Development and Characterization of Rice Husk and Recycled Polypropylene Composite Filaments for 3D Printing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

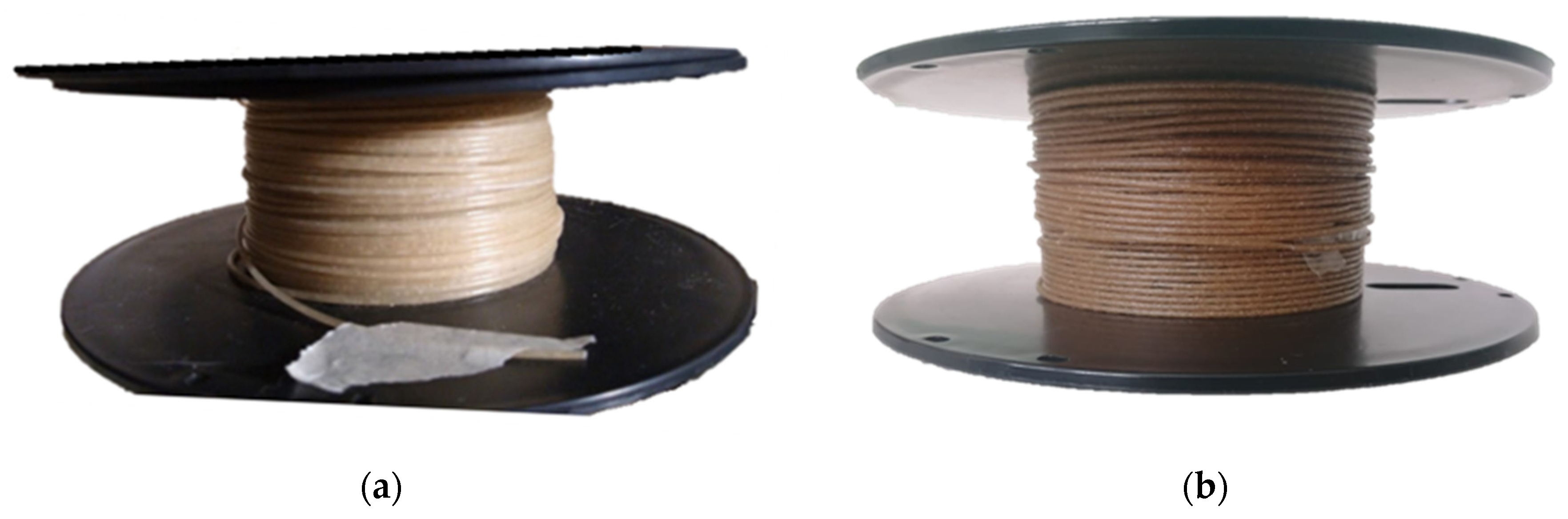

2.2. Extrusion of Composite Filaments

2.3. Density

2.4. Water Absorption and Diameter Swelling Test

2.5. Thermal Analysis

2.6. Specimen Manufacturing

2.7. Mechanical Measurements

2.8. Statistical Analysis

2.9. Scanning Electron Microscopy Measurements

3. Results and Discussion

3.1. Physical Properties

3.2. Thermal Analysis

3.3. Mechanical Properties

3.4. Tensile Test Specimens Fracture Morphology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schwab, K. The Fourth Industrial Revolution, 1st ed.; Crown Business: New York, NY, USA, 2016; ISBN 978-1-5247-5886-8. [Google Scholar]

- Markets of Tomorrow: Pathways to a New Economy. Insigth Report. October 2020; World Economic Forum: Cologny, Switzerland, 2020.

- Klitkou, A.; Bozell, J.; Panoutsou, C.; Kuhndt, M.; Kuusisaari, J.; Beckmann, J. Bioeconomy and Digitalization: Background Paper; MISTRA; The Swedish Foundation for Strategic Environmental Research: Stockholm, Sweden, 2017. [Google Scholar]

- Global Agenda Council on the Future of Software and Society World Economic Forum. Deep Shift—Technology Tipping Points and Societal Impact; Survey Report; World Economic Forum: Cologny, Switzerland, 2015. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pol, V.G.; Thiyagarajan, P. Remediating Plastic Waste into Carbon Nanotubes. J. Environ. Monit. 2010, 12, 455–459. [Google Scholar] [CrossRef]

- Shah, A.A.; Hasan, F.; Hameed, A.; Ahmed, S. Biological Degradation of Plastics: A Comprehensive Review. Biotechnol. Adv. 2008, 26, 246–265. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic Waste Inputs from Land into the Ocean. Science 2015. [Google Scholar] [CrossRef]

- Ahmed, T.; Shahid, M.; Azeem, F.; Rasul, I.; Shah, A.A.; Noman, M.; Hameed, A.; Manzoor, N.; Manzoor, I.; Muhammad, S. Biodegradation of Plastics: Current Scenario and Future Prospects for Environmental Safety. Environ. Sci. Pollut. Res. 2018, 25, 7287–7298. [Google Scholar] [CrossRef]

- Barboza, L.G.A.; Dick Vethaak, A.; Lavorante, B.R.B.O.; Lundebye, A.K.; Guilhermino, L. Marine Microplastic Debris: An Emerging Issue for Food Security, Food Safety and Human Health. Marine Pollut. Bull. 2018, 133, 336–348. [Google Scholar] [CrossRef]

- Van Cauwenberghe, L.; Janssen, C.R. Microplastics in Bivalves Cultured for Human Consumption. Environ. Pollut. 2014. [Google Scholar] [CrossRef] [PubMed]

- Rainieri, S.; Barranco, A. Microplastics, a Food Safety Issue? Trends Food Sci. Technol. 2019, 84, 55–57. [Google Scholar] [CrossRef]

- EFSA. Presence of Microplastics and Nanoplastics in Food, with Particular Focus on Seafood. EFSA J. 2016, 14, e04501. [Google Scholar] [CrossRef] [Green Version]

- Marzouk, O.Y.; Dheilly, R.M.; Queneudec, M. Valorization of Post-Consumer Waste Plastic in Cementitious Concrete Composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of Plastic Solid Waste: A State of Art Review and Future Applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Grigore, M.E. Methods of Recycling, Properties and Applications of Recycled Thermoplastic Polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef] [Green Version]

- Cury, R.K.; Aguas, M.Y.; Martinez, M.A.; Olivero, V.R.; Chams, C.L. Residuos Agroindustriales Su Impacto, Manejo y Aprovechamiento. Rev. Colomb. Cienc. Anim. Recia 2017. [Google Scholar] [CrossRef] [Green Version]

- Peñaranda, L.V.; Montenegro, S.P.; Giraldo, P.A. Aprovechamiento de Residuos Agroindustriales En Colombia. Rev. Investig. Agrar. Ambient. 2017, 8, 141–150. [Google Scholar] [CrossRef] [Green Version]

- Rice, M.P.; Meurah, T.; Mahlia, I.; Saba, N.; Hassan, A.; Jawaid, M. Mechanical and Thermal Properties of Montmorillonite-Reinforced Polypropylene/ Rice Husk Hybrind Nanocomposites. Polymers 2019, 11, 1557. [Google Scholar] [CrossRef] [Green Version]

- Basanta, R.; García, M.A.; Cervantes, J.E.; Mata, H.; Bustos, G. Sustainable Recycling of Waste from Sugarcane Agroindustry: A Review. Cienc. Tecnol. Aliment. 2007, 5, 293–305. [Google Scholar] [CrossRef]

- Ghiani, G.; Laganà, D.; Manni, E.; Musmanno, R.; Vigo, D. Operations Research in Solid Waste Management: A Survey of Strategic and Tactical Issues. Comput. Oper. Res. 2014, 44, 22–32. [Google Scholar] [CrossRef]

- Jiang, L.; Peng, X.; Walczyk, D. 3D Printing of Biofiber-Reinforced Composites and Their Mechanical Properties: A Review. Rapid Prototyp. J. 2020, 26, 1113–1129. [Google Scholar] [CrossRef]

- Suthar, S. Recycling of Agro-Industrial Sludge through Vermitechnology. Ecol. Eng. 2010, 36, 1028–1036. [Google Scholar] [CrossRef]

- Keskisaari, A.; Kärki, T. The Use of Waste Materials in Wood-Plastic Composites and Their Impact on the Profitability of the Product. Resour. Conserv. Recycl. 2018, 134, 257–261. [Google Scholar] [CrossRef]

- Ayre, D. Technology Advancing Polymers and Polymer Composites towards Sustainability: A Review. Curr. Opin. Green Sustain. Chem. 2018, 13, 108–112. [Google Scholar] [CrossRef]

- Ricciardi, P.; Cillari, G.; Carnevale Miino, M.; Collivignarelli, M.C. Valorization of Agro-Industry Residues in the Building and Environmental Sector: A Review. Waste Manag. Res. 2020, 38, 487–513. [Google Scholar] [CrossRef] [PubMed]

- Go, J.; Hart, A.J. A Framework for Teaching the Fundamentals of Additive Manufacturing and Enabling Rapid Innovation. Addit. Manuf. 2016. [Google Scholar] [CrossRef]

- Brooks, H.; Molony, S. Design and Evaluation of Additively Manufactured Parts with Three Dimensional Continuous Fibre Reinforcement. Mater. Des. 2016. [Google Scholar] [CrossRef] [Green Version]

- Yang, T.C. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Depositionmodeling. Polymers 2018, 10, 976. [Google Scholar] [CrossRef] [Green Version]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive Manufacturing of Carbon Fiber Reinforced Thermoplastic Composites Using Fused Deposition Modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Galantucci, L.M.; Lavecchia, F.; Percoco, G. Quantitative Analysis of a Chemical Treatment to Reduce Roughness of Parts Fabricated Using Fused Deposition Modeling. Cirp Ann. Manuf. Technol. 2010. [Google Scholar] [CrossRef]

- Chinga-Carrasco, G.; Ehman, N.V.; Pettersson, J.; Vallejos, M.E.; Brodin, M.W.; Felissia, F.E.; Hakansson, J.; Area, M.C. Pulping and Pretreatment Affect the Characteristics of Bagasse Inks for Three-Dimensional Printing. ACS Sustain. Chem. Eng. 2018. [Google Scholar] [CrossRef] [Green Version]

- Bandyopadhyay, A.; Bose, S.; Das, S. 3D Printing of Biomaterials. MRS Bull. 2015. [Google Scholar] [CrossRef] [Green Version]

- Ji, A.; Zhang, S.; Bhagia, S.; Yoo, C.G.; Ragauskas, A.J. 3D Printing of Biomass-Derived Composites: Application and Characterization Approaches. RSC Adv. 2020, 10, 21698–21723. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Xiao, H.; Ding, S.; Huang, C. Effects of Printing Parameters of Fused Deposition Modeling on Mechanical Properties, Surface Quality, and Microstructure of PEEK. J. Mater. Process. Technol. 2019, 271, 62–74. [Google Scholar] [CrossRef]

- Jaisingh Sheoran, A.; Kumar, H. Fused Deposition Modeling Process Parameters Optimization and Effect on Mechanical Properties and Part Quality: Review and Reflection on Present Research. Mater. Today Proc. 2020, 21, 1659–1672. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Liu, T.; Cao, Y.; Li, D. 3D Printing for Continuous Fiber Reinforced Thermoplastic Composites: Mechanism and Performance. Rapid Prototyp. J. 2017. [Google Scholar] [CrossRef]

- Klippstein, H.; Diaz De Cerio Sanchez, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Fused Deposition Modeling for Unmanned Aerial Vehicles (UAVs): A Review. Adv. Eng. Mater. 2018, 20, 1700552. [Google Scholar] [CrossRef] [Green Version]

- Diaz-Perete, D.; Mercado-Colmenero, J.M.; Valderrama-Zafra, J.M.; Martin-Doñate, C. New Procedure for BIM Characterization of Architectural Models Manufactured Using Fused Deposition Modeling and Plastic Materials in 4.0 Advanced Construction Environments. Polymers 2020, 12, 1498. [Google Scholar] [CrossRef]

- Belka, M.; Ulenberg, S.; Bączek, T. Fused Deposition Modeling Enables the Low-Cost Fabrication of Porous, Customized-Shape Sorbents for Small-Molecule Extraction. Anal. Chem. 2017, 89, 4373–4376. [Google Scholar] [CrossRef]

- Guerrica-Echevarría, G.; Eguiazábal, J.I.; Nazábal, J. Effects of Reprocessing Conditions on the Properties of Unfilled and Talc-Filled Polypropylene. Polym. Degrad. Stab. 1996. [Google Scholar] [CrossRef]

- Chabowski, B.R.; Mena, J.A.; Gonzalez-Padron, T.L. The Structure of Sustainability Research in Marketing, 1958–2008: A Basis for Future Research Opportunities. J. Acad. Mark. Sci. 2011. [Google Scholar] [CrossRef]

- Fitzharris, E.R.; Watanabe, N.; Rosen, D.W.; Shofner, M.L. Effects of Material Properties on Warpage in Fused Deposition Modeling Parts. Int. J. Adv. Manuf. Technol. 2018, 95, 2059–2070. [Google Scholar] [CrossRef]

- Pickering, K.; Stoof, D. Sustainable Composite Fused Deposition Modelling Filament Using Post-Consumer Recycled Polypropylene. J. Compos. Sci. 2017, 1, 17. [Google Scholar] [CrossRef] [Green Version]

- Le Duigou, A.; Castro, M.; Bevan, R.; Martin, N. 3D Printing of Wood Fibre Biocomposites: From Mechanical to Actuation Functionality. Mater. Des. 2016. [Google Scholar] [CrossRef]

- Lebedev, S.M.; Gefle, O.S.; Amitov, E.T.; Zhuravlev, D.V.; Berchuk, D.Y.; Mikutskiy, E.A. Mechanical Properties of PLA-Based Composites for Fused Deposition Modeling Technology. Int. J. Adv. Manuf. Technol. 2018, 97, 511–518. [Google Scholar] [CrossRef]

- Travieso-Rodriguez, J.A.; Zandi, M.D.; Jerez-Mesa, R.; Lluma-Fuentes, J. Fatigue Behavior of PLA-Wood Composite Manufactured by Fused Filament Fabrication. J. Mater. Res. Technol. 2020, 9, 8507–8516. [Google Scholar] [CrossRef]

- Landes, S.; Letcher, T. Mechanical Strength of Bamboo Filled PLA Composite Material in Fused Filament Fabrication. J. Compos. Sci. 2020, 4, 159. [Google Scholar] [CrossRef]

- Caminero, M.; Chacón, J.; García-Plaza, E.; Núñez, P.; Reverte, J.; Becar, J. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zandi, M.D.; Jerez-Mesa, R.; Lluma-Fuentes, J.; Jorba-Peiro, J.; Travieso-Rodriguez, J.A. Study of the Manufacturing Process Effects of Fused Filament Fabrication and Injection Molding on Tensile Properties of Composite PLA-Wood Parts. Int. J. Adv. Manuf. Technol. 2020, 108, 1725–1735. [Google Scholar] [CrossRef]

- Reverte, J.M.; Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Becar, J.P. Mechanical and Geometric Performance of PLA-Based Polymer Composites Processed by the Fused Filament Fabrication Additive Manufacturing Technique. Materials 2020, 13, 1924. [Google Scholar] [CrossRef] [Green Version]

- Rejeski, D.; Zhao, F.; Huang, Y. Research Needs and Recommendations on Environmental Implications of Additive Manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, W.; Alnajjar, F.; Zaneldin, E.; Al-Marzouqi, A.H.; Gochoo, M.; Khalid, S. Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite. Materials 2020, 13, 4065. [Google Scholar] [CrossRef] [PubMed]

- Beckermann, G. Performance of Hemp-Fibre Reinforced Polypropylene Composite Materials. Ph.D. Thesis, University of Waikato, Hamilton, New Zeland, 2007. [Google Scholar]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of Their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [Green Version]

- Huang, B.; He, H.; Meng, S.; Jia, Y. Optimizing 3D Printing Performance of Acrylonitrile-butadiene-styrene Composites with Cellulose Nanocrystals/Silica Nanohybrids. Polym. Int. 2019, 68, 1351–1360. [Google Scholar] [CrossRef]

- Le Duigou, A.; Correa, D.; Ueda, M.; Matsuzaki, R.; Castro, M. A Review of 3D and 4D Printing of Natural Fibre Biocomposites. Mater. Des. 2020, 194, 108911. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, J.; Yao, Q.; Ji, C.; Liu, J.; Zhu, Q. 3D Printing with Cellulose Materials. Cellulose 2018, 25, 4275–4301. [Google Scholar] [CrossRef]

- Le Guen, M.J.; Hill, S.; Smith, D.; Theobald, B.; Gaugler, E.; Barakat, A.; Mayer-Laigle, C. Influence of Rice Husk and Wood Biomass Properties on the Manufacture of Filaments for Fused Deposition Modeling. Front. Chem. 2019, 7. [Google Scholar] [CrossRef]

- Liles, K.P.; Greene, A.F.; Danielson, M.K.; Colley, N.D.; Wellen, A.; Fisher, J.M.; Barnes, J.C. Photoredox-Based Actuation of an Artificial Molecular Muscle. Macromol. Rapid Commun. 2018, 39, 1700781. [Google Scholar] [CrossRef]

- Deb, D.; Jafferson, J.M. Natural Fibers Reinforced FDM 3D Printing Filaments. Mater. Today Proc. 2021, S2214785321015170. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Balla, V.K.; Tadimeti, J.G.D.; Kate, K.H.; Satyavolu, J. 3D Printing of Modified Soybean Hull Fiber/Polymer Composites. Mater. Chem. Phys. 2020, 254, 123452. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive Manufacturing of Natural Fiber Reinforced Polymer Composites: Processing and Prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Tsou, C.H.; Yao, W.H.; Wu, C.S.; Tsou, C.Y.; Hung, W.S.; Chen, J.C.; Guo, J.; Yuan, S.; Wen, E.; Wang, R.Y.; et al. Preparation and Characterization of Renewable Composites from Polylactide and Rice Husk for 3D Printing Applications. J. Polym. Res. 2019, 26. [Google Scholar] [CrossRef]

- Wu, C.S.; Tsou, C.H. Fabrication, Characterization, and Application of Biocomposites from Poly(Lactic Acid) with Renewable Rice Husk as Reinforcement. J. Polym. Res. 2019, 26. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K. Recycled Poly(Lactic Acid)–Based 3D Printed Sustainable Biocomposites: A Comparative Study with Injection Molding. Mater. Today Sustain. 2020, 7–8, 100027. [Google Scholar] [CrossRef]

- Carrete, I.A.; Quiñonez, P.A.; Bermudez, D.; Roberson, D.A. Incorporating Textile-Derived Cellulose Fibers for the Strengthening of Recycled Polyethylene Terephthalate for 3D Printing Feedstock Materials. J. Polym. Environ. 2021, 29, 662–671. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled Polypropylene Blends as Novel 3D Printing Materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K. Sustainable Composite Fused Deposition Modelling Filament Using Recycled Pre-Consumer Polypropylene. Compos. Part B Eng. 2018, 135, 110–118. [Google Scholar] [CrossRef]

- Milosevic, M.; Stoof, D.; Pickering, K.L. Characterizing the Mechanical Properties of Fused Deposition Modelling Natural Fiber Recycled Polypropylene Composites. J. Compos. Sci. 2017, 1, 7. [Google Scholar] [CrossRef] [Green Version]

- Spoerk, M.; Holzer, C.; Gonzalez-Gutierrez, J. Material Extrusion-based Additive Manufacturing of Polypropylene: A Review on How to Improve Dimensional Inaccuracy and Warpage. J. Appl. Polym. Sci. 2020, 137, 48545. [Google Scholar] [CrossRef]

- Spoerk, M.; Sapkota, J.; Weingrill, G.; Fischinger, T.; Arbeiter, F.; Holzer, C. Shrinkage and Warpage Optimization of Expanded-Perlite-Filled Polypropylene Composites in Extrusion-Based Additive Manufacturing. Macromol. Mater. Eng. 2017, 302, 1700143. [Google Scholar] [CrossRef]

- Plásticos En Colombia 2020–2021. Available online: https://www.acoplasticos.org/index.php/mnu-nos/mnu-pyr/mnu-pyr-pi/378 (accessed on 17 March 2021).

- Acosta-Coley, I.; Olivero-Verbel, J. Microplastic Resin Pellets on an Urban Tropical Beach in Colombia. Environ. Monit. Assess. 2015, 187, 435. [Google Scholar] [CrossRef]

- Mourad, A.H.I.; Akkad, R.O.; Soliman, A.A.; Madkour, T.M. Characterisation of Thermally Treated and Untreated Polyethylene- Polypropylene Blends Using DSC, TGA and IR Techniques. Plast. Rubber Compos. 2009, 38, 265–278. [Google Scholar] [CrossRef]

- Osswald, T.A.; Hernández-Ortiz, J.P. Polymer Processing; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2006; ISBN 978-3-446-40381-9. [Google Scholar]

- Qahtani, M.; Wu, F.; Misra, M.; Gregori, S.; Mielewski, D.F.; Mohanty, A.K. Experimental Design of Sustainable 3D-Printed Poly(Lactic Acid)/Biobased Poly(Butylene Succinate) Blends via Fused Deposition Modeling. ACS Sustain. Chem. Eng. 2019, 7, 14460–14470. [Google Scholar] [CrossRef] [Green Version]

- Joseph, P.V.; Joseph, K.; Thomas, S.; Pillai, C.K.S.; Prasad, V.S.; Groeninckx, G.; Sarkissova, M. The Thermal and Crystallisation Studies of Short Sisal Fibre Reinforced Polypropylene Composites. Compos. Part Appl. Sci. Manuf. 2003, 34, 253–266. [Google Scholar] [CrossRef]

- Hidalgo-Salazar, M.A.; Muñoz, M.F.; Mina, J.H. Influence of Incorporation of Natural Fibers on the Physical, Mechanical, and Thermal Properties of Composites LDPE-Al Reinforced with Fique Fibers. Int. J. Polym. Sci. 2015, 2015, 1–8. [Google Scholar] [CrossRef] [Green Version]

- van der Wal, A.; Mulder, J.J.; Gaymans, R.J. Fracture of Polypropylene. Polymer 1998, 39, 5477–5481. [Google Scholar] [CrossRef]

- Lanyi, F.J.; Wenzke, N.; Kaschta, J.; Schubert, D.W. On the Determination of the Enthalpy of Fusion of Α-Crystalline Isotactic Polypropylene Using Differential Scanning Calorimetry, X-Ray Diffraction, and Fourier-Transform Infrared Spectroscopy: An Old Story Revisited. Adv. Eng. Mater. 2020, 22, 1900796. [Google Scholar] [CrossRef] [Green Version]

- De Sousa, R.R., Jr.; Gouveia, J.R.; Nacas, A.M.; Tavares, L.B.; Ito, N.M.; de Moura, E.N.; Gaia, F.A.; Pereira, R.F.; dos Santos, D.J. Improvement of Polypropylene Adhesion by Kraft Lignin Incorporation. Mater. Res. 2019, 22, e20180123. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley & Sons: Hoboken, NY, USA, 2012; ISBN 978-1-118-14692-7. [Google Scholar]

- Olupot, P.W.; Candia, A.; Menya, E.; Walozi, R. Characterization of Rice Husk Varieties in Uganda for Biofuels and Their Techno-Economic Feasibility in Gasification. Chem. Eng. Res. Des. 2016, 107, 63–72. [Google Scholar] [CrossRef]

- Shakuntala, O.; Raghavendra, G.; Samir Kumar, A. Effect of Filler Loading on Mechanical and Tribological Properties of Wood Apple Shell Reinforced Epoxy Composite. Adv. Mater. Sci. Eng. 2014, 2014, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Salgado, P.R.; Schmidt, V.C.; Molina Ortiz, S.E.; Mauri, A.N.; Laurindo, J.B. Biodegradable Foams Based on Cassava Starch, Sunflower Proteins and Cellulose Fibers Obtained by a Baking Process. J. Food Eng. 2008, 85, 435–443. [Google Scholar] [CrossRef]

- Edhirej, A.; Sapuan, S.M.; Jawaid, M.; Zahari, N.I. Cassava/Sugar Palm Fiber Reinforced Cassava Starch Hybrid Composites: Physical, Thermal and Structural Properties. Int. J. Biol. Macromol. 2017, 101, 75–83. [Google Scholar] [CrossRef]

- D20 Committee. ASTM D792—20 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement; ASTM International: West Conshohcken, PA, USA, 2008.

- Holbery, J.; Houston, D. Natural-Fiber-Reinforced Polymer Composites in Automotive Applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Westman, M.P.; Fifield, L.S.; Simmons, K.L.; Laddha, S.; Kafentzis, T.A. Natural Fiber Composites: A Review; U.S. Department of Energy: Washington, DC, USA, 2010; p. PNNL-19220. [CrossRef] [Green Version]

- Verma, D.; Senal, I. Natural fiber-reinforced polymer composites. In Biomass, Biopolymer-Based Materials, and Bioenergy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 103–122. ISBN 978-0-08-102426-3. [Google Scholar]

- Ouarhim, W.; Zari, N.; Bouhfid, R.; Qaiss, A. Mechanical performance of natural fibers—based thermosetting composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2019; Chapter 3; pp. 43–60. ISBN 978-0-08-102292-4. [Google Scholar]

- Rahman, R.; Zhafer Firdaus Syed Putra, S. Tensile properties of natural and synthetic fiber-reinforced polymer composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2019; Chapter 5; pp. 81–102. ISBN 978-0-08-102292-4. [Google Scholar]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6. [Google Scholar] [CrossRef]

- Razavi-Nouri, M.; Jafarzadeh, F.; Oromiehie, A.; Langroudi, A. Mechanical Properties and Water Absorption Behaviour of Chopped Rice Husk Filled Polypropylene Composites. Iran. Polym. J. Engl. Ed. 2006, 15, 757–766. [Google Scholar]

- Le Duigou, A.; Bourmaud, A.; Davies, P.; Baley, C. Long Term Immersion in Natural Seawater of Flax/PLA Biocomposite. Ocean Eng. 2014, 90, 140–148. [Google Scholar] [CrossRef] [Green Version]

- Gholampour, A.; Ozbakkaloglu, T. A Review of Natural Fiber Composites: Properties, Modification and Processing Techniques, Characterization, Applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Al-Maharma, A.; Al-Huniti, N. Critical Review of the Parameters Affecting the Effectiveness of Moisture Absorption Treatments Used for Natural Composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef] [Green Version]

- Pan, Y.; Zhong, Z. A Nonlinear Constitutive Model of Unidirectional Natural Fiber Reinforced Composites Considering Moisture Absorption. J. Mech. Phys. Solids 2014, 69, 132–142. [Google Scholar] [CrossRef]

- Banik, N.; Dey, V.; Sastry, G.R.K. An Overview of Lignin & Hemicellulose Effect Upon Biodegradable Bamboo Fiber Composites Due to Moisture. Mater. Today Proc. 2017, 4, 3222–3232. [Google Scholar] [CrossRef]

- Jauhari, N.; Mishra, R.; Thakur, H. Natural Fibre Reinforced Composite Laminates—A Review. Mater. Today Proc. 2015, 2, 2868–2877. [Google Scholar] [CrossRef]

- Joseph, S. A Comparison of the Mechanical Properties of Phenol Formaldehyde Composites Reinforced with Banana Fibres and Glass Fibres. Compos. Sci. Technol. 2002, 62, 1857–1868. [Google Scholar] [CrossRef]

- Ho, M.; Wang, H.; Lee, J.-H.; Ho, C.; Lau, K.; Leng, J.; Hui, D. Critical Factors on Manufacturing Processes of Natural Fibre Composites. Compos. Part B Eng. 2012, 43, 3549–3562. [Google Scholar] [CrossRef]

- Yashas Gowda, T.G.; Sanjay, M.R.; Subrahmanya Bhat, K.; Madhu, P.; Senthamaraikannan, P.; Yogesha, B. Polymer Matrix-Natural Fiber Composites: An Overview. Cogent Eng. 2018, 5, 1446667. [Google Scholar] [CrossRef]

- Aji, I.; Zainudin, E.; Abdan, K.; Sapuan, S.; Khairul, M. Mechanical Properties and Water Absorption Behavior of Hybridized Kenaf/Pineapple Leaf Fibre-Reinforced High-Density Polyethylene Composite. J. Compos. Mater. 2013, 47, 979–990. [Google Scholar] [CrossRef]

- Zaman, H.U.; Beg, M. Preparation, Structure, and Properties of the Coir Fiber/Polypropylene Composites. J. Compos. Mater. 2014, 48, 3293–3301. [Google Scholar] [CrossRef]

- Montalvo Navarrete, J.I.; Hidalgo-Salazar, M.A.; Escobar Nunez, E.; Rojas Arciniegas, A.J. Thermal and Mechanical Behavior of Biocomposites Using Additive Manufacturing. Int. J. Interact. Des. Manuf. IJIDeM 2018, 12, 449–458. [Google Scholar] [CrossRef]

- Tran, T.N.; Bayer, I.S.; Heredia-Guerrero, J.A.; Frugone, M.; Lagomarsino, M.; Maggio, F.; Athanassiou, A. Cocoa Shell Waste Biofilaments for 3D Printing Applications. Macromol. Mater. Eng. 2017, 302, 1–10. [Google Scholar] [CrossRef]

- Pet, P.P.; Composites, M. Development of Crystalline Morphology and Its Relationship with Mechanical Properties Of PP/PET Microfibrillar Composites Containing POE and Poe-g-MA. Polymers 2018, 10, 291. [Google Scholar] [CrossRef] [Green Version]

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S.Q. Development and Application Ofwood Flour-Filled Polylactic Acid Composite Filament for 3d Printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef] [Green Version]

- Girdis, J.; Gaudion, L.; Proust, G.; Löschke, S.; Dong, A. Rethinking Timber: Investigation into the Use of Waste Macadamia Nut Shells for Additive Manufacturing. JOM 2017, 69, 575–579. [Google Scholar] [CrossRef]

- Siqueira, G.; Fraschini, C.; Bras, J.; Dufresne, A.; Prud’Homme, R.; Laborie, M.P. Impact of the Nature and Shape of Cellulosic Nanoparticles on the Isothermal Crystallization Kinetics of Poly(-Caprolactone). Eur. Polym. J. 2011. [Google Scholar] [CrossRef]

- Zeidler, H.; Klemm, D.; Böttger-Hiller, F.; Fritsch, S.; Le Guen, M.J.; Singamneni, S. 3D Printing of Biodegradable Parts Using Renewable Biobased Materials. Proc. Manuf. 2018, 21, 117–124. [Google Scholar] [CrossRef]

- Osman, M.A.; Atia, M.R.A. Investigation of ABS-Rice Straw Composite Feedstock Filament for FDM. Rapid Prototyp. J. 2018. [Google Scholar] [CrossRef]

- Tisserat, B.; Liu, Z.; Finkenstadt, V.; Lewandowski, B.; Ott, S.; Reifschneider, L. 3D Printing Biocomposites. Spe Plast. Res. Online 2015. [Google Scholar] [CrossRef]

- Šafka, J.; Ackermann, M.; Bobek, J.; Seidl, M.; Habr, J.; Běhálek, L. Use of Composite Materials for FDM 3D Print Technology. Mater. Sci. Forum 2016, 862, 174–181. [Google Scholar] [CrossRef]

- Gkartzou, E.; Koumoulos, E.P.; Charitidis, C.A. Production and 3D Printing Processing of Bio-Based Thermoplastic Filament. Manuf. Rev. 2017. [Google Scholar] [CrossRef]

- Liu, H.; He, H.; Peng, X.; Huang, B.; Li, J. Three-Dimensional Printing of Poly(Lactic Acid) Bio-Based Composites with Sugarcane Bagasse Fiber: Effect of Printing Orientation on Tensile Performance. Polym. Adv. Technol. 2019. [Google Scholar] [CrossRef]

- Askeland, D.R.; Fulay, P.P.; Wright, W.J. The Science and Engineering of Materials, 6th ed.; Cengage Learning: Boston, MA, USA, 2011; ISBN 978-0-495-29602-7. [Google Scholar]

- Rajpurohit, S.R.; Dave, H.K. Analysis of Tensile Strength of a Fused Filament Fabricated PLA Part Using an Open-Source 3D Printer. Int. J. Adv. Manuf. Technol. 2019, 101, 1525–1536. [Google Scholar] [CrossRef]

- Garg, A.; Bhattacharya, A.; Batish, A. Chemical Vapor Treatment of ABS Parts Built by FDM: Analysis of Surface Finish and Mechanical Strength. Int. J. Adv. Manuf. Technol. 2017, 89, 2175–2191. [Google Scholar] [CrossRef]

- Bendahou, A.; Kaddami, H.; Sautereau, H.; Raihane, M.; Erchiqui, F.; Dufresne, A. Short Palm Tree Fibers Poly Olefin Composites: Effect of Filler Content and Coupling Agent on Physical Properties. Macromol. Mater. Eng. 2008. [Google Scholar] [CrossRef]

- Chen, P.; Lu, C.; Yu, Q.; Gao, Y.; Li, J.; Li, X. Influence of Fiber Wettability on the Interfacial Adhesion of Continuous Fiber-Reinforced PPESK Composite. J. Appl. Polym. Sci. 2006. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A Review of Recent Developments in Natural Fibre Composites and Their Mechanical Performance. Compos. Part Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Sinha, E.; Panigrahi, S. Effect of Plasma Treatment on Structure, Wettability of Jute Fiber and Flexural Strength of Its Composite. J. Compos. Mater. 2009, 43, 1791–1802. [Google Scholar] [CrossRef]

- Filgueira, D.; Holmen, S.; Melbø, J.K.; Moldes, D.; Echtermeyer, A.T.; Chinga-Carrasco, G. 3D Printable Filaments Made of Biobased Polyethylene Biocomposites. Polymers 2018, 10, 314. [Google Scholar] [CrossRef] [Green Version]

- Sood, M.; Dwivedi, G. Effect of Fiber Treatment on Flexural Properties of Natural Fiber Reinforced Composites: A Review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Manalo, A.C.; Wani, E.; Zukarnain, N.A.; Karunasena, W.; Lau, K.T. Effects of Alkali Treatment and Elevated Temperature on the Mechanical Properties of Bamboo Fibre-Polyester Composites. Compos. Part B Eng. 2015. [Google Scholar] [CrossRef] [Green Version]

- Sood, M.; Dharmpal, D.; Gupta, V.K. Effect of Fiber Chemical Treatment on Mechanical Properties of Sisal Fiber/Recycled HDPE Composite. Mater. Today Proc. 2015, 2, 3149–3155. [Google Scholar] [CrossRef]

- van de Werken, N.; Hurley, J.; Khanbolouki, P.; Sarvestani, A.N.; Tamijani, A.Y.; Tehrani, M. Design Considerations and Modeling of Fiber Reinforced 3D Printed Parts. Compos. Part B Eng. 2019, 160, 684–692. [Google Scholar] [CrossRef]

| Sample | Density (g/cm3) |

|---|---|

| rPP | 0.893 ± 0.001 |

| rPP/RH (5%) | 0.883 ± 0.004 |

| rPP/RH (10%) | 0.876 ± 0.004 |

| Sample | Crystallization | Melting | %Crystallinity | ||

|---|---|---|---|---|---|

| Tc (°C) | ΔHc (J/g) | Tm (°C) | ΔHm (J/g) | Based on ΔHPP0 | |

| rPP | 135.07 | 84.28 | 167.27 | 94.83 | 45.81 |

| rPP/RH (5 wt.%) | 132.39 | 81.01 | 167.39 | 73.98 | 37.62 |

| rPP/RH (10 wt.%) | 134.26 | 84.63 | 167.24 | 80.54 | 43.23 |

| Raster Angle | Specimen | Tensile Strength (MPa) | Tensile Elongation (%) | Young Modulus (GPa) |

|---|---|---|---|---|

| 0° | rPP | 26.02 ± 0.47 | 6.16 ± 0.19 | 1.34 ± 0.05 |

| rPP/RH (5 wt.%) | 13.62 ± 2.71 | 4.10 ± 0.20 | 1.06 ± 0.13 | |

| rPP/RH (10 wt.%) | 13.78 ± 0.59 | 5.06 ± 0.16 | 1.04 ± 0.04 | |

| 90° | rPP | 4.33 ± 1.73 | 1.01 ± 0.35 | 0.74 ± 0.37 |

| rPP/RH (5 wt.%) | 7.92 ± 0.67 | 2.04 ± 0.43 | 1.01 ± 0.12 | |

| rPP/RH (10 wt.%) | 5.66 ± 0.82 | 3.07 ± 0.45 | 0.66 ± 0.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales, M.A.; Atencio Martinez, C.L.; Maranon, A.; Hernandez, C.; Michaud, V.; Porras, A. Development and Characterization of Rice Husk and Recycled Polypropylene Composite Filaments for 3D Printing. Polymers 2021, 13, 1067. https://doi.org/10.3390/polym13071067

Morales MA, Atencio Martinez CL, Maranon A, Hernandez C, Michaud V, Porras A. Development and Characterization of Rice Husk and Recycled Polypropylene Composite Filaments for 3D Printing. Polymers. 2021; 13(7):1067. https://doi.org/10.3390/polym13071067

Chicago/Turabian StyleMorales, Maria A., Cindy L. Atencio Martinez, Alejandro Maranon, Camilo Hernandez, Veronique Michaud, and Alicia Porras. 2021. "Development and Characterization of Rice Husk and Recycled Polypropylene Composite Filaments for 3D Printing" Polymers 13, no. 7: 1067. https://doi.org/10.3390/polym13071067

APA StyleMorales, M. A., Atencio Martinez, C. L., Maranon, A., Hernandez, C., Michaud, V., & Porras, A. (2021). Development and Characterization of Rice Husk and Recycled Polypropylene Composite Filaments for 3D Printing. Polymers, 13(7), 1067. https://doi.org/10.3390/polym13071067