A Cost Modelling System for Recycling Carbon Fiber-Reinforced Composites

Abstract

1. Introduction

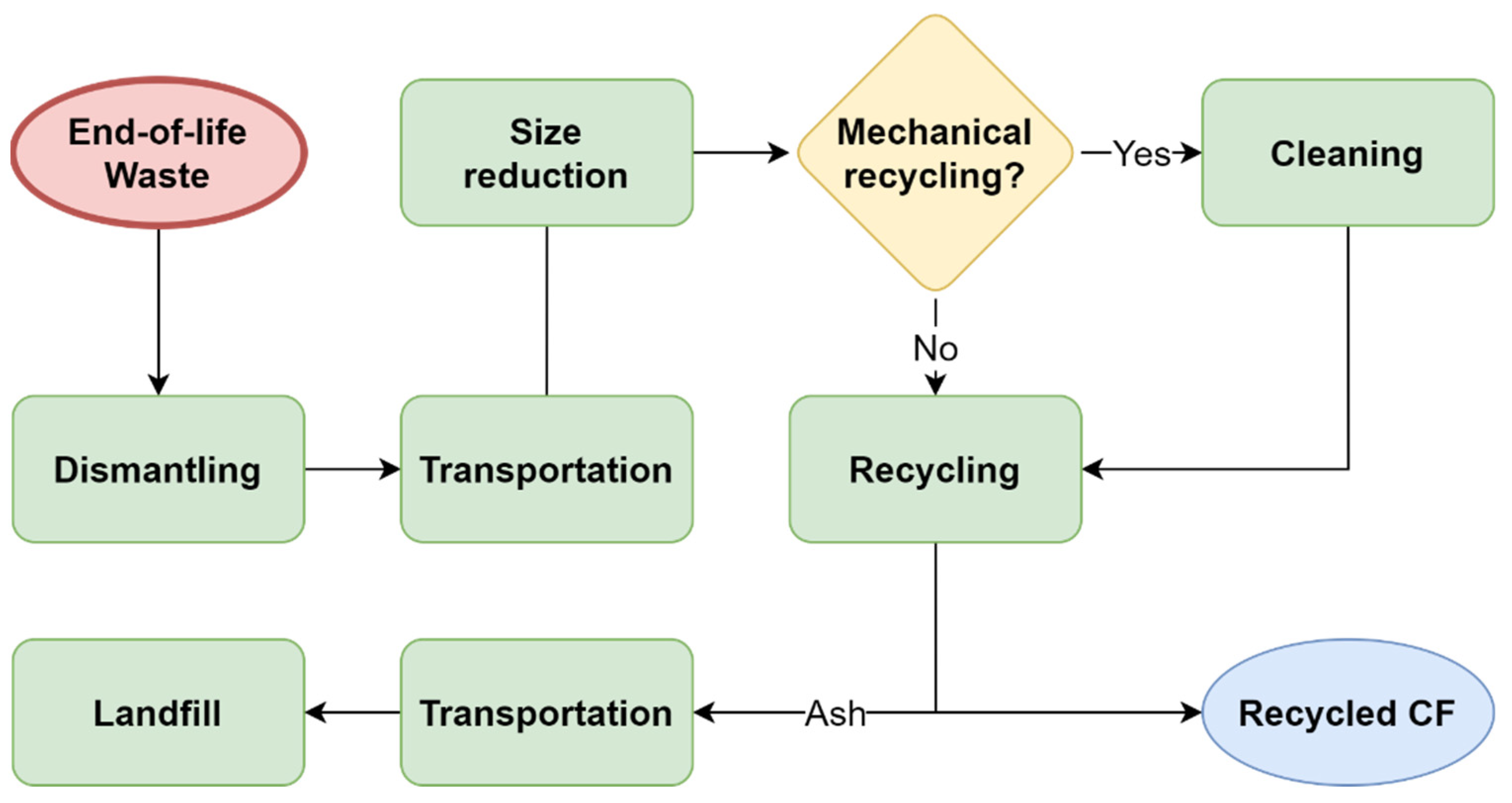

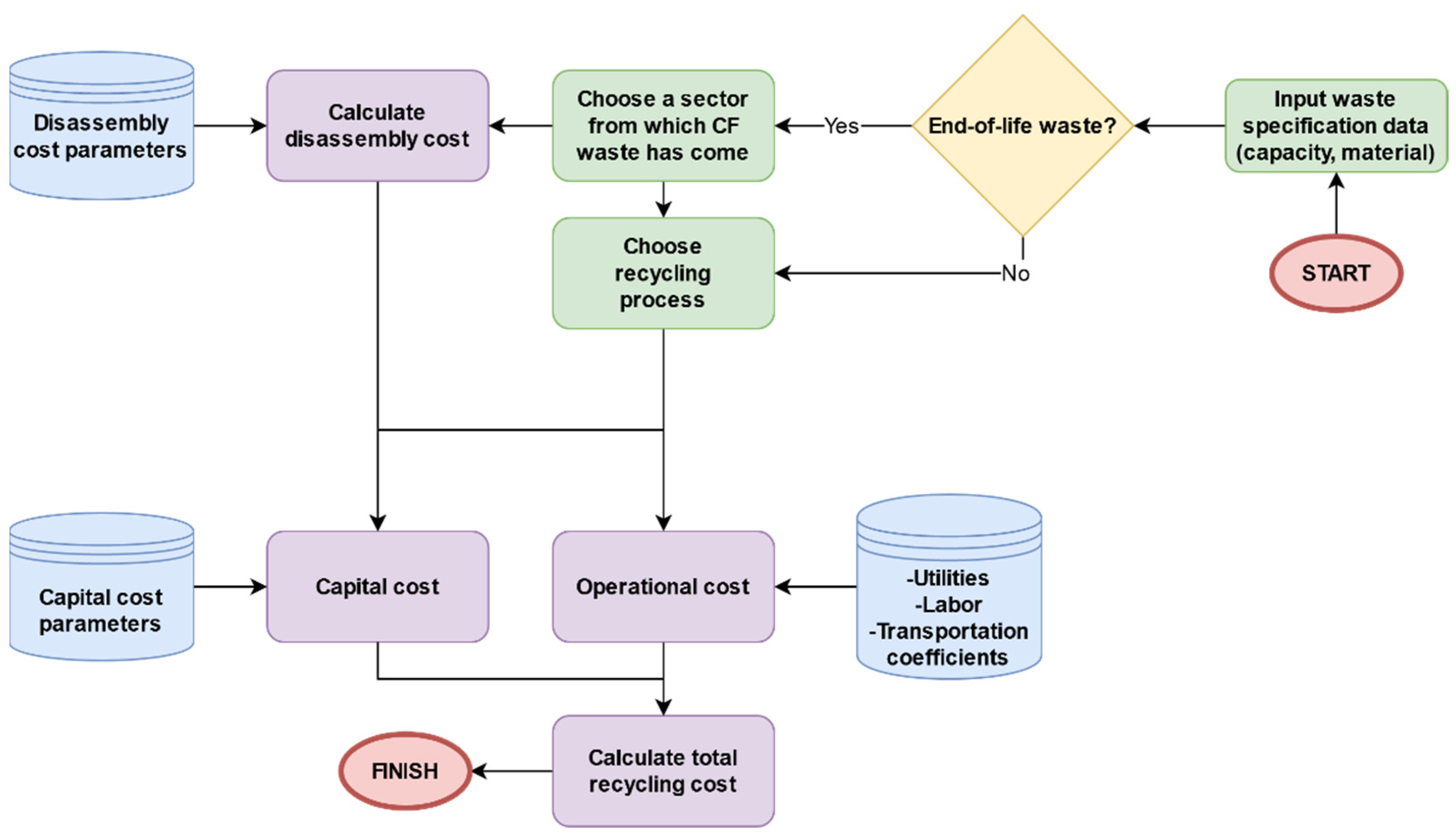

2. Development of a Cost Model for Recycling CFRPs

- Utilities cost per 1 kg of waste (UC). This represents the sum of all utility expenses for the chosen method.

- An average unit cost per 1 kg of waste recovered (UCW). For this purpose, a break-even value at zero net present value (NPV) is calculated. A discount rate of 10% is assumed for calculations.

- The main parameter assessed is the average unit cost per 1 kg of fiber recovered (UCF). This parameter allows determining the break-even price of selling the recovered product.

- —total capital costs

- —tax rate (in this study, it is assumed to be zero (0))

- —depreciation (linear)

- —discount rate (10%)

2.1. Cost Elements

2.1.1. Capital Cost

- —capital costs of a plant for a capacity ton per year

- —reference capital costs of a plant from the literature

- —indicated capacity in the literature

- —CEPCI index in 2019

- —CEPCI index for the year of a reference plant

2.1.2. Pyrolysis

2.1.3. Mechanical Recycling

- E—energy consumption in MJ/kg

- —capacity at kg/hour

2.1.4. Fluidized Bed Process

2.1.5. Supercritical Water

2.1.6. Transportation Cost

2.1.7. Disassembly Cost

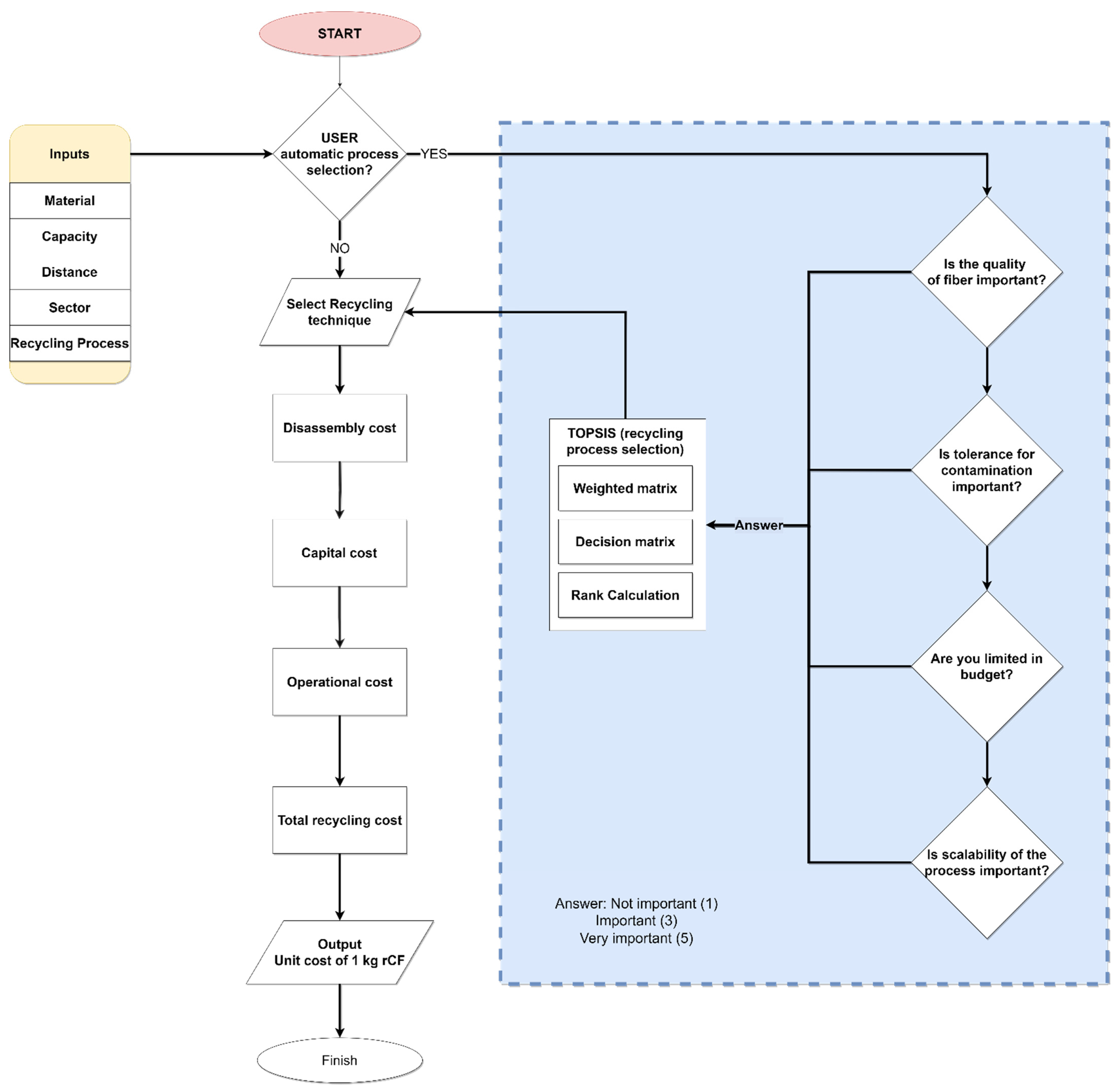

3. Proposed Modeling Approach of Carbon Fiber (CF) Recycling Costs

3.1. The Overall Architecture of the Proposed System

3.2. Optimization Module

Criteria Quantification

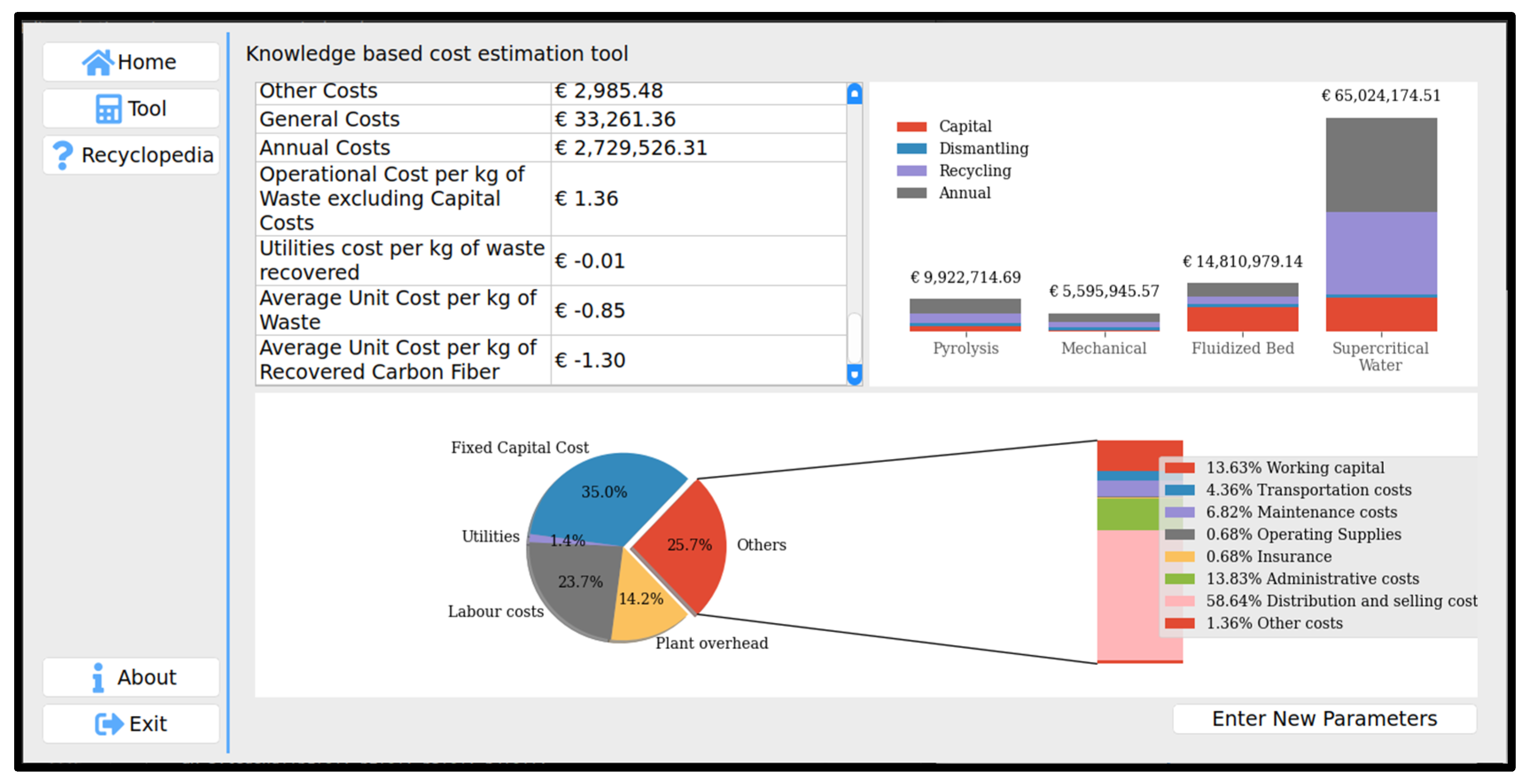

3.3. System Implementation and Validation

3.3.1. System Validation: Case Study

3.3.2. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oliveux, G.; Dandy, L.O.; Leeke, G. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Research and Markets. Global $7.8 Billion Carbon Fiber Market Forecast to 2029—Potential Opportunities in New Applications Such as Geo-Polymer and Medical Composites. 2019. Available online: https://www.prnewswire.com/news-releases/global-7-8-billion-carbon-fiber-market-forecast-to-2029---potential-opportunities-in-new-applications-such-as-geo-polymer-and-medical-composites-300931306.html (accessed on 15 June 2020).

- Bledzki, A.; Seidlitz, H.; Goracy, K.; Urbaniak, M.; Rösch, J. Recycling of carbon fiber reinforced composite polymers—Review—Part 1: Volume of production, recycling technologies, legislative aspects. Polymers 2021, 13, 300. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Boeing 787 dreamliner. Struct. Health Monit. Aerosp. Compos. 2016, 1, 1–23. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef]

- Wong, K.; Rudd, C.; Pickering, S.; Liu, X. Composites recycling solutions for the aviation industry. Sci. China Ser. E Technol. Sci. 2017, 60, 1291–1300. [Google Scholar] [CrossRef]

- Heida, L. Boom Time for Carbon Fibre Recycling—Recycle International. 2016. Available online: http://terratechmedia.com/boomtime/ (accessed on 25 October 2020).

- European Council. Directive 200053EC of the European parliament and of the council on end-of life vehicles. Off. J. Eur. Communities 2020, L269, 1–15. [Google Scholar]

- Sukanto, H.; Raharjo, W.W.; Ariawan, D.; Triyono, J. Carbon fibers recovery from CFRP recycling process and their usage: A review. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Malang, Indonesia, 7–9 October 2021; Volume 1034, p. 012087. [Google Scholar] [CrossRef]

- Sauer, M.; Kühnel, M. AVK Composites Market Report 2018—Market Developments, Trends, Outlooks and Challenges. 2018. Available online: https://pdfs.semanticscholar.org/6ce8/06e60748f0751b7743c69104a40d5a201784.pdf?_ga=2.173122405.736430940.1590357216-2086283048.1586625318 (accessed on 15 October 2021).

- Pickering, S.; Kelly, R.; Kennerley, J.; Rudd, C.; Fenwick, N. A fluidised-bed process for the recovery of glass fibres from scrap thermoset composites. Compos. Sci. Technol. 2000, 60, 509–523. [Google Scholar] [CrossRef]

- Shehab, E.; Meiirbekov, A.; Sarfraz, S. Challenges in cost modelling of recycling carbon fiber composites. In Proceedings of the 27th International Conference on Transdisciplinary Engineering (TE2020), Warsaw, Poland, 6–10 July 2020. [Google Scholar] [CrossRef]

- Boeing. Boeing, ELG Carbon Fibre Find New Life for Airplane Structure Material in Groundbreaking Partnership. Available online: https://boeing.mediaroom.com/2018-12-05-Boeing-ELG-Carbon-Fibre-find-new-life-for-airplane-structure-material-in-groundbreaking-partnership (accessed on 14 November 2020).

- Meng, F. Environmental and Cost Analysis of Carbon Fibre Composites Recycling. Ph.D. Thesis, University of Nottingham, Notthingham, UK, 2017. Available online: http://eprints.nottingham.ac.uk/46518/1/PhD%20thesis_Fanran%20Meng_4201331_after%20correction_final.pdf (accessed on 20 October 2020).

- Giorgini, L.; Benelli, T.; Brancolini, G.; Mazzocchetti, L. Recycling of carbon fiber reinforced composite waste to close their life cycle in a cradle-to-cradle approach. Curr. Opin. Green Sustain. Chem. 2020, 26, 100368. [Google Scholar] [CrossRef]

- Fernández, A.; Lopes, C.S.; González, C.; López, F.A. Characterization of carbon fibers recovered by pyrolysis of cured prepregs and their reuse in new composites. In Recent Developments in the Field of Carbon Fibers [Preprint]; IntechOpen Press: London, UK, 2018. [Google Scholar] [CrossRef]

- Mativenga, P.; Shuaib, N.A.; Howarth, J.; Pestalozzi, F.; Woidasky, J. High voltage fragmentation and mechanical recycling of glass fibre thermoset composite. CIRP Ann. 2016, 65, 45–48. [Google Scholar] [CrossRef]

- Hagnell, M.; Akermo, M. The economic and mechanical potential of closed loop material usage and recycling of fibre-reinforced composite materials. J. Clean. Prod. 2019, 223, 957–968. [Google Scholar] [CrossRef]

- Jiang, G.; Pickering, S.; Rudd, C.D. WO 2012/172357 Al: Recycling Fibres from Polymer Composites. 2012. Available online: https://patentimages.storage.googleapis.com/a6/ae/30/070e9c43b90f33/WO2012172357A1.pdf.27 (accessed on 11 November 2020).

- ELG Carbon Fibre International Gmbh. Pyrolysis System and Method of Recovering Carbon Fibres From Carbon-Fibre-Containing Plastics. 2018. Available online: https://patents.justia.com/patent/10899042.9 (accessed on 22 November 2020).

- Sun, H.; Guo, G.; Memon, S.A.; Xu, W.; Zhang, Q.; Zhu, J.-H.; Xing, F. Recycling of carbon fibers from carbon fiber reinforced polymer using electrochemical method. Compos. Part A Appl. Sci. Manuf. 2015, 78, 10–17. [Google Scholar] [CrossRef]

- Li, X.; Bai, R.; McKechnie, J. Environmental and financial performance of mechanical recycling of carbon fibre reinforced polymers and comparison with conventional disposal routes. J. Clean. Prod. 2016, 127, 451–460. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Pickering, S.J. An assessment of financial viability of recycled carbon fibre in automotive applications. Compos. Part A Appl. Sci. Manuf. 2018, 109, 207–220. [Google Scholar] [CrossRef]

- Dong, P.A.V.; Azzaro-Pantel, C.; Cadene, A.-L. Economic and environmental assessment of recovery and disposal pathways for CFRP waste management. Resour. Conserv. Recycl. 2018, 133, 63–75. [Google Scholar] [CrossRef]

- Xu, Y.; Sanchez, J.F.; Njuguna, J. Cost modelling to support optimised selection of End-of-Life options for automotive components. Int. J. Adv. Manuf. Technol. 2014, 73, 399–407. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Yerro, X.; Jean-Marie, A.; Vo Dong, P.A.; Azzaro-Pantel, C. Modelling pyrolysis process for CFRP recycling in a closed-loop supply chain approach. In Proceedings of the 27th European Symposium on Computer Aided Process Engineering, Barcelona, Spain, 1–5 October 2017; pp. 2029–2034. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Greco, S.; Tosto, C.; Cicala, G. LCA and LCC of a chemical recycling process of waste CF-thermoset composites for the production of novel CF-thermoplastic composites. Open loop and closed loop scenarios. J. Clean. Prod. 2021, 304, 127158. [Google Scholar] [CrossRef]

- Hoefer, M. Wind Turbine Blade Recycling: An Economic Decision Framework—Technical Report; Iowa State Univerity Press: Ames, IA, USA, 2015. [Google Scholar] [CrossRef]

- Whitesides, R.W. Process Equipment Cost Estimating by Ratio and Proportion. 2012. Available online: https://www.pdhonline.com/courses/g127/g127content.pdf. (accessed on 18 November 2020).

- Eurostat. Electricity Prices for Non-Household Consumers—Bi-Annual Data (From 2007 Onwards). 2020. Available online: https://ec.europa.eu/eurostat/web/products-datasets/-/nrg_pc_205%0A (accessed on 16 October 2020).

- Eurostat. Natural Gas Prices for Non-Household Consumers. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Natural_gas_price_statistics#Natural_gas_prices_for_non-household_consumers (accessed on 16 October 2020).

- Eurostat. Labour Costs Annual Data—NACE Rev. 2. 2019. Available online: https://ec.europa.eu/eurostat/databrowser/view/tps00173/default/table?lang=en (accessed on 16 October 2020).

- Knight, C.C. Recycling High-Performance Carbon Fiber Reinforced Polymer Composites Using Sub- Critical and Supercritical Water; Florida State University: Tallahassee, FL, USA, 2013; Available online: https://fsu.digital.flvc.org/islandora/object/fsu%3A183778/datastream/PDF/view (accessed on 20 July 2020).

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.-H. Current status of carbon fibre and carbon fibre composites recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Humphreys, K. Project and Cost Engineer’s Handbook, 4th ed.; Routledge: Abingdon, UK, 2005; Available online: http://ndl.ethernet.edu.et/bitstream/123456789/90353/19/4_6003704340903102029.pdf (accessed on 15 June 2020).

- Dysert, L.R. Sharpen Your Cost Estimating Skills. Chem. Eng. 2003, 45, 22–30. Available online: https://www.costengineering.eu/images/papers/Sharpen_Your_Cost_Estimating_Skills.pdf (accessed on 2 October 2020).

- Jenkins, S. Chemical Engineering Plant Cost Index Annual Average. 2019. Available online: https://www.chemengonline.com/2019-chemical-engineering-plant-cost-index-annual-average/ (accessed on 5 November 2020).

- Jenkins, S. Economic Indicators: CEPCI. 2015. Available online: https://www.chemengonline.com/economic-indicators-cepci/?printmode=1 (accessed on 1 November 2020).

- Halliwell, S. End of Life Options for Composite Waste, National Composites Network. Best Practice Guide. 2006. Available online: https://compositesuk.co.uk/system/files/documents/endoflifeoptions.pdf (accessed on 25 October 2020).

- Vatavuk, W.M. Updating the CE Plant Cost Index. Chem. Eng. 2002, 109, 62–70. Available online: https://www.chemengonline.com/Assets/File/CEPCI_2002.pdf (accessed on 28 October 2020).

- Laleh, A.P. Cost Estimation. 2020. Available online: http://www.salvasolution.com/costing.htm (accessed on 5 October 2020).

- Gopalraj, S.K.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 433. [Google Scholar] [CrossRef]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life cycle energy analysis of fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Pickering, S. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Palmer, J.A.T. Mechanical Recycling of Automotive Composites for Use as Reinforcement in Thermoset Composites; University of Exeter Press: Exeter, UK, 2009. [Google Scholar]

- Siwertel, B. Hammer Mill (Dry Materials). 2020. Available online: https://www.bruks-siwertell.com/grinding-milling/hammer-mill-dry-materials (accessed on 15 November 2020).

- Job, S. Composite Recycling: Summary of Research and Development. Available online: https://compositesuk.co.uk/system/files/documents/Composite%20Recycling.pdf (accessed on 10 November 2020).

- Howarth, J.; Mareddy, S.S.; Mativenga, P. Energy intensity and environmental analysis of mechanical recycling of carbon fibre composite. J. Clean. Prod. 2014, 81, 46–50. [Google Scholar] [CrossRef]

- Zheng, Y.; Shen, Z.; Ma, S.; Cai, C.; Zhao, X.; Xing, Y. A novel approach to recycling of glass fibers from nonmetal materials of waste printed circuit boards. J. Hazard. Mater. 2009, 170, 978–982. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Mckechnie, J.; Pickering, S. Towards a circular economy for end-of-life carbon fibre composite materials via fluidised bed process. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017; pp. 20–25. [Google Scholar]

- Yuyan, L.; Guohua, S.; Linghui, M. Recycling of carbon fibre reinforced composites using water in subcritical conditions. Mater. Sci. Eng. A 2009, 520, 179–183. [Google Scholar] [CrossRef]

- Kim, Y.-O.; Kim, S.Y.; Park, M.; Yang, B.; Kim, J.; Jung, Y.C. Application of supercritical water for green recycling of epoxy-based carbon fiber reinforced plastic. Compos. Sci. Technol. 2019, 173, 66–72. [Google Scholar] [CrossRef]

- Kritzer, P. Corrosion in high-temperature and supercritical water and aqueous solutions: A review. J. Supercrit. Fluids 2004, 29, 1–29. [Google Scholar] [CrossRef]

- Suncor Energy Products. Suncor Energy Adelaide Wind Power Project Decommissioning Plan Report. 2012. Available online: https://www.suncor.com/-/media/project/suncor/files/about-us/adelaide-wind-power-project/2012-11-adelaide-wind-power-project-decommissioning-plan-report-en.pdf?la=en-ca&modified=20210121181324&hash=76F5FD80B6B0BD64D3ED0920C60F61B5C980AE56 (accessed on 10 November 2020).

- Cacciottolo, M. BBC News—How Do You Recycle a Jumbo Jet? 2010. Available online: http://news.bbc.co.uk/2/hi/uk_news/magazine/8542482.stm (accessed on 14 October 2020).

- Rahman, S.; Perera, S.; Odeyinka, H.; Bi, Y. A conceptual knowledge-based cost model for optimizing the selection of materials and technology for building design. In Proceedings of the 24th Annual Conference, Cardiff, UK, 1–3 September 2008; pp. 217–225. [Google Scholar]

- Lee, H.C.; Chang, C. Comparative analysis of MCDM methods for ranking renewable energy sources in Taiwan. In Renewable and Sustainable Energy Reviews; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; Volume 92, pp. 883–896. [Google Scholar] [CrossRef]

- Delvere, I.; Iltina, M.; Shanbayev, M.; Abildayeva, A.; Kuzhamberdieva, S.; Blumberga, D. Evaluation of polymer matrix composite waste recycling methods. Environ. Clim. Technol. 2019, 23, 168–187. [Google Scholar] [CrossRef]

- Rossum, G.; Drake, F.L. An Introduction to Python: Release 2.2.2; Network Theory Limited: Bristol, UK, 2003. [Google Scholar]

- Pypi.org. Project Description. Available online: https://pypi.org/project/PyQt5/. (accessed on 10 November 2020).

- Holmes, M. Recycled carbon fiber composites become a reality. Reinf. Plast. 2018, 62, 148–153. [Google Scholar] [CrossRef]

- Baker, D.A.; Rials, T.G. Recent advances in low-cost carbon fiber manufacture from lignin. J. Appl. Polym. Sci. 2013, 130, 713–728. [Google Scholar] [CrossRef]

- Shama, R.; Simha, T.G.A.; Rao, K.P.; Kumar, G.V.V.R. Carbon Composites Are Becoming Competitive and Cost Effective; Infosys Limited: Bengaluru, India, 2018; pp. 1–12. Available online: https://www.infosys.com/engineering-services/white-papers/Documents/carbon-composites-cost-effective.pdf. (accessed on 10 November 2020).

| Matrix Type | Market Size (bln USD) | Market Share | ||

|---|---|---|---|---|

| Hybrid | 1.2 | 5.2% | ||

| Metal Matrix | 0.82 | 3.5% | ||

| Ceramic matrix | 4.65 | 20.1% | ||

| Polymer matrix | Thermoplastic | 4.72 | 28.8% | 71.2% |

| Thermoset | 11.37 | 69.0% | ||

| Hybrid and Others | 0.36 | 2.2% | ||

| Cost Type | Estimate Calculation |

|---|---|

| Fixed capital costs (Cfc) | Capital investments |

| Working capital costs, (Cwc) | 10% of Cfc |

| Total capital costs | A sum of fixed and working capital costs |

| Dismantling costs | Based on a sector type |

| Recycling costs | |

| Direct | |

| Utilities | Based on a technique type |

| Labor costs | 4 operating staff members |

| Transportation costs | Based on a chosen distance |

| Maintenance costs | 5% of Cfc |

| Operating supplies | 10% of Maintenance costs |

| Indirect | |

| Plant overheads | 60% of Operating labor |

| Insurance | 0.5% of Cfc |

| Depreciation, D | 10% linear |

| General costs | |

| Administrative costs | 25% of plant overhead costs |

| Other costs | 1% of Cfc |

| Distribution and selling costs | 1% of all expenses |

| Technique | Capital Investment According to Literature | CEPCI Year | CEPCI Index | Adjusted Capital Costs in the Model |

|---|---|---|---|---|

| Pyrolysis | EUR 10,000,000 for a capacity of avg. 50,000 tons per year [24] | 2012 | 585 [39] | EUR 10,384,615 for a capacity of avg. 50,000 tons per year |

| Mechanical | EUR 200,000 for a capacity of 4000 tons per year (only shredder) [40] | 1990 | 350 [41] | EUR 452,514 for a capacity of 4000 tons per year (a hammer miller included) |

| Fluidized bed | EUR 4,100,000 for a capacity of 1000 tons per year [23] | 2015 | 558 [23] | EUR 4,483,058 for a capacity of 1000 tons per year |

| Supercritical Water | EUR 5,770,000 for a capacity of 150 kg per hour [33] | 2013 | 567 [42] | EUR 6,178,874 for a capacity of 150 kg per hour |

| Utility Type | Cost per Unit |

|---|---|

| Electricity | EUR 0.0801 per kWh [30] |

| Natural gas | EUR 0.0308 per kWh (EUR 0.32 per m3) [31] |

| Cooling water | EUR 12.58 per 1000 kg [33] |

| Pure water | EUR 2.08 per kg [33] |

| IF | (Quality of recovered fibers is not important) | AND |

| (Scalability of the process is very important) | AND | |

| (Tolerance for contamination is very important) | AND | |

| (Capital cost amount is not important) | ||

| THEN | (The recycling process is pyrolysis) | |

| IF | (Quality of recovered fibers is not important) | AND |

| (Scalability of the process is very important) | AND | |

| (Tolerance for contamination is very important) | AND | |

| (Capital cost amount is very important) | ||

| THEN | (The recycling process is mechanical) | |

| IF | (Quality of recovered fibers is very important) | AND |

| (Scalability of the process is not important) | AND | |

| (Tolerance for contamination is very important) | AND | |

| (Capital cost amount is not important) | ||

| THEN | (The recycling process is solvolysis) |

| Recycling Methods | Quality of Recovered Fibers | Scalability and Technology Development Level | Tolerance for Contamination | Capital Costs |

|---|---|---|---|---|

| Mechanical recycling | 1 | 5 | 2 | 5 |

| Pyrolysis | 3 | 4 | 4 | 3 |

| Fluidized bed process | 3 | 3 | 5 | 2 |

| Supercritical water | 5 | 2 | 4 | 1 |

| Input Parameters | Value |

| Weight | 1300.0 tons/year |

| Distance | 0.0 km |

| Type | Prepregs (manufacturing waste) |

| Recycling process | Pyrolysis |

| Working capital coefficient | 10% |

| Distribution and selling costs | 5% |

| Number of people | 60 |

| Hourly wage | EUR 31.4 |

| Output | |

| Average unit cost per kg of waste | EUR 3.90 |

| Average unit cost per kg of recovered carbon fiber | EUR 6.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shehab, E.; Meiirbekov, A.; Amantayeva, A.; Suleimen, A.; Tokbolat, S.; Sarfraz, S. A Cost Modelling System for Recycling Carbon Fiber-Reinforced Composites. Polymers 2021, 13, 4208. https://doi.org/10.3390/polym13234208

Shehab E, Meiirbekov A, Amantayeva A, Suleimen A, Tokbolat S, Sarfraz S. A Cost Modelling System for Recycling Carbon Fiber-Reinforced Composites. Polymers. 2021; 13(23):4208. https://doi.org/10.3390/polym13234208

Chicago/Turabian StyleShehab, Essam, Arshyn Meiirbekov, Akniyet Amantayeva, Aidar Suleimen, Serik Tokbolat, and Shoaib Sarfraz. 2021. "A Cost Modelling System for Recycling Carbon Fiber-Reinforced Composites" Polymers 13, no. 23: 4208. https://doi.org/10.3390/polym13234208

APA StyleShehab, E., Meiirbekov, A., Amantayeva, A., Suleimen, A., Tokbolat, S., & Sarfraz, S. (2021). A Cost Modelling System for Recycling Carbon Fiber-Reinforced Composites. Polymers, 13(23), 4208. https://doi.org/10.3390/polym13234208