Fabrication and Thermo-Electro and Mechanical Properties Evaluation of Helical Multiwall Carbon Nanotube-Carbon Fiber/Epoxy Composite Laminates

Abstract

:1. Introduction

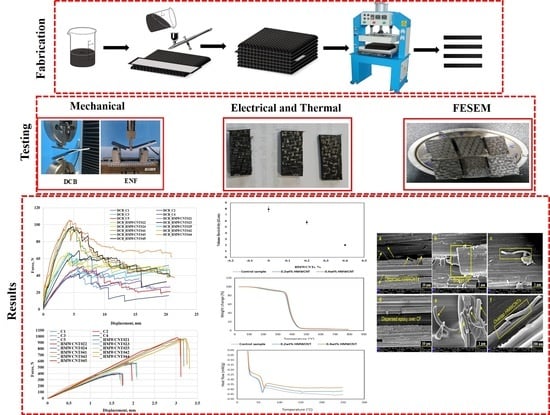

2. Materials and Methods

2.1. Materials

2.2. Dispersion of Epoxy and HMWCNTs

2.3. Preparation of HMWCNTs Composite Laminates

2.4. Fracture Tests

2.4.1. Double Cantilever Beam (DCB) Test

2.4.2. End Notched Flexure (ENF) Test

2.5. Field Emission Scanning Electron Microscopy (FESEM)

2.6. Thermogravimetric Analysis (TGA)

2.7. Differential Scanning Calorimetry (DSC)

2.8. Electrical Conductivity

3. Results and Discussion

3.1. Mode I Interlaminar Fracture Toughness

3.2. Mode II Interlaminar Fracture Toughness

3.3. Fractographic Analysis

3.4. Thermogravimetric Analysis (TGA)

3.5. Differential Scanning Calorimetry (DSC)

3.6. Electrical Conductivity

4. Conclusions

- i.

- Mode I fracture interlaminar toughness analysis by DCB showed a 39.15% improvement in fracture toughness for the 0.2 wt.% HMWCNT loading composite sample, while the higher loading of the 0.4 wt.% HMWCNT filler composite sample registered a remarkable increase in the fracture toughness by 115.05%. Mode II interlaminar fracture toughness analysis by ENF showed a 50.88% and 190% increase in the 0.2 wt.% and 0.4 wt.% HMWCNT composite laminates, respectively.

- ii.

- The delamination in the control sample occurred because of the tensile crack in the matrix related to the carbon fiber bridging that resisted the growth of delamination at the crack tip. In the case of the HMWCNTs, the same mechanism was observed, but at the same time, another mechanism was noted with additional energy consumption, and the HMWCNTs also bridged the crack tip interface and resulted in improved crack propagation resistance.

- iii.

- The FESEM analysis further confirmed the HMWCNT bridging and pull-out at the fracture zones of the CF/E, confirming the improved interlaminar fracture toughness. The TGA analysis showed that 0.4 wt.% HMWCNT laminates degraded 3 °C later than the 0.2 wt.% HMWCNT, generating a good bond between the epoxy and HMWCNT that could delay the diffusion of small molecules from the resin matrix at a high temperature, and therefore result in enhanced thermal stability.

- iv.

- The DSC analysis show that the addition of HMWCNTs shifted the Tg to higher temperatures. The thermal analysis showed that by increasing the wt.% of the HMWNCTs, the thermal stability of the sample was further improved. The volume resistivity of the 0.4 wt.% HMWCNT showed the lowest resistivity among all the laminates because of the increase in the amount of conductive HMWCNTs in the insulating matrix.

- v.

- Thus, this work presents an all-inclusive mode I and II inter- and intra-laminar fracture toughness, TGA and DSC analyses, and electrical conductivity on HMWCNTs-CF/E composite laminates, registering significant improvements in the respective properties. This is lacking in the existing works and, as such, the above experimental findings provide concrete evidence that the created interfacial intermolecular interaction between the epoxy and HMWCNT was strengthened by the dispersion technique that improved the fracture toughness. This has not only contributed immensely to the body of knowledge, but also constitutes a novel outcome that forms the basis for further research in this area.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Soutis, C. Carbon fiber reinforced plastics in aircraft construction. Mater. Sci. Eng. A 2005, 412, 171–176. [Google Scholar] [CrossRef]

- Rezaei, F.; Yunus, R.; Ibrahim, N.A.; Mahdi, E.S. Development of Short-Carbon-Fiber-Reinforced Polypropylene Composite for Car Bonnet. Polym. Technol. Eng. 2008, 47, 351–357. [Google Scholar] [CrossRef]

- Huang, Y.J.; Wang, C.H.; Huang, Y.L.; Guo, G.; Nutt, S.R. Enhancing specific strength and stiffness of phenolic microsphere syntactic foams through carbon fiber reinforcement. Polym. Compos. 2010, 31, 256–262. [Google Scholar] [CrossRef]

- Irina, M.; Azmi, A.; Tan, C.; Lee, C.; Khalil, A. Evaluation of Mechanical Properties of Hybrid Fiber Reinforced Polymer Composites and their Architecture. Procedia Manuf. 2015, 2, 236–240. [Google Scholar] [CrossRef] [Green Version]

- Tehrani, M.; Boroujeni, A.; Hartman, T.; Haugh, T.; Case, S.; Al-Haik, M. Mechanical characterization and impact damage assessment of a woven carbon fiber reinforced carbon nanotube–epoxy composite. Compos. Sci. Technol. 2013, 75, 42–48. [Google Scholar] [CrossRef]

- Boroujeni, A.; Tehrani, M.; Nelson, A.; Al-Haik, M. Hybrid carbon nanotube–carbon fiber composites with improved in-plane mechanical properties. Compos. Part B Eng. 2014, 66, 475–483. [Google Scholar] [CrossRef]

- Borowski, E.; Soliman, E.; Kandil, U.F.; Taha, M.R. Interlaminar Fracture Toughness of CFRP Laminates Incorporating Multi-Walled Carbon Nanotubes. Polymers 2015, 7, 1020–1045. [Google Scholar] [CrossRef] [Green Version]

- Elchalakani, M. CFRP strengthening and rehabilitation of degraded steel welded RHS beams under combined bending and bearing. Thin-Walled Struct. 2014, 77, 86–108. [Google Scholar] [CrossRef]

- Liu, L.; Jia, C.; He, J.; Zhao, F.; Fan, D.; Xing, L.; Wang, M.; Wang, F.; Jiang, Z.; Huang, Y. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites. Compos. Sci. Technol. 2015, 121, 56–72. [Google Scholar] [CrossRef]

- Zhandarov, S.; Mäder, E. Characterization of fiber/matrix interface strength: Applicability of different tests, approaches and parameters. Compos. Sci. Technol. 2005, 65, 149–160. [Google Scholar] [CrossRef]

- Koloor, S.; Abdullah, M.; Tamin, M.; Ayatollahi, M. Fatigue damage of cohesive interfaces in fiber-reinforced polymer composite laminates. Compos. Sci. Technol. 2019, 183, 107779. [Google Scholar] [CrossRef]

- Köllner, A. Predicting buckling-driven delamination propagation in composite laminates: An analytical modelling ap-proach. Compos. Struct. 2021, 266, 113776. [Google Scholar] [CrossRef]

- Lopes, C.S.; Sádaba, S.; Gonz’alez, C.; Llorca, J.; Camanho, P.P. Physically-sound simulation of low-velocity impact on fiber rein-forced laminates. Int. J. Impact Eng. 2016, 92, 3–17. [Google Scholar] [CrossRef] [Green Version]

- Zhao, L.; Gong, Y.; Zhang, J.; Wang, Y.; Lu, Z.; Peng, L.; Hu, N. A novel interpretation of fatigue delamination growth behavior in CFRP multidirectional laminates. Compos. Sci. Technol. 2016, 133, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Hojo, M.; Tanaka, K.; Gustafson, C.G.; Hayashi, R. Effect of stress ratio on near threshold propagation of delamination fatigue cracks in unidirectional CFRP. Compos. Sci. Technol. 1987, 29, 273–292. [Google Scholar] [CrossRef]

- Bruyneel, M. Optimization of laminated composite structures: Problems, solution procedures and applications. In Composite Materials Research Progess; NOVA Science Publishers: Angleur, Belgium, 2008. [Google Scholar]

- Haruna, V.N.; Abdulrahman, A.S.; Zubairu, P.T.; Isezuo, L.O.; Abdulrahman, M.A.; Onuoha, D.C. Prospects and challenges of compo-sites in a developing country. ARPN J. Eng. Appl. Sci. 2014, 9, 1069–1075. [Google Scholar]

- Rodríguez-González, J.; Rubio-González, C. Influence of sprayed multi-walled carbon nanotubes on mode I and mode II interlaminar fracture toughness of carbon fiber/epoxy composites. Adv. Compos. Mater. 2018, 28, 1–18. [Google Scholar] [CrossRef]

- Patra, A.K.; Mitra, N. Mixed-mode fracture of sandwich composites: Performance improvement with multiwalled carbon nanotube sonicated resin. J. Sandw. Struct. Mater. 2018, 20, 379–395. [Google Scholar] [CrossRef]

- Seyhan, A.T.; Tanoglu, M.; Schulte, K. Mode I and mode II fracture toughness of E-glass non-crimp fabric/carbon nanotube (CNT) modified polymer based composites. Eng. Fract. Mech. 2008, 75, 5151–5162. [Google Scholar] [CrossRef] [Green Version]

- Tamuzs, V.; Tarasovs, S.; Vilks, U. Delamination properties of translaminar-reinforced composites. Compos. Sci. Technol. 2003, 63, 1423–1431. [Google Scholar] [CrossRef]

- Turon, A.; Dávila, C.G.; Camanho, P.P.; Costa, J. An Engineering Solution for Using Coarse Meshes in the Simulation of De-Lamination with Cohesive Zone Models; NASA: Washington, DC, USA, 2005.

- Campilho, R.D.; Banea, M.D.; Neto, J.; da Silva, L.F. Modelling adhesive joints with cohesive zone models: Effect of the cohe-sive law shape of the adhesive layer. Int. J. Adhes. Adhes. 2013, 44, 48–56. [Google Scholar] [CrossRef] [Green Version]

- Swindeman, M.J. A Regularized Extended Finite Element Method for Modeling the Coupled Cracking and Delamination of Composite Materials. Ph.D. Thesis, University of Dayton, Dayton, OH, USA, 2011. [Google Scholar]

- Orifici, A.; Herszberg, I.; Thomson, R. Review of methodologies for composite material modelling incorporating failure. Compos. Struct. 2008, 86, 194–210. [Google Scholar] [CrossRef]

- Fu, T.; Zhao, J.-L.; Xu, K.-W. The designable elastic modulus of 3-D fabric reinforced biocomposites. Mater. Lett. 2007, 61, 330–333. [Google Scholar] [CrossRef]

- Brandt, J.; Drechsler, K.; Mohamed, M.; Gu, P. Manufacture and performance of carbon/epoxy 3-D woven composites. In Proceedings of the 37th Ininternational SAMPE Symposium and Exhibition, Anaheim, CA, USA, 1 January 1992. [Google Scholar]

- Beier, U.; Fischer, F.; Sandler, J.K.; Altstädt, V.; Weimer, C.; Buchs, W. Mechanical performance of carbon fibre-reinforced composites based on stitched preforms. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1655–1663. [Google Scholar] [CrossRef]

- Jain, L.K.; Dransfield, K.A.; Mai, Y.-W. Effect of Reinforcing Tabs on the Mode I Delamination Toughness of Stitched CFRPs. J. Compos. Mater. 1998, 32, 2016–2041. [Google Scholar] [CrossRef]

- Mouritz, A.P. Compression properties of z-pinned sandwich composites. J. Mater. Sci. 2006, 41, 5771–5774. [Google Scholar] [CrossRef]

- Mouritz, A.; Cox, B. A mechanistic interpretation of the comparative in-plane mechanical properties of 3D woven, stitched and pinned composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 709–728. [Google Scholar] [CrossRef] [Green Version]

- Sager, R.J.; Klein, P.J.; Davis, D.C.; Lagoudas, D.C.; Warren, G.L.; Sue, H.-J. Interlaminar fracture toughness of woven fabric composite laminates with carbon nanotube/epoxy interleaf films. J. Appl. Polym. Sci. 2011, 121, 2394–2405. [Google Scholar] [CrossRef]

- Arca, M.; Coker, D. Experimental investigation of CNT effect on curved beam strength and interlaminar fracture toughness of CFRP laminates. J. Phys. Conf. Ser. 2014, 524, 012038. [Google Scholar] [CrossRef] [Green Version]

- Böger, L.; Sumfleth, J.; Hedemann, H.; Schulte, K. Improvement of fatigue life by incorporation of nanoparticles in glass fibre reinforced epoxy. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1419–1424. [Google Scholar] [CrossRef]

- Zhou, Y.; Jeelani, S.; Lacy, T. Experimental study on the mechanical behavior of carbon/epoxy composites with a carbon nano-fiber-modified matrix. J. Compos. Mater. 2014, 48, 3659–3672. [Google Scholar] [CrossRef]

- Salimi, N.M.; Merajin, T.M.; Givi, B.M.K. Enhanced mechanical properties of multifunctional multiscale glass/carbon/epoxy composite reinforced with carbon nanotubes and simultaneous carbon nanotubes/nanoclays. J. Compos. Mater. 2017, 51, 745–758. [Google Scholar] [CrossRef]

- Karapappas, P.; Vavouliotis, A.; Tsotra, P.; Kostopoulos, V.; Paipetis, A. Enhanced fracture properties of carbon reinforced com-posites by the addition of multi-wall carbon nanotubes. J. Compos. Mater. 2009, 43, 977–985. [Google Scholar] [CrossRef]

- Cha, J.; Kim, J.H.; Ryu, S.W.; Hong, S.H. Comparison to mechanical properties of epoxy nanocomposites reinforced by function-alized carbon nanotubes and graphene nanoplatelets. Compos. B Eng. 2019, 162, 283–288. [Google Scholar] [CrossRef]

- Takakura, A.; Beppu, K.; Nishihara, T.; Fukui, A.; Kozeki, T.; Namazu, T.; Miyauchi, Y.; Itami, K. Strength of carbon nanotubes de-pends on their chemical structures. Nat. Commun. 2019, 10, 1–7. [Google Scholar] [CrossRef]

- Liebscher, M.; Domurath, J.; Krause, B.; Saphiannikova, M.; Heinrich, G.; Pötschke, P. Electrical and melt rheological characteriza-tion of PC and co-continuous PC/SAN blends filled with CNTs: Relationship between melt-mixing parameters, filler dis-persion, and filler aspect ratio. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Cruz, H.; Son, Y. Effect of Aspect Ratio on Electrical, Rheological and Glass Transition Properties of PC/MWCNT Nanocomposites. J. Nanosci. Nanotechnol. 2018, 18, 943–950. [Google Scholar] [CrossRef] [PubMed]

- Caradonna, A.; Badini, C.; Padovano, E.; Pietroluongo, M. Electrical and Thermal Conductivity of Epoxy-Carbon Filler Composites Processed by Calendaring. Materials 2019, 12, 1522. [Google Scholar] [CrossRef] [Green Version]

- Siochi, E.J.; Harrison, J.S. Structural nanocomposites for aerospace applications. MRS Bull. 2015, 40, 829–835. [Google Scholar] [CrossRef] [Green Version]

- Sezer, H.K.; Eren, O. FDM 3D printing of MWCNT reinforced ABS nano-composite parts with enhanced mechanical and elec-trical properties. J. Manuf. Processes 2019, 37, 339–347. [Google Scholar] [CrossRef]

- Mazov, I.; Burmistrov, I.; Il’Inykh, I.; Stepashkin, A.; Kuznetsov, D.; Issi, J.-P. Anisotropic thermal conductivity of polypropylene composites filled with carbon fibers and multiwall carbon nanotubes. Polym. Compos. 2014, 36, 1951–1957. [Google Scholar] [CrossRef]

- De Villoria, R.G.; Miravete, A.; Cuartero, J.; Chiminelli, A.; Tolosana, N. Mechanical properties of SWNT/epoxy composites using two different curing cycles. Compos. B Eng. 2006, 37, 273–277. [Google Scholar] [CrossRef]

- Mani, A.R.; Lau, H.C.; Ramakrishna, S. CNT-reinforced metal and steel nanocomposites: A comprehensive assessment of progress and future directions. Compos. Part A Appl. Sci. Manuf. 2018, 114, 170–187. [Google Scholar]

- Sager, R.; Klein, P.; Lagoudas, D.; Zhang, Q.; Liu, J.; Dai, L.; Baur, J. Effect of carbon nanotubes on the interfacial shear strength of T650 carbon fiber in an epoxy matrix. Compos. Sci. Technol. 2009, 69, 898–904. [Google Scholar] [CrossRef]

- Zu, M.; Li, Q.; Zhu, Y.; Dey, M.; Wang, G.; Lu, W.; Deitzel, J.M.; Gillespie, J.W.; Byun, J.-H.; Chou, T.-W. The effective interfacial shear strength of carbon nanotube fibers in an epoxy matrix characterized by a microdroplet test. Carbon 2012, 50, 1271–1279. [Google Scholar] [CrossRef]

- Ismail, K.; Sultan, M.; Shah, A.; Jawaid, M.; Safri, S. Low velocity impact and compression after impact properties of hybrid bio-composites modified with multi-walled carbon nanotubes. Compos. Part B Eng. 2019, 163, 455–463. [Google Scholar] [CrossRef]

- Erdogan, G.; Bilisik, K. Compression after low-velocity impact (CAI) properties of multistitched composites. Mech. Adv. Mater. Struct. 2018, 25, 1–14. [Google Scholar] [CrossRef]

- Wicks, S.S.; de Villoria, R.G.; Wardle, B.L. Interlaminar and intralaminar reinforcement of composite laminates with aligned carbon nanotubes. Compos. Sci. Technol. 2010, 70, 20–28. [Google Scholar] [CrossRef]

- Almuhammadi, K.; Alfano, M.; Yang, Y.; Lubineau, G. Analysis of interlaminar fracture toughness and damage mechanisms in composite laminates reinforced with sprayed multi-walled carbon nanotubes. Mater. Des. 2014, 53, 921–927. [Google Scholar] [CrossRef]

- Al Sheheri, S.Z.; Al-Amshany, Z.M.; Al Sulami, Q.A.; Tashkandi, N.Y.; Hussein, M.A.; El-Shishtawy, R.M. The preparation of carbon nanofillers and their role on the performance of variable polymer nanocomposites. Des. Monomers Polym. 2019, 22, 8–53. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Oliveira, A.D.; Beatrice, C.A.G. Polymer nanocomposites with different types of nanofiller. Nanocompos. Recent Evol. 2018. [Google Scholar] [CrossRef] [Green Version]

- Papageorgiou, D.G.; Li, Z.; Liu, M.; Kinloch, I.A.; Young, R.J. Mechanisms of mechanical reinforcement by graphene and carbon nanotubes in polymer nanocomposites. Nanoscale 2020, 12, 2228–2267. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Socher, R.; Krause, B.; Müller, M.T.; Boldt, R.; Pötschke, P. The influence of matrix viscosity on MWCNT dispersion and electrical properties in different thermoplastic nanocomposites. Polymers 2012, 53, 495–504. [Google Scholar] [CrossRef]

- Pötschke, P.; Mothes, F.; Krause, B.; Voit, B. Melt-Mixed PP/MWCNT Composites: Influence of CNT Incorporation Strategy and Matrix Viscosity on Filler Dispersion and Electrical Resistivity. Polymers 2019, 11, 189. [Google Scholar] [CrossRef] [Green Version]

- Zare, Y.; Rhee, K.Y. Effects of interphase regions and filler networks on the viscosity of PLA/PEO/carbon nanotubes biosensor. Polym. Compos. 2019, 40, 4135–4141. [Google Scholar] [CrossRef]

- Cheng, J.; Pu, H. Influences of matrix viscosity on alignment of multi-walled carbon nanotubes in one-dimensional confined space. Eur. Polym. J. 2017, 89, 431–439. [Google Scholar] [CrossRef]

- Bilisik, K.; Karaduman, N.S.; Sapanci, E. Flexural characterization of 3D prepreg/stitched carbon/epoxy/multiwalled carbon nanotube preforms and composites. J. Compos. Mater. 2018, 53, 563–577. [Google Scholar] [CrossRef]

- Mad Desa, M.S.Z.; Hassan, A.; Arsad, A. The effect of natural rubber toughening on mechanical properties of poly (lactic acid)/multiwalled carbon nanotube nanocomposite. Adv. Mater. Res. 2013, 747, 639–642. [Google Scholar] [CrossRef]

- Mondal, S.; Khastgir, D. Elastomer reinforcement by graphene nanoplatelets and synergistic improvements of electrical and mechanical properties of composites by hybrid nano fillers of graphene-carbon black & graphene-MWCNT. Compos. Part A Appl. Sci. Manuf. 2017, 102, 154–165. [Google Scholar]

- Ivanov, E.; Kotsilkova, R.; Xia, H.; Chen, Y.; Donato, R.K.; Donato, K.; Godoy, A.P.; Di Maio, R.; Silvestre, C.; Cimmino, S.; et al. PLA/Graphene/MWCNT Composites with Improved Electrical and Thermal Properties Suitable for FDM 3D Printing Applications. Appl. Sci. 2019, 9, 1209. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-González, J.A.; Rubio-González, C.; Jiménez-Mora, M.; Ramos-Galicia, L.; Velasco-Santos, C. Influence of the Hybrid Combination of Multiwalled Carbon Nanotubes and Graphene Oxide on Interlaminar Mechanical Properties of Carbon Fiber/Epoxy Laminates. Appl. Compos. Mater. 2017, 25, 1115–1131. [Google Scholar] [CrossRef]

- ASTM D5528-94a. Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Continuous Fiber Reinforced Polymer Matrix Composites; ASTM: Philadelphia, PA, USA, 1994. [Google Scholar]

- ASTM D7905/D7905M-14. Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Compos; ASTM: Philadelphia, PA, USA, 2014. [Google Scholar]

- Gliszczynski, A.; Wiącek, N. Experimental and numerical benchmark study of mode II interlaminar fracture toughness of unidirectional GFRP laminates under shear loading using the end-notched flexure (ENF) test. Compos. Struct. 2021, 258, 113190. [Google Scholar] [CrossRef]

- ASTM F390-98. Standard Test Method For Sheet Resistance Of Thin Metallic Films With A Collinear Four-Probe Array; ASTM: Philadelphia, PA, USA, 1998. [Google Scholar]

- Kim, W.J.; Kang, S.; Ah, C.S.; Lee, Y.W.; Ha, D.H.; Insung, C.I.C.; Yun, W.S. Functionalization of Shortened SWCNTs Using Esterification. Bull. Korean Chem. Soc. 2004, 25, 1301–1302. [Google Scholar]

- Saadati, Y.; Jean-Francois, C.; Gilbert, L.; Yves, B.; Philippe, B.; Nicolas, V. A study of the interlaminar fracture toughness of unidirectional flax/epoxy composites. J. Compos. Sci. 2020, 4, 66. [Google Scholar] [CrossRef]

- Lau, A.K.-T.; Hui, D. The revolutionary creation of new advanced materials—carbon nanotube composites. Compos. Part B Eng. 2002, 33, 263–277. [Google Scholar] [CrossRef]

- Carraro, P.A.; Meneghetti, G.; Quaresimin, M.; Ricotta, M. Crack propagation analysis in composite bonded joints un-der mixed-mode (I+II) static and fatigue loading: Experimental investigation and phenomenological modelling. J. Adhes. Sci. Technol. 2013, 27, 1179–1196. [Google Scholar] [CrossRef]

- Quaresimin, M.; Salviato, M.; Zappalorto, M. Fracture and interlaminar properties of clay-modified epoxies and their glass reinforced laminates. Eng. Fract. Mech. 2012, 81, 80–93. [Google Scholar] [CrossRef]

- Salviato, M.; Kirane, K.; Bažant, Z.P.; Cusatis, G. Mode I and II Interlaminar Fracture in Laminated Composites: A Size Effect Study. J. Appl. Mech. 2019, 86, 1–36. [Google Scholar] [CrossRef] [Green Version]

- Salviato, M.; Kirane, K.; Ashari, S.E.; Bažant, Z.P.; Cusatis, G. Experimental and numerical investigation of intra-laminar energy dissipation and size effect in two-dimensional textile composites. Compos. Sci. Technol. 2016, 135, 67–75. [Google Scholar] [CrossRef] [Green Version]

- Zhou, G.; Mikinka, E.; Golding, J.; Bao, X.; Sun, W.; Ashby, A. Investigation of thermal degradation and decomposition of both pristine and damaged carbon/epoxy samples with thermal history. Compos. Part B Eng. 2020, 201, 108382. [Google Scholar] [CrossRef]

- Wu, C.S.; Liu, Y.L.; Chiu, Y.C. Thermal stability of epoxy resins containing flame retardant components: An evaluation with thermogravimetric analysis. Polym. Degrad. Stab. 2002, 78, 41–48. [Google Scholar] [CrossRef]

- Noël, D.; Hechler, J.-J.; Cole, K.C.; Chouliotis, A.; Overbury, K.C. Quantitative thermal characterization of carbon-epoxy compo-sites using differential scanning calorimetry and thermogravimetric analysis. Thermochim. Acta 1988, 125, 191–208. [Google Scholar] [CrossRef]

- Mansfield, E.; Kar, A.; Hooker, S.A. Applications of TGA in quality control of SWCNTs. Anal. Bioanal. Chem. 2010, 396, 1071–1077. [Google Scholar] [CrossRef]

- Zhou, Y.; Pervin, F.; Lewis, L.; Jeelani, S. Experimental study on the thermal and mechanical properties of multi-walled carbon nanotube-reinforced epoxy. Mater. Sci. Eng. A 2007, 452–453, 657–664. [Google Scholar] [CrossRef]

- Ciecierska, E.; Boczkowska, A.; Kurzydlowski, K.J.; Rosca, I.D.; Van Hoa, S. The effect of carbon nanotubes on epoxy matrix nanocomposites. J. Therm. Anal. Calorim. 2013, 111, 1019–1024. [Google Scholar] [CrossRef] [Green Version]

- Loos, M.R.; Coelho, L.A.F.; Pezzin, S.H.; Amico, S.C. Effect of carbon nanotubes addition on the mechanical and thermal properties of epoxy matrices. Mater. Res. 2008, 11, 347–352. [Google Scholar] [CrossRef]

- Mahajan, A.; Kingon, A.; Kukovecz, Á.; Konya, Z.; Vilarinho, P.M. Studies on the thermal decomposition of multiwall carbon nanotubes under different atmospheres. Mater. Lett. 2013, 90, 165–168. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y.; Li, R.; Sun, X.; Abou-Rachid, H. Thermal and chemical durability of nitrogen-doped carbon nanotubes. J. Nanopart. Res. 2012, 14, 1016. [Google Scholar] [CrossRef]

- Wolfrum, J.; Eibl, S.; Lietch, L. Rapid evaluation of long-term thermal degradation of carbon fibre epoxy composites. Compos. Sci. Technol. 2009, 69, 523–530. [Google Scholar] [CrossRef]

- Startsev, O.V.; Vapirov, Y.M.; Lebedev, M.P.; Kychkin, A.K. Comparison of glass-transition temperatures for epoxy polymers ob-tained by methods of thermal analysis. Mech. Compos. Mater. 2020, 56, 227–240. [Google Scholar] [CrossRef]

- Michels, J.; Widmann, R.; Czaderski, C.; Allahvirdizadeh, R.; Motavalli, M. Glass transition evaluation of commercially available epoxy resins used for civil engineering applications. Compos. Part B Eng. 2015, 77, 484–493. [Google Scholar] [CrossRef]

- Maljaee, H.; Ghiassi, B.; Lourenço, P.B. Effect of synergistic environmental conditions on thermal properties of a cold curing epoxy resin. Compos. Part B Eng. 2017, 113, 152–163. [Google Scholar] [CrossRef]

- Allaoui, A.; El Bounia, N.-E. How carbon nanotubes affect the cure kinetics and glass transition temperature of their epoxy composites?—A review. Express Polym. Lett. 2009, 3, 588–594. [Google Scholar] [CrossRef]

| Theories | Equation for Mode I Fracture Toughness | Symbols |

|---|---|---|

| Modified Beam Theory (MBT) | P = Load, δ = Displacement, b = Width, a = Delamination length, A1 = Slope of plot of a/b versus C1/3, n = Slope of plot of Log c versus Log a, ∆ = Effective delamination extension to correct for the rotation of DCB arms at the delamination front | |

| Compliance Calibration Method (CCM) | ||

| Modified Compliance Calibration (MCC) |

| S/N | Performed Tests | Specimen Dimensions | Standard Used |

|---|---|---|---|

| 1 | Double Cantilever Beam (DCB) | 200 mm length (L), 20 mm width (b), 50 mm initial crack length (a0) and 4.6 mm thickness (h) with Teflon film of 12 μm thickness at their middle plane. | ASTM D5528 [66] |

| 2 | End Notched Flexure (ENF) | 200 mm length (L), 20 mm width (b), 50 mm initial crack length, and 4.6 mm thickness (h). Span length (S) of 100 mm. | ASTM D7905 [67] |

| HMWCNTs Content (wt.%) | Interlaminar Fracture Toughness GIC, KJ/m2 | |||||

|---|---|---|---|---|---|---|

| Initiation | Average Propagation | |||||

| MBT | CCM | MCC | MBT | CCM | MCC | |

| Control | 0.264 | 0.311 | 0.304 | 0.259 | 0.274 | 0.283 |

| 0.2 wt.% HMWCNTs | 0.279 | 0.318 | 0.324 | 0.3604 | 0.362 | 0.388 |

| 0.4 wt.% HMWCNTs | 0.527 | 0.609 | 0.633 | 0.557 | 0.603 | 0.608 |

| HMWCNTs Content (wt.%) | Interlaminar Fracture Toughness Increments for GIC & GIIC | ||||||

|---|---|---|---|---|---|---|---|

| GIC Initiation% | GIC Average Propagation% | GIIC % | |||||

| MBT | CCM | MCC | MBT | CCM | MCC | ||

| 0.2 wt.% HMWCNTs | 5.68 | 2.25 | 6.57 | 39.15 | 32.11 | 37.10 | 50.88 |

| 0.4 wt.% HMWCNTs | 99.62 | 95.81 | 108.22 | 115.05 | 120.07 | 114.84 | 190 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, A.; Andriyana, A.; Hassan, S.B.A.; Ang, B.C. Fabrication and Thermo-Electro and Mechanical Properties Evaluation of Helical Multiwall Carbon Nanotube-Carbon Fiber/Epoxy Composite Laminates. Polymers 2021, 13, 1437. https://doi.org/10.3390/polym13091437

Ali A, Andriyana A, Hassan SBA, Ang BC. Fabrication and Thermo-Electro and Mechanical Properties Evaluation of Helical Multiwall Carbon Nanotube-Carbon Fiber/Epoxy Composite Laminates. Polymers. 2021; 13(9):1437. https://doi.org/10.3390/polym13091437

Chicago/Turabian StyleAli, Alamry, Andri Andriyana, Shukur Bin Abu Hassan, and Bee Chin Ang. 2021. "Fabrication and Thermo-Electro and Mechanical Properties Evaluation of Helical Multiwall Carbon Nanotube-Carbon Fiber/Epoxy Composite Laminates" Polymers 13, no. 9: 1437. https://doi.org/10.3390/polym13091437

APA StyleAli, A., Andriyana, A., Hassan, S. B. A., & Ang, B. C. (2021). Fabrication and Thermo-Electro and Mechanical Properties Evaluation of Helical Multiwall Carbon Nanotube-Carbon Fiber/Epoxy Composite Laminates. Polymers, 13(9), 1437. https://doi.org/10.3390/polym13091437