The Impact of Fiber from Buckwheat Hulls Waste on the Pasting, Rheological and Textural Properties of Normal and Waxy Potato Starch Gels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Sample Preparations

2.2.2. Pasting Characteristics

- (a)

- Heating from 30 to 95 °C heated at 1.5 °C/min;

- (b)

- Maintaining samples for 5 min at 95 °C;

- (c)

- Cooling 95 to 50 °C with 1.5 °C/min;

- (d)

- Constant agitation at 75 rpm.

2.2.3. Flow Curves

2.2.4. Oscillatory Measurements

2.2.5. Textural Properties

2.2.6. Statistics

3. Results

3.1. Pasting Properties of Starch/Fiber Mixtures

3.2. Rheological Properties of Starch/Fiber Mixtures

3.2.1. Flow Curves Properties

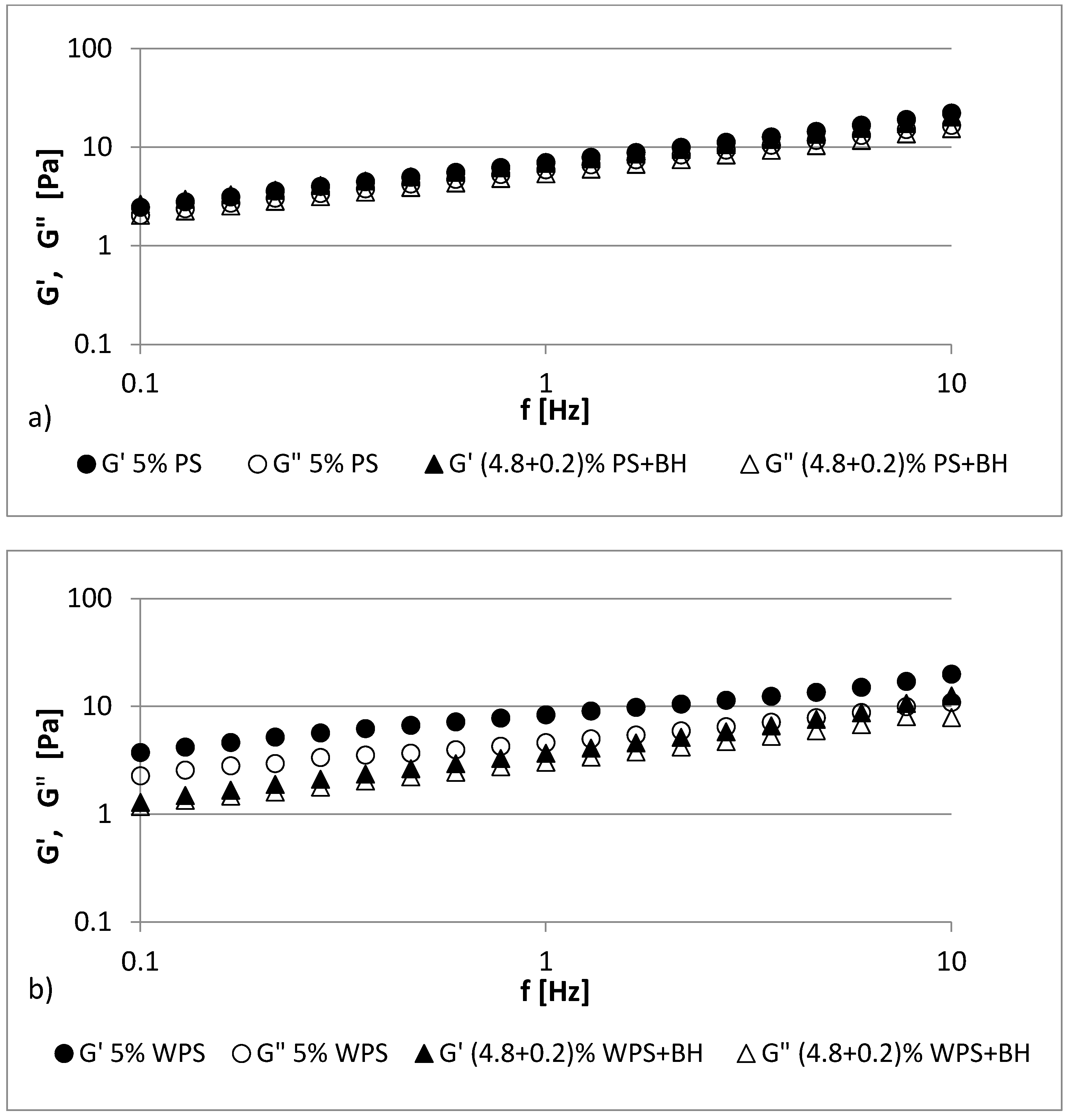

3.2.2. Viscoelastic Properties

3.3. Textural Properties of Starch/Fiber Mixtures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Whistler, R.L.; BeMiller, J.N. Carbohydrate Chemistry for Food Scientists; Eagan Press: St. Paul, MN, USA, 1997; pp. 117–164. [Google Scholar]

- Adamczyk, G.; Krystyjan, M.; Jaworska, G. The effect of the addition of dietary fibers from apple and oat on the rheo-logical and textural properties of waxy potato starch. Polymers 2020, 12, 321. [Google Scholar] [CrossRef] [Green Version]

- Villegas, M.D.L.A.C.; Acosta-Osorio, A.; Rojas-Molina, I.; Gutiérrez-Cortéz, E.; Quiroga, M.; Gaytán, M.; Herrera, G.; Rodriguez-Garcia, M.E. Study of the physicochemical and pasting properties of instant corn flour added with calcium and fibers from nopal powder. J. Food Eng. 2010, 96, 401–409. [Google Scholar] [CrossRef]

- Krystyjan, M.; Adamczyk, G.; Sikora, M.; Tomasik, P. Long-term storage stability of selected potato starch—Non-starchy hydrocolloid binary gels. Food Hydrocoll. 2013, 31, 270–276. [Google Scholar] [CrossRef]

- Gurmeric, V.E.; Dogan, M.; Toker, O.S.; Senyigit, E.; Ersoz, N.B. Application of different multi-criteria decision techniques to determine optimum flavour of prebiotic pudding based on sensory analyses. Food Bioprocess Technol. 2013, 6, 2844–2859. [Google Scholar] [CrossRef]

- Guan, Z.-W.; Yu, E.-Z.; Feng, Q. Soluble Dietary Fiber, One of the Most Important Nutrients for the Gut Microbiota. Molecules 2021, 26, 6802. [Google Scholar] [CrossRef]

- Chawla, R.; Patil, G.R. Soluble dietary fiber. Compr. Rev. Food Sci. Food Saf. 2010, 9, 178–196. [Google Scholar] [CrossRef]

- Matseychik, I.V.; Korpacheva, S.M.; Lomovsky, I.O.; Serasutdinova, K.R. Influence of buckwheat by-products on the antioxidant activity of functional desserts. Earth Environ. Sci. 2021, 640, 022038. [Google Scholar] [CrossRef]

- Korpacheva, S.; Serasutdinova, K.; Lomovsky, I.; Chugunova, O. Technological aspects of obtaining melanin and powder from buckwheat hull and their use in food technology. E3S Web Conf. 2021, 296, 07007. [Google Scholar] [CrossRef]

- Vaickelionis, G.; Valančienė, V. Lightweight Concrete with an Agricultural Waste—Buckwheat Husk. Mater. Sci. 2016, 22, 98–104. [Google Scholar] [CrossRef] [Green Version]

- Yu, K.; Zhang, Z.; Liang, J.; Liang, C. Natural biomass-derived porous carbons from buckwheat hulls used as anode for lith-iumion batteries. Diam. Relat. Mater. 2021, 119, 1085553. [Google Scholar] [CrossRef]

- Tomczak, E.; Kaminski, W. Dynamics modeling of multicomponent metal ions’ removal onto low-cost buckwheat hulls. Environ. Sci. Pollut. Res. 2021, 28, 46504–46513. [Google Scholar] [CrossRef] [PubMed]

- Park, B.; Kim, J.; Lee, K.; Lim, T.; Hwang, K.T. Flavonoids in common and tartary buckwheat hull extracts and antioxidant activity of the extracts against lipids in mayonnaise. J. Food Sci. Technol. 2019, 56, 2712–2720. [Google Scholar] [CrossRef]

- Radoš, K.; Mustač, N.Č.; Benković, M.; Kuzmić, I.; Novotni, D.; Drakula, S.; Habuš, M.; Voučko, B.; Ćurić, D. The quality and shelf life of biscuits with cryo-ground proso millet and buckwheat by-products. J. Food Process. Preserv. 2021, 15532. [Google Scholar] [CrossRef]

- Yildiz, Ö.; Yurt, B.; Baştürk, A.; Toker, Ö.S.; Yilmaz, M.T.; Karaman, S.; Dağlıoğlu, O. Pasting properties, texture profile and stress–relaxation behaviour of wheat starch/dietary fibre systems. Food Res. Int. 2013, 53, 278–290. [Google Scholar] [CrossRef]

- Debiagi, F.; Mali, S.; Grossmann, M.V.E.; Yamashita, F. Effects of vegetal fibers on properties of cassava starch biodegradable composites produced by extrusion. Ciência Agrotecnologia 2010, 34, 1522–1529. [Google Scholar] [CrossRef] [Green Version]

- Cunniff, P. AOAC 991.43. Official Methods of Analysis, 14th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2006. [Google Scholar]

- Steffe, J.F. Rheological Methods in Food Process Engineering; Freeman Press: East Lansing, MI, USA, 1996; pp. 1–91. [Google Scholar]

- Sikora, M.; Adamczyk, G.; Krystyjan, M.; Dobosz, A.; Tomasik, P.; Berski, W.; Łukasiewicz, M.; Izak, P. Thixotropic properties of normal potato starch depending on the degree of the granules pasting. Carbohydr. Polym. 2015, 121, 254–264. [Google Scholar] [CrossRef]

- Krystyjan, M.; Sikora, M.; Adamczyk, G.; Dobosz, A.; Tomasik, P.; Berski, W.; Łukasiewicz, M.; Izak, P. Thixotropic properties of waxy potato starch depending on the degree of the granules pasting. Carbohydr. Polym. 2016, 141, 126–134. [Google Scholar] [CrossRef]

- Krystyjan, M.; Ciesielski, W.; Khachatryan, G.; Sikora, M.; Tomasik, P. Structure, rheological, textural and thermal properties of potato starch—Inulin gels. LWT 2015, 60, 131–136. [Google Scholar] [CrossRef]

- Leite, T.D.; Nicoleti, J.F.; Penna, A.L.B.; Franco, C.M.L. Effect of addition of different hydrocolloids on pasting, thermal, and rheological properties of cassava starch. Food Sci. Technol. 2012, 32, 579–587. [Google Scholar] [CrossRef] [Green Version]

- Ragaee, S.; Abdel-Aal, E.M. Pasting properties of starch and protein in selected cereals and quality of their food products. Food Chem. 2006, 95, 9–18. [Google Scholar] [CrossRef]

- Burisova, A.; Hromadkova, Z.; Ebringerova, A.; Stadlerova, K.; Dandar, A. Flow properties study of corn starch after addition of hemicelluloses from buckwheat hulls. Żywność. Nauka. Technol. Jakość 2002, 4, 50–56. [Google Scholar]

- Sikora, M.; Kowalski, S.; Tomasik, P. Binary hydrocolloids from starches and xanthan gum. Food Hydrocoll. 2008, 22, 943–952. [Google Scholar] [CrossRef]

- Krystyjan, M.; Khachatryan, G.; Ciesielski, W.; Buksa, K.; Sikora, M. Preparation and characteristics of mechanical and func-tional properties of starch/Plantago psyllium seeds mucilage films. Starch Staerke 2017, 69, 1700014. [Google Scholar] [CrossRef]

- Wu, Y.; Lin, Q.; Chen, Z.; Xiao, H. The interaction between tea polyphenols and rice starch during gelatinization. Food Sci. Technol. Int. 2011, 17, 569–577. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Sun, B.; Zhang, S.; Zhu, Y.; Tian, Y. Inhibition of wheat starch retrogradation by tea derivatives. Carbohydr. Polym. 2015, 134, 413–417. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F.; Cai, Y.-Z.; Sun, M.; Corke, H. Effect of phenolic compounds on the pasting and textural properties of wheat starch. Starch Stärke 2008, 60, 609–616. [Google Scholar] [CrossRef]

- Brennan, C.S. Dietary fibre, glycaemic response, and diabetes. Mol. Nutr. Food Res. 2005, 49, 560–570. [Google Scholar] [CrossRef] [PubMed]

- Tudorica, C.M.; Kuri, V.; Brennan, C.S. Nutritional and physicochemical characteristics of dietary fibre enriched pasta. J. Agric. Food Chem. 2002, 50, 347–356. [Google Scholar] [CrossRef] [PubMed]

- Young, G.P.; Hu, Y.; Le Leu, R.K.; Nyskohus, L. Dietary fibre and colorectal cancer: A model for environment gene interactions, Review. Mol. Nutr. Food Res. 2005, 49, 571–584. [Google Scholar] [CrossRef]

- Gumul, D.; Krystyjan, M.; Buksa, K.; Ziobro, R.; Zięba, T. The influence of oxidation, extrusion and oxidation/extrusion on physico-chemical properties of potato starch. Starch Stärke 2014, 66, 190–198. [Google Scholar] [CrossRef]

- Krystyjan, M.; Ciesielski, W.; Gumul, D.; Buksa, K.; Ziobro, R.; Sikora, M. Physico-chemical and rheological properties of gelatinized/freeze-dried cereal starches. Int. Agrophys. 2017, 31, 357–365. [Google Scholar] [CrossRef] [Green Version]

- Rao, M.A.; Tattiyakul, J. Granule size and rheological behaviour of heated tapioca starch dispersions. Carbohydr. Polym. 1999, 38, 123–132. [Google Scholar] [CrossRef]

- Wang, B.; Li, D.; Wang, L.-J.; Özkan, N. Anti-thixotropic properties of waxy maize starch dispersions with different pasting conditions. Carbohydr. Polym. 2010, 79, 1130–1139. [Google Scholar] [CrossRef]

- Tattiyakul, J.; Rao, M.A. Rheological behaviour of cross-linked waxy maize starch dispersions during and after heating. Carbohydr. Polym. 2000, 43, 215–222. [Google Scholar] [CrossRef]

- Mandala, G.I. Viscoelastic properties of starch and non-starch thickeners in simple mixtures or model food. chapter 10. In Viscoelasticity—From Theory to Biological Applications; Intech: London, UK, 2012; pp. 217–236. [Google Scholar]

- Singh, J.; Singh, N. Studies on the morphological, thermal and rheological properties of starch separated from some Indian potato cultivars. Food Chem. 2001, 75, 67–77. [Google Scholar] [CrossRef]

- Mandala, I.G.; Palogou, E.D. Effect of Preparation conditions and starch/xanthan concentration on gelation process of potato starch systems. Int. J. Food Prop. 2003, 6, 311–328. [Google Scholar] [CrossRef]

- Rao, M.A. Phase transitions, food texture and structure. In Texture in Food. Semi-Solid Foods, I; McKenna, B.M., Ed.; Woodhead Publishing: Cambridge, UK, 2003. [Google Scholar]

- Yu, S.; Ma, Y.; Sun, D.-W. Impact of amylose content on starch retrogradation and texture of cooked milled rice during storage. J. Cereal Sci. 2009, 50, 139–144. [Google Scholar] [CrossRef]

- Funami, T.; Kataoka, Y.; Omoto, T.; Goto, Y.; Asai, I.; Nishinari, K. Effects of non-ionic polysaccharides on the gelatinization and retrogradation behavior of wheat starch. Food Hydrocoll. 2005, 19, 1–13. [Google Scholar] [CrossRef]

- Vandeputte, G.E.; Vermeylen, R.; Geeroms, J.; Delcour, J.A. Rice starches. III. Structural aspects provide insight in amylopectin retrogradation properties and gel texture. J. Cereal Sci. 2003, 38, 61–68. [Google Scholar] [CrossRef]

- Dobosz, A.; Sikora, M.; Krystyjan, M.; Tomasik, P.; Lach, R.; Borczak, B.; Berski, W.; Łukasiewicz, M. Short- and long-term retrogradation of potato starches with varying amylose content. J. Sci. Food Agric. 2019, 99, 2393–2403. [Google Scholar] [CrossRef] [PubMed]

| Sample | T0 (°C) | ηmax (BU) | Tηmax (°C) | η95°C (BU) | η95°Cafter5min (BU) | ηmin (BU) | BD (BU) | η50°C (BU) |

|---|---|---|---|---|---|---|---|---|

| 4% PS | 63.5 ± 0.07 a | 878.0 ± 5.66 b | 87.7 ± 0.14 c | 760.5 ± 0.71 c | 600.0 ± 0.00 b | 512.0 ± 1.41 b | 278.0 ± 5.66 b | 619.5 ± 4.95 b |

| (3.8 + 0.2)% PS + BH | 65.3 ± 0.00 ab | 712.0 ± 8.49 a | 92.5 ± 0.71 d | 704.5 ± 6.36 b | 549.0 ± 2.83 b | 529.5 ± 7.78 b | 118.0 ± 11.31 a | 657.5 ± 0.71 c |

| 4% WPS | 70.7 ± 3.89 b | 943.5 ± 55.86 b | 73.4 ± 0.07 a | 412.0 ± 15.56 a | 349.0 ± 14.14 a | 309.5 ± 10.6 a | 594.5 ± 41.72 c | 345.0 ± 12.73 a |

| (3.8 + 0.2)% WPS + BH | 68.5 ± 0.14 ab | 903.5 ± 17.68 b | 74.5 ± 0.14 b | 433.5 ± 10.61 a | 357.0 ± 9.90 a | 311.5 ± 7.78 a | 546.5 ± 7.78 c | 341.5 ± 9.19 a |

| Sample | T0 (°C) | ηmax (BU) | Tηmax (°C) | η95°C (BU) | η95°Cafter min (BU) | ηmin (BU) | BD (BU) | η50°C (BU) |

|---|---|---|---|---|---|---|---|---|

| 5% PS | 62.9 ± 0.00 a | 1364.5 ± 36.06 c | 80.4 ± 0.78 b | 962.5 ± 12.02 b | 768.0 ± 7.07 b | 665.5 ± 4.95 b | 596.5 ± 28.99 b | 826.0 ± 7.07 b |

| (4.8 + 0.2)% PS + BH | 65.1 ± 0.07 b | 979.0 ± 69.3 a | 88.6 ± 0.14 c | 905.5 ± 68.59 b | 732.5 ± 60.1 b | 637.0 ± 36.8 b | 246.5 ± 9.19 a | 797.5 ± 50.2 b |

| 5% WPS | 67.6 ± 0.14 c | 1386.5 ± 0.71 c | 72.9 ± 0.14 a | 575.5 ± 3.54 a | 483.0 ± 5.66 a | 436.00 ± 1.41 a | 903.5 ± 6.36 d | 494.5 ± 0.71 a |

| (4.8 + 0.2)% WPS + BH | 67.9 ± 0.00 d | 1300.0 ± 11.3 b | 72.95 ± 0.07 a | 552.0 ± 4.24 a | 462.00 ± 5.66 a | 412.5 ± 4.95 a | 838.0 ± 5.66 c | 461.5 ± 9.19 a |

| Sample | Ostwald–de Waele Model | Areas of the Hysteresis Loops (Pa/s) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| K (Pa∙sn) | n (-) | R2 | A | T | A+T | ||||

| 0–300 s−1 | 300–0 s−1 | 0–300 s−1 | 300–0 s−1 | 0–300 s−1 | 300–0 s−1 | ||||

| 4% PS | 0.96 ± 0.21 b | 7.38 ± 0.43 c | 0.92 ± 0.04 c | 0.55 ± 0.01 c | 0.998 | 0.999 | 466.8 b | - | 466.8 b |

| (3.8 + 0.2)% PS + BH | 0.51 ± 0.08 a | 5.49 ± 0.12 a | 0.95 ± 0.03 c | 0.53 ± 0.01 b | 0.997 | 0.999 | 471.3 b | - | 471.3 b |

| 4% WPS | 2.06 ± 0.15 c | 6.89 ± 0.28 b | 0.69 ± 0.01 a | 0.46 ± 0.01 a | 0.987 | 0.999 | 172.3 a | 23.6 a | 195.9 a |

| (3.8 + 0.2)% WPS + BH | 1.07 ± 0.08 b | 5.53 ± 0.11 a | 0.77 ± 0.01 b | 0.47 ± 0.01 a | 0.980 | 0.999 | 187.2 a | 19.9 a | 207.1 a |

| Sample | Ostwald–de Waele Model | Areas of the Hysteresis Loops (Pa/s) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| K (Pa∙sn) | n (-) | R2 | A | T | A+T | ||||

| 0–300 s−1 | 300–0 s−1 | 0–300 s−1 | 300–0 s−1 | 0–300 s−1 | 300–0 s−1 | ||||

| 5% PS | 1.24 ± 0.07 a | 11.42 ± 0.23 b | 0.93 ± 0.11 a | 0.53 ± 0.01 b | 0.994 | 0.999 | 1180.9 c | - | 1180.9 c |

| (4.8 + 0.2)% PS + BH | 1.19 ± 0.14 b | 10.76 ± 0.33 b | 0.93 ± 0.08 a | 0.50 ± 0.00 c | 0.989 | 0.999 | 510.4 b | - | 510.4 b |

| 5% WPS | 2.01 ± 0.24 c | 7.58 ± 0.43 a | 0.81 ± 0.09 b | 0.44 ± 0.01 a | 0.985 | 0.999 | 382.9 a | 7.7 a | 390.6 a |

| (4.8 + 0.2)% WPS + BH | 1.03 ± 0.19 b | 7.26 ± 0.04 a | 0.86 ± 0.04 b | 0.47 ± 0.01 b | 0.977 | 0.999 | 280.6 a | 48.4 b | 329.0 a |

| Samples | Hardness (N) | ||

|---|---|---|---|

| H0 | H1 | H7 | |

| 4% PS | 0.40 ± 0.03 b | 2.26 ± 0.21 c | 2.88 ± 0.42 c |

| (3.8 + 0.2)% PS + BH | 0.43 ± 0.02 b | 1.54 ± 0.02 b | 2.08 ± 0.05 c |

| 4% WPS | 0.13 ± 0.01 a | 0.18 ± 0.05 a | 0.61 ± 0.12 b |

| (3.8 + 0.2)% WPS + BH | 0.17 ± 0.01 a | 0.18 ± 0.01 a | 0.27 ± 0.04 a |

| Samples | Hardness (N) | ||

|---|---|---|---|

| H0 | H1 | H7 | |

| 5% PS | 0.60 ± 0.00 b | 3.85 ± 0.44 c | 3.63 ± 0.25 c |

| (4.8 + 0.2)% PS + BH | 0.42 ± 0.00 b | 2.15 ± 0.05 b | 2.14 ± 0.05 b |

| 5% WPS | 0.18 ± 0.01 a | 0.18 ± 0.01 a | 0.94 ± 0.02 a |

| (4.8 + 0.2)%WPS + BH | 0.19 ± 0.03 a | 0.24 ± 0,04 a | 0.85 ± 0.04 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamczyk, G.; Krystyjan, M.; Witczak, M. The Impact of Fiber from Buckwheat Hulls Waste on the Pasting, Rheological and Textural Properties of Normal and Waxy Potato Starch Gels. Polymers 2021, 13, 4148. https://doi.org/10.3390/polym13234148

Adamczyk G, Krystyjan M, Witczak M. The Impact of Fiber from Buckwheat Hulls Waste on the Pasting, Rheological and Textural Properties of Normal and Waxy Potato Starch Gels. Polymers. 2021; 13(23):4148. https://doi.org/10.3390/polym13234148

Chicago/Turabian StyleAdamczyk, Greta, Magdalena Krystyjan, and Mariusz Witczak. 2021. "The Impact of Fiber from Buckwheat Hulls Waste on the Pasting, Rheological and Textural Properties of Normal and Waxy Potato Starch Gels" Polymers 13, no. 23: 4148. https://doi.org/10.3390/polym13234148

APA StyleAdamczyk, G., Krystyjan, M., & Witczak, M. (2021). The Impact of Fiber from Buckwheat Hulls Waste on the Pasting, Rheological and Textural Properties of Normal and Waxy Potato Starch Gels. Polymers, 13(23), 4148. https://doi.org/10.3390/polym13234148