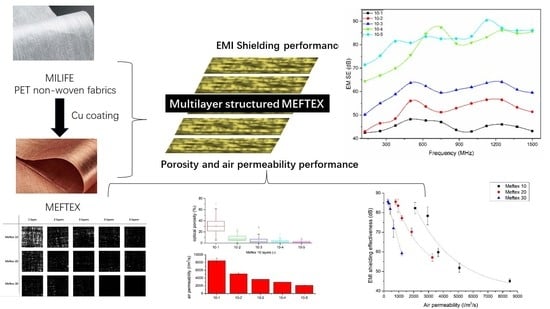

Ultrathin Multilayer Textile Structure with Enhanced EMI Shielding and Air-Permeable Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Geometric and Properties

2.2. Metal Coating

2.3. Characterization

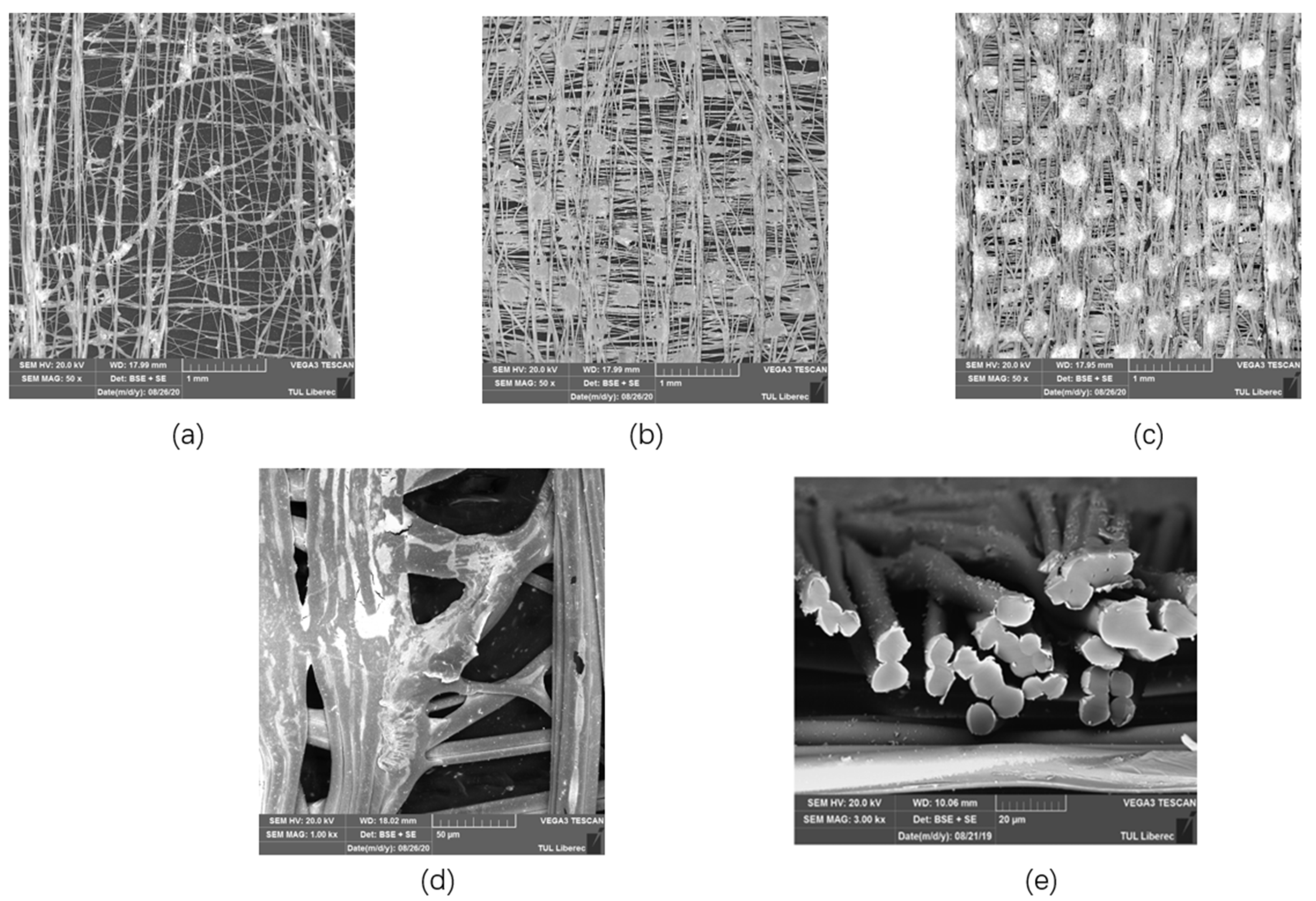

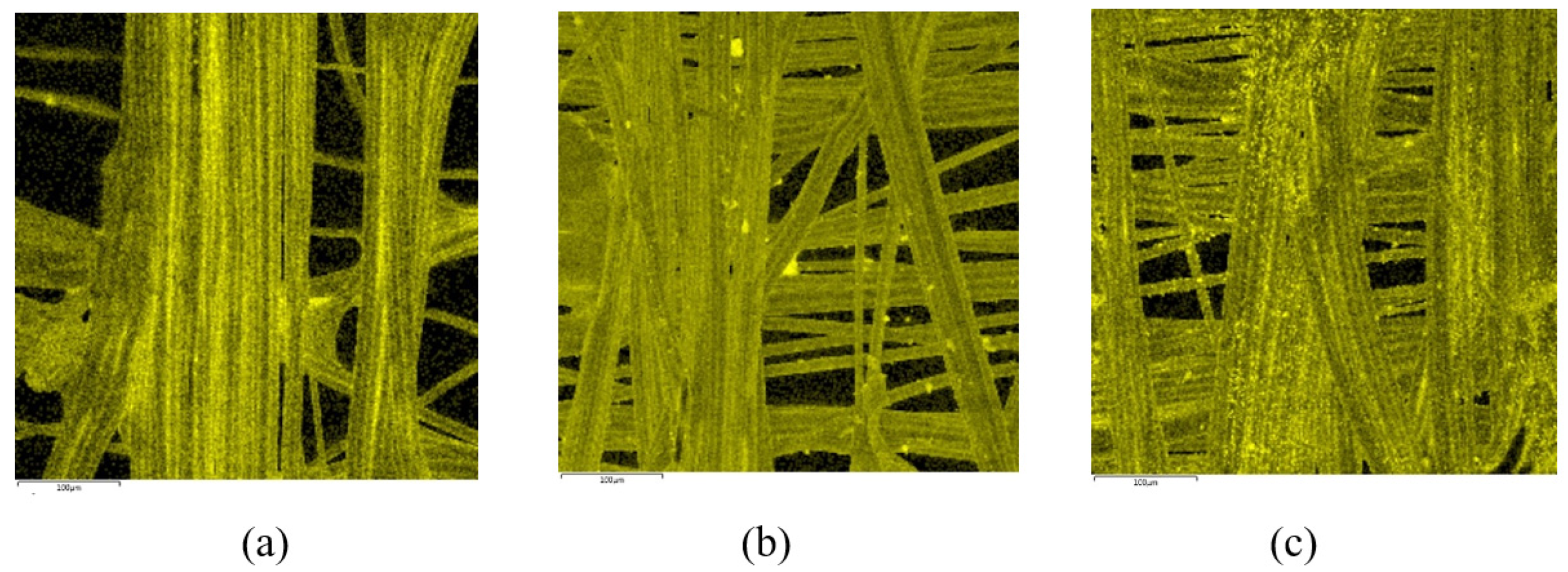

2.3.1. SEM and EDX

2.3.2. EMSE Measurements

2.3.3. Volume Resistivity Test

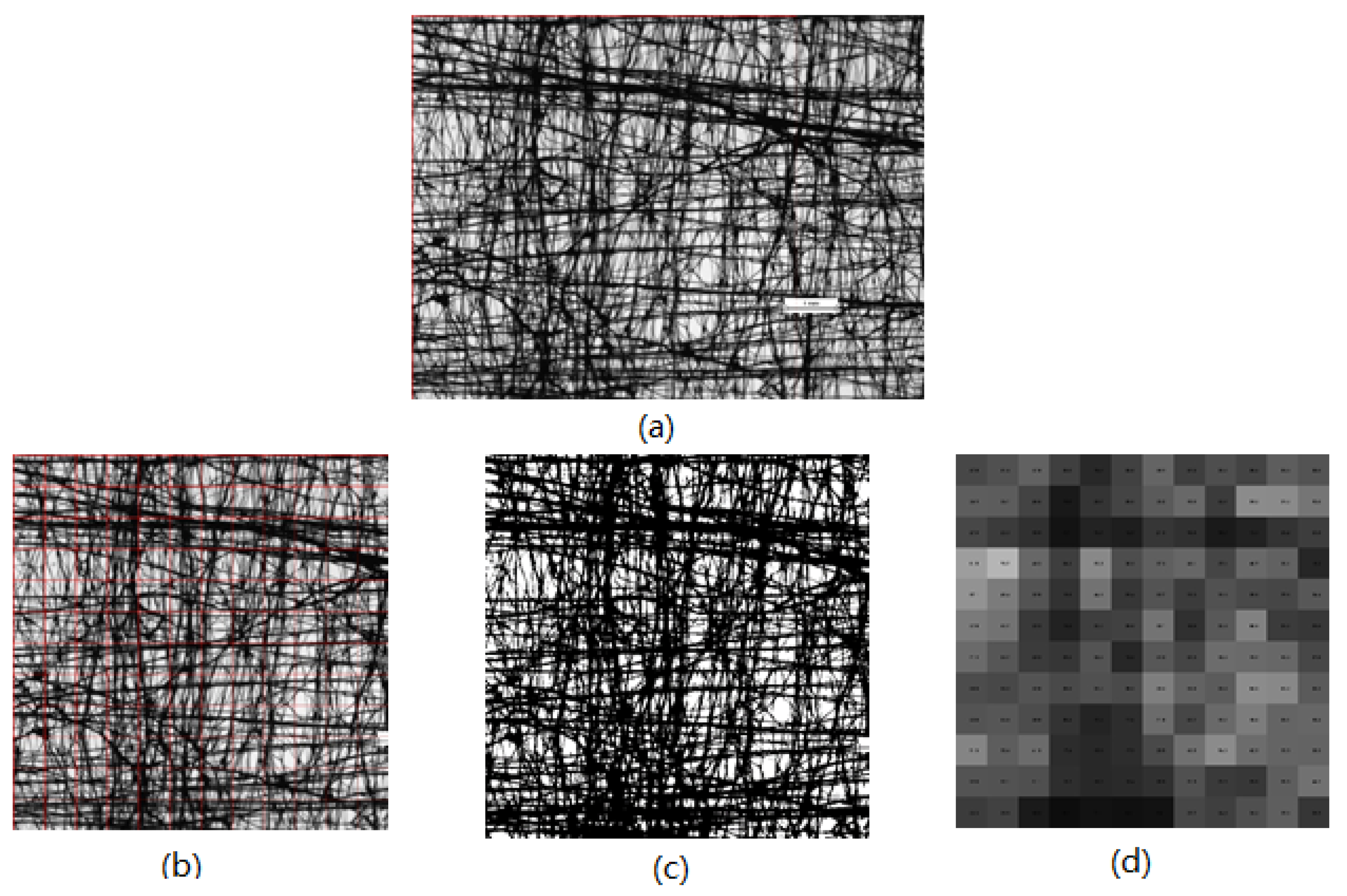

2.3.4. Porosity (Optical) Analysis and Air Permeability

3. Results and Discussion

3.1. Morphology Analysis and Elemental Analysis

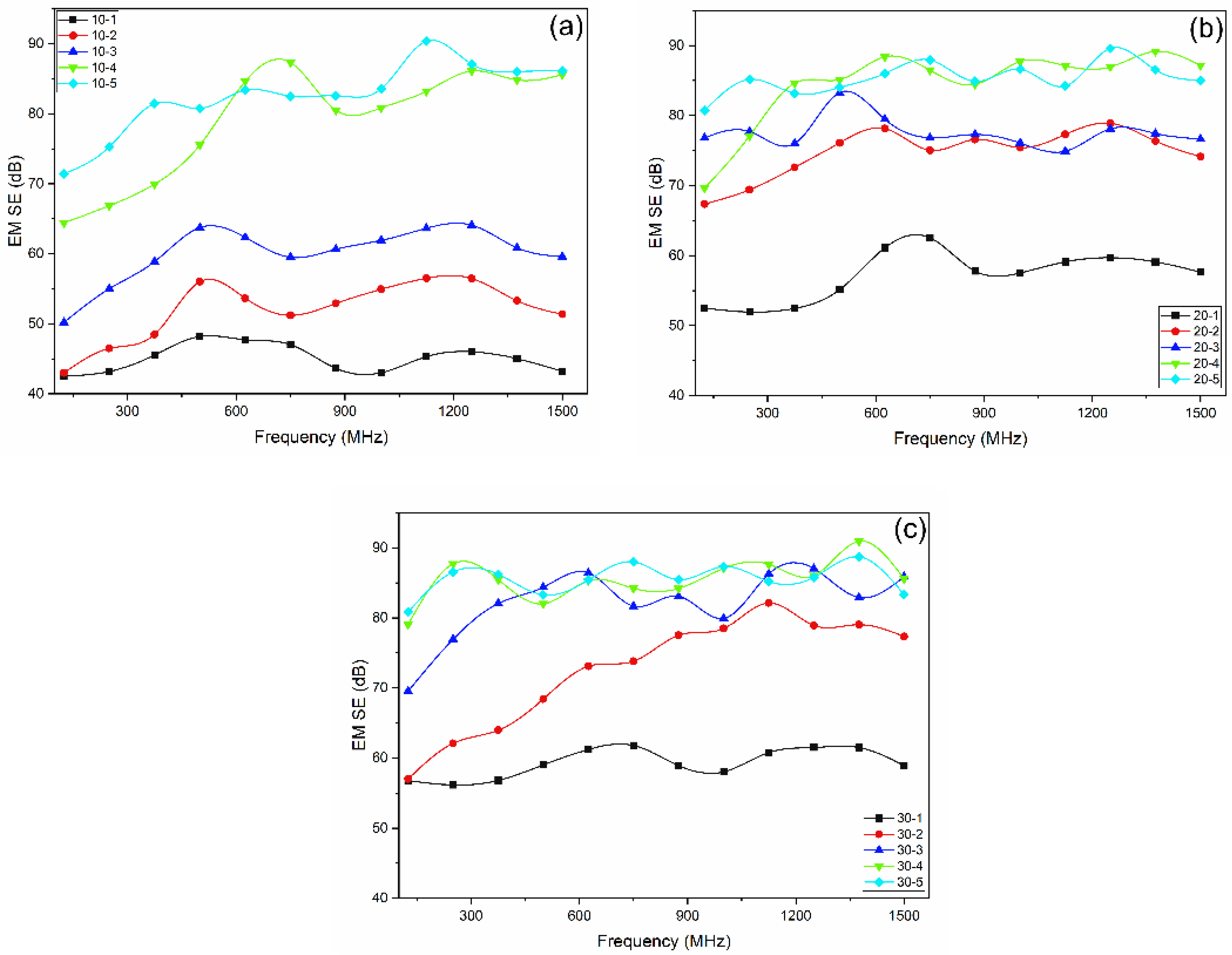

3.2. Single Layer EMSE of MEFTEX

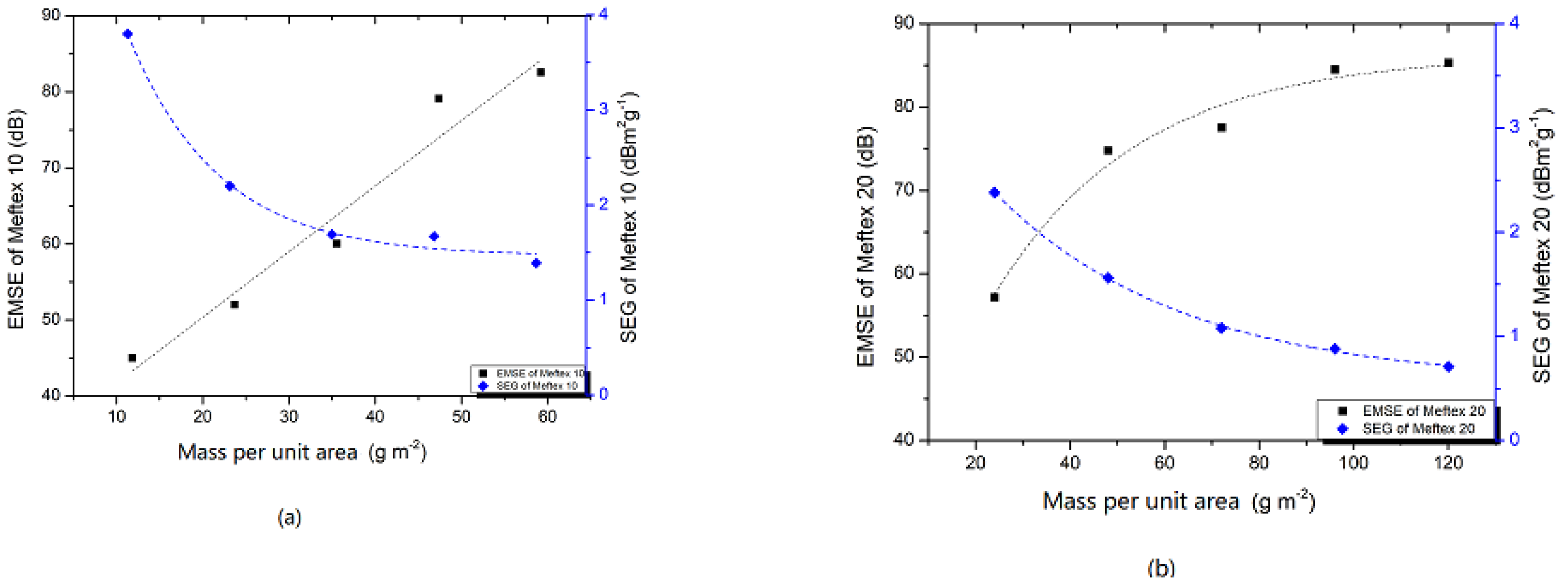

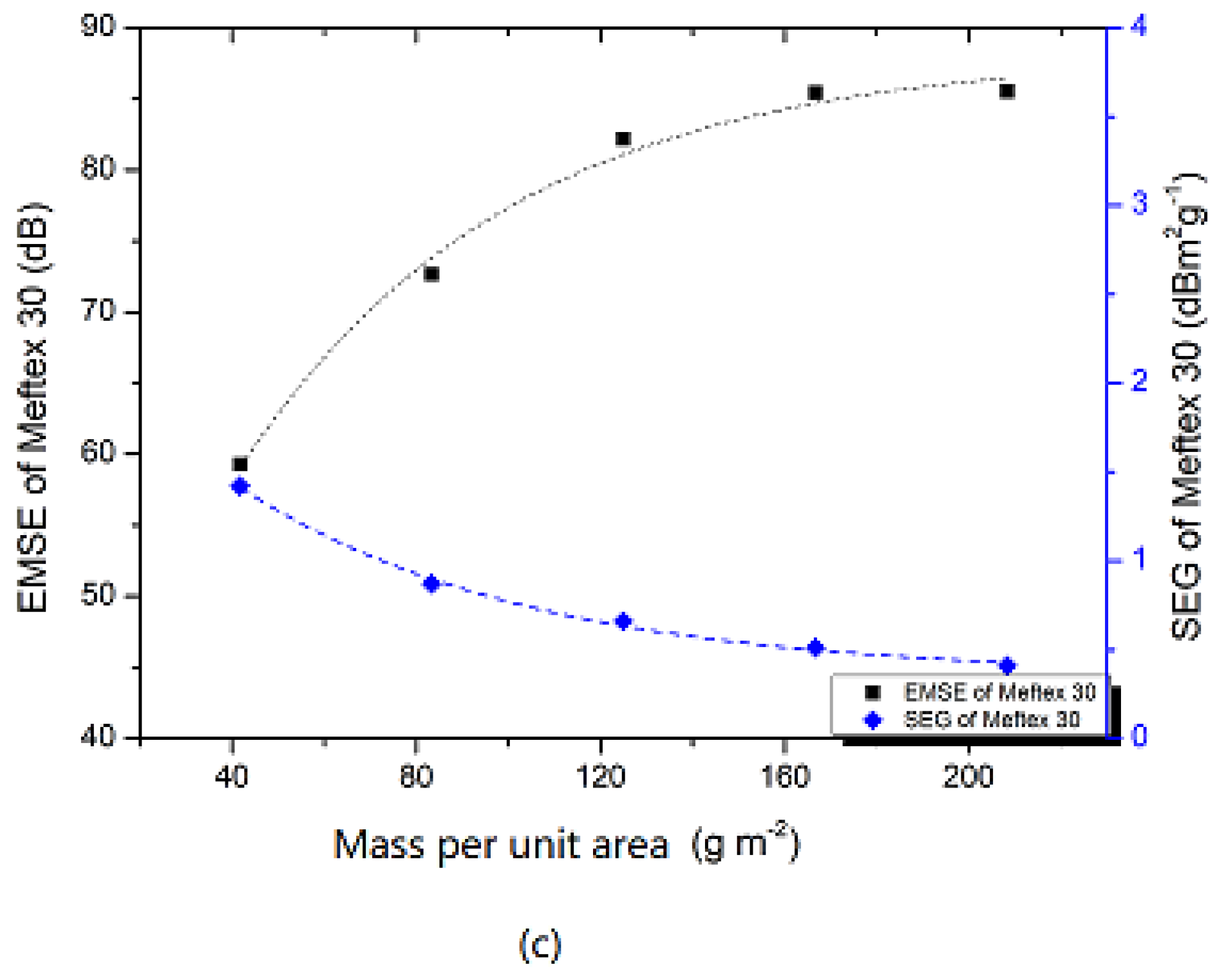

3.3. Multilayer MEFTEX SE and SEG

3.4. Air Permeability Is Influenced by the Multilayer Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Type | Grade | Shielding Effectiveness (dB) | Classification | Percentage of Electromagnetic Shielding (%) |

|---|---|---|---|---|

| Class I Professional use | AAAAA | SE > 60 dB | Excellent | ES > 99.9999% |

| AAAA | 60 dB ≥ SE > 50 dB | Very good | 99.9999% ≥ ES > 99.999% | |

| AAA | 50 dB ≥ SE > 40 dB | Good | 99.999% ≥ ES > 99.99% | |

| AA | 40 dB ≥ SE > 30 dB | Moderate | 99.99% ≥ ES > 99.9% | |

| A | 30 dB ≥ SE > 20 dB | Fair | 99.9% ≥ ES > 99.0% | |

| Class II General use | AAAAA | SE > 30 dB | Excellent | ES > 99.9% |

References

- Garvanova, M.; Garvanov, I.; Borissova, D. The influence of electromagnetic fields on human brain. In Proceedings of the 2020 21st International Symposium on Electrical Apparatus & Technologies (SIELA), Bourgas, Bulgaria, 6 June 2020. [Google Scholar] [CrossRef]

- Rahimpour, S.; Kiyani, M.; Hodges, S.E.; Turner, D.A. Deep brain stimulation and electromagnetic interference. Clin. Neurol. Neurosurg. 2021, 203, 106577. [Google Scholar] [CrossRef]

- Chen, H.C.; Lee, K.C.; Lin, J.H.; Koch, M. Fabrication of conductive woven fabric and analysis of electromagnetic shielding via measurement and empirical equation. J. Mater. Process. Technol. 2007, 184, 124–130. [Google Scholar] [CrossRef]

- Chung, D.D.L. Materials for electromagnetic interference shielding. Mater. Chem. Phys. 2020, 255, 123587. [Google Scholar] [CrossRef]

- Rathebe, P.; Weyers, C.; Raphela, F. A health and safety model for occupational exposure to radiofrequency fields and static magnetic fields from 1.5 and 3 T MRI scanners. Health Technol. 2019, 10, 39–50. [Google Scholar] [CrossRef]

- Cao, W.; Ma, C.; Tan, S.; Ma, M.; Wan, P.; Chen, F. Ultrathin and Flexible CNTs/MXene/Cellulose Nanofibrils Composite Paper for Electromagnetic Interference Shielding. Nano-Micro. Lett. 2019, 11, 1. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roh, J.-S.; Chi, Y.-S.; Kang, T.J.; Nam, S.-W. Electromagnetic Shielding Effectiveness of Multifunctional Metal Composite Fabrics. Text. Res. J. 2008, 78, 825–835. [Google Scholar] [CrossRef]

- Geetha, S.; Satheesh Kumar, K.K.; Rao, C.R.K.; Vijayan, M.; Trivedi, D.C. EMI shielding: Methods and materials—A review. J. Appl. Polym. Sci. 2009, 112, 2073–2086. [Google Scholar] [CrossRef]

- Militký, J.; Šafářová, V. Numerical and experimental study of the shielding effectiveness of hybrid fabrics. Vlak. A Text. 2012, 19, 21–27. [Google Scholar]

- Zeng, W.; Tao, X.M.; Chen, S.; Shang, S.; Chan, H.L.W.; Choy, S.H. Highly durable all-fiber nanogenerator for mechanical energy harvesting. Energy Environ. Sci. 2013, 6, 2631–2638. [Google Scholar] [CrossRef]

- Moazzenchi, B.; Montazer, M. Click electroless plating of nickel nanoparticles on polyester fabric: Electrical conductivity, magnetic and EMI shielding properties. Colloids Surfaces A Physicochem. Eng. Asp. 2019, 571, 110–124. [Google Scholar] [CrossRef]

- Rajavel, K.; Hu, Y.; Zhu, P.; Sun, R.; Wong, C. MXene/metal oxides-Ag ternary nanostructures for electromagnetic interference shielding. Chem. Eng. J. 2020, 399, 125791. [Google Scholar] [CrossRef]

- Mantecca, P.; Kasemets, K.; Deokar, A.; Perelshtein, I.; Gedanken, A.; Bahk, Y.K.; Kianfar, B.; Wang, J. Airborne Nanoparticle Release and Toxicological Risk from Metal-Oxide-Coated Textiles: Toward a Multiscale Safe-by-Design Approach. Environ. Sci. Technol. 2017, 51, 9305–9317. [Google Scholar] [CrossRef]

- Xiao, H.; Shi, M.W.; Wang, Q.; Liu, Q. The electromagnetic shielding and reflective properties of electromagnetic textiles with pores, planar periodic units and space structures. Text. Res. J. 2014, 84, 1679–1691. [Google Scholar] [CrossRef]

- Palanisamy, S.; Tunakova, V.; Hu, S.; Yang, T.; Kremenakova, D.; Venkataraman, M.; Petru, M.; Militky, J. Electromagnetic Interference Shielding of Metal Coated Ultrathin Nonwoven Fabrics and Their Factorial Design. Polymers 2021, 13, 484. [Google Scholar] [CrossRef] [PubMed]

- ASTM International ASTM D 4935. Standard Test Method for Measuring the Electromagnetic Shielding Effectiveness of Planar Materials; ASTM International: West Conshohocken, PA, USA, 1999; Volume 10, pp. 1–10. [Google Scholar] [CrossRef]

- ASTM D3776/D3776M-20. Standard Test Methods for Mass Per Unit Area (Weight) of Fabric. Available online: https://www.astm.org/Standards/D3776.htm (accessed on 11 March 2021).

- ASTM D5729-97(2004)e1. Standard Test Method for Thickness of Nonwoven Fabrics (Withdrawn 2008). Available online: https://www.astm.org/Standards/D5729.htm (accessed on 11 March 2021).

- Marciniak, K.; Grabowska, K.E.; Stempień, Z.; Stempień, S.; Luiza, I.; Bel, C.-W. Shielding of electromagnetic radiation by multilayer textile sets. Text. Res. J. 2019, 89, 948–958. [Google Scholar] [CrossRef]

- ASTM D257-14. Standard Test Methods for DC Resistance or Conductance of Insulating Materials. Standard 2012, 1, 1–18. [Google Scholar] [CrossRef]

- ISO. ISO 9237: 1995 Textiles—Determination of the Permeability of Fabrics to Air; ISO: Geneva, Switzerland, 1995. [Google Scholar]

- Militký, J.; Křemenáková, D.; Venkataraman, M.; Večerník, J. Exceptional Electromagnetic Shielding Properties of Lightweight and Porous Multifunctional Layers. ACS Appl. Electron. Mater. 2020, 2, 1138–1144. [Google Scholar] [CrossRef]

- Tezel, S.; Kavuşturan, Y.; Vandenbosch, G.A.; Volski, V. Comparison of electromagnetic shielding effectiveness of conductive single jersey fabrics with coaxial transmission line and free space measurement techniques. Text. Res. J. 2014, 84, 461–476. [Google Scholar] [CrossRef]

- Schelkunoff, S.A. Transmission theory of plane electromagnetic waves. Proc. Inst. Radio Eng. 1937, 25, 1457–1492. [Google Scholar] [CrossRef] [Green Version]

- Perumalraj, R.; Dasaradan, B.S.; Anbarasu, R.; Arokiaraj, P.; Harish, S.L. Electromagnetic shielding effectiveness of copper core-woven fabrics. J. Text. Inst. 2009, 100, 512–524. [Google Scholar] [CrossRef]

- Tong, X.C. Advanced Materials and Design for Electromagnetic Interference Shielding; CRC Press: Boca Raton, FL, USA, 2009; p. 324. [Google Scholar]

- Shinagawa, S.; Kumagai, Y.; Urabe, K. Conductive papers containing metallized polyester fibers for electromagnetic interference shielding. J. Porous Mater. 1999, 6, 185–190. [Google Scholar] [CrossRef]

- White, D.R.J. A Handbook Series on Electromagnetic Interference and Compatibility: Electrical Noise and EMI Specifications; Interference Control Technologies, Inc.: Germantown, MD, USA, 1971. [Google Scholar]

- Palanisamy, S.; Tunakova, V.; Militky, J. Fiber-based structures for electromagnetic shielding—Comparison of different materials and textile structures. Text. Res. J. 2018, 88, 1992–2012. [Google Scholar] [CrossRef]

- Liu, J.L. Electromagnetic Wave Shielding and Absorbing Materials, 1st ed.; Xing, T., Ed.; Beijing Chemical Industry Press: Beijing, China, 2006; ISBN 978-7-5025-9341-4. [Google Scholar]

| Sample Number | Sample Details | Thickness (1 Layer) (mm) | Mass Per Unit Area (1 Layer) (g/m2) | Deposit of Cu Per Unit Area (g/m2) |

|---|---|---|---|---|

| MEFTEX 10 | 100% PET nonwoven | 0.042 ± 0.11 | 11.84 | 1.84 |

| MEFTEX 20 | 100% PET nonwoven | 0.074 ± 0.008 | 24.01 | 4.01 |

| MEFTEX 30 | 100% PET nonwoven | 0.112 ± 0.01 | 41.67 | 11.67 |

| Sample Number | Element | Wt [%] | Standard Deviation | Element | Wt [%] | Standard Deviation |

|---|---|---|---|---|---|---|

| Meftex 10 | Cu | 75.87 | 2.12 | C | 16.32 | 1.03 |

| O | 7.28 | 0.87 | Ti | 0.36 | 0.08 | |

| Ca | 0.16 | 0.32 | ||||

| Meftex 20 | Cu | 45.2 | 1.21 | C | 33.49 | 1.09 |

| O | 20.18 | 0.38 | Ti | 0.47 | 0.04 | |

| Ca | 0.67 | 0.15 | ||||

| Meftex 30 | Cu | 63.52 | 2.01 | C | 23.94 | 0.9 |

| O | 11.94 | 1.08 | Ti | 0.35 | 0.02 | |

| Ca | 0.24 | 0.14 |

| Sample Number | Thickness [mm] | Volume Electrical Resistivity [Ω·mm] | The Experiment Result of EM SE on 1.5 GHz [dB] | SER [dB] | SEA [dB] | SEM [dB] | The Theoretical Calculated Result of EM SE on 1.5 GHz [dB] |

|---|---|---|---|---|---|---|---|

| MEFTEX 10 | 0.042 | 5022.78 | 45.2 | 36.79 | 8.41 | −1.47 | 51.58 |

| MEFTEX 20 | 0.074 | 1676.40 | 57.64 | 44.71 | 12.93 | - | 56.34 |

| MEFTEX 30 | 0.112 | 991.50 | 58.91 | 43.76 | 15.14 | - | 58.62 |

| Sample Code * | Volume Electrical Resistivity [Ω·mm] | Sample Code * | Volume Electrical Resistivity [Ω·mm] | Sample Code * | Volume Electrical Resistivity [Ω·mm] |

|---|---|---|---|---|---|

| 10-1 | 5022.78 | 20-1 | 1676.40 | 30-1 | 991.50 |

| 10-2 | 1640.93 | 20-2 | 663.40 | 30-2 | 430.43 |

| 10-3 | 963.80 | 20-3 | 433.67 | 30-3 | 297.05 |

| 10-4 | 126.70 | 20-4 | 325.73 | 30-4 | 248.19 |

| 10-5 | 60.04 | 20-5 | 249.12 | 30-5 | 204.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Wang, D.; Periyasamy, A.P.; Kremenakova, D.; Militky, J.; Tunak, M. Ultrathin Multilayer Textile Structure with Enhanced EMI Shielding and Air-Permeable Properties. Polymers 2021, 13, 4176. https://doi.org/10.3390/polym13234176

Hu S, Wang D, Periyasamy AP, Kremenakova D, Militky J, Tunak M. Ultrathin Multilayer Textile Structure with Enhanced EMI Shielding and Air-Permeable Properties. Polymers. 2021; 13(23):4176. https://doi.org/10.3390/polym13234176

Chicago/Turabian StyleHu, Shi, Dan Wang, Aravin Prince Periyasamy, Dana Kremenakova, Jiri Militky, and Maros Tunak. 2021. "Ultrathin Multilayer Textile Structure with Enhanced EMI Shielding and Air-Permeable Properties" Polymers 13, no. 23: 4176. https://doi.org/10.3390/polym13234176

APA StyleHu, S., Wang, D., Periyasamy, A. P., Kremenakova, D., Militky, J., & Tunak, M. (2021). Ultrathin Multilayer Textile Structure with Enhanced EMI Shielding and Air-Permeable Properties. Polymers, 13(23), 4176. https://doi.org/10.3390/polym13234176