Mycelium-Based Composites in Art, Architecture, and Interior Design: A Review

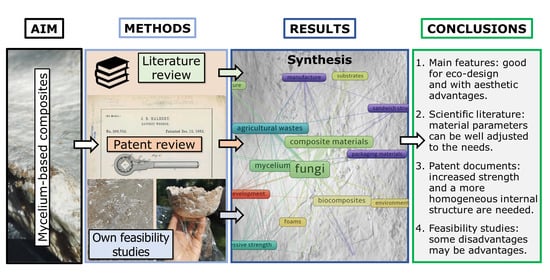

Abstract

:1. Introduction

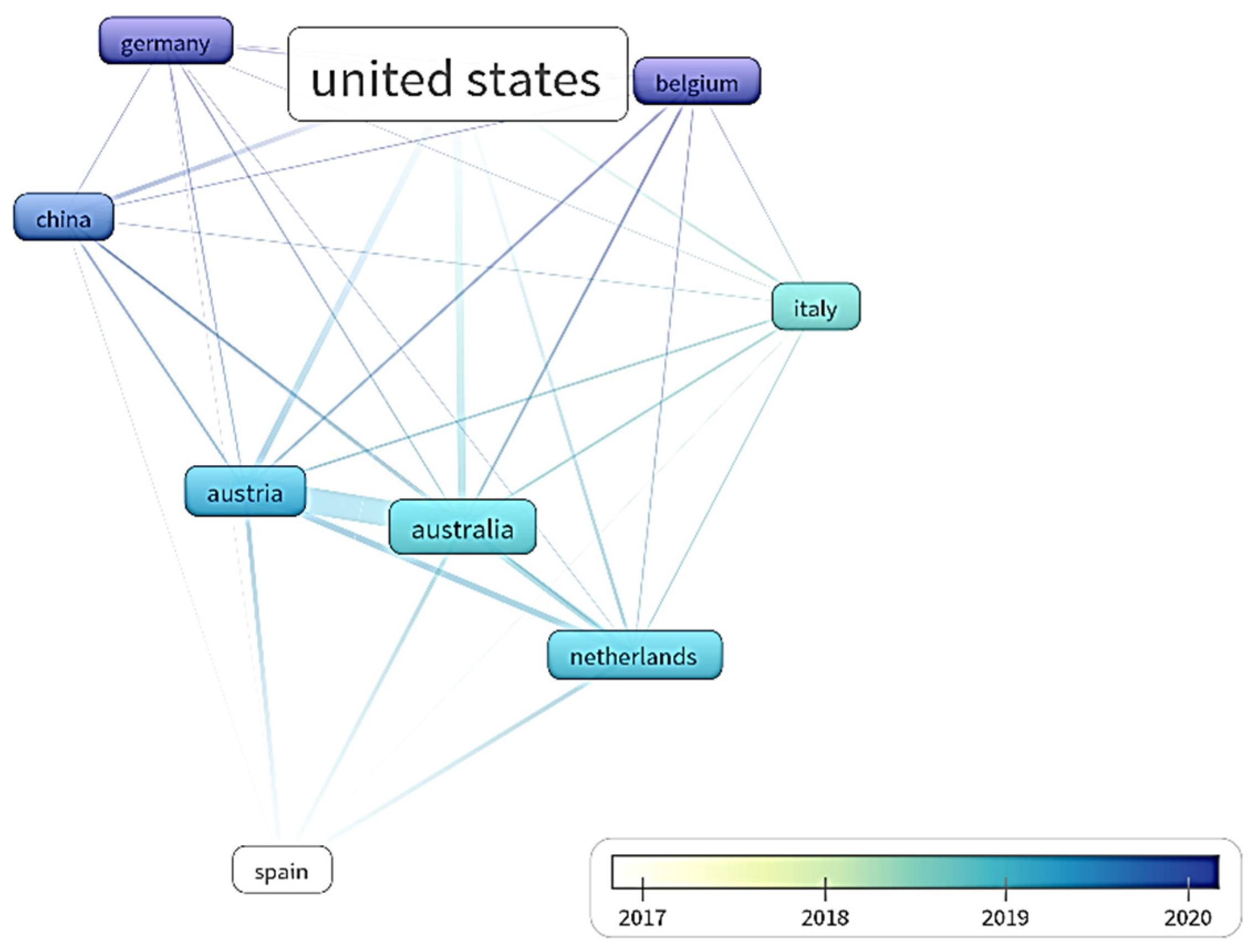

2. Results of the Literature Review

3. Results of Patents Documents Analysis

- The size of the patent family—the assumption: “only an invention with high application potential can be submitted for protection in many patent offices because the patent procedure is paid”.

- Number of citations of a patent document in other, later patent documents—the assumption: “if multiple patent documents refer to a particular document, it indicates that this document describes (and perhaps at least partially solves) a significant problem.

- (1)

- The chosen mycelium specie is pre-grown in a Petri dish with a growth medium solidified with agar.

- (2)

- The substrate for the culture of mycelium is homogenized (the substrate is a mix of selected biopolymers with defined granulation and proportion). The substrate is also sterilized to kill or deactivate all microorganisms in it.

- (3)

- The pre-grown mycelium and sterile water are added to the substrate. Additional nutrients can also be added. The inoculated substrate is packed in a sterile mould (a bag or a container).

- (4)

- The mycelium grows trough the substrate in a controlled micro-climate (temperature, air humidity, without light). The mycelium composite can be created initially in the mould to its internal reinforcement, and then outside the mould to solidify its surface.

- (5)

- The mycelium composite is sterilized to end the growth process and then dried to the target moisture content.

- (6)

- A pressing, machining, coating or other required product post-processing is applied.

4. Mycelium-Based Material in Elements of Interior Design—Case Study

5. Conclusions

- MBCs (mycelium-based composites) offer favourable production price, ecological value, and high artistic value. Their weaknesses are insufficient design properties and not fully known reliability (quality during use), therefore both scientific research and engineering creativity, which is manifested by patents documents, are heading in this direction.

- A review of the scientific literature shows that the material parameters of MBCs can be adjusted to the needs: by selecting the type of substrate and fungus species, by controlling the growth conditions, the method of inactivation of the mycelium after growth, and the drying method. In this way, it is possible to meet certain requirements, e.g., increase the structural load-bearing capacity to an acceptable level and reduce the affinity with water, and additionally improve the acoustic and thermal insulation. However, the problem is the almost infinite number of combinations: properties of the input biomaterials, characteristics of the mushroom species, and parameters during growth and subsequent processing of the MBC.

- The review of patent documents shows that two current technological challenges are related to the creation of MBCs with the properties required by the final product. Especially, looking for an effective method of increasing strength, for example by increasing the density, the search for a method of obtaining a more homogeneous internal structure.

- The described own technological experiments, consisting of the production of various everyday objects, indicate that some disadvantages of MBCs can be considered advantages. Such an unexpected advantage is the interesting and unrepeatable surface texture resulting from the natural unevenness of the internal structure of MBCs, which can be controlled to some extent.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ekblad, A.; Wallander, H.; Godbold, D.L.; Cruz, C.; Johnson, D.; Baldrian, P.; Björk, R.; Epron, D.; Kieliszewska-Rokicka, B.; Kjøller, R. The Production and Turnover of Extramatrical Mycelium of Ectomycorrhizal Fungi in Forest Soils: Role in Carbon Cycling. Plant Soil 2013, 366, 1–27. [Google Scholar] [CrossRef] [Green Version]

- Webster, J.; Weber, R. Introduction to Fungi, 3rd ed.; Cambridge University Press: Leiden, The Netherlands, 2007; ISBN 978-0-511-27783-2. [Google Scholar]

- Kavanagh, K. (Ed.) Fungi: Biology and Applications, 3rd ed.; Wiley: Hoboken, NJ, USA, 2017; ISBN 978-1-119-37416-9. [Google Scholar]

- Elsacker, E. Interdisciplinary Exploration of the Fabrication and Properties of Mycelium-Based Materials. Ph.D. Thesis, Vrije Universiteit Brussel, Brussel, Belgium, 2021. [Google Scholar]

- Ţura, D.; Wasser, S.P.; Zmitrovich, I.V. Wood-Inhabiting Fungi: Applied Aspects. In Fungi: Applications and Management Strategies; Deshmukh, S.K., Misra, J.K., Tewari, J.P., Papp, T., Eds.; Progress in Mycological Research; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2016; pp. 245–292. ISBN 978-1-4987-2492-0. [Google Scholar]

- Rothschild, L.J.; Maurer, C.; Paulino Lima, I.G.; Senesky, D.; Wipat, A.; Head, J., III. Myco-Architecture off Planet: Growing Surface Structures at Destination. NIAC 2018 Phase I Final Report; NASA Ames Research Center: Mountain View, CA, USA, 2019; p. 58. [Google Scholar]

- Heisel, F.; Lee, J.; Schlesier, K.; Rippmann, M.; Saeidi, N.; Javadian, A.; Nugroho, A.R.; Mele, T.V.; Block, P.; Hebel, D.E. Design, Cultivation and Application of Load-Bearing Mycelium Components: The MycoTree at the 2017 Seoul Biennale of Architecture and Urbanism. IJSED 2017, 6, 296–303. [Google Scholar] [CrossRef]

- Ratti, C. A Living Architecture for the Digital Era. Diségno 2019, 4, 177–188. [Google Scholar]

- Joachim, M.; Aiolova, M. Design with Life; ACTAR Publishers: New York, NY, USA, 2019; ISBN 978-1-948765-20-6. [Google Scholar]

- Goidea, A.; Floudas, D.; Andréen, D. Pulp Faction: 3d Printed Material Assemblies through Microbial Biotransformation. In Fabricate 2020: Making Resilient Architecture; Burry, J., Sabin, J., Sheil, B., Skavara, M., Eds.; Fabricate; UCL Press: London, UK, 2020; pp. 42–49. ISBN 978-1-78735-811-9. [Google Scholar]

- Dias, J. Hyper Articulated Myco-Morphs. Available online: https://www.biobabes.co.uk/mycomorphs (accessed on 27 December 2021).

- Meyer, V.; Schmidt, B.; Pohl, C.; Cerimi, K.; Schubert, B.; Weber, B.; Neubauer, P.; Junne, S.; Zakeri, Z.; Rapp, R.; et al. Mind the Fungi; Meyer, V., Rapp, R., Eds.; Universitätsverlag der TU Berlin: Berlin, Germany, 2020; ISBN 978-3-7983-3169-3. [Google Scholar]

- Sheldrake, M. Entangled Life: How Fungi Make Our Worlds, Change Our Minds & Shape Our Futures, 5th ed.; Random House: New York, NY, USA, 2020; ISBN 978-0-525-51032-1. [Google Scholar]

- Holt, G.A.; Mcintyre, G.; Flagg, D.; Bayer, E.; Wanjura, J.D.; Pelletier, M.G. Fungal Mycelium and Cotton Plant Materials in the Manufacture of Biodegradable Molded Packaging Material: Evaluation Study of Select Blends of Cotton Byproducts. J. Biobased Mat. Bioenergy 2012, 6, 431–439. [Google Scholar] [CrossRef]

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D.; Bayer, E.; McIntyre, G. An Evaluation Study of Mycelium Based Acoustic Absorbers Grown on Agricultural By-Product Substrates. Ind. Crops Prod. 2013, 51, 480–485. [Google Scholar] [CrossRef]

- Arifin, Y.H.; Yusuf, Y. Mycelium Fibers as New Resource for Environmental Sustainability. Procedia Eng. 2013, 53, 504–508. [Google Scholar] [CrossRef] [Green Version]

- Travaglini, S.; Noble, J.; Ross, P.G.; Dharan, C.K.H. Mycology Matrix Composites. In Proceedings of the American Society for Composites—Twenty-Eighth Technical Conference, State College, PA, USA, 9–11 September 2013; Bakis, C., Ed.; DEStech Publications, Inc.: Lancaster, PA, USA, 2013; Volume 1, pp. 9–11. [Google Scholar]

- Velasco, P.M.; Ortiz, M.P.M.; Giro, M.A.M.; Castelló, M.C.J.; Velasco, L.M. Development of Better Insulation Bricks by Adding Mushroom Compost Wastes. Energy Build. 2014, 80, 17–22. [Google Scholar] [CrossRef]

- Travaglini, S.; Dharan, C.K.H.; Ross, P.G. Mycology Matrix Sandwich Composites Flexural Characterization. In Proceedings of the American Society for Composites 2014—Twenty-Ninth Technical Conference on Composite Materials, La Jolla, CA, USA, 8–10 September 2014; DEStech Publications, Inc.: Lancaster, PA, USA, 2014; Volume 3, pp. 1941–1955. [Google Scholar]

- He, J.; Cheng, C.M.; Su, D.G.; Zhong, M.F. Study on the Mechanical Properties of the Latex-Mycelium Composite. AMM 2014, 507, 415–420. [Google Scholar] [CrossRef]

- Lelivelt, R.; Lindner, G.; Teuffel, P.; Lamers, H. The Production Process and Compressive Strength of Mycelium-Based Materials. In Proceedings of the First International Conference on Bio-based Building Materials, Clermont-Ferrand, France, 22–25 June 2015; Eindhoven University of Technology: Clermont-Ferrand, France, 2015; pp. 1–6. [Google Scholar]

- Travaglini, S.; Dharan, C.K.H.; Ross, P.G. Thermal Properties of Mycology Materials. In Proceedings of the American Society for Composites—Thirtieth Technical Conference, East Lansing, MI, USA, 28–30 September 2015; Xiao, X., Loos, A.C., Liu, D., Eds.; DEStech Publications: Lancaster, PA, USA, 2015; Volume 3, pp. 1453–1460. [Google Scholar]

- Jiang, L.; Walczyk, D.; McIntyre, G.; Bucinell, R. A New Approach to Manufacturing Biocomposite Sandwich Structures: Mycelium-Based Cores. In Proceedings of the ASME 2016 11th International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June–1 July 2016; American Society of Mechanical Engineers: Blacksburg, VA, USA, 2016; Volume 1, p. V001T02A025. [Google Scholar]

- López Nava, J.A.; Méndez González, J.; Ruelas Chacón, X.; Nájera Luna, J.A. Assessment of Edible Fungi and Films Bio-Based Material Simulating Expanded Polystyrene. Mater. Manuf. Processes 2016, 31, 1085–1090. [Google Scholar] [CrossRef]

- Mayoral González, E.; González Diez, I. Bacterial Induced Cementation Processes and Mycelium Panel Growth from Agricultural Waste. KEM 2016, 663, 42–49. [Google Scholar] [CrossRef]

- Ziegler, A.R.; Bajwa, S.; Holt, G.; Mcintyre, G.; Bajwa, D.S. Evaluation of Physico-Mechanical Properties of Mycelium Reinforced Green Biocomposites Made from Cellulosic Fibers. Appl. Eng. Agric. 2016, 32, 931–938. [Google Scholar] [CrossRef]

- Travaglini, S.; Dharan, C.K.H.; Ross, P.G. Manufacturing of Mycology Composites. In Proceedings of the American Society for Composites Thirty-First Technical Conference, Williamsburg, VA, USA, 19–21 September 2016; Davidson, B.D., Czabaj, M.W., Eds.; American Society for Composites (ASC): Dayton, OH, USA, 2016; Volume 4, pp. 2670–2680. [Google Scholar]

- Haneef, M.; Ceseracciu, L.; Canale, C.; Bayer, I.S.; Heredia-Guerrero, J.A.; Athanassiou, A. Advanced Materials From Fungal Mycelium: Fabrication and Tuning of Physical Properties. Sci. Rep. 2017, 7, 41292. [Google Scholar] [CrossRef]

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D.; Lara, A.J.; Tapia-Carillo, A.; McIntyre, G.; Bayer, E. An Evaluation Study of Pressure-Compressed Acoustic Absorbers Grown on Agricultural by-Products. Ind. Crops Prod. 2017, 95, 342–347. [Google Scholar] [CrossRef]

- Travaglini, S.; Dharan, C.K.H.; Ross, P.G. Biomimetic Mycology Biocomposites. In Proceedings of the 32nd Technical Conference of the American Society for Composites 2017, West Lafayette, IN, USA, 23–25 October 2017; Yu, W., Pipes, R.B., Goodsell, J., Eds.; Curran Associates, Inc.: Red Hook, NY, USA, 2017; Volume 1, pp. 409–419. [Google Scholar]

- Attias, N.; Danai, O.; Tarazi, E.; Grobman, Y. Developing Novel Applications of Mycelium Based Bio-Composite Materials for Architecture and Design. In Books of Abstracts of the Final COST Action FP1303 International Scientific Conference, Proceedings of Building with Bio-Based Materials: Best Practice and Performance Specification, Zagreb, Croatia, 6–7 September 2017; University of Zagreb Croatia: Zagreb, Croatia, 2017; pp. 76–78. [Google Scholar]

- Bajwa, D.S.; Holt, G.A.; Bajwa, S.G.; Duke, S.E.; McIntyre, G. Enhancement of Termite (Reticulitermes Flavipes L.) Resistance in Mycelium Reinforced Biofiber-Composites. Ind. Crops Prod. 2017, 107, 420–426. [Google Scholar] [CrossRef]

- Moser, F.J.; Wormit, A.; Reimer, J.J.; Jacobs, G.; Trautz, M.; Hillringhaus, F.; Usadel, B.; Löwer, M.; Beger, A.-L. Fungal Mycelium as a Building Material. In Proceedings of the IASS Annual Symposia, IASS 2017, Beijing, China, 10–14 September 2017; International Association for Shell and Spatial Structures (IASS): Hamburg, Germany, 2017; Volume 2017, pp. 1–7. [Google Scholar]

- Jiang, L.; Walczyk, D.; McIntyre, G.; Bucinell, R.; Tudryn, G. Manufacturing of Biocomposite Sandwich Structures Using Mycelium-Bound Cores and Preforms. J. Manuf. Processes 2017, 28, 50–59. [Google Scholar] [CrossRef]

- Campbell, S.; Correa, D.; Wood, D.; Menges, A. Modular Mycelia. Scaling Fungal Growth for Architectural Assembly. In Proceedings of the Computational Fabrication—eCAADe RIS 2017, Cardiff, UK, 27–28 April 2017; Spaeth, B.A., Jabi, W., Eds.; Cardiff University, Welsh School of Architecture: Cardiff, UK, 2017; pp. 125–134. [Google Scholar]

- Islam, M.R.; Tudryn, G.; Bucinell, R.; Schadler, L.; Picu, R.C. Morphology and Mechanics of Fungal Mycelium. Sci. Rep. 2017, 7, 13070. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Zhang, F.; Still, B.; White, M.; Amstislavski, P. Physical and Mechanical Properties of Fungal Mycelium-Based Biofoam. J. Mater. Civ. Eng. 2017, 29, 04017030. [Google Scholar] [CrossRef]

- Travaglini, S.; Dharan, C.K.H. Advanced Manufacturing of Mycological Bio-Based Composites. In Proceedings of the 33rd Technical Conference of the American Society for Composites 2018; DEStech Publications Inc.: Seattle, WA, USA, 2018; Volume 5, pp. 3387–3399. [Google Scholar]

- Läkk, H.; Krijgsheld, P.; Montalti, M.; Wösten, H. Fungal Based Biocomposite for Habitat Structures on the Moon and Mars. In Proceedings of the International Astronautical Congress (IAC 2018), Bremen, Germany, 1–5 October 2018; International Astronautical Federation: Paris, France, 2018; Volume 22, pp. 16102–16112. [Google Scholar]

- Xing, Y.; Brewer, M.; El-Gharabawy, H.; Griffith, G.; Jones, P. Growing and Testing Mycelium Bricks as Building Insulation Materials. IOP Conf. Ser. Earth Environ. Sci. 2018, 121, 022032. [Google Scholar] [CrossRef]

- Appels, F.V.W.; Dijksterhuis, J.; Lukasiewicz, C.E.; Jansen, K.M.B.; Wösten, H.A.B.; Krijgsheld, P. Hydrophobin Gene Deletion and Environmental Growth Conditions Impact Mechanical Properties of Mycelium by Affecting the Density of the Material. Sci. Rep. 2018, 8, 4703. [Google Scholar] [CrossRef]

- Jones, M.; Huynh, T.; John, S. Inherent Species Characteristic Influence and Growth Performance Assessment for Mycelium Composite Applications. Adv. Mater. Lett. 2018, 9, 71–80. [Google Scholar] [CrossRef]

- Islam, M.R.; Tudryn, G.; Bucinell, R.; Schadler, L.; Picu, R.C. Mechanical Behavior of Mycelium-Based Particulate Composites. J. Mater. Sci. 2018, 53, 16371–16382. [Google Scholar] [CrossRef]

- Tudryn, G.J.; Smith, L.C.; Freitag, J.; Bucinell, R.; Schadler, L.S. Processing and Morphology Impacts on Mechanical Properties of Fungal Based Biopolymer Composites. J. Polym. Environ. 2018, 26, 1473–1483. [Google Scholar] [CrossRef]

- Jones, M.; Bhat, T.; Kandare, E.; Thomas, A.; Joseph, P.; Dekiwadia, C.; Yuen, R.; John, S.; Ma, J.; Wang, C.-H. Thermal Degradation and Fire Properties of Fungal Mycelium and Mycelium—Biomass Composite Materials. Sci. Rep. 2018, 8, 17583. [Google Scholar] [CrossRef] [PubMed]

- Jones, M.; Bhat, T.; Huynh, T.; Kandare, E.; Yuen, R.; Wang, C.H.; John, S. Waste-Derived Low-Cost Mycelium Composite Construction Materials with Improved Fire Safety. Fire Mater. 2018, 42, 816–825. [Google Scholar] [CrossRef]

- Karana, E.; Blauwhoff, D.; Hultink, E.J.; Camere, S. When the Material Grows: A Case Study on Designing (with) Mycelium-Based Materials. Int. J. Des. 2018, 12, 119–136. [Google Scholar]

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D.; Greetham, L.; McIntyre, G.; Bayer, E.; Kaplan-Bie, J. Acoustic Evaluation of Mycological Biopolymer, an All-Natural Closed Cell Foam Alternative. Ind. Crops Prod. 2019, 139, 111533. [Google Scholar] [CrossRef]

- Jones, M.P.; Lawrie, A.C.; Huynh, T.T.; Morrison, P.D.; Mautner, A.; Bismarck, A.; John, S. Agricultural By-Product Suitability for the Production of Chitinous Composites and Nanofibers Utilising Trametes Versicolor and Polyporus Brumalis Mycelial Growth. Process Biochem. 2019, 80, 95–102. [Google Scholar] [CrossRef]

- Jiang, L.; Walczyk, D.; McIntyre, G.; Bucinell, R.; Li, B. Bioresin Infused Then Cured Mycelium-Based Sandwich-Structure Biocomposites: Resin Transfer Molding (RTM) Process, Flexural Properties, and Simulation. J. Clean. Prod. 2019, 207, 123–135. [Google Scholar] [CrossRef]

- Vidholdová, Z.; Kormúthová, D.; Ždinský, J.I.; Lagaňa, R. Compressive Resistance of the Mycelium Composite. Ann. Wars. Univ. Life Sci.-SGGW 2019, 107, 31–36. [Google Scholar] [CrossRef]

- Appels, F.V.W.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.B.; Dijksterhuis, J.; Krijgsheld, P.; Wösten, H.A.B. Fabrication Factors Influencing Mechanical, Moisture- and Water-Related Properties of Mycelium-Based Composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Sun, W.; Tajvidi, M.; Hunt, C.G.; McIntyre, G.; Gardner, D.J. Fully Bio-Based Hybrid Composites Made of Wood, Fungal Mycelium and Cellulose Nanofibrils. Sci. Rep. 2019, 9, 3766. [Google Scholar] [CrossRef]

- Wimmers, G.; Klick, J.; Tackaberry, L.; Zwiesigk, C.; Egger, K.; Massicotte, H. Fundamental Studies for Designing Insulation Panels from Wood Shavings and Filamentous Fungi. BioResources 2019, 14, 5506–5520. [Google Scholar] [CrossRef]

- Bruscato, C.; Malvessi, E.; Brandalise, R.N.; Camassola, M. High Performance of Macrofungi in the Production of Mycelium-Based Biofoams Using Sawdust—Sustainable Technology for Waste Reduction. J. Clean. Prod. 2019, 234, 225–232. [Google Scholar] [CrossRef]

- Attias, N.; Danai, O.; Tarazi, E.; Pereman, I.; Grobman, Y.J. Implementing Bio-Design Tools to Develop Mycelium-Based Products. Des. J. 2019, 22, 1647–1657. [Google Scholar] [CrossRef] [Green Version]

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; De Laet, L. Mechanical, Physical and Chemical Characterisation of Mycelium-Based Composites with Different Types of Lignocellulosic Substrates. PLoS ONE 2019, 14, e0213954. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Matos, M.P.; Teixeira, J.L.; Nascimento, B.L.; Griza, S.; Holanda, F.S.R.; Marino, R.H. Production of Biocomposites from the Reuse of Coconut Powder Colonized by Shiitake Mushroom. Ciênc. Agrotec. 2019, 43, e003819. [Google Scholar] [CrossRef]

- Zhang, X.; Han, C.; Wnek, G.; Yu, X. (Bill) Thermal Stability Improvement of Fungal Mycelium. In Proceedings of the Materials Science & Technology (MS&T) 2019, Portland, OR, USA, 29 September–3 October 2019; Association for Iron & Steel Technology (AIST): Warrendale, PA, USA, 2019; pp. 1367–1375. [Google Scholar]

- Bhardwaj, A.; Vasselli, J.; Lucht, M.; Pei, Z.; Shaw, B.; Grasley, Z.; Wei, X.; Zou, N. 3D Printing of Biomass-Fungi Composite Material: A Preliminary Study. Manuf. Lett. 2020, 24, 96–99. [Google Scholar] [CrossRef]

- Tacer-Caba, Z.; Varis, J.J.; Lankinen, P.; Mikkonen, K.S. Comparison of Novel Fungal Mycelia Strains and Sustainable Growth Substrates to Produce Humidity-Resistant Biocomposites. Mater. Des. 2020, 192, 108728. [Google Scholar] [CrossRef]

- Soh, E.; Chew, Z.Y.; Saeidi, N.; Javadian, A.; Hebel, D.; Le Ferrand, H. Development of an Extrudable Paste to Build Mycelium-Bound Composites. Mater. Des. 2020, 195, 109058. [Google Scholar] [CrossRef]

- Silverman, J.; Cao, H.; Cobb, K. Development of Mushroom Mycelium Composites for Footwear Products. Cloth. Text. Res. J. 2020, 38, 119–133. [Google Scholar] [CrossRef]

- Antinori, M.E.; Ceseracciu, L.; Mancini, G.; Heredia-Guerrero, J.A.; Athanassiou, A. Fine-Tuning of Physicochemical Properties and Growth Dynamics of Mycelium-Based Materials. ACS Appl. Bio Mater. 2020, 3, 1044–1051. [Google Scholar] [CrossRef]

- Zimele, Z.; Irbe, I.; Grinins, J.; Bikovens, O.; Verovkins, A.; Bajare, D. Novel Mycelium-Based Biocomposites (MBB) as Building Materials. J. Renew. Mater. 2020, 8, 1067–1076. [Google Scholar] [CrossRef]

- Ridzqo, I.F.; Susanto, D.; Panjaitan, T.H.; Putra, N. Sustainable Material: Development Experiment of Bamboo Composite Through Biologically Binding Mechanism. IOP Conf. Ser. Mater. Sci. Eng. 2020, 713, 012010. [Google Scholar] [CrossRef]

- Alves, R.M.E.; Alves, M.L.; Campos, M.J. Morphology and Thermal Behaviour of New Mycelium-Based Composites with Different Types of Substrates. In Progress in Digital and Physical Manufacturing; Almeida, H.A., Vasco, J.C., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2020; pp. 189–197. ISBN 978-3-030-29040-5. [Google Scholar]

- Bhardwaj, A.; Rahman, A.M.; Wei, X.; Pei, Z.; Truong, D.; Lucht, M.; Zou, N. 3D Printing of Biomass–Fungi Composite Material: Effects of Mixture Composition on Print Quality. JMMP 2021, 5, 112. [Google Scholar] [CrossRef]

- Saez, D.; Grizmann, D.; Trautz, M.; Werner, A. Analyzing a Fungal Mycelium and Chipped Wood Composite for Use in Construction. In Proceedings of the IASS Annual Symposium 2020/21 and the 7th International Conference on Spatial Structures Inspiring the Next Generation, Guilford, UK, 23–27 August 2021; Behnejad, S.A., Parke, G.A.R., Samavati, O.A., Eds.; IASS: Madrid, Spain, 2021; pp. 1–10. [Google Scholar]

- Müller, C.; Klemm, S.; Fleck, C. Bracket Fungi, Natural Lightweight Construction Materials: Hierarchical Microstructure and Compressive Behavior of Fomes Fomentarius Fruit Bodies. Appl. Phys. A 2021, 127, 178. [Google Scholar] [CrossRef]

- Irbe, I.; Filipova, I.; Skute, M.; Zajakina, A.; Spunde, K.; Juhna, T. Characterization of Novel Biopolymer Blend Mycocel from Plant Cellulose and Fungal Fibers. Polymers 2021, 13, 1086. [Google Scholar] [CrossRef] [PubMed]

- Sivaprasad, S.; Byju, S.K.; Prajith, C.; Shaju, J.; Rejeesh, C.R. Development of a Novel Mycelium Bio-Composite Material to Substitute for Polystyrene in Packaging Applications. Mater. Today Proc. 2021, 47, 5038–5044. [Google Scholar] [CrossRef]

- Jauk, J.; Vašatko, H.; Gosch, L.; Christian, I.; Klaus, A.; Stavric, M. Digital Fabrication of Growth-Combining Digital Manufacturing of Clay with Natural Growth of Mycelium. In Proceedings of the 26th CAADRIA Conference, Hong Kong, China, 29 March–1 April 2021; Association for Computer Aided Architectural Design Research in Asia (CAADRIA): Hong Kong, China, 2021; Volume 1, pp. 753–762. [Google Scholar]

- Nashiruddin, N.I.; Chua, K.S.; Mansor, A.F.; Rahman, R.A.; Lai, J.C.; Wan Azelee, N.I.; El Enshasy, H. Effect of Growth Factors on the Production of Mycelium-Based Biofoam. Clean Technol. Environ. Policy 2021. [Google Scholar] [CrossRef]

- Răut, I.; Călin, M.; Vuluga, Z.; Oancea, F.; Paceagiu, J.; Radu, N.; Doni, M.; Alexandrescu, E.; Purcar, V.; Gurban, A.-M.; et al. Fungal Based Biopolymer Composites for Construction Materials. Materials 2021, 14, 2906. [Google Scholar] [CrossRef] [PubMed]

- Elsacker, E.; Søndergaard, A.; Van Wylick, A.; Peeters, E.; De Laet, L. Growing Living and Multifunctional Mycelium Composites for Large-Scale Formwork Applications Using Robotic Abrasive Wire-Cutting. Constr. Build. Mater. 2021, 283, 122732. [Google Scholar] [CrossRef]

- Santos, I.S.; Nascimento, B.L.; Marino, R.H.; Sussuchi, E.M.; Matos, M.P.; Griza, S. Influence of Drying Heat Treatments on the Mechanical Behavior and Physico-Chemical Properties of Mycelial Biocomposite. Compos. Part B Eng. 2021, 217, 108870. [Google Scholar] [CrossRef]

- Jose, J.; Uvais, K.N.; Sreenadh, T.S.; Deepak, A.V.; Rejeesh, C.R. Investigations into the Development of a Mycelium Biocomposite to Substitute Polystyrene in Packaging Applications. Arab J. Sci. Eng. 2021, 46, 2975–2984. [Google Scholar] [CrossRef]

- Stelzer, L.; Hoberg, F.; Bach, V.; Schmidt, B.; Pfeiffer, S.; Meyer, V.; Finkbeiner, M. Life Cycle Assessment of Fungal-Based Composite Bricks. Sustainability 2021, 13, 11573. [Google Scholar] [CrossRef]

- Adamatzky, A.; Gandia, A. Living Mycelium Composites Discern Weights via Patterns of Electrical Activity. J. Biores. Bioprod. 2021. [Google Scholar] [CrossRef]

- Chan, X.Y.; Saeidi, N.; Javadian, A.; Hebel, D.E.; Gupta, M. Mechanical Properties of Dense Mycelium-Bound Composites under Accelerated Tropical Weathering Conditions. Sci. Rep. 2021, 11, 22112. [Google Scholar] [CrossRef]

- Gou, L.; Li, S.; Yin, J.; Li, T.; Liu, X. Morphological and Physico-Mechanical Properties of Mycelium Biocomposites with Natural Reinforcement Particles. Constr. Build. Mater. 2021, 304, 124656. [Google Scholar] [CrossRef]

- Lee, T.; Choi, J. Mycelium-Composite Panels for Atmospheric Particulate Matter Adsorption. Results Mater. 2021, 11, 100208. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, X.; Han, C.; Li, Y.; Price, E.; Wnek, G.; Liao, Y.-T.T.; Yu, X. (Bill) Novel Strategies to Grow Natural Fibers with Improved Thermal Stability and Fire Resistance. J. Clean. Prod. 2021, 320, 128729. [Google Scholar] [CrossRef]

- Kuribayashi, T.; Lankinen, P.; Hietala, S.; Mikkonen, K.S. Dense and Continuous Networks of Aerial Hyphae Improve Flexibility and Shape Retention of Mycelium Composite in the Wet State. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106688. [Google Scholar] [CrossRef]

- Attias, N.; Danai, O.; Abitbol, T.; Tarazi, E.; Ezov, N.; Pereman, I.; Grobman, Y.J. Mycelium Bio-Composites in Industrial Design and Architecture: Comparative Review and Experimental Analysis. J. Clean. Prod. 2020, 246, 119037. [Google Scholar] [CrossRef]

- Jiang, L.; Walczyk, D.; Mooney, L.; Putney, S. Manufacturing of Mycelium-Based Biocomposites. In Proceedings of the International SAMPE Technical Conference, Covina, CA, USA, 6–9 May 2013; Beckwith, S.W., Ed.; Society for the Advancement of Material and Process Engineering: Long Beach, CA, USA, 2013; pp. 1944–1955. [Google Scholar]

- Jiang, L.; Walczyk, D.; McIntyre, G.; Chan, W.K. Cost Modeling and Optimization of a Manufacturing System for Mycelium-Based Biocomposite Parts. J. Manuf. Syst. 2016, 41, 8–20. [Google Scholar] [CrossRef]

- Da Conceição Van Nieuwenhuizen, J.B.; Blauwhoff, D.R.L.M.; De Werdt, M.F.C.; Van Der Zanden, W.G.N.; Van Rhee, D.J.J.L.; Bottger, W.O.J. The Compressive Strength of Mycelium Derived from a Mushroom Production Process. Acad. J. Civ. Eng. 2017, 265–271. [Google Scholar] [CrossRef]

- Jones, M.; Huynh, T.; Dekiwadia, C.; Daver, F.; John, S. Mycelium Composites: A Review of Engineering Characteristics and Growth Kinetics. J. Bionanosci. 2017, 11, 241–257. [Google Scholar] [CrossRef]

- Abhijith, R.; Ashok, A.; Rejeesh, C.R. Sustainable Packaging Applications from Mycelium to Substitute Polystyrene: A Review. Mater. Today Proc. 2018, 5, 2139–2145. [Google Scholar] [CrossRef]

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Pellegrini, M.; Savino, E. Physico-Mechanical and Thermodynamic Properties of Mycelium-Based Biocomposites: A Review. Sustainability 2019, 11, 281. [Google Scholar] [CrossRef] [Green Version]

- Travaglini, S.; Parlevliet, P.P.; Dharan, C.K.H. Bio-Based Mycelium Materials for Aerospace Applications. In Proceedings of the American Society for Composites—4th Technical Conference, ASC 2019, Atlanta, GA, USA, 23–25 September 2019; DEStech Publications, Inc.: Lancaster, PA, USA, 2019. [Google Scholar]

- Cerimi, K.; Akkaya, K.C.; Pohl, C.; Schmidt, B.; Neubauer, P. Fungi as Source for New Bio-Based Materials: A Patent Review. Fungal Biol. Biotechnol. 2019, 6, 17. [Google Scholar] [CrossRef] [Green Version]

- Robertson, O.; Høgdal, F.; Mckay, L.; Lenau, T. Fungal Future: A Review of Mycelium Biocomposites as an Ecological Alternative Insulation Material. In Proceedings of the Balancing Innovation and operation, Lyngby, Denmark, 12–14 August 2020; Design Society: Glasgow, UK, 2020; Volume 101, pp. 55–68. [Google Scholar]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered Mycelium Composite Construction Materials from Fungal Biorefineries: A Critical Review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Van Wylick, A.; Ruytinx, J.; De Laet, L.; Peeters, E. A Comprehensive Framework for the Production of Mycelium-Based Lignocellulosic Composites. Sci. Total Environ. 2020, 725, 138431. [Google Scholar] [CrossRef]

- Manan, S.; Ullah, M.W.; Ul-Islam, M.; Atta, O.M.; Yang, G. Synthesis and Applications of Fungal Mycelium-Based Advanced Functional Materials. J. Bioresour. Bioprod. 2021, 6, 1–10. [Google Scholar] [CrossRef]

- Feijóo-Vivas, K.; Bermúdez-Puga, S.A.; Rebolledo, H.; Figueroa, J.M.; Zamora, P.; Naranjo-Briceño, L. Bioproductos Desarrollados a Partir de Micelio de Hongos: Una Nueva Cultura Material y Su Impacto En La Transición Hacia Una Economía Sostenible. RB 2021, 6, 1637–1652. [Google Scholar] [CrossRef]

- Ghazvinian, A. A Sustainable Alternative to Architectural Materials: Mycelium-Based Bio-Composites. In Proceedings of the Divergence in Architectural Research, Atlanta, GA, USA, 15 February 2021; Georgia Institute of Technology: Atlanta, GA, USA; pp. 159–167. [Google Scholar]

- Rafiee, K.; Kaur, G.; Brar, S.K. Fungal Biocomposites: How Process Engineering Affects Composition and Properties? Bioresour. Technol. Rep. 2021, 14, 100692. [Google Scholar] [CrossRef]

- Yang, L.; Park, D.; Qin, Z. Material Function of Mycelium-Based Bio-Composite: A Review. Front. Mater. 2021, 8, 737377. [Google Scholar] [CrossRef]

- Angelova, G.V.; Brazkova, M.S.; Krastanov, A.I. Renewable Mycelium Based Composite–Sustainable Approach for Lignocellulose Waste Recovery and Alternative to Synthetic Materials—A Review. Z. Nat. C 2021, 76, 431–442. [Google Scholar] [CrossRef]

- Gandia, A.; van den Brandhof, J.G.; Appels, F.V.W.; Jones, M.P. Flexible Fungal Materials: Shaping the Future. Trends Biotechnol. 2021, 39, 1321–1331. [Google Scholar] [CrossRef]

- Javadian, A.; Ferrand, H.L.; Hebel, D.E.; Saeidi, N. Application of Mycelium-Bound Composite Materials in Construction Industry: A Short Review. SOJ Mater. Sci. Eng. 2020, 7, 1–9. [Google Scholar]

- Bayer, E.; McIntyre, G.; Swersey, B.L. Method for Producing Grown Materials and Products Made Thereby. Patent Application US 2008/0145577, 30 March 2016. [Google Scholar]

- Smith, M.J.; Goldman, J.; Boulet-Audet, M.; Tom, S.J.; Li, H.; Hurlburt, T.J. Composite Material, and Methods for Production Thereof. U.S. Patent 11015059 B2, 25 May 2021. [Google Scholar]

- Bayer, E.; McIntyre, G. Method for Producing Grown Materials and Products Made Thereby. U.S. Patent 9485917 B2, 8 November 2016. [Google Scholar]

- Bayer, E.; McIntyre, G. Method for Producing Rapidly Renewable Chitinous Material Using Fungal Fruiting Bodies and Product Made Thereby. U.S. Patent 8001719 B2, 23 August 2011. [Google Scholar]

- Kalisz, R.E.; Rocco, C.A.; Tengler, E.C.J.; Petrella-Lovasik, R.L. Injection Molded Mycelium and Method. U.S. Patent 8313939 B2, 20 November 2012. [Google Scholar]

- Rocco, C.A.; Kalisz, R.E. Mycelium Structure with Self-Attaching Coverstock and Method. U.S. Patent 8298810 B2, 30 October 2012. [Google Scholar]

- Kalisz, R.E.; Rocco, C.A. Method of Making Foamed Mycelium Structure. U.S. Patent 8227233 B2, 24 July 2012. [Google Scholar]

- Kalisz, R.E.; Rocco, C.A. Method of Making Molded Part Comprising Mycelium Coupled to Mechanical Device. U.S. Patent 8227224 B2, 24 July 2012. [Google Scholar]

- Rocco, C.A.; Kalisz, R.E. Plasticized Mycelium Composite and Method. U.S. Patent 8227225 B2, 24 July 2012. [Google Scholar]

- Rocco, C.A.; Kalisz, R.E. Mycelium Structures Containing Nanocomposite Materials and Method. U.S. Patent 8283153 B2, 9 October 2012. [Google Scholar]

- Kalisz, R.E.; Rocco, C.A. Method of Making a Hardened Elongate Structure from Mycelium. U.S. Patent 8298809 B2, 30 October 2012. [Google Scholar]

- Kalisz, R.E.; Rocco, C.A. The Sheet Stock Mycelium of Cutting and Method. Patent CN 102329512 B, 1 June 2016. [Google Scholar]

- Ross, P. Method for Producing Fungus Structures. U.S. Patent 9410116 B2, 9 August 2016. [Google Scholar]

- McIntyre, G.; Bayer, E.; Flagg, D. Method of Producing A Chitinous Polymer Derived from Fungal Mycelium. U.S. Patent 9879219 B2, 30 January 2018. [Google Scholar]

- Bayer, E.; Mcintyre, G. Method for Making Dehydrated Mycelium Elements and Product Made Thereby. Patent CA 2834095 C, 11 December 2018. [Google Scholar]

- McIntyre, G.; Bayer, E.; Palazzolo, A. Method of Growing Mycological Biomaterials. U.S. Patent 10154627 B2, 18 December 2018. [Google Scholar]

- Laboutiere, L.; Lemiere, E.; Mechineau, A. Process for Manufacturing a Composite Material Based On Natural Fibres Seeded with Mycelium and Part Obtained with Such a Process. Patent FR 3006693 B1, 1 April 2016. [Google Scholar]

- Bayer, E.; McIntyre, G. Method of Growing Electrically Conductive Tissue. U.S. Patent 9253889 B2, 2 February 2016. [Google Scholar]

- Winiski, J.M.; Hook, S.S.V. Tissue Morphology Produced with the Fungus Pycnoporus Cinnabarinus. U.S. Patent 9085763 B2, 21 July 2015. [Google Scholar]

- Bayer, E.; Mcintyre, G.; Swersey, B. Self Supporting Composite Material. Patent AU 2013/251269 B2, 1 October 2015. [Google Scholar]

- McIntyre, G.R.; Tudryn, G.; Betts, J.; Winiski, J. Stiff Mycelium Bound Part and Method of Producing Stiff Mycelium Bound Parts. U.S. Patent 10144149 B2, 4 December 2018. [Google Scholar]

- Bayer, E.; McIntyre, G.R. Method for Growing Mycological Materials. U.S. Patent 9394512 B2, 19 July 2016. [Google Scholar]

- Schaak, D.D.; Lucht, M.J. Biofilm Treatment of Composite Materials Containing Mycelium. U.S. Patent 9469838 B2, 18 October 2016. [Google Scholar]

- Chen, Q.; Peng, Z.; Chen, Q.; Liu, H.; Chen, C.; Zhang, Y.; Liu, Y. Production Method for Biomass Packing Material. Patent CN 105292758 B, 8 December 2017. [Google Scholar]

- Betts, J.D.; Mcintyre, G.R.; Mooney, L.; Tudryn, G.J. Method of Manufacturing a Stiff Engineered Composite. AU 2015/271912 B2, 20 February 2020. [Google Scholar]

- Winiski, J.; Hook, S.V.; Lucht, M.; McIntyre, G. Process for Solid-State Cultivation of Mycelium on a Lignocellulose Substrate. U.S. Patent 9914906 B2, 13 March 2018. [Google Scholar]

- Deng, Y.; Xu, Y.; Gao, C.; Yu, S.; Dong, W. Method for Preparing Degradable Buffer Material by Using Macro Fungi Mycelia. Patent CN 106148199 B, 18 October 2019. [Google Scholar]

- Chen, Q.; Peng, Z.; Chen, Q.; Liu, H.; Chen, C.; Zhang, Y.; Liu, Y. Using Bagasse as Fungi Based Biomass Packaging Material of Major Ingredient and Preparation Method Thereof. Patent CN 106633989 B, 24 May 2019. [Google Scholar]

- Amstislavski, P.; Yang, Z.; White, M.D. Thermal Insulation Material from Mycelium and Forestry Byproducts. U.S. Patent 10604734 B2, 31 March 2020. [Google Scholar]

- Lee, B.G. An Eco-Friendly Packing Materials Comprising Mushroom Mycelium and the Process for the Preparation Thereof. Patent KR 102256335 B1, 26 May 2021. [Google Scholar]

- Sydor, M. Geometry of Wood Screws: A Patent Review. Eur. J. Wood Prod. 2019, 77, 93–103. [Google Scholar] [CrossRef] [Green Version]

- Bayer, E.; McIntyre, G. Method for Making Dehydrated Mycelium Elements and Product Made Thereby. Patent Application US 20120270302, 25 October 2012. [Google Scholar]

- Kaplan-Bie, J.H.; Bonesteel, I.T.; Greetham, L.; McIntyre, G.R. Increased Homogeneity of Mycological Biopolymer Grown into Void Space. Patent Application WO 2019/099474 A1, 23 May 2019. [Google Scholar]

- Ross, P. Method for Producing Fungus Structures. Patent Application US 2012/0135504 A1, 9 August 2016. [Google Scholar]

- Kaplan-Bie, J.H. Solution Based Post-Processing Methods for Mycological Biopolymer Material and Mycological Product Made Thereby. Patent Application US 2018/0282529 A1, 4 October 2018. [Google Scholar]

- Carlton, A.; Bayer, E.; McIntyre, G.; Kaplan-Bie, J. Method of Producing a Mycological Product and Product Made Thereby. Patent Application US 2020/0024577 A1, 23 January 2020. [Google Scholar]

- Elsacker, E.; Peters, K.; Poncelet, W. Hard Mycelium Materials Manual; Manuals & guides; BioFabForum: Sint-Denijs-Westrem, Belgium, 2018. [Google Scholar]

- Branowski, B.; Zabłocki, M.; Sydor, M. Experimental Analysis of New Furniture Joints. Bioresources 2018, 13, 370–382. [Google Scholar] [CrossRef] [Green Version]

- Branowski, B.; Starczewski, K.; Zabłocki, M.; Sydor, M. Design Issues of Innovative Furniture Fasteners for Wood-Based Boards. Bioresources 2020, 15, 8472–8495. [Google Scholar] [CrossRef]

- Sydor, M.; Wieloch, G. Construction Properties of Wood Taken into Consideration in Engineering Practice. Drewno 2009, 52, 63–73. [Google Scholar]

- Antov, P.; Savov, V. Possibilities for Manufacturing Eco-Friendly Medium Density Fibreboards from Recycled Fibres—A Review. In Proceedings of the 30th International Conference on Wood Science and Technology, ICWST 2019 and 70th Anniversary of Drvna industrija Journal: Implementation of Wood Science in Woodworking Sector, Zagreb, Croatia, 12–13 December 2019; Lucic, R.B., Zivkovic, V., Barcic, A.P., Vlaovic, Z., Eds.; University of Zagreb, Faculty of Forestry: Zagreb, Croatia, 2019; pp. 18–24. [Google Scholar]

- Branowski, B.; Zabłocki, M.; Sydor, M. The Material Indices Method in the Sustainable Engineering Design Process: A Review. Sustainability 2019, 11, 5465. [Google Scholar] [CrossRef] [Green Version]

- Vukoje, M.; Itrić Ivanda, K.; Kulčar, R.; Marošević Dolovski, A. Spectroscopic Stability Studies of Pressure Sensitive Labels Facestock Made from Recycled Post-Consumer Waste and Agro-Industrial By-Products. Forests 2021, 12, 1703. [Google Scholar] [CrossRef]

- Jivkov, V.; Simeonova, R.; Antov, P.; Marinova, A.; Petrova, B.; Kristak, L. Structural Application of Lightweight Panels Made of Waste Cardboard and Beech Veneer. Materials 2021, 14, 5064. [Google Scholar] [CrossRef] [PubMed]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of Eco-Friendly Particleboards Bonded with Lignosulfonate-Urea-Formaldehyde Adhesives and PMDI as a Crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef] [PubMed]

- Antov, P.; Savov, V.; Trichkov, N.; Krišťák, Ľ.; Réh, R.; Papadopoulos, A.N.; Taghiyari, H.R.; Pizzi, A.; Kunecová, D.; Pachikova, M. Properties of High-Density Fiberboard Bonded with Urea–Formaldehyde Resin and Ammonium Lignosulfonate as a Bio-Based Additive. Polymers 2021, 13, 2775. [Google Scholar] [CrossRef]

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative Lignocellulosic Raw Materials in Particleboard Production: A Review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

| Year | Title | Type | No. of Citations | Reference |

|---|---|---|---|---|

| 2017 | Advanced Materials from Fungal Mycelium: Fabrication and Tuning of Physical Properties | original | 128 | [28] |

| 2017 | Morphology and mechanics of fungal mycelium | original | 80 | [36] |

| 2017 | Mycelium composites: A review of engineering characteristics and growth kinetics | review | 74 | [90] |

| 2012 | Fungal mycelium and cotton plant materials in the manufacture of biodegradable moulded packaging material: Evaluation study of select blends of cotton by-products | original | 74 | [14] |

| 2019 | Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites | original | 66 | [52] |

| Fungi | Substrate | Product/Application | Main Results (MBC = Mycelium-Based Composites) | Reference |

|---|---|---|---|---|

| Ganoderma sp. | Cotton-based (carpel, seed hull) starch, and gypsum | Packaging material | MBC meets or exceeds the characteristics of extruded polystyrene foam | [14] |

| Not specified (possibly as [14]) | Rice straw, hemp seed, kenaf fibre, switch grass, sorghum fibre, cotton bur fibre, flax shive | Insulation panel | Optimal performance at the noise frequency of 1000 Hz. MBC are comparable to polyurethane foam board and are better than plywood | [15] |

| G. lucidum, P. ostreatus | Cellulose and potato-dextrose broth (PDB) | Fibrous mycelium film | The substrate should be homogeneous. The PDB in the substrate increases the stiffness of MBC | [28] |

| T. versicolor | Glass fines, wheat grains, and rice hulls | Fire safe mycelium biocomposites | MBC are safer than the typical construction materials: producing much lower heat release rates, less smoke and CO2 and longer time to flashover. Composites with glass fines had the best fire performance | [46] |

| T. ochracea, P. ostreatus | Beech sawdust, rapeseed straw, bran. Non-woven cotton fibre | Board | Straw-based mycelium composites are stiffer and less moisture-resistant than cotton based | [52] |

| T. versicolor, P. brumalis | Wheat straw, rice hulls, sugarcane bagasse, blackstrap molasses, wheat grains, malt extract | Pure mycelium | Mycelium grew slow on rice hull, sugarcane bagasse and wheat straw. Liquid blackstrap molasses accelerates growth, outperforming laboratory malt extracts. | [49] |

| T. versicolor | Flax dust, flax long, wheat straw dust, wheat straw, hemp fibres and pine wood shavings | Thermal insulation | The thermal conductivity and water absorption of MBCs are comparable to those of rock wool, glass wool, and extruded polystyrene. The mechanical properties depend more on the fibre arrangement than on the chemical composition of the fibres | [57] |

| Not specified (white-rot basidiomycete mycelium) | Mixture of spruce, pine, and fir | Particleboard | Cellulose nanofibers added to the substrate improved the mechanical properties of MBC by 5% | [53] |

| P. ostreatus, F. oxysporum | Sodium silicate | Pure mycelium | 3% sodium silicate improve thermal stability. The P. ostreatus compared to the F. oxysporum beter improve material thermal stability (higher decomposition temperature and residual weight, lower degradation rate) | [59,84] |

| G. lucidum, P. ostreatus | Clay, sawdust, bleached and unbleached cellulose | Printed cylinders | The mycelium improves the 3D printing (better water resistance, material stiffness and surface hardness) | [73] |

| Year | Reference | No. of Cited Documents | No. of Citations in Scopus | Main Findings |

|---|---|---|---|---|

| 2016 | [88] | 32 | 22 | A production cost model is described which includes labour, material and overhead costs for structured sandwich products produced from MBCs. |

| 2017 | [90] | 170 | 74 | 1. MBCs are kind of biopolymer foam, but most studies admit that mechanical performance can be improved in the future. 2. Current use is limited to the packaging and chosen construction applications. New applications have been proposed (acoustic dampers, super absorbents, paper, textiles, structural and electronic parts). |

| 2018 | [91] | 21 | 34 | 1. MBCs can be used for a variety of purposes with the advantage of a lower cost and the better disposal than polystyrene that is an environmental problem. 2. The biggest challenge is the negative public perception of fungus-derived products. |

| 2019 | [94] | 11 | 26 | MBCs are profitable renewable and degradable material and have the potential to replace petroleum-based materials. |

| 2019 | [92] | 108 | 37 | Improvement in know-how is expected to improve the mechanical properties and to standardize the productive process, whereas insulation and thermal properties already have shown competitive results. |

| 2020 | [86] | 58 | 21 | 1. There is a correlation between raw input material composition and final material properties. 2. MBCs have implications for sustainable architecture and products. 3. The unique aesthetics of MBCs should be further explored and more clearly identified. |

| 2020 | [96] | 80 | 44 | 1. Fungal biorefinery upcycles by-products into cheap and sustainable composite materials. 2. Can replace foam, timber and plastic insulation, door cores, panels, flooring, furnishings. 3. Low density and thermal conductivity, high acoustic absorption, and fire safety. 4. MBCs are suitable as thermal and acoustic insulation foams. |

| 2021 | [98] | 77 | 6 | 1. MBCs are more suitable for thermal and acoustic insulation than synthetic foam and wood fibres. 2. MBCs are stiff, lightweight and biodegradable, thus are an alternative to petroleum-based packaging materials. |

| 2021 | [101] | 101 | 0 | The process of engineering affects the properties of MBCs. Bioreactor designs such as tray, packed bed and millilitre reactors, influence of mycelium growth conditions and strategies for controlling mycelium microenvironment are discussed to allow optimal process development. |

| 2021 | [102] | 118 | 0 | 1. MBCs are advantageous as packaging materials with sufficient acoustic, and thermal insulation, slightly worse than expanded polystyrene. 2. The standardized process to produce an optimized material property has yet to be identified, production is less standardized than conventional engineering materials, and it is not clear how to customize the substrates for a particular species of fungi to optimize the composite mechanics. |

| 2021 | [103] | 80 | 0 | 1. MBCs support a circular economy. 2. Finding the ways of enhancing their physicochemical properties will expand the application areas. 3. The properties of MBCs are competitive with those of synthetic polymers used in construction, interior architecture, and other industries. |

| 2021 | [104] | 94 | 2 | With the wide variety of fungal species and substrates available, MBCs can improve environmental sustainability of many industrial products. |

| Order No. | Patent No., Application Year–Granted Year, Reference | Details |

|---|---|---|

| 1 | US 9,485,917 B2, 2007–2016, [108] | ED (Ecovative Design LLC). Method for producing grown materials and products made thereby |

| 2 | US 8,001,719 B2, 2009–2011, [109] | ED. Method for producing rapidly renewable chitinous material using fungal fruiting bodies and product made thereby |

| 3 | US 8,313,939 B2, 2010–2012, [110] | FGT, ACH (Ford Global Technologies LLC, Automotive Components Holdings LLC). A method of making a moulded automotive part with a liquid fungal mixture. |

| 4 | US 8,298,810 B2, 2010–2012, [111] | |

| 5 | US 8,227,233 B2 [112] | |

| 6 | US 8,227,224 B2 [113] | FGT, ACH. Method of making moulded part comprising mycelium coupled to mechanical device |

| 7 | US 8,227,225 B2 [114] | FGT, ACH. Plasticized mycelium composite and method |

| 8 | US 8,283,153 B2 [115] | FGT, ACH. Mycelium structures containing nanocomposite materials and method |

| 9 | US 8,298,809 B2 [116] | FGT, ACH. Method of making a hardened elongate structure from mycelium |

| 10 | CN 102,329,512 B [117] | Ford Global Technologies LLC. The sheet stock mycelium of cutting and method |

| 11 | US 9,410,116 B2, 2011–2016, [118] | Mycoworks Inc. building materials |

| 12 | US 9,879,219 B2, 2012–2018, [119] | ED. A method of producing a chitinous polymer derived from fungal growth |

| 13 | CA 2,834,095 C, 2012–2018, [120] | ED. Dehydrated mycelium panels. |

| 14 | US 10,154,627 B2, 2013–2018, [121] | ED. Growing mycological biomaterials in tools that are consumed or enveloped during the growth process |

| 15 | FR 3,006,693 B1 2013–2016, [122] | Menuiseries Elva. A method of producing a composite material based on natural fibres inoculated with mycelium and parts obtained with this method |

| 16 | US 9,253,889 B2 2012–2016 [123] | ED. Sheet built-in an electrical circuit |

| 17 | US 9,085,763 B2, 2013–2015, [124] | ED. Production dehydrated mycelium elements to form tissue morphology using Pycnoporus cinnabarinus |

| 18 | AU 2013/251269 B2, 2013–2015, [125] | ED. Self-supporting composite material |

| 19 | US 10,144,149 B2, 2014–2018, [126] | ED. Stiff mycelium bound part and method of producing stiff mycelium bound parts |

| 20 | US 9,394,512 B2, 2015–2016, [127] | ED. Method for growing mycological materials |

| 21 | US 9,469,838 B2, 2015–2016, [128] | Mycoworks Inc. Set of mycelium-based materials with wood timber |

| 22 | CN 105,292,758 B 2016–2017, [129] | Shenzhen Zeqingyuan Technology Dev Service Co Ltd., Univ Sichuan Agricultural. Production method for biomass packing material |

| 23 | AU 2015/271912 B2, 2015–2020, [130] | ED. Method of manufacturing a stiff engineered composite |

| 24 | US 9,914,906 B2, 2016–2018, [131] | ED. Process for solid-state cultivation of mycelium on a lignocellulose substrate |

| 25 | CN 106,148,199 B, 2016–2019, [132] | Jiangxi University of Technology. Agricultural waste-based mycelium material with good a cushion performance and mechanical property |

| 26 | CN 106,633,989 B, 2016–2019, [133] | Shenzhen Zeqingyuan Technology Development Service Co Ltd. Using bagasse as fungi-based biomass packaging material of major ingredient and preparation method thereof |

| 27 | US 10,604,734 B2, 2017–2020, [134] | University of Alaska Anchorage. Thermal insulation material from mycelium and forestry by-products |

| 28 | KR 102,256,335 B1, 2019–2021, [135] | Lee Beom Geun. Eco-friendly packing materials comprising mushroom mycelium and the process for the preparation thereof |

| 29 | US 11,015,059 B2, 2019–2021, [107] | Bolt Threads Inc. Composite material, and methods for production thereof |

| No. | Patent Document | Extended Patent Family Size | Number of Citations of the Patent Document in Other Patent Documents |

|---|---|---|---|

| 1 | US 2008/0145577 A1 “Method for producing grown materials and products made thereby” [106] | 43 | 44 |

| 2 | US 2012/0270302 A1 “Method for Making Dehydrated Mycelium Elements and Product Made Thereby” [137] | 15 | 4 |

| 3 | WO 2019/099474 A1 “Increased Homogeneity of Mycological Biopolymer Grown into Void Space” [138] | 12 | 8 |

| 4 | US 2012/0135504 A1 “Method for Producing Fungus Structures” [139] | 11 | 20 |

| 5 | US 2018/0282529 A1 “Solution Based Post-Processing Methods for Mycological Biopolymer Material and Mycological Product Made Thereby” [140] | 9 | 5 |

| 6 | US 2020/0024577 A1 “Method of Producing a Mycological Product and Product Made Thereby” [141] | 7 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sydor, M.; Bonenberg, A.; Doczekalska, B.; Cofta, G. Mycelium-Based Composites in Art, Architecture, and Interior Design: A Review. Polymers 2022, 14, 145. https://doi.org/10.3390/polym14010145

Sydor M, Bonenberg A, Doczekalska B, Cofta G. Mycelium-Based Composites in Art, Architecture, and Interior Design: A Review. Polymers. 2022; 14(1):145. https://doi.org/10.3390/polym14010145

Chicago/Turabian StyleSydor, Maciej, Agata Bonenberg, Beata Doczekalska, and Grzegorz Cofta. 2022. "Mycelium-Based Composites in Art, Architecture, and Interior Design: A Review" Polymers 14, no. 1: 145. https://doi.org/10.3390/polym14010145

APA StyleSydor, M., Bonenberg, A., Doczekalska, B., & Cofta, G. (2022). Mycelium-Based Composites in Art, Architecture, and Interior Design: A Review. Polymers, 14(1), 145. https://doi.org/10.3390/polym14010145