Alkali Concentration and Diluent Effects on Properties of Grape Cane Fiber-Reinforced Polymer Composites

Abstract

:1. Introduction

2. Materials and Methods

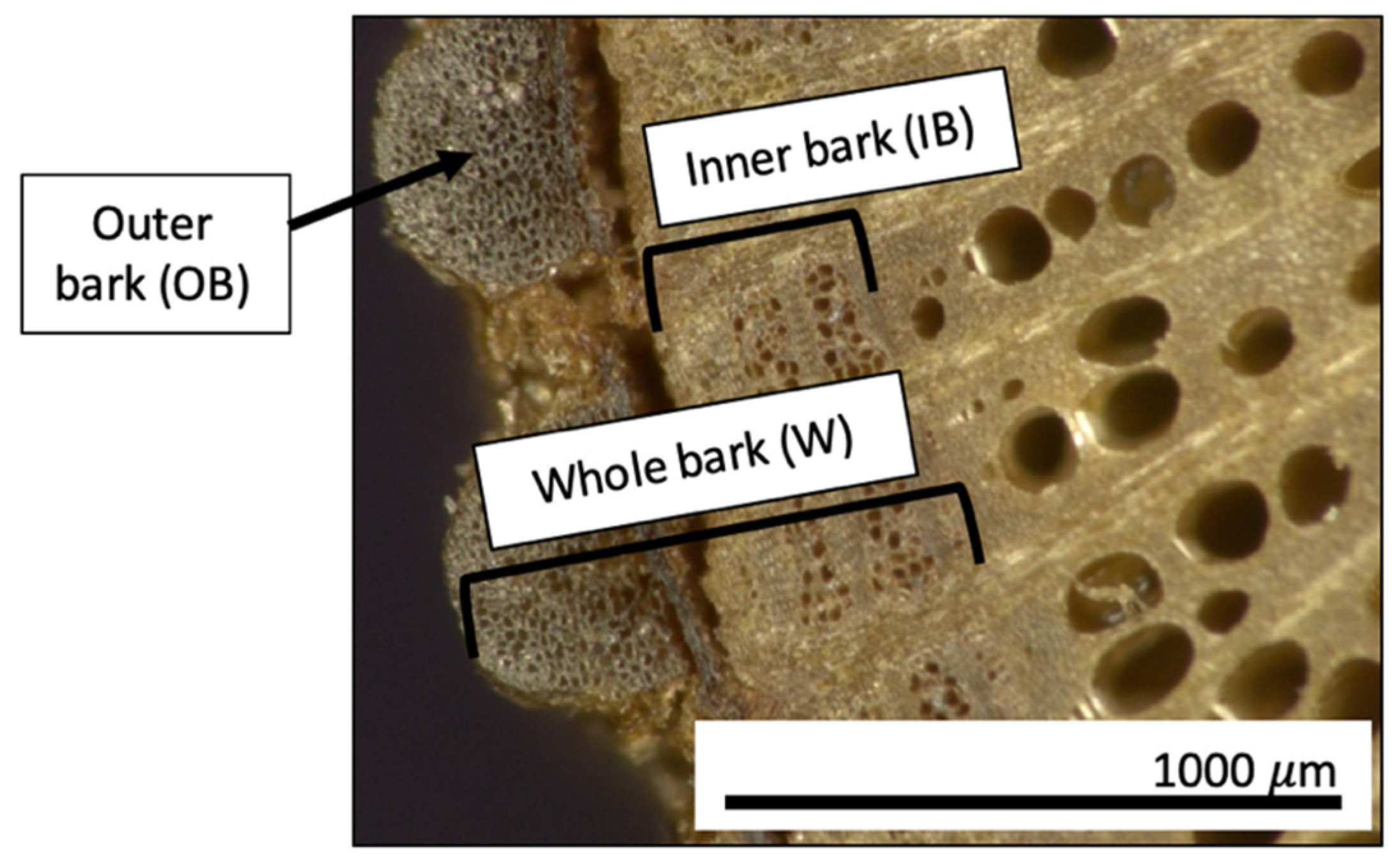

2.1. Grape Cane Fibers

2.2. Fiber Treatment

2.3. Fiber Mat Preparation

2.4. Resin

2.5. Resin Preparation

2.6. Fabrication of Grape Cane Fiber-Reinforced Composites

2.7. Mechanical Testing

2.8. Water Absorption

2.9. Scanning Electron Microscopy

2.10. Statistical Analysis

3. Results and Discussion

3.1. Mechanical Properties

3.2. Influence of Resin Types on Mechanical Properties of Grape Cane Fiber Panels

3.2.1. Resin Control Panels

3.2.2. Grape Cane Fiber-Reinforced UPE Resin Composites

- AESO–grape cane panels

- Styrene-Based Panels

3.3. Water Absorption

3.4. SEM Images

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ilyas, R.A.; Sapuan, S.M. Biopolymers and Biocomposites: Chemistry and Technology. CAC 2020, 16, 500–503. [Google Scholar] [CrossRef]

- Ahmad, F.; Choi, H.S.; Park, M.K. A Review: Natural Fiber Composites Selection in View of Mechanical, Light Weight, and Economic Properties. Macromol. Mater. Eng. 2015, 300, 10–24. [Google Scholar] [CrossRef]

- Nurazzi, M. A Review: Fibres, Polymer Matrices and Composites. Pertanika J. Sci. Technol. 2017, 25, 1085–1102. [Google Scholar]

- Yashas Gowda, T.G.; Sanjay, M.R.; Subrahmanya Bhat, K.; Madhu, P.; Senthamaraikannan, P.; Yogesha, B. Polymer Matrix-Natural Fiber Composites: An Overview. Cogent Eng. 2018, 5, 1–13. [Google Scholar] [CrossRef]

- Sathishkumar, T.; Satheeshkumar, S.; Naveen, J. Glass Fiber-Reinforced Polymer Composites—A Review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural Fibres: Can They Replace Glass in Fibre Reinforced Plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Liu, W.; Chen, T.; Fei, M.; Qiu, R.; Yu, D.; Fu, T.; Qiu, J. Properties of Natural Fiber-Reinforced Biobased Thermoset Biocomposites: Effects of Fiber Type and Resin Composition. Compos. Part B Eng. 2019, 171, 87–95. [Google Scholar] [CrossRef]

- Zwawi, M. A Review on Natural Fiber Bio-Composites, Surface Modifications and Applications. Molecules 2021, 26, 404. [Google Scholar] [CrossRef] [PubMed]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Suardana, N.P.G.; Jung, D.Y.; Choi, K.-S.; Lim, J.K. Effect of Diameters and Alkali Treatment on the Tensile Properties of Date Palm Fiber Reinforced Epoxy Composites. Int. J. Precis. Eng. Manuf. 2012, 13, 1199–1206. [Google Scholar] [CrossRef]

- Alves, C.; Ferrão, P.M.C.; Silva, A.J.; Reis, L.G.; Freitas, M.; Rodrigues, L.B.; Alves, D.E. Ecodesign of Automotive Components Making Use of Natural Jute Fiber Composites. J. Clean. Prod. 2010, 18, 313–327. [Google Scholar] [CrossRef]

- Chen, T.; Liu, W.; Qiu, R. Mechanical Properties and Water Absorption of Hemp Fibers–Reinforced Unsaturated Polyester Composites: Effect of Fiber Surface Treatment with a Heterofunctional Monomer. BioResources 2013, 8, 2780–2791. [Google Scholar] [CrossRef]

- Benyahia, A.; Merrouche, A.; Rokbi, M.; Kouadri, Z. Study the Effect of Alkali Treatment of Natural Fibers on the Mechanical Behavior of the Composite Unsaturated Polyester-Fiber Alfa. In Proceedings of the Composites, Bordeaux, France, 26–30 August 2013; p. 6. [Google Scholar]

- Chikouche, M.D.L.; Merrouche, A.; Azizi, A.; Rokbi, M.; Walter, S. Influence of Alkali Treatment on the Mechanical Properties of New Cane Fibre/Polyester Composites. J. Reinf. Plast. Compos. 2015, 34, 1329–1339. [Google Scholar] [CrossRef]

- Oushabi, A.; Sair, S.; Oudrhiri Hassani, F.; Abboud, Y.; Tanane, O.; El Bouari, A. The Effect of Alkali Treatment on Mechanical, Morphological and Thermal Properties of Date Palm Fibers (DPFs): Study of the Interface of DPF–Polyurethane Composite. S. Afr. J. Chem. Eng. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- Lucintel. Global Unsaturated Polyester Resin Market 2013–2018; Lucintel: Dallas, TX, USA, 2013. [Google Scholar]

- Li, K.; Qiu, R.; Liu, W. Improvement of Interfacial Adhesion in Natural Plant Fiber-Reinforced Unsaturated Polyester Composites: A Critical Review. Rev. Adhes. Adhes. 2015, 3, 98–120. [Google Scholar] [CrossRef]

- Liu, W.; Fei, M.; Ban, Y.; Jia, A.; Qiu, R.; Qiu, J. Concurrent Improvements in Crosslinking Degree and Interfacial Adhesion of Hemp Fibers Reinforced Acrylated Epoxidized Soybean Oil Composites. Compos. Sci. Technol. 2018, 160, 60–68. [Google Scholar] [CrossRef]

- Poillucci, R.A.; Hansen, C.J. Reducing Use of Styrene Monomer in Unsaturated Polyester Resins; Academic Research Program; The Toxic Use Reduction Institute, University of Massachusetts Lowell: Lowell, MA, USA, 2013; p. 23. [Google Scholar]

- Wu, Y.; Li, K. Replacement of Styrene with Acrylated Epoxidized Soybean Oil in an Unsaturated Polyester Resin from Propylene Glycol, Isophthalic Acid, and Maleic Anhydride. J. Appl. Polym. Sci. 2016, 133, 1–6. [Google Scholar] [CrossRef]

- Wu, Y.; Li, K. Replacement of Styrene with Acrylated Epoxidized Soybean Oil in an Unsaturated Polyester Resin from Propylene Glycol and Maleic Anhydride. J. Appl. Polym. Sci. 2017, 134, 45056. [Google Scholar] [CrossRef]

- Bender, A.B.B.; Speroni, C.S.; Moro, K.I.B.; Morisso, F.D.P.; dos Santos, D.R.; da Silva, L.P.; Penna, N.G. Effects of Micronization on Dietary Fiber Composition, Physicochemical Properties, Phenolic Compounds, and Antioxidant Capacity of Grape Pomace and Its Dietary Fiber Concentrate. LWT 2020, 117, 108652. [Google Scholar] [CrossRef]

- Antonic, B.; Dordevic, D.; Jancikova, S.; Holeckova, D.; Tremlova, B.; Kulawik, P. Effect of Grape Seed Flour on the Antioxidant Profile, Textural and Sensory Properties of Waffles. Processes 2021, 9, 131. [Google Scholar] [CrossRef]

- Strik, B.C. Growing Table Grapes; Oregon State University, Extension Service: Corvallis, OR, USA, 2011. [Google Scholar]

- Alma, M.H.; Basturk, M.A. Liquefaction of Grapevine Cane (Vitis vinisera L.) Waste and Its Application to Phenol–Formaldehyde Type Adhesive. Ind. Crop. Prod. 2006, 24, 171–176. [Google Scholar] [CrossRef]

- Vecino, X.; Devesa-Rey, R.; Moldes, A.B.; Cruz, J.M. Formulation of an Alginate-Vineyard Pruning Waste Composite as a New Eco-Friendly Adsorbent to Remove Micronutrients from Agroindustrial Effluents. Chemosphere 2014, 111, 24–31. [Google Scholar] [CrossRef]

- Spinelli, R.; Nati, C.; Pari, L.; Mescalchin, E.; Magagnotti, N. Production and Quality of Biomass Fuels from Mechanized Collection and Processing of Vineyard Pruning Residues. Appl. Energy 2012, 89, 374–379. [Google Scholar] [CrossRef]

- McKinley, P.; Sinha, A.; Kamke, F.A. Understanding the Effect of Weathering on Adhesive Bonds for Wood Composites Using Digital Image Correlation (DIC). Holzforschung 2019, 73, 155–164. [Google Scholar] [CrossRef]

- Bakar, B.F.A.; Kamke, F.A. Effect of Alkali Treatment on the Tensile Properties of Grape Cane Fibers by Integrating Digital Image Correlation Method. Wood Fiber Sci. 2020, 52, 365–379. [Google Scholar] [CrossRef]

- Bachtiar, D.; Salit, M.S.; Zainudin, E.; Abdan, K. Effects of Alkaline Treatment and a Compatibilizing Agent on Tensile Properties of Sugar Palm Fibre- Reinforced High Impact Polystyrene Composites. Mater. Des. 2008, 29, 10. [Google Scholar] [CrossRef]

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Li, Y.; Waterhouse, G.I.N. Effect of Alkali Treatment on Interfacial Bonding in Abaca Fiber-Reinforced Composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 589–597. [Google Scholar] [CrossRef]

- Sanchez, E.M.S.; Zavaglia, C.A.C.; Felisberti, M.I. Unsaturated Polyester Resins: Influence of the Styrene Concentration on the Miscibility and Mechanical Properties. Polymer 2000, 41, 765–769. [Google Scholar] [CrossRef]

- Campise, F.; Agudelo, D.C.; Acosta, R.H.; Villar, M.A.; Vallés, E.M.; Monti, G.A.; Vega, D.A. Contribution of Entanglements to Polymer Network Elasticity. Macromolecules 2017, 50, 2964–2972. [Google Scholar] [CrossRef]

- Panagiotou, E.; Millett, K.; Atzberger, P. Topological Methods for Polymeric Materials: Characterizing the Relationship Between Polymer Entanglement and Viscoelasticity. Polymers 2019, 11, 437. [Google Scholar] [CrossRef] [Green Version]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A New Eco-Friendly Chemical Treatment of Natural Fibres: Effect of Sodium Bicarbonate on Properties of Sisal Fibre and Its Epoxy Composites. Compos. Part B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- Pereira, H. The chemical composition of cork. In Cork; Elsevier: Amsterdam, The Netherlands, 2007; pp. 55–99. ISBN 978-0-444-52967-1. [Google Scholar]

- Tavares, F.; Quilhó, T.; Pereira, H. Wood and Bark Fiber Characteristics of Acacia Melanoxylon and Comparison to Eucalyptus Globules. Cerne 2011, 17, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Bakar, B.F.A.; Kamke, F.A. Comparison of Alkali Treatments on Selected Chemical, Physical and Mechanical Properties of Grape Cane Fibers. Cellulose 2020, 27, 7371–7387. [Google Scholar] [CrossRef]

- Al-Kaabi, K.; Al-Khanbashi, A.; Hammami, A. Date Palm Fibers as Polymeric Matrix Reinforcement: DPF/Polyester Composite Properties. Polym. Compos. 2005, 26, 604–613. [Google Scholar] [CrossRef]

- Bindal, A.; Singh, S.; Batra, N.K.; Khanna, R.; Bindal, A.; Singh, S.; Batra, N.K.; Khanna, R. Development of Glass/Jute Fibers Reinforced Polyester Composite, Development of Glass/Jute Fibers Reinforced Polyester Composite. Indian J. Mater. Sci. Indian J. Mater. Sci. 2013, 2013, e675264. [Google Scholar] [CrossRef] [Green Version]

- Rajesh, G.; Siripurapu, G.; Lella, A. Evaluating Tensile Properties of Successive Alkali Treated Continuous Pineapple Leaf Fiber Reinforced Polyester Composites. Mater. Today Proc. 2018, 5, 13146–13151. [Google Scholar] [CrossRef]

- Murali Mohan Rao, K.; Mohana Rao, K.; Ratna Prasad, A.V. Fabrication and Testing of Natural Fibre Composites: Vakka, Sisal, Bamboo and Banana. Mater. Des. 2010, 31, 508–513. [Google Scholar] [CrossRef]

- Surata, I.W.; Suriadi, I.G.A.K.; Arnis, K. Mechanical Properties of Rice Husks Fiber Reinforced Polyester Composites. IJMMM 2014, 2, 165–168. [Google Scholar] [CrossRef] [Green Version]

- Naguib, H.M.; Kandil, U.F.; Hashem, A.I.; Boghdadi, Y.M. Effect of Fiber Loading on the Mechanical and Physical Properties of “Green” Bagasse–Polyester Composite. J. Radiat. Res. Appl. Sci. 2015, 8, 544–548. [Google Scholar] [CrossRef] [Green Version]

- Haameem, J.A.M.; Abdul Majid, M.S.; Afendi, M.; Marzuki, H.F.A.; Fahmi, I.; Gibson, A.G. Mechanical Properties of Napier Grass Fibre/Polyester Composites. Compos. Struct. 2016, 136, 1–10. [Google Scholar] [CrossRef]

- Biswas, S.; Ahsan, Q.; Cenna, A.; Hasan, M.; Hassan, A. Physical and Mechanical Properties of Jute, Bamboo and Coir Natural Fiber. Fibers Polym. 2013, 14, 1762–1767. [Google Scholar] [CrossRef]

- Zaman, H.U.; Khan, M.A.; Khan, R.A. Comparative Experimental Measurements of Jute Fiber/Polypropylene and Coir Fiber/Polypropylene Composites as Ionizing Radiation. Polym. Compos. 2012, 33, 1077–1084. [Google Scholar] [CrossRef]

- Muñoz, E.; García-Manrique, J.A. Water Absorption Behaviour and Its Effect on the Mechanical Properties of Flax Fibre Reinforced Bioepoxy Composites. Int. J. Polym. Sci. 2015, 2015, 390275. [Google Scholar] [CrossRef] [Green Version]

- Balaji, V.; Senthil, A.K. Mechanical Characterization of Coir Fiber and Cotton Fiber Reinforced Unsaturated Polyester Composites for Packaging Applications. J. Appl. Packag. Res. 2017, 9, 2. [Google Scholar]

- Mahjoub, R.; Yatim, J.M.; Mohd Sam, A.R.; Raftari, M. Characteristics of Continuous Unidirectional Kenaf Fiber Reinforced Epoxy Composites. Mater. Des. 2014, 64, 640–649. [Google Scholar] [CrossRef]

- Saba, N.; Alothman, O.Y.; Almutairi, Z.; Jawaid, M.; Ghori, W. Date Palm Reinforced Epoxy Composites: Tensile, Impact and Morphological Properties. J. Mater. Res. Technol. 2019, 8, 3959–3969. [Google Scholar] [CrossRef]

| Fiber | Resin | Label |

|---|---|---|

| Outer bark | Styrene–UPE | SO |

| Outer bark | AESO–UPE | AO |

| Whole bark | AESO–UPE | AW |

| - | AESO–UPE | CA |

| - | Styrene–UPE | CS |

| Panel | Treatment | Tensile | Flexural | ||

|---|---|---|---|---|---|

| Strength, MPa | Modulus, GPa | Strength, MPa | Modulus, GPa | ||

| AO | CS | 23.7 a | 3.2 a | 90.7 a | 3.2 a |

| (0.8) | (1.0) | (9.9) | (0.2) | ||

| CA | 9.1 b | 0.4 b | 12.6 c | 0.3 c | |

| (2.3) | (0.2) | (5.5) | (0.1) | ||

| N1 | 23.8 a | 2.9 a | 45.3 b | 2.2 b | |

| (3.3) | (0.9) | (7.1) | (0.6) | ||

| N3 | 22.1 a | 2.7 a | 43.0 b | 2.4 b | |

| (4.8) | (0.9) | (8.6) | (0.7) | ||

| AW | CS | 23.7 b′ | 3.2 a′ | 90.7 a′ | 3.2 a′ |

| (0.8) | (1.0) | (9.9) | (0.2) | ||

| CA | 9.1 c′ | 0.4 b′ | 12.6 c′ | 0.3 c′ | |

| (2.3) | (0.2) | (5.5) | (0.1) | ||

| N1 | 22.3 b′ | 3.5 a′ | 50.5 b′ | 2.3 b′ | |

| (9.3) | (0.5) | (6.8) | (0.4) | ||

| N3 | 33.8 a′ | 3.3 a′ | 50.0 b′ | 2.3 b′ | |

| (6.2) | (0.3) | (12.5) | (0.6) | ||

| SO | CS | 23.7 a″ | 3.2 a″ | 90.7 a″ | 3.2 a″ |

| (0.8) | (1.0) | (9.9) | (0.2) | ||

| CA | 9.1 c″ | 0.4 b″ | 12.6 c″ | 0.3 c″ | |

| (2.3) | (0.2) | (5.5) | (0.1) | ||

| N1 | 22.3 b″ | 3.8 a″ | 44.3 b″ | 2.5 b″ | |

| (3.8) | (0.7) | (5.8) | (0.4) | ||

| N3 | 33.8 a″ | 3.7 a″ | 48.4 b″ | 3.0 b″ | |

| (6.3) | (0.4) | (9.5) | (0.7) | ||

| Panel | Tensile | Flexural | ||

|---|---|---|---|---|

| Strength, MPa | Modulus, GPa | Strength, MPa | Modulus, GPa | |

| AO | 22.9 a | 2.8 b | 44.1 a | 2.3 a |

| (4.0) | (0.8) | (7.6) | (0.6) | |

| AW | 28.0 a | 3.4 a | 50.2 a | 2.3 a |

| (9.7) | (0.4) | (9.6) | (0.5) | |

| SO | 25.0 a | 3.7 a | 46.4 a | 2.8 a |

| (5.0) | (0.6) | (7.8) | (0.6) | |

| Panel | Treatment | Tensile | Flexural | ||

|---|---|---|---|---|---|

| Strength | Modulus | Strength | Modulus | ||

| AO | N1 | 162 | 625 | 260 | 633 |

| N3 | 143 | 575 | 241 | 700 | |

| AW | N1 | 145 | 775 | 301 | 667 |

| N3 | 271 | 725 | 297 | 667 | |

| Panel | Treatment | Tensile | Flexural | ||

|---|---|---|---|---|---|

| Strength | Modulus | Strength | Modulus | ||

| SO | N1 | (6) | 19 | (51) | (22) |

| N3 | 43 | 16 | (47) | (6) | |

| Panel/Treatment | AO | AW | SO |

|---|---|---|---|

| CA | 1.3 c | 1.3 c | 1.3 b |

| (0.2) | (0.2) | (0.2) | |

| CS | 1.1 c | 1.1 c | 1.1 b |

| (0.1) | (0.1) | (0.1) | |

| N1 | 33.7 b | 38.0 b | 36.4 a |

| (4.0) | (1.1) | (2.9) | |

| N3 | 41.9 a | 42.3 a | 35.8 a |

| (1.5) | (3.1) | (5.1) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bakar, B.F.A.; Kamke, F.A. Alkali Concentration and Diluent Effects on Properties of Grape Cane Fiber-Reinforced Polymer Composites. Polymers 2021, 13, 4055. https://doi.org/10.3390/polym13234055

Bakar BFA, Kamke FA. Alkali Concentration and Diluent Effects on Properties of Grape Cane Fiber-Reinforced Polymer Composites. Polymers. 2021; 13(23):4055. https://doi.org/10.3390/polym13234055

Chicago/Turabian StyleBakar, Balkis F. A., and Frederick A. Kamke. 2021. "Alkali Concentration and Diluent Effects on Properties of Grape Cane Fiber-Reinforced Polymer Composites" Polymers 13, no. 23: 4055. https://doi.org/10.3390/polym13234055

APA StyleBakar, B. F. A., & Kamke, F. A. (2021). Alkali Concentration and Diluent Effects on Properties of Grape Cane Fiber-Reinforced Polymer Composites. Polymers, 13(23), 4055. https://doi.org/10.3390/polym13234055