Melt Spinning of Highly Stretchable, Electrically Conductive Filament Yarns

Abstract

:1. Introduction

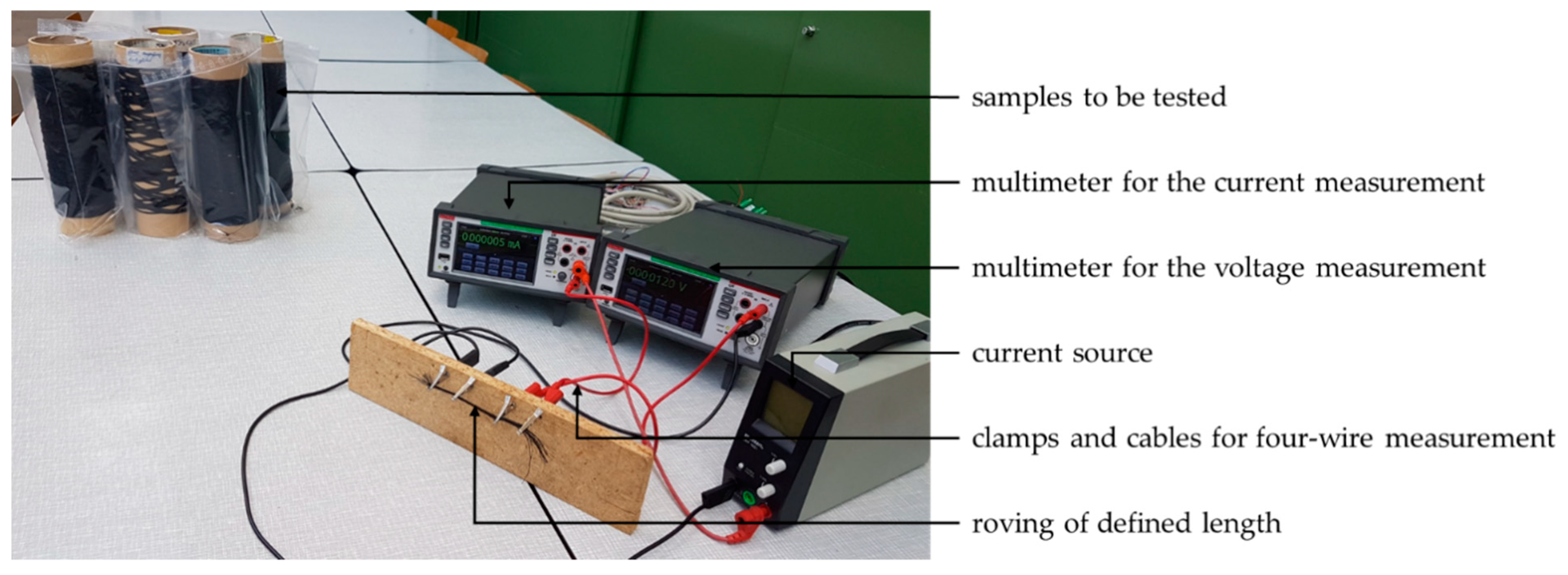

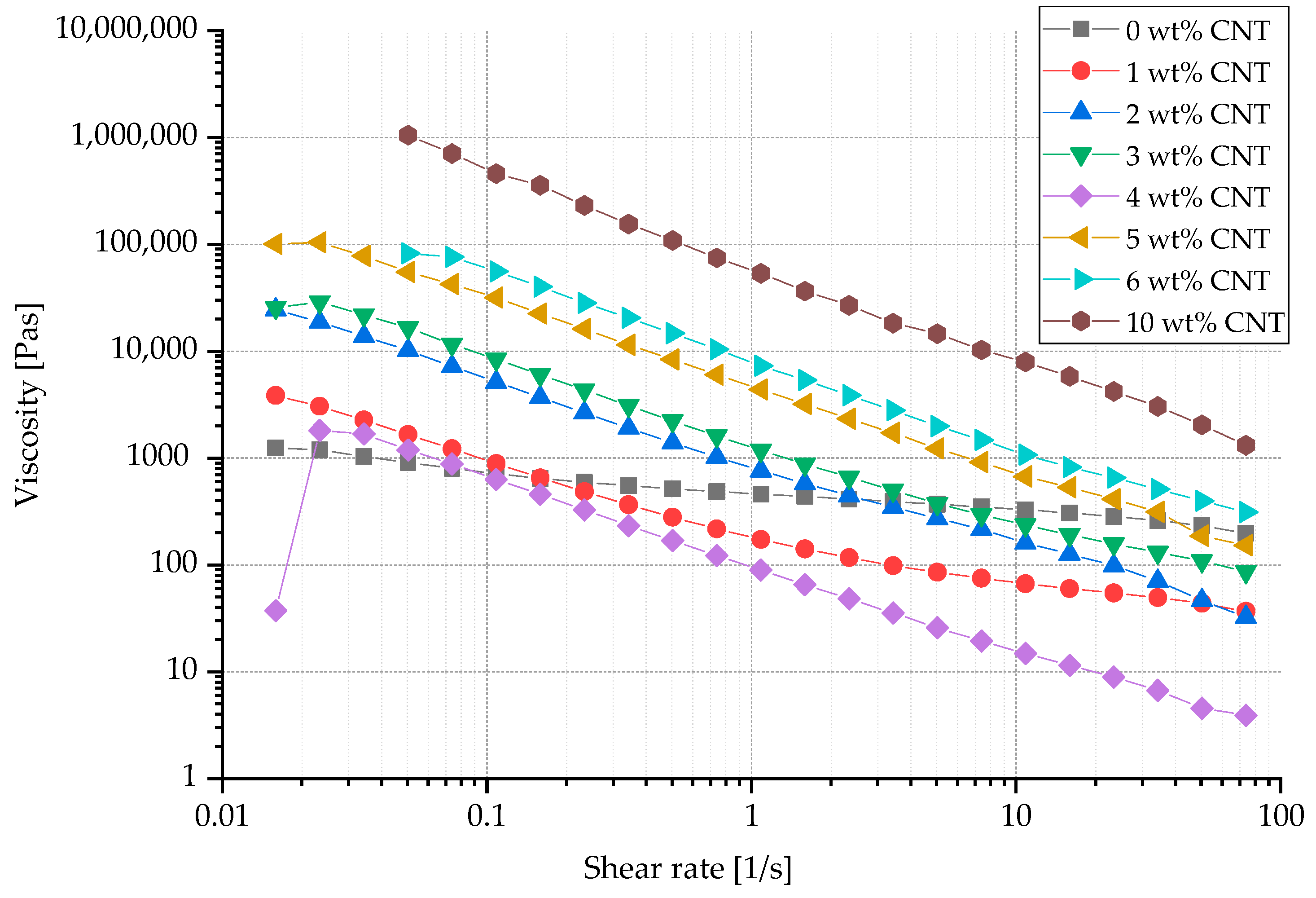

2. Materials and Methods

3. Results and Discussion

3.1. Spinning and Stretching Process

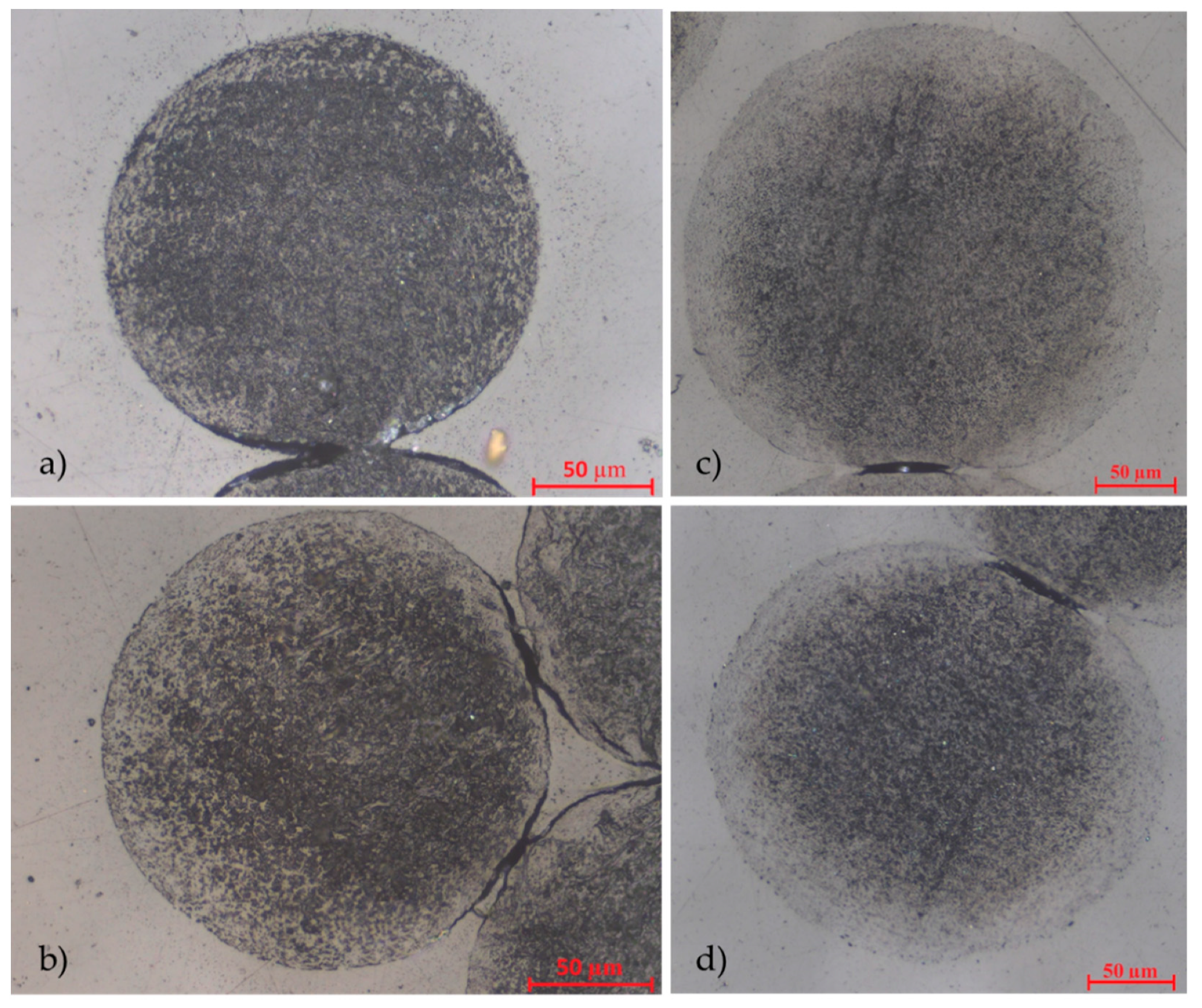

3.2. Microscopic Analyses

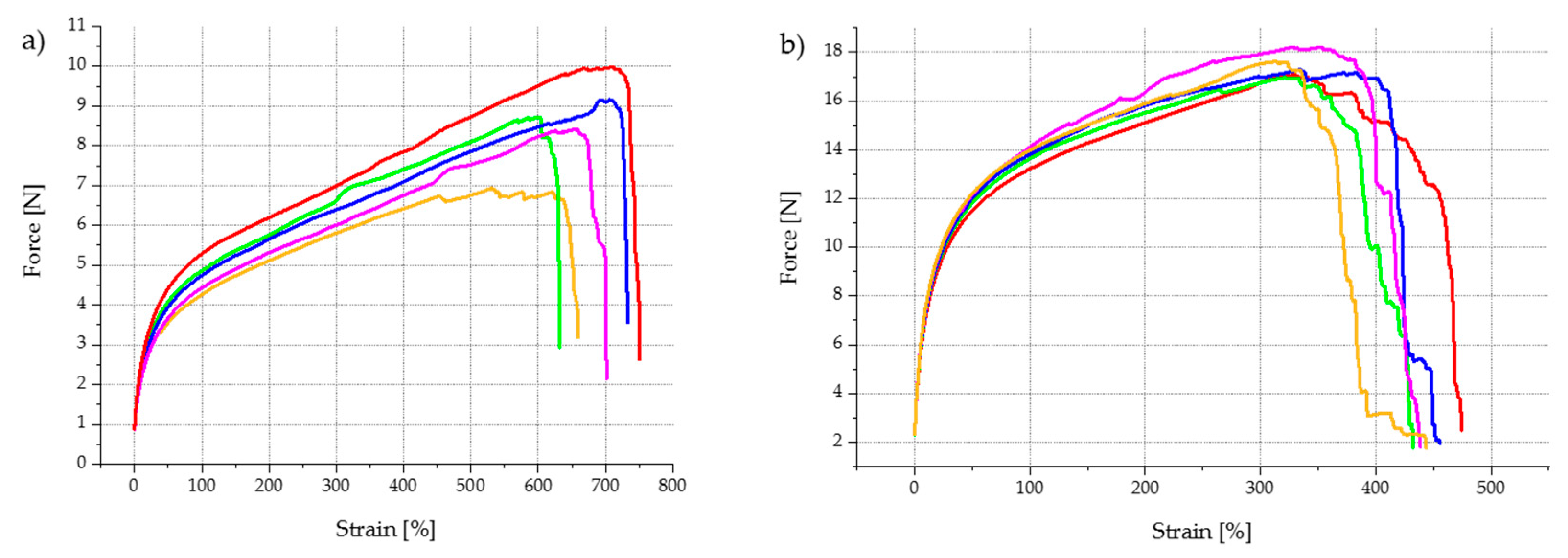

3.3. Stress–Strain Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wendler, J.; Nocke, A.; Aibibu, D.; Cherif, C. Novel temperature sensors based on strain-relieved braiding constructions. Text. Res. J. 2019, 89, 3159–3168. [Google Scholar] [CrossRef]

- Jerkovic, I.; Koncar, V.; Grancaric, A.M. New Textile Sensors for In Situ Structural Health Monitoring of Textile Reinforced Thermoplastic Composites Based on the Conductive Poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) Polymer Complex. Sensors 2017, 17, 2297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nocke, A.; Häntzsche, E.; Wendler, J.; Cherif, C. C7. 2-Textile-based sensor systems for condition monitoring in composite and medical applications. Proc. Sens. 2017, 2017, 405–409. [Google Scholar] [CrossRef]

- Hufenbach, W.A.; Kostka, P.; Maron, B.; Weck, D.; Ehlig, J.; Gude, M.; Zscheyge, M. Development and Investigation of a Textile-reinforced Thermoplastic Leaf Spring with Integrated Sensor Networks. Procedia Mater. Sci. 2013, 2, 173–180. [Google Scholar] [CrossRef] [Green Version]

- Nocke, A.; Schröter, A.; Cherif, C.; Gerlach, G. Miniaturized textile-based multi-layer ph-sensor for wound monitoring applications. Autex Res. J. 2012, 12, 20–22. [Google Scholar] [CrossRef]

- Lugoda, P.; Hughes-Riley, T.; Morris, R.; Dias, T. A Wearable Textile Thermograph. Sensors 2018, 18, 2369. [Google Scholar] [CrossRef] [Green Version]

- Bremer, K.; Weigand, F.; Zheng, Y.; Alwis, L.S.; Helbig, R.; Roth, B. Structural Health Monitoring Using Textile Reinforcement Structures with Integrated Optical Fiber Sensors. Sensors 2017, 17, 345. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Haentzsche, E.; Mueller, R.; Ruder, T.; Nocke, A.; Cherif, C. Integrative Manufacturing of Textile-Based Sensors for Spatially Resolved Structural Health Monitoring Tasks of Large-Scaled Composite Components. In Materials Science Forum; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2015; vol. 825–826, pp. 571–578. [Google Scholar] [CrossRef]

- Haentzsche, E.; Onggar, T.; Nocke, A.; Hund, R.D.; Cherif, C. Multi-layered sensor yarns for in situ monitoring of textile reinforced composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 42012. [Google Scholar] [CrossRef]

- Shyr, T.-W.; Shie, J.-W.; Jiang, C.-H.; Li, J.-J. A textile-based wearable sensing device designed for monitoring the flexion angle of elbow and knee movements. Sensors 2014, 14, 4050–4059. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heo, J.S.; Eom, J.; Kim, Y.-H.; Park, S.K. Recent Progress of Textile-Based Wearable Electronics: A Comprehensive Review of Materials, Devices, and Applications. Small 2018, 14. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Facchetti, A. Mechanically Flexible Conductors for Stretchable and Wearable E-Skin and E-Textile Devices. Adv. Mater. Weinh. 2019, 31, e1901408. [Google Scholar] [CrossRef]

- Fuh, Y.K.; Kuo, C.C.; Huang, Z.M.; Li, S.C.; Liu, E.R. A Transparent and Flexible Graphene-Piezoelectric Fiber Generator. Small 2016, 12, 1875–1881. [Google Scholar] [CrossRef] [PubMed]

- Ashir, M.; Hindahl, J.; Nocke, A.; Cherif, C. Development of adaptive pleated fiber reinforced plastic composites. Compos. Sci. Technol. 2017, 148, 27–34. [Google Scholar] [CrossRef]

- Ashir, M.; Nocke, A.; Cherif, C. Maximum deformation of shape memory alloy based adaptive fiber-reinforced plastics. Compos. Sci. Technol. 2019, 184, 107860. [Google Scholar] [CrossRef]

- Mas, B.; Biggs, D.; Vieito, I.; Cladera, A.; Shaw, J.; Martínez-Abella, F. Superelastic shape memory alloy cables for reinforced concrete applications. Constr. Build. Mater. 2017, 148, 307–320. [Google Scholar] [CrossRef]

- Saghaian, S.M.; Karaca, H.E.; Tobe, H.; Turabi, A.S.; Saedi, S.; Saghaian, S.E.; Chumlyakov, Y.I.; Noebe, R.D. High strength NiTiHf shape memory alloys with tailorable properties. Acta Mater. 2017, 134, 211–220. [Google Scholar] [CrossRef]

- Gök, M.O.; Bilir, M.Z.; Gürcüm, B.H. Shape-Memory Applications in Textile Design. Procedia-Soc. Behav. Sci. 2015, 195, 2160–2169. [Google Scholar] [CrossRef] [Green Version]

- Rapp, S. Shape Memory Polymers in Fiber Composite Structures for Shape Adjustment. Dissertationsschrift; Technische Universität München: München, Germany, 2011. [Google Scholar]

- Leng, J.; Lv, H.; Liu, Y.; Du, S. Synergic effect of carbon black and short carbon fiber on shape memory polymer actuation by electricity. J. Appl. Phys. 2008, 104, 104917. [Google Scholar] [CrossRef]

- Satharasinghe, A.; Hughes-Riley, T.; Dias, T. Photodiode and LED Embedded Textiles for Waerable Healthcare Applications. In Proceedings of the 19th World Textile Conference-Autex, Ghent, Belgium, 11–15 June 2019. [Google Scholar]

- Haentzsche, E.; Mueller, R.; Huebner, M.; Ruder, T.; Unger, R.; Nocke, A.; Cherif, C. Manufacturing technology of integrated textile-based sensor networks for in situ monitoring applications of composite wind turbine blades. Smart Mater. Struct. 2016, 25, 105012. [Google Scholar] [CrossRef]

- Onggar, T.; Amrhein, G.; Abdkader, A.; Hund, R.-D.; Cherif, C. Wet-chemical method for the metallization of a para-aramid filament yarn wound on a cylindrical dyeing package. Text. Res. J. 2017, 87, 1192–1202. [Google Scholar] [CrossRef]

- Grancarić, A.M.; Jerković, I.; Koncar, V.; Cochrane, C.; Kelly, F.M.; Soulat, D.; Legrand, X. Conductive polymers for smart textile applications. J. Ind. Text. 2018, 48, 612–642. [Google Scholar] [CrossRef]

- Lund, A.; Hagström, B. Melt spinning of β-phase poly(vinylidene fluoride) yarns with and without a conductive core. J. Appl. Polym. Sci. 2011, 120, 1080–1089. [Google Scholar] [CrossRef]

- Lund, A. Melt spun piezoelectric textile fibres. In An Experimental Study; Chalmers Univ. of Technology: Göteborg, Sweden, 2013. [Google Scholar]

- Glauß, B.; Jux, M.; Walter, S.; Kubicka, M.; Seide, G.; Wierach, P.; Gries, T.; Roth, G. Poling Effects in Melt-Spun PVDF Bicomponent Fibres. KEM 2015, 644, 110–114. [Google Scholar] [CrossRef]

- Glauß, B.; Steinmann, W.; Walter, S.; Beckers, M.; Seide, G.; Gries, T.; Roth, G. Spinnability and Characteristics of Polyvinylidene Fluoride (PVDF)-based Bicomponent Fibers with a Carbon Nanotube (CNT) Modified Polypropylene Core for Piezoelectric Applications. Materials 2013, 6, 2642–2661. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Steinmann, W.; Walter, S.; Beckers, M.; Seide, G.; Gries, T. Thermal Analysis of Phase Transitions and Crystallization in Polymeric Fibers. In Applications of Calorimetry in a Wide Context: Differential Scanning Calorimetry, Isothermal Titration Calorimetry and Microcalorimetry; Elkordy, A.A., Ed.; InTech: Rijeka, Croatia, 2013; ISBN 978-953-51-0947-1. [Google Scholar]

- Steinmann, W.; Wulfhorst, J.; Vad, T.; Beckers, M.; Seide, G.; Gries, T. Controlling the Structure of Nanocomposite Fibers—Application to Electrically Conductive Fibers and Fiber Based Solar Cells. In Proceedings of the NANOCON 2012, Brno, Czech Republic, 23–25 October 2012. [Google Scholar]

- Guinovart, T.; Parrilla, M.; Crespo, G.A.; Rius, F.X.; Andrade, F.J. Potentiometric sensors using cotton yarns, carbon nanotubes and polymeric membranes. Analyst 2013, 138, 5208–5215. [Google Scholar] [CrossRef] [PubMed]

- Parrilla, M.; Ferré, J.; Guinovart, T.; Andrade, F.J. Wearable Potentiometric Sensors Based on Commercial Carbon Fibres for Monitoring Sodium in Sweat. Electroanalysis 2016, 28, 1267–1275. [Google Scholar] [CrossRef]

- Cuartero, M.; del Río, J.S.; Blondeau, P.; Ortuño, J.A.; Rius, F.X.; Andrade, F.J. Rubber-based substrates modified with carbon nanotubes inks to build flexible electrochemical sensors. Anal. Chim. Acta 2014, 827, 95–102. [Google Scholar] [CrossRef] [PubMed]

- Parrilla, M.; Cánovas, R.; Jeerapan, I.; Andrade, F.J.; Wang, J. A Textile-Based Stretchable Multi-Ion Potentiometric Sensor. Adv. Healthc. Mater. 2016, 5, 996–1001. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, B.; Zheng, G.; Liu, X.; Li, T.; Yan, C.; Cheng, C.; Dai, K.; Liu, C.; Shen, C.; et al. Continuously prepared highly conductive and stretchable SWNT/MWNT synergistically composited electrospun thermoplastic polyurethane yarns for wearable sensing. J. Mater. Chem. C 2018, 6, 2258–2269. [Google Scholar] [CrossRef]

- Schemmer, B.; Kronenbitter, C.; Mecking, S. Thermoplastic Polyurethane Elastomers with Aliphatic Hard Segments Based on Plant-Oil-Derived Long-Chain Diisocyanates. Macromol. Mater. Eng. 2018, 303, 1700416. [Google Scholar] [CrossRef] [Green Version]

- Mirtschin, N. Thermomechanisches Verhalten von Semikristallinem Polyester-Urethan. Ph.D. Thesis, Technische Universität Berlin, Berlin, Germany, 2017. [Google Scholar]

- Szycher, M. Structure–Property Relations in Polyurethanes. In Szycher’s Handbook of Polyurethanes, 2nd ed.; Szycher, M., Ed.; Taylor & Francis: Boca Raton, FL, USA, 2013; pp. 37–86. ISBN 978-1-4398-3958-4. [Google Scholar]

- Kimura, I.; Ishihara, H.; Ono, H.; Yoshihara, N.; Nomura, S.; Kawai, H. Morphology and Deformation Mechanism of Segmented Poly(urethaneureas) in Relation to Spherulitic Crystalline Textures. Macromolecules 1974, 7, 355–363. [Google Scholar] [CrossRef]

- Stribeck, N.; Zeinolebadi, A.; Harpen, F.; Luinstra, G.; Eling, B.; Botta, S. Thermoplastic Polyurethane Cross-Linked by Functionalized Silica. Nanostructure Evolution under Mechanical Load. Macromolecules 2013, 46, 4041–4052. [Google Scholar] [CrossRef]

- Kong, X. Lubricated Dynamic Friction Measurement of Thermoplastic Polyurethane. Ph.D. Thesis, University of Hamburg, Hamburg, Germany, 2019. [Google Scholar]

- Covestro, A.G. Desmopan 9370A GMP: Technical Data Sheet. Available online: https://solutions.covestro.com/en/products/desmopan/desmopan-9370a-gmp_84876836-05124172?SelectedCountry=DE (accessed on 14 April 2020).

- Nanocyl, S.A. DM-T&I-02-TDS-PLASTICYL-TPU1001-V05: Technical Data Sheet Plasticyl TPU1001-V05. Available online: https://www.nanocyl.com/product/plasticyl-pp2001-2/ (accessed on 14 April 2020).

- Bhagavatheswaran, E.S.; Stöckelhuber, K.W.; Vaikuntam, S.R.; Wießner, S.; Pötschke, P.; Heinrich, G.; Das, A. Time and Temperature dependent piezoresistive Behavior of conductive Elastomeric Composites. Rubber Chem. Technol. 2018, 91, 651–667. [Google Scholar] [CrossRef]

- Bertolini, M.C.; Ramoa, S.D.A.S.; Merlini, C.; Barra, G.M.O.; Soares, B.G.; Pegoretti, A. Hybrid Composites Based on Thermoplastic Polyurethane With a Mixture of Carbon Nanotubes and Carbon Black Modified With Polypyrrole for Electromagnetic Shielding. Front. Mater. 2020, 7, 41. [Google Scholar] [CrossRef]

- Becker, F.-M. Formelsammlung. Bis zum Abitur; Formeln, Tabellen, Wissenswertes; Version 1.2; Duden-Paetec-Schulbuchverl.: Berlin, Germany, 2005; ISBN 978-3-89818-700-8. [Google Scholar]

- Wacker Chemie, A.G. Powersil 464 A/B: Electrically Conductive Liquid Rubber. 2020. Available online: https://www.wacker.com/h/de-de/c/powersil-464-ab/p/000011022 (accessed on 12 February 2021).

- Wacker Chemie, A.G. Powersil 466 A/B VP: Electrically Conductive Liquid Rubber. Datenblatt. Available online: https://www.wacker.com/h/de-de/siliconkautschuk/fluessigsiliconkautschuk-lsr/powersil-466-ab/p/000011023 (accessed on 23 July 2020).

| CNT Content in wt.% | Winding Speed in m/min | Fineness in Tex | Elongation at Break in % | Young’s Modulus in kPa | Specific Electrical Resistance in Ωcm | Specific Electrical Resistance in Ωcm at 50% Relative Elongation | Specific Electrical Resistance in Ωcm at 100% Relative Elongation |

|---|---|---|---|---|---|---|---|

| 0 | 400.0 | 53 ± 2 | 717 ± 85 | 37.0 ± 4.4 | > 2 × 105 | > 2 × 105 | > 2 × 105 |

| 650.0 | 50 ± 5 | 793 ± 84 | 21.8 ± 6.9 | > 2 × 105 | > 2 × 105 | > 2 × 105 | |

| 1 | 600.0 | 33 ± 1 | 669 ± 60 | 48.9 ± 9.4 | > 2 × 105 | > 2 × 105 | > 2 × 105 |

| 650.0 | 32 ± 1 | 518 ± 82 | 55.7 ± 14.1 | > 2 × 105 | > 2 × 105 | > 2 × 105 | |

| 2 | 37.2 | 386 ± 74 | 294 ± 26 | 56.9 ± 6.4 | > 2 × 105 | > 2 × 105 | > 2 × 105 |

| 3 | 15.0 | 903 ± 123 | 641 ± 75 | 34.2 ± 2.7 | > 2 × 105 | > 2 × 105 | > 2 × 105 |

| 25.0 | 637 ± 122 | 524 ± 57 | 52.7 ± 5.0 | > 2 × 105 | > 2 × 105 | > 2 × 105 | |

| 37.2 | 271 ± 83 | 177 ± 21 | 74.7 ± 6.9 | > 2 × 105 | > 2 × 105 | > 2 × 105 | |

| 4 | 12.0 | 2102 ± 281 | 350 ± 44 | 27.2 ± 0.9 | 586 ± 411 | 3776 ± 482 | 12,909 ± 314 |

| 15.0 | 1750 ± 208 | 219 ± 49 | 44.8 ± 2.4 | 1777 ± 756 | 9011 ± 2317 | 14,057 ±750 | |

| 20.0 | 1114 ± 133 | 505 ± 38 | 45.9 ± 2.6 | 4213 ± 975 | 12,401 ± 1343 | 9974 ± 274 | |

| 25.0 | 1149 ± 195 | 346 ± 18 | 41.4 ± 1.9 | 6668 ± 662 | 10,808 ± 1521 | 10,048 ± 344 | |

| 30.0 | 1211 ± 86 | 196 ± 32 | 29.9 ± 3.7 | 3904 ± 1553 | 6119 ± 1595 | 9942 ± 392 | |

| 5 | 8.0 | 2314 ± 294 | 292 ± 23 | 63.0 ± 3.4 | 131 ± 48 | 663 ± 221 | 2571 ± 967 |

| 10.0 | 2171 ± 422 | 400 ± 18 | 46.4 ± 5.7 | 110 ± 39 | 1429 ± 303 | 5243 ± 811 | |

| 15.0 | 1664 ± 92 | 383 ± 39 | 51.5 ± 3.8 | 2170 ± 201 | 17,441 ± 646 | 14,377 ± 296 | |

| 6 | 10.0 | 2950 ± 207 | 339 ± 40 | 44.6 ± 1.8 | 151 ± 41 | 723 ± 156 | 2185 ± 608 |

| 15.0 | 2387 ± 258 | 326 ± 8 | 53.4 ± 2.4 | 1045 ± 316 | 1024 ± 424 | 2337 ± 831 | |

| 17.0 | 1764 ± 217 | 293 ± 26 | 80.0 ± 3.0 | 2077 ± 405 | 2429 ± 295 | 10,234 ± 1202 | |

| 20.0 | 1672 ± 272 | 246 ± 28 | 72.8 ± 3.9 | 1717 ± 448 | 1814 ± 239 | 5980 ± 2631 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Probst, H.; Katzer, K.; Nocke, A.; Hickmann, R.; Zimmermann, M.; Cherif, C. Melt Spinning of Highly Stretchable, Electrically Conductive Filament Yarns. Polymers 2021, 13, 590. https://doi.org/10.3390/polym13040590

Probst H, Katzer K, Nocke A, Hickmann R, Zimmermann M, Cherif C. Melt Spinning of Highly Stretchable, Electrically Conductive Filament Yarns. Polymers. 2021; 13(4):590. https://doi.org/10.3390/polym13040590

Chicago/Turabian StyleProbst, Henriette, Konrad Katzer, Andreas Nocke, Rico Hickmann, Martina Zimmermann, and Chokri Cherif. 2021. "Melt Spinning of Highly Stretchable, Electrically Conductive Filament Yarns" Polymers 13, no. 4: 590. https://doi.org/10.3390/polym13040590

APA StyleProbst, H., Katzer, K., Nocke, A., Hickmann, R., Zimmermann, M., & Cherif, C. (2021). Melt Spinning of Highly Stretchable, Electrically Conductive Filament Yarns. Polymers, 13(4), 590. https://doi.org/10.3390/polym13040590