Fire Behavior of Wood-Based Composite Materials

Abstract

:1. Introduction

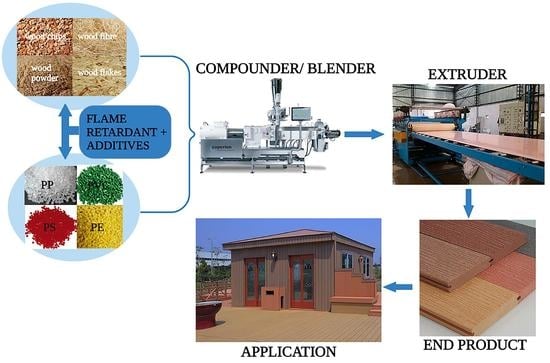

2. Wood Polymer Composites (WPC) and Manufacturing

2.1. Polypropylene (PP) Polymer Composites

2.2. Polystyrene Composites

2.3. Polyethylene Composites

2.4. Polyvinyl Chloride (PVC)

2.5. Polylactic Acid (PLA) Composites

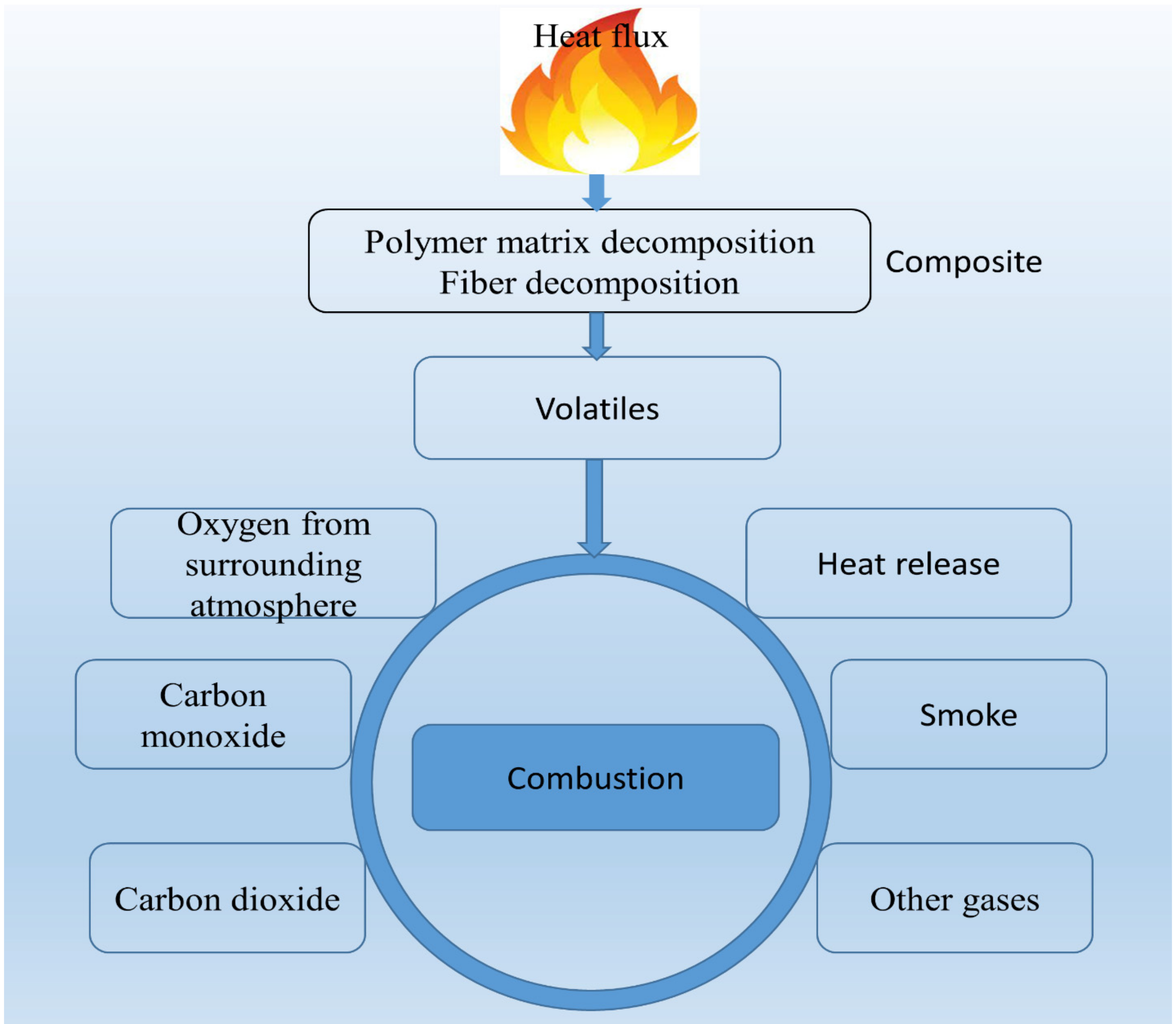

3. Fire Behavior of Wood-Based Composites

4. Properties That Make Wood Suitable as a Reinforcement in Composites

5. Effects of Fire Retardants on WPC Materials

5.1. Halogenated Flame Retardant (HFR)

5.2. Bromine-Based

5.3. Halogen-Free Flame Retardant (HFFR)

5.4. Nitrogen-Based

5.5. Phosphorus-Based

5.6. Boron-Based

5.7. Carbon-Based

5.8. Silicon-Based

5.9. Other Flame Retardant

6. Conclusions and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Goldhahn, C.; Cabane, E.; Chanana, M. Sustainability in wood materials science: An opinion about current material development techniques and the end of lifetime perspectives. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2021, 379, 20200339. [Google Scholar] [CrossRef] [PubMed]

- Trouy, M.C.; Triboulot, P. Materiau bois: Structure et caractéristiques. Technol. L’ingénieur Constr. Bois 2019, 253, 11–18. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Hermawan, D.; Sulastiningsih, I.M.; Basri, E.; Pari, G.; Pari, R.; Abdillah, I.B. Color Change and Physical-Mechanical Properties of Polystyrene-Impregnated Glulam from Three Tropical Fast-Growing Wood Species. Forests 2021, 12, 1420. [Google Scholar] [CrossRef]

- Mariana, M.; Alfatah, T.; Khalil, A.H.P.S.; Yahya, E.B.; Olaiya, N.; Nuryawan, A.; Mistar, E.; Abdullah, C.; Abdulmadjid, S.; Ismail, H.; et al. A current advancement on the role of lignin as sustainable reinforcement material in biopolymeric blends. J. Mater. Res. Technol. 2021, 15, 2287–2316. [Google Scholar] [CrossRef]

- Padinjakkara, A.; Thankappan, A.; Souza, F.G., Jr.; Thomas, S. (Eds.) Biopolymers and Biomaterials; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Wójcik, M. Reframing Wood Construction: Innovation in Architecture through Activating Material Properties with the Use of Digital Technologies. Ph.D. Thesis, The Oslo School of Architecture and Design, Oslo, Norway, 2020. [Google Scholar]

- Srikanth, M.; Asmatulu, R. Nanotechnology Safety in the Construction and Infrastructure Industries; Elsevier BV: Amsterdam, The Netherlands, 2013; pp. 99–113. [Google Scholar]

- Hansen, E. Responding to the Bioeconomy: Business Model Innovation in the Forest Sector. In Handbook of Sustainability in Additive Manufacturing; Springer: Singapore, 2016; pp. 227–248. [Google Scholar]

- Li, Y. Factors Affecting the Structural Integrity of Wood-Based Composites: Elevated Temperature and Adhesive Bonding. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2021; p. 24061. [Google Scholar]

- Robert, J.; Bush, P.A.A. Changes and Trends in the Pallet Industry: Alternative Materials and Industry Structure. Memphis. Hardwood Mark. Rep. 1998, LXXVI, 11–14. [Google Scholar]

- Upton, B.; Miner, R.; Spinney, M.; Heath, L.S. The greenhouse gas and energy impacts of using wood instead of alternatives in residential construction in the United States. Biomass Bioenergy 2008, 32, 1–10. [Google Scholar] [CrossRef]

- Sandberg, D. Additives in Wood Products—Today and Future Development. In Social Life Cycle Assessment; Springer: Singapore, 2016; pp. 105–172. [Google Scholar]

- Papadopoulos, A.N. Advances in Wood Composites. Polymers 2020, 12, 48. [Google Scholar] [CrossRef]

- Sun, X.; He, M.; Li, Z. Novel engineered wood and bamboo composites for structural applications: State-of-art of manufacturing technology and mechanical performance evaluation. Constr. Build. Mater. 2020, 249, 118751. [Google Scholar] [CrossRef]

- Jasmani, L.; Rusli, R.; Khadiran, T.; Jalil, R.; Adnan, S. Application of Nanotechnology in Wood-Based Products Industry: A Review. Nanoscale Res. Lett. 2020, 15, 207. [Google Scholar] [CrossRef]

- Reshmy, R.; Philip, E.; Paul, S.A.; Madhavan, A.; Sindhu, R.; Binod, P.; Pandey, A.; Sirohi, R. Nanocellulose-based products for sustainable applications-recent trends and possibilities. Rev. Environ. Sci. Bio/Technol. 2020, 19, 779–806. [Google Scholar] [CrossRef]

- Braghiroli, F.L.; Passarini, L. Valorization of Biomass Residues from Forest Operations and Wood Manufacturing Presents a Wide Range of Sustainable and Innovative Possibilities. Curr. For. Rep. 2020, 6, 172–183. [Google Scholar] [CrossRef]

- Kretschmann, D.E.; Winandy, J.; Clausen, C.; Wiemann, M.; Bergman, R.; Rowell, R.; Zerbe, J.; Beecher, J.; White, R.; McKeever, D.; et al. Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons, Inc.: New York, NY, USA, 2007; 60p. [Google Scholar]

- Stark, N.; Cai, Z. Chapter 11: Wood-based composite materials: Panel products, glued laminated timber, structural composite lumber, and wood–nonwood composites. In Wood Handbook—Wood as an Engineering Material; General Technical Report FPL-GTR-282; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2021; 29p. [Google Scholar]

- Qian, C.; Fan, W.; Yang, G.; Han, L.; Xing, B.; Lv, X. Influence of crumb rubber particle size and SBS structure on properties of CR/SBS composite modified asphalt. Constr. Build. Mater. 2020, 235, 117517. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. Thermal degradation study of waste polyethylene terephthalate (PET) under inert and oxidative environments. Thermochim. Acta 2019, 679, 178340. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact behaviour of hybrid composites for structural applications: A review. Compos. Part B Eng. 2018, 133, 112–121. [Google Scholar] [CrossRef]

- Lin, J.; Wang, L.; Liu, L.; Lu, K.; Li, G.; Yang, X. Two-stage interface enhancement of aramid fiber composites: Establishment of hierarchical interphase with waterborne polyurethane sizing and oxazolidone-containing epoxy matrix. Compos. Sci. Technol. 2020, 193, 108114. [Google Scholar] [CrossRef]

- Daoud, H.; EL Mahi, A.; Rebière, J.-L.; Taktak, M.; Haddar, M. Characterization of the vibrational behaviour of flax fibre reinforced composites with an interleaved natural viscoelastic layer. Appl. Acoust. 2017, 128, 23–31. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Chandrasekar, M.; Jawaid, M.; Rajini, N.; Alothman, O.Y.; Siengchin, S. Evaluation of mechanical and free vibration properties of the pineapple leaf fibre reinforced polyester composites. Constr. Build. Mater. 2019, 195, 423–431. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M. A review on thermomechanical properties of polymers and fibers reinforced polymer composites. J. Ind. Eng. Chem. 2018, 67, 1–11. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Eskandari, P.; Abousalman-Rezvani, Z.; Roghani-Mamaqani, H.; Salami-Kalajahi, M.; Mardani, H. Polymer grafting on graphene layers by controlled radical polymerization. Adv. Colloid Interface Sci. 2019, 273, 102021. [Google Scholar] [CrossRef]

- Flizikowski, J. (Ed.) Technology and Energy Sources Monitoring: Control, Efficiency, and Optimization: Control, Efficiency, and Optimization; IGI Global: Hershey, PA, USA, 2012. [Google Scholar]

- Shagwira, H.; Mwema, F.M. Advances in animal/plant–plastic composites: Preparation, characterization and applications. In Plant and Animal Based Composites; Walter de Gruyter GmbH: Berlin, Germany, 2021; pp. 25–38. [Google Scholar] [CrossRef]

- Chun, K.S.; Subramaniam, V.; Yeng, C.M.; Meng, P.M.; Ratnam, C.T.; Yeow, T.K.; How, C.K. Wood plastic composites made from post-used polystyrene foam and agricultural waste. J. Thermoplast. Compos. Mater. 2019, 32, 1455–1466. [Google Scholar] [CrossRef]

- Azwa, Z.; Yousif, B.; Manalo, A.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef] [Green Version]

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Haque, M. Property Improvements of Wood and Wood-Plastic Composites. In Wood Polymer Composites; Springer: Singapore, 2021; pp. 67–92. [Google Scholar]

- Wirawan, R.; Zainudin, E.S.; Sapuan, S.M. Mechanical properties of natural fibre reinforced PVC composites: A review. Sains Malaysiana 2009, 38, 531–535. [Google Scholar]

- Martins, G.; Antunes, F.; Mateus, A.; Malça, C. Optimization of a Wood Plastic Composite for Architectural Applications. Procedia Manuf. 2017, 12, 203–220. [Google Scholar] [CrossRef]

- Baek, Y.-M.; Shin, P.-S.; Kim, J.-H.; Park, H.-S.; DeVries, K.L.; Park, J.-M. Thermal transfer, interfacial, and mechanical properties of carbon fiber/polycarbonate-CNT composites using infrared thermography. Polym. Test. 2019, 81, 106247. [Google Scholar] [CrossRef]

- Vogt, D. Hürth Nova-Institut für Ökologie und Innovation. Studie” Wood-Plastic-Composites”-Holz-Kunststoff-Verbundwerkstoffe. Landwirtschaftsverl; Nova-Institut: Hürth, Germany, 1994. [Google Scholar]

- Moreno, D.D.P.; Saron, C. Low-density polyethylene waste/recycled wood composites. Compos. Struct. 2017, 176, 1152–1157. [Google Scholar] [CrossRef]

- Kim, J.K.; Pal, K. Recent Advances in the Processing of Wood-Plastic Composites; Springer: Berlin, Germany, 2010; pp. 23–25. [Google Scholar]

- Gardner, J.D.; Han, Y.; Wang, L. Wood-plastic composite technology. Curr. For. Rep. 2015, 1, 13–150. [Google Scholar] [CrossRef] [Green Version]

- WPC Machines & Equipment, WPC Pellets and Additives. Composites Decking Lumber. 2012. Available online: Wpc-composite-decking.blogspot.com (accessed on 8 July 2021).

- Clemons, C. Wood-plastic composites in the United States: The interfacing of two industries. For. Prod. J. 2002, 52, 10–18. [Google Scholar]

- Matuana, L.; Stark, N. The use of wood fibers as reinforcements in composites. In Biofiber Reinforcements in Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 648–688. [Google Scholar]

- Larsson, P.; Simonson, R. A study of strength, hardness and deformation of acetylated Scandinavian softwoods. Holz Roh Werkst. 1994, 52, 83–86. [Google Scholar] [CrossRef]

- Stark, N. Influence of Moisture Absorption on Mechanical Properties of Wood Flour-Polypropylene Composites. J. Thermoplast. Compos. Mater. 2001, 14, 421–432. [Google Scholar] [CrossRef]

- Oksman, K.; Sain, M. Wood-Polymer Composites; Woodhead Publ. Ltd.: Cambridge, UK, 2008. [Google Scholar]

- Oksman, K.; Skrifvars, M.O.V.; Selin, J.-F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Agro-residue reinforced high-density polyethylene composites: Fiber characterization and analysis of composite properties. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1445–1454. [Google Scholar] [CrossRef]

- Park, J.-M.; Quang, S.T.; Hwang, B.-S.; DeVries, K.L. Interfacial evaluation of modified Jute and Hemp fibers/polypropylene (PP)-maleic anhydride polypropylene copolymers (PP-MAPP) composites using micromechanical technique and nondestructive acoustic emission. Compos. Sci. Technol. 2006, 66, 2686–2699. [Google Scholar] [CrossRef]

- Al-Malaika, S.; Axtell, F.; Rothon, R.; Gilbert, M. Additives for Plastics. In Brydson’s Plastics Materials; Butterworth-Heinemann: Oxford, UK, 2017; pp. 127–168. [Google Scholar]

- Spear, M.J.; Eder, A.; Carus, M. Wood polymer composites. In Wood Composites; Woodhead Publishing: Sawston, UK, 2015; pp. 195–249. [Google Scholar]

- Suethao, S.; Shah, D.U.; Smitthipong, W. Recent Progress in Processing Functionally Graded Polymer Foams. Materials 2020, 13, 4060. [Google Scholar] [CrossRef] [PubMed]

- Pearson, R.G. Polymer Foams; Chapman & Hall: New York, NY, USA, 1990. [Google Scholar]

- Mendoza-Cedeno, S.; Kweon, M.; Newby, S.; Shivokhin, M.; Pehlert, G.; Lee, P. Improved Cell Morphology and Surface Roughness in High-Temperature Foam Injection Molding Using a Long-Chain Branched Polypropylene. Polymers 2021, 13, 2404. [Google Scholar] [CrossRef]

- Shalbafan, A. Investigation of Foam Materials to Be Used in Lightweight Wood-Based Composites. Ph.D. Thesis, Staats- und Universitätsbibliothek Hamburg Carl von Ossietzky, Hamburg, Germany, 2013. [Google Scholar]

- Hammiche, D.; Bourmaud, A.; Boukerrou, A.; Djidjelli, H.; Grohens, Y. Number of processing cycle effect on the properties of the composites based on alfa fiber. J. Thermoplast. Compos. Mater. 2016, 29, 1176–1193. [Google Scholar] [CrossRef]

- Din, R. Wood Polymer Composites: Their Properties and Applications. Master’s Thesis, Univeristy of Wales, Bangor, Wales, 1989; pp. 60–63. [Google Scholar]

- Rowell, R.M.; Konkol, P. Treatments that enhance physical properties of wood. Treat. Enhanc. Phys. Prop. Wood 1987, 55, 12. [Google Scholar] [CrossRef] [Green Version]

- Schaudy, R.; Proksch, E. Wood-plastic combinations with high dimensional stability. Ind. Eng. Chem. Prod. Res. Dev. 1982, 21, 369–375. [Google Scholar] [CrossRef]

- Schneider, M.; Witt, A. History of Wood Polymer Composite Commercialization. Forest Products J. 2004, 54, 19–24. [Google Scholar]

- Stolf, D.O.; Lahr, F.A.R. Wood-polymer composite: Physical and mechanical properties of some wood species impregnated with styrene and methyl methacrylate. Mater. Res. 2004, 7, 611–617. [Google Scholar] [CrossRef] [Green Version]

- Persenaire, O.; Alexandre, M.; Degée, P.; Dubois, P. End-grained wood polyurethane composites, 2a: Dimensional stability and mechanical properties. Macromol. Mater. Eng. 2004, 289, 903–909. [Google Scholar] [CrossRef]

- Gwon, J.G.; Lee, S.Y.; Chun, S.J.; Doh, G.H.; Kim, J.H. Effects of chemical treatments of hybrid fillers on the physical and thermal properties of wood plastic composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1491–1497. [Google Scholar] [CrossRef]

- Ellis, W.D. Wood-Polymer Composites: Review of Processes and Properties. Mol. Cryst. Liq. Cryst. Sci. Technol. Sect. A Mol. Cryst. Liq. Cryst. 2000, 353, 75–84. [Google Scholar] [CrossRef]

- Shubhra, Q.T.H.; Alam, A.K.M.M.; Quaiyyum, M.A. Mechanical properties of polypropylene composites. J. Thermoplast. Compos. Mater. 2013, 26, 362–391. [Google Scholar] [CrossRef]

- Koerner, G.R.; Koerner, R.M. Polymeric Geomembrane Components in Landfill Liners; Elsevier BV: Amsterdam, The Netherlands, 2018; pp. 313–341. [Google Scholar]

- Maier, C.; Calafut, T. Applications. In Polypropylene; Elsevier BV: Amsterdam, The Netherlands, 1998; pp. 87–107. [Google Scholar]

- Sobczak, L.; Lang, R.W.; Haider, A. Polypropylene composites with natural fibers and wood—General mechanical property profiles. Compos. Sci. Technol. 2012, 72, 550–557. [Google Scholar] [CrossRef]

- Deeraj, B.D.; Joseph, K.; Jayan, J.S.; Saritha, A. Dynamic mechanical performance of natural fiber reinforced composites: A brief review. Appl. Sci. Eng. Prog. 2021, 14, 614–623. [Google Scholar]

- Bledzki, A.K.; Faruk, O. Wood Fibre Reinforced Polypropylene Composites: Effect of Fibre Geometry and Coupling Agent on Physico-Mechanical Properties. Appl. Compos. Mater. 2003, 10, 365–379. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Faruk, O. Extrusion and Injection Moulded Microcellular Wood Fibre Reinforced Polypropylene Composites. Cell. Polym. 2004, 23, 211–227. [Google Scholar] [CrossRef]

- Chattopadhyay, S.K.; Khandal, R.K.; Uppaluri, R.; Ghoshal, A.K. Bamboo fiber reinforced polypropylene composites and their mechanical, thermal, and morphological properties. J. Appl. Polym. Sci. 2011, 119, 1619–1626. [Google Scholar] [CrossRef]

- Asumani, O.; Reid, R.G.; Paskaramoorthy, R. The effects of alkali–silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1431–1440. [Google Scholar] [CrossRef]

- Asumani, O.; Paskaramoorthy, R. Fatigue and impact strengths of kenaf fibre reinforced polypropylene composites: Effects of fibre treatments. Adv. Compos. Mater. 2021, 30, 103–115. [Google Scholar] [CrossRef]

- Rana, A.K.; Mandal, A.; Mitra, B.C.; Jacobson, R.; Rowell, R.; Banerjee, A.N. Short jute fibre-reinforced polypropylene composites: Effect of compatibilizer. J. Appl. Polym. Sci. 1998, 69, 329–338. [Google Scholar] [CrossRef]

- Kaewkuk, S.; Sutapun, W.; Jarukumjorn, K. Effects of interfacial modification and fiber content on physical properties of sisal fiber/polypropylene composites. Compos. Part B Eng. 2013, 45, 544–549. [Google Scholar] [CrossRef]

- Das, O.; Bhattacharyya, D.; Hui, D.; Lau, K.-T. Mechanical and flammability characterisations of biochar/polypropylene biocomposites. Compos. Part B Eng. 2016, 106, 120–128. [Google Scholar] [CrossRef]

- Ratnaparkhi, M.P.; Andhale, R.S.; Karnawat, G.R. Nanofibers–A Newer Technology. Res. J. Pharm. Technol. 2021, 14, 2321–2327. [Google Scholar]

- Maul, J.; Frushour, B.G.; Kontoff, J.R.; Eichenauer, H.; Ott, K.-H.; Schade, C. Polystyrene and Styrene Copolymers. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley: New York, NY, USA, 2007. [Google Scholar]

- Begum, S.A.; Rane, A.V.; Kanny, K. Applications of compatibilized polymer blends in automobile industry. In Compatibilization of Polymer Blends; Elsevier BV: Amsterdam, The Netherlands, 2020; pp. 563–593. [Google Scholar]

- Lisperguer, J.; Bustos, X.; Saravia, Y. Thermal and mechanical properties of wood flour-polystyrene blends from postconsumer plastic waste. J. Appl. Polym. Sci. 2011, 119, 443–451. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Pang, S.; Staiger, M. Long-term moisture absorption and thickness swelling behaviour of recycled thermoplastics reinforced with Pinus radiata sawdust. Chem. Eng. J. 2008, 142, 190–198. [Google Scholar] [CrossRef]

- Ratanawilai, T.; Taneerat, K. Alternative polymeric matrices for wood-plastic composites: Effects on mechanical properties and resistance to natural weathering. Constr. Build. Mater. 2018, 172, 349–357. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.J. Mechanical and dynamic mechanical properties of polystyrene composites reinforced with cellulose fibers. J. Thermoplast. Compos. Mater. 2017, 30, 1242–1254. [Google Scholar] [CrossRef]

- Poletto, M.; Dettenborn, J.; Zeni, M.; Zattera, A.J. Characterization of composites based on expanded polystyrene wastes and wood flour. Waste Manag. 2011, 31, 779–784. [Google Scholar] [CrossRef]

- Singha, A.; Rana, R. Natural fiber reinforced polystyrene composites: Effect of fiber loading, fiber dimensions and surface modification on mechanical properties. Mater. Des. 2012, 41, 289–297. [Google Scholar] [CrossRef]

- Ucankus, G.; Ercan, M.; Uzunoglu, D.; Culha, M. Methods for preparation of nanocomposites in environmental remediation. In New Polymer Nanocomposites for Environmental Remediation; Elsevier BV: Amsterdam, The Netherlands, 2018; pp. 1–28. [Google Scholar]

- Zhong, X.; Zhao, X.; Qian, Y.; Zou, Y. Polyethylene plastic production process. Insight Mater. Sci. 2018, 1, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Malkan, S.R. Improving the use of polyolefins in nonwovens. In Polyolefin Fibres; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 285–311. [Google Scholar]

- Donmez Cavdar, A.; Mengeloğlu, F.; Karakus, K. Effect of boric acid and borax on mechanical, fire and thermal properties of wood flour filled high density polyethylene composites. Meas. J. Int. Meas. Confed. 2015, 60, 6–12. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; González-López, M.E.; Pérez-Fonseca, A.A.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Effect of fiber content and surface treatment on the mechanical properties of natural fiber composites produced by rotomolding. Compos. Interfaces 2017, 24, 35–53. [Google Scholar] [CrossRef]

- Torres, F.; Aragon, C. Final product testing of rotational moulded natural fibre-reinforced polyethylene. Polym. Test. 2006, 25, 568–577. [Google Scholar] [CrossRef]

- Wang, B.; Panigrahi, S.; Tabil, L.; Crerar, W. Pre-treatment of Flax Fibers for use in Rotationally Molded Biocomposites. J. Reinf. Plast. Compos. 2007, 26, 447–463. [Google Scholar] [CrossRef]

- Jayaraman, K.; Lin, R.J.; Bose, D.; Maarouf, M. Natural Fibre-Reinforced Thermoplastics Processed by Rotational Moulding. Adv. Mater. Res. 2007, 29–30, 307–310. [Google Scholar] [CrossRef]

- López-Bañuelos, R.; Moscoso, F.; Ortega-Gudiño, P.; Mendizabal, E.; Rodrigue, D.; González-Núñez, R. Rotational molding of polyethylene composites based on agave fibers. Polym. Eng. Sci. 2012, 52, 2489–2497. [Google Scholar] [CrossRef]

- Cisneros-López, E.; Pérez-Fonseca, A.; Talavera, F.J.F.; Anzaldo, J.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J. Rotomolded polyethylene-agave fiber composites: Effect of fiber surface treatment on the mechanical properties. Polym. Eng. Sci. 2016, 56, 856–865. [Google Scholar] [CrossRef]

- Zhao, X.; Li, R.; Bai, S.-L. Mechanical properties of sisal fiber reinforced high density polyethylene composites: Effect of fiber content, interfacial compatibilization, and manufacturing process. Compos. Part A Appl. Sci. Manuf. 2014, 65, 169–174. [Google Scholar] [CrossRef]

- Hanana, F.E.; Rodrigue, D. Effect of particle size, fiber content, and surface treatment on the mechanical properties of maple-reinforced LLDPE produced by rotational molding. Polym. Polym. Compos. 2021, 29, 343–353. [Google Scholar] [CrossRef]

- Ambrogi, V.; Carfagna, C.; Cerruti, P.; Marturano, V. Additives in polymers. In Modification of Polymer Properties; William Andrew Publishing: Burlington, MA, USA, 2017; pp. 87–108. [Google Scholar]

- Hietala, M.; Niinimäki, J.; Oksman, K. Processing of wood chip–plastic composites: Effect on wood particle size, microstructure and mechanical properties. Plast. Rubber Compos. 2011, 40, 49–56. [Google Scholar] [CrossRef]

- Brandt, M.J.; Johnson, K.M.; Elphinston, A.J.; Ratnayaka, D.D. Pipeline Design and Construction. In Twort’s Water Supply; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 693–742. [Google Scholar]

- Tajvidi, M.; Haghdan, S.; Najafi, S.K. Physical properties of novel layered composites of wood flour and PVC. J. Reinf. Plastics Compos. 2008, 27, 1759–1765. [Google Scholar] [CrossRef]

- Ranjan, N.; Kumar, R.; Singh, R.; Kumar, V. On PVC-PP composite matrix for 4D applications: Flowability, mechanical, thermal, and morphological characterizations. J. Thermoplast. Compos. Materials. 2021. [Google Scholar] [CrossRef]

- Doble, M.; Kumar, A. Degradation of Polymers. In Biotreatment of Industrial Effluents; Elsevier BV: Amsterdam, The Netherlands, 2005; pp. 101–110. [Google Scholar]

- Tasouji, M.; Noorbakhsh, A.; Kargarfard, A.; Hosseinkhani, H. Effect of type of lignosullose and nanores on the physical, mechanical and morphological properties of polystyrene wood. Iranian J. Wood Paper Sci. Res. 2012, 27, 189–201. [Google Scholar]

- Aliyegbenoma, C.; Apkobi, J.; Olodu, D. Modelling and Production of Injection Moulded Polyvinylchloride--Sawdust Composite. J. Appl. Sci. Environ. Manag. 2020, 23, 2159. [Google Scholar] [CrossRef] [Green Version]

- Enayati, A.A.; Sani, F.R.; Kavei, F. A Study on Application of Polyvinylchloride (PVC) Waste and Sawdust in Wood-Plastic Composite. Res. Dev. Mater. Sci. 2021, 15, 1662–1666. [Google Scholar] [CrossRef]

- Qian, S.; Wang, H.; Zarei, E.; Sheng, K. Effect of hydrothermal pretreatment on the properties of moso bamboo particles reinforced polyvinyl chloride composites. Compos. Part B Eng. 2015, 82, 23–29. [Google Scholar] [CrossRef]

- Pulngern, T.; Chitsamran, T.; Chucheepsakul, S.; Rosarpitak, V.; Patcharaphun, S.; Sombatsompop, N. Effect of temperature on mechanical properties and creep responses for wood/PVC composites. Constr. Build. Mater. 2016, 111, 191–198. [Google Scholar] [CrossRef]

- Ali, S.F.A.; El Batouti, M.; Abdelhamed, M.; Rafey, E.E. Formulation and characterization of new ternary stable composites: Polyvinyl chloride-wood flour- calcium carbonate of promising physicochemical properties. J. Mater. Res. Technol. 2020, 9, 12840–12854. [Google Scholar] [CrossRef]

- Song, W.; Wei, W.; Wang, D.; Zhang, S. Preparation and properties of new plywood composites made from surface modified veneers and polyvinyl chloride films. BioResources 2017, 12, 8320–8339. [Google Scholar]

- Abreu, A.S.L.M.; De Moura, I.G.; De Sá, A.V.; Machado, A.V.A. Biodegradable Polymernanocomposites for Packaging Applications; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 329–363. [Google Scholar]

- Deshmukh, K.; Basheer Ahamed, M.; Deshmukh, R.R.; Khadheer Pasha, S.K.; Bhagat, P.R.; Chidambaram, K. 3-Biopolymer composites with high dielectric performance: Interface engineering. In Biopolymer Composites in Electronics; Sadasivuni, K.K., Ponnamma, D., Kim, J., Cabibihan, J.-J., AlMaadeed, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 27–128. [Google Scholar] [CrossRef]

- Li, G.; Zhao, M.; Xu, F.; Yang, B.; Li, X.; Meng, X.; Teng, L.; Sun, F.; Li, Y. Synthesis and Biological Application of Polylactic Acid. Molecules 2020, 25, 5023. [Google Scholar] [CrossRef]

- Avinc, O.; Khoddami, A. Overview of Poly(lactic acid) (PLA) Fibre. Fibre Chem. 2009, 41, 391–401. [Google Scholar] [CrossRef]

- Mochizuki, M. Synthesis, properties and structure of polylactic acid fibres. In Handbook of Textile Fibre Structure; Elsevier: Amsterdam, The Netherlands, 2009; Volume 1, pp. 257–275. [Google Scholar]

- Tsukegi, T.; Nagasawa, N.; Horii, T.; Nishida, H. Chemical Recycling Technology of Polylactic Acid/talc—Application into Agricultural Materials. Kobunshi Ronbunshu 2015, 72, 361–368. [Google Scholar] [CrossRef]

- Gupta, B.; Revagade, N.; Hilborn, J. Poly(lactic acid) fiber: An overview. Prog. Polym. Sci. 2007, 32, 455–482. [Google Scholar] [CrossRef]

- Graupner, N.; Herrmann, A.S.; Müssig, J. Natural and man-made cellulose fibre-reinforced poly(lactic acid) (PLA) composites: An overview about mechanical characteristics and application areas. Compos. Part A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Du, Y.; Wu, T.; Yan, N.; Kortschot, M.; Farnood, R. Fabrication and characterization of fully biodegradable natural fiber-reinforced poly(lactic acid) composites. Compos. Part B Eng. 2014, 56, 717–723. [Google Scholar] [CrossRef]

- Tan, L.; Liu, L.; Liu, C.; Wang, W. Improvement in the Performance of the Polylactic Acid Composites by Using Deep Eutectic Solvent Treated Pulp Fiber. J. Renew. Mater. 2021, 9, 1897–1911. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Comparative studies of mechanical and morphological properties of polylactic acid and polypropylene based natural fiber composites. J. Reinf. Plast. Compos. 2012, 31, 1712–1724. [Google Scholar] [CrossRef]

- Yu, T.; Jiang, N.; Li, Y. Study on short ramie fibre/poly (lactic acid) composites compatibilized by maleic anhydride. Compos. Part A Appl. Sci. Manuf. 2014, 64, 139–146. [Google Scholar] [CrossRef]

- Singh, T.; Lendvai, L.; Dogossy, G.; Fekete, G. Physical, mechanical, and thermal properties of Dalbergia sissoo wood waste-filled poly(lactic acid) composites. Polym. Compos. 2021, 42, 4380–4389. [Google Scholar] [CrossRef]

- Samouh, Z.; Molnar, K.; Boussu, F.; Cherkaoui, O.; El Moznine, R. Mechanical and thermal characterization of sisal fiber reinforced polylactic acid composites. Polym. Adv. Technol. 2019, 30, 529–537. [Google Scholar] [CrossRef] [Green Version]

- Ertas, M.; Altuntas, E.; Donmez Cavdar, A. Effects of halloysite nanotube on the performance of natural fibre filled poly (lactic acid) composites. Polymer Compos. 2019, 40, 4238–4247. [Google Scholar] [CrossRef]

- Kumar, A.A.J.; Prakash, M. Mechanical and morphological characterization of basalt/Cissus quadrangularis hybrid fiber reinforced polylactic acid composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 2895–2907. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Misra, M.; Mohanty, A.K. Wood-fiber-reinforced poly(lactic acid) composites: Evaluation of the physicomechanical and morphological properties. J. Appl. Polym. Sci. 2006, 102, 4856–4869. [Google Scholar] [CrossRef]

- Prajer, M.; Ansell, M.P. Bio-composites for structural applications: Poly-l-lactide reinforced with long sisal fiber bundles. J. Appl. Polym. Sci. 2014, 131, 40999. [Google Scholar] [CrossRef]

- García, M.; Hidalgo, J.; Garmendia, I.; Garcia-Jaca, J. Wood–plastics composites with better fire retardancy and durability performance. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1772–1776. [Google Scholar] [CrossRef]

- Washington State University Wood Plastic Composites Information Center. Fire Issues in Engineered Wood Composites for Naval Waterfront Facilities. In Proceedings of the 46th International SAMPE Symposium and Exhibition, Long Beach, CA, USA, 7 May 2001. [Google Scholar]

- Idumah, C.I. Emerging advancements in flame retardancy of polypropylene nanocomposites. J. Thermoplast. Compos. Mater. 2020. [Google Scholar] [CrossRef]

- Grexa, O.; Lübke, H. Flammability parameters of wood tested on a cone calorimeter. Polym. Degrad. Stab. 2001, 74, 427–432. [Google Scholar] [CrossRef]

- Harada, T. Time to ignition, heat release rate and fire endurance time of wood in cone calorimeter test. Fire Mater. 2001, 25, 161–167. [Google Scholar] [CrossRef]

- Tran, H.C.; White, R.H. Burning rate of solid wood measured in a heat release rate calorimeter. Fire Mater. 1992, 16, 197–206. [Google Scholar] [CrossRef]

- Babrauskas, V.; Peacock, R.D. Heat release rate: The single most important variable in fire hazard. Fire Saf. J. 1992, 18, 255–272. [Google Scholar] [CrossRef]

- Braun, U.; Schartel, B. Flame retardant mechanisms of red phosphorus and magnesium hydroxide in high impact polystyrene. Macromol. Chem. Phys. 2004, 205, 2185–2196. [Google Scholar] [CrossRef]

- Bryden, K.M.; Hagge, M.J. Modeling the combined impact of moisture and char shrinkage on the pyrolysis of a biomass particle [small star, filled]. Fuel 2003, 82, 1633–1644. [Google Scholar] [CrossRef]

- Babrauskas, V.; Fires, Q. Why was the fire so big? HHR: The role of heat release rate in described fires. Fire Arson Investig. 1997, 47, 54–57. [Google Scholar]

- Fu, Q.; Medina, L.; Li, Y.; Carosio, F.; Hajian, A.; Berglund, L.A. Nanostructured Wood Hybrids for Fire-Retardancy Prepared by Clay Impregnation into the Cell Wall. ACS Appl. Mater. Interfaces 2017, 9, 36154–36163. [Google Scholar] [CrossRef]

- Di Nenno, P.J.; Drysdale, D.; Beyler, C.L.; Walton, W.D.; Custer, R.L.P.; Hall, J.R.; Watts, J.M. Appendices, SFPE Handbook of Fire Protection Engineering, 3rd ed.; National Fire Protection Association: Quincy, MA, USA, 2002; pp. A40–A42. [Google Scholar]

- Kruse, T.M.; Wong, H.-W.; Broadbelt, L.J. Mechanistic Modeling of Polymer Pyrolysis: Polypropylene. Macromolecules 2003, 36, 9594–9607. [Google Scholar] [CrossRef]

- Turku, I.; Kärki, T.; Puurtinen, A. Flammability of wood plastic composites prepared from plastic waste. Fire Mater. 2017, 42, 198–201. [Google Scholar] [CrossRef]

- Turku, I.; Nikolaeva, M.; Kärki, T. The Effect of Fire Retardants on the Flammability, Mechanical Properties, and Wettability of Co-Extruded PP-Based Wood-Plastic Composites. Bioresources 2013, 9, 1539–1551. [Google Scholar] [CrossRef] [Green Version]

- Stark, N.M.; White, R.H.; Clemons, C.M. Heat release rate of wood-plastic composites. SAMPE J. 1997, 33, 26–31. [Google Scholar]

- Kim, Y.; Lee, S.; Yoon, H. Fire-Safe Polymer Composites: Flame-Retardant Effect of Nanofillers. Polymers 2021, 13, 540. [Google Scholar] [CrossRef] [PubMed]

- Vahabi, H.; Rastin, H.; Movahedifar, E.; Antoun, K.; Brosse, N.; Saeb, M.R. Flame Retardancy of Bio-Based Polyurethanes: Opportunities and Challenges. Polymers 2020, 12, 1234. [Google Scholar] [CrossRef]

- Desch, H.E.; Dinwoodie, J.M. Timber Structure, Properties, Conversion and Use; Springer: Singapore, 1996. [Google Scholar]

- Fratzl, P.; Weinkamer, R. Nature’s hierarchical materials. Prog. Mater. Sci. 2007, 52, 1263–1334. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Liu, F.; Jiang, L.; Zhu, J.Y.; Haagenson, D.; Wiesenborn, D.P. Cellulose Nanocrystals vs. Cellulose Nanofibrils: A Comparative Study on Their Microstructures and Effects as Polymer Reinforcing Agents. ACS Appl. Mater. Interfaces 2013, 5, 2999–3009. [Google Scholar] [CrossRef]

- Robledo-Ortíz, J.R.; González-López, M.E.; del Campo, A.S.M.; Pérez-Fonseca, A.A. Lignocellulosic Materials as Reinforcement of Polyhydroxybutyrate and its Copolymer with Hydroxyvalerate: A Review. J. Polym. Environ. 2021, 29, 1350–1364. [Google Scholar] [CrossRef]

- Kozłowski, R.; Władyka-Przybylak, M. Flammability and fire resistance of composites reinforced by natural fibers. Polym. Adv. Technol. 2008, 19, 446–453. [Google Scholar] [CrossRef]

- Helwig, M.; Paukszta, D. Flammability of Composites Based on Polypropylene and Flax Fibres. Mol. Crystals Liquid Crystals 2000, 354, 373–380. [Google Scholar] [CrossRef]

- Borysiak, S.; Paukszta, D.; Helwig, M. Flammability of wood–polypropylene composites. Polym. Degrad. Stab. 2006, 91, 3339–3343. [Google Scholar] [CrossRef]

- Mokhena, T.C.; Sadiku, E.R.; Mochane, M.J.; Ray, S.S. Mechanical properties of fire retardant wood-plastic composites: A review. Express Polym. Lett. 2021, 15, 744–780. [Google Scholar] [CrossRef]

- Zong, G.; Hao, J.; Hao, X.; Fang, Y.; Song, Y.; Wang, H.; Ou, R.; Wang, Q. Enhancing the flame retardancy and mechanical properties of veneered wood flour/poly—Vinyl chloride composites. Polymer Compos. 2020, 41, 848–857. [Google Scholar] [CrossRef]

- Stark, N.M.; Mueller, S.A.; White, R.H.; Osswald, T.A. Effect of fire retardants on heat release rate of wood flour-polyethylene composites. In Proceedings of the 10th International Conference on Wood and Biofiber Plastic Composite and Cellulose Nanocomposites Symposium, Madison, WI, USA, 11–13 May 2009; pp. 103–109. [Google Scholar]

- Salmeia, K.A.; Fage, J.; Liang, S.; Gaan, S. An Overview of Mode of Action and Analytical Methods for Evaluation of Gas Phase Activities of Flame Retardants. Polymers 2015, 7, 504–526. [Google Scholar] [CrossRef] [Green Version]

- Agwuncha, S.C.; Ibrahim, I.D.; Sadiku, E.R. Improving the thermal and flame resistance properties of polyolefins. In Polyolefin Fibres: Structure, Properties and Industrial Applications; Ugbolue, S.C.O., Ed.; Woodhead: Duxford, UK, 2017; pp. 21–448. [Google Scholar]

- Browne, F.L. Theories of the Combustion of Wood and Its Control; Report, No. 2136; Forest Products Laboratory: Madison, WI, USA, 1958. [Google Scholar]

- Jimenez, M.; Duquesne, S.; Bourbigot, S. Intumescent fire protective coating: Toward a better understanding of their mechanism of action. Thermochim. Acta 2006, 449, 16–26. [Google Scholar] [CrossRef]

- Hornsby, P. Fire retardant fillers for polymers. Int. Mater. Rev. 2001, 46, 199–210. [Google Scholar] [CrossRef]

- Qian, X.; Song, L.; Yu, B.; Wang, B.; Yuan, B.; Shi, Y.; Hu, Y.; Yuen, R.K.K. Novel organic–inorganic flame retardants containing exfoliated graphene: Preparation and their performance on the flame retardancy of epoxy resins. J. Mater. Chem. A 2013, 1, 6822–6830. [Google Scholar] [CrossRef]

- Stark, N.M.; White, R.H.; Mueller, S.A.; Osswald, T.A. Evaluation of various fire retardants for use in wood flour–polyethylene composites. Polym. Degrad. Stab. 2010, 95, 1903–1910. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, S.; Chen, H.; Ding, C.; Xuan, Y.; Pan, M.; Mei, C. A Branched Polyelectrolyte Complex Enables Efficient Flame Retardant and Excellent Robustness for Wood/Polymer Composites. Polymers 2020, 12, 2438. [Google Scholar] [CrossRef]

- Pham, L.H.; Nguyen, H.D.; Kim, J.; Hoang, D. Thermal Properties and Fire Retardancy of Polypropylene/Wood Flour Composites Containing Eco-friendly Flame Retardants. Fibers Polym. 2019, 20, 2383–2389. [Google Scholar] [CrossRef]

- Yang, Y.; Haurie, L.; Wen, J.; Zhang, S.; Ollivier, A.; Wang, D.-Y. Effect of oxidized wood flour as functional filler on the mechanical, thermal and flame-retardant properties of polylactide biocomposites. Ind. Crop. Prod. 2019, 130, 301–309. [Google Scholar] [CrossRef]

- Wang, W.; Chen, H.; Li, J. Effects of Maleic Anhydride Grafted Polypropylene on the Physical, Mechanical and Flammability Properties of Wood-flour/Polypropylene/Ammonium Polyphosphate Composites. Fibers Polym. 2021, 22, 1137–1144. [Google Scholar] [CrossRef]

- Alaee, M. An overview of commercially used brominated flame retardants, their applications, their use patterns in different countries/regions and possible modes of release. Environ. Int. 2003, 29, 683–689. [Google Scholar] [CrossRef]

- Ray, S.S.; Kuruma, M. Halogen-Free Flame-Retardant Polymers: Next-Generation Fillers for Polymer Nanocomposite Applications; Springer Nature: Basingstoke, UK, 2019. [Google Scholar]

- Aschberger, K.; Campia, I.; Pesudo, L.Q.; Radovnikovic, A.; Reina, V. Chemical alternatives assessment of different flame retardants—A case study including multi-walled carbon nanotubes as synergist. Environ. Int. 2017, 101, 27–45. [Google Scholar] [CrossRef] [PubMed]

- Chapple, S.; Anandjiwala, R. Flammability of Natural Fiber-reinforced Composites and Strategies for Fire Retardancy: A Review. J. Thermoplast. Compos. Mater. 2010, 23, 871–893. [Google Scholar] [CrossRef]

- Prabhakar, M.; Shah, A.U.R.; Song, J.-I. A Review on the Flammability and Flame Retardant Properties of Natural Fibers and Polymer Matrix Based Composites. Compos. Res. 2015, 28, 29–39. [Google Scholar] [CrossRef] [Green Version]

- Jiang, D.D.; Levchik, G.F.; Levchik, S.V.; Dick, C.; Liggat, J.; Snape, C.; A Wilkie, C. Thermal degradation of cross-linked polyisoprene and polychloroprene. Polym. Degrad. Stab. 2000, 68, 75–82. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Wang, D.; Li, Z.; Li, Z.; Peng, X.; Liu, C.; Zhang, Y.; Zheng, P. Recent Developments in the Flame-Retardant System of Epoxy Resin. Materials 2020, 13, 2145. [Google Scholar] [CrossRef]

- Joseph, P.; Tretsiakova-Mcnally, S. Reactive modifications of some chain-and step-growth polymers with phos-phorus-containing compounds: Effects on flame retardance—A review. Polymers Adv. Technol. 2011, 22, 395–406. [Google Scholar] [CrossRef]

- Joseph, P.; Ebdon, J. Phosphorus-Based Flame Retardants. In Fire Retardancy of Polymeric Materials, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2009; pp. 107–127. [Google Scholar]

- Arao, Y.; Nakamura, S.; Tomita, Y.; Takakuwa, K.; Umemura, T.; Tanaka, T. Improvement on fire retardancy of wood flour/polypropylene composites using various fire retardants. Polym. Degrad. Stab. 2014, 100, 79–85. [Google Scholar] [CrossRef]

- Li, L.; Guo, W.; Guo, C. Synergistic effect of melamine polyphosphate and aluminum hypophosphite on mechanical properties and flame retardancy of HDPE/wood flour composites. Wood Sci. Technol. 2017, 51, 493–506. [Google Scholar] [CrossRef]

- Schirp, A.; Schwarz, B. Influence of compounding conditions, treatment of wood particles with fire-retardants and artificial weathering on properties of wood-polymer composites for façade applications. Holz Roh Werkst. 2021, 79, 821–840. [Google Scholar] [CrossRef]

- Shen, K.K. Review of Recent Advances on the Use of Boron-based Flame Retardants. Polymer Green Flame Retardants 2014, 2014, 367–388. [Google Scholar]

- Dogan, M.; Dogan, S.D.; Savas, L.A.; Ozcelik, G.; Tayfun, U. Flame retardant effect of boron compounds in polymeric materials. Compos. Part B Eng. 2021, 222, 109088. [Google Scholar] [CrossRef]

- Altuntas, E.; Narlioglu, N.; Alma, M.H. Investigation of the fire, thermal, and mechanical properties of zinc borate and synergic fire retardants on composites produced with PP-MDF wastes. Bioresources 2017, 12, 6971–6983. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, Q.; Guo, C.; Song, Y.; Cooper, P.A. Effect of zinc borate and wood flour on thermal degradation and fire retardancy of Polyvinyl chloride (PVC) composites. J. Anal. Appl. Pyrolysis 2013, 100, 230–236. [Google Scholar] [CrossRef]

- Babu, K.; Rendén, G.; Mensah, R.A.; Kim, N.K.; Jiang, L.; Xu, Q.; Restás, A.; Neisiany, R.E.; Hedenqvist, M.S.; Försth, M.; et al. A Review on the Flammability Properties of Carbon-Based Polymeric Composites: State-of-the-Art and Future Trends. Polymers 2020, 12, 1518. [Google Scholar] [CrossRef]

- Szeluga, U.; Pusz, S.; Kumanek, B.; Olszowska, K.; Kobyliukh, A.; Trzebicka, B. Effect of graphene filler structure on electrical, thermal, mechanical, and fire retardant properties of epoxy-graphene nanocomposites—A review. Crit. Rev. Solid State Mater. Sci. 2021, 46, 152–187. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, L.; Lv, J. Effects of expandable graphite and modified ammonium polyphosphate on the flameretardant and mechanical properties of wood flour polypropylene composites. Polym. Polym. Compos. 2013, 21, 449–456. [Google Scholar]

- Zhao, P.; Guo, C.; Li, L. Flame retardancy and thermal degradation properties of polypropylene/wood flour composite modified with aluminum hypophosphite/melamine cyanurate. J. Therm. Anal. Calorim. 2019, 135, 3085–3093. [Google Scholar] [CrossRef]

- Sweet, R.; Gallmeyer, J.H. A Silicone Composition Useful in Flame Retardant. World Patent 2004,063,280, 7 January 2004. [Google Scholar]

- Hamdani, S.; Longuet, C.; Perrin, D.; Lopez-Cuesta, J.-M.; Ganachaud, F. Flame retardancy of silicone-based materials. Polym. Degrad. Stab. 2009, 94, 465–495. [Google Scholar] [CrossRef]

- Ghomi, E.R.; Khosravi, F.; Mossayebi, Z.; Ardahaei, A.S.; Dehaghi, F.M.; Khorasani, M.; Neisiany, R.E.; Das, O.; Marani, A.; Mensah, R.A.; et al. The Flame Retardancy of Polyethylene Composites: From Fundamental Concepts to Nanocomposites. Molecules 2020, 25, 5157. [Google Scholar] [CrossRef]

- Pan, M.; Mei, C.; Du, J.; Li, G. Synergistic effect of nano silicon dioxide and ammonium polyphosphate on flame retardancy of wood fiber–polyethylene composites. Compos. Part A Appl. Sci. Manuf. 2014, 66, 128–134. [Google Scholar] [CrossRef]

- Vahidi, G.; Bajwa, D.S.; Shojaeiarani, J.; Stark, N.; Darabi, A. Advancements in traditional and nanosized flame retardants for polymers—A review. J. Appl. Polym. Sci. 2021, 138, 50050. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Y.-Z. A review on flame retardant technology in China. Part I: Development of flame retardants. Polym. Adv. Technol. 2009, 21, 1–26. [Google Scholar] [CrossRef]

- Katančić, Z.; Krehula, L.K.; Siročić, A.P.; Grozdanić, V.; Hrnjak-Murgić, Z. Effect of modified nanofillers on fire retarded high-density polyethylene/wood composites. J. Compos. Mater. 2014, 48, 3771–3783. [Google Scholar] [CrossRef]

- Kausar, A. Flame Retardant Potential of Clay Nanoparticles; INC: New York, NY, USA, 2020; pp. 169–184. [Google Scholar] [CrossRef]

- Giri, R.; Nayak, L.; Rahaman, M. Flame and fire retardancy of polymer-based composites. Mater. Res. Innov. 2021, 25, 104–132. [Google Scholar] [CrossRef]

- Gilman, J.W.; Jackson, C.L.; Morgan, A.B.; Harris, R.; Manias, E.; Giannelis, E.P.; Phillips, S.H. Flammability properties of polymer− layered-silicate nanocomposites. Polypropylene and polystyrene nanocomposites. Chem. Mater. 2000, 12, 1866–1873. [Google Scholar] [CrossRef]

- Guo, G.; Park, C.; Lee, Y.; Kim, Y.; Sain, M. Flame retarding effects of nanoclay on wood–fiber composites. Polym. Eng. Sci. 2007, 47, 330–336. [Google Scholar] [CrossRef]

| Polymer Matrix Composites | Metal Matrix Composites | Ceramic Matrix Composites |

|---|---|---|

|

Thermosets and Thermoplastics Organic fiber reinforced Glass fiber reinforced Carbon fiber reinforced | Particles reinforced Whiskers reinforced Sheet reinforced | Short fiber composites Long fiber composites |

| Polymer (Plastics) | Heat Release Rate (HRR) W/cm2 | Limiting Oxygen Index (LOI) vol.% |

|---|---|---|

| Polypropylene (PP) | 150.9 | 17–18 |

| Polystyrene (PS) | 110.1 | 18 |

| Polyethylene (PE) | 140.8 | 17–18 |

| Polyvinyl chloride (PVC) | 17.5 | 23–45 |

| Polylactic Acid (PLA) | 27.2 | 21 |

| Formulation | Method of Manufacturing Process | Outcome of the Effect of Fire Retardant on WPC Materials | Ref. |

|---|---|---|---|

| WF/PP(MAPP)/ATH/Zinc borate/graphite/TiO2 | Twin-screw extruder | The effects of FRs on fire scenario of WPC shows that the FRS ATH, ZB and melamine had a great impact on the pHRR which significantly decreased by 8 to 22%. | [145] |

|

WF/PE/MH WF/PE/ZB WF/PE/MP | Twin-Screw Extruder | All fire retardant presented a significant improvement of pHRR and average HRR of WPC. WPC/MH had an excellent performance than the other FRs. However, LOI had n increment of 29%, although WPC/ZB also performed well but the result was not different from WPC/MP. | [166] |

|

WF/HDPE/PEC 15% WF/HDPE/APP 15% | Compression Mold | Flame retardant of WPC/APP increased the LOI value by 23.9%, while WPC/PEC was 24.4% which indicate that PEC can enhance the LOI of WPC better than APP. However, a 25% addition of PEC to WPC obtained a higher LOI of 28.7% which represent a UL-94 V-0 rating. | [167] |

|

PP/WF (50/50) PP/WF/AHP (35/35/30) PP/WF/TPP (35/35/30) | Twin screw extruder | PP/WF composite without fire retardant recorded 28.7% mm/min UL-94 completely burnt the sample with low LOI value of 18%. Employing an addition of AHP and TPP fulfilled the UL-94 HB burning rate of 20.8 mm/min and 11.5 mm/min with LOI values of 19% and 21% under 30 wt.% for both AHP and TPP loading. Incorporation of AHP and TPP improved the fire retardant of PP/WF composite. | [168] |

|

PLA/WF/PEG (80/10/10) PLA/OWF/PEG (80/10/10) PLA (100)/APP PLA/OWF/PEG (80/10/10)/APP | Melt-compounding and hot-compression | Blending oxidized wood flour (OWF) and ammonium polyphosphate (APP) to the biocomposite resulted an excellent fire-retardant performance. Peak heat release rate (pHRR) showed a significant reduction, improving LOI by 30.6% and achieving UL-94 V-0 rating standard also. | [169] |

|

PP/WF (60/40) PP/WF/APP (42/28/30) PP/WF/APP/MAPP-5% (37/28/30/5) PP/WF/APP/MAPP-10% (32/28/30/10) PP/WF/APP/MAPP-15% (27/28/30/15) | CO- Rotating Twin Screw Extruder | LOI value of (PP/WF/APP) increased by 17.7% due to the addition of APP from 20.9 (PP/WF) to 24.6 (PP/WF/APP), revealing that APP had a great influenced on the composite with good fire-retardant performance. There was a further increment of LOI value with the incorporation of MAPP. However, PP/WF/APP/MAPP-10% had a higher LOI value of 25.1 indicating 2% higher compared to (PP/WF/APP). Furthermore, PP/WF/APP/MAPP -10% also showed the lowest pHRR of 546.5 kW/m2, longest duration of ignition time (IT) and the highest residual mass of 24.2 wt% among all the wood plastic composites. Therefore, the addition of MAPP could maximize the fire-retardant effect in the wood plastic composites. | [170] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Renner, J.S.; Mensah, R.A.; Jiang, L.; Xu, Q.; Das, O.; Berto, F. Fire Behavior of Wood-Based Composite Materials. Polymers 2021, 13, 4352. https://doi.org/10.3390/polym13244352

Renner JS, Mensah RA, Jiang L, Xu Q, Das O, Berto F. Fire Behavior of Wood-Based Composite Materials. Polymers. 2021; 13(24):4352. https://doi.org/10.3390/polym13244352

Chicago/Turabian StyleRenner, Juliana Sally, Rhoda Afriyie Mensah, Lin Jiang, Qiang Xu, Oisik Das, and Filippo Berto. 2021. "Fire Behavior of Wood-Based Composite Materials" Polymers 13, no. 24: 4352. https://doi.org/10.3390/polym13244352

APA StyleRenner, J. S., Mensah, R. A., Jiang, L., Xu, Q., Das, O., & Berto, F. (2021). Fire Behavior of Wood-Based Composite Materials. Polymers, 13(24), 4352. https://doi.org/10.3390/polym13244352