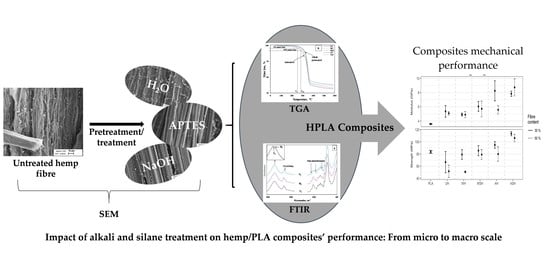

Impact of Alkali and Silane Treatment on Hemp/PLA Composites’ Performance: From Micro to Macro Scale

Abstract

:1. Introduction

- i.

- Show an accurate inference of the fiber pretreatments and treatment on the composite’s mechanical performance by linking the effects reported at the microscale, specifically the impact of the treatments on the fibers’ tensile properties, to their overall impact at the macroscale. The dual scales of observation bring a complementarity to the analysis, which is not often reported in the literature. Fiber composition, tensile mechanical properties, individualization, and dispersion are thoroughly studied, while the fiber content, aspect ratio, and orientation are carefully maintained as equivalent for all the composite formulations.

- ii.

- Provide first-hand information on the suitability of Estonian hemp fibers for composite reinforcement. Indeed, these fibers are a by-product of cannabidiol production for medicinal applications and are currently considered as a waste. PLA is selected for its renewable and compostable properties, along with its comparable performance to common petrochemically derived alternatives [12]. Figure 1 presents a schematic of the main idea and procedure of this study.

2. Materials and Methods

2.1. Materials

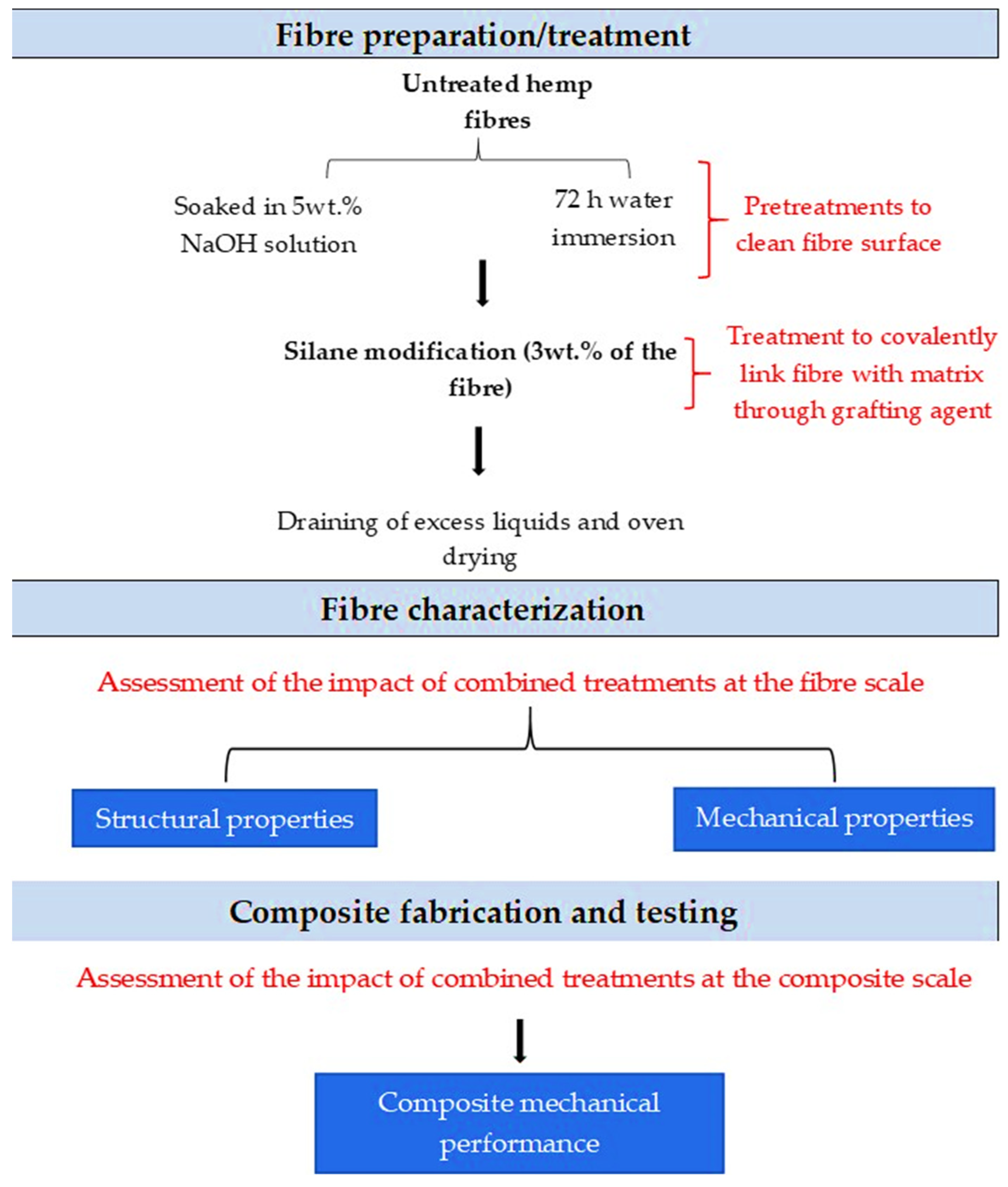

2.2. Fiber Surface Treatments

2.2.1. Water Treatment

2.2.2. Alkali Treatment

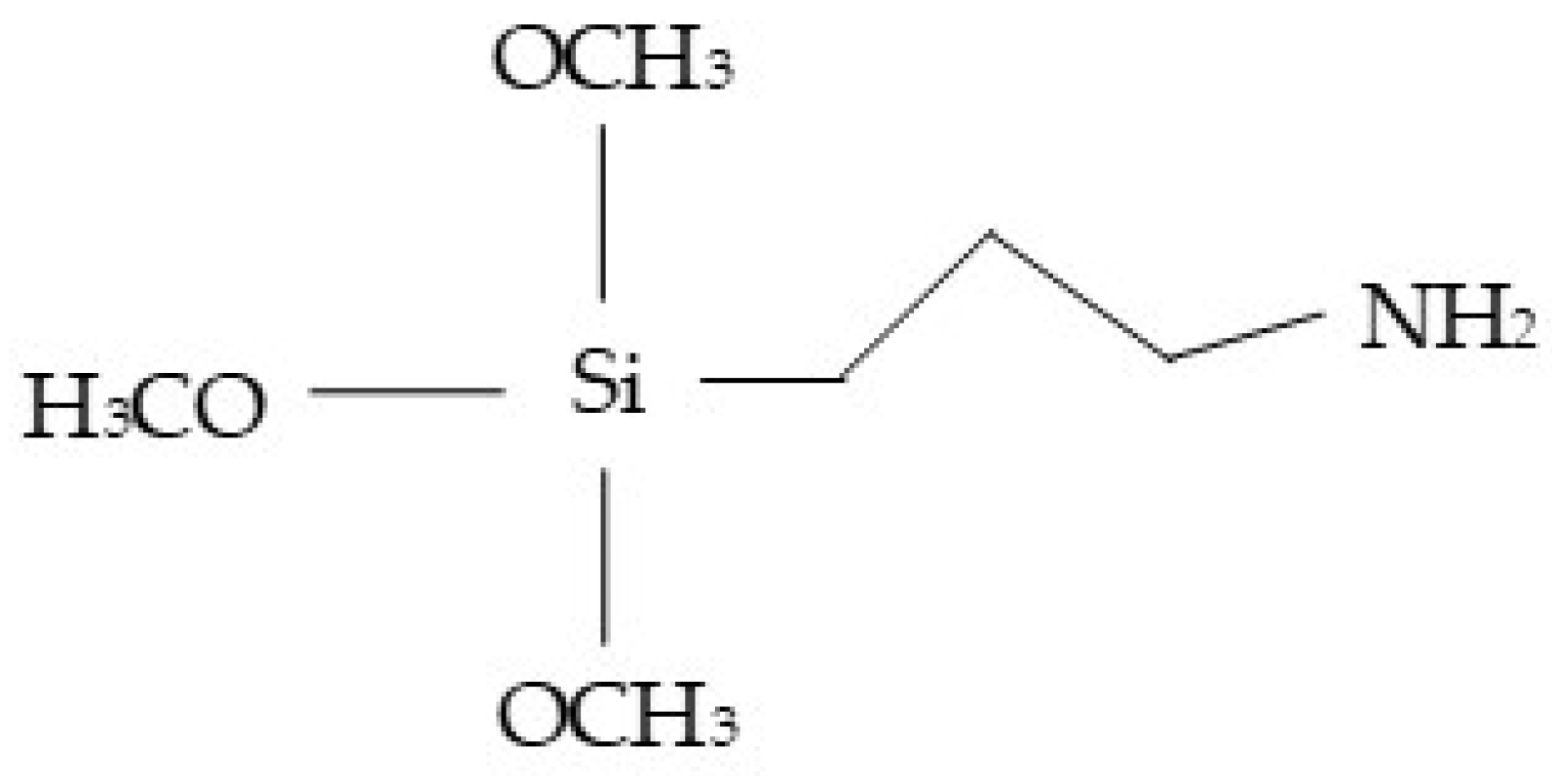

2.2.3. Silane Treatment

2.3. Fabrication of the Hemp Reinforced PLA (HPLA) Composites

2.4. Characterization of Hemp Fibers and HPLA Composites

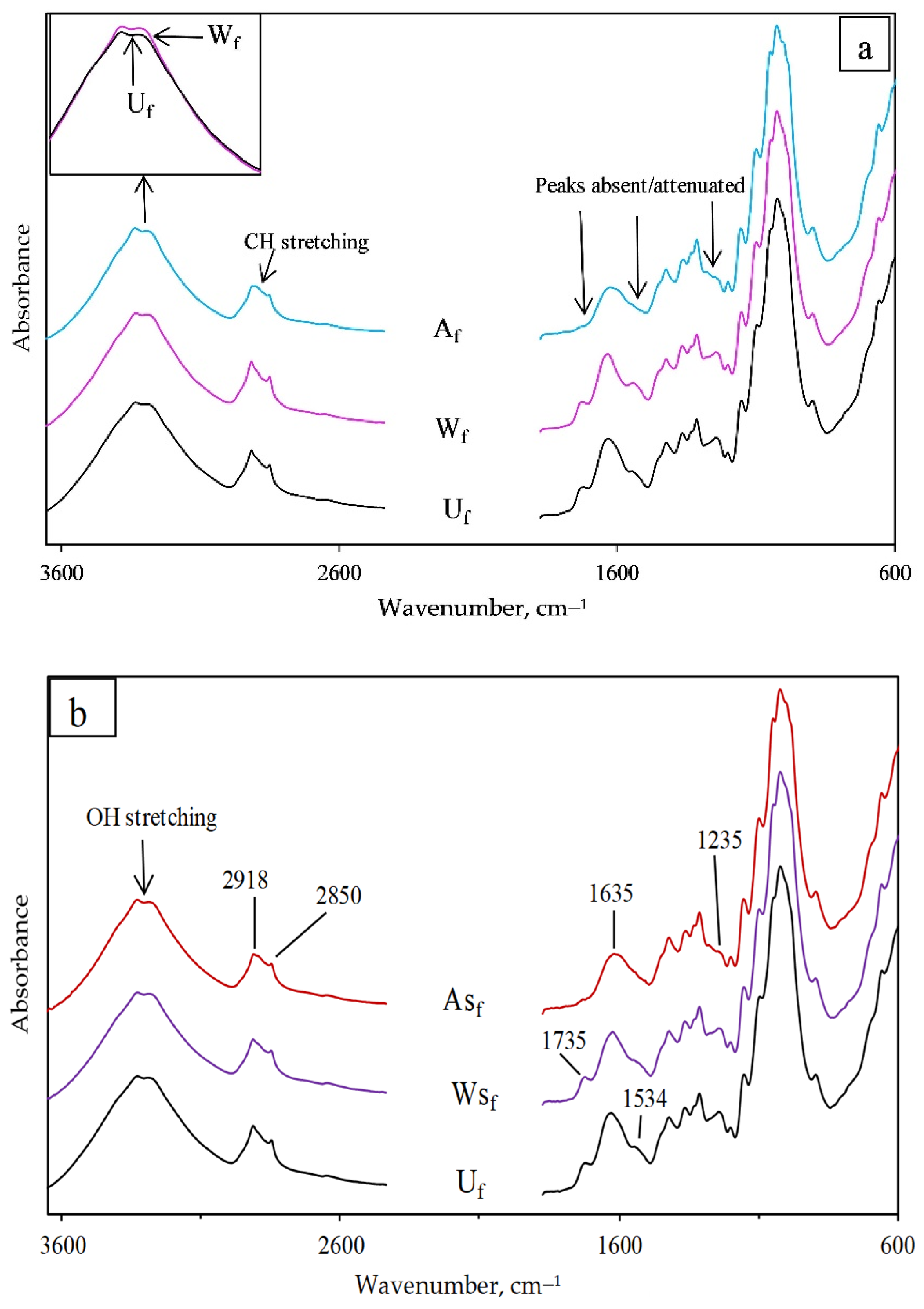

2.4.1. Chemical Composition by Fourier Transform Infrared (FTIR)

2.4.2. Chemical Composition by Thermogravimetric Analysis (TGA)

2.4.3. Microscopical Observations by Scanning Electron Microscopy (SEM)

2.5. Mechanical Properties of Unitary Hemp Fibers and Hemp/PLA Composites

2.6. Statistical Analysis

2.6.1. Statistical Analysis of Fiber Properties

2.6.2. Statistical Analysis of Composite Tensile and Flexural Properties

3. Results and Discussion

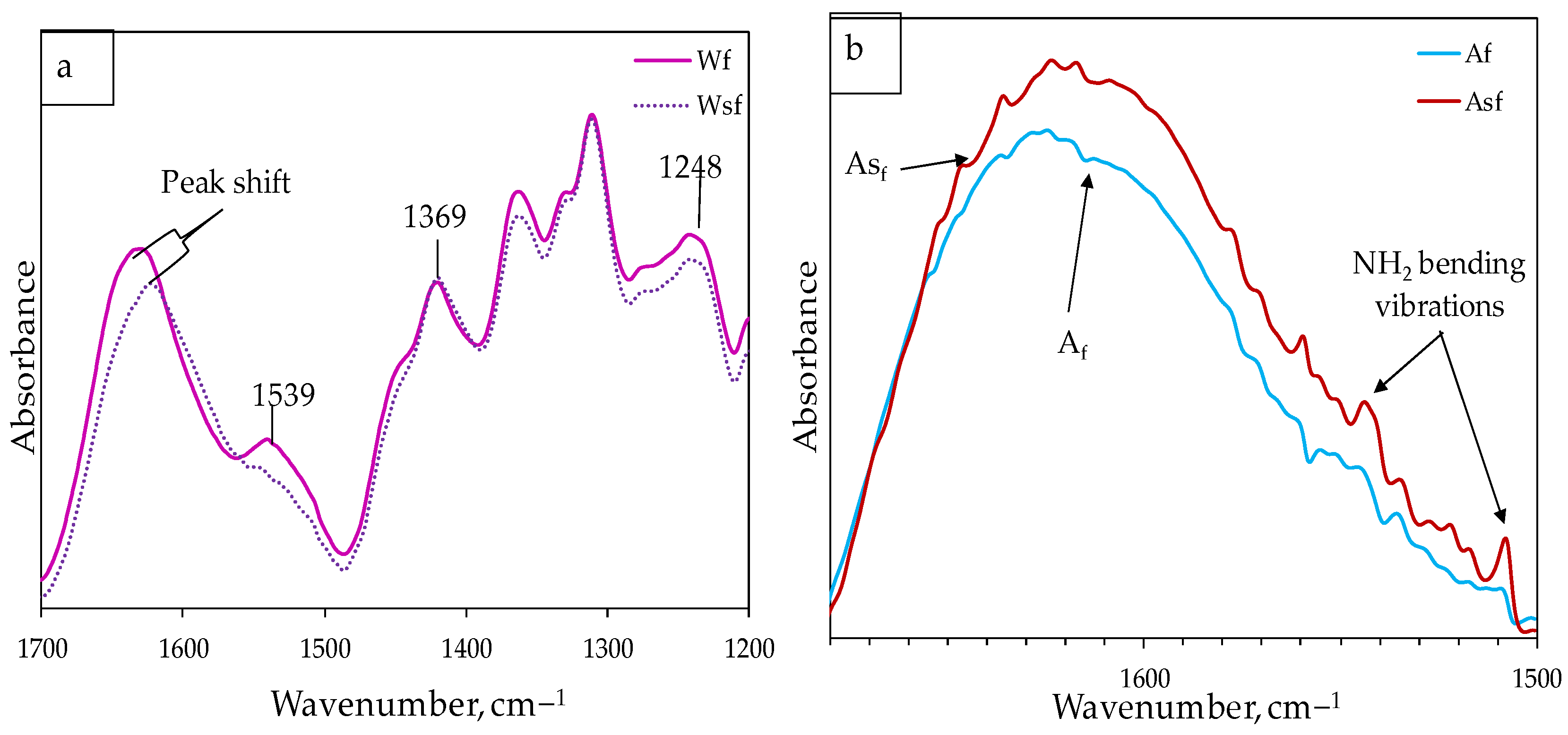

3.1. Chemical Composition by FTIR Analysis

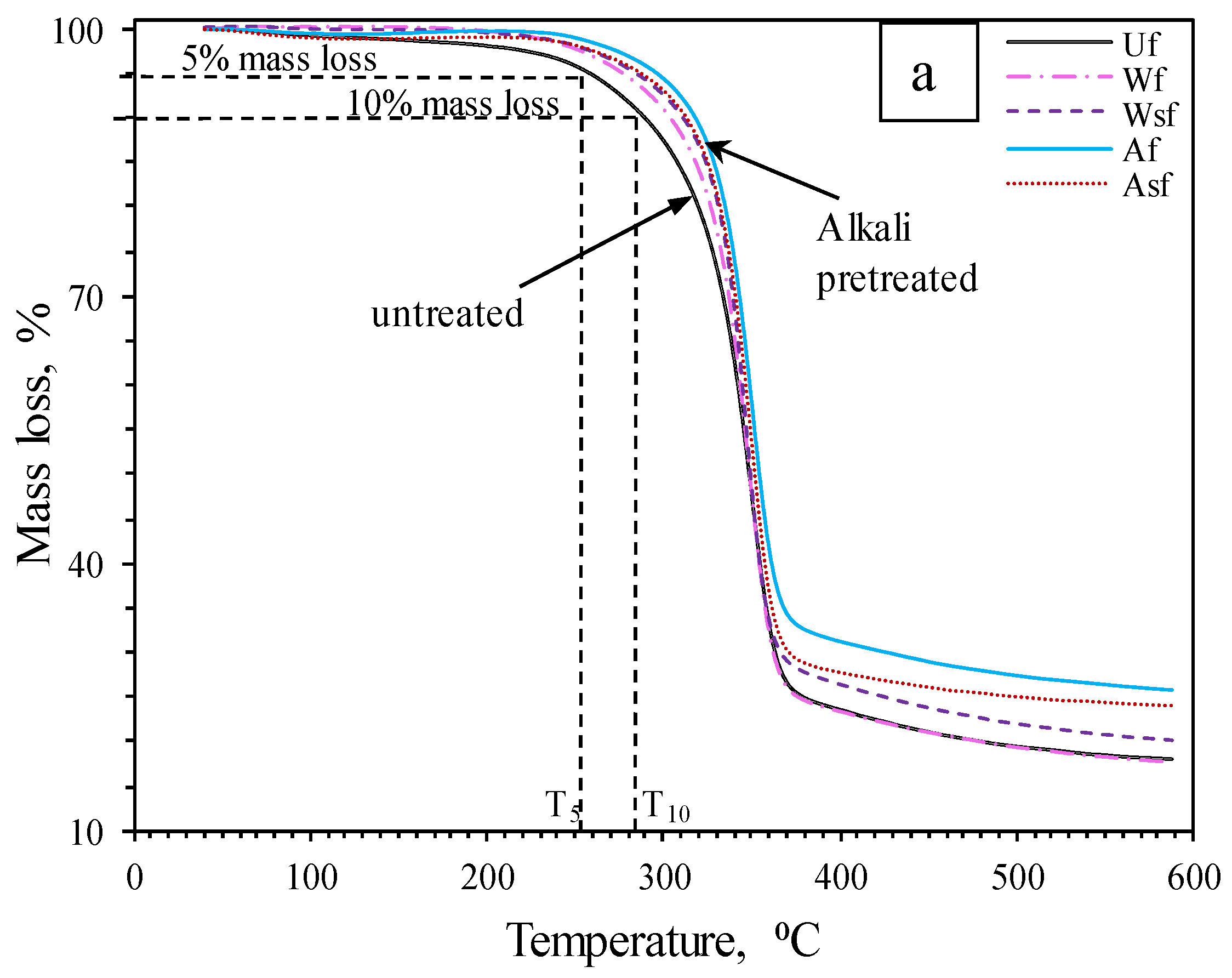

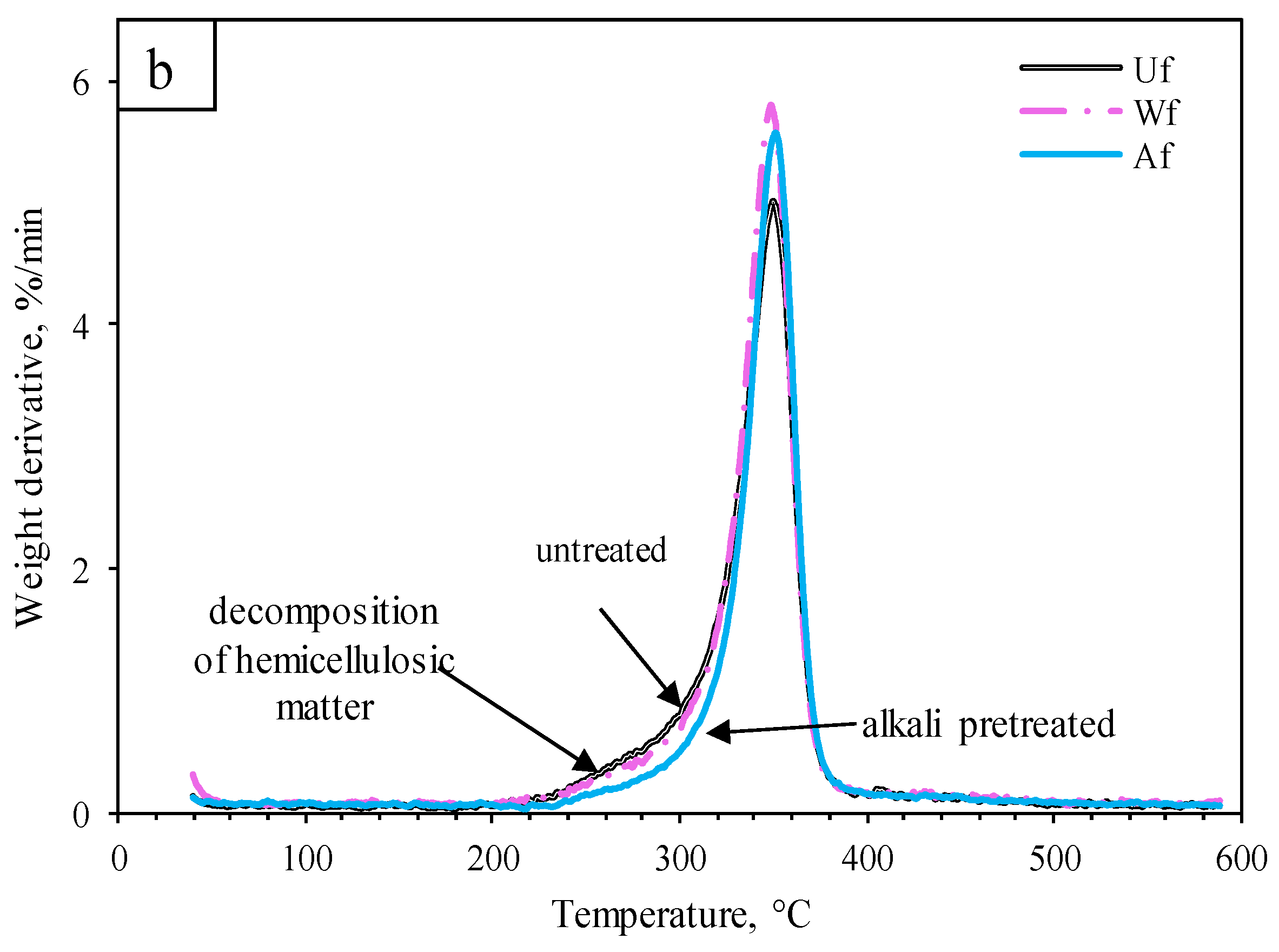

3.2. Chemical Composition by Thermogravimetric Analysis (TGA)

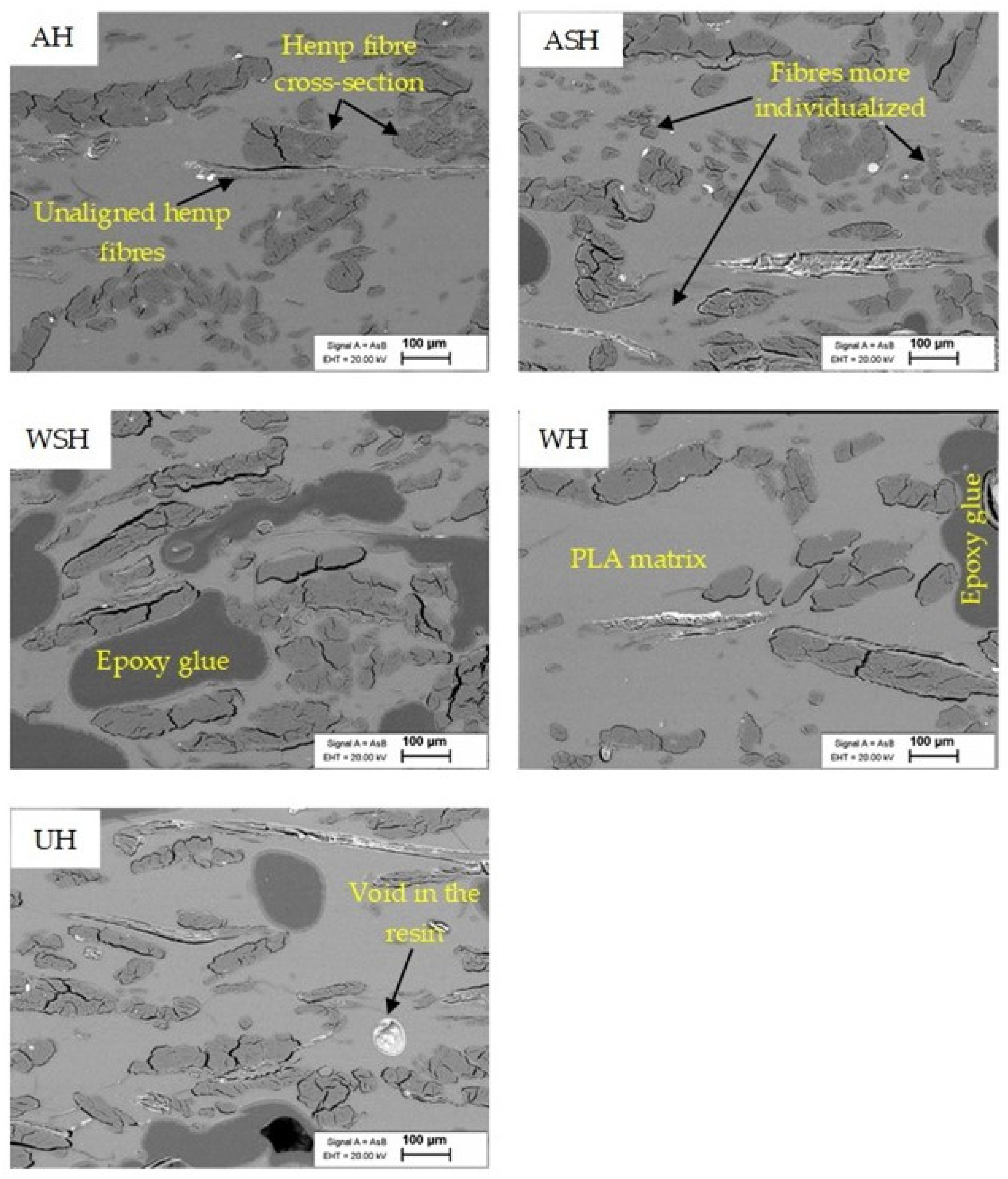

3.3. Scanning Electron Microscopical (SEM) Observations

3.4. Mechanical Properties

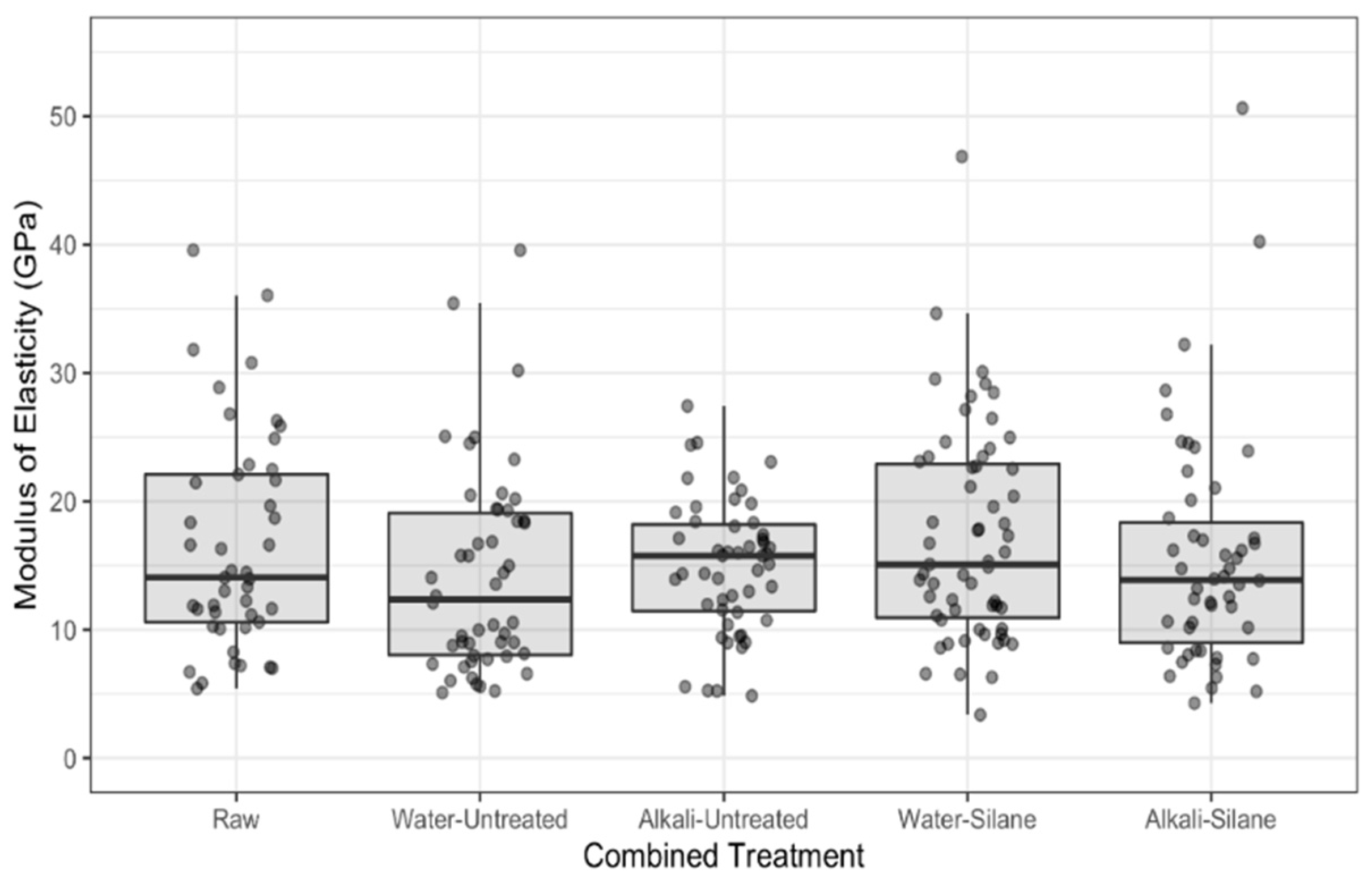

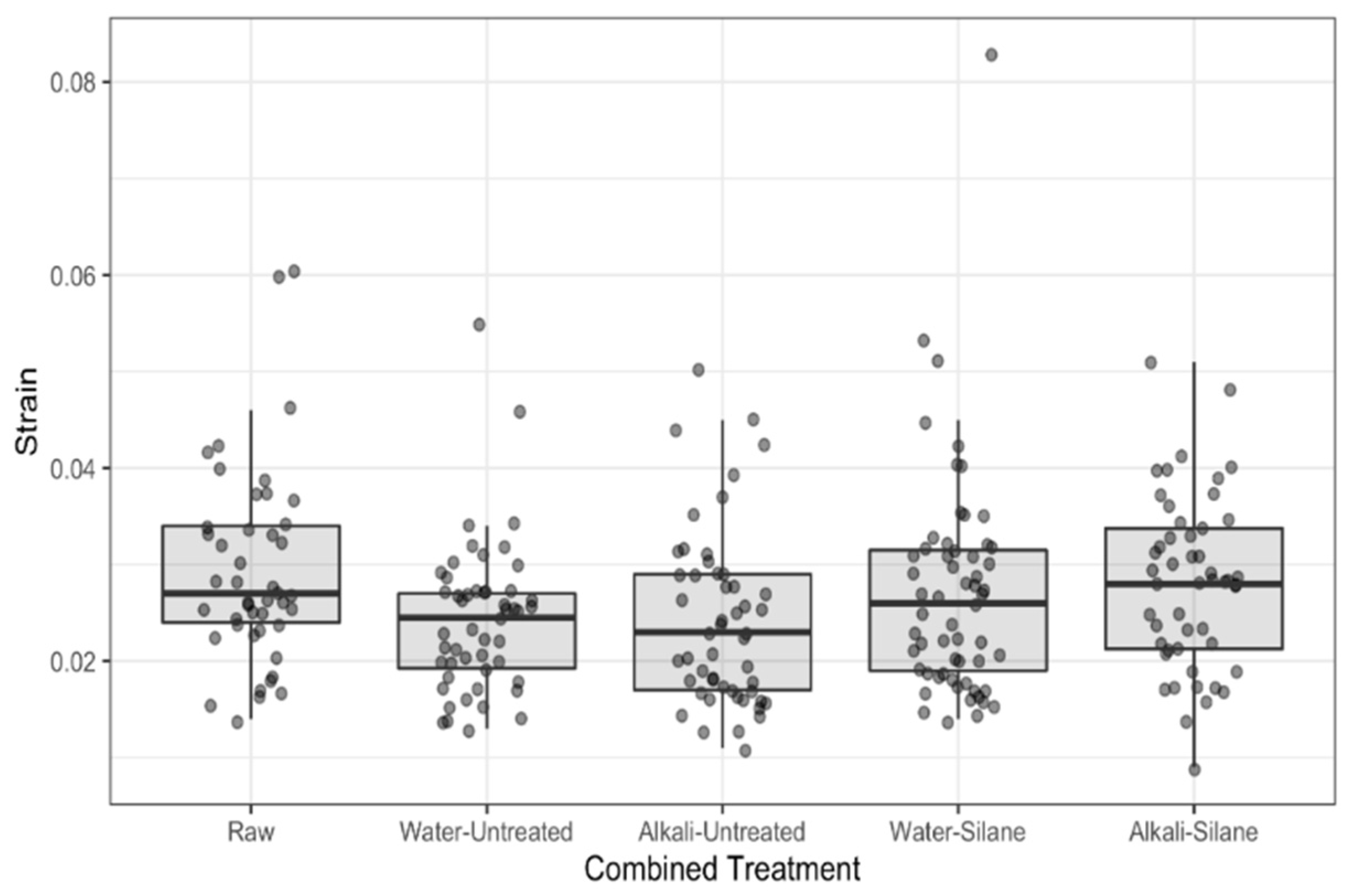

3.4.1. Tensile Properties of the Hemp Fibers

3.4.2. Tensile Properties of HPLA Composites

3.4.3. Flexural Properties of HPLA Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baley, C.; Bourmaud, A.; Davies, P. Eighty years of composites reinforced by flax fibers: A historical review. Compos. Part A Appl. Sci. Manuf. 2021, 144, 106333. [Google Scholar] [CrossRef]

- Marrot, L.; Lefeuvre, A.; Pontoire, B.; Bourmaud, A.; Baley, C. Analysis of the hemp fiber mechanical properties and their scattering (Fedora 17). Ind. Crop. Prod. 2013, 51, 317–327. [Google Scholar] [CrossRef]

- Merotte, J.; Le Duigou, A.; Kervoelen, A.; Bournmaud, A.; Behlouli, K.; Sire, O.; Baley, C. Flax and hemp nonwoven composites: The contribution of interfacial bonding to improving tensile properties. Polym. Test. 2018, 66, 303–311. [Google Scholar] [CrossRef]

- Xiao, B.; Huang, Q.; Chen, H.; Chen, X.; Long, G. A fractal model for capillary flow through a single tortuous capillary with roughened surfaces in fibrous porous media. Fractals 2021, 29, 2150017. [Google Scholar] [CrossRef]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted pre-treatment of hemp bast fibers for optimal performance in biocomposite materials: A review. Ind. Crop. Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef] [Green Version]

- Bourmaud, A.; Morvan, C.; Baley, C. Importance of fiber preparation to optimize the surface and mechanical properties of unitary flax fiber. Ind. Crop. Prod. 2010, 32, 662–667. [Google Scholar] [CrossRef]

- Liu, M.; Meyer, A.; Fernando, D.; Silva, D.A.S.; Daniel, G.; Thygesen, A. Effect of pectin and hemicellulose removal from hemp fibers on the mechanical properties of unidirectional hemp/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 724–735. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Tensile properties of chemically treated hemp fibers as reinforcement for composites. Compos. Part B Eng. 2013, 53, 362–368. [Google Scholar] [CrossRef]

- Coroller, G.; Lefeuvre, A.; Le Duigou, A.; Bourmaud, A.; Ausias, G.; Gaudry, T.; Baley, C. Effect of flax fibers individualisation on tensile failure of flax/epoxy unidirectional composite. Compos. Part A Appl. Sci. Manuf. 2013, 51, 62–70. [Google Scholar] [CrossRef]

- Marrot, L.; Bourmaud, A.; Bono, P.; Baley, C. Multi-scale study of the adhesion between flax fibers and biobased thermoset matrices. Mater. Des. 2014, 62, 47–56. [Google Scholar] [CrossRef]

- Brounstein, Z.; Yeager, C.M.; Labouriau, A. Development of Antimicrobial PLA Composites for Fused Filament Fabrication. Polymers 2021, 13, 580. [Google Scholar] [CrossRef]

- Marrot, L.; Alao, P.F.; Mikli, V.; Kers, J. Properties of frost-retted hemp fibers for the reinforcement of composites. J. Nat. Fibers 2021, in press. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2019; Available online: http://www.r-project.org/index.html (accessed on 16 February 2021).

- RStudio Team. RStudio: Integrated Development for R; RStudio, PBC: Boston, MA, USA, 2020; Available online: http://www.rstudio.com/ (accessed on 16 February 2021).

- Wickham, H.; Averick, M.; Bryan, J.; Chang, W.; McGowan, L.; François, R.; Grolemund, G.; Hayes, A.; Henry, L.; Hester, J.; et al. Welcome to the Tidyverse. J. Open Source Softw. 2019, 4, 1686. [Google Scholar] [CrossRef]

- Lenth, R.; Buerkner, P.; Herve, M.; Love, J.; Riebl, H.; Singmann, H. Emmeans: Estimated Marginal Means, Aka Least-Squares Means 2020. Available online: https://cran.r-project.org/web/packages/emmeans/emmeans.pdf (accessed on 16 February 2021).

- Dayo, A.Q.; Zegaoui, A.; Nizamani, A.A.; Kiran, S.; Wang, J.; Derradji, M.; Cai, W.-A.; Liu, W.-B. The influence of different chemical treatments on the hemp fiber/polybenzoxazine based green composites: Mechanical, thermal and water absorption properties. Mater. Chem. Phys. 2018, 217, 270–277. [Google Scholar] [CrossRef]

- Rasheed, M.; Jawaid, M.; Parveez, B.; Hussain Bhat, A.; Alamery, S. Morphology, Structural, Thermal, and Tensile Properties of Bamboo Microcrystalline Cellulose/Poly(Lactic Acid)/Poly(Butylene Succinate) Composites. Polymers 2021, 13, 465. [Google Scholar] [CrossRef] [PubMed]

- Viscusi, G.; Barra, G.; Verdolotti, L.; Galzerano, B.; Viscardi, M.; Gorrasi, G. Natural fiber reinforced inorganic foam composites from short hemp bast fibers obtained by mechanical decortation of unretted stems from the wastes of hemp cultivations. Mater. Today Proc. 2020, 34, 176–179. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Fierascu, R.C.; Gabor, A.R.; Nicolae, C.A. Effect of hemp fiber length on the mechanical and thermal properties of polypropylene/SEBS/hemp fiber composites. J. Mater. Res. Technol. 2020, 9, 10768–10781. [Google Scholar] [CrossRef]

- Placet, V.; Day, A.; Beaugrand, J. The influence of unintended field retting on the physicochemical and mechanical properties of industrial hemp bast fibers. J. Mater. Sci. 2017, 52, 5759–5777. [Google Scholar] [CrossRef]

- Väisänen, T.; Batello, P.; Lappalainen, R.; Tomppo, L. Modification of hemp fibers (Cannabis Sativa L.) for composite applications. Ind. Crop. Prod. 2018, 111, 422–429. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of various chemical treatments on the fiber structure and tensile properties of industrial hemp fibers. Compos. Part A Appl. Sci. Manuf. 2011, 42, 888–895. [Google Scholar] [CrossRef] [Green Version]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Bourmaud, A.; Beaugrand, J.; Shah, D.U.; Placet, V.; Baley, C. Towards the design of high-performance plant fiber composites. Prog. Mater. Sci. 2018, 97, 347–408. [Google Scholar] [CrossRef]

- Engelund, E.T.; Thygesen, L.G.; Svensson, S.; Hill, C.A.S. A critical discussion of the physics of wood–water interactions. Wood Sci. Technol. 2013, 47, 141–161. [Google Scholar] [CrossRef] [Green Version]

- Pejic, B.M.; Kostic, M.M.; Skundric, P.D.; Praskalo, J.Z. The effects of hemicelluloses and lignin removal on water uptake behavior of hemp fibers. Bioresour. Technol. 2008, 99, 7152–7159. [Google Scholar] [CrossRef]

- Garat, W.; Le Moigne, N.; Corn, S.; Beaugrand, J.; Bergeret, A. Swelling of natural fiber bundles under hygro- and hydrothermal conditions: Determination of hydric expansion coefficients by automated laser scanning. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105803. [Google Scholar] [CrossRef]

- Le Duigou, A.; Bourmaud, A.; Balnois, E.; Davies, P.; Baley, C. Improving the interfacial properties between flax fibers and PLLA by a water fiber treatment and drying cycle. Ind. Crop. Prod. 2012, 39, 31–39. [Google Scholar] [CrossRef]

- Islam, M.S.; Pickering, K.L.; Foreman, N.J. Influence of alkali treatment on the interfacial and physico-mechanical properties of industrial hemp fiber reinforced polylactic acid composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 596–603. [Google Scholar] [CrossRef]

- Beckermann, G.W.; Pickering, K.L. Engineering and evaluation of hemp fiber reinforced polypropylene composites: Fiber treatment and matrix modification. Compos. Part A Appl. Sci. Manuf. 2008, 39, 979–988. [Google Scholar] [CrossRef]

- Sair, S.; Oushabi, A.; Kammouni, A.; Tanane, O.; Abboud, Y.; Hassani, F.O.; Laachachi, A.; El Bouari, A. Effect of surface modification on morphological, mechanical and thermal conductivity of hemp fiber: Characterization of the interface of hemp -Polyurethane composite. Case Stud. Therm. Eng. 2017, 10, 550–559. [Google Scholar] [CrossRef]

- Hu, R.; Lim, J.-K. Fabrication and Mechanical Properties of Completely Biodegradable Hemp Fiber Reinforced Polylactic Acid Composites. J. Compos. Mater. 2007, 41, 1655–1669. [Google Scholar] [CrossRef]

- Pappu, A.; Pickering, K.L.; Thakur, V.K. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibers as reinforcement of poly (lactic acid) via injection moulding. Ind. Crop. Prod. 2019, 137, 260–269. [Google Scholar] [CrossRef]

- Mazian, B.; Bergeret, A.; Benezet, J.C.; Malhautier, L. Influence of field retting duration on the biochemical, microstructural, thermal and mechanical properties of hemp fibers harvested at the beginning of flowering. Ind. Crop. Prod. 2018, 116, 170–181. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

| Abbreviation | Samples |

|---|---|

| Neat PLA | Unreinforced polylactic acid boards from 100% PLA fibers. |

| UH | Untreated hemp fiber (Uf) reinforced polylactide composites. |

| WH | Water-treated hemp fiber (Wf) reinforced polylactide composites. |

| WSH | Combined water- and silane- (WSf) treated hemp fiber reinforced polylactide composites. |

| AH | Alkali-treated hemp fiber (Af) reinforced polylactide composites. |

| ASH | Combined alkali- and silane- (ASf) treated hemp fiber reinforced polylactide composites. |

| Sample | First Mass Loss (%) at 160 °C | T5 (°C) | T10 (°C) |

|---|---|---|---|

| Uf | 1.4 | 254 | 289 |

| Wf | 0.3 | 272 | 299 |

| WSf | 0.3 | 278 | 305 |

| Af | 0.3 | 292 | 313 |

| ASf | 0.3 | 288 | 310 |

| Modulus (GPa) | Tensile Strength (MPa) | Strain% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Combined | Mean | SD * | Median | IQR ** | Mean | SD | Median | IQR | Mean | SD | Median | IQR |

| Raw | 16.6 | 8.5 | 14.1 | 11.5 | 500 | 239 | 464 | 270 | 2.93 | 1.02 | 2.70 | 1.00 |

| Water-Untreated | 14.3 | 7.9 | 12.4 | 11.1 | 376 | 220 | 336 | 257 | 2.43 | 0.78 | 2.45 | 0.78 |

| Alkali-Untreated | 15.0 | 5.2 | 15.8 | 6.7 | 381 | 189 | 369 | 234 | 2.42 | 0.91 | 2.30 | 1.20 |

| Water-Silane | 17.2 | 8.3 | 15.1 | 12.0 | 490 | 210 | 459 | 236 | 2.71 | 1.16 | 2.60 | 1.25 |

| Alkali-Silane | 15.6 | 9.0 | 13.9 | 9.4 | 466 | 287 | 390 | 295 | 2.81 | 0.89 | 2.80 | 1.25 |

| Tensile Strength | Modulus | Strain | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Comparison | Ratio | 95% CI | p-Value | Ratio | 95% CI | p-Value | Ratio | 95% CI | p-Value |

| Raw/Alkali | 1.3 | 1.03 to 1.72 | 0.0255 * | 1.05 | 0.83 to 1.33 | 0.8647 | 1.23 | 1.04 to 1.44 | 0.0092 ** |

| Raw/Water | 1.36 | 1.06 to 1.76 | 0.0131 * | 1.18 | 0.93 to 1.5 | 0.2130 | 1.20 | 1.02 to 1.41 | 0.0261 ** |

| Alkali/Water | 1.03 | 0.8 to 1.32 | 0.9641 | 1.12 | 0.89 to 1.41 | 0.4459 | 0.98 | 0.83 to 1.14 | 0.9289 |

| Silane/Untreated|Alkali | 1.19 | 0.97 to 1.45 | 0.0938 | 0.97 | 0.8 to 1.18 | 0.7777 | 1.18 | 1.03 to 1.35 | 0.0187 * |

| Silane/Untreated|Water | 1.38 | 1.13 to 1.67 | 0.0013 ** | 1.23 | 1.02 to 1.49 | 0.0294 * | 1.09 | 0.95 to 1.24 | 0.2041 |

| Specimen | Density (g/cm−3) | Specific TS σ/ρ | Specific FS σ/ρ | Density (g/cm−3) | Specific TS σ/ρ | Specific FS σ/ρ | ||

|---|---|---|---|---|---|---|---|---|

| 100% | PLA | 1.24 ± 0.01 | 41.29 ± 0.36 | 68.19 ± 2.03 | ||||

| 30 wt.% | UH | 1.19 ± 0.11 | 40.19 ± 2.19 | 60.92 ± 10.51 | 50 wt.% | 1.13 ± 0.05 | 33.06 ± 6.60 | 47.24 ± 5.68 |

| WH | 1.20 ± 0.13 | 42.46 ± 6.05 | 67.05 ± 4.54 | 1.13 ± 0.10 | 42.85 ± 4.39 | 47.51 ± 5.97 | ||

| WSH | 1.18 ± 0.05 | 43.94 ± 3.15 | 70.47 ± 4.01 | 1.13 ± 0.10 | 45.90 ± 3.29 | 71.63 ± 4.50 | ||

| AH | 1.23 ± 0.02 | 45.20 ± 4.67 | 77.22 ± 2.61 | 1.16 ± 0.06 | 45.27 ± 1.98 | 72.59 ± 8.03 | ||

| ASH | 1.21 ± 0.05 | 51.00 ± 2.64 | 93.64 ± 2.69 | 1.16 ± 0.03 | 46.67 ± 6.33 | 94.22 ± 6.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alao, P.F.; Marrot, L.; Burnard, M.D.; Lavrič, G.; Saarna, M.; Kers, J. Impact of Alkali and Silane Treatment on Hemp/PLA Composites’ Performance: From Micro to Macro Scale. Polymers 2021, 13, 851. https://doi.org/10.3390/polym13060851

Alao PF, Marrot L, Burnard MD, Lavrič G, Saarna M, Kers J. Impact of Alkali and Silane Treatment on Hemp/PLA Composites’ Performance: From Micro to Macro Scale. Polymers. 2021; 13(6):851. https://doi.org/10.3390/polym13060851

Chicago/Turabian StyleAlao, Percy Festus, Laetitia Marrot, Michael David Burnard, Gregor Lavrič, Mart Saarna, and Jaan Kers. 2021. "Impact of Alkali and Silane Treatment on Hemp/PLA Composites’ Performance: From Micro to Macro Scale" Polymers 13, no. 6: 851. https://doi.org/10.3390/polym13060851

APA StyleAlao, P. F., Marrot, L., Burnard, M. D., Lavrič, G., Saarna, M., & Kers, J. (2021). Impact of Alkali and Silane Treatment on Hemp/PLA Composites’ Performance: From Micro to Macro Scale. Polymers, 13(6), 851. https://doi.org/10.3390/polym13060851