Incorporation of In Situ Synthesized Nano-Copper Modified Phenol-Formaldehyde Resin to Improve the Mechanical Properties of Chinese Fir: A Preliminary Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

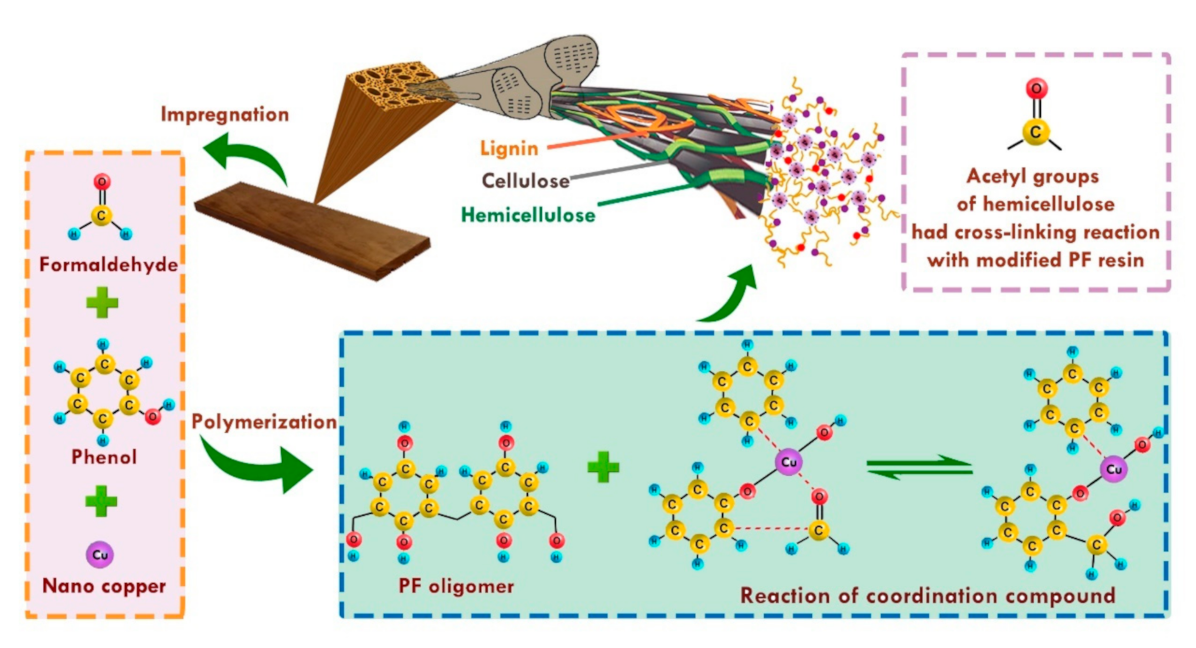

2.2. Preparation of PF Resin

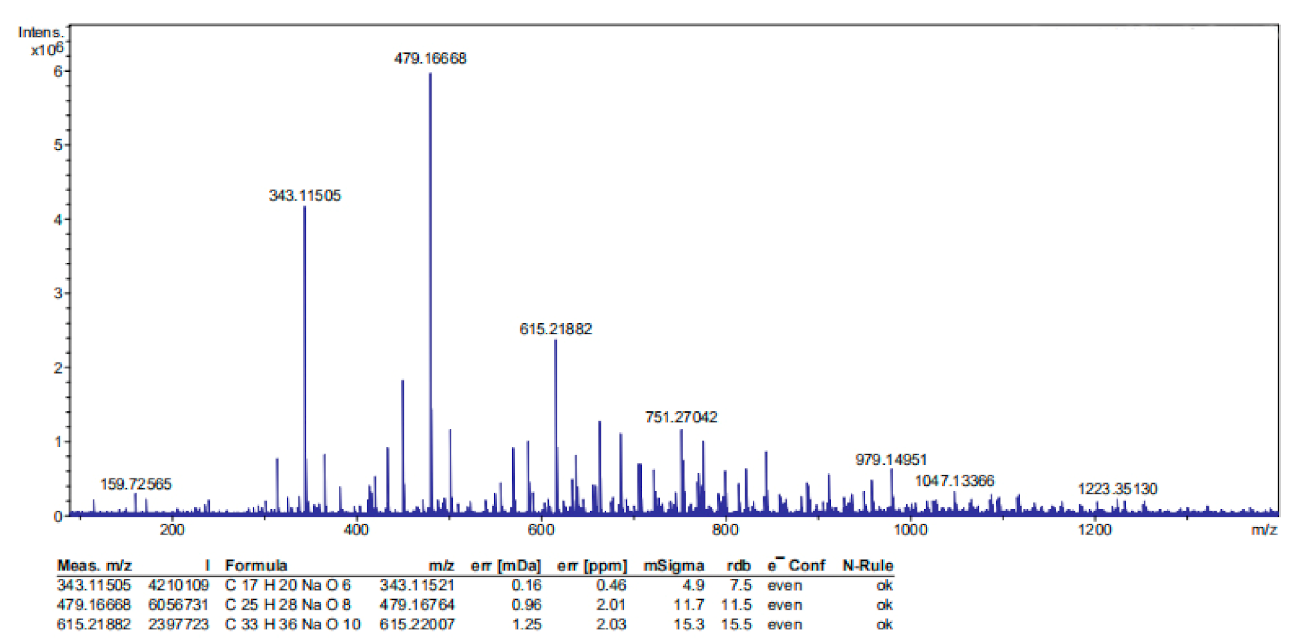

2.3. Preparation of Nano-Copper Modified PF Resin

2.4. Vacuum and High-Pressure Impregnation Treatment

2.5. Characterization

3. Results and Discussion

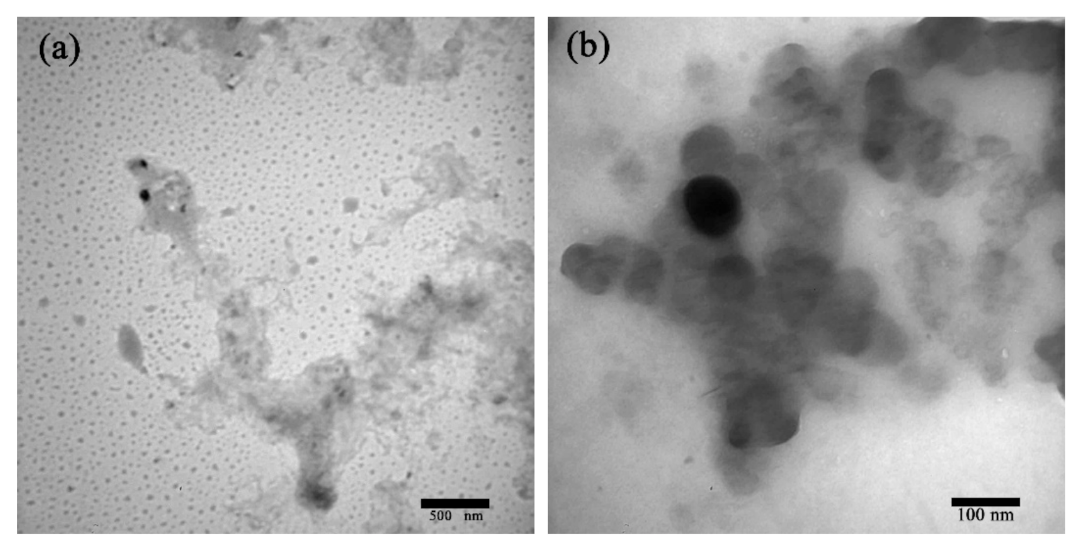

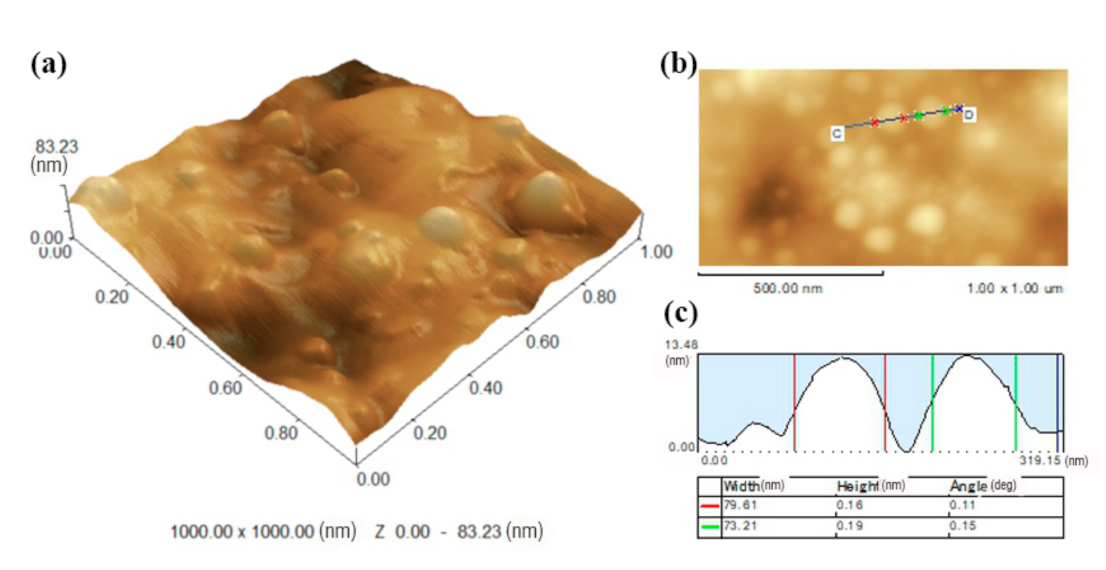

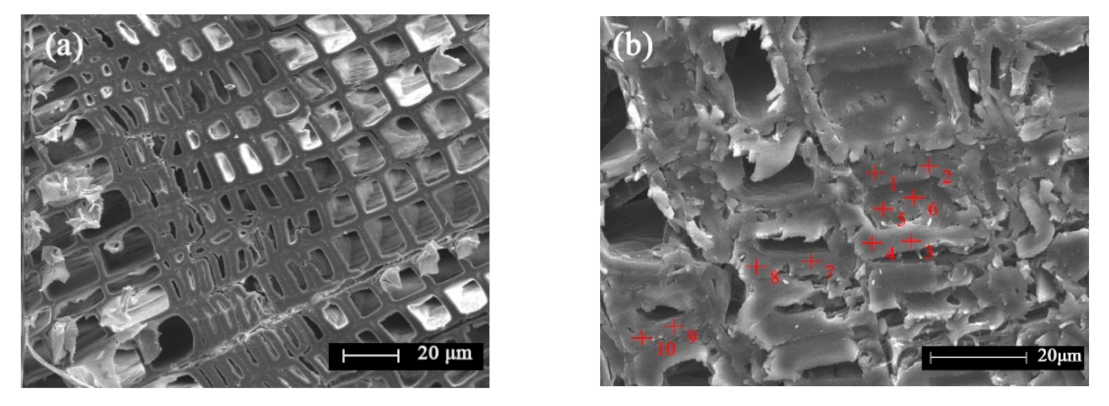

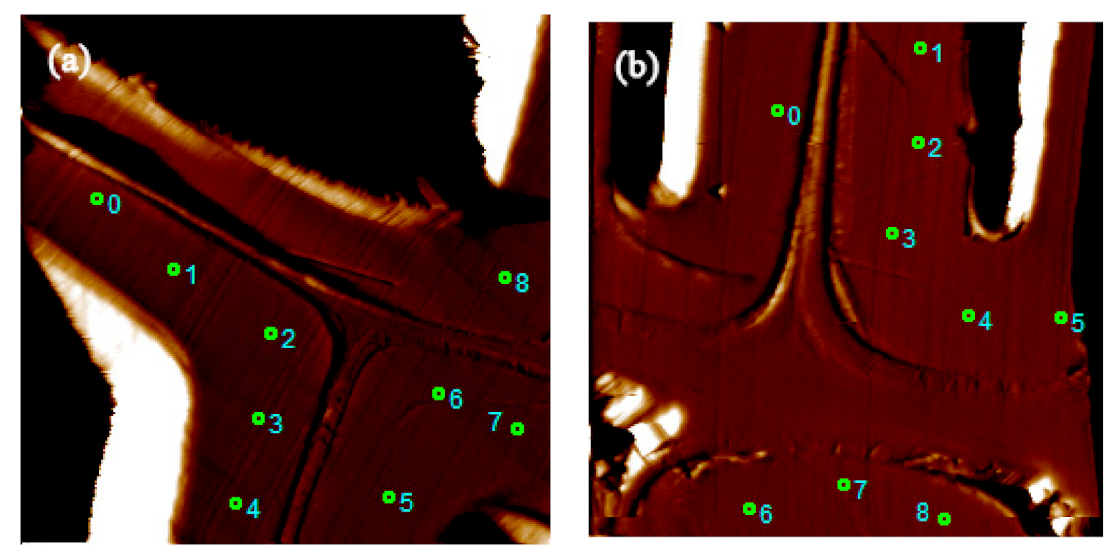

3.1. Dispersion of Low Molecular Weight PF and Nano-Copper in the Wood Cell Walls

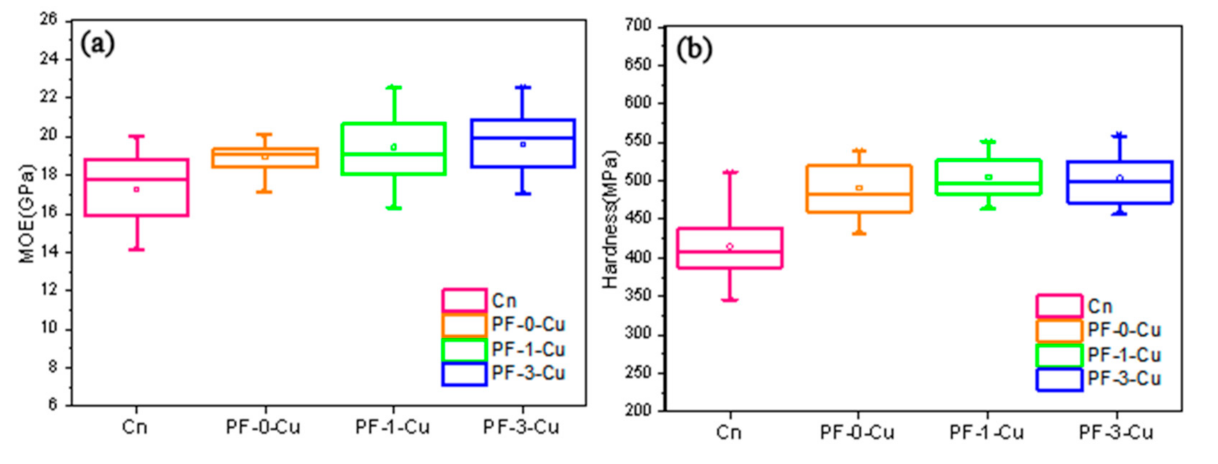

3.2. Improvement of the Micromechanical Properties of the Wood Cell Walls

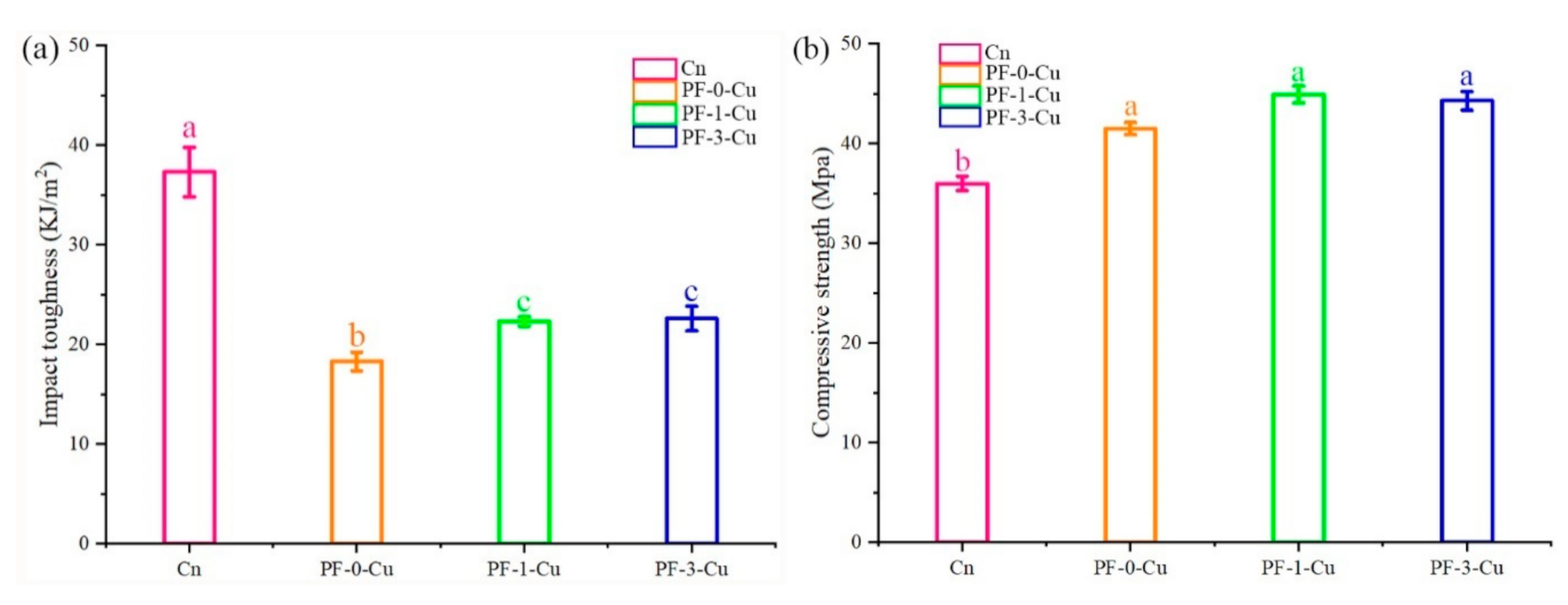

3.3. Mechanical Properties of Chinese Fir after Impregnation

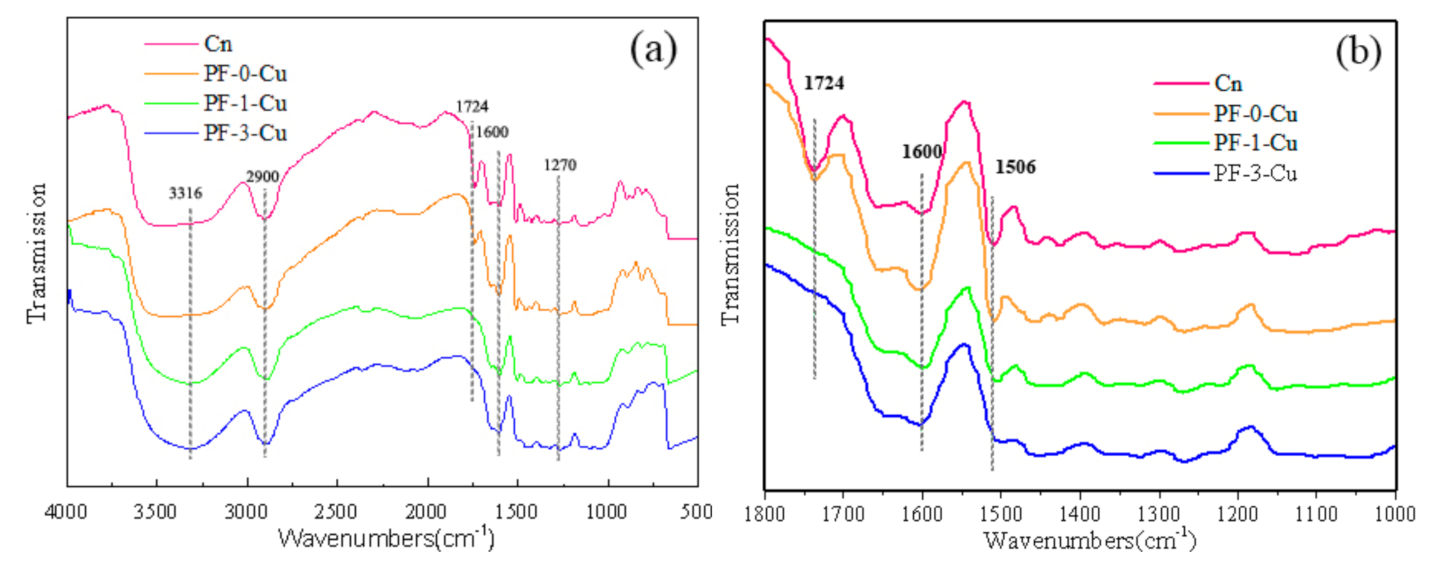

3.4. FTIR Analysis of the Combination of Low Molecular Weight PF, Nano-Copper and Wood Cell Walls

3.5. Novelty, Limitations and Perspectives of the Study

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bao, F.C.; Jiang, Z.H.; Jiang, X.M.; Lu, X.X.; Luo, X.Q.; Zhang, S.Y. Differences in wood properties between juvenile wood and mature wood in 10 species grown in China. Wood Sci. Technol. 2001, 35, 363–375. [Google Scholar] [CrossRef]

- Altgen, M.; Hofmann, T.; Militz, H. Wood moisture content during the thermal modification process affects the improvement in hygroscopicity of Scots pine sapwood. Wood Sci. Technol. 2016, 50, 1181–1195. [Google Scholar] [CrossRef]

- Cai, M.; Fu, Z.; Cai, Y.; Zhang, Y.; Cai, J.; Xu, C. Effect of Impregnation with Maltodextrin and 1,3-Dimethylol-4,5-Dihydroxyethyleneurea on the Conventional Drying Characteristics of Poplar Wood. Appl. Sci. 2019, 9, 473. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, J.; Wang, S.; Feng, X.; Chen, H.; Tang, Q.; Zhang, H. Measurement of mechanical properties of multilayer waterborne coatings on wood by nanoindentation. Holzforschung 2019, 73, 871–877. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N.; et al. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef]

- Gérardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. Forest Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef]

- Croitoru, C.; Patachia, S.; Lunguleasa, A. New Method of Wood Impregnation with Inorganic Compounds Using Ethyl Methylimidazolium Chloride as Carrier. J. Wood Chem. Technol. 2014, 35, 113–128. [Google Scholar] [CrossRef]

- Grinins, J.; Biziks, V.; Marais, B.N.; Rizikovs, J.; Militz, H. Weathering Stability and Durability of Birch Plywood Modified with Different Molecular Weight Phenol-Formaldehyde Oligomers. Polymers 2021, 13, 175. [Google Scholar] [CrossRef]

- Shen, X.; Jiang, P.; Guo, D.; Li, G.; Chu, F.; Yang, S. Effect of Furfurylation on Hierarchical Porous Structure of Poplar Wood. Polymers 2020, 13, 32. [Google Scholar] [CrossRef]

- Hill, C.A. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Gabrielli, C.P.; Kamke, F.A. Phenol–formaldehyde impregnation of densified wood for improved dimensional stability. Wood Sci. Technol. 2010, 44, 95–104. [Google Scholar] [CrossRef]

- Stefanowski, B.; Spear, M.; Pitman, A. Review of the use of PF and related resins for modification of solid wood. Timber 2018, 165–179. [Google Scholar]

- Kajita, H.; Furuno, T.; Imamura, Y. The modification of wood by treatment with low molecular weight phenol-formaldehyde resin: A properties enhancement with neutralized phenolic-resin and resin penetration into wood cell walls. Wood Sci. Technol. 2004, 37, 349–361. [Google Scholar] [CrossRef]

- Ohmae, K.; Minato, K.; Norimoto, M. The Analysis of Dimensional Changes Due to Chemical Treatments and Water Soaking for Hinoki (Chamaecyparis obtusa) Wood. Holzforschung 2002, 56, 98–102. [Google Scholar] [CrossRef]

- Wallström, L.; Lindberg, K. Measurement of cell wall penetration in wood of water-based chemicals using SEM/EDS and STEM/EDS technique. Wood Sci. Technol. 1999, 33, 111–122. [Google Scholar] [CrossRef]

- Rowell, R.M. 14 Chemical Modification of Wood. Handbook of Wood Chemistry and Wood Composites; University of Wisconsin: Madison, WI, USA, 2005. [Google Scholar]

- Khalil, H.A.; Amouzgar, P.; Jawaid, M.; Abdullah, C.; Issam, A.; Zainudin, E.; Paridah, M.; Hassan, A. Physical and thermal properties of microwave-dried wood lumber impregnated with phenol formaldehyde resin. J. Compos. Mater. 2012, 47, 3565–3571. [Google Scholar] [CrossRef]

- Wang, X.; Chen, X.; Xie, X.; Cai, S.; Yuan, Z.; Li, Y.; Wang, C.; Xie, C. Multi-Scale Evaluation of the Effect of Phenol Formaldehyde Resin Impregnation on the Dimensional Stability and Mechanical Properties of Pinus Massoniana Lamb. Forests 2019, 10, 646. [Google Scholar] [CrossRef]

- Sandhya, P.; Sreekala, M.; Padmanabhan, M.; Thomas, S. Mechanical and thermal properties of ZnO anchored GO reinforced phenol formaldehyde resin. Diam. Relat. Mater. 2020, 108, 107961. [Google Scholar] [CrossRef]

- Zhang, R.; Jin, X.; Wen, X.; Chen, Q.; Qin, D. Alumina nanoparticle modified phenol-formaldehyde resin as a wood adhesive. Int. J. Adhes. Adhes. 2018, 81, 79–82. [Google Scholar] [CrossRef]

- Yi, T.; Zhao, S.; Gao, W.; Guo, C.; Yang, L.; Du, G. The similar in-situ polymerization of nano cupric oxide preparation and phenol formaldehyde resin synthesis: The process and mechanism. Int. J. Adhes. Adhes. 2018, 87, 109–118. [Google Scholar] [CrossRef]

- Dukarska, D.; Łęcka, J. The effect of an addition of TiO2 and SiO2 nanomolecules to phenolic resin on properties and colour of glue lines in exterior plywood. For. Wood Technol. 2009, 68, 198–202. [Google Scholar]

- Lin, R.; Fang, L.; Li, X.; Xi, Y.; Zhang, S.; Sun, P. Study on Phenolic Resins Modified by Copper Nanoparticles. Polym. J. 2006, 38, 178–183. [Google Scholar] [CrossRef][Green Version]

- Larsen, T.R.; Andersen, T.L.; Thorning, B.; Horsewell, A.; Vigild, M.E. Changes in the tribological behavior of an epoxy resin by incorporating CuO nanoparticles and PTFE microparticles. Wear 2008, 265, 203–213. [Google Scholar] [CrossRef]

- Guo, C.; Yi, T.; Morrell, J.J.; Gao, W.; Zhao, S.; Zhan, K.; Yang, L.; Du, G. Incorporation of a nano/micro CuO formulation into phenol formaldehyde (PF) resin: Curing kinetics, morphological analysis, and application. J. Wood Chem. Technol. 2019, 39, 372–383. [Google Scholar] [CrossRef]

- Lee, M.J.; Pankras, S.; Cooper, P. Appearance, corrosion properties, and leach resistance of spruce and pine wood treated with Mea modified micronized copper preservative (MCu). Holzforschung 2014, 68, 477–486. [Google Scholar] [CrossRef]

- Biziks, V.; Bicke, S.; Militz, H. Penetration depth of phenol-formaldehyde (PF) resin into beech wood studied by light microscopy. Wood Sci. Technol. 2019, 53, 165–176. [Google Scholar] [CrossRef]

- Lin, R.H.; Wang, F.Y.; Li, S.Y.; Wang, G.Y. Phenol–formaldehyde resins modified by copper nanoparticles. Plast. Rubber Compos. 2007, 36, 423–427. [Google Scholar] [CrossRef]

- Lin, R.; Fang, L.; Li, X.; Zhang, S. Phenolic Resins Modified by Nanocopper Particles and their Service Performances. Polym. Technol. Eng. 2006, 45, 1243–1249. [Google Scholar] [CrossRef]

- Sarkar, A.; Mukherjee, A.T.; Kapoor, S. PVP-Stabilized Copper Nanoparticles: A Reusable Catalyst for “Click” Reaction between Terminal Alkynes and Azides in Nonaqueous Solvents. J. Phys. Chem. C 2008, 112, 3334–3340. [Google Scholar] [CrossRef]

- Imamura, Y.; Kajita, H.; Higuchi, N. Modification of wood by treatment with low molecular phenol-formaldehyde resin (1). Influence of neutral and alkaline resins. In Proceedings of the 48th Annual Meeting of Japan Wood Research Society, Shizuoka, Japan, 3–5 April 1998. (In Japanese). [Google Scholar]

- Smith, W.; Cote, W.; Siau, J.; Vasishth, R. Interactions between water-borne polymer systems and the wood cell wall. J. Coat. Technol. 1985, 57, 2735. [Google Scholar]

- Huang, Y.; Fei, B.; Yu, Y.; Zhao, R. Effect of Modification with Phenol Formaldehyde Resin on the Mechanical Properties of Wood from Chinese Fir. Bioresources 2012, 8, 272–282. [Google Scholar] [CrossRef]

- Wang, X.; Deng, Y.; Li, Y.; Kjoller, K.; Roy, A.; Wang, S. In situ identification of the molecular-scale interactions of phenol-formaldehyde resin and wood cell walls using infrared nanospectroscopy. RSC Adv. 2016, 6, 76318–76324. [Google Scholar] [CrossRef]

- Gao, W.; Du, G. Physico-mechanical properties of plywood bonded by nano cupric oxide (CuO) modified pf resins against subterranean termites. Maderas. Ciencia y Tecnología 2015, 129–138. [Google Scholar] [CrossRef]

- Yue, K.; Wu, J.; Xu, L.; Tang, Z.; Chen, Z.; Liu, W.; Wang, L. Use impregnation and densification to improve mechanical properties and combustion performance of Chinese fir. Constr. Build. Mater. 2020, 241, 118101. [Google Scholar] [CrossRef]

- Wang, F.; Liu, J.; Lyu, W. Effect of Boron Compounds on Properties of Chinese Fir Wood Treated with PMUF Resin. J. Bioresour. Bioprod. 2019, 4, 60. [Google Scholar]

- Allan, G.G.; Neogi, A.N. The Mechanism of Adhesion of Phenol-Formaldehyde Resins to Cellulosic and Lignocellulosic Substrates. J. Adhes. 1971, 3, 13–18. [Google Scholar] [CrossRef]

- Myers, I.B.; McCaulley, M.H.; Most, R. Manual, a Guide to the Development and Use of the Myers-Briggs Type Indicator; Consulting Psychologists Press: Palo Alto, CA, USA, 1985. [Google Scholar]

- De, D.; Adhikari, B.; De, D. Grass fiber reinforced phenol formaldehyde resin composite: preparation, characterization and evaluation of properties of composite. Polym. Advan. Technol. 2007, 18, 72. [Google Scholar] [CrossRef]

- Riedl, B.; He, G. Curing kinetics of phenol formaldehyde resin and wood-resin interactions in the presence of wood substrates. Wood Sci. Technol. 2004, 38, 69–81. [Google Scholar] [CrossRef]

- Altgen, M.; Awais, M.; Altgen, D.; Klüppel, A.; Mäkelä, M.; Rautkari, L. Distribution and curing reactions of melamine formaldehyde resin in cells of impregnation-modified wood. Sci. Rep. 2020, 10, 3366. [Google Scholar] [CrossRef]

- Liao, C.B.; Deng, Y.H.; Wang, X.Z.; Fan, X.L.; Yu, T.; Yang, Y. Manufacture and mechanical properties of biocomposite made of reed and silvergrass. Appl. Mech. Mater. 2013, 248, 237–242. [Google Scholar] [CrossRef]

| Sample | CuSO4 5H2O/mol | EDTA-2Na/g | PVP/g | Sodium Pyrophosphate/g | Seignette Salt/g | Deionized Water/mL | Cu/% |

|---|---|---|---|---|---|---|---|

| Control | - | - | - | - | - | - | - |

| PF-0-Cu | 0 | - | - | - | - | - | 0 |

| PF-1-Cu | 0.05 | 18.61 | 0.433 | 2.659 | 5.645 | 25 | 1 |

| PF-3-Cu | 0.15 | 55.83 | 1.299 | 7.977 | 16.934 | 25 | 3 |

| Sample | pH | Viscosity (mPa·S) | Solids Contents (%) |

|---|---|---|---|

| PF-0-Cu | 10.11 | 32.6 | 0.52 |

| PF-1-Cu | 11.08 | 13.9 | 0.39 |

| PF-3-Cu | 11.07 | 13.8 | 0.40 |

| Sampling Point | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Cu (%) | 2.94 | 4.11 | 0 | 0 | 2.84 | 1.41 | 0 | 2.04 | 3.07 | 1.59 |

| Samples | Average MOE (GPa) | Average Hardness (MPa) | MOE Increase (%) | Hardness Increase (%) |

|---|---|---|---|---|

| Control | 17.3 ± 0.45 B | 415.1 ± 10.92 B | 1 | 1 |

| PF-0-Cu | 18.9 ± 0.19 A | 491.4 ± 24.58 A | 9.9 | 18.4 |

| PF-1-Cu | 19.5 ± 0.48 A | 507.3 ± 10.18 A | 12.8 | 22.2 |

| PF-3-Cu | 19.6 ± 0.44 A | 506.1 ± 10.19 A | 13.7 | 21.9 |

| Wavenumbers (cm−1) | Assignment |

|---|---|

| 3316 | O–H stretching vibration |

| 2900 | C–H stretching vibration of methylene |

| 1724 | C=O stretching vibration in acetyl groups in the hemicellulose |

| 1600 | elongation of C=C |

| 1270 | C–O stretching vibration of aliphatic C–OH, aliphatic C–O, and methylol C–OH |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Ye, C.; Huang, Y.; Liu, X.; Fei, B. Incorporation of In Situ Synthesized Nano-Copper Modified Phenol-Formaldehyde Resin to Improve the Mechanical Properties of Chinese Fir: A Preliminary Study. Polymers 2021, 13, 876. https://doi.org/10.3390/polym13060876

Li F, Ye C, Huang Y, Liu X, Fei B. Incorporation of In Situ Synthesized Nano-Copper Modified Phenol-Formaldehyde Resin to Improve the Mechanical Properties of Chinese Fir: A Preliminary Study. Polymers. 2021; 13(6):876. https://doi.org/10.3390/polym13060876

Chicago/Turabian StyleLi, Fan, Cuiyin Ye, Yanhui Huang, Xianmiao Liu, and Benhua Fei. 2021. "Incorporation of In Situ Synthesized Nano-Copper Modified Phenol-Formaldehyde Resin to Improve the Mechanical Properties of Chinese Fir: A Preliminary Study" Polymers 13, no. 6: 876. https://doi.org/10.3390/polym13060876

APA StyleLi, F., Ye, C., Huang, Y., Liu, X., & Fei, B. (2021). Incorporation of In Situ Synthesized Nano-Copper Modified Phenol-Formaldehyde Resin to Improve the Mechanical Properties of Chinese Fir: A Preliminary Study. Polymers, 13(6), 876. https://doi.org/10.3390/polym13060876