Analysis of the Damage Mechanism around the Crack Tip for Two Rubber-Toughened PLA-Based Blends

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- Poly (lactic acid; PLA) Ingeo™ Biopolymer 20003D (thermoforming and extrusion grade) purchased from NatureWorks (Melt Flow Index (MFI): 6 g/10 min (210 °C, 2.16 kg); density: 1.24 g cm3; nominal average molar mass: 200,000 g/mol);

- Poly (butylene adipate-co-terephtalate; PBAT) (Figure 2) C1200, trade name Ecoflex®, purchased from BASF. It is a fully biodegradable aliphatic-aromatic copolyester based on the monomers 1,4-butanediol, adipic acid, and terephthalic acid (MFI: 2.7–5 g/10 min (190 °C, 2.16 kg); density: 1.26 g/cm3, nominal average molar mass: 126,000 g/mol);

- Polyolefin elastomers with grafted glycidyl methacrylate (POE-g-GMA) (Figure 2), trade name SOG-02, purchased from Fine-blend Compatibilizer Jiangsu Co., Ltd. (Nanjing, China) (MFI: 2–5 g/10 min (190 °C, 2.16 kg); density: 0.88 g/cm3; nominal average molar mass of 220,000 g/mol and grafted ratio of 0.8–1.2 wt.%);

- Epoxy resin, Elan-tech® EC147/W147, with a low viscosity two-component epoxy system, purchased from Elantas Italia (resin density: 1.13 g/cm3; curing agent density: 1 g/cm3). This resin was used to embed the four-point bending (4PBD) fractured specimens to “freeze” the cracks for the subsequent sectioning according to the procedure explained in Section 2.2.3.

2.2. Methods

2.2.1. Blends and Specimen Preparation

2.2.2. Mechanical and Morphological Characterization

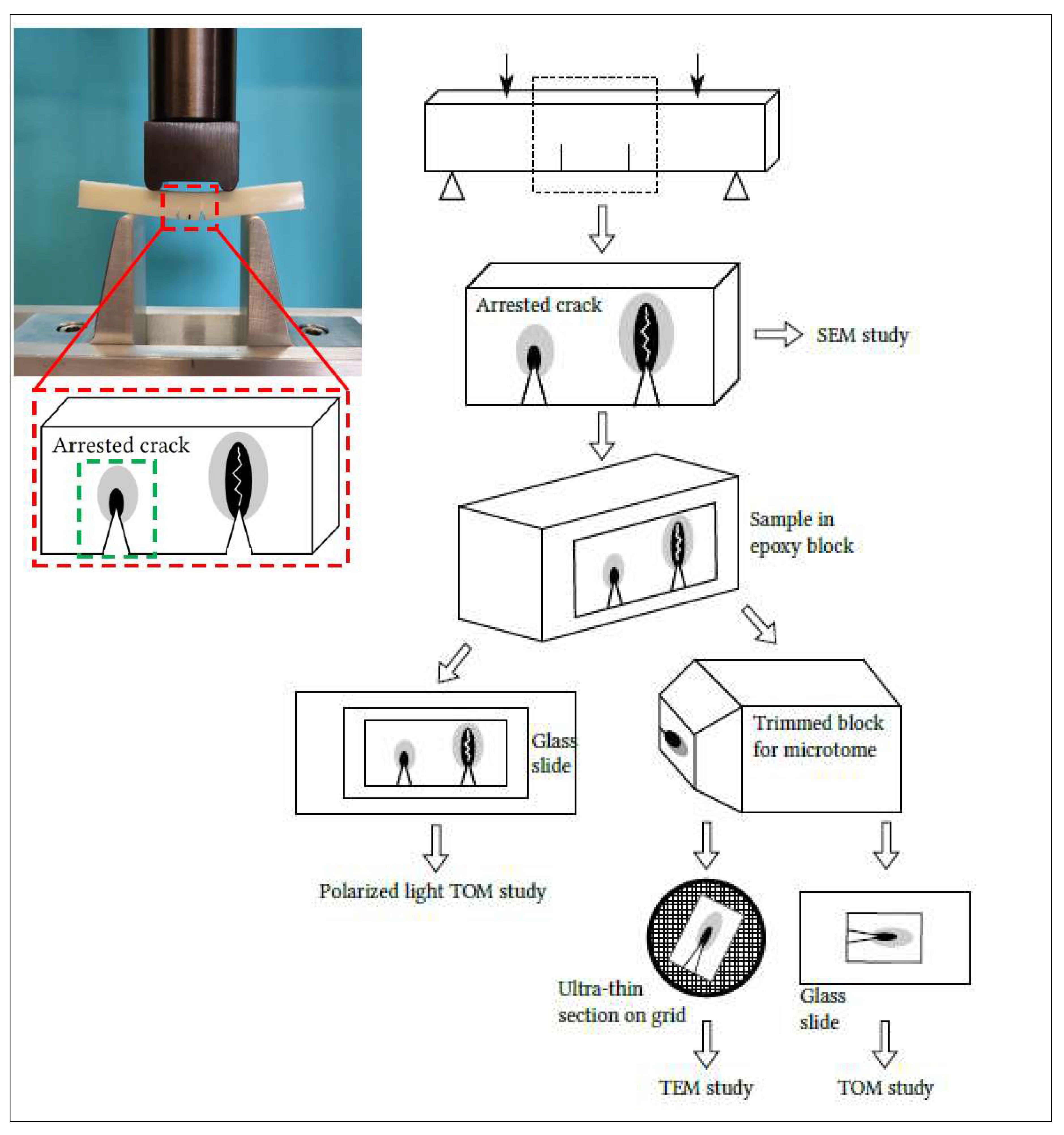

2.2.3. Single-Edge Double-Notch Four-Point Bend (SEDN-4PB) Technique

3. Results and Discussion

3.1. Mechanichal and Morphological Results

3.2. SEDN-4PB Results

3.2.1. SEM Results

3.2.2. TOM Results

3.2.3. TEM Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Michler, G.H.; Bucknall, C.B. New toughening mechanisms in rubber modified polymers. Plast. Rubber Compos. 2001, 30, 110–115. [Google Scholar] [CrossRef]

- Bucknall, C.B.; Heather, P.S.; Lazzeri, A. Rubber toughening of plastics. J. Mater. Sci. 1989, 24, 2255–2261. [Google Scholar] [CrossRef]

- Deblieck, R.; Remerie, K.; Van den Fonteyne, W.; Boerakker, M. A Morphology-Based Model to Describe the Low-Temperature Impact Behaviour of Rubber-Toughened Polypropylene. Polymers 2021, 13, 2218. [Google Scholar] [CrossRef]

- Zanjanijam, A.R.; Hakim, S.; Azizi, H. Morphological, dynamic mechanical, rheological and impact strength properties of the PP/PVB blends: The effect of waste PVB as a toughener. RSC Adv. 2016, 6, 44673–44686. [Google Scholar] [CrossRef]

- Zanjanijam, A.R.; Hakim, S.; Azizi, H. Rheological, mechanical and thermal properties of the PA/PVB blends and their nanocomposites: Structure-property relationships. Polym. Test. 2018, 66, 48–63. [Google Scholar] [CrossRef]

- Liang, J.Z.; Li, R.K.Y. Rubber toughening in polypropylene: A review. J. Appl. Polym. Sci. 2000, 77, 409–417. [Google Scholar] [CrossRef]

- Michler, G.H. Micromechanics of polymers. J. Macromol. Sci. 1999, 38, 787–802. [Google Scholar] [CrossRef]

- Pukanszky, B.; Voros, G. Mechanism of interfacial interactions in particulate filled composites. Compos. Interfaces 1993, 1, 411–427. [Google Scholar] [CrossRef]

- Pearson, R.A. Introduction to the Toughening of Polymers; ACS Publications: Washington DC, USA, 2000; ISBN 1947-5918. [Google Scholar]

- Tijssens, M.G.A.; Van der Giessen, E.; Sluys, L.J. Modeling of crazing using a cohesive surface methodology. Mech. Mater. 2000, 32, 19–35. [Google Scholar] [CrossRef] [Green Version]

- Socrate, S.; Boyce, M.C.; Lazzeri, A. A micromechanical model for multiple crazing in high impact polystyrene. Mech. Mater. 2001, 33, 155–175. [Google Scholar] [CrossRef]

- Walker, I.; Collyer, A.A. Rubber toughening mechanisms in polymeric materials. In Rubber Toughened Engineering Plastics; Springer: Dordrecht, The Netherlands, 1994; pp. 29–56. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on Polylactic Acid (PLA) based Sustainable Materials for Durable Applications: Focus on Toughness and Heat Resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Agnelli, S.; Baldi, F.; Castellani, L.; Pisoni, K.; Vighi, M.; Laiarinandrasana, L. Study of the plastic deformation behaviour of ductile polymers: Use of the material key curves. Mech. Mater. 2018, 117, 105–115. [Google Scholar] [CrossRef]

- Lazzeri, A.; Bucknall, C.B. Dilatational bands in rubber-toughened polymers. J. Mater. Sci. 1993, 28, 6799–6808. [Google Scholar] [CrossRef]

- Lazzeri, A.; Bucknall, C.B. Applications of a dilatational yielding model to rubber-toughened polymers. Polymer 1995, 36, 2895–2902. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.B.; Lazzeri, A. Volume change during creep and micromechanical deformation processes in PLA–PBSA binary blends. Polymers 2021, 13, 2379. [Google Scholar] [CrossRef]

- Shang, M.; Wu, Y.; Shentu, B.; Weng, Z. Toughening of pbt by poe/poe-g-gma elastomer through regulating interfacial adhesion and toughening mechanism. Ind. Eng. Chem. Res. 2019, 58, 12650–12663. [Google Scholar] [CrossRef]

- Lazzeri, A.; Bucknall, C.B. Recent developments in the modeling of dilatational yielding in toughened plastics. In Toughening of Plastics: Advances in Modeling and Experiments; ACS Publications: Washington DC, USA, 2000; p. 264. ISBN 1947-5918. [Google Scholar]

- Argon, A.S.; Cohen, R.E. Toughenability of polymers. Polymer 2003, 44, 6013–6032. [Google Scholar] [CrossRef]

- Aliotta, L.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rigid filler toughening in PLA-Calcium Carbonate composites: Effect of particle surface treatment and matrix plasticization. Eur. Polym. J. 2019, 113, 78–88. [Google Scholar] [CrossRef]

- Pearson, R.A.; Yee, A.F. Toughening mechanisms in elastomer-modified epoxies. J. Mater. Sci. 1989, 24, 2571–2580. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.-H.; Mai, Y.-W. Micromechanics of rubber–toughened polymers. J. Mater. Sci. 1998, 33, 3529–3539. [Google Scholar] [CrossRef]

- Riew, C.K.; Kinloch, A.J. Toughened Plastics I: Science and Engineering; American Chemical Society: Washington, DC, USA, 1993. [Google Scholar]

- Sue, H.J.; Yee, A.F. Toughening mechanisms in a multi-phase alloy of nylon 6,6/polyphenylene oxide. J. Mater. Sci. 1989, 24, 1447–1457. [Google Scholar] [CrossRef] [Green Version]

- Sue, H.J. Craze-like damage in a core-shell rubber-modified epoxy system. J. Mater. Sci. 1992, 27, 3098–3107. [Google Scholar] [CrossRef]

- Zebarjad, S.M.; Lazzeri, A.; Bagheri, R.; Seyed Reihani, S.M.; Frounchi, M. Fracture mechanism under dynamic loading of elastomer-modified polypropylene. Mater. Lett. 2003, 57, 2733–2741. [Google Scholar] [CrossRef]

- Lu, J.; Wei, G.; Sue, H.; Chu, J. Toughening mechanisms in commercial thermoplastic polyolefin blends. J. Appl. Polym. Sci. 2000, 76, 311–319. [Google Scholar] [CrossRef]

- Sue, H. Study of rubber-modified brittle epoxy systems. Part I: Fracture toughness measurements using the double-notch four-point-bend method. Polym. Eng. Sci. 1991, 31, 270–274. [Google Scholar] [CrossRef]

- Lim, S.-H.; Dasari, A.; Yu, Z.-Z.; Mai, Y.-W.; Liu, S.; Yong, M.S. Fracture toughness of nylon 6/organoclay/elastomer nanocomposites. Compos. Sci. Technol. 2007, 67, 2914–2923. [Google Scholar] [CrossRef]

- Bagheri, R.; Pearson, R.A. Role of particle cavitation in rubber-toughened epoxies: 1. Microvoid toughening. Polymer 1996, 37, 4529–4538. [Google Scholar] [CrossRef]

- Arias, M.L.; Frontini, P.M.; Williams, R.J.J. Analysis of the damage zone around the crack tip for two rubber-modified epoxy matrices exhibiting different toughenability. Polymer 2003, 44, 1537–1546. [Google Scholar] [CrossRef]

- Abadyan, M.; Khademi, V.; Bagheri, R.; Motamedi, P.; Kouchakzadeh, M.A.; Haddadpour, H. Loading rate-induced transition in toughening mechanism of rubber-modified epoxy. J. Macromol. Sci. Part B Phys. 2010, 49, 602–614. [Google Scholar] [CrossRef]

- Bagheri, R.; Marouf, B.T.; Pearson, R.A. Rubber-Toughened Epoxies: A Critical Review. Polym. Rev. 2009, 49, 201–225. [Google Scholar] [CrossRef]

- Panda, B.P.; Mohanty, S.; Nayak, S.K. Mechanism of Toughening in Rubber Toughened Polyolefin—A Review. Polym.-Plast. Technol. Eng. 2015, 54, 462–473. [Google Scholar] [CrossRef]

- Wu, J.; Yu, D.M.; Mai, Y.W.; Yee, A.F. Fracture toughness and fracture mechanisms of PBT/PC/IM blends. Part IV. Impact toughness and failure mechanisms of PBT/PC blends without impact modifier. J. Mater. Sci. 2000, 35, 307–315. [Google Scholar] [CrossRef]

- Van Dommelen, J.A.W.; Brekelmans, W.A.M.; Baaijens, F.P.T. Micromechanical modeling of particle-toughening of polymers by locally induced anisotropy. Mech. Mater. 2003, 35, 845–863. [Google Scholar] [CrossRef] [Green Version]

- Fasce, L.A.; Frontini, P.M.; Wong, S.C.; Mai, Y.W. Polypropylene Modified with Elastomeric Metallocene-Catalyzed Polyolefin Blends: Fracture Behavior and Development of Damage Mechanisms. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 1075–1089. [Google Scholar] [CrossRef]

- Nofar, M.; Sacligil, D.; Carreau, P.J.; Kamal, M.R.; Heuzey, M.C. Poly (lactic acid) blends: Processing, properties and applications. Int. J. Biol. Macromol. 2019, 125, 307–360. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Ayyoob, M.; Joo, J.; Deri, F. Polylactic acid blends: The future of green, light and tough. Prog. Polym. Sci. 2018, 85, 83–127. [Google Scholar] [CrossRef]

- Pietrosanto, A.; Scarfato, P.; Di Maio, L.; Incarnato, L. Development of PLA/PHB Blown Films with Improved Performance for Food Packaging Applications. Chem. Eng. Trans. 2021, 87, 91–96. [Google Scholar]

- Gigante, V.; Canesi, I.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rubber Toughening of Polylactic Acid (PLA) with Poly(butylene adipate-co-terephthalate) (PBAT): Mechanical Properties, Fracture Mechanics and Analysis of Ductile-to-Brittle Behavior while Varying Temperature and Test Speed. Eur. Polym. J. 2019, 115, 125–137. [Google Scholar] [CrossRef]

- Gigante, V.; Aliotta, L.; Coltelli, M.B.; Cinelli, P.; Botta, L.; La Mantia, F.P.; Lazzeri, A. Fracture behavior and mechanical, thermal, and rheological properties of biodegradable films extruded by flat die and calender. J. Polym. Sci. 2020, 58, 3264–3282. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Acucella, O.; Signori, F.; Lazzeri, A. Thermal, Mechanical and Micromechanical Analysis of PLA/PBAT/POE-g-GMA Extruded Ternary Blends. Front. Mater. 2020, 7, 130. [Google Scholar] [CrossRef]

- Tripathi, N.; Misra, M.; Mohanty, A.K. Durable Polylactic Acid (PLA)-Based Sustainable Engineered Blends and Biocomposites: Recent Developments, Challenges, and Opportunities. ACS Eng. Au 2021, 1, 7–38. [Google Scholar] [CrossRef]

- Pegoretti, A.; Dong, Y.; Slouf, M. Editorial: Biodegradable Matrices and Composites. Front. Mater. 2020, 7, 265. [Google Scholar] [CrossRef]

- Krishnan, S.; Pandey, P.; Mohanty, S.; Nayak, S.K. Toughening of Polylactic Acid: An Overview of Research Progress. Polym. Plast. Technol. Eng. 2016, 55, 1623–1652. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, H.; Wang, X.; Yu, X.; Zhou, W.; Peng, S. Super tough poly (lactic acid) blends: A comprehensive review. RSC Adv. 2020, 10, 13316–13368. [Google Scholar] [CrossRef] [Green Version]

- Formela, K.; Hejna, A.; Haponiuk, J.; Tercjak, A. In situ processing of biocomposites via reactive extrusion. In Biocomposites for High-Performance Applications: Current Barriers and Future Needs Towards Industrial Development; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 195–246. ISBN 9780081007945. [Google Scholar]

- Lu, X.; Zhao, J.; Yang, X.; Xiao, P. Morphology and properties of biodegradable poly (lactic acid)/poly (butylene adipate-co-terephthalate) blends with different viscosity ratio. Polym. Test. 2017, 60, 58–67. [Google Scholar] [CrossRef]

- Li, X.; Ai, X.; Pan, H.; Yang, J.; Gao, G.; Zhang, H.; Yang, H.; Dong, L. The morphological, mechanical, rheological, and thermal properties of PLA/PBAT blown films with chain extender. Polym. Adv. Technol. 2018, 29, 1706–1717. [Google Scholar] [CrossRef]

- Teamsinsungvon, A.; Jarapanyacheep, R.; Ruksakulpiwat, Y.; Jarukumjorn, K. Melt processing of maleic anhydride grafted poly (lactic acid) and its compatibilizing effect on poly (lactic acid)/poly (butylene adipate-co-terephthalate) blend and their composite. Polym. Sci. Ser. A 2017, 59, 384–396. [Google Scholar] [CrossRef]

- Jiang, L.; Wolcott, M.P.; Zhang, J. Study of biodegradable polylactide/poly(butylene adipate-co-terephthalate) blends. Biomacromolecules 2006, 7, 199–207. [Google Scholar] [CrossRef]

- Wang, X.; Mi, J.; Wang, J.; Zhou, H.; Wang, X. Multiple actions of poly(ethylene octene) grafted with glycidyl methacrylate on the performance of poly(lactic acid). RSC Adv. 2018, 8, 34418–34427. [Google Scholar] [CrossRef] [Green Version]

- Feng, Y.; Hu, Y.; Yin, J.; Zhao, G.; Jiang, W. High impact poly (lactic acid)/poly (ethylene octene) blends prepared by reactive blending. Polym. Eng. Sci. 2013, 53, 389–396. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Cinelli, P.; Coltelli, M.-B.; Lazzeri, A. Effect of a Bio-Based Dispersing Aid (Einar® 101) on PLA-Arbocel® Biocomposites: Evaluation of the Interfacial Shear Stress on the Final Mechanical Properties. Biomolecules 2020, 10, 1549. [Google Scholar] [CrossRef]

- Stojimirovic, A.; Kadota, K.; Chudnovsky, A. An equilibrial process zone in polymeric materials. J. Appl. Polym. Sci. 1992, 46, 1051–1056. [Google Scholar] [CrossRef]

- Kim, A.; Garrett, L.V.; Bosnyak, C.P.; Chudnovsky, A. Kinetics and characterization of the process-zone evolution in polycarbonate. J. Appl. Polym. Sci. 1993, 49, 885–892. [Google Scholar] [CrossRef]

- Chudnovsky, A.; Shulkin, Y.; Baron, D.; Lin, K.P. New method of lifetime prediction for brittle fracture of polyethylene. J. Appl. Polym. Sci. 1995, 56, 1465–1478. [Google Scholar] [CrossRef]

- Haddaoui, N.; Chudnovsky, A.; Moet, A. Ductile fatigue crack propagation in polycarbonate. Polymer 1986, 27, 1377–1384. [Google Scholar] [CrossRef]

- Donald, A.M.; Kramer, E.J. Plane stress deformation zones at crack tips in polycarbonate. J. Mater. Sci. 1981, 16, 2967–2976. [Google Scholar] [CrossRef]

- Yee, A.F.; Du, J.; Thouless, M.D. Toughening of epoxies. Polym. Blends 2000, 2, 225–267. [Google Scholar]

- Bucknall, C.B. Applications of microscopy to the deformation and fracture of rubber-toughened polymers. J. Microsc. 2001, 201, 221–229. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cohen, L.J.; Ishai, O. The Elastic Properties of Three-Phase Composites. J. Compos. Mater. 1967, 1, 390–403. [Google Scholar] [CrossRef]

| Blend Name | PLA (wt.%) | PBAT (wt.%) | POE-g-GMA (wt.%) |

|---|---|---|---|

| P10 | 90 | 10 | 0 |

| P20 | 80 | 20 | 0 |

| S10 | 90 | 0 | 10 |

| S20 | 80 | 0 | 20 |

| Parameter | Value |

|---|---|

| Temperature profile from feeder to the injection zone (°C) | 180/180/185 |

| Mold temperature (°C) | 60 |

| Injection holding time (s) | 5 |

| Cooling time (s) | 25 |

| Injection pressure (bar) | 90 |

| Formulation | Elastic Modulus (GPa) | Stress at Yield (MPa) | Stress at Break (MPa) | Elongation at Break (%) | Tensile Toughness (MJ/m3) | Charpy Impact Strength (kJ/m2) |

|---|---|---|---|---|---|---|

| PLA [56] | 3.4 ± 0.2 | / | 59.4 ± 1.2 | 3.8 ± 1.5 | 1.05 ± 0.1 | 3.0 ± 0.4 |

| P10 | 2.8 ± 0.1 | 51.3 ± 0.5 | 26.2 ± 0.6 | 9.3 ± 2.5 | 3.10 ± 0.3 | 3.9 ± 0.8 |

| P20 | 2.0 ± 0.1 | 45.1 ± 1.8 | 28.1 ± 1.5 | 276.3 ± 8.1 | 62.76 ± 5.2 | 4.7 ± 0.2 |

| S10 | 2.8 ± 0.1 | 49.5 ± 1.0 | 37.5 ± 3.1 | 4.5 ± 0.2 | 1.14 ± 0.1 | 5.6 ± 0.6 |

| S20 | 2.3 ± 0.1 | 38.6 ± 0.5 | 30.1 ± 2.3 | 20.9 ± 4.6 | 5.84 ± 1.3 | 9.4 ± 1.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gigante, V.; Bosi, L.; Parlanti, P.; Gemmi, M.; Aliotta, L.; Lazzeri, A. Analysis of the Damage Mechanism around the Crack Tip for Two Rubber-Toughened PLA-Based Blends. Polymers 2021, 13, 4053. https://doi.org/10.3390/polym13224053

Gigante V, Bosi L, Parlanti P, Gemmi M, Aliotta L, Lazzeri A. Analysis of the Damage Mechanism around the Crack Tip for Two Rubber-Toughened PLA-Based Blends. Polymers. 2021; 13(22):4053. https://doi.org/10.3390/polym13224053

Chicago/Turabian StyleGigante, Vito, Luca Bosi, Paola Parlanti, Mauro Gemmi, Laura Aliotta, and Andrea Lazzeri. 2021. "Analysis of the Damage Mechanism around the Crack Tip for Two Rubber-Toughened PLA-Based Blends" Polymers 13, no. 22: 4053. https://doi.org/10.3390/polym13224053