Study on High Frequency Surface Discharge Characteristics of SiO2 Modified Polyimide Film

Abstract

:1. Introduction

2. Materials and Methods

3. Experimental Results

3.1. Influence Mechanism of Absorption of Light Energy

3.2. Influence Mechanism of Material Structure

3.3. Development Morphology of High Frequency Creeping Discharge

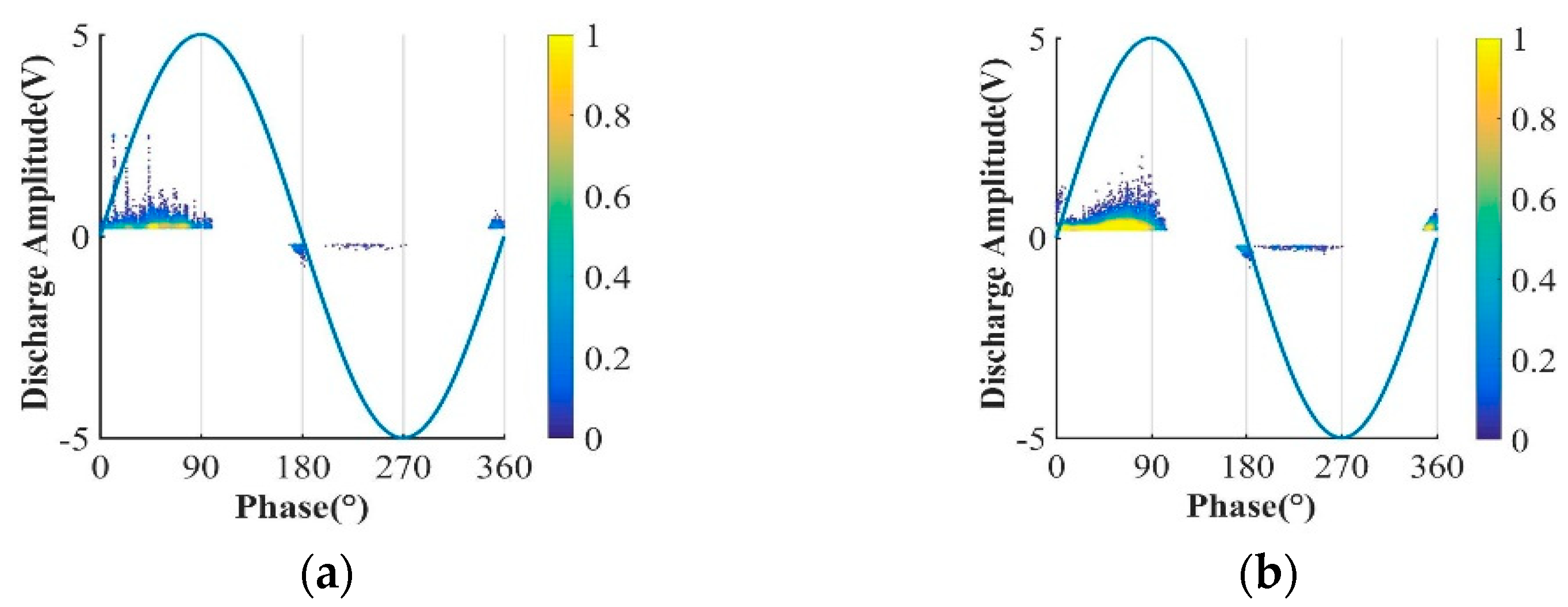

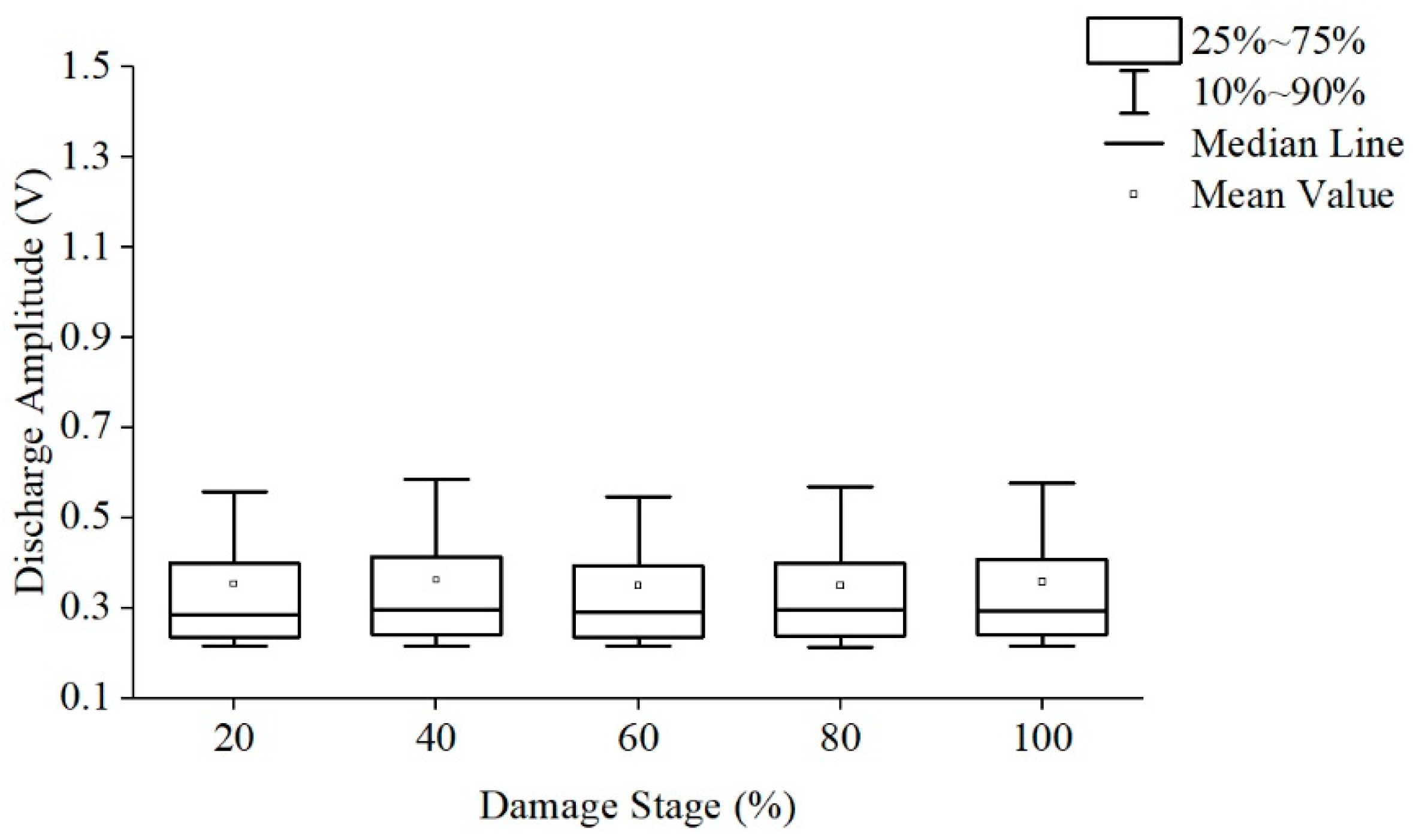

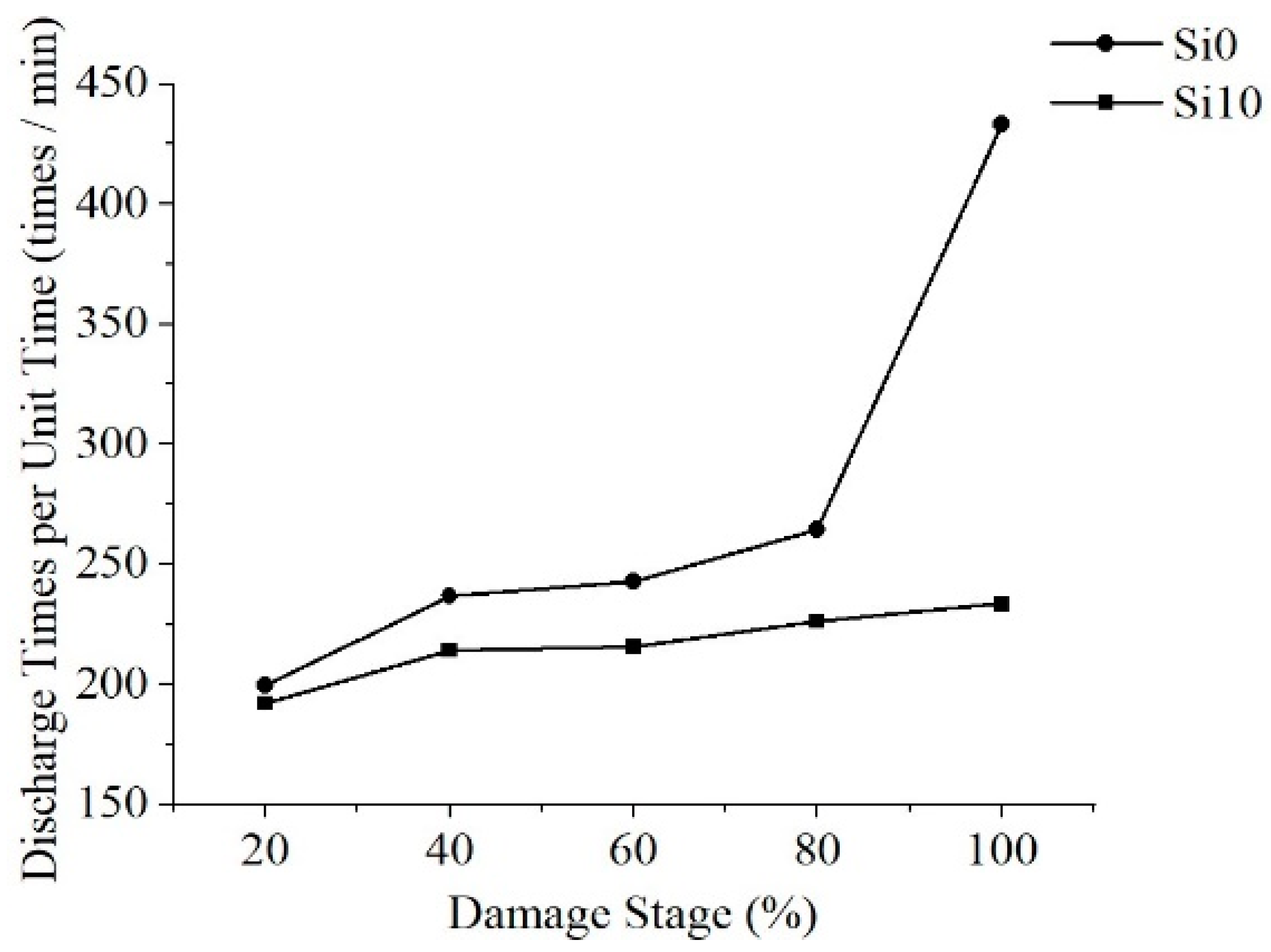

3.4. Acquisition and Analysis of High Frequency Creeping Discharge Signal

4. Discussion on Influence Mechanism

4.1. Influence Mechanism of Carrier Migration

4.2. Influence Mechanism of Dielectric Properties

4.3. Influence Mechanism of Dielectric Properties

5. Conclusions

- (1)

- After the doped nano-SiO2 particles are modified by nano-composite, the high-frequency creeping discharge life of polyimide increases with the increase of doping content, and the life of Si10 is the longest, which is 3.40 times that of pure polyimide Si0.

- (2)

- In the process of discharge development, compared with the power frequency, both of the coronas of Si0 and Si10 are more likely to develop forward, and the flashover causes greater damage to the film. Both of them show more intense discharge at the positive half cycle and polarity reversal. However, in the development of corona and film white spot, Si10 is faster than Si0.

- (3)

- In terms of the characteristics of high-frequency creeping discharge signals, for the positive half cycle and the whole, the discharge amplitude and discharge times per unit time of Si10 are lower than those of Si0, and the negative half cycle is opposite. The discharge amplitudes of the two films fluctuated first and then increased to the peak, and the discharge times per unit time continued to increase. In the early stage, the discharge amplitude of Si10 is large, and the number of discharge is close to that of Si0. However, in the middle and late stages, Si0 develops rapidly, which is significantly larger than that of Si10, resulting in rapid breakdown.

- (4)

- The influence mechanism of nano-composite modification on life is revealed as the following:

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, G.; Choi, M.; Lee, D.; Ha, C. 2D-aligned graphene sheets in transparent polyimide/graphene nanocomposite films based on noncovalent interactions between poly (amic acid) and graphene carboxylic acid. Macromol. Mater. Eng. 2012, 297, 303–311. [Google Scholar] [CrossRef]

- Aggeler, D.; Biela, J.; Kolar, J. A compact, high voltage 25 kW, 50 kHz DC-DC converter based on SiC JFETs. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition, Austin, TX, USA, 24–28 February 2008. [Google Scholar]

- Le Besnerais, J.; Fasquelle, A.; Hecquet, M.; Pelle, J.; Lanfranchi, V.; Harmand, S.; Brochet, P.; Randria, A. Multiphysics Modeling: Electro-Vibro-Acoustics and Heat Transfer of PWM-Fed Induction Machines. IEEE Trans. Ind. Electron. 2010, 57, 1279–1287. [Google Scholar] [CrossRef]

- Du, S.; Baek, Y.; Wang, G.; Bhattacharya, S. Design Considerations of High Voltage and High Frequency Transformer for Solid State Transformer Application. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 421–426. [Google Scholar]

- Yi, H.; Qin, J.; Yi, G. Polyimide–silica hybrid films made from polyamic acids containing phenolic hydroxyl groups. J. Appl. Polym. Sci. 2004, 93, 1198–1202. [Google Scholar]

- Liu, L.; Shi, H.; Weng, L.; Ding, J.; Cui, W. The effects of particle size on the morphology and properties of polyimide/nano-Al2O3 composite films. Polym. Polym. Compos. 2014, 22, 117–121. [Google Scholar] [CrossRef]

- Zha, J.; Song, H.; Dang, Z.; Shi, C.; Bai, J. Mechanism analysis of improved corona-resistant characteristic in polyimide/TiO2 nanohybrid films. Appl. Phys. Lett. 2008, 93, 192911–192913. [Google Scholar] [CrossRef]

- Vernigorov, K.; AYAlent’Ev Muzafarov, A.; Novikov, L.; Chernik, V. Erosion of polyimide modified by amorphous silica sol in the stream of oxygen plasma. J. Surf. Investig. 2011, 5, 263–268. [Google Scholar] [CrossRef]

- Li, J.; Xue, B.; Yang, H.; Liu, L.; Xie, H.; Pei, Y.; Lu, P.; Wang, G.; Wang, J.; Li, J. Fabrication of LED Full-Color Display Matrix with Small Pixel. In Proceedings of the Fourteenth International Conference on Solid State Lighting and LED-Based Illumination Systems, San Diego, CA, USA, 9–13 August 2015; p. 95710Y. [Google Scholar]

- Kim, K.; Kim, H.; Kim, M.; Kim, H.; Choi, S.; Kim, S. Two-step polyimide curing technique for flexible plastic liquid crystal devices. JPN J. Appl. Phys. 2009, 48, 978–981. [Google Scholar] [CrossRef]

- Zhou, Q.; Huang, X.; Wei, B.; Le, L. Impulse Life Evaluation Method of MOV Based on Weibull Distribution. IEEE Access 2021, 9, 34818–34828. [Google Scholar] [CrossRef]

- Huang, X.; Wang, J.; Li, Q.; Lin, J.; Wang, Z. Impact of the phenyl thioether contents on the high frequency dielectric loss characteristics of the modified polyimide films. Surf. Coat. Technol. 2019, 360, 205–212. [Google Scholar] [CrossRef]

- Li, S.; Yin, G.; Chen, G.; Li, J.; Bai, S.; Zhong, L.; Zhang, Y.; Lei, Q. Short-term breakdown and long-term failure in nanodielectrics: A review. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1523–1535. [Google Scholar] [CrossRef] [Green Version]

- Min, D.; Li, S.; Ohki, Y. Numerical simulation on molecular displacement and DC breakdown of LDPE. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 507–516. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, L.; Li, Z.; Zhao, T.; Zou, L. Analysis of the Phenomena and Characteristics of Gas-Solid Insulation Surface Discharge under High Frequency Sinusoidal Electrical Stress. Trans. China Electrotech. Soc. 2019, 34, 3275–3284. [Google Scholar]

- Li, Z.; Xu, H.; Zheng, X.; Zhang, L.; Li, S. Unraveling the transition from secondary electron emission dominated to surface charge trap dominated electronic avalanche process along the solid dielectric surface in vacuum. Appl. Phys. Lett. 2020, 116, 131601. [Google Scholar] [CrossRef]

- Lin, H.; Wang, R.; Xie, Q.; Zhang, S.; Shao, T. Rapid surface modification by plasma jet to promote surface charge decaying. Trans. China Electrotech. Soc. 2017, 32, 256–264. [Google Scholar]

- Zhang, X.; Tang, X.; Guo, Y.; Liu, K.; Kang, Y.; Li, Y.; Wu, G. Effect of High-speed Airflow on the Surface DC Discharge Characteristics of the Needle Plate. Proc. CSEE 2019, 39, 7074–7082, 7120. [Google Scholar]

- Zhang, Y.; Lu, S.; Li, Y.; Dang, Z.; Xin, J.; Fu, S.; Li, G.; Guo, R.; Li, L. Novel Silica Tube/Polymide Composite Films with Variable Low Dielectric Constant. Adv. Mater. 2005, 17, 1056–1059. [Google Scholar] [CrossRef]

- Rogti, F. Space charge dynamic at the physical interface in cross-linked polyethylene under DC field. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 888–899. [Google Scholar] [CrossRef]

- Akyuz, M.; Gao, L.; Cooray, V.; Gustavsson, T.; Gubanski, S. LarssonPositive streamer discharges along insulating surfaces. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 902–910. [Google Scholar] [CrossRef]

| Name | Purity | Supplier |

|---|---|---|

| Pyromellitic dianhydride | 99% | Shanghai Macklin Biochemical Co., Ltd., Shanghai, China |

| 4,4′-Diaminodiphenyl ether | 98% | Shanghai Macklin Biochemical Co., Ltd., Shanghai, China |

| 4,4′-thiobisbenzenamine | 99% | Jiangxi Renming Pharmaceutical Chemical Co., Ltd., Jiangxi, China |

| N,N-Dimethylacetamide | 99% | Sinopharm Chemical Reagent Co., Ltd., Shanghai, China |

| Type | Si0 | Si2 | Si4 | Si6 | Si8 | Si10 |

|---|---|---|---|---|---|---|

| Life/min | 23.12 | 42.40 | 45.40 | 53.50 | 69.11 | 78.11 |

| Type | Si0 | Si10 | |

|---|---|---|---|

| Average | Overall | 0.399 | 0.354 |

| discharge | Positive half week | 0.407 | 0.359 |

| amplitude | Negative half week | 0.288 | 0.302 |

| Average | Overall | 267.67 | 216.35 |

| discharge | Positive half week | 249.59 | 197.35 |

| times | Negative half week | 18.08 | 19 |

| Type | Si0 | Si10 |

|---|---|---|

| volume resistivity (1013 Ω/m) | 7.838 | 6.554 |

| surface resistivity (1010 Ω/m) | 2.613 | 2.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, Z.; Chen, W.; Li, Z.; Xue, N.; Li, F.; Dai, X.; Guo, S.; Cui, H. Study on High Frequency Surface Discharge Characteristics of SiO2 Modified Polyimide Film. Polymers 2021, 13, 4387. https://doi.org/10.3390/polym13244387

Xing Z, Chen W, Li Z, Xue N, Li F, Dai X, Guo S, Cui H. Study on High Frequency Surface Discharge Characteristics of SiO2 Modified Polyimide Film. Polymers. 2021; 13(24):4387. https://doi.org/10.3390/polym13244387

Chicago/Turabian StyleXing, Zhaoliang, Wenhan Chen, Zhihui Li, Naifan Xue, Fei Li, Xiying Dai, Shaowei Guo, and Huize Cui. 2021. "Study on High Frequency Surface Discharge Characteristics of SiO2 Modified Polyimide Film" Polymers 13, no. 24: 4387. https://doi.org/10.3390/polym13244387

APA StyleXing, Z., Chen, W., Li, Z., Xue, N., Li, F., Dai, X., Guo, S., & Cui, H. (2021). Study on High Frequency Surface Discharge Characteristics of SiO2 Modified Polyimide Film. Polymers, 13(24), 4387. https://doi.org/10.3390/polym13244387