The Effect of DBD Plasma Activation Time on the Dyeability of Woven Polyester Fabric with Disperse Dye

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

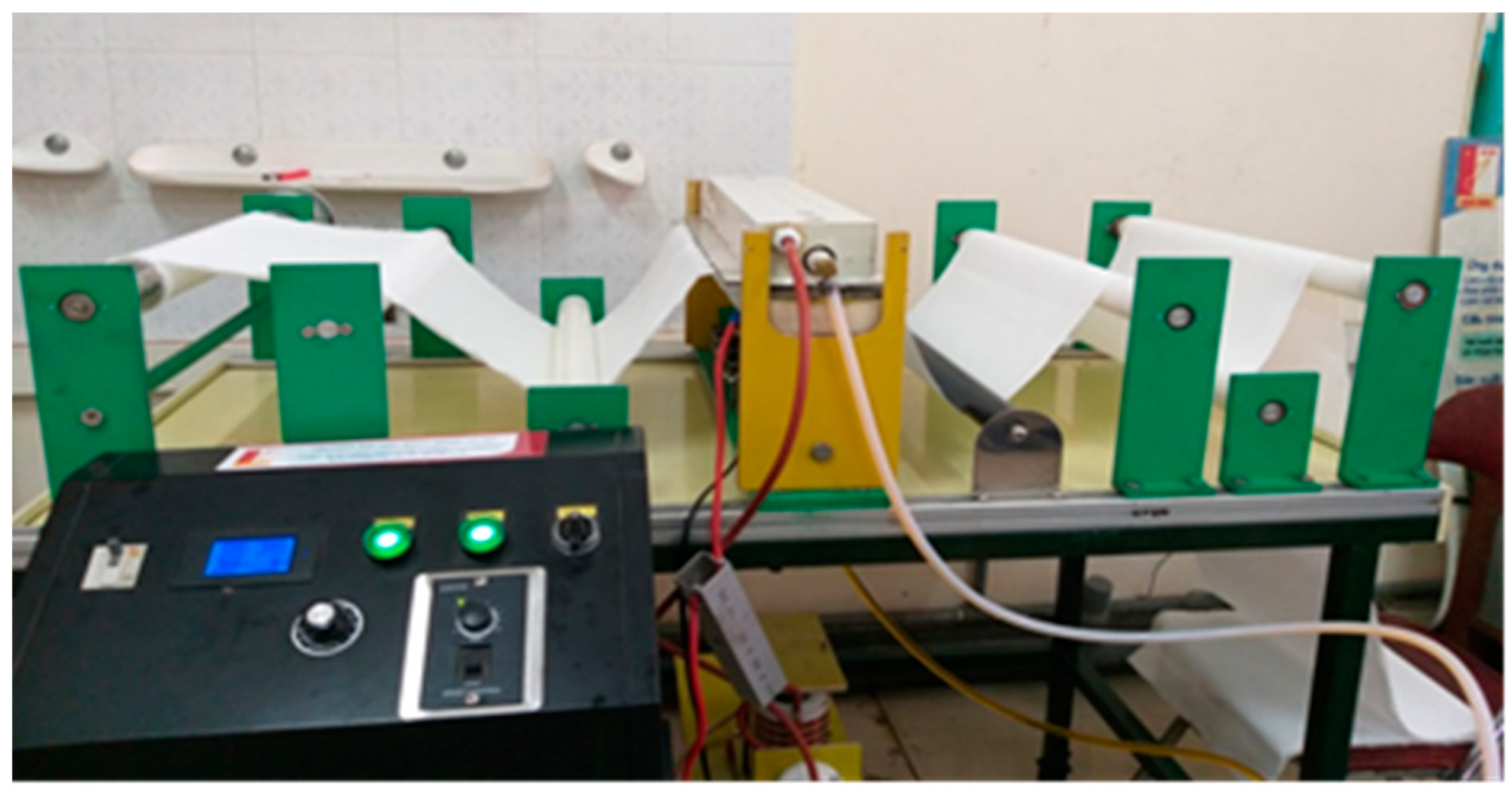

2.2.1. Plasma Treatment Process for Polyester Fabric

2.2.2. Characterization of the Control and Plasma-Treated Polyester Fabric

- Capillary measurement

- Tensile strength test

- Scanning Electron Microscope (SEM) images

- X-ray Photoelectron Spectroscopy (XPS) measurement

2.2.3. Dyeing Procedure for the Untreated and Plasma-Treated Polyester Fabric

2.2.4. Rinsing the Dyed Samples with Acetone

2.2.5. Color Measurement

- Color strength (K/S) measurement

- K absorption coefficient;

- S scattering coefficient;

- R reflection factor.

- Color intensities of the samples

- Observation of the dyed fiber surface

3. Results

3.1. Results of Characterization of the Control and Plasma-Treated Polyester Fabric

3.1.1. The Effect of Plasma Exposure Time on the Tensile Strength of the Woven Polyester Fabric

3.1.2. Effect of Plasma Treatment on the Water Capillary of Fabric

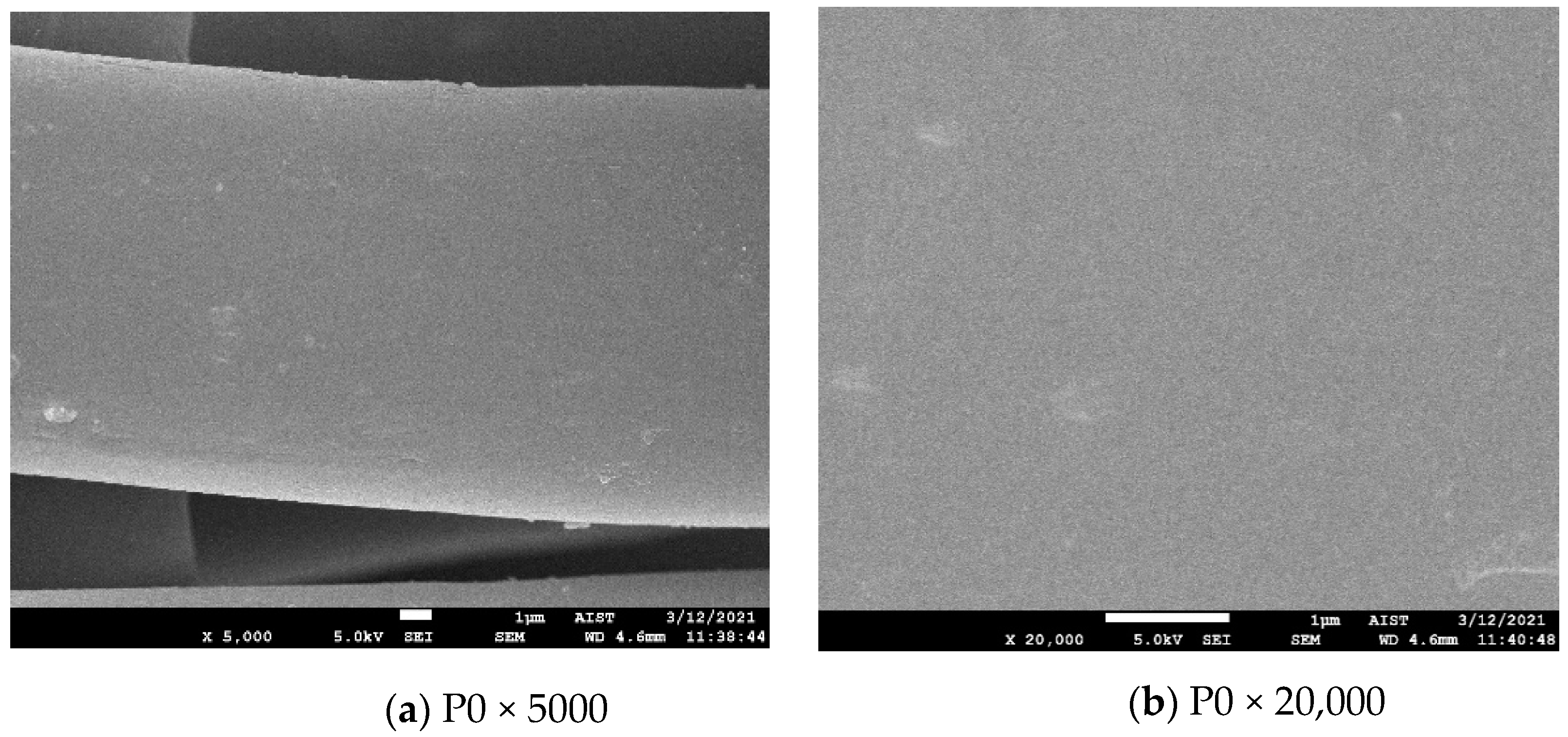

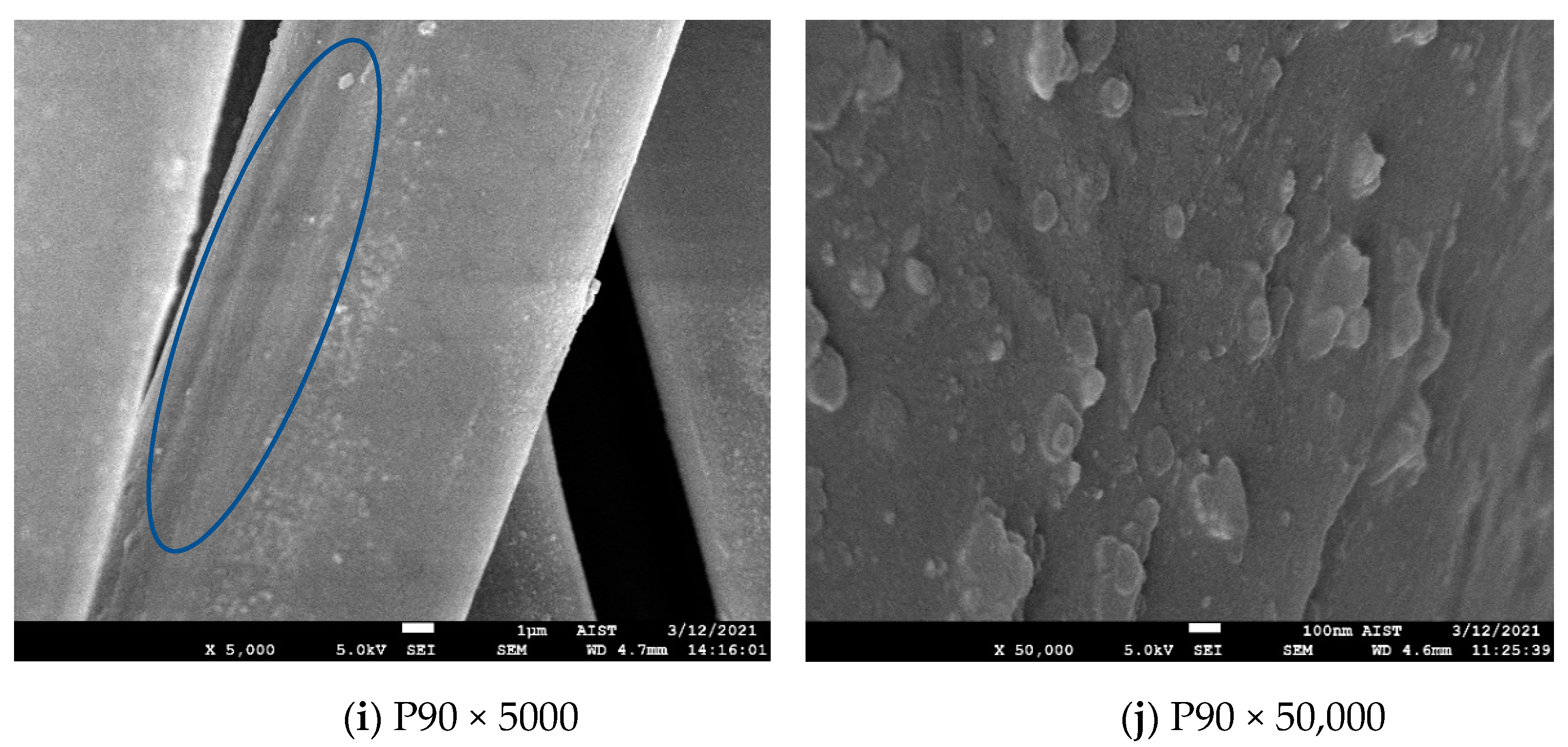

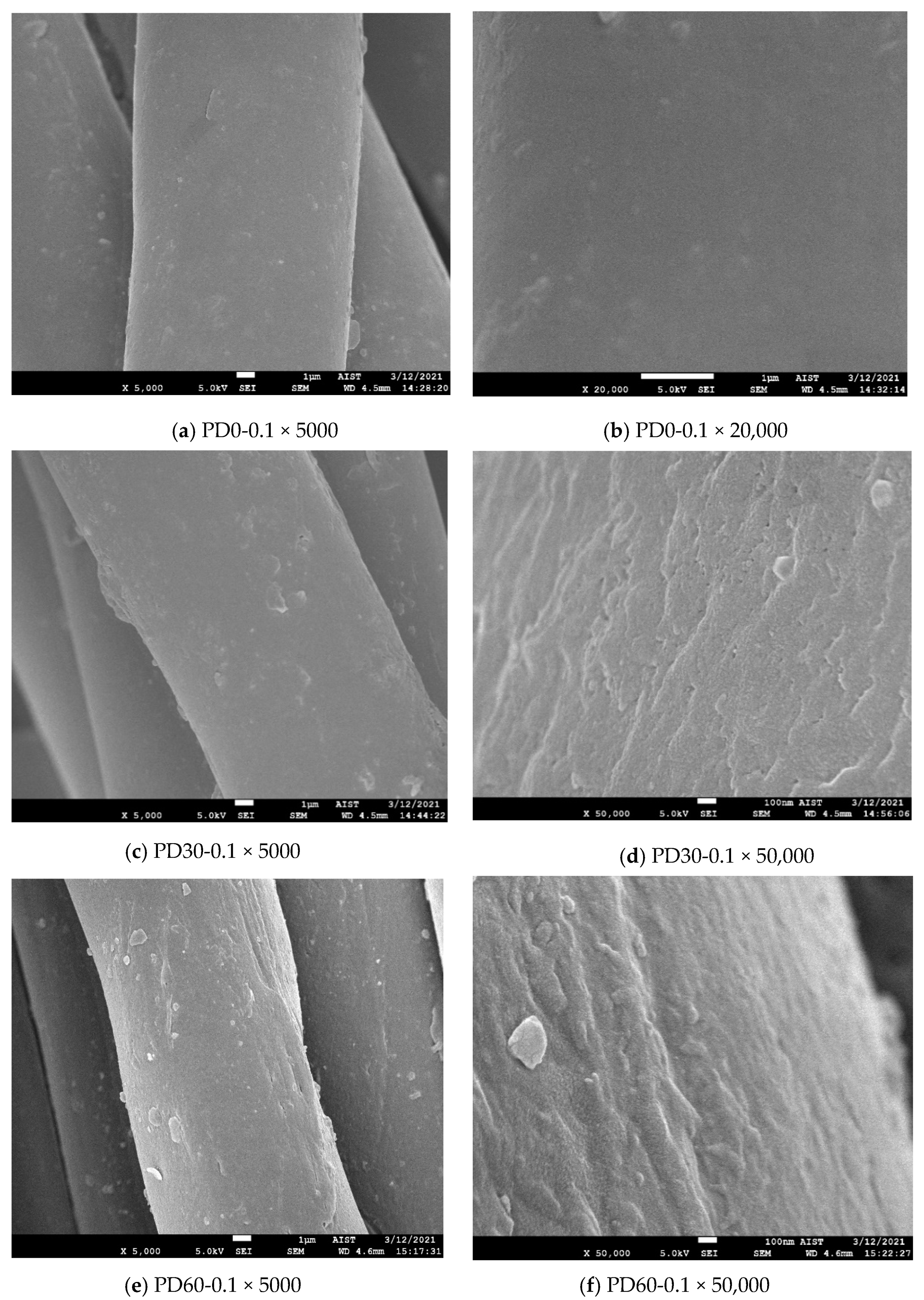

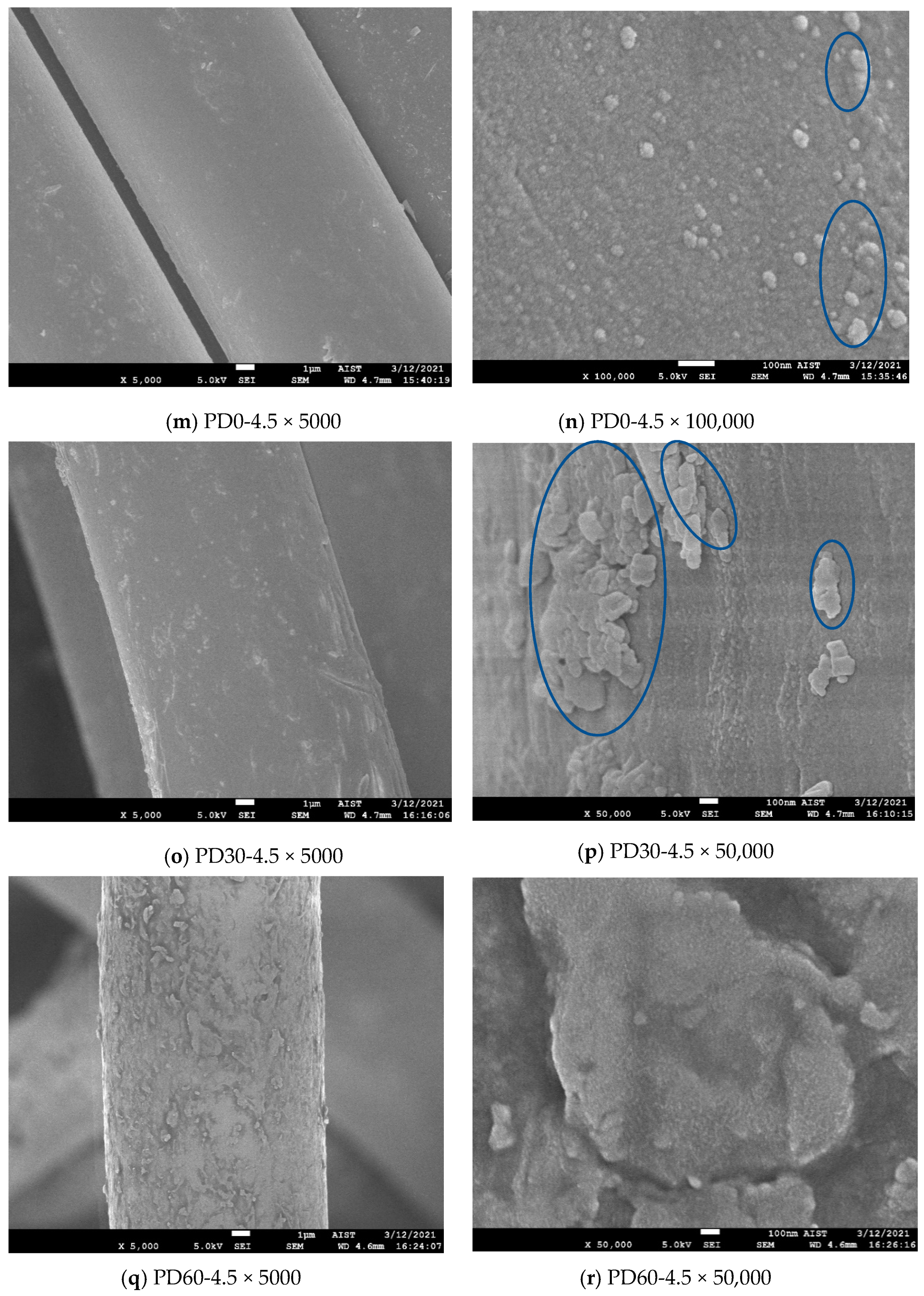

3.1.3. Effect of Plasma Treatment Time on the Surface of Polyester Fiber

3.1.4. Analysis of X-ray Photoelectron Spectrum (XPS) of the Untreated and Plasma-Treated Samples

3.2. Effect of Plasma on the Dyeability of the Polyester Fabric

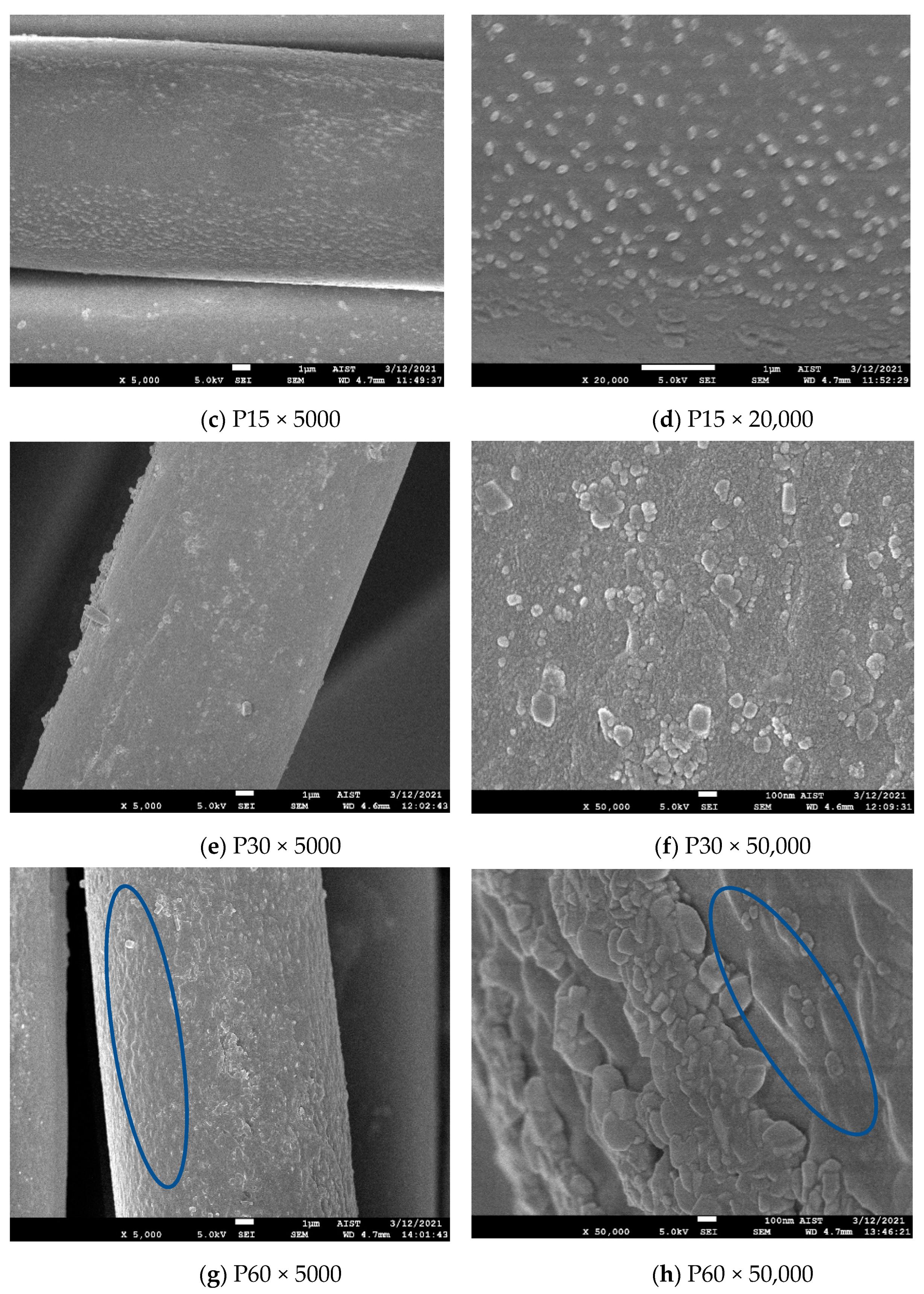

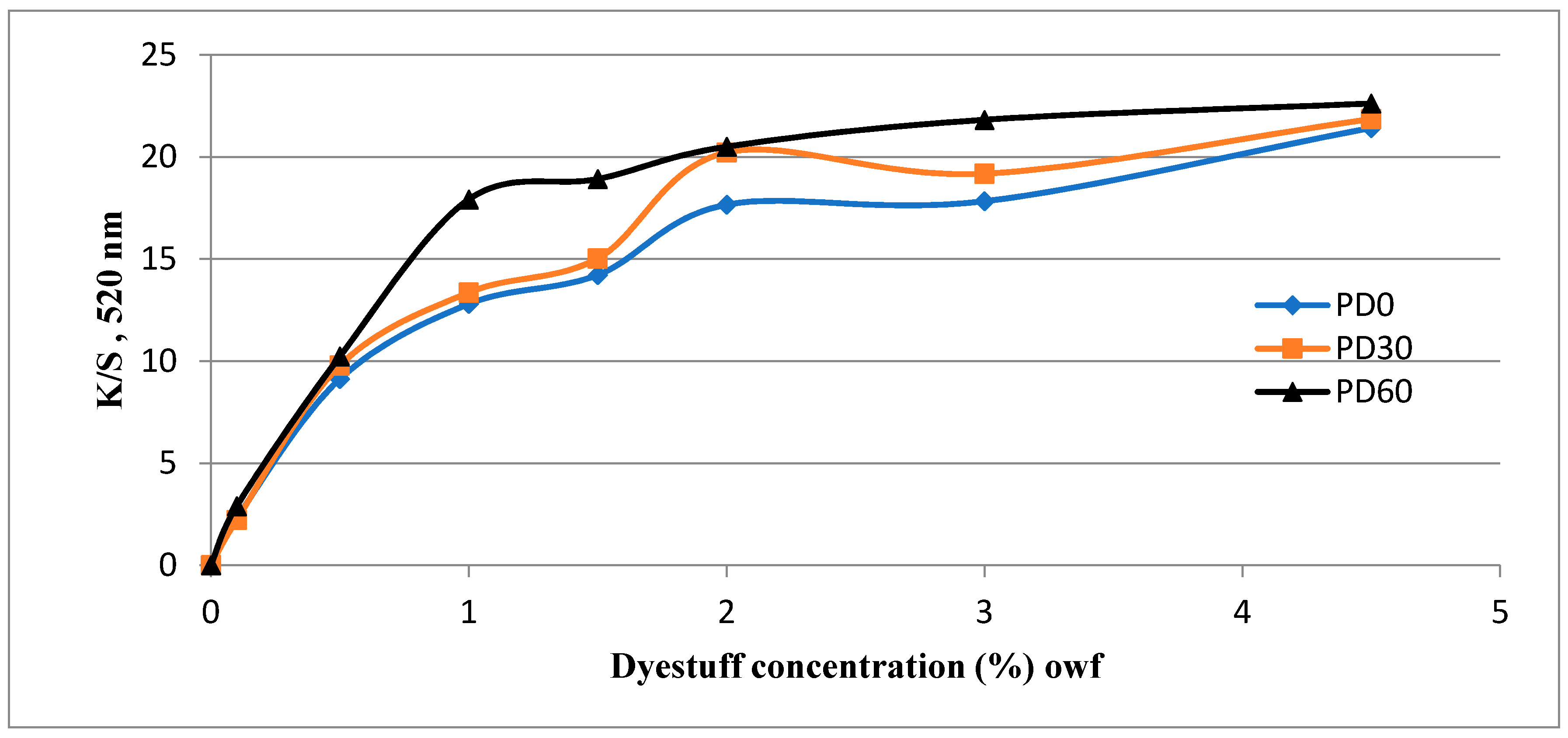

3.2.1. Effect of Plasma Treatment Time on the Color Strength (K/S) Spectra of the Dyed Polyester Fabric

3.2.2. Effect of Plasma Treatment Time on the Color Strength (K/S) of the Dyed Polyester Fabric/Rinsed with Acetone

3.2.3. Color intensities of the dyed and acetone-rinsed samples

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hatch, K.L. Textile Science; West Publishing Company: Eagan, MN, USA, 1993. [Google Scholar]

- Textile Exchange. Preferred Fiber & Materials: Market Report. 2019. Available online: https://textileexchange.org/wp-content/uploads/2020/06/Textile-Exchange_Preferred-Fiber-Material-Market-Report_2020.pdf (accessed on 1 January 2019).

- Kumar, J.A.; Kumar, M.S. A Study on Improving Dyeability of Polyester Fabric Using Lipase Enzyme. AUTEX Res. J. 2019, 20, 243–249. [Google Scholar] [CrossRef]

- Dave, H.; Ledwani, L.; Chandwani, N.; Desai, B.; Nema, S.K. Surface activation of polyester fabric using ammonia dielectric barrier discharge and improvement in colour depth. Indian J. Fiber Text. Res. 2014, 39, 274–281. [Google Scholar]

- Mashaly, H.M.; Abdelghaffar, R.A.; Kamel, M.M.; Youssef, B.M. Dyeing of polyester fabric using nano disperse dyes and improving their light fastness using ZnO nano powder. Indian J. Sci. Technol. 2014, 7, 960–967. [Google Scholar] [CrossRef]

- Do Carmo, R.S.A.; De Arauz, L.J.; Rosa, J.M.; Ramos, J.B.; Araujo, M.D.C. Dyeability of polyester and polyamide fabrics employing citric acid. J. Text. Sci. Technol. 2017, 13, 31–44. [Google Scholar] [CrossRef] [Green Version]

- Najafzadeh, N.; Habibi, S.; Ghasri, M.A. Dyeing of polyester with reactive dyestuffs using nano-chitosan. J. Eng. Fibers Fabr. 2018, 13, 47–51. [Google Scholar] [CrossRef] [Green Version]

- Shahidi, S.; Wiener, J.; Ghoranneviss, M. Surface modification methods for improving the dyeability of textile fabrics. In Eco-Friendly Textile Dyeing and Finishing; Gunay, M., Ed.; InTech: Rijeka, Croatia, 2013; pp. 34–50. [Google Scholar]

- Bendak, A.; El-Marsafi, S.M. Effects of chemical modifications on polyester fibres. J. Islamic Acad. Sci. 1991, 4, 275–284. [Google Scholar]

- Dumecha, B.; Nalankilli, G. Anionic dyeability of polyester fabric by chemical surfave modification. Int. J. Mod. Trends Eng. Sci. 2017, 4, 3–14. [Google Scholar]

- Akiwowo, K.; Kane, F.; Tyrer, J.; Weaver, G.; Filarowski, A. Digital laser-dyeing for polyester fabrics. J. Text. Des. Res. Pract. 2014, 2, 133–151. [Google Scholar] [CrossRef] [Green Version]

- Zille, A. Plasma technology in fashion and textiles. In Sustainable Technologies for Fashion and Textiles; Nayak, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 117–142. [Google Scholar]

- Huong, N.T.; Khanh, V.T.H.; Thanh, N.H.; Nam, P.D. Application of Plasma Activation in Flame-Retardant Treatment for Cotton Fabric. Polymers 2020, 12, 1575. [Google Scholar]

- Sun, D. Surface modification of natural fibers using plasma treatment. In Biodegradable Green Composites; Kalia, S., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 18–39. [Google Scholar]

- Lv, J.; Zhou, Q.; Zhi, T.; Gao, D.; Wang, C. Environmentally friendly surface modification of polyethylene terephthalate (PET) fabric by low-temperature oxygen plasma and carboxymethyl chitosan. J. Clean. Prod. 2016, 118, 187–196. [Google Scholar] [CrossRef]

- Kamel, M.M.; El Zawahry, M.M.; Helmy, H.; Eid, M.A. Improvements in the dyeability of polyester fabrics by atmospheric pressure oxygen plasma treatment. J. Text. Inst. 2011, 102, 220–231. [Google Scholar] [CrossRef]

- Shahidi, S.; Ghoranneviss, M.; Wiener, J. Improving synthetic and natural dyeability of polyester fabrics by dielectric barrier discharge. J. Plast. Film Sheeting 2015, 31, 286–308. [Google Scholar] [CrossRef]

- Kerkeni, A.; Behary, N.; Perwuelz, A.; Gupta, D. Dyeing of woven polyester fabric with curcumin: Effect of dye concentrations and surface pre-activation using air atmospheric plasma and ultraviolet excimer treatment. Coloration Technol. 2012, 128, 223–229. [Google Scholar] [CrossRef]

- Hebeish, A.; Elmaaty, T.A.; Ramadan, M.; Magdy, H. Microwave and plasma treatments for functionalization of polyester fabrics. Int. J. Curr. Microbiol. Appl. Sci. 2015, 4, 703–715. [Google Scholar]

- Raslan, W.M.; Rashed, U.S.; El-Sayad, H.; El-Halwagy, A. Ultraviolet protection, flame retardancy and antibacterial properties of treated polyester fabric using plasma-nano technology. Mater. Sci. Appl. 2011, 2, 1432. [Google Scholar] [CrossRef] [Green Version]

- Gotoh, K.; Yasukawa, A. Atmospheric pressure plasma modification of polyester fabric for improvement of textile-specific properties. Text. Res. J. 2010, 81, 368–378. [Google Scholar] [CrossRef]

- Lima da Silva, R.C.; Alves, C.; Nascimento, J.H.; Neves, J.R.O.; Teixeira, V. Surface Modification of Polyester Fabric by Non-Thermal Plasma Treatment. J. Phys. Conf. Ser. 2012, 406, 012017. [Google Scholar] [CrossRef]

- Ghranjig, K.; Sadeghi-Kiakhani, M.; Tehrani-Bgha, A.R.; Khosravi, A.; Menger, F.M. Solubility of Two Disperse Dyes Derived from N-Alkyl and N-Carboxylic Acid Naphthalimides in the Presence of Gemini Cationic Surfactants. J. Surfact. Deterg. 2011, 14, 381–389. [Google Scholar] [CrossRef]

- Warken, F.; Vetsch, E.; Meschede, D.; Sokolowski, M.; Rauschenbeutel, A. Ultra-sensitive surface absorption spectroscopy using sub-wavelength diameter optical fibers. Opt. Express 2007, 15, 11952–11958. [Google Scholar] [CrossRef] [Green Version]

- Kale, K.H.; Desai, A.N. Atmospheric pressure plasma treatment of textiles using non-polymerising gases. Indian J. Fibre Text. Res. 2011, 36, 289–299. [Google Scholar]

| Plasma Exposure Time (s) | In Warp Direction | In Weft Direction | ||

|---|---|---|---|---|

| PMAX (N) | Difference of PMAX (%) | PMAX (N) | Difference of PMAX (%) | |

| 0 | 1642 ± 11 | - | 1059 ± 31 | - |

| 15 | 1648 ± 33 | +0.4 | 1083 ± 31 | +2.3 |

| 30 | 1649 ± 20 | +0.4 | 1102 ± 27 | +4.1 |

| 45 | 1650 ± 25 | +0.5 | 1123 ± 23 | +6.0 |

| 60 | 1651 ± 41 | +0.5 | 1137 ± 27 | +7.4 |

| 75 | 1653 ± 16 | +0.7 | 1140 ± 28 | +7.6 |

| 90 | 1659 ± 11 | +1.0 | 1148 ± 28 | +8.4 |

| Plasma Exposure Time (s) | Wicking Height of Samples in Warp Direction (cm) Measured after | |||||

|---|---|---|---|---|---|---|

| 5 min | 10 min | 15 min | 20 min | 25 min | 30 min | |

| 0 | 6.3 ± 0.2 | 8.3 ± 0.1 | 9.4 ± 0.2 | 10.0 ± 0.2 | 10.5 ± 0.1 | 10.7 ± 0.2 |

| 15 | 6.6 ± 0.3 | 9.4 ± 0.2 | 10.8 ± 0.2 | 11.4 ± 0.2 | 12.0 ± 0.1 | 12.3 ± 0.1 |

| 30 | 7.0 ± 0.2 | 9.5 ± 0.4 | 10.6 ± 0.1 | 11.6 ± 0.4 | 12.2 ± 0.6 | 12.4 ± 0.5 |

| 45 | 7.4 ± 0.2 | 8.9 ± 0.3 | 10.9 ± 0.1 | 11.5 ± 0.3 | 12.2 ± 0.2 | 12.6 ± 0.3 |

| 60 | 7.7 ± 0.3 | 10.2 ± 0.4 | 11.3 ± 0.3 | 12.3 ± 0.3 | 12.8 ± 0.5 | 12.5 ± 0.8 |

| 75 | 7.5 ± 0.3 | 10.5 ± 0.4 | 11.4 ± 0.4 | 12.3 ± 0.6 | 12.6 ± 0.7 | 13.1 ± 0.7 |

| 90 | 7.5 ± 0.1 | 10.4 ± 0.1 | 11.5 ± 0.2 | 12.1 ± 0.3 | 12.6 ± 0.2 | 13.1 ± 0.2 |

| Plasma Exposure Time (s) | Wicking Height of Samples in Weft Direction (cm) Measured after | |||||

|---|---|---|---|---|---|---|

| 5 min | 10 min | 15 min | 20 min | 25 min | 30 min | |

| 0 | 5.9 ± 0.1 | 7.9 ± 0.1 | 9.1 ± 0.2 | 9.7 ± 0.2 | 10.4 ± 0.3 | 10.6 ± 0.2 |

| 15 | 5.8 ± 0.3 | 7.6 ± 0.3 | 8.2 ± 0.4 | 9.1 ± 0.2 | 9.6 ± 0.3 | 10.0 ± 0.4 |

| 30 | 5.9 ± 0.1 | 7.9 ± 0.1 | 9.1 ± 0.1 | 9.7 ± 0.2 | 10.4 ± 0.1 | 10.7 ± 0.2 |

| 45 | 6.1 ± 0.1 | 8.1 ± 0.1 | 9.2 ± 0.2 | 10.0 ± 0.2 | 10.4 ± 0.2 | 10.9 ± 0.3 |

| 60 | 6.7 ± 0.1 | 8.4 ± 0.2 | 9.4 ± 0.2 | 10.0 ± 0.2 | 10.4 ± 0.2 | 10.6 ± 0.1 |

| 75 | 6.0 ± 0.2 | 7.9 ± 0.2 | 8.9 ± 0.2 | 9.6 ± 0.2 | 10.1 ± 0.3 | 10.3 ± 0.3 |

| 90 | 5.7 ± 0.2 | 7.5 ± 0.1 | 8.5 ± 0.1 | 9.3 ± 0.2 | 9.7 ± 0.2 | 10.0 ± 0.2 |

| Plasma Exposure Time for the Samples (s) | Percentage of Functional Groups on the Surface of the Polyester Fibers (%) | |||

|---|---|---|---|---|

| C-C/C-H | C-O/C-OH | O-C-O/C=O | O=C-O | |

| 0 | 39.35 | 49.78 | - | 10.87 |

| 45 | 47.62 | 30.40 | 0.93 | 21.05 |

| 90 | 51.00 | 27.06 | 0.95 | 20.98 |

| Dye Concentration (%) | Type of Sample | |||||

|---|---|---|---|---|---|---|

| PD0 | PD0′ | PD30 | PD30′ | PD60 | PD60′ | |

| 0 | 0.01 ± 0.00 | 0.01 ± 0.00 | 0.01 ± 0.00 | 0.01 ± 0.00 | 0.01 ± 0.00 | 0.01 ± 0.00 |

| 0.1 | 2.38 ± 0.07 | 2.15 ± 0.11 | 2.21 ± 0.02 | 2.17 ± 0.04 | 3.16 ± 0.23 | 3.05 ± 0.01 |

| 0.5 | 9.36 ± 0.28 | 8.53 ± 0.06 | 10.07 ± 0.07 | 10.28 ± 0.23 | 10.49 ± 0.23 | 12.21 ± 1.72 |

| 1 | 12.56 ± 0.25 | 12.44 ± 0.28 | 13.84 ± 0.41 | 13.29 ± 0.29 | 18.00 ± 009 | 17.21 ± 0.23 |

| 1.5 | 13.23 ± 0.87 | 13.39 ± 0.56 | 15.07 ± 0.04 | 17.30 ± 1.51 | 18.93 ± 0.10 | 20.02 ± 0.86 |

| 2 | 17.78 ± 0.12 | 18.73 ± 0.53 | 20.15 ± 0.57 | 20.14 ± 0.42 | 20.61 ± 0.11 | 21.02 ± 0.33 |

| 3 | 18.47 ± 0.60 | 20.63 ± 1.34 | 19.25 ± 0.52 | 21.03 ± 0.60 | 22.06 ± 0.21 | 25.72 ± 1.25 |

| 4.5 | 21.69 ± 0.54 | 23.68 ± 0.54 | 22.15 ± 0.26 | 24.89 ± 0.40 | 22.64 ± 0.15 | 25.32 ± 0.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.N.T.; Vu Thi Hong, K.; Vu Thi, N.; Vu Manh, H. The Effect of DBD Plasma Activation Time on the Dyeability of Woven Polyester Fabric with Disperse Dye. Polymers 2021, 13, 1434. https://doi.org/10.3390/polym13091434

Kim TNT, Vu Thi Hong K, Vu Thi N, Vu Manh H. The Effect of DBD Plasma Activation Time on the Dyeability of Woven Polyester Fabric with Disperse Dye. Polymers. 2021; 13(9):1434. https://doi.org/10.3390/polym13091434

Chicago/Turabian StyleKim, Thu Nguyen Thi, Khanh Vu Thi Hong, Nguyen Vu Thi, and Hai Vu Manh. 2021. "The Effect of DBD Plasma Activation Time on the Dyeability of Woven Polyester Fabric with Disperse Dye" Polymers 13, no. 9: 1434. https://doi.org/10.3390/polym13091434