction Stir Welding and Adhesive Bonding (FSW-AB)

4. Conclusions and Future Perspectives

- A wide variety of adhesives are available from a range of adhesive manufacturers. The adhesive selection process is difficult as there is no universal adhesive that will fulfil every application. Properties of adhesive can vary greatly, and an appropriate selection is necessary depending on the hybrid process used. Epoxy adhesives use is still the most widespread, due to their peculiar characteristics (high strength, temperature resistance, low cure temperatures, ease of use, and low cost). The polyurethane adhesives are mainly used in hybrid joints because of their superior flexibility at low temperatures, resistance to fatigue, impact resistance and durability. Polyimide-based adhesives find their niche in the case of the hybrid joining technology FSW-AB, due to the need to use suitable polymeric adhesives with high thermal resistance, good wetting and flow characteristics in order to obtain a good-quality bond of the metal surfaces;

- In a hybrid-bonded fastened joint the load sharing depends on a combination of materials and geometric parameters. Moreover, as confirmed by several authors, hybrid joints using rivets or bolts bear an increased maximum load and have higher initial stiffness, strength and energy absorption in comparison with nonhybrid joints. The improvement in hybrid fastened-bonded joints performance compared to both individual joints is achievable when there is substantial load sharing between the adhesive and the fastener. The load sharing in these joints depends on a combination of materials and geometric parameters and attaining appropriate load sharing in the hybrid joint design is a challenge. Most of the new advanced fastened hybrid joining processes (e.g., mechanical clinching and self-pierce riveting) do not need an additional connecting part, which helps to reduce weight. They also do not require predrilled holes. Thus, they enable a sensible reduction of the overall joining time;

- Adhesive bonding combined with welding technologies provides joints with improved fatigue characteristics when compared to spot welding, due to reduction in stress concentrations at the weld-nugget periphery. They also exhibit improved mechanical and thermal properties. In particular, in weld-bonded joints the stress concentration decreases providing better mechanical properties as an increase in tensile shear and/or compressive buckling load. Finally, another key feature of the weld-bonding technology is the optimization of the quality of the sealing and the improvement of the overall resistance to corrosion. However, some technologies are not currently ready for practical application in industry (e.g., combining adhesive bonding and arc or beam fusion processes) and further developments are necessary.

- Due to their complexity and relatively recent development, there is a need for the development of robust design and process simulation tools for hybrid joining processes. The development of numerical models of the hybrid processes would allow a better understanding of all the phenomena involved. At the same time, they will represent a valuable tool for determining the influence of process parameters on the quality of the hybrid joints. This would greatly advance the understanding of these processes and promote further process development and optimization to expand their area of applications in industry;

- There is a need to investigate the effect of environmental factors (e.g., the influence of radiation, humidity and temperature) on the hybrid joints. These issues will need to be addressed before any potential implementation of hybrid joining technologies involving adhesives in industry;

- The development of new adhesives is continuously increasing. The adhesives need to have some specific characteristics depending on the hybrid process used. For example, for fastening adhesive hybrid joints the ideal adhesive to be used should have low stiffness, extreme elongation to failure and reversible deformation, while for weld-bonded joints the adhesives need to withstand high temperatures. There is a need to study a new class of adhesive (e.g., elastomers) to be used in hybrid joining processes;

- In several industries (e.g., aerospace, automotive, rail and naval transport industries), the use of hybrid joining technology could be considered as a potential solution in order to reduce the mass as well as the manufacturing cost. In addition, due to the increasing aspirations for more environmentally friendly technologies and lightweight materials, the joining of polymers, composites and multi-material hybrid structures for industrial applications is still a growing research and development area. Thus, there is a need for new developments on advanced hybrid joining technologies for new advanced materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Budhe, S.; Banea, M.D.; de Barros, S.; da Silva, L.F.M. An updated review of adhesively bonded joints in composite materials. Int. J. Adhes. Adhes. 2017, 72, 30–42. [Google Scholar] [CrossRef]

- American Welding Society (AWS). Adhesive bonding. In WHB Welding Handbook 9.3-Welding Processes, Part 2; American Welding Society (AWS): Miami, FL, USA, 2007; Volume 3, pp. 334–341. [Google Scholar]

- Banea, M.D. Influence of adherend properties on the strength of adhesively bonded joints. MRS Bull. 2019, 44, 625–629. [Google Scholar] [CrossRef]

- Brockmann, W.; Paul Ludwig, G.; Klingen, J.; Schröder, B. Adhesive Bonding: Materials, Applications and Technology; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2008. [Google Scholar]

- White, C.C.; Tan, K.; Wolf, A.T.; Carbary, L.D. Advances in structural silicone adhesives. In Advances in Structural Adhesive Bonding; Woodhead Publishing: Cambridge, UK, 2010; pp. 66–95. [Google Scholar] [CrossRef]

- Das, A.; Mahanwar, P. A brief discussion on advances in polyurethane applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Raju, K.V.S.N. Structural engineering of polyurethane coatings for high performance applications. Prog. Polym. Sci. 2007, 32, 352–418. [Google Scholar] [CrossRef]

- Somarathna, H.M.C.C.; Raman, S.N.; Mohotti, D.; Mutalib, A.A.; Badri, K.H. The use of polyurethane for structural and infrastructural engineering applications: A state-of-the-art review. Constr. Build. Mater. 2018, 190, 995–1014. [Google Scholar] [CrossRef]

- Klemarczyk, P.; Guthrie, J. Advances in anaerobic and cyanoacrylate adhesives. In Advances in Structural Adhesive Bonding; Elsevier Inc.: Amsterdam, The Netherlands, 2010; pp. 96–131. [Google Scholar]

- Mouriz, A.P. Polymers for aerospace structures. Introd. Aerosp. Mater. 2012, 268–302. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; Blaga, L.A. Joining of polymer-metal hybrid structures: Principles and applications, 1st ed.; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Viana, G.; Costa, M.; Banea, M.D.; Da Silva, L.F.M. A review on the temperature and moisture degradation of adhesive joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2017, 231, 488–501. [Google Scholar] [CrossRef]

- Ashcroft, D.A.; Briskham, D. Designing adhesive joints for fatigue and creep load conditions. Adv. Struct. Adhes. Bond. 2010, 469–515. [Google Scholar]

- Banea, M.D.; da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- El-Sayed, M.M.; Shash, A.Y.; Abd-Rabou, M.; ElSherbiny, M.G. Welding and processing of metallic materials by using friction stir technique: A review. J. Adv. Join. Process. 2021, 3, 100059. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Cao, J.; Shen, J.; dos Santos, J.F. Recent progress on control strategies for inherent issues in friction stir welding. Prog. Mater. Sci. 2021, 115, 100706. [Google Scholar] [CrossRef]

- Cui, C.; Liu, W. Recent advances in wet adhesives: Adhesion mechanism, design principle and applications. Prog. Polym. Sci. 2021, 116, 101388. [Google Scholar] [CrossRef]

- Iliev, G.; Hardan, L.; Kassis, C.; Bourgi, R.; Cuevas-Suárez, C.E.; Lukomska-Szymanska, M.; Mancino, D.; Haikel, Y.; Kharouf, N. Shelf Life and Storage Conditions of Universal Adhesives: A Literature Review. Polymers 2021, 13, 2708. [Google Scholar] [CrossRef]

- Pistone, A.; Scolaro, C.; Visco, A. Mechanical Properties of Protective Coatings against Marine Fouling: A Review. Polymers 2021, 13, 173. [Google Scholar] [CrossRef] [PubMed]

- Eshtayeh, M.M.; Hrairi, M.; Mohiuddin, A.K.M. Clinching process for joining dissimilar materials: State of the art. Int. J. Adv. Manuf. Technol. 2016, 82, 179–195. [Google Scholar] [CrossRef]

- Banea, M.D. Debonding on demand of adhesively bonded joints: A critical review. Rev. Adhes. Adhes. 2019, 7, 33–50. [Google Scholar] [CrossRef]

- Banea, M.D.; Rosioara, M.; Carbas, R.J.C.; da Silva, L.F.M. Multi-material adhesive joints for automotive industry. Compos. Part B Eng. 2018, 151, 71–77. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Marques, E.A.S.; Campilho, R.D.S.G. Design rules and methods to improve joint strength. In Handbook of Adhesion Technology; Öchsner, A., da Silva, L.F.M., Adams, R.D., Eds.; Springer International Publishing: Berlin, Germany, 2018; pp. 774–796. [Google Scholar]

- Bodjona, K.; Lessard, L. Hybrid bonded-fastened joints and their application in composite structures: A general review. J. Reinf. Plast. Compos. 2016, 35, 764–781. [Google Scholar] [CrossRef]

- Gupta, K. Advanced Manufacturing Technologies: Modern Machining, Advanced Joining, Sustainable Manufacturing; Gupta, K., Ed.; Springer International Publishing: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Moroni, F.; Pirondi, A. Technology of rivet: Adhesive joints. Adv. Struct. Mater. 2011, 6, 79–108. [Google Scholar]

- Atzeni, E.; Ippolito, R.; Settineri, L. Experimental and numerical appraisal of self-piercing riveting. CIRP Ann.- Manuf. Technol. 2009, 58, 17–20. [Google Scholar] [CrossRef]

- Nong, N.; Keju, O.; Yu, Z.; Zhiyuan, Q.; Changcheng, T.; Feipeng, L. Research on press joining technology for automotive metallic sheets. J. Mater. Process. Technol. 2003, 137, 159–163. [Google Scholar] [CrossRef]

- Spišák, E.; Kaščák, Ľ. Joining Car Body Steel Sheets Using the Clinching Method. Acta Mech. Slovaca 2011, 15, 28–35. [Google Scholar] [CrossRef] [Green Version]

- He, X. Clinching for sheet materials. Sci. Technol. Adv. Mater. 2017, 18, 381–405. [Google Scholar] [CrossRef] [Green Version]

- Pirondi, A.; Moroni, F. Science of clinch-adhesive joints. In Advanced Structured Materials; Springer: Berlin/Heidelberg, Germany, 2011; Volume 6, pp. 109–147. [Google Scholar]

- Carboni, M.; Beretta, S.; Monno, M. Fatigue behaviour of tensile-shear loaded clinched joints. Eng. Fract. Mech. 2006, 73, 178–190. [Google Scholar] [CrossRef]

- Gonçalves, V.M.; Martins, P.A.F. Joining stainless steel parts by means of weld bonding. Int. J. Mech. Mater. Des. 2006, 3, 91–101. [Google Scholar] [CrossRef]

- Messler, R.W. Joining of Advanced Materials, 1st ed.; Butterworth-Heinemann: Oxford, UK, 1993. [Google Scholar]

- Petrie, E.M. Weldbonding-a hybrid method of assembly. Met. Finish. 2013, 111, 42–44. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Besharati-Givi, M.K.; Asadi, P. Advances in Friction-Stir Welding and Processing, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Martinsen, K.; Hu, S.J.; Carlson, B.E. Joining of dissimilar materials. CIRP Ann.- Manuf. Technol. 2015, 64, 679–699. [Google Scholar] [CrossRef] [Green Version]

- Kah, P.; Suoranta, R.; Martikainen, J.; Magnus, C. Techniques for joining dissimilar materials: Metals and polymers. Rev. Adv. Mater. Sci. 2014, 36, 152–164. [Google Scholar]

- Maggiore, S.; Pedemonte, M.; Bazurro, A.; Stagnaro, P.; Utzeri, R.; Luciano, G. Characterization of the effect of an epoxy adhesive in hybrid FSW-bonding aluminium-steel joints for naval application. Int. J. Adhes. Adhes. 2020, 103, 102702. [Google Scholar] [CrossRef]

- Yau, Y.H.; Hussain, A.; Lalwani, R.K.; Chan, H.K.; Hakimi, N. Temperature distribution study during the friction stir welding process of Al2024-T3 aluminum alloy. Int. J. Miner. Metall. Mater. 2013, 20, 779–787. [Google Scholar] [CrossRef]

- Gfeller, B.; Zanetti, M.; Properzi, M.; Pizzi, A.; Pichelin, F.; Lehmann, M.; Delmotte, L. Wood Bonding By Vibrational Welding. J. Adhes. Sci. Technol. 2003, 17, 1425–1590. [Google Scholar] [CrossRef]

- Kanazawa, F.; Pizzi, A.; Properzi, M.; Delmotte, L.; Pichelin, F. Influence Parameters in Wood Dowels Welding by High Speed Rotation. J. Adhes. Sci. Technol. 2005, 12, 1025–1038. [Google Scholar] [CrossRef]

- Leban, J.M.; Pizzi, A.; Properzi, M.; Pichelin, F.; Gelhaye, P.; Rose, C. Wood Welding. A Challenging Alternative to Conventional Wood Gluing. Scand. J. For. Res. 2005, 20, 534–538. [Google Scholar] [CrossRef]

- Rahbarpour, R.; Azdas, T.; Rahbarpour, H.; Shishavan, S.M. Feasibility study of friction stir welding of wood–plastic composites. Sci. Technol. Weld. Join. 2014, 19, 673–681. [Google Scholar] [CrossRef]

- Xie, Y.; Huang, Y.; Meng, X.; Li, J.; Cao, J. Friction stir spot welding of aluminum and wood with polymer intermediate layers. Constr. Build. Mater. 2020, 240, 117952. [Google Scholar] [CrossRef]

- Chowdhury, N.; Chiu, W.K.; Wang, J.; Chang, P. Static and fatigue testing thin riveted, bonded and hybrid carbon fiber double lap joints used in aircraft structures. Compos. Struct. 2015, 121, 315–323. [Google Scholar] [CrossRef]

- Fu, M.; Mallick, P.K. Fatigue of hybrid (adhesive/bolted) joints in SRIM composites. Int. J. Adhes. Adhes. 2001, 21, 145–159. [Google Scholar] [CrossRef]

- Kelly, G. Load transfer in hybrid (bonded/bolted) composite single-lap joints. Compos. Struct. 2005, 69, 35–43. [Google Scholar] [CrossRef]

- Kweon, J.H.; Jung, J.W.; Kim, T.H.; Choi, J.H.; Kim, D.H. Failure of carbon composite-to-aluminum joints with combined mechanical fastening and adhesive bonding. Compos. Struct. 2006, 75, 192–198. [Google Scholar] [CrossRef]

- Chan, W.S.; Vedhagiri, S. Analysis of Composite Bonded/Bolted Joints Used in Repairing. J. Compos. Mater. 2001, 35, 1045–1061. [Google Scholar] [CrossRef]

- Barut, A.; Madenci, E. Analysis of bolted–bonded composite single-lap joints under combined in-plane and transverse loading. Compos. Struct. 2009, 88, 579–594. [Google Scholar] [CrossRef]

- Bois, C.; Wargnier, H.; Wahl, J.C.; Le Goff, E. An analytical model for the strength prediction of hybrid (bolted/bonded) composite joints. Compos. Struct. 2013, 97, 252–260. [Google Scholar] [CrossRef]

- Lopez-Cruz, P.; Laliberté, J.; Lessard, L. Investigation of bolted/bonded composite joint behaviour using design of experiments. Compos. Struct. 2017, 170, 192–201. [Google Scholar] [CrossRef]

- Loureiro, A.L.; Da Silva, L.F.M.; Sato, C.; Figueiredo, M.A. V Comparison of the Mechanical Behaviour between Stiff and Flexible Adhesive Joints for the Automotive Industry. J. Adhes. 2010, 86, 765–787. [Google Scholar] [CrossRef]

- Hoang-Ngoc, C.T.; Paroissien, E. Simulation of single-lap bonded and hybrid (bolted/bonded) joints with flexible adhesive. Int. J. Adhes. Adhes. 2010, 30, 117–129. [Google Scholar] [CrossRef] [Green Version]

- Crocker, L.E.; Duncan, C.; Hughes, R.G.; Urquhart, J.M. Hyperelastic modelling of flexible adhesives. In Performance of Adhesive Joints Programme Project PAJ1-Failure Criteria and their Application to Visco-Elastic/Visco-Plastic Materials; National Physical Laboratory (NPL): London, UK, 1999. [Google Scholar]

- Duncan, B.; Dean, G. Measurements and models for design with modern adhesives. Int. J. Adhes. Adhes. 2003, 23, 141–149. [Google Scholar] [CrossRef]

- Chowdhury, N.M.; Wang, J.; Chiu, W.K.; Chang, P. Experimental and finite element studies of thin bonded and hybrid carbon fibre double lap joints used in aircraft structures. Compos. Part B Eng. 2015, 85, 233–242. [Google Scholar] [CrossRef]

- Lee, Y.H.; Lim, D.W.; Choi, J.H.; Kweon, J.H.; Yoon, M.K. Failure load evaluation and prediction of hybrid composite double lap joints. Compos. Struct. 2010, 92, 2916–2926. [Google Scholar] [CrossRef]

- Lin, W.-H.; Jen, M.-H.R. The Strength of Bolted and Bonded Single-Lapped Composite Joints in Tension. J. Compos. Mater. 1999, 33, 640–666. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Wu, Z.; Keller, T. Resistance and ductility of FRP composite hybrid joints. Compos. Struct. 2021, 255, 113001. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, L.; Liu, Z.; Zhu, P. Research in failure behaviors of hybrid single lap aluminum-CFRP (plain woven) joints. Thin-Walled Struct. 2021, 161, 107488. [Google Scholar] [CrossRef]

- Imanaka, M.; Haraga, K.; Nishikawa, T. Fatigue strength of adhesive/rivet combined lap joints. J. Adhes. 1995, 49, 197–209. [Google Scholar] [CrossRef]

- Habibi, H.; Ramezani, S. Experimental study of nanocomposite hybrid adhesive rivet joints. Arch. Civ. Mech. Eng. 2021, 21, 105. [Google Scholar] [CrossRef]

- Gómez, S.; Oñoro, J.; Pecharromán, J. A simple mechanical model of a structural hybrid adhesive/riveted single lap joint. Int. J. Adhes. Adhes. 2007, 27, 263–267. [Google Scholar] [CrossRef]

- Paroissien, E.; Sartor, M.; Huet, J.; Lachaud, F. Analytical Two-Dimensional Model of a Hybrid (Bolted/Bonded) Single-Lap Joint. J. Aircr. 2007, 44, 573–582. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Lopez-Cruz, P.; Heidari-Rarani, M.; Laliberté, J.; Lessard, L. An experimental study on the mechanical behaviour of bonded and hybrid bonded-bolted composite joints using digital image correlation (DIC) technique. Compos. Struct. 2021, 276, 114544. [Google Scholar] [CrossRef]

- Paroissien, E.; Lachaud, F. On the potential static strength of hybrid (Bolted/Bonded) lap joints with functionally graded adhesives. AIAA J. 2019, 57, 4093–4103. [Google Scholar] [CrossRef]

- Li, G.; Jiang, H.; Zhang, X.; Cui, J. Mechanical properties and fatigue behavior of electromagnetic riveted lap joints influenced by shear loading. J. Manuf. Process. 2017, 26, 226–239. [Google Scholar] [CrossRef]

- Jiang, H.; Zeng, C.; Li, G.; Cui, J. Effect of locking mode on mechanical properties and failure behavior of CFRP/Al electromagnetic riveted joint. Compos. Struct. 2021, 257, 113162. [Google Scholar] [CrossRef]

- Jiang, H.; Hong, Z.; Li, G.; Cui, J. Numerical and experiment investigation on joining process and failure behaviors of CFRP/Al electromagnetic riveted joint. Mech. Adv. Mater. Struct. 2020. [Google Scholar] [CrossRef]

- Di Franco, G.; Fratini, L.; Pasta, A. Analysis of the mechanical performance of hybrid (SPR/bonded) single-lap joints between CFRP panels and aluminum blanks. Int. J. Adhes. Adhes. 2013, 41, 24–32. [Google Scholar] [CrossRef]

- Moroni, F.; Pirondi, A.; Kleiner, F. Experimental analysis and comparison of the strength of simple and hybrid structural joints. Int. J. Adhes. Adhes. 2010, 30, 367–379. [Google Scholar] [CrossRef]

- Marannano, G.; Zuccarello, B. Numerical experimental analysis of hybrid double lap aluminum-CFRP joints. Compos. Part B Eng. 2015, 71, 28–39. [Google Scholar] [CrossRef] [Green Version]

- Sadowski, T.; Golewski, P. Numerical study of the prestressed connectors and their distribution on the strength of a single lap, a double lap and hybrid joints subjected to uniaxial tensile test. Arch. Metall. Mater. 2013, 58, 580–585. [Google Scholar] [CrossRef] [Green Version]

- Golewski, P.; Sadowski, T. Investigation of the effect of chamfer size on the behaviour of hybrid joints made by adhesive bonding and riveting. Int. J. Adhes. Adhes. 2017, 77, 174–182. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T. The Influence of Single Lap Geometry in Adhesive and Hybrid Joints on Their Load Carrying Capacity. Materials 2019, 12, 1884. [Google Scholar] [CrossRef] [Green Version]

- Presse, J.; Künkler, B.; Michler, T. Stress-based approach for fatigue life calculation of multi-material connections hybrid joined by self-piercing rivets and adhesive. Thin-Walled Struct. 2021, 159, 107192. [Google Scholar] [CrossRef]

- Romanov, V.S.; Heidari-Rarani, M.; Lessard, L. A parametric study on static behavior and load sharing of multi-bolt hybrid bonded/bolted composite joints. Compos. Part B Eng. 2021, 217, 108897. [Google Scholar] [CrossRef]

- Selahi, E. Failure Study of Hybrid Bonded-bolted Composite Single and Double Lap Joints Article info. J. Stress Anal. 2018, 3, 37–46. [Google Scholar]

- Sadowski, T.; Balawender, T. Technology of Clinch–Adhesive Joints. Adv. Struct. Mater. 2010, 6, 149–176. [Google Scholar]

- Gerstmann, T.; Awiszus, B. Hybrid joining: Numerical process development of flat-clinch-bonding. J. Mater. Process. Technol. 2020, 277, 116421. [Google Scholar] [CrossRef]

- Balawender, T.; Sadowski, T.; Kneć, M. Technological Problems and Experimental Investigation of Hybrid: Clinched- Adhesively Bonded Joint. Arch. Metall. Mater. 2011, 56, 438–446. [Google Scholar] [CrossRef]

- Darwish, S.M.H.; Ghanya, A. Critical assessment of weld-bonded technologies. J. Mater. Process. Technol. 2000, 105, 221–229. [Google Scholar] [CrossRef]

- Darwish, S.M. Weldbonding strengthens and balances the stresses in spot-welded dissimilar thickness joints. J. Mater. Process. Technol. 2003, 134, 352–362. [Google Scholar] [CrossRef]

- Darwish, S.M.; Al-Samhan, A.M. Peel and shear strength of spot-welded and weld-bonded dissimilar thickness joints. J. Mater. Process. Technol. 2004, 147, 51–59. [Google Scholar] [CrossRef]

- Charbonnet, P.; Clad, A.; Di Fant-Jaeckels, H.; Thirion, J.L. Weldbonding: A very well adapted joining technique to decrease the weight of steel structures. Rev. Metall. Cah. Inf. Tech. 2000, 97, 543–551. [Google Scholar] [CrossRef]

- Peroni, L.; Avalle, M.; Belingardi, G. Comparison of the energy absorption capability of crash boxes assembled by spot-weld and continuous joining techniques. Int. J. Impact Eng. 2009, 36, 498–511. [Google Scholar] [CrossRef]

- Sadowski, T.; Golewski, P.; Kneć, M. Experimental investigation and numerical modelling of spot welding-adhesive joints response. Compos. Struct. 2014, 112, 66–77. [Google Scholar] [CrossRef]

- Piwowarczyk, T.; Korzeniowski, M. Quality analysis of hybrid adhesive-spot welded joints. J. Adhes. Sci. Technol. 2017, 32, 656–672. [Google Scholar] [CrossRef]

- Pizzorni, M.; Lertora, E.; Mandolfino, C.; Gambaro, C. Experimental investigation of the static and fatigue behavior of hybrid ductile adhesive-RSWelded joints in a DP 1000 steel. Int. J. Adhes. Adhes. 2019, 95, 102400. [Google Scholar] [CrossRef]

- Chang, B.; Shi, Y.; Dong, S. Studies on a computational model and the stress field characteristics of weld-bonded joints for a car body steel sheet. J. Mater. Process. Technol. 2000, 100, 171–178. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; Pinto, A.M.G.; Banea, M.D.; Da Silva, L.F.M. Optimization study of hybrid spot-welded/bonded single-lap joints. Int. J. Adhes. Adhes. 2012, 37, 86–95. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Chen, D.L.; Liu, L.; Mori, H.; Zhou, Y. Microstructure and mechanical properties of weld-bonded and resistance spot welded magnesium-to-steel dissimilar joints. Mater. Sci. Eng. A 2011, 537, 11–24. [Google Scholar] [CrossRef]

- Peng, H.; Chen, D.L.; Bai, X.F.; Wang, P.Q.; Li, D.Y.; Jiang, X.Q. Microstructure and mechanical properties of Mg-to-Al dissimilar welded joints with an Ag interlayer using ultrasonic spot welding. J. Magnes. Alloy. 2020, 8, 552–563. [Google Scholar] [CrossRef]

- Marques, G.P.; Campilho, R.D.S.G.; Da Silva, F.J.G.; Moreira, R.D.F. Adhesive selection for hybrid spot-welded/bonded single-lap joints: Experimentation and numerical analysis. Compos. Part B Eng. 2016, 84, 248–257. [Google Scholar] [CrossRef]

- Zhang, Q.; Sekol, R.C.; Zhang, C.; Li, Y.; Carlson, B.E. Joining Lithium-Ion Battery Tabs Using Solder-Reinforced Adhesive. J. Manuf. Sci. Eng. Trans. ASME 2019, 141, 044502. [Google Scholar] [CrossRef]

- Maciel, R.; Bento, T.; Braga, D.F.O.; da Silva, L.F.M.; Moreira, P.M.G.P.; Infante, V. Fatigue properties of combined friction stir and adhesively bonded AA6082-T6 overlap joints. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2169–2180. [Google Scholar] [CrossRef]

- Chowdhury, S.H.; Chen, D.L.; Bhole, S.D.; Cao, X.; Wanjara, P. Lap shear strength and fatigue behavior of friction stir spot welded dissimilar magnesium-to-aluminum joints with adhesive. Mater. Sci. Eng. A 2013, 562, 53–60. [Google Scholar] [CrossRef]

- Braga, D.F.O.; Maciel, R.; Bergmann, L.; Silva, L.F.M.; Infante, V.; Santos, J.F.; Moreira, P.M.G.P. Fatigue performance of hybrid overlap friction stir welding and adhesive bonding of an Al-Mg-Cu alloy. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1262–1270. [Google Scholar] [CrossRef]

- Lertora, E.; Mandolfino, C.; Pizzorni, M.; Gambaro, C. Influence of adhesive in FSW: Investigation on fatigue behavior of welded, weld-bonded, and adhesive-bonded joints in aluminum AA 6082 T6. Materials 2019, 12, 1242. [Google Scholar] [CrossRef] [Green Version]

- Fortunato, J.; Anand, C.; Braga, D.F.O.; Groves, R.M.; Moreira, P.M.G.P.; Infante, V. Friction stir weld-bonding defect inspection using phased array ultrasonic testing. Int. J. Adv. Manuf. Technol. 2017, 93, 3125–3134. [Google Scholar] [CrossRef]

| Parameters of Workpiece Materials | Geometric Parameters | Type of Joint Configuration | Adhesive | Types of Fasteners 1 |

|---|---|---|---|---|

| Nature of material | Thickness of adherends | Single-lap and double-lap joints | Epoxy | Sphere type pin fastener |

| Thickness | Length of overlap | Stepped lap joint | Polyurethane | Wedge type pin fastener |

| Similar or dissimilar system of materials | Adhesive Thickness | Scarf joint | Rounded shaped head type fastener | |

| Strength of material | Fastener–hole clearance | T-joint | Protruding type fastener head | |

| Young’s modulus of material | Width | Butt joint | Countersunk type fastener head |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maggiore, S.; Banea, M.D.; Stagnaro, P.; Luciano, G. A Review of Structural Adhesive Joints in Hybrid Joining Processes. Polymers 2021, 13, 3961. https://doi.org/10.3390/polym13223961

Maggiore S, Banea MD, Stagnaro P, Luciano G. A Review of Structural Adhesive Joints in Hybrid Joining Processes. Polymers. 2021; 13(22):3961. https://doi.org/10.3390/polym13223961

Chicago/Turabian StyleMaggiore, Sofia, Mariana D. Banea, Paola Stagnaro, and Giorgio Luciano. 2021. "A Review of Structural Adhesive Joints in Hybrid Joining Processes" Polymers 13, no. 22: 3961. https://doi.org/10.3390/polym13223961

APA StyleMaggiore, S., Banea, M. D., Stagnaro, P., & Luciano, G. (2021). A Review of Structural Adhesive Joints in Hybrid Joining Processes. Polymers, 13(22), 3961. https://doi.org/10.3390/polym13223961