Bonded CFRP/Steel Systems, Remedies of Bond Degradation and Behaviour of CFRP Repaired Steel: An Overview

Abstract

:1. Introduction

2. Bond Behaviour between CFRP and Steel

2.1. Bond Test Fabrication and Method

2.2. Failure Modes of CFRP/Steel Systems

- (a) Steel and adhesive interface failure.

- (b) Cohesive failure (adhesive layer failure).

- (c) CFRP and adhesive interface failure.

- (d) CFRP delamination (separation of some carbon fibres from the resin matrix).

- (e) CFRP ruptures.

- (f) Steel yielding.

2.3. Factors That Affect the Performance of Bonded CFRP/Steel Systems

2.3.1. Adhesive Selection and Application

- Tensile strength and modulus, to ensure the strength is sufficient and the stiffness is compatible with the FRP material.

- Shear strength and ductility, in order to provide the necessary load transfer capabilities, deformability, and toughness.

- Fatigue resistance, which is critical in tension members subjected to cyclic loads such as bridge trusses or transmission line poles in windy areas.

- Environmental durability, especially when repairing structures that operate in aggressive environments.

- Curing time and temperature, in order to attain the design strength rapidly and preferably without the need of artificial heating.

- Workability, as adhesives must be viscous enough to remain in place during bonding.

- Pot life, where higher values benefit constructability by facilitating installation over large areas.

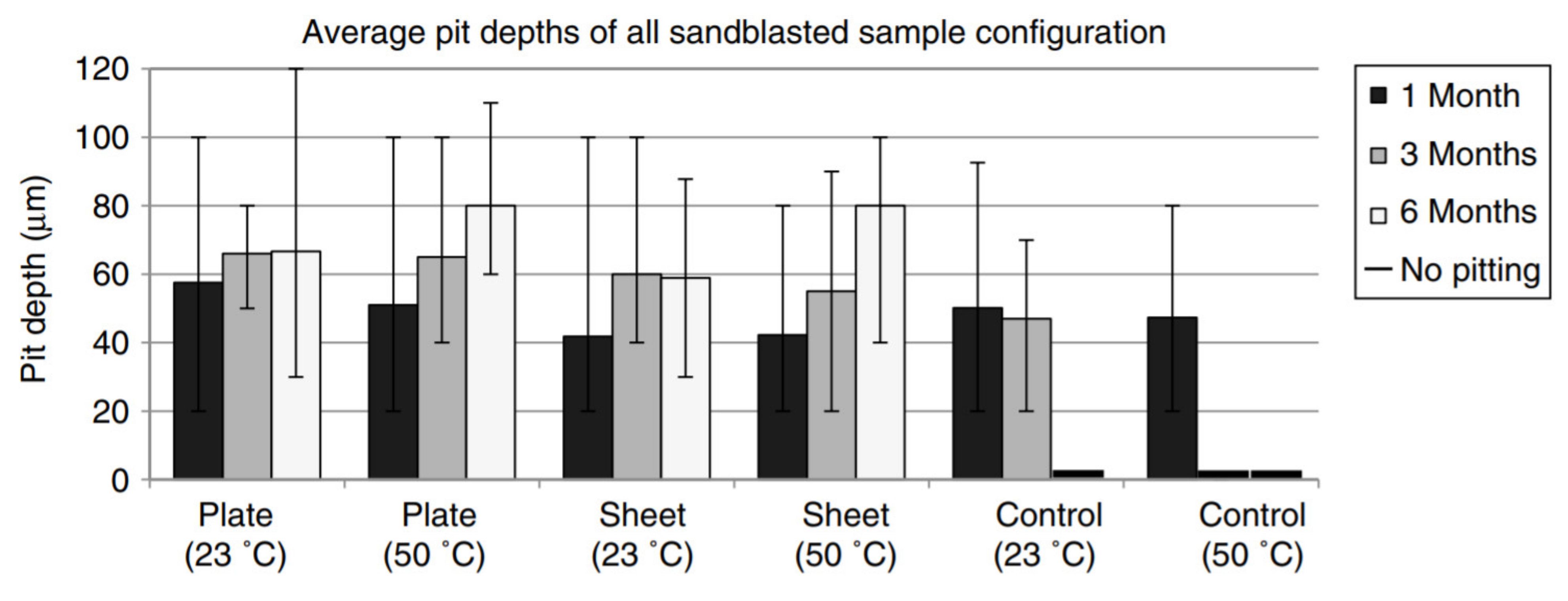

2.3.2. Galvanic Corrosion

2.3.3. Sustained Loading

2.3.4. Fatigue Loading

2.3.5. Elevated Temperature

2.3.6. Moisture and Saturation

3. Current Remedies for Bond Degradation

3.1. Material Insulation

3.2. Surface Priming

3.3. Adhesive Modification

4. Behaviour of CFRP Repaired Steel

4.1. Experimental Repair of Fatigued Steel Plates

4.2. Strengthening of Steel Members under Static Bending

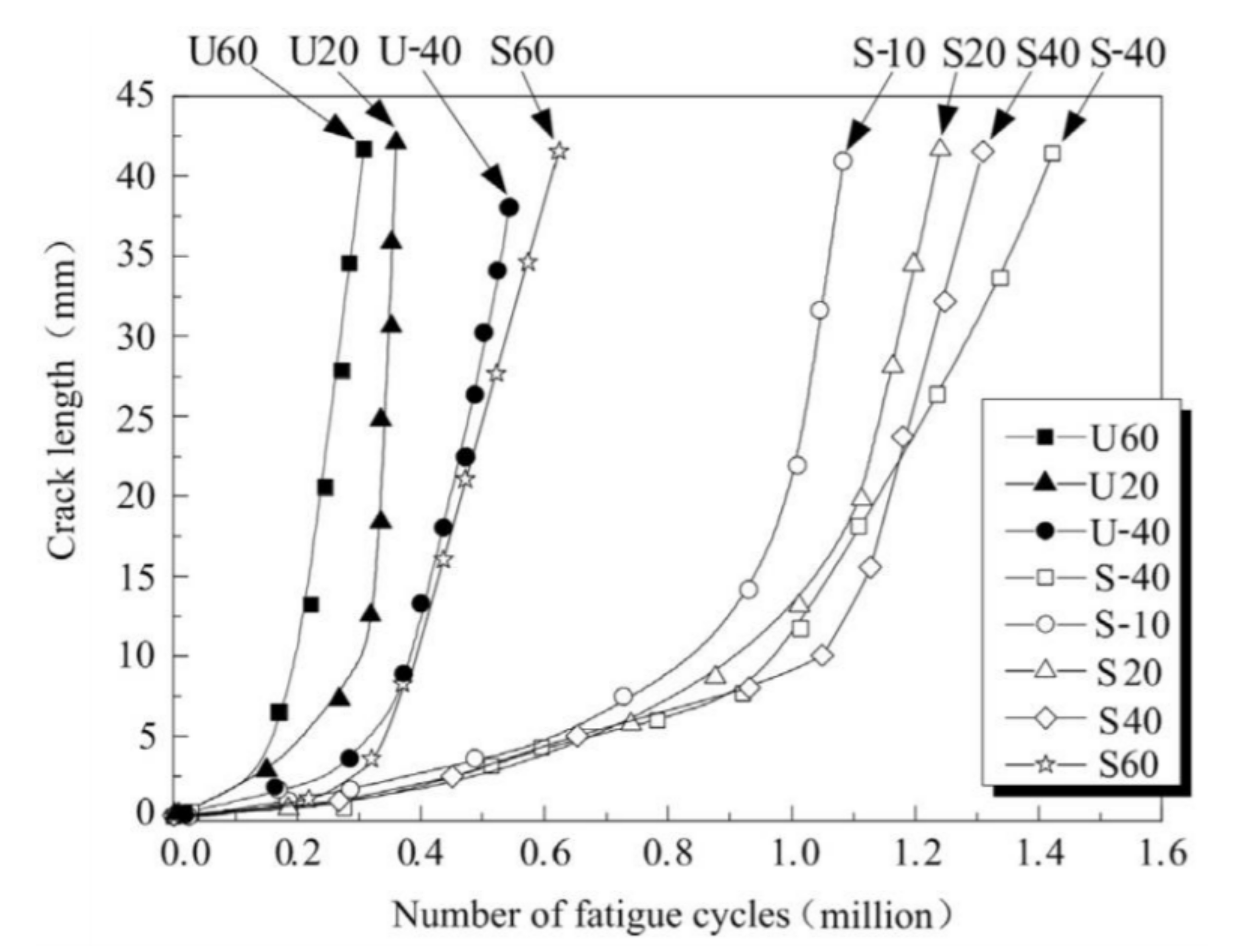

4.3. Strengthening of Steel Members under Bending Fatigue

4.4. Experimental Repair with Environmental Exposure

5. Prospects

- Several steel/CFRP configurations successfully survive fatigue loading and environmental exposures, when applied consecutively. However, it may be more accurate and relevant to investigate the simultaneous application of environmental exposure with fatigue loading. Concurrent conditioning removes the potential for systems to experience levels of recovery once isolated from the harsh environment. Simultaneous exposure or wet/dry cycling, combined with fatigue loading would better replicate the potential extreme industrial scenarios. However, this process may create an unrealistically short exposure time, therefore, specimens may need to undergo pre-exposure to reach saturation before simultaneous loading.

- As high modulus materials exhibit superior fatigue performance, investigations into ultra-high modulus and pre-stressed CFRP laminates under environmental exposure may be valuable. Currently, more research is required to determine if the laminated materials are better at resisting environmental degradation while maintaining good fatigue resistance.

- Adhesive performance remains critical to the strength and durability of wet layup composite systems. The common epoxy adhesives used for wet layup fabrication degrade during elevated temperature seawater exposure. Hence, it may be beneficial to investigate the performance of techniques that minimise the quantity of applied adhesives, such as laminates or unbonded CFRP systems, under environmental exposure. The challenge with unbonded systems, is to find an anchorage system that maintains strength during submergence without environmental degradation.

- Real time structural health monitoring, primarily of adhered CFRP systems. With adhesive and CFRP layers preventing inspection of repaired surfaces, it would be beneficial to investigate techniques to accurately view and monitor surfaces underneath composite patches.

- Silane pre-treatment occasionally creates varying signs of improved longevity and durability of CFRP/steel systems. Silane’s improvement depends heavily on the failure mode, which makes it important to consider silane pre-treatment to various CFRP configurations, to better determine its effectiveness at restricting degradation during moisture exposure. Configurations involving laminates or normal modulus materials may result in more significant improvements from silane pre-treatment as they experience more interfacial and cohesion failures. To further validate the use of silane, it may be required to quantify the proportion of bond strength provided by both the mechanical and chemical components of pre-treated adhered CFRP/steel systems. The portion provided by chemical bonding, for certain CFRP configurations, may pre-determine the potential effectiveness of silane to provide improved adhesion.

- Experiments involving silane pre-treatment also suggested hydrolysis occurred from moisture ingress during environmental submergence. However, this phenomenon requires investigative confirmation by examining the chemical composition of pre-treated steel surfaces, after submergence, to determine if hydrolysis has definitively taken place. This will require the development of a technique to successfully remove residual adhesive from the steel surface, or utilise CFRP systems that undergo steel/adhesive interfacial failure. The surface must then be examined as soon as possible to limit the chemical changes transpiring from atmospheric exposure.

- With environmental exposure occasionally causing levels of debonding it may be applicable to investigate the formation of the debonding region of CFRP/steel systems caused by environmental conditioning and fatigue loading.

- Analytical models require further development to incorporate the significant number of variables related to industrial applications. For example, as failure modes can potentially change as a result of environmental degradation, their fatigue performance significantly alters. Hence, the enhanced model would benefit from a further modification that integrates expected failure modes of CFRP configurations to accurately mimic the reduced performance.

6. Summary

- The galvanic interaction of CFRP/steel systems and their potential to create areas of isolated pitting, which can become high stress regions and the site of premature structural failure.

- The combined effects of environmental exposure and fatigue loading on CFRP/steel joints. Primarily investigating the effect of fatigue stress range, number of applied cycles as well as the exposure temperature and duration. The influence of these variables will allow the design, performance and durability of such bonds to be better understood under industrial conditions.

- The use of adhesive modifiers and chemical primers to restrict the amount of bond degradation witnessed after environmental exposure and fatigue. With durability of such systems being a big threat to their implementation bond strength optimisation is a key to their success.

- The fatigue performance of CFRP repaired steel exposed to environmental conditioning, utilising techniques that proved successful in previously conducted CFRP/steel joint investigations.

- The theoretical prediction of the fatigue life of CFRP repaired steel incorporating the influences of environmental exposure on existing fracture mechanics theories.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Karbhari, V.; Shulley, S. Use of composites for rehabilitation of steel structures—Determination of bond durability. J. Mater. Civ. Eng. 1995, 7, 239–245. [Google Scholar] [CrossRef]

- Masoud, S.; Soudki, K.; Topper, T. CFRP-strengthened and corroded RC beams under monotonic and fatigue loads. J. Compos. Constr. 2001, 5, 228–236. [Google Scholar] [CrossRef]

- Zhao, X.-L.; Zhang, L. State-of-the-art review on FRP strengthened steel structures. Eng. Struct. 2007, 29, 1808–1823. [Google Scholar] [CrossRef]

- Schnerch, D.; Dawood, M.; Rizkalla, S.; Sumner, E. Proposed design guidelines for strengthening of steel bridges with FRP materials. Constr. Build. Mater. 2007, 21, 1001–1010. [Google Scholar] [CrossRef]

- Motaleb, M.; Lindquist, W.; Ibrahim, A.; Hindi, R. Repair assessment for distortion-induced fatigue cracks in a seismically retrofitted double-deck bridge complex. Eng. Struct. 2019, 183, 124–134. [Google Scholar] [CrossRef]

- Fisher, J.W. Evolution of fatigue-resistant steel bridges. Transp. Res. Rec. 1997, 1594, 5–17. [Google Scholar] [CrossRef]

- Hollaway, L.; Cadei, J. Progress in the technique of upgrading metallic structures with advanced polymer composites. Prog. Struct. Eng. Mater. 2002, 4, 131–148. [Google Scholar] [CrossRef]

- Schnerch, D.; Stanford, K.; Lanier, B.; Rizkalla, S. Use of high modulus carbon fiber reinforced polymers (CFRP) for strengthening steel structures. In Proceedings of the Second International Workshop on Structural Composites for Infrastructure Applications, Cairo, Egypt, 16–18 December 2003. [Google Scholar]

- Hollaway, L. Laminate theory: Macroanalyses of composite laminates. In Polymer Composites for Civil and Structural Engineering; Springer Science+Business Media: Dordrecht, The Netherlands, 1993; pp. 63–95. [Google Scholar]

- Miller, T.C.; Chajes, M.J.; Mertz, D.R.; Hastings, J.N. Strengthening of a steel bridge girder using CFRP plates. J. Bridge Eng. 2001, 6, 514–522. [Google Scholar] [CrossRef]

- Kosmatka, S.H.; Kerkhoff, B.; Panarese, W.C. Design and Control of Concrete Mixtures; Portland Cement Association: Skokie, IL, USA, 2002; Volume 5420. [Google Scholar]

- Nanni, A. North American design guidelines for concrete reinforcement and strengthening using FRP: Principles, applications and unresolved issues. Constr. Build. Mater. 2003, 17, 439–446. [Google Scholar] [CrossRef]

- Neale, K. FRPs for structural rehabilitation: A survey of recent progress. Prog. Struct. Eng. Mater. 2000, 2, 133–138. [Google Scholar] [CrossRef]

- Rizkalla, S.; Hassan, T.; Hassan, N. Design recommendations for the use of FRP for reinforcement and strengthening of concrete structures. Prog. Struct. Eng. Mater. 2003, 5, 16–28. [Google Scholar] [CrossRef]

- Teng, J.; Chen, J.-F.; Smith, S.T.; Lam, L. FRP: Strengthened RC Structures; John Wiley & Sons, Ltd.: Chichester, UK, 2001. [Google Scholar]

- Tang, Y.; Yao, Y.; Cang, J. Structural and sensing performance of RC beams strengthened with prestressed near-surface mounted self-sensing basalt FRP bar. Compos. Struct. 2021, 259, 113474. [Google Scholar] [CrossRef]

- Colombo, C.; Vergani, L.; Burman, M. Static and fatigue characterisation of new basalt fibre reinforced composites. Compos. Struct. 2012, 94, 1165–1174. [Google Scholar] [CrossRef]

- Sen, R. Advances in the application of FRP for repairing corrosion damage. Prog. Struct. Eng. Mater. 2003, 5, 99–113. [Google Scholar] [CrossRef]

- Cadei, J.; Stratford, T.; Hollaway, L.; Dcukett, W. Strengthening Metallic Structures Using Externally Bonded Fibre-Reinforced Polymers; Ciria: London, UK, 2004. [Google Scholar]

- Karbhari, V.M. Rehabilitation of Metallic Civil Infrastructure Using Fiber Reinforced Polymer (FRP) Composites: Types Properties and Testing Methods; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- Zhao, X.-L. FRP-Strengthened Metallic Structures; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Bakis, C.E.; Bank, L.C.; Brown, V.; Cosenza, E.; Davalos, J.; Lesko, J.; Machida, A.; Rizkalla, S.; Triantafillou, T. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef] [Green Version]

- Böer, P.; Holliday, L.; Kang, T.H.-K. Independent environmental effects on durability of fiber-reinforced polymer wraps in civil applications: A review. Constr. Build. Mater. 2013, 48, 360–370. [Google Scholar] [CrossRef]

- Shaat, A.; Schnerch, D.; Fam, A.; Rizkalla, S. Retrofit of steel structures using fiber-reinforced polymers (FRP): State-of-the-art. In Proceedings of the Transportation Research Board (TRB) Annual Meeting, Washington, DC, USA, 11–15 January 2004. [Google Scholar]

- Zhao, X.-L.; Bai, Y.; Al-Mahaidi, R.; Rizkalla, S. Effect of dynamic loading and environmental conditions on the bond between CFRP and steel: State-of-the-art review. J. Compos. Constr. 2014, 18, A4013005. [Google Scholar] [CrossRef]

- Mertz, D.R.; Gillespie, J.; Chajes, M.J.; Sabol, S.A. The Rehabilitation of Steel Bridge Girders Using Advanced Composite Materials; Final Report for NCHRP-IDEA Project 51; NCHRP IDEA: Washington, DC, USA, 2002. [Google Scholar]

- Buyukozturk, O.; Gunes, O.; Karaca, E. Progress on understanding debonding problems in reinforced concrete and steel members strengthened using FRP composites. Constr. Build. Mater. 2004, 18, 9–19. [Google Scholar] [CrossRef]

- Tavakkolizadeh, M.; Saadatmanesh, H. Galvanic corrosion of carbon and steel in aggressive environments. J. Compos. Constr. 2001, 5, 200–210. [Google Scholar] [CrossRef]

- Ghafoori, E.; Motavalli, M. Innovative CFRP-prestressing system for strengthening metallic structures. J. Compos. Constr. 2015, 19, 04015006. [Google Scholar] [CrossRef]

- Ghafoori, E.; Motavalli, M.; Nussbaumer, A.; Herwig, A.; Prinz, G.; Fontana, M. Design criterion for fatigue strengthening of riveted beams in a 120-year-old railway metallic bridge using pre-stressed CFRP plates. Compos. Part B Eng. 2015, 68, 1–13. [Google Scholar] [CrossRef]

- Ghafoori, E.; Motavalli, M. Normal, high and ultra-high modulus carbon fiber-reinforced polymer laminates for bonded and un-bonded strengthening of steel beams. Mater. Des. 2015, 67, 232–243. [Google Scholar] [CrossRef]

- Schnerch, D.; Dawood, M.; Rizkalla, S.; Sumner, E.; Stanford, K. Bond behavior of CFRP strengthened steel structures. Adv. Struct. Eng. 2006, 9, 805–817. [Google Scholar] [CrossRef]

- Teng, J.-G.; Fernando, D.; Yu, T.; Zhao, X. Treatment of steel surfaces for effective adhesive bonding. In Advances in FRP Composites in Civil Engineering, Proceedings of the 5th International Conference on FRP Composites in Civil Engineering, CICE 2010, Beijing, China, 27–29 September 2010; Springer: Berlin/Heidelberg, Germany, 2011; pp. 865–868. [Google Scholar]

- Hutchinson, A. Surface pretreatment–the key to durability. In Proceedings of the International Conference on Structural Faults & Repair, University of London, London, UK, 7–9 July 1987; pp. 235–244. [Google Scholar]

- Sykes, J.; Moloney, A.; Briggs, D.; Dahm, R. Surface Analysis and Pretreatment of Plastics and Metals; Applied Science Publication: London, UK, 1982; p. 153. [Google Scholar]

- Teng, J.; Yu, T.; Fernando, D. Strengthening of steel structures with fiber-reinforced polymer composites. J. Constr. Steel Res. 2012, 78, 131–143. [Google Scholar] [CrossRef]

- Fawzia, S. Bond Characteristics between Steel and Carbon Fibre Reinforced Polymer (CFRP) Composites; Monash University: Melbourne, Australia, 2007. [Google Scholar]

- Liu, H.; Zhao, X.L.; Al-Mahaidi, R. Effect of fatigue loading on bond strength between CFRP sheets and steel plates. Int. J. Struct. Stab. Dyn. 2010, 10, 1–20. [Google Scholar] [CrossRef]

- Xia, S.; Teng, J. Behaviour of FRP-to-steel bonded joints. In Proceedings of the International Symposium on Bond Behaviour of FRP in Structures, BBFS 2005, Hong Kong, 7–9 December 2005; International Institute for FRP in Construction (IIFC): Hong Kong, 2005; pp. 411–418. [Google Scholar]

- Wu, C.; Zhao, X.; Duan, W.H.; Al-Mahaidi, R. Bond characteristics between ultra high modulus CFRP laminates and steel. Thin-Walled Struct. 2012, 51, 147–157. [Google Scholar] [CrossRef]

- Czaderski, C.; Martinelli, E.; Michels, J.; Motavalli, M. Effect of curing conditions on strength development in an epoxy resin for structural strengthening. Compos. Part B Eng. 2012, 43, 398–410. [Google Scholar] [CrossRef]

- Danieley, N.D.; Long, E.R., Jr. Effects of curing on the glass transition temperature and moisture absorption of a neat epoxy resin. J. Polym. Sci. Polym. Chem. Ed. 1981, 19, 2443–2449. [Google Scholar] [CrossRef]

- Dodiuk, H.; Kenig, S. Low temperature curing epoxies for structural repair. Prog. Polym. Sci. 1994, 19, 439–467. [Google Scholar] [CrossRef]

- Hollaway, L.; Zhang, L.; Photiou, N.; Teng, J.; Zhang, S. Advances in adhesive joining of carbon fibre/polymer composites to steel members for repair and rehabilitation of bridge structures. Adv. Struct. Eng. 2006, 9, 791–803. [Google Scholar] [CrossRef]

- Lapique, F.; Redford, K. Curing effects on viscosity and mechanical properties of a commercial epoxy resin adhesive. Int. J. Adhes. Adhes. 2002, 22, 337–346. [Google Scholar] [CrossRef]

- Matsui, K. Effects of curing conditions and test temperatures on the strength of adhesive-bonded joints. Int. J. Adhes. Adhes. 1990, 10, 277–284. [Google Scholar] [CrossRef]

- Nguyen, T.-C.; Bai, Y.; Zhao, X.-L.; Al-Mahaidi, R. Curing effects on steel/CFRP double strap joints under combined mechanical load, temperature and humidity. Constr. Build. Mater. 2013, 40, 899–907. [Google Scholar] [CrossRef]

- Photiou, N.K.; Hollaway, L.C.; Chryssanthopoulos, M.K. Selection of carbon-fiber-reinforced polymer systems for steelwork upgrading. J. Mater. Civ. Eng. 2006, 18, 641–649. [Google Scholar] [CrossRef]

- Hollaway, L.C.; Teng, J.-G. Strengthening and Rehabilitation of Civil Infrastructures Using Fibre-Reinforced Polymer (FRP) Composites; Woodhead Publishing: Cambridge, UK, 2008. [Google Scholar]

- Sizemore, J.; Aidoo, J.; Harries, K.A.; Monnell, J. Use of Silane Adhesion Promoter to Enhance FRP-to-Steel Bond Performance. In Proceedings of the 4th International Conference on Durability and Sustainability of Fiber Reinforced Polymer (FRP) Composites for Construction and Rehabilitation, CDCC’ 2011, Quebec City, QC, Canada, 20–22 July 2011. [Google Scholar]

- Xiao, Z.-G.; Zhao, X.-L. CFRP repaired welded thin-walled cross-beam connections subject to in-plane fatigue loading. Int. J. Struct. Stab. Dyn. 2012, 12, 195–211. [Google Scholar] [CrossRef]

- Wu, G.; Wang, H.-T.; Wu, Z.-S.; Liu, H.-Y.; Ren, Y. Experimental study on the fatigue behavior of steel beams strengthened with different fiber-reinforced composite plates. J. Compos. Constr. 2012, 16, 127–137. [Google Scholar] [CrossRef]

- Fawzia, S.; Zhao, X.-L.; Al-Mahaidi, R. Bond–slip models for double strap joints strengthened by CFRP. Compos. Struct. 2010, 92, 2137–2145. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.; Zhao, X.-L.; Al-Mahaidi, R.; Emdad, M.R.; Duan, W. Fatigue tests of cracked steel plates strengthened with UHM CFRP plates. Adv. Struct. Eng. 2012, 15, 1801–1815. [Google Scholar] [CrossRef]

- Yu, T.; Fernando, D.; Teng, J.; Zhao, X.L. Experimental study on CFRP-to-steel bonded interfaces. Compos. Part B Eng. 2012, 43, 2279–2289. [Google Scholar] [CrossRef]

- Torres-Acosta, A.A. Galvanic corrosion of steel in contact with carbon-polymer composites. I: Experiments in mortar. J. Compos. Constr. 2002, 6, 112–115. [Google Scholar] [CrossRef]

- Tucker, W.C.; Brown, R.; Russell, L. Corrosion between a graphite/polymer composite and metals. J. Compos. Mater. 1990, 24, 92–102. [Google Scholar] [CrossRef]

- Borrie, D.; Raman, R.S.; Zhao, X.-L.; Adnan, N. Quantifying corrosion between Carbon Fibre Reinforced Polymers (CFRP) and steel caused by high temperature marine environments. Adv. Struct. Eng. 2014, 17, 1761–1770. [Google Scholar] [CrossRef]

- Dawood, M.; Rizkalla, S. Environmental durability of a CFRP system for strengthening steel structures. Constr. Build. Mater. 2010, 24, 1682–1689. [Google Scholar] [CrossRef]

- Agarwal, A.; Foster, S.J.; Hamed, E. Wet thermo-mechanical behavior of steel–CFRP joints—An experimental study. Compos. Part B Eng. 2015, 83, 284–296. [Google Scholar] [CrossRef]

- Nguyen, T.-C.; Bai, Y.; Al-Mahaidi, R.; Zhao, X.-L. Time-dependent behaviour of steel/CFRP double strap joints subjected to combined thermal and mechanical loading. Compos. Struct. 2012, 94, 1826–1833. [Google Scholar] [CrossRef]

- Nguyen, T.-C.; Bai, Y.; Zhao, X.-L.; Al-Mahaidi, R. Durability of steel/CFRP double strap joints exposed to sea water, cyclic temperature and humidity. Compos. Struct. 2012, 94, 1834–1845. [Google Scholar] [CrossRef]

- Nguyen, T.-C.; Bai, Y.; Zhao, X.-L.; Al-Mahaidi, R. Effects of ultraviolet radiation and associated elevated temperature on mechanical performance of steel/CFRP double strap joints. Compos. Struct. 2012, 94, 3563–3573. [Google Scholar] [CrossRef]

- Bowditch, M. The durability of adhesive joints in the presence of water. Int. J. Adhes. Adhes. 1996, 16, 73–79. [Google Scholar] [CrossRef]

- Kinloch, A.J. Adhesion and Adhesives: Science and Technology; Springer Science & Business Media: Heidelberg, Germany, 2012. [Google Scholar]

- Bocciarelli, M.; Colombi, P.; Fava, G.; Poggi, C. Fatigue performance of tensile steel members strengthened with CFRP plates. Compos. Struct. 2009, 87, 334–343. [Google Scholar] [CrossRef]

- Matta, F. Bond between Steel and CFRP Laminates for Rehabilitation of Metallic Bridges; Faculty of Engineering, University of Padua: Padua, Italy, 2003. [Google Scholar]

- Wu, C.; Zhao, X.L.; Chiu, W.K.; Al-Mahaidi, R.; Duan, W.H. Effect of fatigue loading on the bond behaviour between UHM CFRP plates and steel plates. Compos. Part B Eng. 2013, 50, 344–353. [Google Scholar] [CrossRef]

- Zhang, Y.; Vassilopoulos, A.P.; Keller, T. Effects of low and high temperatures on tensile behavior of adhesively-bonded GFRP joints. Compos. Struct. 2010, 92, 1631–1639. [Google Scholar] [CrossRef]

- Cao, S.; Zhis, W.; Wang, X. Tensile properties of CFRP and hybrid FRP composites at elevated temperatures. J. Compos. Mater. 2009, 43, 315–330. [Google Scholar]

- Di Ludovico, M.; Piscitelli, F.; Prota, A.; Lavorgna, M.; Mensitieri, G.; Manfredi, G. Improved mechanical properties of CFRP laminates at elevated temperatures and freeze–thaw cycling. Constr. Build. Mater. 2012, 31, 273–283. [Google Scholar] [CrossRef]

- Nardone, F.; Di Ludovico, M.; y Basalo, F.J.D.C.; Prota, A.; Nanni, A. Tensile behavior of epoxy based FRP composites under extreme service conditions. Compos. Part B Eng. 2012, 43, 1468–1474. [Google Scholar] [CrossRef]

- Al-Shawaf, A.; Zhao, X.-L. Adhesive rheology impact on wet lay-up CFRP/steel joints’ behaviour under infrastructural subzero exposures. Compos. Part B Eng. 2013, 47, 207–219. [Google Scholar] [CrossRef]

- Al-Shawaf, A.; Al-Mahaidi, R.; Zhao, X.-L. Effect of elevated temperature on bond behaviour of high modulus CFRP/steel double-strap joints. Aust. J. Struct. Eng. 2009, 10, 63–74. [Google Scholar] [CrossRef]

- Nguyen, T.-C.; Bai, Y.; Zhao, X.-L.; Al-Mahaidi, R. Mechanical characterization of steel/CFRP double strap joints at elevated temperatures. Compos. Struct. 2011, 93, 1604–1612. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, X.L.; Bai, Y.; Singh, R.; Rizkalla, S.; Bandyopadhyay, S. The effect of elevated temperature on the bond between high modulus carbon fibre-reinforced polymer sheet and steel. Aust. J. Struct. Eng. 2014, 15, 355–366. [Google Scholar] [CrossRef]

- Kinloch, A.; Dukes, W.; Gledhill, R. Durability of adhesive joints. Polym. Sci. Technol. 1975, 98, 597–614. [Google Scholar]

- Kinloch, A.; Korenberg, C.; Tan, K.T.; Watts, J. Durability of Structural Adhesive Joints; Applied Science Publication: London, UK, 1983. [Google Scholar]

- Wright, W. The effect of diffusion of water into epoxy resins and their carbon-fibre reinforced composites. Composites 1981, 12, 201–205. [Google Scholar] [CrossRef]

- Gledhill, R.; Kinloch, A. Environmental failure of structural adhesive joints. J. Adhes. 1974, 6, 315–330. [Google Scholar] [CrossRef]

- Abanilla, M.A.; Li, Y.; Karbhari, V.M. Durability characterization of wet layup graphite/epoxy composites used in external strengthening. Compos. Part B Eng. 2005, 37, 200–212. [Google Scholar] [CrossRef]

- Selzer, R.; Friedrich, K. Mechanical properties and failure behaviour of carbon fibre-reinforced polymer composites under the influence of moisture. Compos. Part A Appl. Sci. Manuf. 1997, 28, 595–604. [Google Scholar] [CrossRef]

- John, S.; Kinloch, A.; Matthews, F. Measuring and predicting the durability of bonded carbon fibre/epoxy composite joints. Composites 1991, 22, 121–127. [Google Scholar] [CrossRef]

- Seica, M.V.; Packer, J.A. FRP materials for the rehabilitation of tubular steel structures, for underwater applications. Compos. Struct. 2007, 80, 440–450. [Google Scholar] [CrossRef]

- Karbhari, V.; Chin, J.; Hunston, D.; Benmokrane, B.; Juska, T.; Morgan, R.; Lesko, J.; Sorathia, U. Reynaud, Durability gap analysis for fiber-reinforced polymer composites in civil infrastructure. J. Compos. Constr. 2003, 7, 238–247. [Google Scholar] [CrossRef] [Green Version]

- Gillespie, J., Jr.; West, T. Enhancements to the Bond between Advanced Composite Materials and Steel for Bridge Rehabilitation; Center for Composite Materials, University of Delaware: Newark, DE, USA, 2002. [Google Scholar]

- Brown, S.; Deluccia, J. Corrosion characteristics of naval aircraft metals and alloys in contact with graphite-epoxy composites. In Proceedings of the Environmental Degradation of Engineering Materials Conference, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 10–12 October 1977; pp. 277–288. [Google Scholar]

- Choqueuse, D.; Davies, P.; Mazeas, F.; Baizeau, R. Aging of composites in water: Comparison of five materials in terms of absorption kinetics and evolution of mechanical properties. In High Temperature and Environmental Effects on Polymeric Composites: 2nd Volume; ASTM International: Washington, DC, USA, 1997. [Google Scholar]

- Sloan, F.; Talbot, J. Corrosion of graphite-fiber-reinforced composites I—Galvanic coupling damage. Corrosion 1992, 48, 830–838. [Google Scholar] [CrossRef]

- Photiou, N.; Hollaway, L.; Chryssanthopoulos, M. Strengthening of an artificially degraded steel beam utilising a carbon/glass composite system. In Advanced Polymer Composites for Structural Applications in Construction; Elsevier: Amsterdam, The Netherlands, 2004; pp. 274–283. [Google Scholar]

- Photiou, N.; Hollaway, L.; Chryssanthopoulos, M. Selection of CFRP systems for steelwork upgrading. In Proceedings of the Conference on Innovative Materials and Technologies for Construction and Restoration (IMTCR), Lecce, Italy, 6–9 June 2004; pp. 524–539. [Google Scholar]

- Photiou, N.; Hollaway, L.; Chryssanthopoulos, M. An ultra-high modulus carbon/glass fibre composite system for structural upgrading of steel members. In Proceedings of the 2nd International Conference on FRP Composites in Civil Engineering–CICE 2004, Adelaide, Australia, 8–10 December 2004; pp. 8–10. [Google Scholar]

- Dawood, M. Durability of steel components strengthened with fiber-reinforced polymer (FRP) composites. In Rehabilitation of Metallic Civil Infrastructure Using Fiber Reinforced Polymer (FRP) Composites; Elsevier: Amsterdam, The Netherlands, 2014; pp. 96–114. [Google Scholar]

- Plueddemann, E.P. Chemistry of silane coupling agents. In Silane Coupling Agents; Springer: Berlin/Heidelberg, Germany, 1991; pp. 31–54. [Google Scholar]

- Van Ooij, W.; Zhu, D.; Stacy, M.; Seth, A.; Mugada, T.; Gandhi, J.; Puomi, P. Corrosion protection properties of organofunctional silanes—An overview. Tsinghua Sci. Technol. 2005, 10, 639–664. [Google Scholar] [CrossRef]

- Baldan, A. Adhesively-bonded joints and repairs in metallic alloys, polymers and composite materials: Adhesives, adhesion theories and surface pretreatment. J. Mater. Sci. 2004, 39, 1–49. [Google Scholar] [CrossRef]

- Critchlow, G.; Brewis, D. Influence of surface macroroughness on the durability of epoxide-aluminium joints. Int. J. Adhes. Adhes. 1995, 15, 173–176. [Google Scholar] [CrossRef]

- Walker, P. Organosilanes as adhesion promoters. J. Adhes. Sci. Technol. 1991, 5, 279–305. [Google Scholar] [CrossRef]

- Tod, D.; Atkins, R.; Shaw, S. Use of primers to enhance adhesive bonds. Int. J. Adhes. Adhes. 1992, 12, 159–163. [Google Scholar] [CrossRef]

- Gledhill, R.; Shaw, S.; Tod, D. Durability of adhesive-bonded joints employing organosilane coupling agents. Int. J. Adhes. Adhes. 1990, 10, 192–198. [Google Scholar] [CrossRef]

- Knox, E.; Cowling, M. A rapid durability test method for adhesives. Int. J. Adhes. Adhes. 2000, 20, 201–208. [Google Scholar] [CrossRef]

- Borrie, D.; Al-Saadi, S.; Zhao, X.; Raman, R.S.; Bai, Y. Effects of CNT modified adhesives and silane chemical pre-treatment on CFRP/steel bond behaviour and durability. Constr. Build. Mater. 2021, 273, 121803. [Google Scholar] [CrossRef]

- Martone, A.; Formicola, C.; Giordano, M.; Zarrelli, M. Reinforcement efficiency of multi-walled carbon nanotube/epoxy nano composites. Compos. Sci. Technol. 2010, 70, 1154–1160. [Google Scholar] [CrossRef]

- Abot, J.; Song, Y.; Schulz, M.; Shanov, V. Novel carbon nanotube array-reinforced laminated composite materials with higher interlaminar elastic properties. Compos. Sci. Technol. 2008, 68, 2755–2760. [Google Scholar] [CrossRef]

- Adohi, B.-P.; Mdarhri, A.; Prunier, C.; Haidar, B.; Brosseau, C. A comparison between physical properties of carbon black-polymer and carbon nanotubes-polymer composites. J. Appl. Phys. 2010, 108, 074108. [Google Scholar] [CrossRef]

- Godara, A.; Mezzo, L.; Luizi, F.; Warrier, A.; Lomov, S.V.; Van Vuure, A.W.; Gorbatikh, L.; Moldenaers, P.; Verpoest, I. Influence of carbon nanotube reinforcement on the processing and the mechanical behaviour of carbon fiber/epoxy composites. Carbon 2009, 47, 2914–2923. [Google Scholar] [CrossRef]

- Korayem, A.H.; Li, C.Y.; Zhang, Q.H.; Zhao, X.L.; Duan, W.H. Effect of carbon nanotube modified epoxy adhesive on CFRP-to-steel interface. Compos. Part B Eng. 2015, 79, 95–104. [Google Scholar] [CrossRef]

- Liao, Y.-H.; Marietta-Tondin, O.; Liang, Z.; Zhang, C.; Wang, B. Investigation of the dispersion process of SWNTs/SC-15 epoxy resin nanocomposites. Mater. Sci. Eng. A 2004, 385, 175–181. [Google Scholar] [CrossRef]

- Puglia, D.; Valentini, L.; Armentano, I.; Kenny, J. Effects of single-walled carbon nanotube incorporation on the cure reaction of epoxy resin and its detection by Raman spectroscopy. Diam. Relat. Mater. 2003, 12, 827–832. [Google Scholar] [CrossRef]

- Korayem, A.H.; Barati, M.R.; Simon, G.P.; Zhao, X.L.; Duan, W.H. Reinforcing brittle and ductile epoxy matrices using carbon nanotubes masterbatch. Compos. Part A Appl. Sci. Manuf. 2014, 61, 126–133. [Google Scholar] [CrossRef]

- Korayem, A.H.; Liu, Y.M.; Zhao, X.L.; Duan, W.H. Bond characterization of steel-CFRP with carbon nanotube modified epoxy adhesive via pull-off tests. Int. J. Struct. Stab. Dyn. 2015, 15, 1540027. [Google Scholar] [CrossRef]

- Denney, J.; Mall, S. Characterization of disbond effects on fatigue crack growth behavior in aluminum plate with bonded composite patch. Eng. Fract. Mech. 1997, 57, 507–525. [Google Scholar] [CrossRef]

- Domazet, Ž. Comparison of fatigue crack retardation methods. Eng. Fail. Anal. 1996, 3, 137–147. [Google Scholar] [CrossRef]

- Fam, A.; Witt, S.; Rizkalla, S. Repair of damaged aluminum truss joints of highway overhead sign structures using FRP. Constr. Build. Mater. 2006, 20, 948–956. [Google Scholar] [CrossRef]

- Nadauld, J.D.; Pantelides, C.P. Rehabilitation of cracked aluminum connections with GFRP composites for fatigue stresses. J. Compos. Constr. 2007, 11, 328–335. [Google Scholar] [CrossRef]

- Pantelides, C.P.; Nadauld, J.; Cercone, L. Repair of cracked aluminum overhead sign structures with glass fiber reinforced polymer composites. J. Compos. Constr. 2003, 7, 118–126. [Google Scholar] [CrossRef]

- Bassetti, A.; Nussbaumer, A.; Hirt, M. Crack repair and fatigue life extension of riveted bridge members using composite materials. In Proceedings of the Bridge Engineering Conference; The Egyptian Society of Engineers: Sharm El-Sheikh, Egypt, 2000; pp. 227–238. [Google Scholar]

- Bassetti, A.; Liechti, P.; Nussbaumer, A. Fatigue Resistance and Repairs of Riveted Bridge Members. Eur. Struct. Integr. Soc. 1999, 23, 207–218. [Google Scholar]

- Bassetti, A.; Nussbaumer, A.; Hirt, M.A. Fatigue life extension of riveted bridge members using prestressed carbon fiber composite. In Proceedings of the International Conference on Steel Structures of the 2000’s ECCS, Istanbul, Turkey, 11–13 September 2000; pp. 375–380. [Google Scholar]

- Feng, P.; Hu, L.; Zhao, X.-L.; Cheng, L.; Xu, S. Study on thermal effects on fatigue behavior of cracked steel plates strengthened by CFRP sheets. Thin-Walled Struct. 2014, 82, 311–320. [Google Scholar] [CrossRef]

- Colombi, P.; Bassetti, A.; Nussbaumer, A. Analysis of cracked steel members reinforced by pre-stress composite patch. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 59–66. [Google Scholar] [CrossRef] [Green Version]

- Okura, I.; Fukui, T.; Nakamura, K.; Matsugami, T.; Iwai, Y. Application of CFRP sheets to repair of fatigue cracks in steel plates. J. Constr. Steel Jpn. 2000, 8, 689–696. [Google Scholar]

- Jones, S.C.; Civjan, S.A. Application of fiber reinforced polymer overlays to extend steel fatigue life. J. Compos. Constr. 2003, 7, 331–338. [Google Scholar] [CrossRef]

- Colombi, P.; Fava, G.; Sonzogni, L. Fatigue crack growth in CFRP-strengthened steel plates. Compos. Part B Eng. 2015, 72, 87–96. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y.; Ye, L.; Lu, X.; Yue, Q. Experimental study on fatigue behavior of tensile steel plates strengthened with CFRP plates. In Proceedings of the Third International Conference on FRP in Composites in Civil Engineering (CICE 2006), Miami, FL, USA, 13–15 December 2006. [Google Scholar]

- Suzuki, H. Experimental study on repair of cracked steel member by CFRP strip and stop hole. In Proceedings of the 11th European Conference on Composite Materials, Rhodes, Greece, 31 May–3 June 2004. [Google Scholar]

- Tsouvalis, N.G.; Mirisiotis, L.S.; Dimou, D.N. Experimental and numerical study of the fatigue behaviour of composite patch reinforced cracked steel plates. Int. J. Fatigue 2009, 31, 1613–1627. [Google Scholar] [CrossRef]

- Liu, H.; Al-Mahaidi, R.; Zhao, X.-L. Experimental study of fatigue crack growth behaviour in adhesively reinforced steel structures. Compos. Struct. 2009, 90, 12–20. [Google Scholar] [CrossRef]

- Yu, Q.Q.; Chen, T.; Gu, X.L.; Zhao, X.L.; Xiao, Z. Fatigue behaviour of CFRP strengthened steel plates with different degrees of damage. Thin Walled Struct. 2013, 69, 10–17. [Google Scholar] [CrossRef]

- Yu, Q.-Q.; Chen, T.; Gu, X.-L.; Zhang, N.-X. Fatigue behaviour of CFRP strengthened out-of-plane gusset welded joints with double cracks. Polymers 2015, 7, 1617–1637. [Google Scholar] [CrossRef] [Green Version]

- Al-Saidy, A.H.; Klaiber, F.; Wipf, T. Repair of steel composite beams with carbon fiber-reinforced polymer plates. J. Compos. Constr. 2004, 8, 163–172. [Google Scholar] [CrossRef]

- Schnerch, D.; Rizkalla, S. Flexural strengthening of steel bridges with high modulus CFRP strips. J. Bridge Eng. 2008, 13, 192–201. [Google Scholar] [CrossRef]

- Sen, R.; Liby, L.; Mullins, G. Strengthening steel bridge sections using CFRP laminates. Compos. Part B Eng. 2001, 32, 309–322. [Google Scholar] [CrossRef]

- Tavakkolizadeh, M.; Saadatmanesh, H. Strengthening of steel-concrete composite girders using carbon fiber reinforced polymers sheets. J. Struct. Eng. 2003, 129, 30–40. [Google Scholar] [CrossRef] [Green Version]

- Tavakkolizadeh, M.; Saadatmanesh, H. Repair of damaged steel-concrete composite girders using carbon fiber-reinforced polymer sheets. J. Compos. Constr. 2003, 7, 311–322. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Nanni, A.; Silva, P.F.; Laboube, R.A. Rehabilitation of steel bridge columns with FRP composite materials. Proc. CCC 2001, 10–12. [Google Scholar]

- Shaat, A.; Fam, A. Repair of cracked steel girders connected to concrete slabs using carbon-fiber-reinforced polymer sheets. J. Compos. Constr. 2008, 12, 650–659. [Google Scholar] [CrossRef]

- Fam, A.; MacDougall, C.; Shaat, A. Upgrading steel–concrete composite girders and repair of damaged steel beams using bonded CFRP laminates. Thin Walled Struct. 2009, 47, 1122–1135. [Google Scholar] [CrossRef]

- Nozaka, K.; Shield, C.K.; Hajjar, J.F. Effective bond length of carbon-fiber-reinforced polymer strips bonded to fatigued steel bridge I-girders. J. Bridge Eng. 2005, 10, 195–205. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; Jumaat, M.Z.; Ramli Sulong, N.; Islam, A. A review on strengthening steel beams using FRP under fatigue. Sci. World J. 2014, 2014, 702537. [Google Scholar] [CrossRef] [Green Version]

- Rizkalla, S.; Dawood, M.; Schnerch, D. Development of a carbon fiber reinforced polymer system for strengthening steel structures. Compos. Part A Appl. Sci. Manuf. 2008, 39, 388–397. [Google Scholar] [CrossRef]

- Nikouka, F.; Lee, M.; Moy, S. Strengthening of metallic structures using carbon fibre composites. In Proceedings of the IABSE Symposium: Towards a Better Built Environment—Innovation, Sustainability, Information Technology, Melbourne, Australia, 11–13 September 2002; International Association for Bridge and Structural Engineering: Zurich, Switzerland, 2002; pp. 121–127. [Google Scholar]

- Suzuki, H. Strengthening of a steel beam with carbon fiber reinforced polymer strip. In Proceedings of the First International Conference on Bridge Maintenance, Safety and Management IABMAS 2002, Barcelona, Spain, 14–17 July 2002. [Google Scholar]

- Tavakkolizadeh, M.; Saadatmanesh, H. Fatigue strength of steel girders strengthened with carbon fiber reinforced polymer patch. J. Struct. Eng. 2003, 129, 186–196. [Google Scholar] [CrossRef] [Green Version]

- Deng, J.; Lee, M.M. Fatigue performance of metallic beam strengthened with a bonded CFRP plate. Compos. Struct. 2007, 78, 222–231. [Google Scholar] [CrossRef]

- Ghafoori, E.; Motavalli, M.; Nussbaumer, A.; Herwig, A.; Prinz, G.; Fontana, M. Determination of minimum CFRP pre-stress levels for fatigue crack prevention in retrofitted metallic beams. Eng. Struct. 2015, 84, 29–41. [Google Scholar] [CrossRef]

- Ghafoori, E.; Motavalli, M.; Botsis, J.; Herwig, A.; Galli, M. Fatigue strengthening of damaged metallic beams using prestressed unbonded and bonded CFRP plates. Int. J. Fatigue 2012, 44, 303–315. [Google Scholar] [CrossRef]

- Colombi, P.; Fava, G. Experimental study on the fatigue behaviour of cracked steel beams repaired with CFRP plates. Eng. Fract. Mech. 2015, 145, 128–142. [Google Scholar] [CrossRef] [Green Version]

| Steel Type | Carbon Fibre and Carbon Fibre Reinforced Polymer (CFRP) Specification | Test Method | Highlights | Ref. |

|---|---|---|---|---|

| Low-alloy steel (16-gauge A242 cold-rolled steel) | Unimpregnated Fibre (in tow-sheet form), C1:20 (weight: 200 g/cm2, Tensile strength: 3480 MPa, Tensile modulus: 228 GPa). C1:30 (weight: 300 g/cm2, Tensile strength: 3480 MPa, Tensile modulus: 228 GPa). C5:30 (weight: 300 g/cm2, Tensile strength: 2940 MPa, Tensile modulus: 370 GPa). | Wedge test: The modified wedge-crack specimens (of nominal size 25.4 by 203 mm), which were used to simultaneously evaluate the adhesive steel and adhesive composite bonds. |

| [1] |

| A36 steel bar (1/2″ × 1.5″ × 36″) | CFRP plate (0.21″ × 1.44″ × 18″) | Tensile test: A series of increasing tensile loads was applied using an Instron Model 1332 testing machine and the accompanying strain data was recorded. A constant strain rate of 3000 lbs./min was used. |

| [26] |

| Fatigue test: A series of small-scale double reinforcement specimens was tested under cyclic loads at a stress range corresponding to the fatigue threshold for common fatigue-sensitive conditions. Double reinforcement specimen is fatigued at a stress range of 12 ksi for 2.55 million cycles. |

| |||

| Steel beam (S355J0 (ST 52-3)) | CFRP plate (150/2000, width: 50 mm and thickness: 1.2 mm) | Pull-Off Test: Three CFRP plates are gripped inside a friction clamp. Each CFRP plate is pulled using a single-FRP clamp, which is connected to an actuator. The actuators are connected to a hydraulic jack that provides equal pressure for each actuator. An inclined test setup was used due to the deviation of the CFRP plates about 12° in the proposed trapezoidal PUR system. |

| [29] |

| Flexural Test: Three steel beams (one unstrengthened reference and two strengthened with 15% and 31% prestress levels, respectively), were statically tested until failure. A symmetric four-point bending setup is used. The loading span is 1700 mm, whereas the support span is 5000 mm. The test is carried out using a hydraulic testing machine (Pulsator P960) with 250 kN actuator capacity and a force control system. |

| |||

| Steel beam (type IPE 120) yield strain: 1.9 mm/m. Young’s modulus: 199.3 GPa. Yield strength: 383 MPa. Tensile strength: 462 MPa. | CFRP laminates - Normal modulus (150/2000 50/1.4, width: 50 mm, thickness: 1.4 mm, cross-sectional area 70 mm2, Young’s modulus: 165 GPa). - High modulus (200/2000 50/1.4, width: 50 mm, thickness: 1.4 mm, cross-sectional area 70 mm2, Young’s modulus: 205 GPa). - Ultra-High modulus (Carbolam THM 450 50 × 1.2, width: 50 mm, thickness: 1.4 mm, cross-sectional area 60 mm2, Young’s modulus: 440 GPa). | Simply supported four-point bending set-up: Two bearings at the right and left sides of the beam to restrain the vertical and lateral displacements. Only one is free to move longitudinally. Rotations about the longitudinal axis is prevented using fork constraints at both ends of the beam. The test specimens were then loaded vertically using two hydraulic actuators, each having a 100 kN static load capacity. The support span is 1200 mm, while the actuators produce a constant bending moment over a length of 400 mm in the middle of the beam. |

| [31] |

| Steel plates (210 mm long, 50 mm wide and 5 mm thick). Mechanical properties (mean elastic modulus: 195 GPa, yield stress: 359 MPa and tensile strength: 484 MPa). | Carbon fibre sheets, MBrace CF 130 (elastic modulus: 240 GPa, ultimate tensile strength: 3800 MPa and ultimate tensile elongation: 1.55%). MBrace CF 530 (elastic modulus: 640 GPa, ultimate tensile strength: 2650 MPa and ultimate tensile elongation: 0.4%). | Fatigue test: number of fatigue cycles (N) ranging from 0.5 million to 6 million at different levels of constant amplitude stress ranges. |

| [38] |

| Two steel plates (12 mm thick) are welded to a two rectangular hollow sections (70 mm × 50 mm) of 3 mm thickness. | CFRP plate | Two pull-off tests are carried out on each steel block, one on each of the two thick steel plates. |

| [39] |

| Steel plates (hot rolled structural steel HA300). The nominal yield stress is 300 MPa. The steel plates are all 20 mm thick and 50 mm width. | CFRP laminates (MBRACEs LAMINATE 460/1500). It is an ultra-high modulus laminate with a nominal elastic modulus of 460 GPa and a nominal tensile strength of 1500 MPa. The laminate thickness is 1.45 mm. | Tension test: Baldwin Universal Testing machine is used (loading rate is 2 mm/min). |

| [40] |

| Stress Range (MPa) | Un-Retrofitted | Retrofitted Beams | Ratio of Fatigue Lives |

|---|---|---|---|

| Fatigue Life (No. Cycles) | Fatigue Life (No. Cycles) | ||

| 207 | 119,140 | 379,824 | 3.2 |

| 241 | 71,278 | 241,965 | 3.4 |

| 276 | 35,710 | 105,345 | 3.0 |

| 310 | 30,216 | 75,910 | 2.5 |

| 345 | 19,068 | 54,300 | 2.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borrie, D.; Al-Saadi, S.; Zhao, X.-L.; Raman, R.K.S.; Bai, Y. Bonded CFRP/Steel Systems, Remedies of Bond Degradation and Behaviour of CFRP Repaired Steel: An Overview. Polymers 2021, 13, 1533. https://doi.org/10.3390/polym13091533

Borrie D, Al-Saadi S, Zhao X-L, Raman RKS, Bai Y. Bonded CFRP/Steel Systems, Remedies of Bond Degradation and Behaviour of CFRP Repaired Steel: An Overview. Polymers. 2021; 13(9):1533. https://doi.org/10.3390/polym13091533

Chicago/Turabian StyleBorrie, Daniel, Saad Al-Saadi, Xiao-Ling Zhao, R. K. Singh Raman, and Yu Bai. 2021. "Bonded CFRP/Steel Systems, Remedies of Bond Degradation and Behaviour of CFRP Repaired Steel: An Overview" Polymers 13, no. 9: 1533. https://doi.org/10.3390/polym13091533

APA StyleBorrie, D., Al-Saadi, S., Zhao, X.-L., Raman, R. K. S., & Bai, Y. (2021). Bonded CFRP/Steel Systems, Remedies of Bond Degradation and Behaviour of CFRP Repaired Steel: An Overview. Polymers, 13(9), 1533. https://doi.org/10.3390/polym13091533