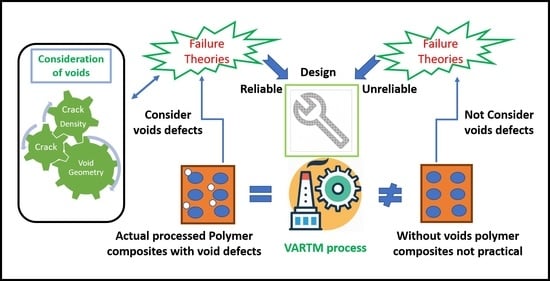

Review and Suggestion of Failure Theories in Voids Scenario for VARTM Processed Composite Materials

Abstract

Share and Cite

Dhimole, V.K.; Serrao, P.; Cho, C. Review and Suggestion of Failure Theories in Voids Scenario for VARTM Processed Composite Materials. Polymers 2021, 13, 969. https://doi.org/10.3390/polym13060969

Dhimole VK, Serrao P, Cho C. Review and Suggestion of Failure Theories in Voids Scenario for VARTM Processed Composite Materials. Polymers. 2021; 13(6):969. https://doi.org/10.3390/polym13060969

Chicago/Turabian StyleDhimole, Vivek Kumar, Pruthvi Serrao, and Chongdu Cho. 2021. "Review and Suggestion of Failure Theories in Voids Scenario for VARTM Processed Composite Materials" Polymers 13, no. 6: 969. https://doi.org/10.3390/polym13060969

APA StyleDhimole, V. K., Serrao, P., & Cho, C. (2021). Review and Suggestion of Failure Theories in Voids Scenario for VARTM Processed Composite Materials. Polymers, 13(6), 969. https://doi.org/10.3390/polym13060969