3D Printed Masks for Powders and Viruses Safety Protection Using Food Grade Polymers: Empirical Tests

Abstract

1. Introduction

2. Materials and Methods

2.1. Mask Models

2.1.1. Frames of Emergency Masks

2.1.2. Filter Support and Eco-Masks Frame

2.1.3. Self-Adaptable Mask

2.2. Cleaning and Disinfection

2.3. Material Mechanical Characterization

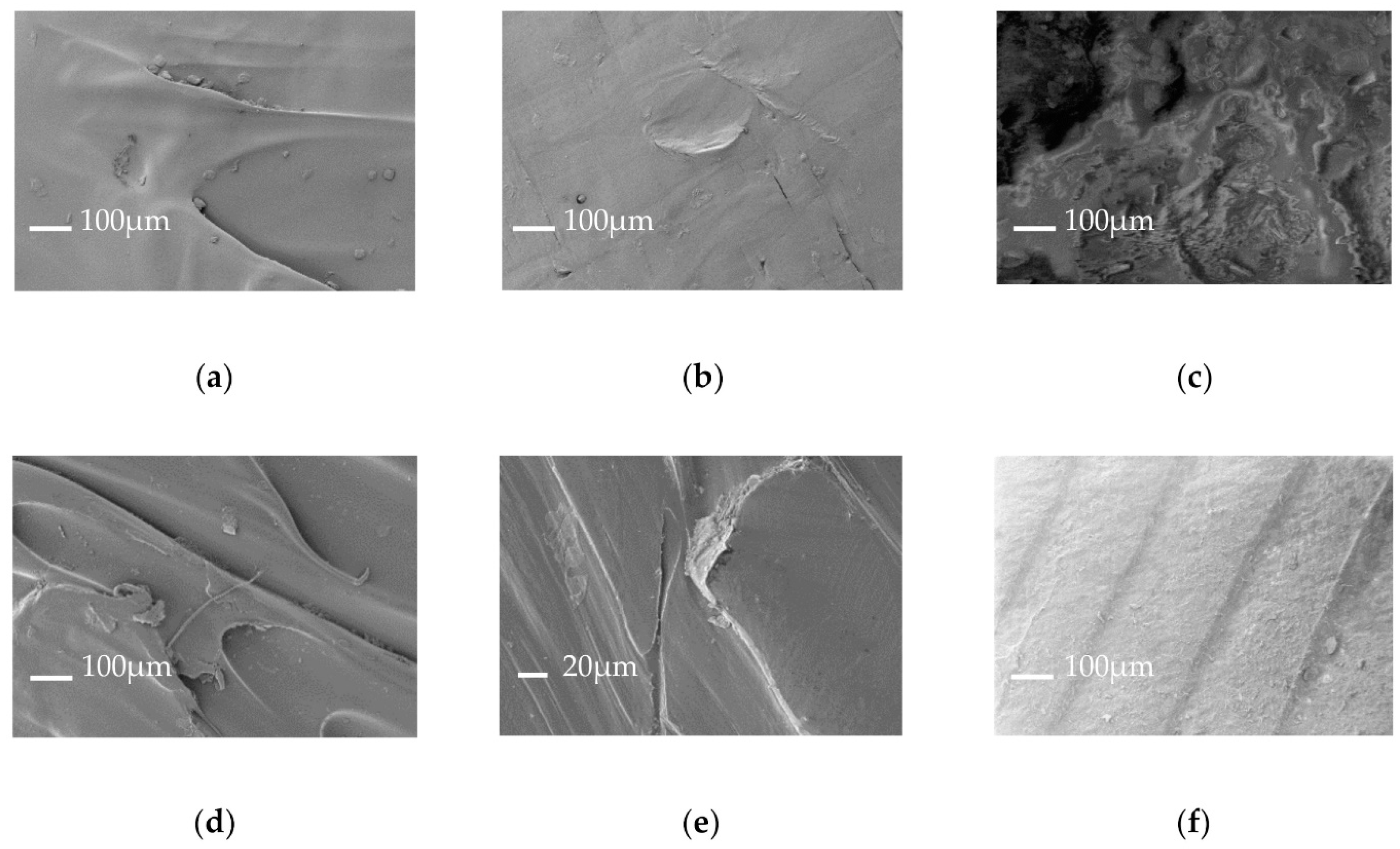

2.4. Morphological Characterization

2.5. In Vitro Biological Tests

2.6. Filter and Melting Analyses

2.7. Statistical Analysis

3. Results and Discussion

3.1. Prototyped Masks

3.2. Mechanical Characterization

3.3. In Vitro Biological Tests

3.4. Electrospinned Filter

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kate, J.T.; Smit, G.; Breedveld, P. 3D-printed upper limb prostheses: A review. Disabil. Rehabil. Assist. Technol. 2017, 12, 300–314. [Google Scholar] [CrossRef]

- Foresti, R.; Macaluso, C.; Rossi, S.; Selleri, S.; Perini, P.; Freyrie, A.; Raposio, E.; Fenaroli, P.; Concari, G.; De Filippo, M.; et al. 3D reconstruction cutting and smart devices for personalized medicine. In Proceedings of the 2020 Italian Conference on Optics and Photonics (ICOP), Venice, Italy, 9–10 April 2020. [Google Scholar]

- Parisi, L.; Toffoli, A.; Ghiacci, G.; Macaluso, G.M. Tailoring the Interface of Biomaterials to Design Effective Scaffolds. J. Funct. Biomater. 2018, 9, 50. [Google Scholar] [CrossRef]

- Guarino, V.; Scaglione, S.; Sandri, M.; Sprio, S.; Tampieri, A.; Ambrosio, L. Composite Scaffolds for Bone and Osteochondral Defects; Elsevier: Amsterdam, The Netherlands, 2019; pp. 297–337. [Google Scholar]

- Foresti, R.; Rossi, S.; Selleri, S. Bio composite materials: Nano functionalization of 4D bio engineered scaffold. In Proceedings of the 2019 IEEE International Conference on BioPhotonics (BioPhotonics), Taipei, Taiwan, 15–18 September 2019. [Google Scholar]

- Foresti, R.; Rossi, S.; Pinelli, S.; Alinovi, R.; Sciancalepore, C.; Delmonte, N.; Selleri, S.; Caffarra, C.; Raposio, E.; Macaluso, G.; et al. In-vivo vascular application via ultra-fast bioprinting for future 5D personalised nanomedicine. Sci. Rep. 2020, 10, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Foresti, R.; Rossi, S.; Pinelli, S.; Alinovi, R.; Barozzi, M.; Sciancalepore, C.; Galetti, M.; Caffarra, C.; Lagonegro, P.; Scavia, G.; et al. Highly-defined bioprinting of long-term vascularized scaffolds with Bio-Trap: Complex geometry functionalization and process parameters with computer aided tissue engineering. Materialia 2020, 9, 100560. [Google Scholar] [CrossRef]

- Elviri, L.; Foresti, R.; Bergonzi, C.; Zimetti, F.; Marchi, C.; Bianchera, A.; Bernini, F.; Silvestri, M.; Bettini, R. Highly defined 3D printed chitosan scaffolds featuring improved cell growth. Biomed. Mater. 2017, 12, 045009. [Google Scholar] [CrossRef]

- Foresti, R.; Rossi, S.; Magnani, M.; Bianco, C.G.L.; Delmonte, N. Smart society and artificial intelligence: Big Data scheduling and the global standard method applied to smart maintenance. Engeering 2020, 6, 835–846. [Google Scholar] [CrossRef]

- Avventuroso, G.; Foresti, R.; Silvestri, M.; Frazzon, E.M. Production paradigms for additive manufacturing systems: A simulation-based analysis. In Proceedings of the 2017 International Conference on Engineering, Technology and Innovation (ICE/ITMC), Madeira Island, Portugal, 27–29 June 2017. [Google Scholar]

- Elviri, L.; Foresti, R.; Bianchera, A.; Silvestri, M.; Bettini, R. 3D-printed polylactic acid supports for enhanced ionization efficiency in desorption electrospray mass spectrometry analysis of liquid and gel samples. Talanta 2016, 155, 321–328. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Morales, J.C.; Tarancón, A.; Canales-Vázquez, J.; Méndez-Ramos, J.; Hernández-Afonso, L.; Acosta-Mora, P.; Rueda, J.R.M.; Fernández-González, R. Three dimensional printing of components and functional devices for energy and environmental applications. Energy Environ. Sci. 2017, 10, 846–859. [Google Scholar] [CrossRef]

- Peng, T. Analysis of energy utilization in 3D printing processes. Procedia CIRP 2016, 40, 62–67. [Google Scholar] [CrossRef]

- Gaweł, A.; Kuciel, S. The Study of physico-mechanical properties of polylactide composites with different level of infill produced by the fdm method. Polymers 2020, 12, 3056. [Google Scholar] [CrossRef] [PubMed]

- Maia-Pinto, M.O.C.; Brochado, A.C.B.; Teixeira, B.N.; Sartoretto, S.C.; Uzeda, M.J.; Alves, A.T.N.N.; Alves, G.G.; Calasans-Maia, M.D.; Thiré, R.M.S.M. Biomimetic mineralization on 3D Printed PLA scaffolds: On the response of human primary osteoblasts spheroids and in vivo implantation. Polymers 2020, 13, 74. [Google Scholar] [CrossRef]

- Ehrmann, G.; Ehrmann, A. Investigation of the shape-memory properties of 3D printed PLA Structures with different infills. Polymers 2021, 13, 164. [Google Scholar] [CrossRef]

- Sun, J.; Peng, Z.; Zhou, W.; Fuh, J.Y.; Hong, G.S.; Chiu, A. A review on 3D printing for customized food fabrication. Procedia Manuf. 2015, 1, 308–319. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength of PLA components fabricated with fused deposition technology using a desktop 3D printer as a function of geometrical parameters of the process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef] [PubMed]

- American Society Mechanical Engineers. Medical Additive Manufacturing/3D Printing Year in Review 2019–2020; ASME: New York, NY, USA, 2019. [Google Scholar]

- Kim, Y.; Yoon, C.; Ham, S.; Park, J.; Kim, S.; Kwon, O.; Tsai, P.-J. Emissions of nanoparticles and gaseous material from 3D printer operation. Environ. Sci. Technol. 2015, 49, 12044–12053. [Google Scholar] [CrossRef] [PubMed]

- Barbeck, M.; Serra, T.; Booms, P.; Stojanovic, S.; Najman, S.; Engel, E.; Sader, R.; Kirkpatrick, C.J.; Navarro, M.; Ghanaati, S. Analysis of the in vitro degradation and the in vivo tissue response to bi-layered 3D-printed scaffolds combining PLA and biphasic PLA/bioglass components—Guidance of the inflammatory response as basis for osteochondral regeneration. Bioact. Mater. 2017, 2, 208–223. [Google Scholar] [CrossRef]

- Guo, T.; Lim, C.G.; Noshin, M.; Ringel, J.P.; Fisher, J.P. 3D printing bioactive PLGA scaffolds using DMSO as a removable solvent. Bioprinting 2018, 10, e00038. [Google Scholar] [CrossRef] [PubMed]

- Swennen, G.R.; Pottel, L.; Haers, P.E. Custom-made 3D-printed face masks in case of pandemic crisis situations with a lack of commercially available FFP2/3 masks. Int. J. Oral Maxillofac. Surg. 2020, 49, 673–677. [Google Scholar] [CrossRef]

- Henning, L.M.; Cubas, D.D.; Colmenares, M.G.; Schmidt, J.; Bekheet, M.F.; Pauw, B.R.; Gurlo, A.; Simon, U. High specific surface area ordered mesoporous silica COK-12 with tailored pore size. Microporous Mesoporous Mater. 2019, 280, 133–143. [Google Scholar] [CrossRef]

- Gallud, A.; Delaval, M.; Kinaret, P.; Marwah, V.S.; Fortino, V.; Ytterberg, J.; Zubarev, R.; Skoog, T.; Kere, J.; Correia, M.; et al. Multiparametric profiling of engineered nanomaterials: Unmasking the surface coating effect. Adv. Sci. 2020, 7, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Ivanchenko, P.; Delgado-López, J.M.; Iafisco, M.; Morales, J.G.; Tampieri, A.; Martra, G.; Sakhno, Y. On the surface effects of citrates on nano-apatites: Evidence of a decreased hydrophilicity. Sci. Rep. 2017, 7, 1–10. [Google Scholar] [CrossRef]

- Raj, S.A.; Muthukumaran, E.; Jayakrishna, K. A case study of 3D printed PLA and its mechanical properties. Mater. Today Proc. 2018, 5, 11219–11226. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, Y.; Zhou, Y. Novel mechanical models of tensile strength and elastic property of FDM AM PLA materials: Experimental and theoretical analyses. Mater. Des. 2019, 181, 108089. [Google Scholar] [CrossRef]

- Merritt, S.R.; Exner, A.A.; Lee, Z.; Von Recum, H.A. Electrospinning and imaging. Adv. Eng. Mater. 2011, 14, B266–B278. [Google Scholar] [CrossRef]

- Liu, Y.; Hao, M.; Chen, Z.; Liu, L.; Liu, Y.; Yang, W.; Ramakrishna, S. A review on recent advances in application of electrospun nanofiber materials as biosensors. Curr. Opin. Biomed. Eng. 2020, 13, 174–189. [Google Scholar] [CrossRef]

- Nazarnezhad, S.; Baino, F.; Kim, H.-W.; Webster, T.J.; Kargozar, S. Electrospun nanofibers for improved angiogenesis: Promises for tissue engineering applications. Nanomaterials 2020, 10, 1609. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.; Chen, Y.; Wang, X.; Xu, X.; Shen, Y.; Khan, A.U.R.; Aldalbahi, A.; Fetz, A.E.; Bowlin, G.L.; El-Newehy, M.; et al. Electrospinning nanofiber scaffolds for soft and hard tissue regeneration. J. Mater. Sci. Technol. 2020, 59, 243–261. [Google Scholar] [CrossRef]

- Jain, R.; Shetty, S.; Yadav, K.S. Unfolding the electrospinning potential of biopolymers for preparation of nanofibers. J. Drug Deliv. Sci. Technol. 2020, 57, 101604. [Google Scholar] [CrossRef]

- Liang, J.; Zhao, H.; Yue, L.; Fan, G.; Li, T.S.; Lu, S.; Chen, G.; Gao, S.; Asiri, A.M.; Sun, X. Recent advances in electrospun nanofibers for supercapacitors. J. Mater. Chem. A 2020, 8, 16747–16789. [Google Scholar] [CrossRef]

- Rutala, W. New disinfection and sterilization methods. Emerg. Infect. Dis. 2001, 7, 348–353. [Google Scholar] [CrossRef] [PubMed]

- Rutala, W.A.; Weber, D.J. Disinfection and sterilization in health care facilities. Infect. Dis. Clin. N. Am. 2016, 30, 609–637. [Google Scholar] [CrossRef] [PubMed]

- Bergonzi, L.; Vettori, M.; Pirondi, A.; Moroni, F.; Musiari, F. Numerical and experimental validation of a non-standard specimen for uniaxial tensile test. Procedia Struct. Integr. 2018, 12, 392–403. [Google Scholar] [CrossRef]

- Lagonegro, P.; Rossi, F.; Galli, C.; Smerieri, A.; Alinovi, R.; Pinelli, S.; Rimoldi, T.; Attolini, G.; Macaluso, G.; Saddow, S.; et al. A cytotoxicity study of silicon oxycarbide nanowires as cell scaffold for biomedical applications. Mater. Sci. Eng. C 2017, 73, 465–471. [Google Scholar] [CrossRef] [PubMed]

- Grandjean, P.; Heilmann, C.; Weihe, P.; Nielsen, F.; Timmermann, A.; Clinic, P.; Islands, F. Estimated exposures to perfluorinated compounds in infancy predict attenuated vaccine antibody concentrations at age 5-years. J. Immunotoxicol. 2018, 14, 188–195. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Foresti, R.; Ghezzi, B.; Vettori, M.; Bergonzi, L.; Attolino, S.; Rossi, S.; Tarabella, G.; Vurro, D.; von Zeppelin, D.; Iannotta, S.; et al. 3D Printed Masks for Powders and Viruses Safety Protection Using Food Grade Polymers: Empirical Tests. Polymers 2021, 13, 617. https://doi.org/10.3390/polym13040617

Foresti R, Ghezzi B, Vettori M, Bergonzi L, Attolino S, Rossi S, Tarabella G, Vurro D, von Zeppelin D, Iannotta S, et al. 3D Printed Masks for Powders and Viruses Safety Protection Using Food Grade Polymers: Empirical Tests. Polymers. 2021; 13(4):617. https://doi.org/10.3390/polym13040617

Chicago/Turabian StyleForesti, Ruben, Benedetta Ghezzi, Matteo Vettori, Lorenzo Bergonzi, Silvia Attolino, Stefano Rossi, Giuseppe Tarabella, Davide Vurro, Didier von Zeppelin, Salvatore Iannotta, and et al. 2021. "3D Printed Masks for Powders and Viruses Safety Protection Using Food Grade Polymers: Empirical Tests" Polymers 13, no. 4: 617. https://doi.org/10.3390/polym13040617

APA StyleForesti, R., Ghezzi, B., Vettori, M., Bergonzi, L., Attolino, S., Rossi, S., Tarabella, G., Vurro, D., von Zeppelin, D., Iannotta, S., Zappettini, A., Macaluso, G. M., Miragoli, M., Maggio, M. G., Costantino, C., Selleri, S., & Macaluso, C. (2021). 3D Printed Masks for Powders and Viruses Safety Protection Using Food Grade Polymers: Empirical Tests. Polymers, 13(4), 617. https://doi.org/10.3390/polym13040617