Microplastic Contamination in Soils: A Review from Geotechnical Engineering View

Abstract

1. Introduction

2. Formation and Existence of Microplastics in Soils

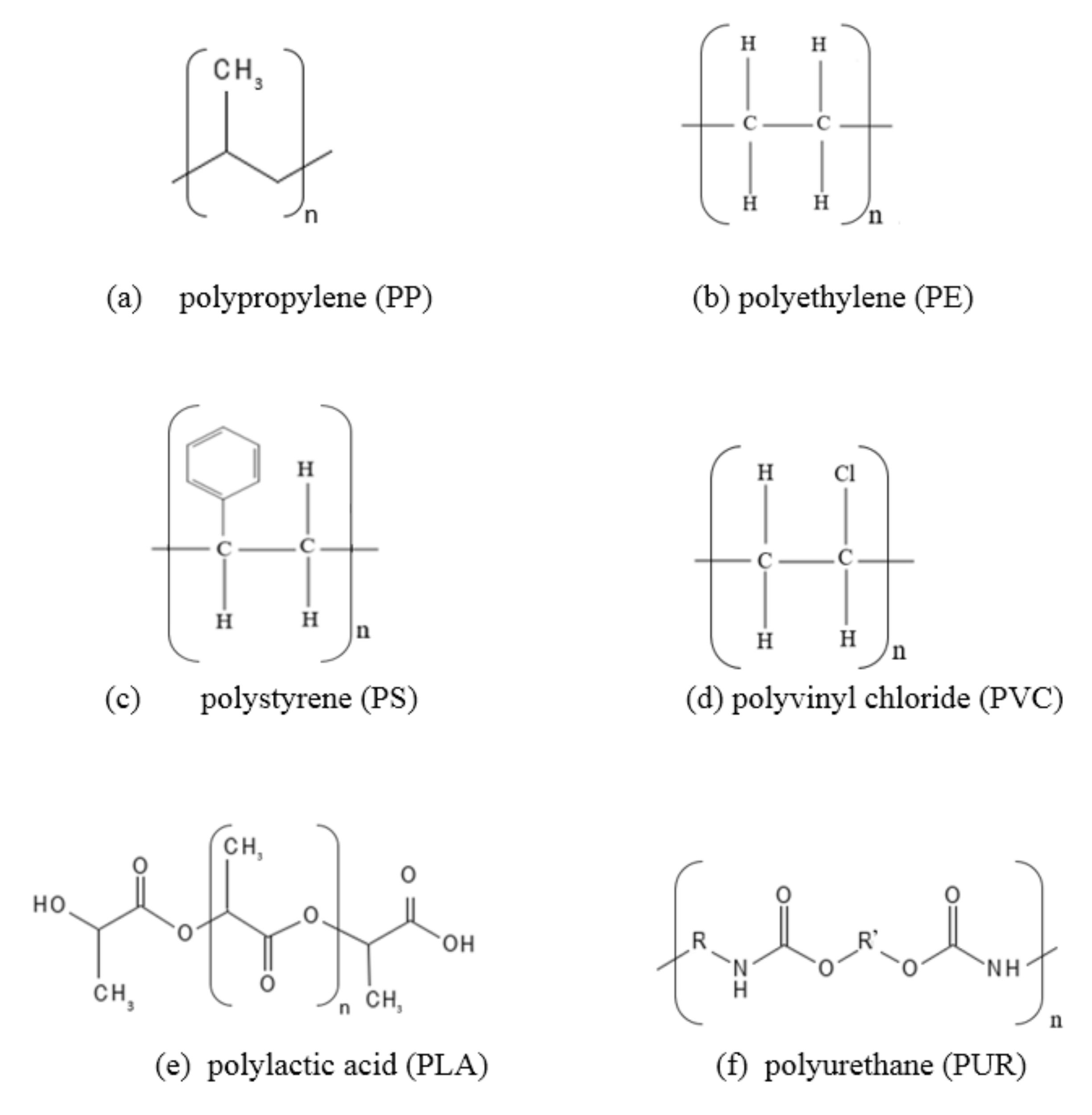

2.1. Degradation Processes

2.2. Existence of Microplastics in Soils

2.3. Persistence of Microplastics in Soils

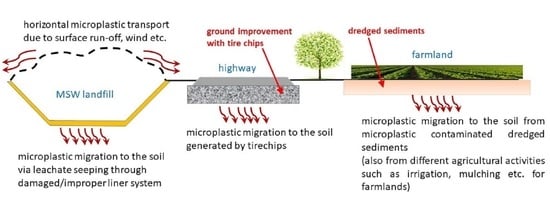

3. Solid Waste Disposal Facilities and Their Potential Role as a Source for Microplastics

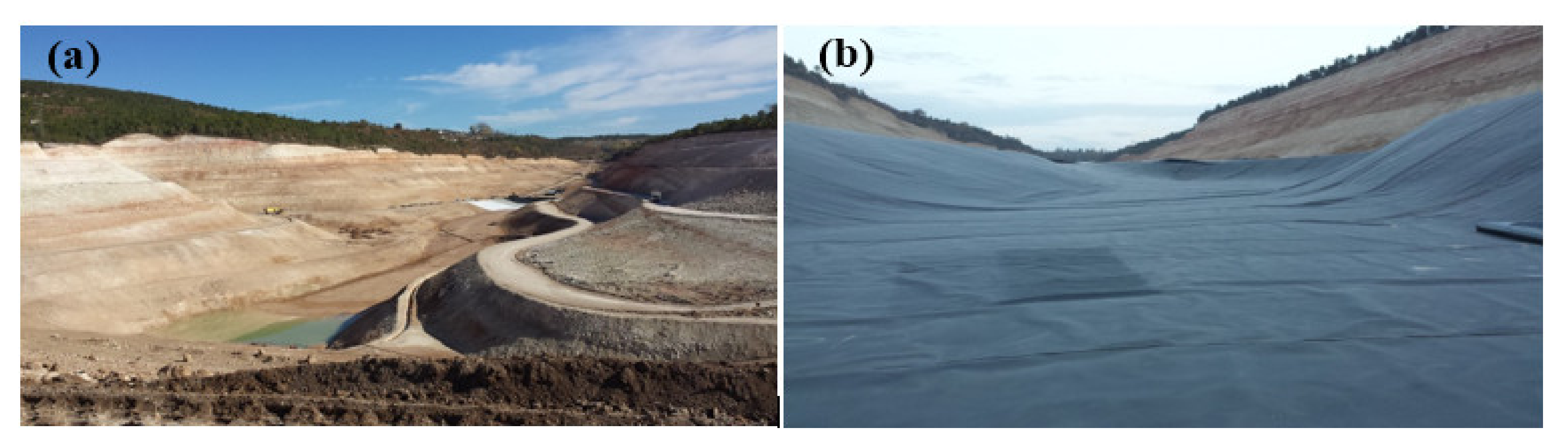

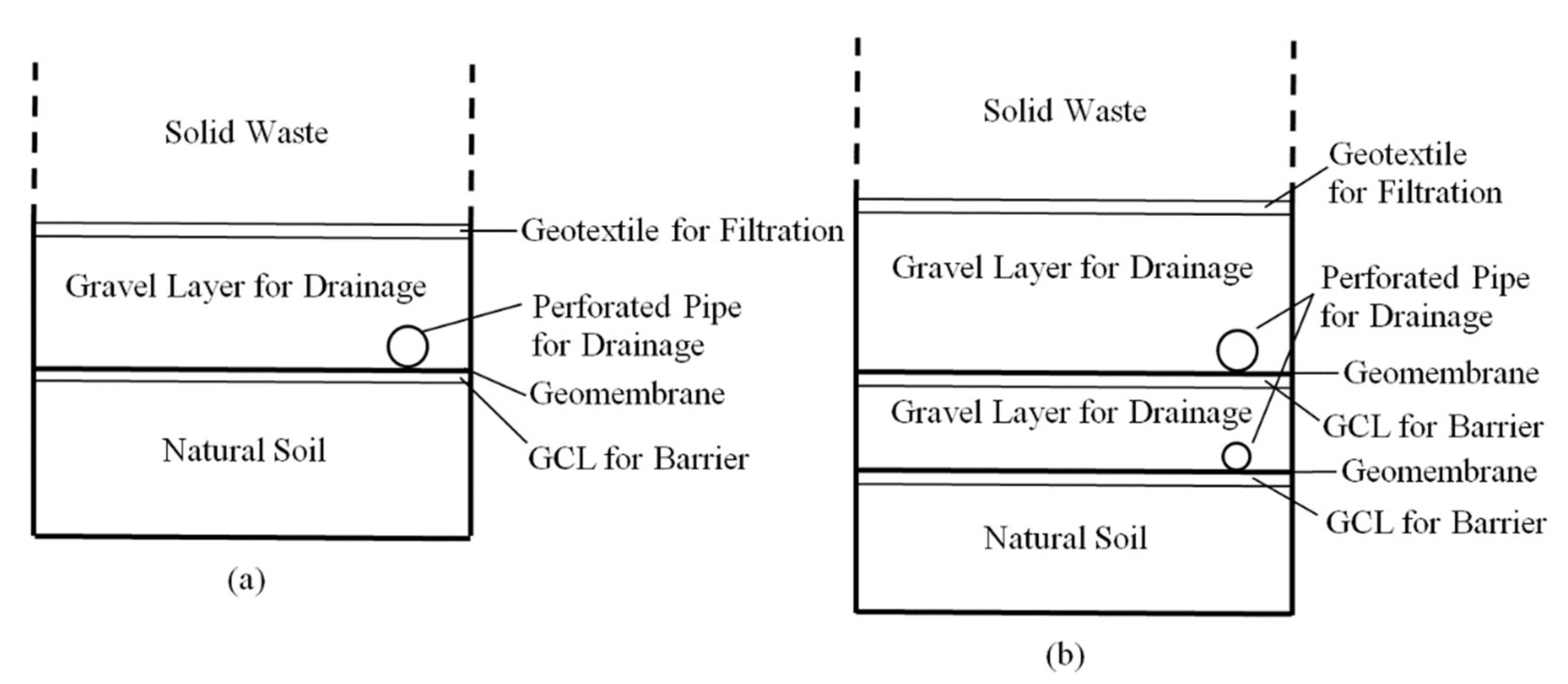

3.1. Solid Waste Disposal Facilities and Their Geotechnical Design

3.2. The Risk of Microplastic Migration from Landfills to Soil and Other Environments

4. Some Geotechnical Engineering Applications as Potential Source for Microplastics

4.1. Soil Improvement with Tire Chips

4.2. Dredge Sediments from Water Resources Used as Filling Materials

4.3. Soil Improvement with Synthetic Polymer-Based Fibers

4.4. Geotechnical Applications with Expanded Polystyrene as a Lightweight Fill Material

4.4.1. Polystyrene Based Microplastics in Soils

4.4.2. Geotechnical Applications with Polystyrene Based Lightweight Fills

5. Benefitting Geotechnical Engineering as a Mitigation Tool for Microplastics, Future Research and Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lim, X.Z. Microplastics Are Everywhere—But Are They Harmful? Nature 2021, 593, 22–25. [Google Scholar] [CrossRef] [PubMed]

- Da Costa, J.P.; Rocha Santos, T.; Duarte, A. The Environmental Impacts of Plastics and Micro-Plastics Use, Waste and Pollution: EU and National Measures. Eur. Union 2020, 76. [Google Scholar]

- PlasticsEurope—Association of Plastics Manufactures Plastics—The Facts 2020. PlasticsEurope 2020, 1–64. Available online: https://plasticseurope.org/wp-content/uploads/2021/09/Plastics_the_facts-WEB-2020_versionJun2021_final.pdf (accessed on 8 September 2021).

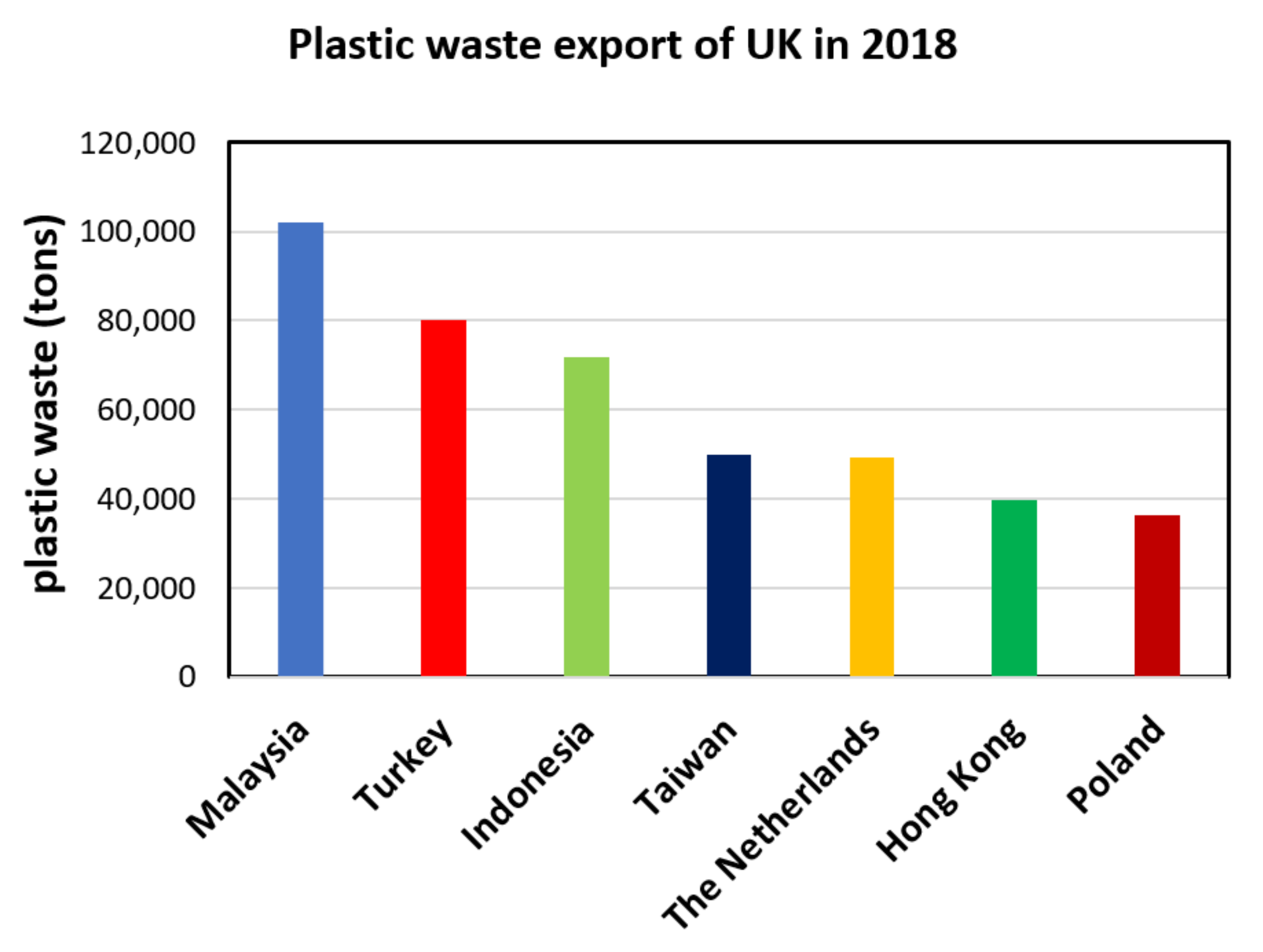

- Brooks, A.L.; Wang, S.; Jambeck, J.R. The Chinese Import Ban and Its Impact on Global Plastic Waste Trade. Sci. Adv. 2018, 4, 52. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Liu, M.; Du, H.; Gong, Y. The Evolutionary Trend and Impact of Global Plastic Waste Trade Network. Sustainability 2021, 13, 3662. [Google Scholar] [CrossRef]

- Fuhr, L.; Franklin, M. The PLASTIC ATLAS 2019; Heinrich Böll Foundation: Berlin, Germany, 2019; ISBN 9783869282114. [Google Scholar]

- Ataş, N.T. Plastik Atık İthalatına Karşı Zafere Giden Yolculuk. Available online: https://www.greenpeace.org/turkey/blog/plastik-atik-ithalatina-karsi-zafere-giden-yolculuk/ (accessed on 15 November 2021).

- Snowdon, K. UK Plastic Waste Being Dumped and Burned in Turkey, Says Greenpeace. Available online: https://www.bbc.com/news/uk-57139474 (accessed on 15 November 2021).

- EPA Advancing Sustainable Materials Management. United States Environmental Protection Agency; Office of Resource Conservation and Recovery: Washington, WA, USA, 2020; p. 184. [Google Scholar]

- Thompson, R.C.; Olsen, Y.; Mitchell, R.P.; Davis, A.; Rowland, S.J.; John, A.W.G.; Mcgonigle, D.; Russell, A.E. Lost at Sea: Where Is All the Plastic? Science 2004, 304, 838. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Shao, H.; Liu, J.; Cao, R.; Shang, E.; Liu, S.; Li, Y. Transport and Transformation of Microplastics and Nanoplastics in the Soil Environment: A Critical Review. Soil Use Manag. 2021, 37, 224–242. [Google Scholar] [CrossRef]

- Ng, E.L.; Huerta Lwanga, E.; Eldridge, S.M.; Johnston, P.; Hu, H.W.; Geissen, V.; Chen, D. An Overview of Microplastic and Nanoplastic Pollution in Agroecosystems. Sci. Total. Environ. 2018, 627, 1377–1388. [Google Scholar] [CrossRef]

- Gigault, J.; Ter Halle, A.; Baudrimont, M.; Pascal, P.Y.; Gauffre, F.; Phi, T.L.; el Hadri, H.; Grassl, B.; Reynaud, S. Current Opinion: What Is a Nanoplastic? Environ. Pollut. 2018, 235, 1030–1034. [Google Scholar] [CrossRef] [PubMed]

- UNEP (UN Environmental Programme). UNEP Year Book 2014: Emerging Issues in Our Global Environment; UNEP, Division of Early Warning and Assessment: Nairobi, Kenya, 2014; p. 71. [Google Scholar]

- O’Kelly, B.C.; El-Zein, A.; Liu, X.; Patel, A.; Fei, X.; Sharma, S.; Mohammad, A.; Goli, V.S.N.S.; Wang, J.J.; Li, D.; et al. Microplastics in Soils: An Environmental Geotechnics Perspective. Environ. Geotech. 2021, 2000179, 1–30. [Google Scholar] [CrossRef]

- Jahnke, A.; Arp, H.P.H.; Escher, B.I.; Gewert, B.; Gorokhova, E.; Kühnel, D.; Ogonowski, M.; Potthoff, A.; Rummel, C.; Schmitt-Jansen, M.; et al. Reducing Uncertainty and Confronting Ignorance about the Possible Impacts of Weathering Plastic in the Marine Environment. Environ. Sci. Technol. Lett. 2017, 4, 85–90. [Google Scholar] [CrossRef]

- Połeć, M.; Aleksander-Kwaterczak, U.; Wątor, K.; Kmiecik, E. The Occurrence of Microplastics in Freshwater Systems—Preliminary Results from Krakow (Poland). Geol. Geophys. Environ. 2018, 44, 391. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, J.; Zou, M.; Jia, Z.; Zhou, S.; Li, Y. Microplastics in Soils: A Review of Methods, Occurrence, Fate, Transport, Ecological and Environmental Risks. Sci. Total Environ. 2020, 748, 141368. [Google Scholar] [CrossRef]

- Nizzetto, L.; Bussi, G.; Futter, M.N.; Butterfield, D.; Whitehead, P.G. A Theoretical Assessment of Microplastic Transport in River Catchments and Their Retention by Soils and River Sediments. Environ. Sci. Process. Impacts 2016, 18, 1050–1059. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Yang, X.; Gertsen, H.; Peters, P.; Salánki, T.; Geissen, V. A Simple Method for the Extraction and Identification of Light Density Microplastics from Soil. Sci. Total Environ. 2018, 616–617, 1056–1065. [Google Scholar] [CrossRef]

- Zhu, F.; Zhu, C.; Wang, C.; Gu, C. Occurrence and Ecological Impacts of Microplastics in Soil Systems: A Review. Bull. Environ. Contam. Toxicol. 2019, 102, 741–749. [Google Scholar] [CrossRef] [PubMed]

- da Costa, J.P.; Paço, A.; Santos, P.S.M.; Duarte, A.C.; Rocha-Santos, T. Microplastics in Soils: Assessment, Analytics and Risks. Environ. Chem. 2019, 16, 18–30. [Google Scholar] [CrossRef]

- Möller, J.N.; Löder, M.G.J.; Laforsch, C. Finding Microplastics in Soils: A Review of Analytical Methods. Environ. Sci. Technol. 2020, 54, 2078–2090. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Ge, J.; Yu, X.; Li, H. Environmental Fate and Impacts of Microplastics in Soil Ecosystems: Progress and Perspective. Sci. Total Environ. 2020, 708, 134841. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Wufuer, R.; Duo, J.; Wang, S.; Luo, Y.; Zhang, D.; Pan, X. Microplastics in Agricultural Soils: Extraction and Characterization after Different Periods of Polythene Film Mulching in an Arid Region. Sci. Total Environ. 2020, 749, 141420. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.J.; Huang, X.P.; Xiang, L.; Wang, Y.Z.; Li, Y.W.; Li, H.; Cai, Q.Y.; Mo, C.H.; Wong, M.H. Source, Migration and Toxicology of Microplastics in Soil. Environ. Int. 2020, 137, 105263. [Google Scholar] [CrossRef] [PubMed]

- Corradini, F.; Meza, P.; Eguiluz, R.; Casado, F.; Huerta-Lwanga, E.; Geissen, V. Evidence of Microplastic Accumulation in Agricultural Soils from Sewage Sludge Disposal. Sci. Total Environ. 2019, 671, 411–420. [Google Scholar] [CrossRef] [PubMed]

- Crossman, J.; Hurley, R.R.; Futter, M.; Nizzetto, L. Transfer and Transport of Microplastics from Biosolids to Agricultural Soils and the Wider Environment. Sci. Total Environ. 2020, 724, 138334. [Google Scholar] [CrossRef]

- Zhang, G.S.; Liu, Y.F. The Distribution of Microplastics in Soil Aggregate Fractions in Southwestern China. Sci. Total Environ. 2018, 642, 12–20. [Google Scholar] [CrossRef]

- de Souza MacHado, A.A.; Lau, C.W.; Till, J.; Kloas, W.; Lehmann, A.; Becker, R.; Rillig, M.C. Impacts of Microplastics on the Soil Biophysical Environment. Environ. Sci. Technol. 2018, 52, 9656–9665. [Google Scholar] [CrossRef] [PubMed]

- Steinmetz, Z.; Wollmann, C.; Schaefer, M.; Buchmann, C.; David, J.; Tröger, J.; Muñoz, K.; Frör, O.; Schaumann, G.E. Plastic Mulching in Agriculture. Trading Short-Term Agronomic Benefits for Long-Term Soil Degradation? Sci. Total Environ. 2016, 550, 690–705. [Google Scholar] [CrossRef]

- Dexter, A.R. Soil Physical Quality: Part, I. Theory, Effects of Soil Texture, Density, and Organic Matter, and Effects on Root Growth. Geoderma 2004, 120, 201–214. [Google Scholar] [CrossRef]

- Monkul, M.M.; Aydın, N.G.; Demirhan, B.; Şahin, M. Undrained Shear Strength and Monotonic Behavior of Different Nonplastic Silts: Sand-Like or Clay-Like? Geotech. Test. J. 2020, 43, 20180147. [Google Scholar] [CrossRef]

- Monkul, M.M.; Ozden, G. Compressional Behavior of Clayey Sand and Transition Fines Content. Eng. Geol. 2007, 89, 195–205. [Google Scholar] [CrossRef]

- Duncan, J.M.; Wright, S.G. Soil Strength Slope Stab, 1st ed.; Wiley: Hoboken, NJ, USA, 2005; ISBN 9780471691631. [Google Scholar]

- Coduto, D.P. Foundation Design: Principles and Practices, 2nd ed.Pearson: London, UK, 2001. [Google Scholar]

- Van‘t Hoff, J.; van der Kolff, A.N. Hydraulic Fill Manual: For Dredging and Reclamation Works; CRC Press/Balkema Taylor & Francis Group: London, UK, 2012. [Google Scholar]

- Qian, G.; Koerner, R.M.; Gray, D. Geotechnical Aspects of Landfill Design and Construction; Pearson: London, UK, 2001. [Google Scholar]

- Lambert, S.; Wagner, M. Formation of Microscopic Particles during the Degradation of Different Polymers. Chemosphere 2016, 161, 510–517. [Google Scholar] [CrossRef] [PubMed]

- Singh, B.; Sharma, N. Mechanistic Implications of Plastic Degradation. Polym. Degrad. Stab. 2008, 93, 561–584. [Google Scholar] [CrossRef]

- Zou, W.; Xia, M.; Jiang, K.; Cao, Z.; Zhang, X.; Hu, X. Photo-Oxidative Degradation Mitigated the Developmental Toxicity of Polyamide Microplastics to Zebrafish Larvae by Modulating Macrophage-Triggered Proinflammatory Responses and Apoptosis. Environ. Sci. Technol. 2020, 54, 13888–13898. [Google Scholar] [CrossRef] [PubMed]

- Kliem, S.; Kreutzbruck, M.; Bonten, C. Review on the Biological Degradation of Polymers in Various Environments. Materials 2020, 13, 4586. [Google Scholar] [CrossRef]

- Zheng, Y.; Yanful, E.K.; Bassi, A.S. A Review of Plastic Waste Biodegradation. Crit. Rev. Biotechnol. 2005, 25, 243–250. [Google Scholar] [CrossRef] [PubMed]

- Crabbe, J.R.; Campbell, J.R.; Thompson, L.; Walz, S.L.; Schultz, W.W. Biodegradation of a Colloidal Ester-Based Polyurethane by Soil Fungi. Int. Biodeterior. Biodegrad. 1994, 33, 103–113. [Google Scholar] [CrossRef]

- Yoshida, S.; Hiraga, K.; Takehana, T.; Taniguchi, I.; Yamaji, H.; Maeda, Y.; Toyohara, K.; Miyamoto, K.; Kimura, Y.; Oda, K. A Bacterium That Degrades and Assimilates Poly(Ethylene Terephthalate). Science 2016, 351, 1196–1199. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Yue, Y.; Zheng, M.; Li, Y.; Zhang, Q.; Wang, W. IsPETase- AndIsMHETase-Catalyzed Cascade Degradation Mechanism toward Polyethylene Terephthalate. ACS Sustain. Chem. Eng. 2021, 9, 9823–9832. [Google Scholar] [CrossRef]

- Orhan, Y.; Hrenović, J.; Büyükgüngör, H. Biodegradation of Plastic Compost Bags under Controlled Soil Conditions. Acta Chim. Slov. 2004, 51, 579–588. [Google Scholar]

- Kyrikou, I.; Briassoulis, D. Biodegradation of Agricultural Plastic Films: A Critical Review. J. Polym. Environ. 2007, 15, 125–150. [Google Scholar] [CrossRef]

- Palmisano, A.C.; Pettigrew, C.A. Biodegradability of Plastics. BioScience 1992, 42, 680–685. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.P.; Ugwu, C.U.; Aiba, S. Biodegradability of Plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef]

- Lwanga, E.H.; Vega, J.M.; Quej, V.K.; de los Angeles Chi, J.; Del Cid, L.S.; Chi, C.; Segura, G.E.; Gertsen, H.; Salánki, T.; van der Ploeg, M.; et al. Field Evidence for Transfer of Plastic Debris along a Terrestrial Food Chain. Sci. Rep. 2017, 7, 1–7. [Google Scholar] [CrossRef]

- van den Berg, P.; Huerta-Lwanga, E.; Corradini, F.; Geissen, V. Sewage Sludge Application as a Vehicle for Microplastics in Eastern Spanish Agricultural Soils. Environ. Pollut. 2020, 261, 114198. [Google Scholar] [CrossRef] [PubMed]

- Dahl, M.; Bergman, S.; Björk, M.; Diaz-Almela, E.; Granberg, M.; Gullström, M.; Leiva-Dueñas, C.; Magnusson, K.; Marco-Méndez, C.; Piñeiro-Juncal, N.; et al. A Temporal Record of Microplastic Pollution in Mediterranean Seagrass Soils. Environ. Pollut. 2021, 273, 116451. [Google Scholar] [CrossRef]

- Coduto, D.P.; Yeung, M.R.; Kitch, W.A. Geotechnical Engineering: Principles and Practices, 2nd ed.; Pearson: London, UK, 2010; ISBN 0131354256. [Google Scholar]

- Holtz, R.D.; Kovacs, W.D.; Sheahan, T.C. An Introduction to Geotechnical Engineering, 2nd ed.; Pearson: London, UK, 2010. [Google Scholar]

- O’Connor, D.; Pan, S.; Shen, Z.; Song, Y.; Jin, Y.; Wu, W.M.; Hou, D. Microplastics Undergo Accelerated Vertical Migration in Sand Soil Due to Small Size and Wet-Dry Cycles. Environ. Pollut. 2019, 249, 527–534. [Google Scholar] [CrossRef] [PubMed]

- Terzaghi, K.; Peck, R.B.; Mesri, G. Soil Mechanics in Engineering Practice, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Wu, X.; Lyu, X.; Li, Z.; Gao, B.; Zeng, X.; Wu, J.; Sun, Y. Transport of Polystyrene Nanoplastics in Natural Soils: Effect of Soil Properties, Ionic Strength and Cation Type. Sci. Total Environ. 2020, 707, 136065. [Google Scholar] [CrossRef] [PubMed]

- Cooper, D.A.; Corcoran, P.L. Effects of Mechanical and Chemical Processes on the Degradation of Plastic Beach Debris on the Island of Kauai, Hawaii. Mar. Pollut. Bull. 2010, 60, 650–654. [Google Scholar] [CrossRef]

- Krueger, M.C.; Harms, H.; Schlosser, D. Prospects for Microbiological Solutions to Environmental Pollution with Plastics. Appl. Microbiol. Biotechnol. 2015, 99, 8857–8874. [Google Scholar] [CrossRef] [PubMed]

- Briassoulis, D.; Babou, E.; Hiskakis, M.; Kyrikou, I. Analysis of Long-Term Degradation Behaviour of Polyethylene Mulching Films with pro-Oxidants under Real Cultivation and Soil Burial Conditions. Environ. Sci. Pollut. Res. 2015, 22, 2584–2598. [Google Scholar] [CrossRef]

- Reddy, M.M.; Gupta, R.K.; Gupta, R.K.; Bhattacharya, S.N.; Parthasarathy, R. Abiotic Oxidation Studies of Oxo-Biodegradable Polyethylene. J. Polym. Environ. 2008, 16, 27–34. [Google Scholar] [CrossRef]

- Albertsson, A.C.; Karlsson, S. The Three Stages in Degradation of Polymers—Polyethylene as a Model Substance. J. Appl. Polym. Sci. 1988, 35, 1289–1302. [Google Scholar] [CrossRef]

- Otake, Y.; Kobayashi, T.; Asabe, H.; Murakami, N.; Ono, K. Biodegradation of Low-density Polyethylene, Polystyrene, Polyvinyl Chloride, and Urea Formaldehyde Resin Buried under Soil for over 32 Years. J. Appl. Polym. Sci. 1995, 56, 1789–1796. [Google Scholar] [CrossRef]

- Tabone, M.D.; Cregg, J.J.; Beckman, E.J.; Landis, A.E. Sustainability Metrics: Life Cycle Assessment and Green Design in Polymers. Environ. Sci. Technol. 2010, 45, 8264–8269. [Google Scholar] [CrossRef] [PubMed]

- Karamanlioglu, M.; Robson, G.D. The Influence of Biotic and Abiotic Factors on the Rate of Degradation of Poly(Lactic) Acid (PLA) Coupons Buried in Compost and Soil. Polym. Degrad. Stab. 2013, 98, 2063–2071. [Google Scholar] [CrossRef]

- Akbulut, S. Katı atık depo alanlarının geoteknik tasarımı. Mühendislik Bilimleri Derg. 2003, 9, 223–230. [Google Scholar]

- Ghosh, S.K.; Agamuthu, P. Plastics in municipal solid waste: What, where, how and when? Waste Manag. Res. 2019, 37, 1061–1062. [Google Scholar] [CrossRef] [PubMed]

- Hughes, K.L.; Christy, A.D.; Heimlich, J.E. Landfill Types and Liner Systems. Extension Fact Sheet; The Ohio State University: Columbus, OH, USA, 2005. [Google Scholar]

- Daniel, D.E.; Wu, Y. Compacted Clay Liners and Covers for Arid Sites. J. Geotech. Eng. 1993, 119, 223–237. [Google Scholar] [CrossRef]

- Qian, X.; Gray, D.H.; Koerner, R.M. Estimation of Maximum Liquid Head over Landfill Barriers. J. Geotech. Geoenviron. Eng. 2004, 130, 488–497. [Google Scholar] [CrossRef]

- Koerner, R.M. Designing with Geosynthetics; Pearson: London, UK, 2005. [Google Scholar]

- Sharma, D.H.; Lewis, P.S. Waste Containment Systems, Waste Stabilization and Landfills, Design and Evaluation, Waste Characterization and Solid-Waste Interaction; John Wiley & Sons: Hoboken, NJ, USA, 1994. [Google Scholar]

- Koerner, G.R. Assessing Potential Geomembrane Damage from Direct Construction Equipment Contact. Geo Front. Congr. 2005, 1, 1–3. [Google Scholar] [CrossRef]

- Ben Othmen, A.; Bouassida, M. Detecting defects in geomembranes of landfill liner systems: Durable electrical method. Int. J. Geotech. Eng. 2013, 7, 130–135. [Google Scholar] [CrossRef]

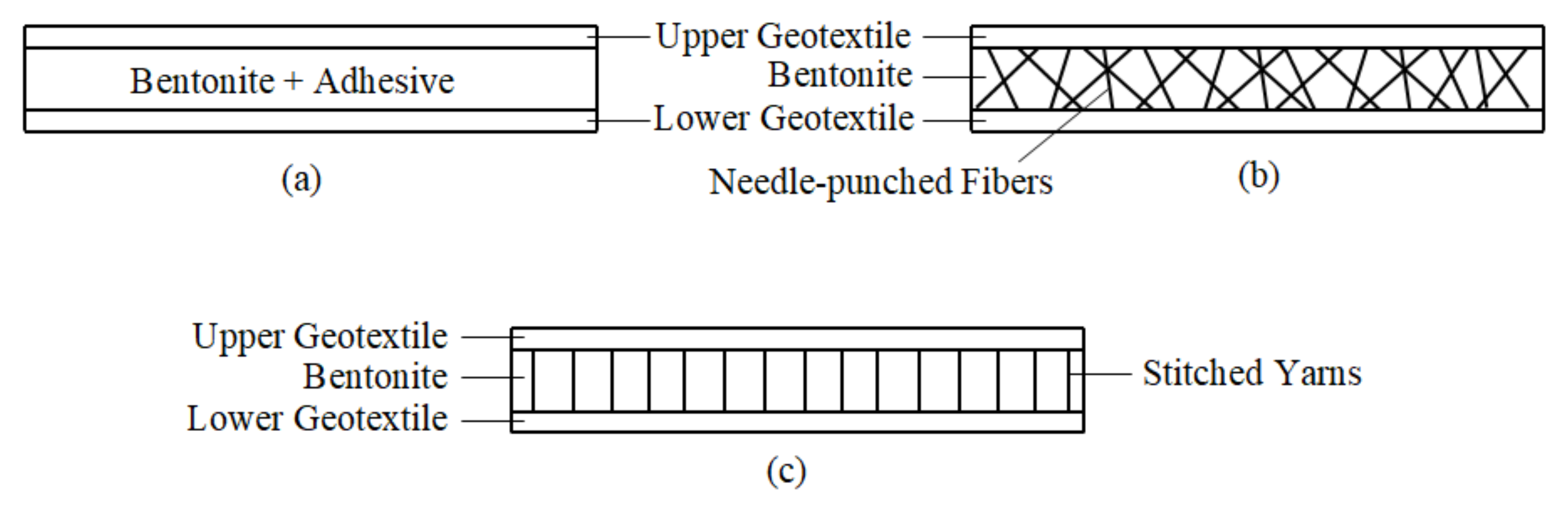

- Bouazza, A. Geosynthetic clay liners. Geotext. Geomembr. 2002, 20, 3–17. [Google Scholar] [CrossRef]

- Benson, C.H.; Meer, S.R. Relative abundance of monovalent and divalent cations and the impact of desiccation on geosynthetic clay liners. J. Geotech. Geoenviron. Eng. 2009, 135, 349–358. [Google Scholar] [CrossRef]

- Güler, E.; Özhan, H.O.; Karaoglu, S. Hydraulic performance of anionic polymer-treated bentonite-granular soil mixtures. Appl. Clay Sci. 2018, 157, 139–147. [Google Scholar] [CrossRef]

- Liu, Y.; Gates, W.P.; Bouazza, A. Acid induced degradation of the bentonite component used in geosynthetic clay liners. Geotext. Geomembr. 2013, 36, 71–80. [Google Scholar] [CrossRef]

- Özhan, H.O.; Güler, E. Use of Perforated Base Pedestal to Simulate the Gravel Subbase in Evaluating the Internal Erosion of Geosynthetic Clay Liners. Geotech. Test. J. 2013, 36, 418–428. [Google Scholar] [CrossRef]

- Özhan, H.O.; Güler, E. Factors affecting failure by internal erosion of geosynthetic clay liners used in fresh water reservoirs. Environ. Eng. Geosci. 2016, 22, 157–169. [Google Scholar] [CrossRef]

- Giroud, J.; Soderman, K. Criterion for Acceptable Bentonite Loss From a GCL Incorporated Into a Liner System. Geosynth. Int. 2000, 7, 529–581. [Google Scholar] [CrossRef]

- Orsini, C.; Rowe, R.K. Testing procedure and results for the study of internal erosion of geosynthetic clay liners. In Proceedings of the Geosynthetics, Portland, OR, USA, 12–14 February 2001; pp. 189–201. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, 25–29. [Google Scholar] [CrossRef] [PubMed]

- He, P.; Chen, L.; Shao, L.; Zhang, H.; Lü, F. Municipal solid waste (MSW) landfill: A source of microplastics? -Evidence of microplastics in landfill leachate. Water Res. 2019, 159, 38–45. [Google Scholar] [CrossRef] [PubMed]

- Hanson, J.L.; Yesiller, N.; Kendall, L.A. Integrated temperature and gas analysis at a municipal solid wast landfill. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering: Geotechnology in Harmony with the Global Environment, Osaka, Japan, 12 September 2005. [Google Scholar]

- Mahon, A.M.; O’Connell, B.; Healy, M.; O’Connor, I.; Officer, R.; Nash, R.; Morrison, L. Microplastics in Sewage Sludge: Effects of Treatment. Environ. Sci. Technol. 2017, 51, 810–818. [Google Scholar] [CrossRef] [PubMed]

- Sundt, P.; Schulze, P.E.; Syversen, F. Sources of microplastic pollution to the marine environment. Mepex Rep. Nor. Environ. Agency 2014, 49–50. [Google Scholar]

- Zettler, E.; Mincer, T.; Amaral-Zettler, L.A. Life in the “Plastisphere”: Microbial Communities on Plastic Marine Debris. Environ. Sci. Technol. 2013, 47, 7137–7146. [Google Scholar] [CrossRef]

- Xu, Z.; Sui, Q.; Li, A.; Sun, M.; Zhang, L.; Lyu, S.; Zhao, W. How to detect small microplastics (20–100 μm) in freshwater, municipal wastewaters and landfill leachates? A trial from sampling to identification. Sci. Total Environ. 2020, 733, 139218. [Google Scholar] [CrossRef] [PubMed]

- Yang, N.; Damgaard, A.; Kjeldsen, P.; Shao, L.-M.; He, P.-J. Quantification of regional leachate variance from municipal solid waste landfills in China. Waste Manag. 2015, 46, 362–372. [Google Scholar] [CrossRef] [PubMed]

- Van Praagh, M.; Hartman, C.; Brandmyr, E. Brandmyr, E. Microplastics in Landfill leachates in the Nordic Countries. Tema.Nord. 2019. Nordic Council of Ministers, Copenhagen, TN2018-557. Available online: https://norden.diva-portal.org/smash/get/diva2:1277395/FULLTEXT01.pdf (accessed on 5 October 2021).

- Su, Y.; Zhang, Z.; Wu, D.; Zhan, L.; Shi, H.; Xie, B. Occurrence of microplastics in landfill systems and their fate with landfill age. Water Res. 2019, 164, 114968. [Google Scholar] [CrossRef] [PubMed]

- Narevski, A.C.; Novaković, M.I.; Petrović, M.Z.; Mihajlović, I.J.; Maoduš, N.B.; Vujić, G.V. Occurrence of bisphenol A and microplastics in landfill leachate: Lessons from South East Europe. Environ. Sci. Pollut. Res. 2021, 28, 42196–42203. [Google Scholar] [CrossRef] [PubMed]

- Ficociello, G.; Gerardi, V.; Uccelletti, D.; Setini, A. Molecular and cellular responses to short exposure to bisphenols A, F, and S and eluates of microplastics in C. elegans. Environ. Sci. Pollut. Res. 2021, 28, 805–818. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Shi, H.; Xie, B.; Dionysiou, D.D.; Zhao, Y. Microplastics as Both a Sink and a Source of Bisphenol A in the Marine Environment. Environ. Sci. Technol. 2019, 53, 10188–10196. [Google Scholar] [CrossRef] [PubMed]

- Beckingham, B.; Ghosh, U. Differential bioavailability of polychlorinated biphenyls associated with environmental particles: Microplastic in comparison to wood, coal and biochar. Environ. Pollut. 2017, 220, 150–158. [Google Scholar] [CrossRef] [PubMed]

- Hodson, M.E.; Duffus-Hodson, C.A.; Clark, A.; Prendergast-Miller, M.T.; Thorpe, K.L. Plastic bag derived-microplastics as a vector for metal exposure in terrestrial invertebrates. Environ. Sci. Technol. 2017, 51, 4714–4721. [Google Scholar] [CrossRef] [PubMed]

- Foose, G.J.; Benson, C.H.; Edil, T.B. Predicting Leakage through Composite Landfill Liners. J. Geotech. Geoenviron. Eng. 2001, 127, 510–520. [Google Scholar] [CrossRef]

- Manikanda, B.K.; Usha, N.; Vaikunth, R.; Praveen, K.R.; Ruthra, R.; Srinivasalu, S. Spatial Distribution of Microplastic Concentration around Landfill Sites and its Potential Risk on Groundwater. Chemosphere 2021, 277, 130263. [Google Scholar] [CrossRef]

- Afrin, S.; Uddin, K.; Rahman, M. Microplastics contamination in the soil from Urban Landfill site, Dhaka, Bangladesh. Heliyon 2020, 6, e05572. [Google Scholar] [CrossRef] [PubMed]

- Puthcharoen, A.; Leungprasert, S. Determination of microplastics in soil and leachate from the landfills. Thai Environ. Eng. J. 2019, 33, 39–46. [Google Scholar]

- Browne, M.A.; Underwood, A.J.; Chapman, M.G.; Williams, R.; Thompson, R.; Van Franeker, J.A. Linking effects of anthropogenic debris to ecological impacts. Proc. R. Soc. B Biol. Sci. 2015, 282, 20142929. [Google Scholar] [CrossRef]

- Horton, A.A.; Walton, A.; Spurgeon, D.J.; Lahive, E.; Svendsen, C. Microplastics in freshwater and terrestrial environments: Evaluating the current understanding to identify the knowledge gaps and future research priorities. Sci. Total Environ. 2017, 586, 127–141. [Google Scholar] [CrossRef] [PubMed]

- Zylstra, E. Accumulation of wind-dispersed trash in desert environments. J. Arid. Environ. 2013, 89, 13–15. [Google Scholar] [CrossRef]

- Kilponen, J. Microplastics and harmful substances in urban runoffs and landfill leachates: Possible emission sources to marine environment. In Faculty of Technology, Volume Environmental Technology; Lahti University of Applied Sciences: Lahti, Finland, 2016. [Google Scholar]

- Hurley, R.R.; Lusher, A.L.; Olsen, M.; Nizzetto, L. Validation of a Method for Extracting Microplastics from Complex, Organic-Rich, Environmental Matrices. Environ. Sci. Technol. 2018, 52, 7409–7417. [Google Scholar] [CrossRef] [PubMed]

- Kazour, M.; Terki, S.; Rabhi, K.; Jemaa, S.; Khalaf, G.; Amara, R. Sources of microplastics pollution in the marine environment: Importance of wastewater treatment plant and coastal landfill. Mar. Pollut. Bull. 2019, 146, 608–618. [Google Scholar] [CrossRef]

- Rezaei, M.; Riksen, M.J.; Sirjani, E.; Sameni, A.; Geissen, V. Wind erosion as a driver for transport of light density microplastics. Sci. Total Environ. 2019, 669, 273–281. [Google Scholar] [CrossRef] [PubMed]

- Prata, J.C.; da Costa, J.P.; Lopes, I.; Duarte, A.C.; Rocha-Santos, T. Environmental exposure to microplastics: An overview on possible human health effects. Sci. Total Environ. 2020, 702, 134455. [Google Scholar] [CrossRef] [PubMed]

- Wright, S.L.; Kelly, F.J. Plastic and Human Health: A Micro Issue? Environ. Sci. Technol. 2017, 51, 6634–6647. [Google Scholar] [CrossRef] [PubMed]

- Kole, P.J.; Löhr, A.J.; Van Belleghem, F.G.A.J.; Ragas, A.M.J. Wear and Tear of Tyres: A Stealthy Source of Microplastics in the Environment. Int. J. Environ. Res. Public Health 2017, 14, 1265. [Google Scholar] [CrossRef] [PubMed]

- Meixner, K.; Kubiczek, M.; Fritz, I. Microplastic in soil—Current status in Europe with special focus on method tests with Austrian samples. AIMS Environ. Sci. 2020, 7, 174–191. [Google Scholar] [CrossRef]

- PlasticsEurope-Association of Plastics Manufactures. Plastics–the Facts 2019. PlasticsEurope 2019, 1–42. Available online: https://plasticseurope.org/wp-content/uploads/2021/10/2019-Plastics-the-facts.pdf (accessed on 27 September 2021).

- Daud, K.A. Soil improvement using waste tire chips. Int. J. Civ. Eng. Technol. 2018, 9, 1338–1345. [Google Scholar]

- Promputthangkoona, P.; Karnchanachetaneea, B. Geomaterial prepared from waste tyres, soil and cement. Procedia Soc. Behav. Sci. 2013, 91, 421–428. [Google Scholar] [CrossRef][Green Version]

- Singh, J.; Sonthwal, V.K. Improvement of engineering properties of clayey soil using shredded rubber tyre. Int. J. Theor. Appl. Sci. 2017, 9, 1–6. [Google Scholar]

- Solanki, D.; Dave, M.; Purohit, D.G.M. Stabilization of clay soil mixed with rubber tyre chips for design in road construction. Int. J. Eng. Sci. Invent. 2017, 6, 88–91. [Google Scholar]

- Al-Neami, M.A. Stabilization of sandy soil using recycle waste tire chips. Int. J. 2018, 15, 175–180. [Google Scholar] [CrossRef]

- Reddy, V.R.; Reddy, I.S.; Prasad, D.S.V. Improvement of soil characteristics using shredded rubber. IOSR J. Mech. Civ. Eng. 2016, 13, 44–48. [Google Scholar]

- Ji, X.; Ma, Y.; Zeng, G.; Xu, X.; Mei, K.; Wang, Z.; Chen, Z.; Dahlgren, R.; Zhang, M.; Shang, X. Transport and fate of microplastics from riverine sediment dredge piles: Implications for disposal. J. Hazard. Mater. 2021, 404, 124132. [Google Scholar] [CrossRef]

- Monkul, M.M.; Yükselen-Aksoy, Y. Sustainable usage of dredge materials at engineering fills and investigation of their performance with different additives. In Geotechnical Special Publication No 273: Sustainable Waste Management and Remediation; ASCE: Reston, VI, USA, 2016; pp. 471–480. ISBN 978-0-7844-8016-8. [Google Scholar]

- US Army Corps of Engineers (USACE). Dredging Quality Management. 2014. Available online: http://dqm.usace.army.mil/, (accessed on 19 October 2021).

- Islam, M.; Nasrin, M.; Khan, A. Foundation alternatives in dredge fill soils overlaying organic clay. Lowl. Technol. Int. 2013, 15, 1–14. [Google Scholar] [CrossRef]

- Zhejiang Provincial Bureau of Statistics. Power Conversion Structure Optimization and Quality Improvement-Zhejiang’s Economic Performance in 2017. Available online: http://tjj.zj.gov.cn/art/2018/11/23/art_1562012_25740568.html (accessed on 19 October 2021).

- Zhejiang Provincial Bureau of Statistics. Zhejiang’s Economy is Operating Steadily in 2016. Available online: http://tjj.zj.gov.cn/art/2018/11/23/art_1562012_25740525.html (accessed on 19 October 2021).

- Tingle, J.S.; Newman, J.K.; Larson, S.L.; Weiss, C.A.; Rushing, J.F. Stabilization Mechanisms of Nontraditional Additives. Transp. Res. Rec. J. Transp. Res. Board 2007, 1989, 59–67. [Google Scholar] [CrossRef]

- Abdel Hadi, N.A.R. Utilization of polymer fibers and crushed limestone sand for stabilization of expansive clays in Amman area. Int. J. Geotech. Eng. 2016, 10, 428–434. [Google Scholar] [CrossRef]

- Chen, M.; Shen, S.-L.; Arulrajah, A.; Wu, H.-N.; Hou, D.-W.; Xu, Y.-S. Laboratory evaluation on the effectiveness of polypropylene fibers on the strength of fiber-reinforced and cement-stabilized Shanghai soft clay. Geotext. Geomembr. 2015, 43, 515–523. [Google Scholar] [CrossRef]

- Hamidi, A.; Hooresfand, M. Effect of fiber reinforcement on triaxial shear behavior of cement treated sand. Geotext. Geomembr. 2013, 36, 1–9. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Ayeldeen, M.; Kitazume, M. Using fiber and liquid polymer to improve the behaviour of cement-stabilized soft clay. Geotext. Geomembranes 2017, 45, 592–602. [Google Scholar] [CrossRef]

- Öncü, Ş.; Bilsel, H. Influence of Polymeric Fiber Reinforcement on Strength Properties of Sand-stabilized Expansive Soil. Polym. Technol. Eng. 2017, 56, 391–399. [Google Scholar] [CrossRef]

- Yılmaz, Y.; Sevencan, Ü. Investigation of some geotechnical properties of polypropylene fiber and fly ash amended Ankara clay. In Proceedings of the 13th National Conference on Soil Mechanics and Foundation Engineering, Istanbul, Turkey, 5–10 January 1994; pp. 133–142. [Google Scholar]

- Punthutaecha, K.; Puppala, A.J.; Vanapalli, S.K.; Inyang, H. Volume Change Behaviors of Expansive Soils Stabilized with Recycled Ashes and Fibers. J. Mater. Civ. Eng. 2006, 18, 295–306. [Google Scholar] [CrossRef]

- Wei, L.; Chai, S.X.; Zhang, H.Y.; Shi, Q. Mechanical properties of soil reinforced with both lime and four kinds of fiber. Constr. Build. Mater. 2018, 172, 300–308. [Google Scholar] [CrossRef]

- Ahmed, M.R.; Meguid, M.; Whalen, J.; Eng, P. Laboratory Measurement of the load reduction on buried structures overlain by EPS geofoam. In Proceedings of the 66th Canadian Geotechnical Conference, Montreal, QC, Canada, 29 September–3 October 2013. [Google Scholar]

- Hwang, J.; Choi, D.; Han, S.; Jung, S.Y.; Choi, J.; Hong, J. Potential toxicity of polystyrene microplastic particles. Sci. Rep. 2020, 10, 7391. [Google Scholar] [CrossRef] [PubMed]

- Schellenberg, J. Syndiotactic Polystyrene: Synthesis, Characterization, Processing, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Kukharchyk, T.; Chernyuk, V. Microplastic of polystyrene in soil and water: Fluxes study from industrial site. In Proceedings of the EGU General Assembly 2020, Vienna, Austria, 4–8 May 2020. Online. [Google Scholar]

- Abbasimaedeh, P.; Ghanbari, A.; O’Kelly, B.; Tavanafar, M.; Irdmoosa, K. Geomechanical Behaviour of Uncemented Expanded Polystyrene (EPS) Beads–Clayey Soil Mixtures as Lightweight Fill. Geotechnics 2021, 1, 38–58. [Google Scholar] [CrossRef]

- Özer, A.T.; Akay, O. Interface Shear Strength Characteristics of Interlocked EPS-Block Geofoam. J. Mater. Civ. Eng. 2016, 28, 04015156. [Google Scholar] [CrossRef]

- Stark, T.D.; Arellano, D.; Horvath, J.S.; Leshchinsky, D. Geofoam Applications in the Design and Construction of Highway Embankments; Transportation Research Board: Washington, WA, USA, 2004. [Google Scholar]

- Tsuchida, T.; Egashira, K. The Lightweight Treated Soil Method-New Geomaterials for Soft Ground Engineering in Coastal Areas; Balkema: Liden, The Netherlands, 2004. [Google Scholar]

- Arellano, D.; Stark, T.D.; Horvath, J.S.; Leshchinsky, D. Guidelines for geofoam applications in slope stability projects. In Research Results Digest 380; National Cooperative Highway Research Program, The National Academies Press: Washington, WA, USA, 2013. [Google Scholar]

- Gan, C.H.; Tan, S.M. Some construction experiences on soft soil using light weight materials. In Proceedings of the 2nd International Conference on Advances in Soft Soil Engineering and Technology, Putrajaya, Malaysia, 2–4 July 2003. [Google Scholar]

- Moorsel, D.; Kilpeläinen, T.; Meuwissen, E.; Neirinckx, L.; Tepper, H.; Thompsett, D.; Zipp, K. EPS White Book, EUMEPS Background Information on Standardization of EPS; EUMEPS Construction: Maaseik, Belgium, 2014. [Google Scholar]

- Daigavane, P.B.; Dawande, G.M.; Gulhane, S.W.; Chaudhari, N.D. Improvement of B. C. Soil Using Geofoam Prefabricated Vertical Drain. In Proceedings of the Indian Geotechnical Conference GEOtrendz, Mumbai, India, 16–18 December 2010. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monkul, M.M.; Özhan, H.O. Microplastic Contamination in Soils: A Review from Geotechnical Engineering View. Polymers 2021, 13, 4129. https://doi.org/10.3390/polym13234129

Monkul MM, Özhan HO. Microplastic Contamination in Soils: A Review from Geotechnical Engineering View. Polymers. 2021; 13(23):4129. https://doi.org/10.3390/polym13234129

Chicago/Turabian StyleMonkul, Mehmet Murat, and Hakkı O. Özhan. 2021. "Microplastic Contamination in Soils: A Review from Geotechnical Engineering View" Polymers 13, no. 23: 4129. https://doi.org/10.3390/polym13234129

APA StyleMonkul, M. M., & Özhan, H. O. (2021). Microplastic Contamination in Soils: A Review from Geotechnical Engineering View. Polymers, 13(23), 4129. https://doi.org/10.3390/polym13234129