Development of a Subpath Extrusion Tip and Die for Peripheral Inserted Central Catheter Shaft with Multi Lumen

Abstract

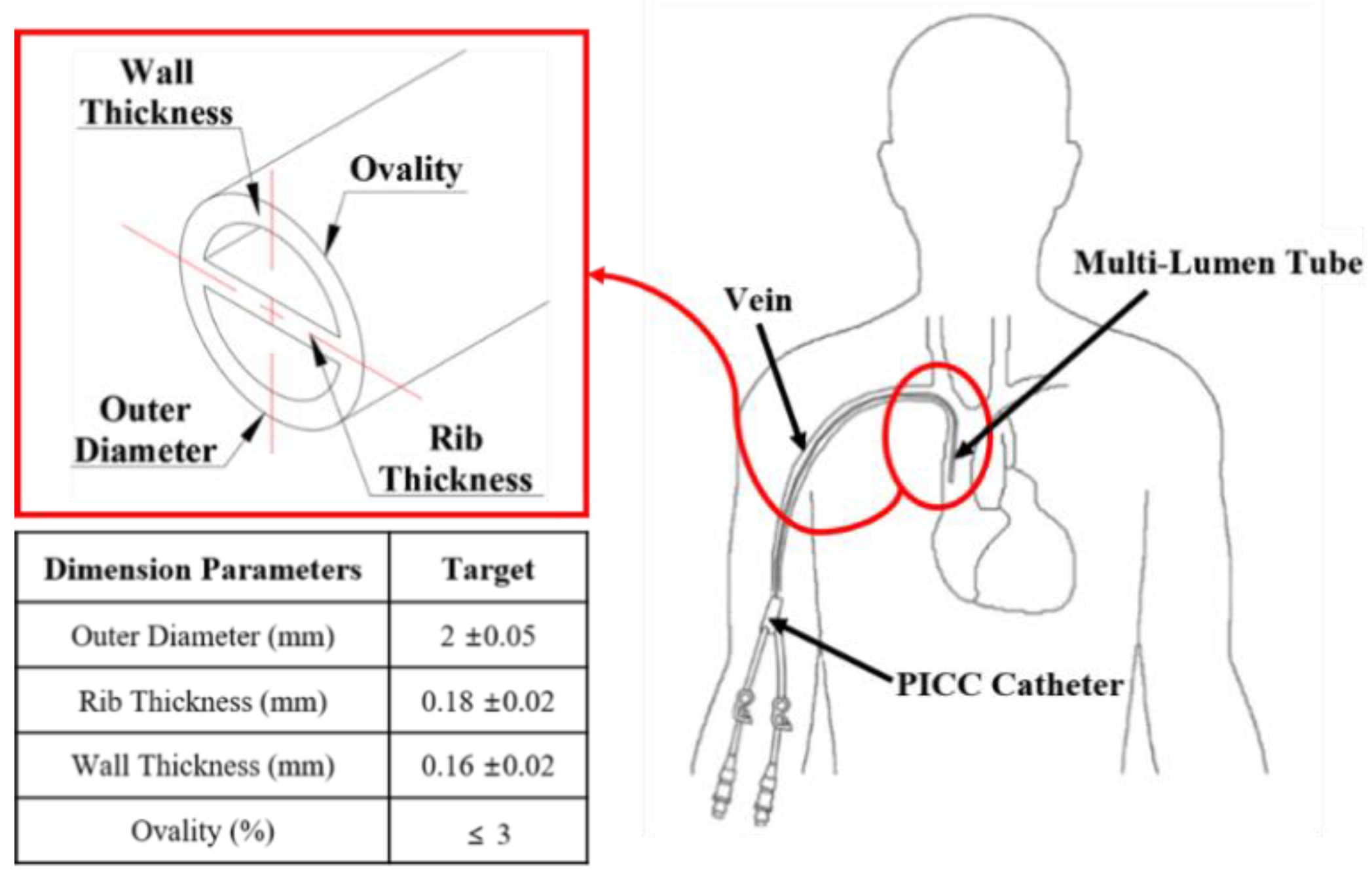

1. Introduction

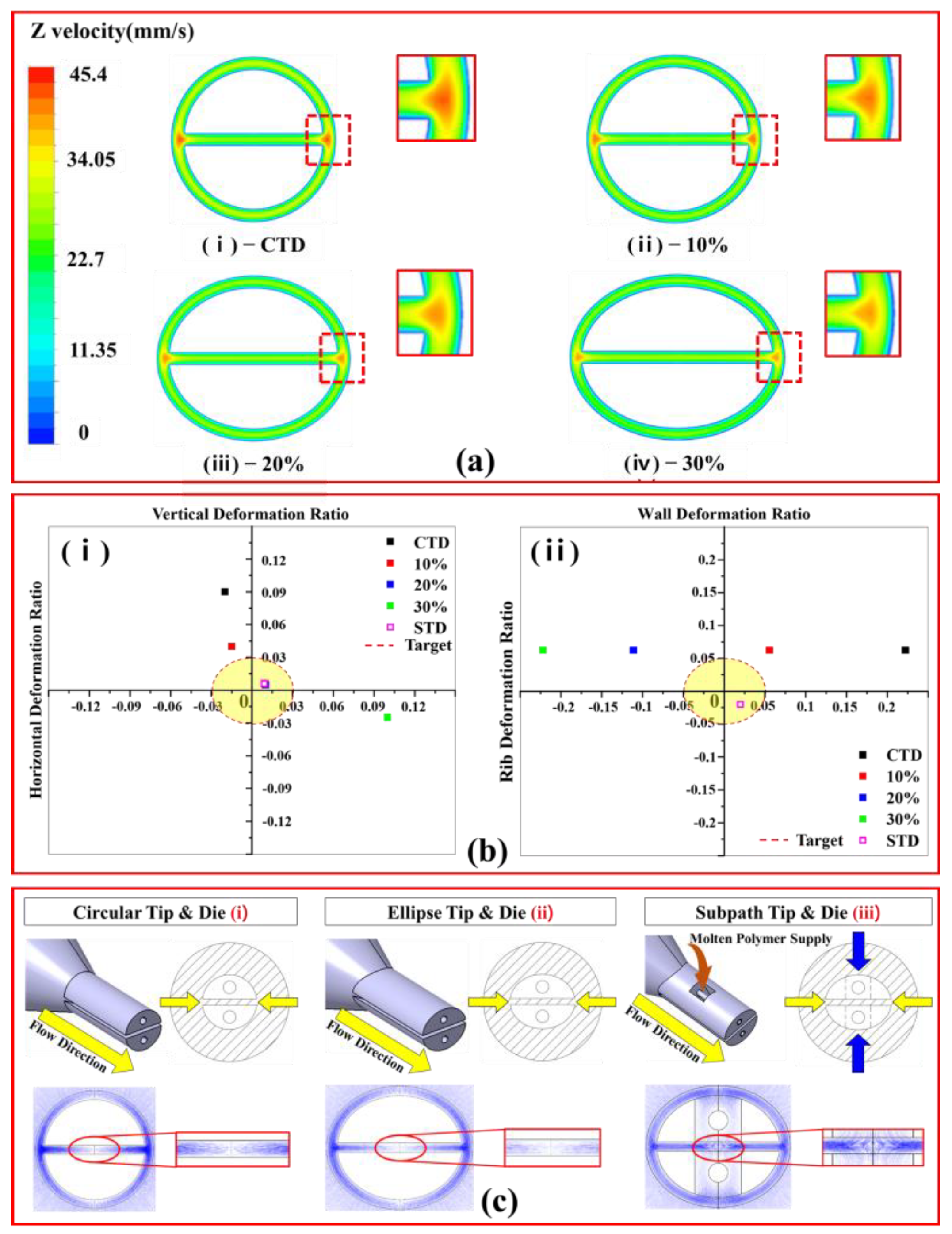

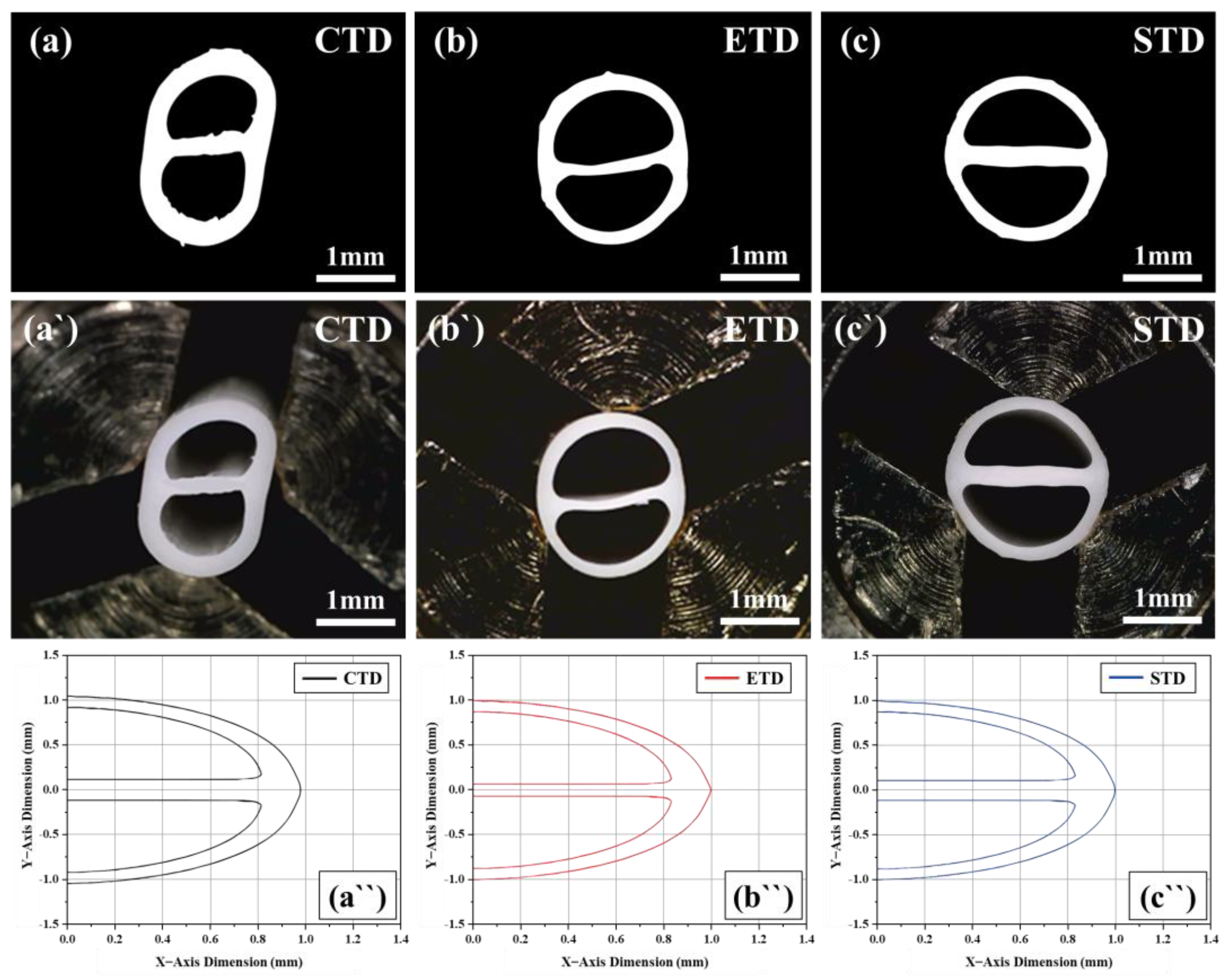

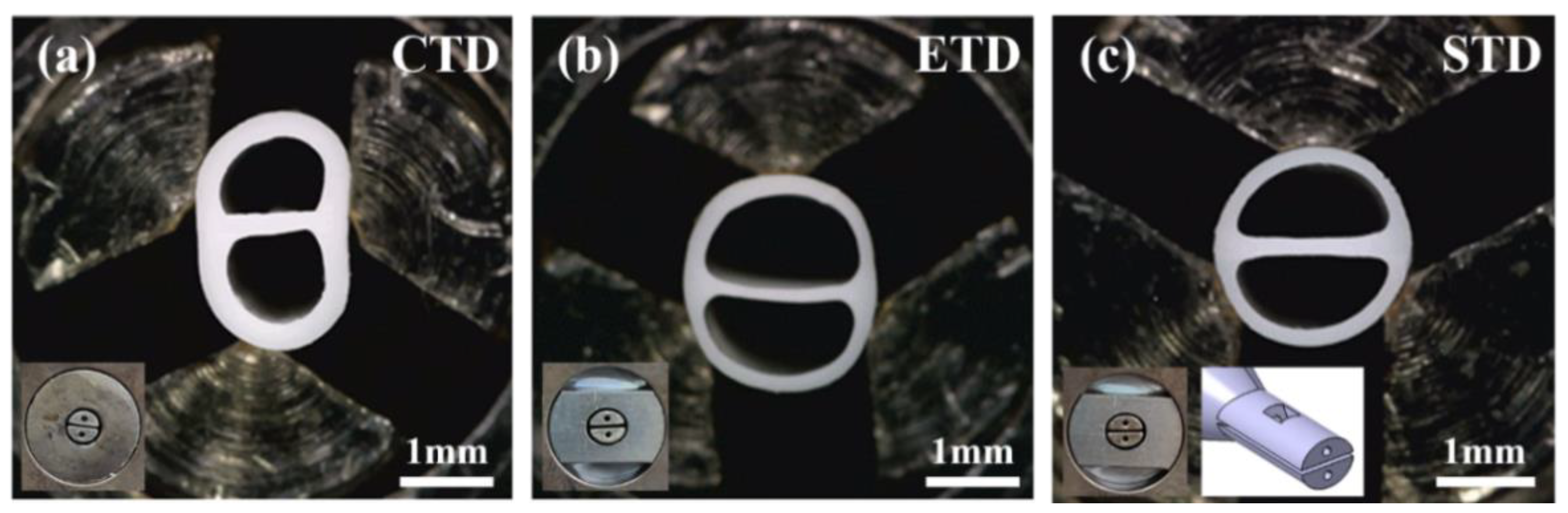

- (1)

- Circular tip and die (CTD).

- (2)

- Ellipse tip and die (ETD).

- (3)

- Sub path tip and die (STD).

2. Materials, Method, and Numerical Modeling

2.1. Materials

2.2. Design Method

2.3. Numerical Modeling

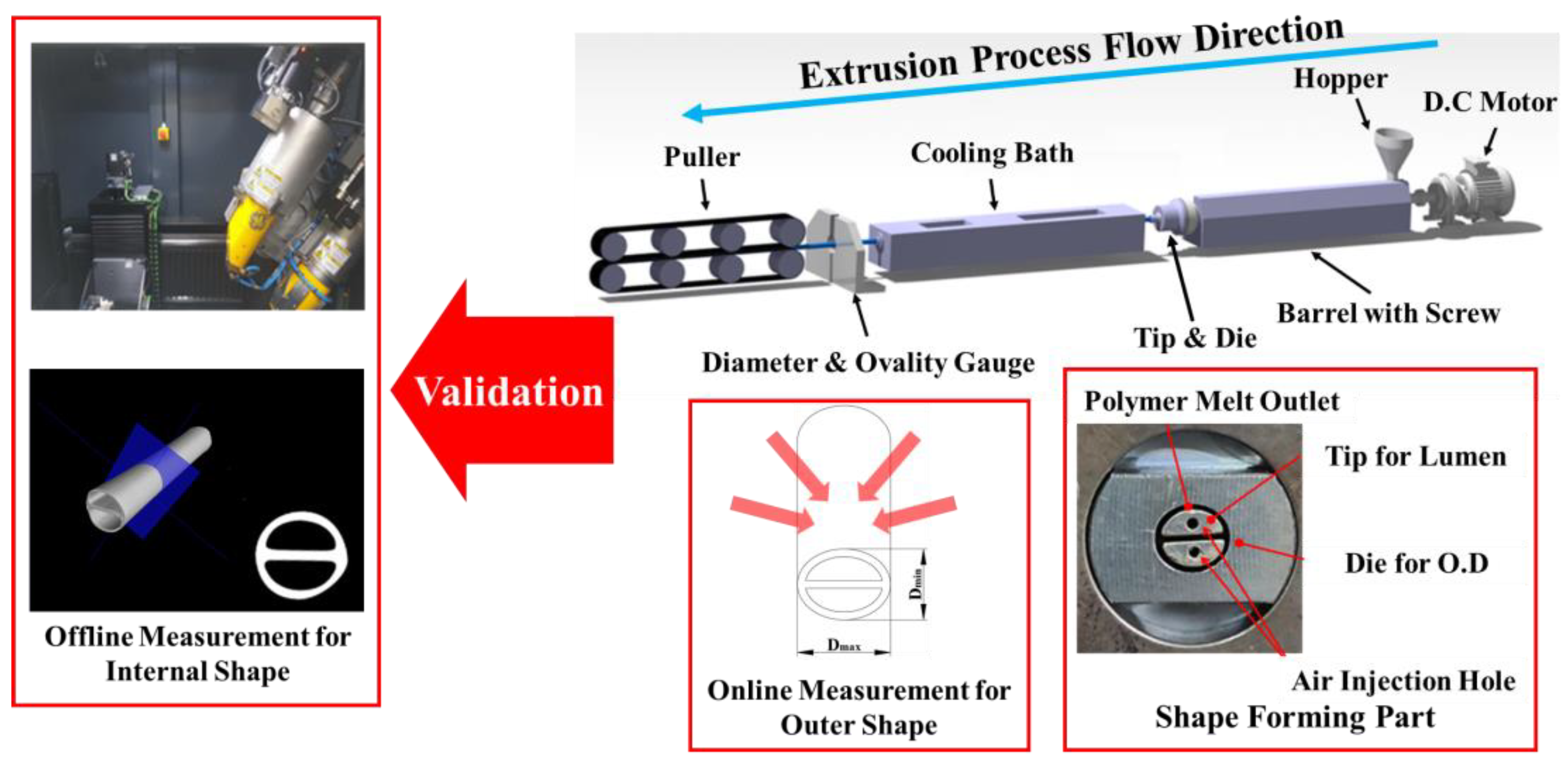

2.4. Experiment Setup

3. Results and Discussion

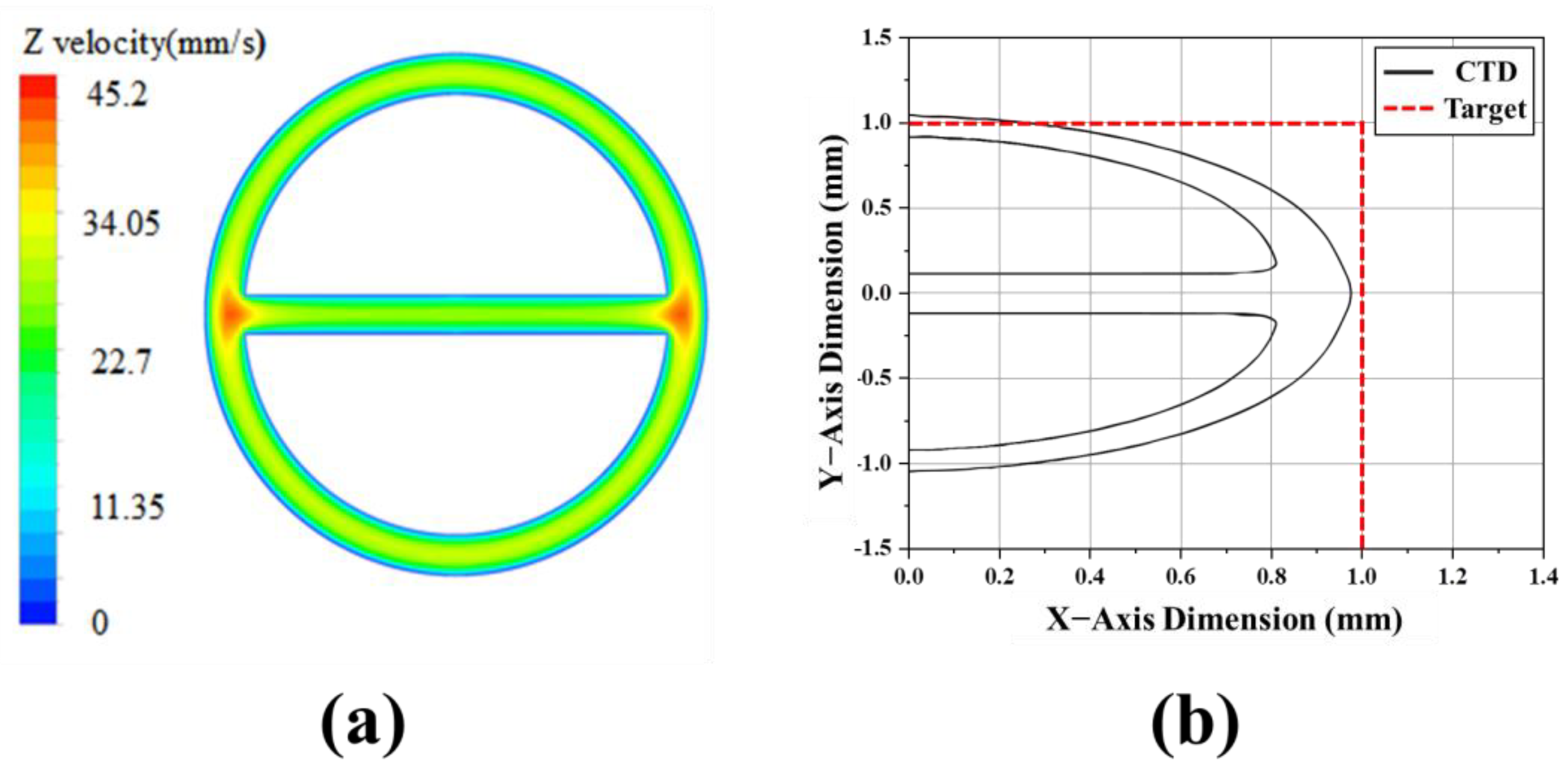

3.1. Numerical Analysis Result

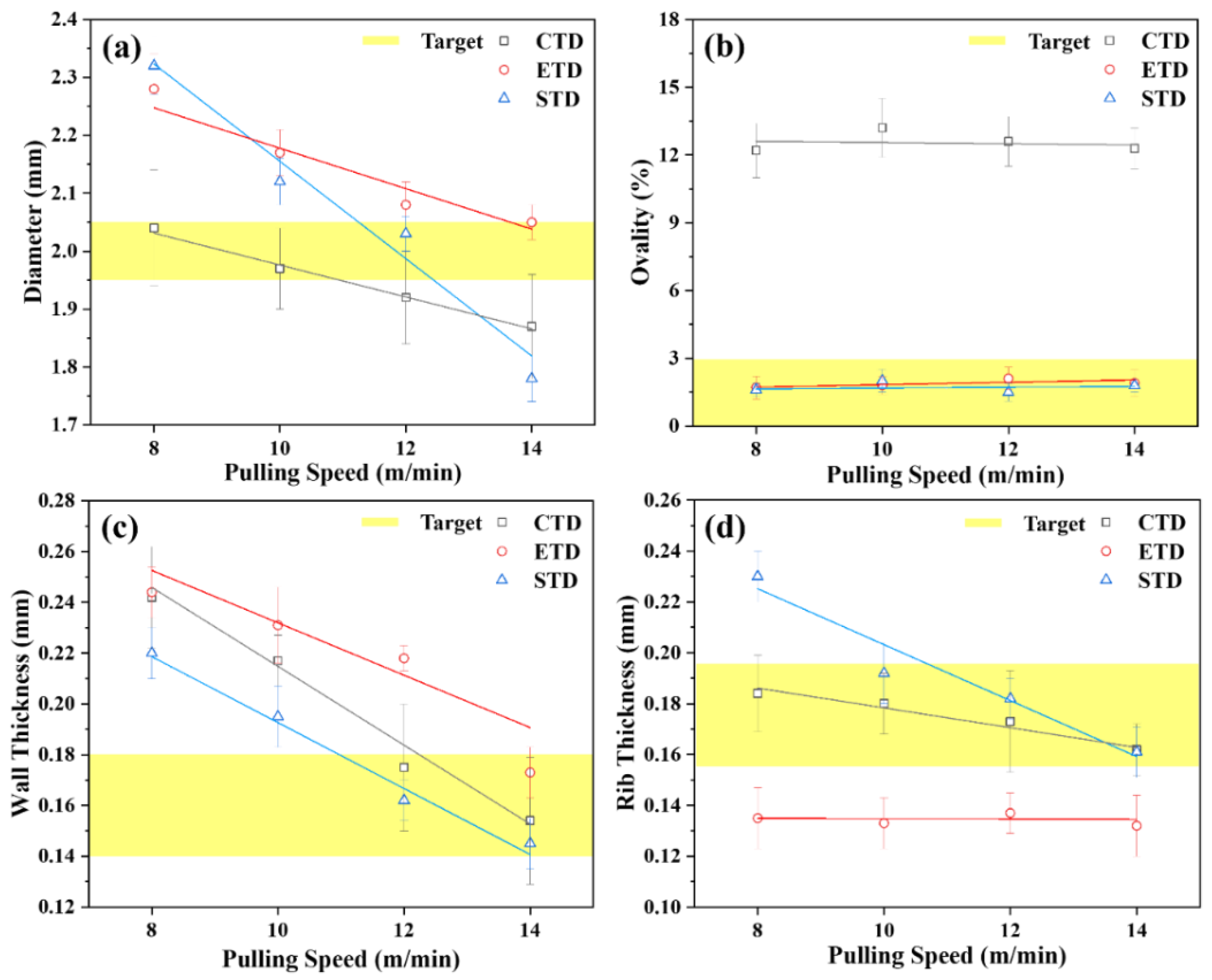

3.2. Experiment Result

3.3. Discussion

3.3.1. Comparison of Numerical Analysis and Experimental Results

3.3.2. Comparison of Multi Lumen Tubes

4. Conclusions

- Through numerical analysis, the deformation of the tube due to the flow velocity imbalance of the molten polymer in the tip and die was calculated, and a novel tip and die structure was proposed to resolve this problem. In the actual extrusion process, when the swelling force applied to the molten polymer and air pressures are stably balanced, a tube with low ovality can be formed.

- As the cross-sectional area of the tip and die increased, the flow velocity decreased and the internal path of the polymer increased, resulting in a lack of supply to the center of the tip. To solve this problem, a structure in which a sub-path was added to the tip was proposed, and the stability of the flow of the molten polymer was numerically validated. It was confirmed that the tube manufactured through the extrusion process also showed similar performance to the numerical analysis results.

- Based on the above research results, a tip and die design method which can control the ovality, rib and wall thickness simultaneously is proposed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Joh, J.H. Early experience of surgeon-handed angiography and intervention. Korean J. Vasc. Endovasc. Surg. 2007, 23, 153–158. [Google Scholar]

- Fukuda, S.; Nakajima, K.; Miyazaki, Y.; Takahashi, T.; Kurokawa, Y.; Yamasaki, M.; Miyata, H.; Takiguchi, S.; Mori, M.; Doki, Y. Use of double-lumen peripherally inserted central catheters for safer perioperative management of esophageal cancer patients. J. Vasc. Access. 2015, 16, 338–343. [Google Scholar] [CrossRef] [PubMed]

- Yi, M.; Kim, I.R.; Choi, E.K.; Lee, S.; Kwak, M.; Cho, J.; Ahn, J.S.; Kwon, I.G. Discomfort related to peripherally inserted central catheters in cancer patient. Asian Oncol. Nurs. 2017, 17, 229–236. [Google Scholar] [CrossRef]

- Hopmann, C.; Michaeli, W. Extrusion Dies for Plastics and Rubber, 4th ed.; Hanser Publications: Cincinnati, OH, USA, 2016; pp. 13–17. ISBN 978-1-56990-623-1. [Google Scholar]

- Rauwendaal, C. Polymer Extrusion, 5th ed.; Hanser Publications: Cincinnati, OH, USA, 2014; pp. 367–375. ISBN 978-1569905166. [Google Scholar]

- Dufrancatel-Veiller, L.; Lacrampe, M.F.; Pabiot, J. Die swell of thermoplastic polyurethanes: A peculiar behavior. J. Appl. Polym. Sci. 2001, 80, 1710–1724. [Google Scholar] [CrossRef]

- Jin, G.B.; Wang, M.J.; Zhao, D.Y.; Tian, H.Q.; Jin, Y.F. Design and experiments of extrusion die for polypropylene five-lumen micro tube. J. Mater. Process. Technol. 2014, 214, 50–59. [Google Scholar] [CrossRef]

- Jin, G.; Jin, Y.; Zhao, D.; Dai, G.; Zhang, Q. Cross-section design of multi-lumen extrusion dies: Study on the effects of die swell and gas flow rate of the lumen. Microsyst. Technol. 2017, 23, 5093–5104. [Google Scholar] [CrossRef]

- Tian, H.; Zhao, D.; Wang, M.; Jin, G.; Jin, Y. Study on extrudate swell of polypropylene in double-lumen micro profile extrusion. J. Mater. Process. Technol. 2015, 225, 357–368. [Google Scholar] [CrossRef]

- Liu, W.; Kim, W.; Park, J.M. Numerical study on the optimization of polymer extrusion process for a single-lumen micro catheter. Trans. Korean Soc. Mech. Eng. A 2018, 42, 1059–1065. [Google Scholar] [CrossRef]

- Cho, H.; Lyu, M.Y. Flow Characteristics of polymer melt for die shapes for the extrusion of catheter tubing. Polym. Korea 2018, 42, 197–205. [Google Scholar] [CrossRef]

- Cho, S.; Lee, E.; Jo, S.; Kim, G.M.; Kim, W. Extrusion characteristics of thin walled tubes for catheters using thermoplastic elastomer. Polymers 2020, 12, 1628. [Google Scholar] [CrossRef]

- Pierson, I.; Chen, E.; Padsalgikar, A.D.; Abbott, R. Rheological characterization of medical thermoplastic polyurethanes. In Proceedings of the MN SPE ANTEC Anaheim 2017 Conference, Anaheim, CA, USA, 8–10 May 2017; pp. 1880–1884. [Google Scholar]

- Lubrizol Advanced Materials, Inc. Tecoflex Medical Grade Aliphatic Polyether-based Thermoplastic Polyurethanes (TPUs). 2019. Available online: https://www.lubrizol.com/-/media/Lubrizol/Life-Sciences/Documents/TDS/Tecoflex-TPU-Clear.pdf (accessed on 23 April 2019).

- Yoshida, T.; Hirose, R.; Naito, Y.; Inoue, K.; Dohi, O.; Yoshida, N.; Kamada, K.; Uchiyama, K.; Ishikawa, T.; Takagi, T.; et al. Viscosity: An important factor in predicting the performance of submucosal injection materials. J. Matdes 2020, 195, 109008. [Google Scholar] [CrossRef]

- Barnes, H.A.; Hutton, J.F.; Walters, K. An Introduction to Rheology, 1st ed.; Elsevier: Amsterdam, The Netherlands, 1989; pp. 16–23. ISBN 978-0444871404. [Google Scholar]

- Jun Ho, M.; Ju Hyeon, K.; Sang Ho, M.; See Jo, K. Modeling and numerical simulation of multiflux die in the multilayer co-extrusion process. J. Korea Aust. Rheol. 2017, 2, 51–57. [Google Scholar] [CrossRef]

- Xian, W.; Song, L.; Liu, B.; Ding, H.; Li, Z.; Cheng, M.; Ma, L. Rheological and mechanical properties of thermoplastic polyurethane elastomer derived from CO2 copolymer diol. J. Appl. Polym. Sci. 2018, 135, 45974. [Google Scholar] [CrossRef]

- Girardot, T.; Monard, C.; Rimmelé, T. Dialysis catheters in the ICU: Selection, insertion and maintenance. Curr. Opin. Crit. Care 2018, 24, 469–475. [Google Scholar] [CrossRef]

- Silk, D.B.; Quinn, D.G. Dual-purpose gastric decompression and enteral feeding tubes rationale and design of novel nasogastric and nasogastrojejunal tubes. J. Parenter. Enter. Nutr. 2014, 39, 531–543. [Google Scholar] [CrossRef] [PubMed]

- Carneiro, O. Design of Extrusion Forming Tools, 1st ed.; Smithers Rapra: Shawbury, UK, 2012; pp. 17–18. ISBN 978-1847355171. [Google Scholar]

- Rahimi, F.; Eivani, A.R.; Kiani, M. Effect of die design parameters on the deformation behavior in pure shear extrusion. J. Matdes 2015, 83, 144–153. [Google Scholar] [CrossRef]

- Zhang, H.; Li, X.; Deng, X.; Reynolds, A.P.; Sutton, M.A. Numerical simulation of friction extrusion process. J. Mater. Process. Technol. 2018, 253, 17–26. [Google Scholar] [CrossRef]

- Kim, S.J. Dimensionless analysis of three-dimensional residence time distribution in single-screw extrusion processes. J. Korea Aust. Rheol. 2018, 8, 179–188. [Google Scholar] [CrossRef]

- Wan, Y.; Fu, Z.H.; Zhang, J.X.; Zang, G.Z.; Zhang, L. Simulation and experiment on extrusion molding of five-lumen medical catheter. MSF 2018, 923, 149–155. [Google Scholar] [CrossRef]

- Ren, Z.; Huang, X.; Xiong, Z. Experimental and numerical studies for the gas-assisted extrusion forming of polypropylene micro-tube. Int. J. Mater. Form 2019, 13, 235–256. [Google Scholar] [CrossRef]

- Ren, Z. Numerical simulation of gas-assisted extrusion of four-lumen micro-catheter based on fem method. J. Phys. Conf. Ser. 2020, 1622, 012050. [Google Scholar] [CrossRef]

- Jo, S.; Lee, E. Numerical study on the effects of the manufacturing parameters for multi-lumen catheter extrusion. J. Korean Soc. Precis. Eng. 2020, 37, 17–24. [Google Scholar] [CrossRef]

- Tseng, J.W.; Liu, C.Y.; Yen, Y.K.; Belkner, J.; Bremicker, T.; Liu, B.H.; Sun, T.J.; Wang, A.B. Screw extrusion-based additive manufacturing of PEEK. J. Matdes 2018, 140, 209–221. [Google Scholar] [CrossRef]

| Mechanical Properties | Unit | Value |

|---|---|---|

| Hardness | Shore A | 85 |

| Density | kg/m3 | 1250 |

| Melting Point | °C | 180 |

| Flexural Modulus | MPa | 18.6 |

| Tensile Stress at Break | MPa | 38.9 |

| Temperature [°C] | Fitting Parameters | |||

|---|---|---|---|---|

[Pa·s] | [Pa·s] | [s] | n | |

| 190 | 655.89 | 1.91 × 10−6 | 0.0089 | 0.6 |

| 200 | 183.83 | 1.85 × 10−5 | 0.002 | 0.65 |

| 210 | 74.7 | 2.45 × 10−5 | 0.001 | 0.7 |

| Test No. | Screw Speed (rpm) | Air Pressure (Pa) | Pulling Speed (m/min) |

|---|---|---|---|

| 1 | 10 | 2490 | 8 |

| 2 | 10 | ||

| 3 | 12 | ||

| 4 | 14 |

| Dimension | Tip and Die Type | Unit | |||||

|---|---|---|---|---|---|---|---|

| Circular (CTD) | Ellipse (ETD) | Subpath (STD) | |||||

| Analysis | Experiment | Analysis | Experiment | Analysis | Experiment | ||

| Dmax | 2.15 | 2.14 ± 0.07 | 2.02 | 2.20 ± 0.04 | 2.00 | 2.20 ± 0.03 | mm |

| Dmin | 1.95 | 1.87 ± 0.07 | 1.99 | 2.16 ± 0.03 | 1.98 | 2.18 ± 0.03 | |

| Rib Thickness | 0.221 | 0.182 ± 0.012 | 0.163 | 0.133 ± 0.01 | 0.181 | 0.192 ± 0.012 | |

| Wall Thickness | 0.151 | 0.217 ± 0.01 | 0.152 | 0.231 ± 0.015 | 0.152 | 0.198 ± 0.012 | |

| Ovality | 9.75 | 13.47 | 1.50 | 1.83 | 1.01 | 0.91 | % |

| Dimension | Tip and Die Type | Unit | |||

|---|---|---|---|---|---|

| Target Model | Circular (CTD) | Ellipse (ETD) | Subpath (STD) | ||

| Diameter | 2.00 ± 0.05 | 1.92 ± 0.08 | 2.08 ± 0.04 | 2.03 ± 0.03 | mm |

| Rib Thickness | 0.18 ± 0.02 | 0.183 ± 0.02 | 0.132 ± 0.008 | 0.182 ± 0.008 | |

| Wall Thickness | 0.16 ± 0.02 | 0.155 ± 0.025 | 0.173 ± 0.005 | 0.161 ± 0.005 | |

| Ovality | ≤3 | 12.6 ± 1.1 | 2.1 ±0.5 | 1.5 ± 0.4 | % |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.C.; Jeong, J.; Jo, S.; Choi, D.Y.; Kim, G.M.; Kim, W. Development of a Subpath Extrusion Tip and Die for Peripheral Inserted Central Catheter Shaft with Multi Lumen. Polymers 2021, 13, 1308. https://doi.org/10.3390/polym13081308

Lee HC, Jeong J, Jo S, Choi DY, Kim GM, Kim W. Development of a Subpath Extrusion Tip and Die for Peripheral Inserted Central Catheter Shaft with Multi Lumen. Polymers. 2021; 13(8):1308. https://doi.org/10.3390/polym13081308

Chicago/Turabian StyleLee, Han Chang, Jinhyuk Jeong, Seunggi Jo, Dong Yun Choi, Gyu Man Kim, and Woojin Kim. 2021. "Development of a Subpath Extrusion Tip and Die for Peripheral Inserted Central Catheter Shaft with Multi Lumen" Polymers 13, no. 8: 1308. https://doi.org/10.3390/polym13081308

APA StyleLee, H. C., Jeong, J., Jo, S., Choi, D. Y., Kim, G. M., & Kim, W. (2021). Development of a Subpath Extrusion Tip and Die for Peripheral Inserted Central Catheter Shaft with Multi Lumen. Polymers, 13(8), 1308. https://doi.org/10.3390/polym13081308