Preparation and Applications of Electrospun Optically Transparent Fibrous Membrane

Abstract

:1. Introduction

2. Optically Transparent Materials

2.1. Ceramic Materials

2.2. Metal Materials

2.3. Polymer Materials

3. Light Transmission Mechanism of Electrospinning Fibers

3.1. Materials Selection

3.2. Controllable Microstructure of Electrospun Fibrous Membrane

3.3. Topological Arrangement of Electrospun Fibrous Membrane

4. Preparation Methods of Transparent Electrospun Fibrous Membrane

4.1. Direct Electrospinning

4.2. Solution Treatment after Electrospinning

4.2.1. Solution Casting

4.2.2. Dipping

4.3. Heat Treatment after Electrospinning

4.3.1. Hot Pressing after Electrospinning

4.3.2. Annealing after Electrospinning

4.3.3. Thermal Treatment after Electrospinning

4.4. Electroless Deposition after Electrospinning

4.5. Surface Modification after Electrospinning

5. Application of Transparent Electrospun Fibrous Membrane

5.1. Alcohol Dipstick

5.2. Air Purification

5.3. Self-Cleaning Materials

5.4. Biomedicine

5.5. Sensors

5.6. Energy and Optoelectronics

5.7. Oil–Water Separation

5.8. Food Packaging

5.9. Anti-Icing Coating

5.10. Anti-Corrosion Material

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, D.; Xia, Y. Electrospinning of nanofibers: Reinventing the wheel? Adv. Mater. 2004, 16, 1151–1170. [Google Scholar] [CrossRef]

- Wan, Z.; Wang, L.; Yang, X.; Guo, J.; Yin, S. Enhanced water resistance properties of bacterial cellulose multilayer films by incorporating interlayers of electrospun zein fibers. Food Hydrocoll. 2016, 61, 269–276. [Google Scholar] [CrossRef]

- Chen, H.-T.; Lin, H.-L.; Chen, I.-G.; Kuo, C. Conducting silver networks based on electrospun poly(methyl methacrylate) and silver trifluoroacetate. ACS Appl. Mater. Interfaces 2015, 7, 9479–9485. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, L.; Liu, J.; Li, C. A flexible bimodal sensor based on an electrospun nanofibrous structure for simultaneous pressure–temperature detection. Nanoscale 2019, 11, 14242–14249. [Google Scholar] [CrossRef]

- Bergshoef, M.M.; Vancso, G.J. Transparent nanocomposites with ultrathin, electrospun nylon-4,6 fiber reinforcement. Adv. Mater. 1999, 11, 1362–1365. [Google Scholar] [CrossRef]

- Babu, K.J.; Kaur, G.; Biswal, L.; De, G.; Ghosh, H.N. Ultrafast charge delocalization dynamics of ambient stable CsPbBr 3 nanocrystals encapsulated in polystyrene fiber. Chemistry 2020, 27, 683–691. [Google Scholar] [CrossRef]

- Du, L.; Zhang, Y.; Li, X.; Wang, J.; Chen, M.; Zuo, X.; Yang, W.; Yousefzadeh, M.; Ramakrishana, S.; Li, H. High performance anti-smog window screens via electrospun nanofibers. J. Appl. Polym. Sci. 2019, 137. [Google Scholar] [CrossRef]

- Li, F.; Li, Q.; Kim, H. Spray deposition of electrospun TiO2 nanoparticles with self-cleaning and transparent properties onto glass. Appl. Surf. Sci. 2013, 276, 390–396. [Google Scholar] [CrossRef]

- Kim, J.I.; Kim, J.Y.; Park, C.H. Fabrication of transparent hemispherical 3D nanofibrous scaffolds with radially aligned patterns via a novel electrospinning method. Sci. Rep. 2018, 8, 1–13. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, X.; Wang, P.; Xie, K.; Jian, J.; Zhang, Y.; Zhang, J.; Yuan, Y.; Na, P.; Yi, M.; et al. Transparent thermoplastic polyurethane air filters for efficient electrostatic capture of particulate matter pollutants. Nanotechnology 2019, 30, 015703. [Google Scholar] [CrossRef] [PubMed]

- Busuioc, C.; Evanghelidis, A.; Galatanu, A.; Enculescu, I. Direct and contactless electrical control of temperature of paper and textile foldable substrates using electrospun metallic-web transparent electrodes. Sci. Rep. 2016, 6, 34584. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Nagapudi, K.; Apkarian, R.P.; Chaikof, E.L. Engineered collagen–PEO nanofibers and fabrics. J. Biomater. Sci. Polym. Ed. 2001, 12, 979–993. [Google Scholar] [CrossRef]

- Fuh, Y.K.; Lien, L.-C. Pattern transfer of aligned metal nano/microwires as flexible transparent electrodes using an electrospun nanofiber template. Nanotechnology 2013, 24, 055301. [Google Scholar] [CrossRef]

- Xu, J.; Liu, C.; Hsu, P.-C.; Liu, K.; Zhang, R.; Liu, Y.; Cui, Y. Roll-to-roll transfer of electrospun nanofiber film for high-efficiency transparent air filter. Nano Lett. 2016, 16, 1270–1275. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Lu, T.; Li, F.; Wang, Y.; Lei, J.; Ma, W.; Zou, Y.; Huang, C. Flexible and transparent composite nanofibre membrane that was fabricated via a “green” electrospinning method for efficient particulate matter 2.5 capture. J. Colloid Interface Sci. 2020, 582, 506–514. [Google Scholar] [CrossRef] [PubMed]

- Whitted, T. An improved illumination model for shaded display. Commun. ACM 1980, 23, 343–349. [Google Scholar] [CrossRef]

- Hendy, S.C. Light scattering in transparent glass ceramics. Appl. Phys. Lett. 2002, 81, 1171–1173. [Google Scholar] [CrossRef]

- Fedorov, P.; Luginina, A.; Popov, A. Transparent oxyfluoride glass ceramics. J. Fluor. Chem. 2015, 172, 22–50. [Google Scholar] [CrossRef]

- Berthier, T.; Fokin, V.M.; Zanotto, E.D. New large grain, highly crystalline, transparent glass–ceramics. J. Non-Cryst. Solids 2008, 354, 1721–1730. [Google Scholar] [CrossRef]

- Tsukuma, K.; Yamashita, I.; Kusunose, T. Transparent 8 mol% Y2O3–ZrO2(8Y) ceramics. J. Am. Ceram. Soc. 2008, 91, 813–818. [Google Scholar] [CrossRef]

- Krell, A.; Klimke, J.; Hutzler, T. Transparent compact ceramics: Inherent physical issues. Opt. Mater. 2009, 31, 1144–1150. [Google Scholar] [CrossRef]

- Zhang, H.; Kim, B.-N.; Morita, K.; Yoshida, H.; Lim, J.-H.; Hiraga, K. Optimization of high-pressure sintering of transparent zirconia with nano-sized grains. J. Alloys Compd. 2010, 508, 196–199. [Google Scholar] [CrossRef]

- Zhang, H.; Kim, B.-N.; Morita, K.; Yoshida, H.; Lim, J.-H.; Hiraga, K. Optical properties and microstructure of nanocrystalline cubic zirconia prepared by high-pressure spark plasma sintering. J. Am. Ceram. Soc. 2011, 94, 2981–2986. [Google Scholar] [CrossRef]

- Miao, X.; Huo, X.; Liu, L.; Tang, S.; Guo, M.; Cheng, F.; Zhang, M. Crystallisation kinetics and structural stability of transparent CaF2 glass ceramics: Dependence of light transmittance on the amount of CaF2 added. Ceram. Int. 2020, 46, 15314–15324. [Google Scholar] [CrossRef]

- Zhao, X.; Chao, X.; Wu, D.; Liang, P.; Yang, Z. Evaluation of birefringence contribution to transparency in (1−x)KNN-xSr(Al0.5Ta0.5)O3 ceramics: A phase structure tailoring. J. Alloys Compd. 2019, 798, 669–677. [Google Scholar] [CrossRef]

- Zhang, K.; Li, W.; Zeng, J.; Deng, T.; Luo, B.; Zhang, H.; Huang, X. Preparation of (La0.2Nd0.2Sm0.2Gd0.2Yb0.2)2Zr2O7 high-entropy transparent ceramic using combustion synthesized nanopowder. J. Alloys Compd. 2020, 817, 153328. [Google Scholar] [CrossRef]

- Zhao, X.; Chai, Q.; Chen, B.; Chao, X.; Yang, Z. Improved transmittance and ferroelectric properties realized in KNN ceramics via SAN modification. J. Am. Ceram. Soc. 2018, 101, 5127–5137. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, H.; Li, D.; Lin, Y. Excellent energy density and power density achieved in K0.5Na0.5NbO3-based ceramics with high optical transparency. J. Alloys Compd. 2020, 829, 154565. [Google Scholar] [CrossRef]

- Belyaev, A.; Basyrova, L.; Sysoev, V.; Lelet, M.; Balabanov, S.; Kalganov, V.; Mikhailovski, V.; Baranov, M.; Stepanidenko, E.; Vitkin, V.; et al. Microstructure, doping and optical properties of Co2+:ZnAl2O4 transparent ceramics for saturable absorbers: Effect of the ZnF2 sintering additive. J. Alloys Compd. 2020, 829, 154514. [Google Scholar] [CrossRef]

- Chen, X.; Liu, X.; Feng, Y.; Li, X.; Chen, H.; Xie, T.; Kou, H.; Kučerková, R.; Beitlerová, A.; Mihóková, E.; et al. Microstructure evolution in two-step-sintering process toward transparent Ce:(Y,Gd)3(Ga,Al)5O12 scintillation ceramics. J. Alloys Compd. 2020, 846, 156377. [Google Scholar] [CrossRef]

- Li, Q.L.; Cheung, S.W.; Wu, D.; Yuk, T.I. Optically transparent dual-band mimo antenna using micro-metal mesh conductive film for WLAN system. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 920–923. [Google Scholar] [CrossRef]

- Song, R.; Li, X.; Gu, F.; Fei, L.; Ma, Q.; Chai, Y. An ultra-long and low junction-resistance Ag transparent electrode by electrospun nanofibers. RSC Adv. 2016, 6, 91641–91648. [Google Scholar] [CrossRef]

- Azuma, K.; Sakajiri, K.; Matsumoto, H.; Kang, S.; Watanabe, J.; Tokita, M. Facile fabrication of transparent and conductive nanowire networks by wet chemical etching with an electrospun nanofiber mask template. Mater. Lett. 2014, 115, 187–189. [Google Scholar] [CrossRef]

- Wang, J.; Jiu, J.; Sugahara, T.; Nagao, S.; Nogi, M.; Koga, H.; He, P.; Suganuma, K.; Uchida, H. Highly reliable silver nanowire transparent electrode employing selectively patterned barrier shaped by self-masked photolithography. ACS Appl. Mater. Interfaces 2015, 7, 23297–23304. [Google Scholar] [CrossRef] [PubMed]

- Kubwimana, J.L.; Kirsch, N.J.; Ziegler, C.; Kontopidis, G.; Turner, B. Dual-polarized 5.75 GHz optically transparent antenna arrays. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 1512–1516. [Google Scholar] [CrossRef]

- Lee, S.; Kim, S.-W.; Ghidelli, M.; An, H.S.; Jang, J.; Bassi, A.L.; Lee, S.-Y.; Park, J. Integration of transparent supercapacitors and electrodes using nanostructured metallic glass films for wirelessly rechargeable, skin heat patches. Nano Lett. 2020, 20, 4872–4881. [Google Scholar] [CrossRef]

- Himeno, Y.; Matsuda, M.; Shida, K.; Matsuda, M. Dopant-free transparent ZrO2 with monoclinic structure produced by oxidation process using Zr metal. Scr. Mater. 2020, 187, 103–106. [Google Scholar] [CrossRef]

- Jo, H.; Yang, J.-H.; Choi, S.-W.; Park, J.; Song, E.J.; Shin, M.; Ahn, J.-H.; Kwon, J.-D. Highly transparent and conductive oxide-metal-oxide electrodes optimized at the percolation thickness of AgOx for transparent silicon thin-film solar cells. Sol. Energy Mater. Sol. Cells 2019, 202, 110131. [Google Scholar] [CrossRef]

- Wu, C.; Li, R.; Wang, Y.; Lu, S.; Lin, J.; Liu, Y.; Zhang, X. Strong metal–support interactions enable highly transparent Pt–Mo2C counter electrodes of bifacial dye-sensitized solar cells. Chem. Commun. 2020. [Google Scholar] [CrossRef]

- Wu, X.; Zheng, S.; Bellido-Aguilar, D.A.; Silberschmidt, V.V.; Chen, Z. Transparent icephobic coatings using bio-based epoxy resin. Mater. Des. 2018, 140, 516–523. [Google Scholar] [CrossRef]

- Park, S.-A.; Eom, Y.; Jeon, H.; Koo, J.M.; Lee, E.S.; Jegal, J.; Hwang, S.Y.; Oh, D.X.; Park, J. Preparation of synergistically reinforced transparent bio-polycarbonate nanocomposites with highly dispersed cellulose nanocrystals. Green Chem. 2019, 21, 5212–5221. [Google Scholar] [CrossRef]

- Cárdenas-Martínez, J.; España-Sánchez, B.L.; Esparza, R.; Ávila-Niño, J.A. Flexible and transparent supercapacitors using electrospun PEDOT:PSS electrodes. Synth. Met. 2020, 267, 116436. [Google Scholar] [CrossRef]

- Ishigami, A.; Watanabe, K.; Kurose, T.; Ito, H. Physical and morphological properties of tough and transparent PMMA-based blends modified with polyrotaxane. Polymers (Basel) 2020, 12, 1790. [Google Scholar] [CrossRef] [PubMed]

- Trachtenberg, A.; Vinod, T.; Jelinek, R. Transparent, conductive polystyrene in three dimensional configurations. Polymer 2014, 55, 5095–5101. [Google Scholar] [CrossRef]

- Kim, J.-H.; Mun, C.; Ma, J.; Park, S.-G.; Lee, S.; Kim, C.S. Simple fabrication of transparent, colorless, and self-disinfecting polyethylene terephthalate film via cold plasma treatment. Nanomaterials 2020, 10, 949. [Google Scholar] [CrossRef]

- Subba Rao, A.N.; Nagarajappa, G.B.; Nair, S.; Chathoth, A.M.; Pandey, K.K. Flexible transparent wood prepared from poplar veneer and polyvinyl alcohol. Compos. Sci. Technol. 2019, 182, 107719. [Google Scholar] [CrossRef]

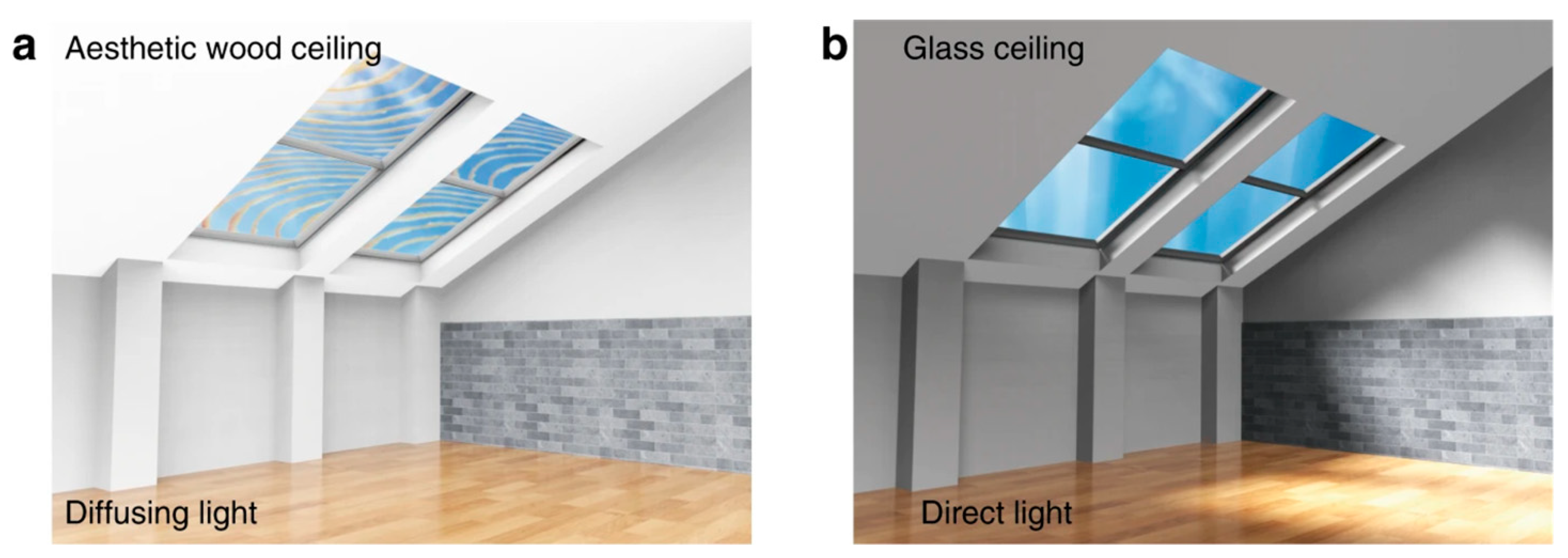

- Liu, Y.; Yang, H.; Ma, C.; Luo, S.; Xu, M.; Wu, Z.; Li, W.; Liu, S. Luminescent transparent wood based on lignin-derived carbon dots as a building material for dual-channel, real-time, and visual detection of formaldehyde gas. ACS Appl. Mater. Interfaces 2020, 12, 36628–36638. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, A.; Zhu, T.; Chen, Z.; Wu, Y.; Gao, Y. Transparent wood composites fabricated by impregnation of epoxy Resin and W-Doped VO2 nanoparticles for application in energy-saving windows. ACS Appl. Mater. Interfaces 2020, 12, 34777–34783. [Google Scholar] [CrossRef]

- Chen, L.; Xu, Z.; Wang, F.; Duan, G.; Xu, W.; Zhang, G.; Yang, H.; Liu, J.; Jiang, S. A flame-retardant and transparent wood/polyimide composite with excellent mechanical strength. Compos. Commun. 2020, 20, 100355. [Google Scholar] [CrossRef]

- Mi, R.; Chen, C.; Keplinger, T.; Pei, Y.; He, S.; Liu, D.; Li, J.; Dai, J.; Hitz, E.; Yang, B.; et al. Scalable aesthetic transparent wood for energy efficient buildings. Nat. Commun. 2020, 11, 3836. [Google Scholar] [CrossRef] [PubMed]

- Liaw, D.-J.; Wang, K.-L.; Huang, Y.-C.; Lee, K.-R.; Lai, J.-Y.; Ha, C.-S. Advanced polyimide materials: Syntheses, physical properties and applications. Prog. Polym. Sci. 2012, 37, 907–974. [Google Scholar] [CrossRef]

- Ni, H.-J.; Liu, J.-G.; Wang, Z.-H.; Yang, S.-Y. A review on colorless and optically transparent polyimide films: Chemistry, process and engineering applications. J. Ind. Eng. Chem. 2015, 28, 16–27. [Google Scholar] [CrossRef]

- Kim, J.W.; Chang, J.-H. Syntheses of colorless and transparent polyimide membranes for microfiltration. Polymers 2020, 12, 1610. [Google Scholar] [CrossRef] [PubMed]

- Tao, P.; Li, Y.; Rungta, A.; Viswanath, A.; Gao, J.; Benicewicz, B.C.; Siegel, R.W.; Schadler, L.S. TiO2 nanocomposites with high refractive index and transparency. J. Mater. Chem. 2011, 21, 18623–18629. [Google Scholar] [CrossRef]

- Wu, M.; Wu, Y.; Liu, Z.; Liu, H. Optically transparent poly(methyl methacrylate) composite films reinforced with electrospun polyacrylonitrile nanofibers. J. Compos. Mater. 2012, 46, 2731–2738. [Google Scholar] [CrossRef]

- Tang, C.; Liu, H. Cellulose nanofiber reinforced poly(vinyl alcohol) composite film with high visible light transmittance. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1638–1643. [Google Scholar] [CrossRef]

- Zhu, H.; Parvinian, S.; Preston, C.; Vaaland, O.; Ruan, Z.; Hu, L. Transparent nanopaper with tailored optical properties. Nanoscale 2013, 5, 3787–3792. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Pan, S.; Yuan, H.; Zhang, Y. Optical and mechanical anisotropies of aligned electrospun nanofibers reinforced transparent PMMA nanocomposites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 380–389. [Google Scholar] [CrossRef]

- Koo, S.H.; Lee, S.G.; Bong, H.; Kwark, Y.-J.; Cho, K.; Lim, H.S.; Cho, J.H. Robust multifunctional superhydrophobic organic–inorganic hybrid macroporous coatings and films. Polymer 2014, 55, 2661–2666. [Google Scholar] [CrossRef]

- Wang, X.-F.; Huang, Z.-M.; Chen, L.-S. Comparison study on transparent composites with different patterns of nanofiber reinforcement. Fibers Polym. 2011, 12, 359–365. [Google Scholar] [CrossRef]

- Cai, J.; Chen, J.; Zhang, Q.; Lei, M.; He, J.; Xiao, A.; Ma, C.; Li, S.; Xiong, H. Well-aligned cellulose nanofiber-reinforced polyvinyl alcohol composite film: Mechanical and optical properties. Carbohydr. Polym. 2016, 140, 238–245. [Google Scholar] [CrossRef]

- Unal, S.; Arslan, S.; Karademir Yilmaz, B.; Kazan, D.; Oktar, F.N.; Gunduz, O. Glioblastoma cell adhesion properties through bacterial cellulose nanocrystals in polycaprolactone/gelatin electrospun nanofibers. Carbohydr. Polym. 2020, 233, 115820. [Google Scholar] [CrossRef]

- Pan, N.; Qin, J.; Feng, P.; Song, B. Window screen inspired fibrous materials with anisotropic thickness gradients for improving light transmittance. Nanoscale 2019, 11, 13521–13531. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Greiner, A.; Agarwal, S. Short nylon-6 nanofiber reinforced transparent and high modulus thermoplastic polymeric composites. Compos. Sci. Technol. 2013, 87, 164–169. [Google Scholar] [CrossRef]

- Matabola, K.P.; de Vries, A.R.; Luyt, A.S.; Kumar, R. Studies on single polymer composites of poly(methyl methacrylate) reinforced with electrospun nanofibers with a focus on their dynamic mechanical properties. Express Polym. Lett. 2011, 5, 635–642. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, M.; Pan, W. Preparation of free-standing flexible conductive silver submicron fiber network by direct electrospinning. Mater. Lett. 2021, 286, 129273. [Google Scholar] [CrossRef]

- Avcı, M.Z.; Saraç, A.S. Transparent poly(methyl methacrylate-co-butyl acrylate) nanofibers. J. Appl. Polym. Sci. 2013, 130, 4264–4272. [Google Scholar] [CrossRef]

- Reddy, C.S.; Zak, A.; Zussman, E. WS2 nanotubes embedded in PMMA nanofibers as energy absorptive material. J. Mater. Chem. 2011, 21, 16086–16093. [Google Scholar] [CrossRef]

- Dulgerbaki, C.; Komur, A.I.; Maslakci, N.N.; Kuralay, F.; Oksuz, A.U. Synergistic tungsten oxide/organic framework hybrid nanofibers for electrochromic device application. Opt. Mater. 2017, 70, 171–179. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, H.; Wang, M.; Zhang, X.; Gan, Z. Thermoplastic polyurethane nanofiber membrane based air filters for efficient removal of ultrafine particulate matter PM0. ACS Appl. Nano Mater. 2021, 4, 182–189. [Google Scholar] [CrossRef]

- Ruan, D.; Qin, L.; Chen, R.; Xu, G.; Su, Z.; Cheng, J.; Xie, S.; Cheng, F.; Ko, F.K. Transparent PAN:TiO2 and PAN-co-PMA:TiO2 nanofiber composite membranes with high efficiency in particulate matter pollutants filtration. Nanoscale Res. Lett. 2020, 15, 7. [Google Scholar] [CrossRef]

- Orash Mahmoud Salehi, A.; Nourbakhsh, M.S.; Rafienia, M.; Baradaran-Rafii, A.; Heidari Keshel, S. Corneal stromal regeneration by hybrid oriented poly (ε-caprolactone)/lyophilized silk fibroin electrospun scaffold. Int. J. Biol. Macromol. 2020, 161, 377–388. [Google Scholar] [CrossRef]

- Behler, K.D.; Stravato, A.; Mochalin, V.; Korneva, G.; Yushin, G.; Gogotsi, Y. Nanodiamond-polymer composite fibers and coatings. ACS Nano 2009, 3, 363–369. [Google Scholar] [CrossRef]

- Lee, C.; Pant, B.; Alam, A.-M.; An, T.; Chung, H.-J.; Hong, S.-T.; Park, S.-J.; Park, M.; Kim, H.Y. Biocompatible and photoluminescent keratin/poly(vinyl alcohol)/carbon quantum dot nanofiber: A novel multipurpose electrospun mat. Macromol. Res. 2016, 24, 924–930. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López de Dicastillo, C.; Garrido, L.; Roa, K.; Galotto, M. Electrospun PVA fibers loaded with antioxidant fillers extracted from Durvillaea antarctica algae and their effect on plasticized PLA bionanocomposites. Eur. Polym. J. 2018, 103, 145–157. [Google Scholar] [CrossRef]

- Najarzadekan, H.; Sereshti, H. Transparent polycaprolactam electrospun nanofibers doped with 1,10-phenanthroline optical sensor for colorimetric determination of iron (II) and vitamin C. Fibers Polym. 2018, 19, 2149–2156. [Google Scholar] [CrossRef]

- Stachewicz, U.; Modaresifar, F.; Bailey, R.J.; Peijs, T.; Barber, A.H. Manufacture of void-free electrospun polymer nanofiber composites with optimized mechanical properties. ACS Appl. Mater. Interfaces 2012, 4, 2577–2582. [Google Scholar] [CrossRef] [PubMed]

- Liao, H.Q.; Wu, Y.Q.; Wu, M.Y.; Zhan, X.R.; Liu, H.Q. Aligned electrospun cellulose fibers reinforced epoxy resin composite films with high visible light transmittance. Cellulose 2012, 19, 111–119. [Google Scholar] [CrossRef]

- Ding, Z.; Zhu, Y.; Branford-White, C.; Sun, K.; Um-I-Zahra, S.; Quan, J.; Nie, H.; Zhu, L. Self-assembled transparent conductive composite films of carboxylated multi-walled carbon nanotubes/poly(vinyl alcohol) electrospun nanofiber mats. Mater. Lett. 2014, 128, 310–313. [Google Scholar] [CrossRef]

- Ma, K.; Qiu, Y.P.; Fu, Y.Q.; Ni, Q.-Q. Electrospun sandwich configuration nanofibers as transparent membranes for skin care drug delivery systems. J. Mater. Sci. 2018, 53, 10617–10626. [Google Scholar] [CrossRef]

- Kurokawa, N.; Hotta, A. Thermomechanical properties of highly transparent self-reinforced polylactide composites with electrospun stereocomplex polylactide nanofibers. Polymer 2018, 153, 214–222. [Google Scholar] [CrossRef]

- Lu, Y.; Xiao, X.D.; Zhan, Y.J.; Cao, Z.Y.; Cheng, H.L.; Huan, C.M.; Qi, S.; Xu, G. Functional transparent nanocomposite film with thermochromic and hydrophobic properties fabricated by electrospinning and hot-pressing approach. Ceram. Int. 2018, 44, 1013–1018. [Google Scholar] [CrossRef]

- Li, B.Y.; Yuan, H.H.; Zhang, Y.Z. Transparent PMMA-based nanocomposite using electrospun graphene-incorporated PA-6 nanofibers as the reinforcement. Compos. Sci. Technol. 2013, 89, 134–141. [Google Scholar] [CrossRef]

- An, T.; Pant, B.; Kim, S.Y.; Park, M.; Park, S.J.; Kim, H.Y. Mechanical and optical properties of electrospun nylon-6,6 nanofiber reinforced cyclic butylene terephthalate composites. J. Ind. Eng. Chem. 2017, 55, 35–39. [Google Scholar] [CrossRef]

- Jiang, S.; Hou, H.; Greiner, A.; Agarwal, S. Tough and transparent nylon-6 electrospun nanofiber reinforced melamine–formaldehyde composites. ACS Appl. Mater. Interfaces 2012, 4, 2597–2603. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.-W.; Cho, W.-J. Carrier concentration and threshold voltage variability of amorphous oxide semiconductors using vacuum rapid thermal annealing. J. Nanosci. Nanotechnol. 2020, 20, 4276–4281. [Google Scholar] [CrossRef]

- Yoon, S.; Kim, H.; Shin, E.-S.; Huh, J.N.; Noh, Y.-Y.; Park, B.; Hwang, I. Toward high conductivity of electrospun indium tin oxide nanofibers with fiber morphology dependent surface coverage: Postannealing and polymer ratio effects. ACS Appl. Mater. Interfaces 2017, 9, 34305–34313. [Google Scholar] [CrossRef]

- Ning, Y.; Zhang, Z.; Teng, F.; Fang, X. Novel transparent and self-powered UV photodetector based on crossed ZnO nanofiber array homojunction. Small 2018, 14, e1703754. [Google Scholar] [CrossRef] [PubMed]

- Lamastra, F.; Nanni, F.; Menchini, F.; Nunziante, P.; Grilli, M.L. Transparent nanostructured electrodes: Electrospun NiO nanofibers/NiO films. Thin Solid Films 2016, 601, 54–58. [Google Scholar] [CrossRef]

- Cherpinski, A.; Torres-Giner, S.; Cabedo, L.; Lagaron, J.M. Post-processing optimization of electrospun submicron poly(3-hydroxybutyrate) fibers to obtain continuous films of interest in food packaging applications. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk. Assess. 2017, 34, 1817–1830. [Google Scholar] [CrossRef] [PubMed]

- Wagner, A.M.; Spencer, D.S.; Peppas, N.A. Advanced architectures in the design of responsive polymers for cancer nanomedicine. J. Appl. Polym. Sci. 2018, 135, 46154. [Google Scholar] [CrossRef] [PubMed]

- Ji, S.; Hyun, B.G.; Kim, K.; Lee, S.Y.; Kim, S.-H.; Kim, J.-Y.; Song, M.H.; Park, J.-U. Photo-patternable and transparent films using cellulose nanofibers for stretchable origami electronics. NPG Asia Mater. 2016, 8, e299. [Google Scholar] [CrossRef]

- Shin, D.-Y.; Park, E.-H.; Kim, K.-H. Moiré-fringeless transparent conductive films with a random serpentine network of medium-field electrospun, chemically annealed silver microfibres. Sci. Rep. 2019, 9, 11226. [Google Scholar] [CrossRef]

- Qiu, J.; Yu, T.; Zhang, W.; Zhao, Z.; Zhang, Y.; Ye, G.; Zhao, Y.; Du, X.; Liu, X.; Yang, L.; et al. A bioinspired, durable, and nondisposable transparent graphene skin electrode for electrophysiological signal detection. ACS Mater. Lett. 2020, 2, 999–1007. [Google Scholar] [CrossRef]

- Hong, E.-K.; Cho, W.-J. Microwave calcination of electrospun ITO nanofibers and improvement of transparent electrode characteristics through vacuum rapid thermal annealing. Mater. Res. Express 2020, 7, 075013. [Google Scholar] [CrossRef]

- Mele, E.; Heredia-Guerrero, J.A.; Bayer, I.S.; Ciofani, G.; Genchi, G.G.; Ceseracciu, L.; Davis, A.; Papadopoulou, E.L.; Barthel, M.J.; Marini, L.; et al. Zwitterionic nanofibers of super-glue for transparent and biocompatible multi-purpose coatings. Sci. Rep. 2015, 5, 14019. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, T.-H.; Wang, Y.-Z.; Tseng, P.-H.; Ho, K.-S.; Tsai, Y.-J. Electrospun highly transparent, conducting Ag@polyacrylonitrile nanofibers prepared by post thermal treatment in the presence of tetraanilines. Polym. Degrad. Stab. 2017, 144, 146–154. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, X.; Zhang, Q.; Li, N. Preparation of transparent polyacrylonitrile reinforced polyurethane film and application as temperature monitor. Polym. Eng. Sci. 2018, 58, 1905–1910. [Google Scholar] [CrossRef]

- Cho, Y.-Y.; Kuo, C. Optical and electrical characterization of electrospun Al-doped zinc oxide nanofibers as transparent electrodes. J. Mater. Chem. C 2016, 4, 7649–7657. [Google Scholar] [CrossRef]

- Preda, N.; Evanghelidis, A.; Enculescu, M.; Florica, C.; Enculescu, I. Zinc oxide electroless deposition on electrospun PMMA fiber mats. Mater. Lett. 2015, 138, 238–242. [Google Scholar] [CrossRef]

- Tao, D.; Wei, Q.; Cai, Y.; Xu, Q.; Sun, L. Functionalization of polyamide 6 nanofibers by electroless deposition of copper. J. Coat. Technol. Res. 2008, 5, 399–403. [Google Scholar] [CrossRef]

- Pinto, N.; Carrión, P.; Quiñones, J. Electroless deposition of nickel on electrospun fibers of 2-acrylamido-2-methyl-1-propanesulfonic acid doped polyaniline. Mater. Sci. Eng. A 2004, 366, 1–5. [Google Scholar] [CrossRef]

- Hsu, P.-C.; Kong, D.; Wang, S.; Wang, H.; Welch, A.J.; Wu, H.; Cui, Y. Electrolessly deposited electrospun metal nanowire transparent electrodes. J. Am. Chem. Soc. 2014, 136, 10593–10596. [Google Scholar] [CrossRef]

- Testa, A.; Bernasconi, R.; Yoshikawa, R.; Takenaka, I.; Magagnin, L.; Shiratori, S. Transparent flexible electrodes based on junctionless copper nanowire network via selective electroless metallization of electrospun nanofibers. J. Electrochem. Soc. 2017, 164, D764–D770. [Google Scholar] [CrossRef]

- Matei, E.; Busuioc, C.; Evanghelidis, A.; Zgura, I.; Enculescu, M.; Beregoi, M.; Enculescu, I. Hierarchical functionalization of electrospun fibers by electrodeposition of zinc oxide nanostructures. Appl. Surf. Sci. 2018, 458, 555–563. [Google Scholar] [CrossRef]

- Kim, G.H.; Woo, H.; Kim, S.; An, T.; Lim, G. Highly-robust, solution-processed flexible transparent electrodes with a junction-free electrospun nanofiber network. RSC Adv. 2020, 10, 9940–9948. [Google Scholar] [CrossRef]

- Vinod, T.; Yin, X.; Jopp, J.; Jelinek, R. Directed self-assembly of graphene oxide on an electrospun polymer fiber template. Carbon 2015, 95, 888–894. [Google Scholar] [CrossRef]

- Singh, S.B.; Hu, Y.; Kshetri, T.; Kim, N.H.; Lee, J.H. An embedded-PVA@Ag nanofiber network for ultra-smooth, high performance transparent conducting electrodes. J. Mater. Chem. C 2017, 5, 4198–4205. [Google Scholar] [CrossRef]

- Jo, H.S.; An, S.; Lee, J.-G.; Park, H.G.; Al-Deyab, S.S.; Yarin, A.L.; Yoon, S.S. Highly flexible, stretchable, patternable, transparent copper fiber heater on a complex 3D surface. NPG Asia Mater. 2017, 9, e347. [Google Scholar] [CrossRef]

- Jiang, D.-H.; Tsai, P.-C.; Kuo, C.-C.; Jhuang, F.-C.; Guo, H.-C.; Chen, S.-P.; Liao, Y.-C.; Satoh, T.; Tung, S. Facile preparation of Cu/Ag core/shell electrospun nanofibers as highly stable and flexible transparent conductive electrodes for optoelectronic devices. ACS Appl. Mater. Interfaces 2019, 11, 10118–10127. [Google Scholar] [CrossRef]

- Daneshvar, F.; Tagliaferri, S.; Chen, H.; Zhang, T.; Liu, C.; Sue, H.-J. Ultra-long electrospun copper-carbon nanotube composite fibers for transparent conductive electrodes with high operational stability. ACS Appl. Electron. Mater. 2020, 2, 2692–2698. [Google Scholar] [CrossRef]

- Beregoi, M.; Preda, N.; Costas, A.; Enculescu, M.; Negrea, R.F.; Iovu, H.; Enculescu, I. Synthesis of core–double shell nylon-ZnO/polypyrrole electrospun nanofibers. Nanomaterials 2020, 10, 2241. [Google Scholar] [CrossRef]

- An, S.; Kim, Y.I.; Jo, H.S.; Kim, M.-W.; Swihart, M.T.; Yarin, A.L.; Yoon, S.S. Oxidation-resistant metallized nanofibers as transparent conducting films and heaters. Acta Mater. 2018, 143, 174–180. [Google Scholar] [CrossRef]

- Luo, H.; Hu, J.; Dou, Y.; Yang, Y.; Hou, J. Rapid visual alcohol dipstick based on transparent detection of hierarchical structured PLA/PVDF electrospun nanofibrous membrane. Compos. Commun. 2020, 22, 100516. [Google Scholar] [CrossRef]

- Liu, C.; Hsu, P.-C.; Lee, H.-W.; Ye, M.; Zheng, G.; Liu, N.; Li, W.; Cui, Y. Transparent air filter for high-efficiency PM2.5 capture. Nat. Commun. 2015, 6, 6205. [Google Scholar] [CrossRef]

- Liu, H.; Huang, J.; Mao, J.; Chen, Z.; Chen, G.; Lai, Y. Transparent antibacterial nanofiber air filters with highly efficient moisture resistance for sustainable particulate matter capture. iScience 2019, 19, 214–223. [Google Scholar] [CrossRef] [PubMed]

- Liang, W.; Xu, Y.; Li, X.; Wang, X.-X.; Zhang, H.-D.; Yu, M.; Ramakrishna, S.; Long, Y.-Z. Transparent polyurethane nanofiber air filter for high-efficiency PM2.5 capture. Nanoscale Res. Lett. 2019, 14, 361. [Google Scholar] [CrossRef]

- Mikheev, A.Y.; Kanev, I.L.; Morozova, T.Y.; Morozov, V.N. Water-soluble filters from ultra-thin polyvinylpirrolidone nanofibers. J. Membr. Sci. 2013, 448, 151–159. [Google Scholar] [CrossRef]

- Parkin, I.P.; Palgrave, R.G. Self-cleaning coatings. J. Mater. Chem. 2005, 15, 1689–1695. [Google Scholar] [CrossRef]

- Erbil, H.Y.; Demirel, A.L.; Avcı, Y.; Mert, O. Transformation of a Simple Plastic into a Superhydrophobic Surface. Science 2003, 299, 1377–1380. [Google Scholar] [CrossRef]

- Matthews, J.A.; Wnek, G.E.; Simpson, D.G.; Bowlin, G.L. Electrospinning of collagen nanofibers. Biomacromolecules 2002, 3, 232–238. [Google Scholar] [CrossRef]

- Arica, T.A.; Guzelgulgen, M.; Yildiz, A.A.; Demir, M.M. Electrospun GelMA fibers and p(HEMA) matrix composite for corneal tissue engineering. Mater. Sci. Eng. C 2021, 120, 111720. [Google Scholar] [CrossRef] [PubMed]

- Tonsomboon, K.; Oyen, M.L. Composite electrospun gelatin fiber-alginate gel scaffolds for mechanically robust tissue engineered cornea. J. Mech. Behav. Biomed. Mater. 2013, 21, 185–194. [Google Scholar] [CrossRef]

- Doshi, J.; Reneker, D.H. Electrospinning process and applications of electrospun fibers. J. Electrost. 1995, 35, 151–160. [Google Scholar] [CrossRef]

- Li, M.; Guo, Y.; Wei, Y.; MacDiarmid, A.G.; Lelkes, P.I. Electrospinning polyaniline-contained gelatin nanofibers for tissue engineering applications. Biomaterials 2006, 27, 2705–2715. [Google Scholar] [CrossRef]

- Jin, H.-J.; Fridrikh, S.V.; Rutledge, G.C.; Kaplan, D.L. Electrospinning Bombyx mori silk with poly(ethylene oxide). Biomacromolecules 2002, 3, 1233–1239. [Google Scholar] [CrossRef] [PubMed]

- Costa, L.M.M.; De Olyveira, G.M.; Basmaji, P.; Filho, L.X. Bacterial cellulose towards functional medical materials. J. Biomater. Tissue Eng. 2012, 2, 185–196. [Google Scholar] [CrossRef]

- Svensson, A.; Nicklasson, E.; Harrah, T.; Panilaitis, B.; Kaplan, D.; Brittberg, M.; Gatenholm, P. Bacterial cellulose as a potential scaffold for tissue engineering of cartilage. Biomaterials 2005, 26, 419–431. [Google Scholar] [CrossRef]

- Kim, D.-H.; Han, K.; Gupta, K.; Kwon, K.W.; Suh, K.-Y.; Levchenko, A. Mechanosensitivity of fibroblast cell shape and movement to anisotropic substratum topography gradients. Biomaterials 2009, 30, 5433–5444. [Google Scholar] [CrossRef]

- Bäckdahl, H.; Helenius, G.; Bodin, A.; Nannmark, U.; Johansson, B.R.; Risberg, B.; Gatenholm, P. Mechanical properties of bacterial cellulose and interactions with smooth muscle cells. Biomaterials 2006, 27, 2141–2149. [Google Scholar] [CrossRef]

- Kim, J.; Kim, S.W.; Park, S.; Lim, K.T.; Seonwoo, H.; Kim, Y.; Hong, B.H.; Choung, Y.-H.; Chung, J.H. Bacterial cellulose nanofibrillar patch as a wound healing platform of tympanic membrane perforation. Adv. Health Mater. 2013, 2, 1525–1531. [Google Scholar] [CrossRef] [PubMed]

- Grill, A. Diamond-like carbon coatings as biocompatible materials—An overview. Diam. Relat. Mater. 2003, 12, 166–170. [Google Scholar] [CrossRef]

- Duy, L.T.; Trung, T.Q.; Hanif, A.; Siddiqui, S.; Roh, E.; Lee, W.; Lee, N.-E. A stretchable and highly sensitive chemical sensor using multilayered network of polyurethane nanofibres with self-assembled reduced graphene oxide. 2D Mater. 2017, 4, 025062. [Google Scholar] [CrossRef]

- Fuh, Y.-K.; Li, S.-C.; Chen, C.-Y.; Tsai, C.-Y. A fully packaged self-powered sensor based on near-field electrospun arrays of poly(vinylidene fluoride) nano/micro fibers. Express Polym. Lett. 2018, 12, 136–145. [Google Scholar] [CrossRef]

- Ünsal, Ö.F.; Altın, Y.; Çelik Bedeloglu, A. Poly(vinylidene fluoride) nanofiber-based piezoelectric nanogenerators using reduced graphene oxide/polyaniline. J. Appl. Polym. Sci. 2019, 137. [Google Scholar] [CrossRef]

- Kim, S.-R.; Yoo, J.-H.; Park, J.-W. Using Electrospun AgNW/P(VDF-TrFE) composite nanofibers to create transparent and wearable single-electrode triboelectric nanogenerators for self-powered touch panels. ACS Appl. Mater. Interfaces 2019, 11, 15088–15096. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Song, Y. Fabrication of Silver Mesh/Grid and Its Applications in Electronics. ACS Appl. Mater. Interfaces 2021, 13, 3493–3511. [Google Scholar] [CrossRef]

- Lv, R.; Li, S.; Jin, T.; Na, B.; Zhou, H.; Liu, H. Hybrid core-shell nanofibers as moisture sensors for human breath monitoring. Compos. Sci. Technol. 2018, 162, 58–63. [Google Scholar] [CrossRef]

- Wang, J.; Lou, Y.; Wang, B.; Sun, Q.; Zhou, M.; Li, X. Highly sensitive, breathable, and flexible pressure sensor based on electrospun membrane with assistance of AgNW/TPU as composite dielectric layer. Sensors 2020, 20, 2459. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Zhang, W.; Ma, J.G.; Wang, X.; Xu, H.Y.; Cong, L.J.; Liu, Y.C. Solution-grown serpentine silver nanofiber meshes for stretchable transparent conductors. Adv. Electron. Mater. 2018, 4, 1800346. [Google Scholar] [CrossRef]

- Choi, S.; Eom, Y.; Kim, S.; Jeong, D.; Han, J.; Koo, J.M.; Hwang, S.Y.; Park, J.; Oh, D.X. A Self-healing nanofiber-based self-responsive time-temperature indicator for securing a cold-supply chain. Adv. Mater. 2020, 32, e1907064. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Li, N.-W.; Zhao, S.; Yuan, Z.; Wang, J.; Du, X.; Wang, B.; Cao, R.; Li, X.; Xu, W.; et al. A breathable and screen-printed pressure sensor based on nanofiber membranes for electronic skins. Adv. Mater. Technol. 2018, 3. [Google Scholar] [CrossRef]

- Miyamoto, A.; Lee, S.; Cooray, N.F.; Lee, S.; Mori, M.; Matsuhisa, N.; Jin, H.; Yoda, L.; Yokota, T.; Itoh, A.; et al. Inflammation-free, gas-permeable, lightweight, stretchable on-skin electronics with nanomeshes. Nat. Nanotechnol. 2017, 12, 907–913. [Google Scholar] [CrossRef]

- Azuma, K.; Sakajiri, K.; Okabe, T.; Matsumoto, H.; Kang, S.; Watanabe, J.; Tokita, M. Zero percolation threshold in electric conductivity of aluminum nanowire network fabricated by chemical etching using an electrospun nanofiber mask. Jpn. J. Appl. Phys. 2017, 56, 095002. [Google Scholar] [CrossRef]

- Chen, H.-T.; Lin, H.-L.; Kuo, C.; Chen, I.-G. UV-induced synthesis of silver nanofiber networks as transparent electrodes. J. Mater. Chem. C 2016, 4, 7675–7682. [Google Scholar] [CrossRef]

- Wu, H.; Hu, L.; Rowell, M.W.; Kong, D.; Cha, J.J.; McDonough, J.R.; Zhu, J.; Yang, Y.; McGehee, M.D.; Cui, Y. Electrospun metal nanofiber webs as high-performance transparent electrode. Nano Lett. 2010, 10, 4242–4248. [Google Scholar] [CrossRef] [PubMed]

- Duzyer, S.; Cunayev, S. Effect of deposition time on the optoelectrical properties of electrospun Pan/Agno3 nanofibers. Tekstİl Ve Konfeksİyon 2019. [Google Scholar] [CrossRef]

- Jung, H.; Chae, S.Y.; Kim, H.; Min, B.K.; Hwang, Y.J. Electrospun Mo-doped BiVO4 photoanode on a transparent conductive substrate for solar water oxidation. Catal. Commun. 2016, 75, 18–22. [Google Scholar] [CrossRef]

- Li, P.; Ma, J.G.; Xu, H.Y.; Xue, X.D.; Liu, Y.C. Highly stable copper wire/alumina/polyimide composite films for stretchable and transparent heaters. J. Mater. Chem. C 2016, 4, 3581–3591. [Google Scholar] [CrossRef]

- Devarayan, K.; Lei, D.; Kim, H.-Y.; Kim, B.-S. Flexible transparent electrode based on PANi nanowire/nylon nanofiber reinforced cellulose acetate thin film as supercapacitor. Chem. Eng. J. 2015, 273, 603–609. [Google Scholar] [CrossRef]

- Wang, Q.X.; Hu, X.T.; Yang, X.; Liu, G.L.; Meng, X.C.; Xie, Y.P.; Xiao, Y.B.; Liu, J.L.; Tan, L.C.; Chen, Y.W. Large-scale ultra-adhesive and mechanically flexible silver grids transparent electrodes by solution process. Org. Electron. 2018, 61, 296–303. [Google Scholar] [CrossRef]

- He, T.; Xie, A.; Reneker, D.H.; Zhu, Y. A Tough and high-performance transparent electrode from a scalable and transfer-free method. ACS Nano 2014, 8, 4782–4789. [Google Scholar] [CrossRef]

- Kim, S.-W.; An, B.W.; Cho, E.; Hyun, B.G.; Moon, Y.-J.; Kim, S.-K.; Park, J. A full-visible-spectrum invisibility cloak for mesoscopic metal wires. Nano Lett. 2018, 18, 3865–3872. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Li, X.; Wang, J.; Qiu, T.; Fang, Y.; Song, Q.; Luo, B.; Zhang, X.; Zhi, L. Reduced graphene oxide nanoribbon networks: A novel approach towards scalable fabrication of transparent conductive films. Small 2013, 9, 820–824. [Google Scholar] [CrossRef]

- Huang, Y.-L.; Baji, A.; Tien, H.-W.; Yang, Y.-K.; Yang, S.-Y.; Wu, S.-Y.; Ma, C.-C.M.; Liu, H.-Y.; Mai, Y.-W.; Wang, N.-H. Self-assembly of silver–graphene hybrid on electrospun polyurethane nanofibers as flexible transparent conductive thin films. Carbon 2012, 50, 3473–3481. [Google Scholar] [CrossRef]

- Tian, W.; Zhai, T.; Zhang, C.; Li, S.-L.; Wang, X.; Liu, F.; Liu, D.; Cai, X.; Tsukagoshi, K.; Golberg, D.; et al. Low-cost fully transparent ultraviolet photodetectors based on electrospun ZnO-SnO2 heterojunction nanofibers. Adv. Mater. 2013, 25, 4625–4630. [Google Scholar] [CrossRef]

- Nasreen, S.A.; Sundarrajan, S.; Nizar, S.A.; Balamurugan, R.; Ramakrishna, S. Advancement in electrospun nanofibrous membranes modification and their application in water treatment. Membranes 2013, 3, 266–284. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Ma, W.; Cui, J.; Wu, S.; Han, J.; Zou, Y.; Huang, C. Hydrothermal synthesized UV-resistance and transparent coating composited superoloephilic electrospun membrane for high efficiency oily wastewater treatment. J. Hazard. Mater. 2020, 383, 121152. [Google Scholar] [CrossRef]

- Ma, W.; Ding, Y.; Zhang, M.; Gao, S.; Li, Y.; Huang, C.; Fu, G. Nature-inspired chemistry toward hierarchical superhydrophobic, antibacterial and biocompatible nanofibrous membranes for effective UV-shielding, self-cleaning and oil-water separation. J. Hazard. Mater. 2020, 384, 121476. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Martinez-Abad, A.; Lagaron, J.M. Zein-based ultrathin fibers containing ceramic nanofillers obtained by electrospinning. II. Mechanical properties, gas barrier, and sustained release capacity of biocide thymol in multilayer polylactide films. J. Appl. Polym. Sci. 2014, 131, 40768. [Google Scholar] [CrossRef]

- Melendez-Rodriguez, B.; Castro-Mayorga, J.L.; Reis, M.A.M.; Sammon, C.; Cabedo, L.; Torres-Giner, S.; Lagaron, J.M. Preparation and characterization of electrospun food biopackaging films of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) derived from fruit pulp biowaste. Front. Sustain. Food Syst. 2018, 2. [Google Scholar] [CrossRef]

- Figueroa-Lopez, K.; Enescu, D.; Torres-Giner, S.; Cabedo, L.; Cerqueira, M.; Pastrana, L.; Fuciños, P.; Lagaron, J. Development of electrospun active films of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by the incorporation of cyclodextrin inclusion complexes containing oregano essential oil. Food Hydrocoll. 2020, 108, 106013. [Google Scholar] [CrossRef]

- Alp-Erbay, E.; Figueroa-Lopez, K.J.; Lagaron, J.M.; Çağlak, E.; Torres-Giner, S. The impact of electrospun films of poly(ε-caprolactone) filled with nanostructured zeolite and silica microparticles on in vitro histamine formation by Staphylococcus aureus and Salmonella Paratyphi A. Food Packag. Shelf Life 2019, 22. [Google Scholar] [CrossRef]

- Wang, Y.; Xue, J.; Wang, Q.; Chen, Q.; Ding, J. Verification of icephobic/anti-icing properties of a superhydrophobic surface. ACS Appl. Mater. Interfaces 2013, 5, 3370–3381. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.; Cheng, Y.; Huang, J.; Xiong, J.; Ge, M.; Mao, J.; Liu, Z.; Dong, X.; Chen, Z.; Lai, Y. A transparent superhydrophobic coating with mechanochemical robustness for anti-icing, photocatalysis and self-cleaning. Chem. Eng. J. 2020, 399, 125746. [Google Scholar] [CrossRef]

- Wu, X.; Chen, Z. A mechanically robust transparent coating for anti-icing and self-cleaning applications. J. Mater. Chem. A 2018, 6, 16043–16052. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Q.; Zhan, X.; Chen, F. Superhydrophobic and anti-icing properties at overcooled temperature of a fluorinated hybrid surface prepared via a sol–gel process. Soft Matter 2015, 11, 4540–4550. [Google Scholar] [CrossRef]

- Tas, M.; Memon, H.; Xu, F.; Ahmed, I.; Hou, X. Electrospun nanofibre membrane based transparent slippery liquid-infused porous surfaces with icephobic properties. Colloids Surf. A Physicochem. Eng. Asp. 2020, 585, 124177. [Google Scholar] [CrossRef]

- Tantawy, A.H.; Mohamed, I.M.; Zhu, J.-H.; Khalaf, M.M. An efficient synthesis of electrospun TiO2-nanofibers/Schiff base phenylalanine composite and its inhibition behavior for C-steel corrosion in acidic chloride environments. J. Taiwan Inst. Chem. Eng. 2020, 112, 306–321. [Google Scholar] [CrossRef]

- Lee, M.W.; An, S.; Lee, C.; Liou, M.; Yarin, A.L.; Yoon, S.S. Self-healing transparent core–shell nanofiber coatings for anti-corrosive protection. J. Mater. Chem. A 2014, 2, 7045–7053. [Google Scholar] [CrossRef]

- Ji, X.; Wang, W.; Li, W.; Zhao, X.; Liu, A.; Wang, X.; Zhang, X.; Fan, W.; Wang, Y.; Lu, Z.; et al. pH-responsible self-healing performance of coating with dual-action core-shell electrospun fibers. J. Taiwan Inst. Chem. Eng. 2019, 104, 227–239. [Google Scholar] [CrossRef]

- Yang, J.; Liu, C.; Wang, B.; Ding, X. Feedback system control optimized electrospinning for fabrication of an excellent superhydrophobic surface. Nanomaterials 2017, 7, 319. [Google Scholar] [CrossRef] [PubMed]

- Uzoma, P.C.; Liu, F.; Han, E.-H.; Uzoma, P.C. Multi-stimuli-triggered and self-repairable fluorocarbon organic coatings with urea-formaldehyde microcapsules filled with fluorosilane. J. Mater. Sci. Technol. 2020, 45, 70–83. [Google Scholar] [CrossRef]

- An, S.; Liou, M.; Song, K.Y.; Jo, H.S.; Lee, M.W.; Al-Deyab, S.S.; Yarin, A.L.; Yoon, S.S. Highly flexible transparent self-healing composite based on electrospun core–shell nanofibers produced by coaxial electrospinning for anti-corrosion and electrical insulation. Nanoscale 2015, 7, 17778–17785. [Google Scholar] [CrossRef] [PubMed]

| Material | Light Transmittance | Thickness | Average Diameter | Preparation Method | Application | Citation |

|---|---|---|---|---|---|---|

| CNWs/epoxy resin | 92% | 0.43 ± 0.03 mm | Dipping after electrospinning | reinforcing material | [78] | |

| PAN/PMMA | 90% | 0.1–0.4 mm | 550 nm | Dipping after electrospinning | windshields for fast-moving objects | [55] |

| PA-6/TPU | >90% | 163 nm | Casting after electrospinning | [64] | ||

| ITO/PVP | 95% | 75.7 nm | 188.0 ± 29.6 nm | Annealing after electrospinning | optoelectronic and sensing applications. | [87] |

| PAN/PU | >95% | Thermal treatment after electrospinning | temperature monitor | [98] | ||

| Cu | 90% | Surface modification after electrospinning | transparent heater | [109] | ||

| ZnO/ PDMS-PI | 93% | Surface modification after electrospinning | oil–water separation membrane | [158] | ||

| Ag/Ag2O | 92% | Surface modification after electrospinning | optoelectronic applications | [153] | ||

| Cu/Ni | 93% | 4.75 μm | Surface modification after electrospinning | transparent heater | [113] | |

| rGO/PVA | 90% | Annealing after electrospinning | conductive film | [154] | ||

| PDMS/PAN | 90% | Direct electrospinning | self-healing anticorrosive material | [174] | ||

| AgNW CuNW | 90% | 70 nm | Electroless deposition after electrospinning | electrical conductivity | [103] | |

| Cu | Electroless deposition after electrospinning | transparent electrode | [104] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Luo, H.; Tang, R.; Hou, J. Preparation and Applications of Electrospun Optically Transparent Fibrous Membrane. Polymers 2021, 13, 506. https://doi.org/10.3390/polym13040506

Xiao Y, Luo H, Tang R, Hou J. Preparation and Applications of Electrospun Optically Transparent Fibrous Membrane. Polymers. 2021; 13(4):506. https://doi.org/10.3390/polym13040506

Chicago/Turabian StyleXiao, Yanan, Hao Luo, Rongxing Tang, and Jiazi Hou. 2021. "Preparation and Applications of Electrospun Optically Transparent Fibrous Membrane" Polymers 13, no. 4: 506. https://doi.org/10.3390/polym13040506