Non-Formaldehyde, Bio-Based Adhesives for Use in Wood-Based Panel Manufacturing Industry—A Review

Abstract

:1. Introduction

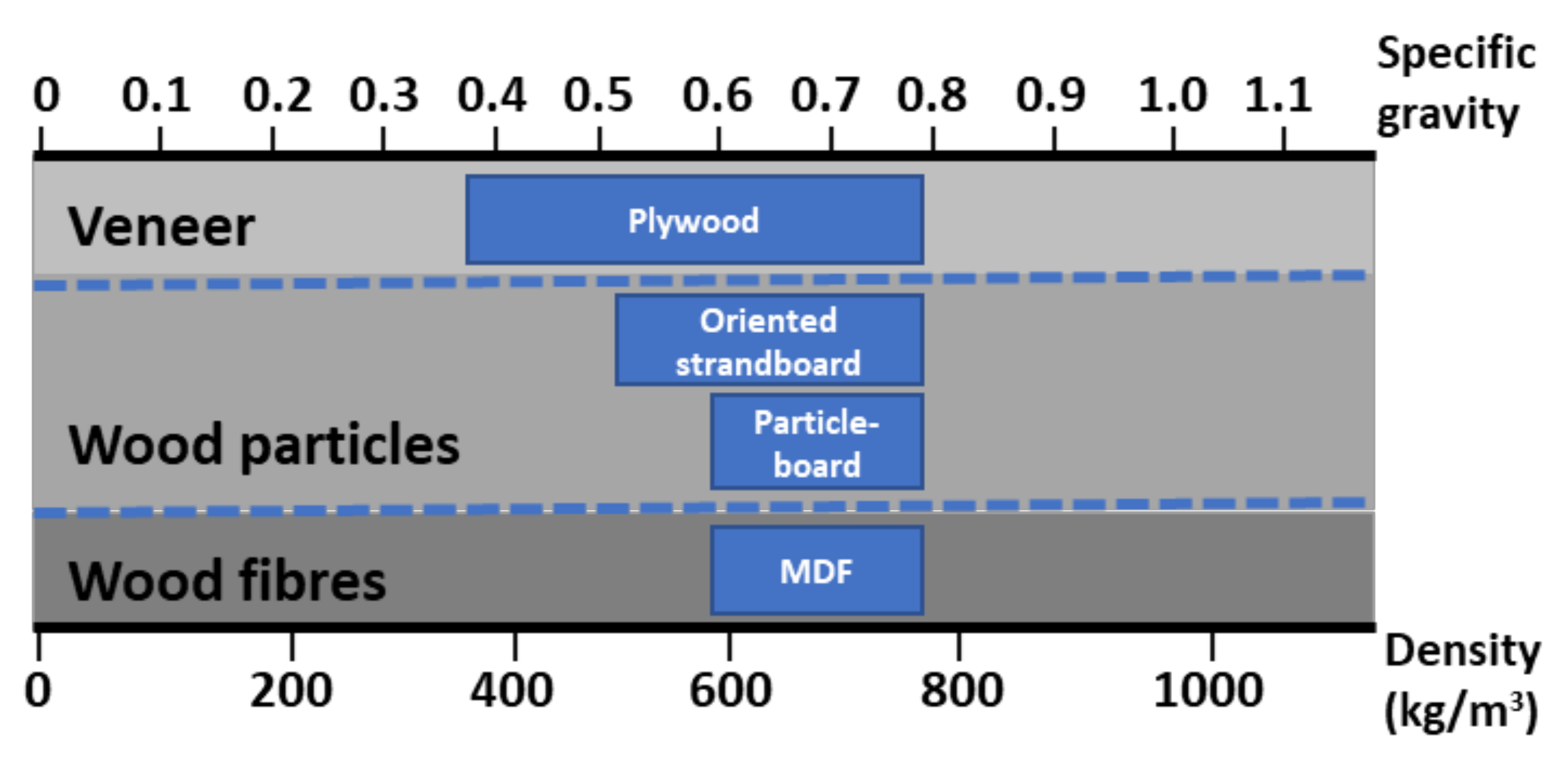

2. Wood-Based Panels (WBPs)

2.1. Particleboard (PB)

2.2. Oriented Strand Board (OSB)

2.3. Medium-Density Fibreboard (MDF)

2.4. Plywood (PLW)

3. Conventional Adhesive Systems for WBPs

3.1. Formaldehyde

3.2. Phenol–Formaldehyde (PF)

3.3. Urea–Formaldehyde (UF)

3.4. Melamine–Formaldehyde (MF)

Melamine–Urea–Formaldehyde (MUF)

3.5. Methylene Diphenyl Diisocyanate (MDI)

4. Testing the Adhesives

- Cohesive failure of the adhesive;

- Adhesive failure at the interface;

- Mixed failure—a combination of 1 and 2;

- Wood cohesive failure or wood failure.

5. Bio-Based Wood Adhesives

5.1. Tannin

5.2. Lignin

5.2.1. Kraft Lignin

5.2.2. Sulphite Lignin

5.2.3. Organosolv Lignin

5.3. Proteins

5.3.1. Soy

5.3.2. Cottonseed

6. Life Cycle Assessment of Bio-Based Adhesives

7. Conclusions and Future Trends

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Centre for European Policy Studies. The EU Furniture Market Situation and a Possible Furniture Products Initiative; Centre for European Policy Studies: Brussels, Belgium, 2015. [Google Scholar]

- Castaño, J. The booming furniture industry in China. Bois For. Trop. 2002, 277, 85–87. [Google Scholar]

- Federation, E.P. Oriented Strand Board. Available online: https://europanels.org/the-wood-based-panel-industry/types-of-wood-based-panels-economic-impact/oriented-strand-board/ (accessed on 28 October 2020).

- Ceresana Adhesives Market Report—Europe. Available online: https://www.ceresana.com/en/market-studies/industry/adhesives-world/ (accessed on 9 October 2020).

- Society, A.C. Formaldehyde. Am. Cancer Soc. Available online: https://www.cancer.org/cancer/cancer-causes/formaldehyde.html (accessed on 28 October 2021).

- ECHA. SUBSTANCE EVALUATION CONCLUSION as Required by REACH Article 48 and EVALUATION REPORT for Formaldehyde EC No 200-001-8 CAS No 50-00-0. 2019. Available online: https://echa.europa.eu/documents/10162/cc0acabf-6e82-f2ed-5dbe-8058f48ce6c4 (accessed on 11 November 2021).

- Antov, P.; Savov, V.; Neykov, N. Reduction of formaldehyde emission from engineered wood panels by formaldehyde scavengers—A review. In Proceedings of the Sustainability of Forest-Based Industries in the Global Economy—Proceedings of Scientific Papers, Vinkovci, Croatia, 28–30 September 2020; pp. 289–294. [Google Scholar]

- Keimel, F. Historical Development of Adhesives and Adhesive Bonding. In Handbook of Adhesive Technology, Revised and Expanded; Marcel Dekker, Inc.: New York, NY, USA, 2003. [Google Scholar]

- Dunky, M. Wood adhesives based on natural resources: A critical review. Rev. Adhes. Adhes. 2021, 9, 189–268. [Google Scholar] [CrossRef]

- Suchsland, O.; Woodson, G.E. Fiberboard Manufacturing Practices in the United States; Forest Products Research Society: Madison, WI, USA, 1986. [Google Scholar]

- Mantanis, G.I.; Athanassiadou, E.T.; Barbu, M.C.; Wijnendaele, K. Adhesive systems used in the European particleboard, MDF and OSB industries*. Wood Mater. Sci. Eng. 2018, 13, 104–116. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations Forest Products Annual Market Review 2018–2019. Int. Organ. 2019. [CrossRef] [Green Version]

- Youngquist, J.A. Wood-based composites and panel products. In Wood Handbook: Wood as an Engineering Material; Forest Products Laboratory, United States Department of Agriculture Forest Service: Madison, WI, USA, 1999; pp. 10.1–10.31. [Google Scholar]

- Carvalho, L.H.; Magalhães, F.D.; Ferra, J.M. Formaldehyde emissions from wood-based panels: Testing methods and industrial perspectives. In Formaldehyde: Chemistry, Applications and Role In Polymerization; Nova Publishers: New York, NY, USA, 2012; pp. 73–108. ISBN 9781622572144. [Google Scholar]

- Federation, E.P. Particleboard. Available online: https://europanels.org/the-wood-based-panel-industry/types-of-wood-based-panels-economic-impact/particleboard/ (accessed on 26 October 2020).

- EN 312: Particleboards—Specifications. 2010, 12. Available online: https://standards.iteh.ai/catalog/standards/cen/310c1aaa-c5c9-4e5d-ad3d-a255c265da52/en-312-2010 (accessed on 27 September 2020).

- European Panel Federation Medium Density Fibreboard. Available online: https://europanels.org/the-wood-based-panel-industry/types-of-wood-based-panels-economic-impact/medium-density-fibreboard/ (accessed on 24 October 2020).

- Federation, E.P. Plywood. Available online: https://europanels.org/the-wood-based-panel-industry/types-of-wood-based-panels-economic-impact/plywood/ (accessed on 27 September 2020).

- EN 314-2: 1993. APA. 2013, Volume 12. Available online: https://apawood-europe.org/official-guidelines/european-standards/individual-standards/en-314-2/ (accessed on 28 October 2020).

- Arias, A.; González-García, S.; González-Rodríguez, S.; Feijoo, G.; Moreira, M.T. Cradle-to-gate Life Cycle Assessment of bio-adhesives for the wood panel industry. A comparison with petrochemical alternatives. Sci. Total Environ. 2020, 738. [Google Scholar] [CrossRef]

- Petrie, E.M. Handbook Adhesive and Sealants; McGraw-Hill: New York, NY, USA; ISBN 9780071479165.

- Hemmilä, V.; Adamopoulos, S.; Karlsson, O.; Kumar, A. Development of sustainable bio-adhesives for engineered wood panels—A Review. RSC Adv. 2017, 7, 38604–38630. [Google Scholar] [CrossRef]

- Research, P.M. Phenolic Resin Market. Polaris Mark. Res. Available online: https://www.polarismarketresearch.com/industry-analysis/phenolic-resin-market (accessed on 28 October 2020).

- MarketsandMarkets. Phenolic Resin Market by Type (Resol Resin, Novolac Resin), Application (Wood Adhesives, Molding, Insulation), End-use Industry (Automotive, building & construction, Furniture)—Global Forecasts to 2021. Available online: https://www.marketsandmarkets.com/Market-Reports/phenolic-resin-market-177821389.html (accessed on 25 October 2020).

- Prescient & Strategic Intelligence Phenolic Resins Market. Available online: https://www.psmarketresearch.com/market-analysis/phenolic-resins-market. (accessed on 25 October 2020).

- Fior Markets Global Urea Formaldehyde Market Is Expected to Reach USD 12.51 Billion by 2025: Fior Markets. Available online: https://www.globenewswire.com/news-release/2020/03/05/1995541/0/en/Global-Urea-Formaldehyde-Market-Is-Expected-to-Reach-USD-12-51-Billion-by-2025-Fior-Markets.html (accessed on 26 October 2020).

- Research, A.M. Melamine Formaldehyde Market, by Application (Laminates, Wood Adhesives, Molding Compounds, Surface Coatings, and Others)—Global Opportunity Analysis and Industry Forecast, 2014–2022. Allied Mark. Res. Available online: https://www.alliedmarketresearch.com/melamine-formaldehyde-market (accessed on 25 October 2020).

- Nuryawan, A.; Alamsyah, E.M. A Review of Isocyanate Wood Adhesive: A Case Study in Indonesia. In Applied Adhesive Bonding in Science and Technology; IntechOpen: Rijeka, Croatia, 2018. [Google Scholar]

- Ebnesajjad, S. Adhesives Technology Handbook, 2nd ed.; William Andrew: Norwich, NY, USA, 2009; ISBN 9780815515333. [Google Scholar]

- Covestro BIO-BASED ANILINE: A Scientific Breakthrough for Greater Sustainability. Available online: https://www.covestro.com/en/sustainability/flagship-solutions/bio-based-aniline (accessed on 30 August 2021).

- ASTM D897-01 Standard Test Method for Tensile Properties of Adhesive Bonds; ASTM lnternational: West Conshehoken, PA, USA, 2001. [CrossRef]

- ASTM D1183-01 Standard Test Method for Tensile Properties of Adhesive Bonds; ASTM lnternational: West Conshehoken, PA, USA, 2019; Volume D1183-03, pp. 11–13. [CrossRef]

- ASTM D1875-03 Standard Test Method for Density of Adhesives in Fluid Form; ASTM lnternational: West Conshehoken, PA, USA, 2018. [CrossRef]

- ASTM D1151-00 Standard Practice for Effect of Moisture and Temperature on Adhesive Bonds; ASTM lnternational: West Conshehoken, PA, USA, 2013. [CrossRef]

- ASTM D1876-08 Standard Practice for Atmospheric Exposure of Adhesive-Bonded Joints and Structures; ASTM lnternational: West Conshehoken, PA, USA, 2013. [CrossRef]

- ASTM D903-98 Standard Test Method for Peel or Stripping Strength of Adhesive Bonds; ASTM lnternational: West Conshehoken, PA, USA, 2017. [CrossRef]

- ASTM D1876-08 Standard Test Method for Peel Resistance of Adhesives (T-Peel Test); ASTM lnternational: West Conshehoken, PA, USA, 2015. [CrossRef]

- ASTM D905-08 Standard Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading; ASTM lnternational: West Conshehoken, PA, USA, 2013. [CrossRef]

- ASTM D1337-10 Standard Practice for Storage Life of Adhesives by Viscosity and Bond Strength; ASTM lnternational: West Conshehoken, PA, USA, 2016. [CrossRef]

- ASTM D1084-16 Standard Test Methods for Viscosity of Adhesives; ASTM lnternational: West Conshehoken, PA, USA, 2021. [CrossRef]

- ASTM D2559-12a Standard Specification for Adhesives for Bonded Structural Wood Products for Use under Exterior Exposure Conditions; ASTM lnternational: West Conshehoken, PA, USA, 2018. [CrossRef]

- Ferdosian, F.; Pan, Z.; Gao, G.; Zhao, B. Bio-based adhesives and evaluation for wood composites application. Polymers 2017, 9, 70. [Google Scholar] [CrossRef] [Green Version]

- Faris, A.H.; Rahim, A.A.; Ibrahim, M.N.M.; Alkurdi, A.M.; Shah, I. Combination of lignin polyol-tannin adhesives and polyethylenimine for the preparation of green water-resistant adhesives. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Tahir, P.M.; Halip, J.A.; Lee, S.H. Tannin-based bioresin as adhesives. In Lignocellulose for Future Bioeconomy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 109–133. ISBN 9780128163542. [Google Scholar]

- Jahanshaei, S.; Tabarsa, T.; Asghari, J. Eco-friendly tannin-phenol formaldehyde resin for producing wood composites. Pigment Resin Technol. 2012, 41, 296–301. [Google Scholar] [CrossRef]

- Sepahvand, S.; Doosthosseini, K.; Pirayesh, H.; Maryan, B.K. Supplementation of natural tannins as an alternative to formaldehyde in urea and melamine formaldehyde resins used in mdf production. Drv. Ind. 2018, 69, 215–221. [Google Scholar] [CrossRef]

- Li, J.; Zhang, A.; Zhang, S.; Gao, Q.; Zhang, W.; Li, J. Larch tannin-based rigid phenolic foam with high compressive strength, low friability, and low thermal conductivity reinforced by cork powder. Compos. Part B Eng. 2019, 156, 368–377. [Google Scholar] [CrossRef]

- Van Langenberg, K.; Grigsby, W.; Ryan, G. Green Adhesives: Options for the Australian Industry—Summary of Recent Research into Green Adhesives from Renewable Materials and Identification of Those That Are Closest to Commercial Uptake; Forest & Wood Products Australia Limited: Melbourne, Australia, 2010; Volume 61, ISBN 9781921763045. [Google Scholar]

- Zhang, J.; Xi, X.; Liang, J.; Pizzi, A.; Du, G.; Deng, S. Tannin-based adhesive cross-linked by furfuryl alcohol-glyoxal and epoxy resins. Int. J. Adhes. Adhes. 2019, 94, 47–52. [Google Scholar] [CrossRef]

- Li, J.; Zhu, W.; Zhang, S.; Gao, Q.; Xia, C.; Zhang, W.; Li, J. Depolymerization and characterization of Acacia mangium tannin for the preparation of mussel-inspired fast-curing tannin-based phenolic resins. Chem. Eng. J. 2019, 370, 420–431. [Google Scholar] [CrossRef]

- Chinese Standard GB/T 14732-2017 (GB/T14732-2017). Available online: https://www.chinesestandard.net/PDF.aspx/GBT14732-2017 (accessed on 30 August 2021).

- Liu, J.; Wang, L.; Li, J.; Li, C.; Zhang, S.; Gao, Q.; Zhang, W.; Li, J. Degradation mechanism of Acacia mangium tannin in NaOH/urea aqueous solution and application of degradation products in phenolic adhesives. Int. J. Adhes. Adhes. 2020, 98. [Google Scholar] [CrossRef]

- Tribot, A.; Amer, G.; Alio, M.A.; Baynast, H.; Delattre, C.; Pons, A.; Mathias, J.-D.; Callois, J.-M.; Vial, C.; Michaud, P.; et al. Wood-lignin: Supply, extraction processes and use as bio-based material. Eur. Polym. J. 2019, 112, 228–240. [Google Scholar] [CrossRef]

- Ahuja, K.M.K. GMI181. Glob. Mark. Insights. Available online: https://www.gminsights.com/industry-analysis/lignin-market (accessed on 9 October 2020).

- Market Research Store Global Lignin Market is Expected to Reach US$900 Million by 2020, Growing at 2.5% CAGR. Available online: https://www.globenewswire.com/en/news-release/2015/11/20/789059/0/en/Global-Lignin-Market-is-Expected-to-Reach-US-900-Million-by-2020-Growing-at-2-5-CAGR.html (accessed on 20 October 2021).

- José Borges Gomes, F.; de Souza, R.E.; Brito, E.O.; Costa Lelis, R.C. A review on lignin sources and uses. J. Appl. Biotechnol. Bioeng. 2020, 7, 100–105. [Google Scholar] [CrossRef]

- Dessbesell, L.; Paleologou, M.; Leitch, M.; Pulkki, R.; Xu, C. Global lignin supply overview and kraft lignin potential as an alternative for petroleum-based polymers. Renew. Sustain. Energy Rev. 2020, 123. [Google Scholar] [CrossRef]

- Bertaud, F.; Tapin-Lingua, S.; Pizzi, A.; Navarrete, P.; Petit-Conil, M. Development of green adhesives for fibreboard manufacturing, using tannins and lignin from pulp mill residues. Cellul. Chem. Technol. 2012, 46, 449–455. [Google Scholar]

- Zhang, W.; Ma, Y.; Wang, C.; Li, S.; Zhang, M.; Chu, F. Preparation and properties of lignin–phenol–formaldehyde resins based on different biorefinery residues of agricultural biomass. Ind. Crops Prod. 2013, 43, 326–333. [Google Scholar] [CrossRef]

- Danielson, B.; Simonson, R. Kraft lignin in phenol formaldehyde resin. Part 1. Partial replacement of phenol by kraft lignin in phenol formaldehyde adhesives for plywood. J. Adhes. Sci. Technol. 1998, 12, 923–939. [Google Scholar] [CrossRef]

- Cavdar, A.D.; Kalaycioglu, H.; Hiziroglu, S. Some of the properties of oriented strandboard manufactured using kraft lignin phenolic resin. J. Mater. Process. Technol. 2008, 202, 559–563. [Google Scholar] [CrossRef]

- Ang, A.F.; Ashaari, Z.; Lee, S.H.; Md Tahir, P.; Halis, R. Lignin-based copolymer adhesives for composite wood panels—A review. Int. J. Adhes. Adhes. 2019, 95, 102408. [Google Scholar] [CrossRef]

- El Mansouri, N.E.; Pizzi, A.; Salvado, J. Lignin-based polycondensation resins for wood adhesives. J. Appl. Polym. Sci. 2007, 103, 1690–1699. [Google Scholar] [CrossRef]

- Mansouri, H.R.; Navarrete, P.; Pizzi, A.; Tapin-Lingua, S.; Benjelloun-Mlayah, B.; Pasch, H.; Rigolet, S. Synthetic-resin-free wood panel adhesives from mixed low molecular mass lignin and tannin. Eur. J. Wood Wood Prod. 2011, 69, 221–229. [Google Scholar] [CrossRef] [Green Version]

- El Mansouri, N.E.; Yuan, Q.; Huang, F. Study of chemical modification of alkaline lignin by the glyoxalation reaction. BioResources 2011, 6, 4523–4536. [Google Scholar] [CrossRef]

- Lei, H.; Pizzi, A.; Du, G. Environmentally friendly mixed tannin/lignin wood resins. J. Appl. Polym. Sci. 2008, 107, 203–209. [Google Scholar] [CrossRef]

- Faris, A.H.; Ibrahim, M.N.M.; Rahim, A.A. Preparation and characterization of green adhesives using modified tannin and hyperbranched poly (amine-ester). Int. J. Adhes. Adhes. 2016, 71, 39–47. [Google Scholar] [CrossRef]

- Norström, E.; Demircan, D.; Fogelström, L.; Khabbaz, F.; Malmström, E. Green Binders for Wood Adhesives. In Applied Adhesive Bonding in Science and Technology; InTech: Rijeka, Croatia, 2018; pp. 49–71. [Google Scholar]

- Ophardt, C.E. Denaturation of Proteins. Elmhurst Coll. Available online: https://scholar.google.com/scholar_lookup?title=Denaturation&author=C.+E.+Ophardt&publication_year=2003 (accessed on 30 August 2021).

- Zeng, Y.; Xu, P.; Yang, W.; Chu, H.; Wang, W.; Dong, W.; Chen, M.; Bai, H.; Ma, P. Soy protein-based adhesive with superior bonding strength and water resistance by designing densely crosslinking networks. Eur. Polym. J. 2021, 142. [Google Scholar] [CrossRef]

- Li, J.; Pradyawong, S.; He, Z.; Sun, X.S.; Wang, D.; Cheng, H.N.; Zhong, J. Assessment and application of phosphorus/calcium-cottonseed protein adhesive for plywood production. J. Clean. Prod. 2019, 229, 454–462. [Google Scholar] [CrossRef]

- Larsen, S.U.; Ambye-Jensen, M.; Jørgensen, H.; Jørgensen, U. Ensiling of the pulp fraction after biorefining of grass into pulp and protein juice. Ind. Crops Prod. 2019, 139. [Google Scholar] [CrossRef]

- Samarakoon, K.; Jeon, Y.J. Bio-functionalities of proteins derived from marine algae—A review. Food Res. Int. 2012, 48, 948–960. [Google Scholar] [CrossRef]

- Bin Azmi, A.A.; Chew, K.W.; Chia, W.Y.; Mubashir, M.; Sankaran, R.; Lam, M.K.; Lim, J.W.; Ho, Y.C.; Show, P.L. Green bioprocessing of protein from Chlorella vulgaris microalgae towards circular bioeconomy. Bioresour. Technol. 2021, 333, 297–302. [Google Scholar] [CrossRef]

- Cheng, E.; Sun, X.; Karr, G.S. Adhesive properties of modified soybean flour in wheat straw particleboard. Compos. Part A Appl. Sci. Manuf. 2004, 35, 297–302. [Google Scholar] [CrossRef]

- Vnucec, D.; Kutnar, A.; Goresek, A. Soy-based adhesives for wood-bonding—A review. J. Adhes. Sci. Technol. 2017, 31, 910–931. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, D.; Sun, X.S. Thermal properties and adhesiveness of soy protein modified with cationic detergent. JAOCS J. Am. Oil Chem. Soc. 2005, 82, 357–363. [Google Scholar] [CrossRef]

- Huang, W.; Sun, X. Adhesive properties of soy proteins modified by sodium dodecyl sulfate and sodium dodecylbenzene sulfonate. J. Am. Oil Chem. Soc. 2000, 77, 705–708. [Google Scholar] [CrossRef]

- Pang, H.; Zhao, S.; Wang, Z.; Zhang, W.; Zhang, S.; Li, J. Development of soy protein-based adhesive with high water resistance and bonding strength by waterborne epoxy crosslinking strategy. Int. J. Adhes. Adhes. 2020, 100, 705–708. [Google Scholar] [CrossRef]

- Salmoral, E.M.; Gonzalez, M.E.; Mariscal, M.P.; Medina, L.F. Comparison of chickpea and soy protein isolate and whole flour as biodegradable plastics. Ind. Crops Prod. 2000, 11, 227–236. [Google Scholar] [CrossRef]

- Cheng, H.N.; Ford, C.; Dowd, M.K.; He, Z. Use of additives to enhance the properties of cottonseed protein as wood adhesives. Int. J. Adhes. Adhes. 2016, 68, 156–160. [Google Scholar] [CrossRef] [Green Version]

- Chinese Standards GB/T 17657-2013 (GBT 17657-2013). Available online: https://www.chinesestandard.net/PDF.aspx/GBT17657-2013 (accessed on 26 March 2021).

- Xu, Y.; Han, Y.; Shi, S.Q.; Gao, Q.; Li, J. Preparation of a moderate viscosity, high performance and adequately-stabilized soy protein-based adhesive via recombination of protein molecules. J. Clean. Prod. 2020, 255. [Google Scholar] [CrossRef]

- Wang, F.; Wang, J.; Chu, F.; Wang, C.; Jin, C.; Wang, S.; Pang, J. Combinations of soy protein and polyacrylate emulsions as wood adhesives. Int. J. Adhes. Adhes. 2018, 82, 160–165. [Google Scholar] [CrossRef]

- Mousavi, S.Y.; Huang, J.; Li, K. A cold-set wood adhesive based on soy protein. Int. J. Adhes. Adhes. 2021, 106, 102801. [Google Scholar] [CrossRef]

- American National Standard for Hardwood and Decorative Plywood (ANSI/HPVA HP-1-2020). Available online: https://www.decorativehardwoods.org/product/ansi-hpva-hp-1-2020 (accessed on 26 March 2021).

- Cheng, H.N.; Dowd, M.K.; He, Z. Investigation of modified cottonseed protein adhesives for wood composites. Ind. Crops Prod. 2013, 46, 399–403. [Google Scholar] [CrossRef]

- Pradyawong, S.; Li, J.; He, Z.; Sun, X.S.; Wang, D.; Cheng, H.N.; Klasson, K.T. Blending cottonseed meal products with different protein contents for cost-effective wood adhesive performances. Ind. Crops Prod. 2018, 126, 31–37. [Google Scholar] [CrossRef]

- Li, J.; Pradyawong, S.; Sun, X.S.; Wang, D.; He, Z.; Zhong, J.; Cheng, H.N. Improving adhesion performance of cottonseed protein by the synergy of phosphoric acid and water soluble calcium salts. Int. J. Adhes. Adhes. 2021, 108. [Google Scholar] [CrossRef]

- He, Z.; Cheng, H.N.; Klasson, K.T.; Ford, C.; Barroso, V.A.B. Optimization and practical application of cottonseed meal-based wood adhesive formulations for small wood item bonding. Int. J. Adhes. Adhes. 2019, 95. [Google Scholar] [CrossRef]

- He, Z.; Chapital, D.C.; Cheng, H.N.; Thomas Klasson, K.; Olanya, O.M.; Uknalis, J. Application of tung oil to improve adhesion strength and water resistance of cottonseed meal and protein adhesives on maple veneer. Ind. Crops Prod. 2014, 61, 398–402. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W. Comparative sustainability evaluation of two engineered wood-based construction materials: Life cycle analysis of CLT versus GLT. Build. Environ. 2021, 204. [Google Scholar] [CrossRef]

- Murphy, F.; Devlin, G.; McDonnell, K. Greenhouse gas and energy based life cycle analysis of products from the Irish wood processing industry. J. Clean. Prod. 2015, 92, 134–141. [Google Scholar] [CrossRef] [Green Version]

- González-García, S.; Feijoo, G.; Widsten, P.; Kandelbauer, A.; Zikulnig-Rusch, E.; Moreira, M.T. Environmental performance assessment of hardboard manufacture. Int. J. Life Cycle Assess. 2009, 14, 456–466. [Google Scholar] [CrossRef]

- Santos, A.; Carvalho, A.; Barbosa-Póvoa, A. An economic and environmental comparison between forest wood products—Uncoated woodfree paper, natural cork stoppers and particle boards. J. Clean. Prod. 2021, 296. [Google Scholar] [CrossRef]

- González-García, S.; Ferro, F.S.; Lopes Silva, D.A.; Feijoo, G.; Lahr, F.A.R.; Moreira, M.T. Cross-country comparison on environmental impacts of particleboard production in Brazil and Spain. Resour. Conserv. Recycl. 2019, 150, 104434. [Google Scholar] [CrossRef]

- Hussain, M.; Naseem Malik, R.; Taylor, A. Carbon footprint as an environmental sustainability indicator for the particleboard produced in Pakistan. Environ. Res. 2017, 155, 385–393. [Google Scholar] [CrossRef]

- Garcia, R.; Freire, F. Carbon footprint of particleboard: A comparison between ISO/TS 14067, GHG Protocol, PAS 2050 and Climate Declaration. J. Clean. Prod. 2014, 66, 199–209. [Google Scholar] [CrossRef]

| Type | PB Application | Standard |

|---|---|---|

| P1 | General-purpose boards for use in dry conditions | EN 312:2010 |

| P2 | Boards for interior fitments (including furniture) for use in dry conditions | EN 312:2010 |

| P3 | Non-load-bearing boards for use in humid conditions | EN 312:2010 |

| P4 | Load-bearing boards for use in dry conditions | EN 312:2010 |

| P5 | Load-bearing boards for use in dry conditions | EN 312:2010 |

| P6 | Heavy-duty load-bearing boards for use in dry conditions | EN 312:2010 |

| P7 | Heavy-duty load-bearing boards for use in humid conditions | EN 312:2010 |

| Grade | Use |

|---|---|

| OSB/1 | General-purpose boards and boards for interior fitments (including furniture) for use in dry conditions |

| OSB/2 | Load-bearing boards for use in dry conditions |

| OSB/3 | Load-bearing boards for use in humid conditions |

| OSB/4 | Heavy-duty load-bearing boards for use in humid conditions |

| Type | Board Application | Standard |

|---|---|---|

| MDF | General-purpose boards for use in dry conditions | EN 622-5 |

| MDF.H | General-purpose boards for use in humid conditions | EN 622-5 |

| MDF.LA | Load-bearing boards for use in dry conditions | EN 622-5 |

| MDF.HLS | Load-bearing boards for use in humid conditions | EN 622-5 |

| L-MDF | Light-MDF boards for use in dry conditions | EN 622-5 |

| L-MDF.H | Light-MDF boards for use in humid conditions | EN 622-5 |

| UL1-MDF | Ultra-light-MDF boards for use in dry conditions | EN 622-5 |

| UL2-MDF | Ultra-light-MDF boards for use in dry conditions | EN 622-5 |

| MDF-RWH | Boards for use in rigid underlays in roofs and walls | EN 622-5 |

| ASTM D1183-03 | Standard Practices for Resistance of Adhesives to Cyclic Laboratory Aging Conditions [32] |

| ASTM D1875-03 | Standard Test Method for Density of Adhesives in Fluid Form [33] |

| ASTM D1151-00 | Standard Practice for Effect of Moisture and Temperature on Adhesive Bonds [34] |

| ASTM D1828-01 | Standard Practice for Atmospheric Exposure of Adhesive-Bonded Joints and Structures [35] |

| ASTM D903-98 | Standard Test Method for Peel or Stripping Strength of Adhesive Bonds [36] |

| ASTM D1876-08 | Standard Test Method for Peel Resistance of Adhesives (T-Peel Test) [37] |

| ASTM D905-08 | Standard Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading [38] |

| ASTM D1337-10 | Standard Practice for Storage Life of Adhesives by Viscosity and Bond Strength [39] |

| ASTM D1084-16 | Standard Test Methods for Viscosity of Adhesives [40] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonçalves, D.; Bordado, J.M.; Marques, A.C.; Galhano dos Santos, R. Non-Formaldehyde, Bio-Based Adhesives for Use in Wood-Based Panel Manufacturing Industry—A Review. Polymers 2021, 13, 4086. https://doi.org/10.3390/polym13234086

Gonçalves D, Bordado JM, Marques AC, Galhano dos Santos R. Non-Formaldehyde, Bio-Based Adhesives for Use in Wood-Based Panel Manufacturing Industry—A Review. Polymers. 2021; 13(23):4086. https://doi.org/10.3390/polym13234086

Chicago/Turabian StyleGonçalves, Diogo, João Moura Bordado, Ana C. Marques, and Rui Galhano dos Santos. 2021. "Non-Formaldehyde, Bio-Based Adhesives for Use in Wood-Based Panel Manufacturing Industry—A Review" Polymers 13, no. 23: 4086. https://doi.org/10.3390/polym13234086

APA StyleGonçalves, D., Bordado, J. M., Marques, A. C., & Galhano dos Santos, R. (2021). Non-Formaldehyde, Bio-Based Adhesives for Use in Wood-Based Panel Manufacturing Industry—A Review. Polymers, 13(23), 4086. https://doi.org/10.3390/polym13234086