Thermal, Mechanical, Morphological and Aesthetical Properties of Rotational Molding PE/Pine Wood Sawdust Composites

Abstract

:1. Introduction

2. Materials and Methods

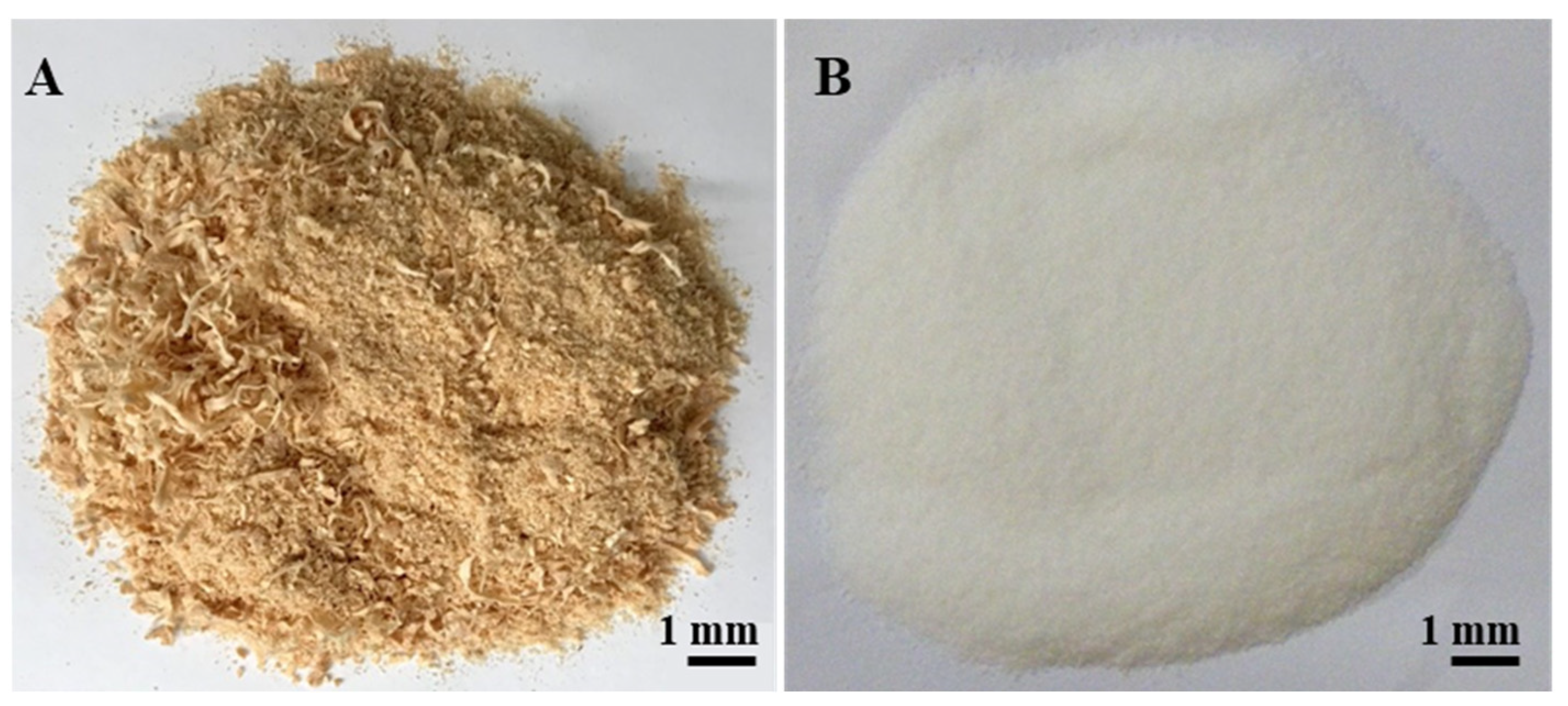

2.1. Pine Wood Sawdust and Polymer Materials

2.2. Apparent Density

2.3. Thermal Properties

2.4. Heat Treatment and Color Determination

2.5. Compounding of Materials and Processing of Parts

2.6. Microscopy Analysis

2.7. Mechanical Tests

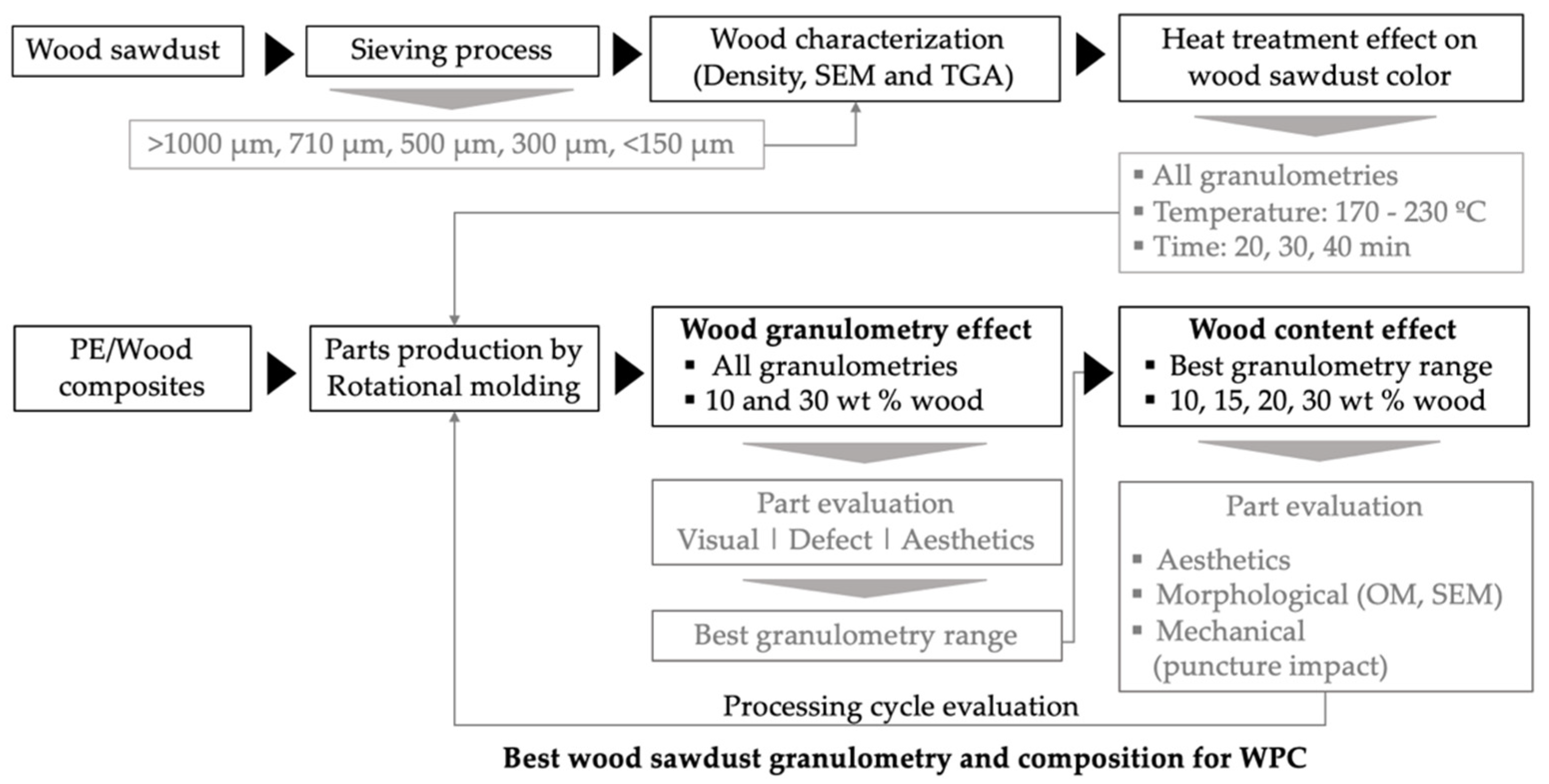

2.8. Methodology Flow Chart

3. Results and Discussion

3.1. Characterization of Raw Materials

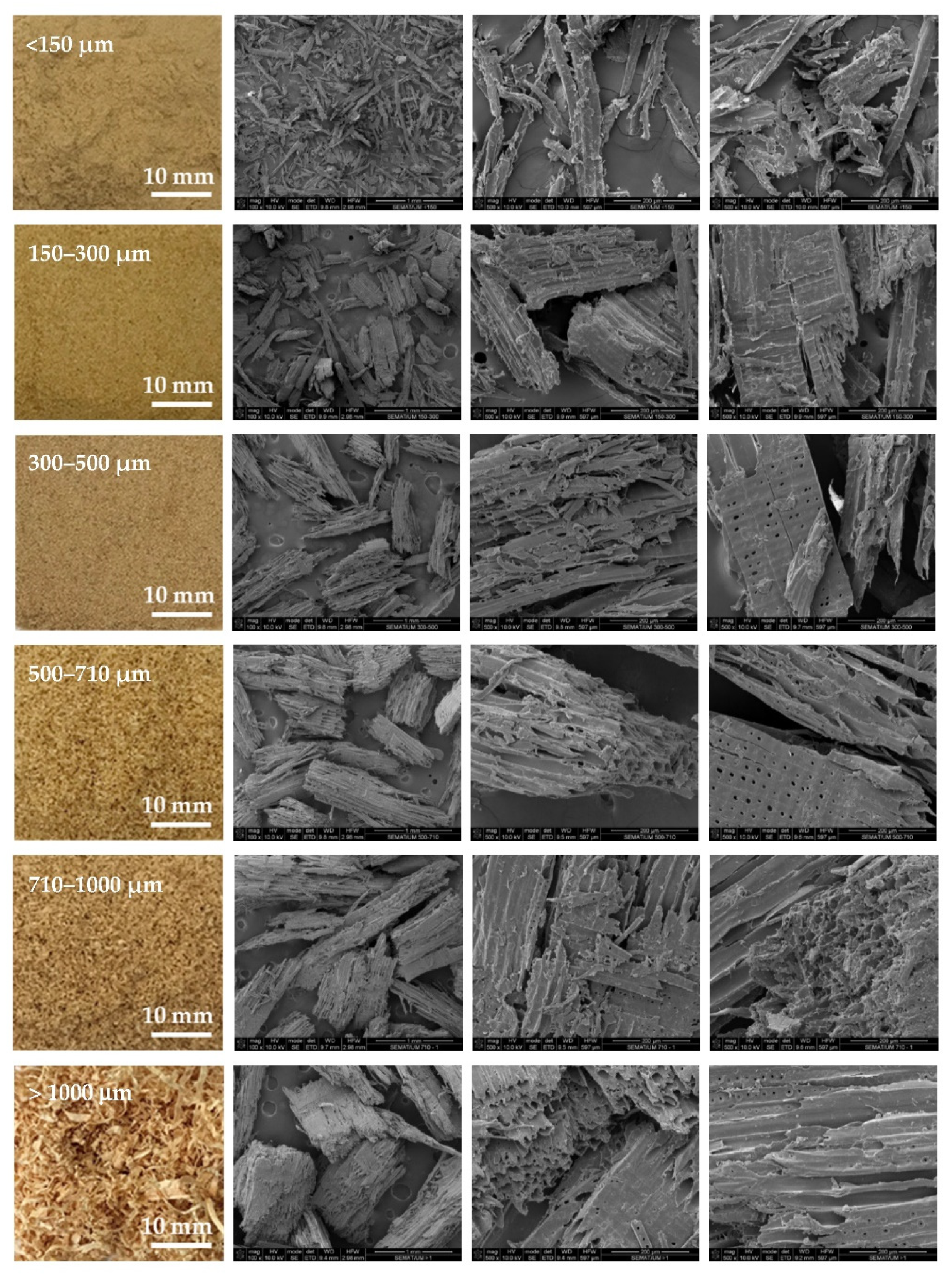

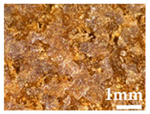

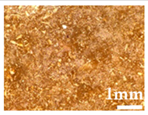

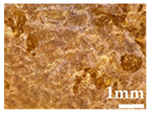

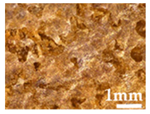

3.1.1. Morphology of Virgin Wood

3.1.2. Apparent Density of Wood Sawdust

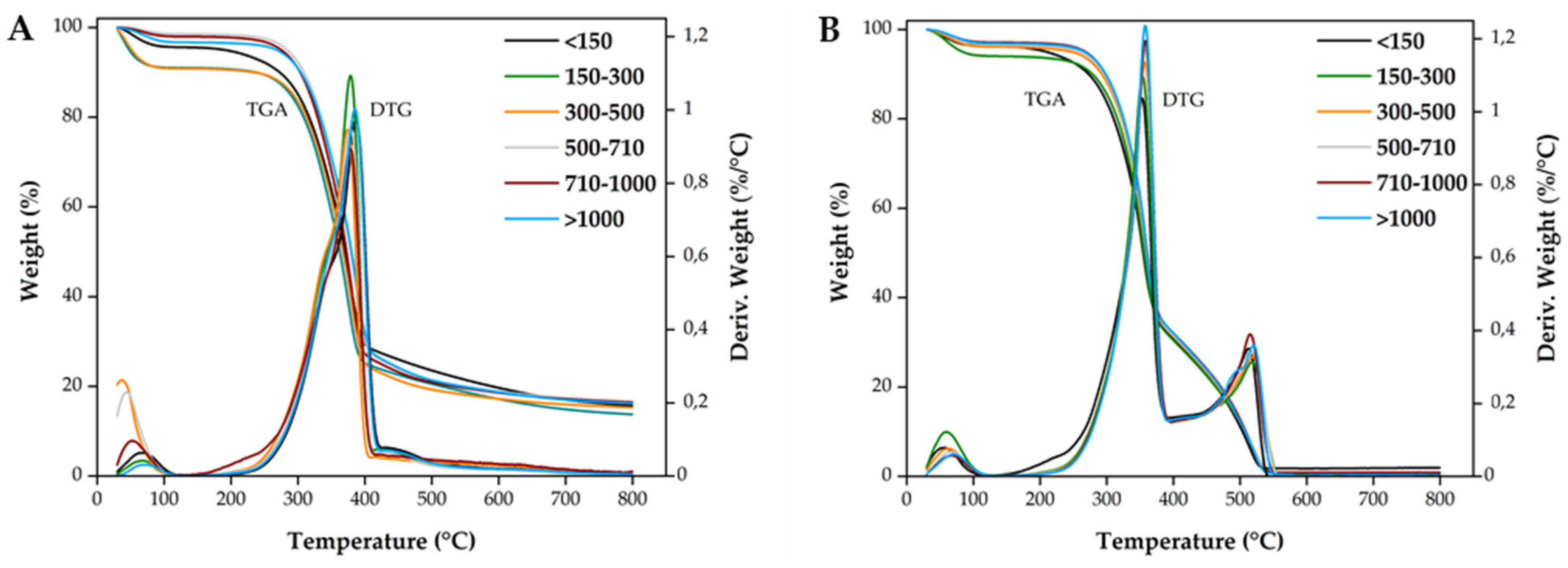

3.1.3. Thermal Analysis of Wood Sawdust

3.1.4. Effect of Heat Treatment of Wood Sawdust

3.2. Production of Parts by Rotational Molding

3.2.1. Evaluation of Processing Cycle

3.2.2. Effect of Wood Sawdust Granulometry

3.2.3. Effect of Wood Content on Part Quality

3.3. Characterization of Rotomolded Parts

3.3.1. Morphology of Parts

3.3.2. Mechanical Properties of Parts

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pereira, P.; Rosa, M.; Cioffi, M.; Benini, K.; Milanese, A.; Voorwald, H.; Mulinari, D. Vegetal fibers in polymeric composites: A review. Polímeros 2015, 25, 9–22. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Stanchev, P.; Katsou, E.; Awad, S.; Fan, M. A circular economy use of recovered sludge cellulose in wood plastic composite production: Recycling and eco-efficiency assessment. Waste Manag. 2019, 99, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Sommerhuber, P.; Welling, J.; Krause, A. Substitution potentials of recycled HDPE and wood particles from post-consumer packaging waste in Wood-Plastic Composites. Waste Manag. 2015, 46, 76–85. [Google Scholar] [CrossRef]

- McCormick, K.; Kautto, N. The Bioeconomy in Europe: An Overview. Sustainability 2013, 5, 2589–2608. [Google Scholar] [CrossRef] [Green Version]

- Joustra, J.; Flipsen, B.; Balkenende, R. Circular design of composite products: A framework based on insights from literature and industry. Sustainability 2021, 13, 7223. [Google Scholar] [CrossRef]

- Saheb, D.; Jog, J. Natural Fiber Polymer Composites: A Review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Venkatesh, G.; Deb, A.; Karmarkar, A.; Gurumoorthy, B. Eco-Friendly Wood Polymer Composites for Sustainable Design Applications. In CIRP Design 2012; Springer: Bangalore, India, 2012; pp. 399–408. ISBN 9781447145073. [Google Scholar]

- Petchwattana, N.; Naknaen, P.; Narupai, B. A circular economy use of waste wood sawdust for wood plastic composite production: Effect of bio-plasticiser on the toughness. Int. J. Sustain. Eng. 2019, 13, 398–410. [Google Scholar] [CrossRef]

- Robledo-Ortíz, J.; González-López, M.; Rodrigue, D.; Gutiérrez-Ruiz, J.; Prezas-Lara, F.; Pérez-Fonseca, A. Improving the Compatibility and Mechanical Properties of Natural Fibers/Green Polyethylene Biocomposites Produced by Rotational Molding. J. Polym. Environ. 2020, 28, 1040–1049. [Google Scholar] [CrossRef]

- Pokhrel, G.; Gardner, D.J.; Han, Y. Properties of wood–plastic composites manufactured from two different wood feedstocks: Wood flour and wood pellets. Polymers 2021, 13, 2769. [Google Scholar] [CrossRef]

- Gardner, D.J.; Han, Y.; Wang, L. Wood–Plastic composite technology. Curr. For. Rep. 2015, 1, 139–150. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, M.; Badrishah, N.S.; Sa’ude, N.; Ibrahim, M.H.I. Sustainable natural bio composite for FDM feedstocks. Appl. Mech. Mater. 2014, 607, 65–69. [Google Scholar] [CrossRef]

- Kohl, D.; Link, P.; Böhm, S. Wood as a Technical Material for Structural Vehicle Components. Procedia CIRP 2016, 40, 557–561. [Google Scholar] [CrossRef] [Green Version]

- Thompson, D.W.; Hansen, E.N.; Knowles, C.; Muszynski, L. Opportunities for wood plastic composite products in the U.S. highway construction sector. BioResources 2010, 5, 1336–1352. [Google Scholar] [CrossRef]

- Santoni, A.; Bonfiglio, P.; Fausti, P.; Marescotti, C.; Mazzanti, V.; Mollica, F.; Pompoli, F. Improving the sound absorption performance of sustainable thermal insulation materials: Natural hemp fibres. Appl. Acoust. 2019, 150, 279–289. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Influence of Additional Bracing Arms as Reinforcement Members in Wooden Timber Cross-Arms on Their Long-Term Creep Responses and Properties. Appl. Sci. 2021, 11, 2061. [Google Scholar] [CrossRef]

- Rizki, M.; Tamai, Y.; Koda, K.; Kojima, Y.; Terazawa, M. Wood density variations of tropical wood species: Implications to the physical properties of sawdust as substrate for mushroom cultivation. Wood Res. 2010, 1, 34–39. [Google Scholar]

- Hanana, F.; Rodrigue, D. Rotational molding of polymer composites reinforced with natural fibers. Plast. Eng. 2015, 71, 28–31. [Google Scholar] [CrossRef]

- León, L.; Escocio, V.; Visconte, L.; Junior, J.; Pacheco, E. Rotomolding and polyethylene composites with rotomolded lignocellulosic materials: A review. J. Reinf. Plast. Compos. 2020, 39, 459–472. [Google Scholar] [CrossRef]

- Affiliation of Rotational Moulding Organisations. ARMO Rotational Moulding Product Showcase. Available online: https://issuu.com/rotoworld/docs/2017_armo_rotational_moulding_produ (accessed on 2 August 2021).

- Crawford, R.; Kearns, M. Practical Guide to Rotational Moulding; iSmithers Rapra Publishing: Shrewsbury, UK, 2003; ISBN 1859573878. [Google Scholar]

- Crawford, R.; Gibson, S. Rotational molding: Some Basics. Pop. Plast. Packag. 2012, 10, 26–28. [Google Scholar]

- Crawford, R.; Throne, J. Processing. In Rotational Molding Technology; William Andrew Publishing: New York, NY, USA, 2002; pp. 201–306. ISBN 1884207855. [Google Scholar]

- Nugent, P. Rotational Molding. In Applied Plastics Engineering Handbook: Processing, Materials, and Applications; Kutz, M., Ed.; Elsevier: Reading, PA, USA, 2017; ISBN 978-0-323-39040-8. [Google Scholar]

- Fletes, R.; López, E.; Sánchez, F.; Mendizábal, E.; Núñez, R.; Rodrigue, D.; Gudiño, P. Morphological and mechanical properties of bilayers wood-plastic composites and foams obtained by rotational molding. Polymers 2020, 12, 503. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, M.; Cramez, M.; Crawford, R. Structure-property relationships in rotationally moulded polyethylene. J. Eng. Appl. Sci. 1996, 31, 2227–2240. [Google Scholar] [CrossRef]

- Oliveira, M.J.; Cramez, M.C.; Oliveira, M.J.; Cramez, M.C. Rotational Molding of polyolefins: Processing, morphology and properties. J. Macromol. Sci. Part B 2001, 40, 457–471. [Google Scholar] [CrossRef]

- Greco, A.; Ferrari, F.; Buccoliero, M.; Trono, G. Thermal and mechanical analysis of polyethylene homo-composites processed by rotational molding. Polymers 2019, 11, 528. [Google Scholar] [CrossRef] [Green Version]

- Saka, S. Structure and Chemical Composition of Wood as a Natural Composite Material. In Recent Research on Wood and Wood-Based Materials; Elsevier: Amsterdam, The Netherlands, 1993; pp. 1–20. [Google Scholar] [CrossRef]

- Rowell, R.; Pettersen, R.; Tshabalala, M. Cell Wall Chemistry. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012; pp. 33–72. ISBN 9781439853818. [Google Scholar]

- Torres, F.; Aguirre, M. Rotational moulding and powder processing of natural fibre reinforced thermoplastics. Int. Polym. Process. 2003, 18, 204–210. [Google Scholar] [CrossRef]

- Arribasplata-Seguin, A.; Quispe-Dominguez, R.; Tupia-Anticona, W.; Acosta-Sullcahuamán, J. Rotational molding parameters of wood-plastic composite materials made of recycled high density polyethylene and wood particles. Compos. Part B 2021, 217, 1–18. [Google Scholar] [CrossRef]

- Cisneros-López, E.; González-López, M.; Pérez-Fonseca, A.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J. Effect of fiber content and surface treatment on the mechanical properties of natural fiber composites produced by rotomolding. Compos. Interfaces 2016, 24, 35–53. [Google Scholar] [CrossRef]

- Oliveira, M.; Pickering, K.; Sunny, T.; Lin, R. Rotational Moulding of Polyethylene Reinforced with Alkali Treated Hemp Fibre. In Chemeca Conference; Institution of Chemical Engineers: Queenstown, New Zealand, 2018; pp. 1–9. ISBN 9781911446682. [Google Scholar]

- Cisneros-Lopez, E.; Perez-Fonseca, A.; Fuentes-Talavera, F. Rotomolded Polyethylene-Agave Fiber Composites: Effect of Fiber Surface Treatment on the Mechanical Properties. Polym. Eng. Sci. 2016, 8, 856–865. [Google Scholar] [CrossRef]

- Bledzki, A.; Reihmane, S.; Gassan, J. Thermoplastics reinforced with wood fillers: A literature review. Polym.-Plast. Technol. Eng. 1998, 37, 451–468. [Google Scholar] [CrossRef]

- Hanana, F.; Rodrigue, D. Effect of particle size, fiber content, and surface treatment on the mechanical properties of maple-reinforced LLDPE produced by rotational molding. Polym. Polym. Compos. 2020, 29, 343–353. [Google Scholar] [CrossRef]

- Hanana, F.; Rodrigue, D. Rotational Molding of Self-Hybrid Composites Based on Linear Low-Density Polyethylene and Maple Fibers. Polym. Compos. 2017, 39, 4094–4103. [Google Scholar] [CrossRef]

- Raymond, A.; Rodrigue, D. Foams and wood composite foams produced by rotomolding. Cell. Polym. 2013, 32, 199–212. [Google Scholar] [CrossRef]

- Jayaraman, K.; Lin, R.; Bose, D.; Maarouf, M. Natural Fibre-Reinforced Thermoplastics Processed by Rotational Moulding. Adv. Mater. Res. 2007, 29–30, 307–310. [Google Scholar] [CrossRef]

- Wang, B.; Panigrahi, S.; Tabil, L.; Crerar, W. Pre-treatment of flax fibers for use in rotationally molded biocomposites. J. Reinf. Plast. Compos. 2007, 26, 447–463. [Google Scholar] [CrossRef]

- Ortega, Z.; Monzón, M.; Benítez, A.; Kearns, M.; McCourt, M.; Hornsby, P. Banana and abaca fiber-reinforced plastic composites obtained by rotational molding process. Mater. Manuf. Process. 2013, 28, 879–883. [Google Scholar] [CrossRef]

- López-Banuelos, R.; Moscoso, F.; Ortega-Gudino, P. Rotational Molding of Polyethylene Composites Based on Agave Fibers. Polym. Eng. Sci. 2012, 46, 486–492. [Google Scholar] [CrossRef]

- Hanana, F.; Chimeni, D.; Rodrigue, D. Morphology and mechanical properties of maple reinforced LLDPE produced by rotational moulding: Effect of fibre content and surface treatment. Polym. Polym. Compos. 2018, 26, 299–308. [Google Scholar] [CrossRef]

- Martins, C.; Gil, V. Processing–Structure–Properties of Cork Polymer Composites. Front. Mater. 2020, 7, 1–12. [Google Scholar] [CrossRef]

- Abhilash, S.; Singaravelu, D. Effect of Fiber Content on Mechanical and Morphological Properties of Bamboo Fiber-Reinforced Linear Low-Density Polyethylene Processed by Rotational Molding. Trans. Indian Inst. Met. 2020, 73, 1549–1554. [Google Scholar] [CrossRef]

- Bekhta, P.; Niemz, P. Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 2003, 57, 539–546. [Google Scholar] [CrossRef]

- Pontes, A.; Ferreira, E.; Mendes, J.; Fonseca, J.; Cramez, M.; Pouzada, A. O Molde; Revista da Cefanol: Marinha Grande, Portugal, 2014; pp. 23–29. [Google Scholar]

- Guo, Q.; Chen, X.; Liu, H. Experimental research on shape and size distribution of biomass particle. Fuel 2012, 94, 551–555. [Google Scholar] [CrossRef]

- Datasheet of ADVANCENE EM-3405-UVH Medium Density Polyethylene (MDPE). Available online: https://www.ulprospector.com/plastics/en/datasheet/381003/advancene-em-3405-uvh (accessed on 4 April 2021).

- González-Díaz, E.; Alonso-López, J. Characterization by thermogravimetric analysis of the wood used in Canary architectural heritage. J. Cult. Herit. 2017, 23, 111–118. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.; Forte, M.; Santana, R. Thermal decomposition of wood: Influence of wood components and cellulose crystallite size. Bioresour. Technol. 2012, 109, 148–153. [Google Scholar] [CrossRef]

- Sebio-Puñal, T.; Naya, S.; López-Beceiro, J.; Tarrío-Saavedra, J.; Artiaga, R. Thermogravimetric analysis of wood, holocellulose, and lignin from five wood species. J. Therm. Anal. Calorim. 2012, 109, 1163–1167. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.; Freitag, C.; Morrell, J. Effects of wood fiber esterification on properties, weatherability and biodurability of wood plastic composites. Polym. Degrad. Stab. 2013, 98, 1348–1361. [Google Scholar] [CrossRef]

- Gebke, S.; Thümmler, K.; Sonnier, R.; Tech, S.; Wagenführ, A.; Fischer, S. Flame retardancy of wood fiber materials using phosphorus-modified wheat starch. Molecules 2020, 25, 335. [Google Scholar] [CrossRef] [Green Version]

- Kučerová, V.; Lagaňa, R.; Výbohová, E.; Hýrošová, T. The Effect of Chemical Changes during Heat Treatment on the Color and Mechanical Properties of Fir Wood. BioResources 2016, 11, 9079–9094. [Google Scholar] [CrossRef]

- Akkuş, M.; Budakçı, M. Determination of color-changing effects of bleaching chemicals on some heat-treated woods. J. Wood Sci. 2020, 66, 1–14. [Google Scholar] [CrossRef]

- Torres, F.G.; Carrillo, M.; Cubillas, M.L. Melt densification of polymeric powder beds filled with natural fibres. Polym. Polym. Compos. 2006, 14, 691–699. [Google Scholar] [CrossRef]

- Ward-Perron, N.; Rodrigue, D. Analysis of wood particle drying for rotomolding application. In Proceedings of the 70th Annual Technical Conference of the Society of Plastics Engineers 2012, ANTEC 2012, Orlando, FL, USA, 2–4 April 2012; 2012; Volume 3, pp. 2259–2262. [Google Scholar]

- Dikobe, D.; Luyt, A. Effect of Filler Content and Size on the Properties of Ethylene Vinyl Acetate Copolymer–Wood Fiber Composites. J. Appl. Polym. Sci. 2007, 103, 3645–3654. [Google Scholar] [CrossRef]

- Marcovich, N.; Villar, M. Thermal and mechanical characterization of linear low-density polyethylene/wood flour composites. J. Appl. Polym. Sci. 2003, 90, 2775–2784. [Google Scholar] [CrossRef]

| MDPE | Wood Sawdust | ||||||

|---|---|---|---|---|---|---|---|

| Granulometry (µm) | <500 | <150 | 150–300 | 300–500 | 500–710 | 710–1000 | >1000 |

| Apparent Density (g/cm3) | 0.42 | 0.22 | 0.19 | 0.19 | 0.18 | 0.18 | 0.08 |

| Powders |  | ||||||

| Granulometry (µm) | Onset Temperature of Decomposition (°C) | Temperature at Maximum Decomposition Rate (°C) | Residue at 800 °C (%) | |||

|---|---|---|---|---|---|---|

| Nitrogen | Air | Nitrogen | Air | Nitrogen | Air | |

| <150 | 302.0 | 287.2 | 366.3 | 379.8 | 15.7 | 1.9 |

| 150–300 | 317.2 | 295.7 | 366.1 | 373.5 | 13.7 | 0.6 |

| 300–500 | 312.7 | 301.8 | 367.7 | 379.5 | 15.3 | 0.6 |

| 500–710 | 311.5 | 305.7 | 368.5 | 385.7 | 16.6 | 0.5 |

| 710–1000 | 313.5 | 308.3 | 368.2 | 379.2 | 16.4 | 0.9 |

| >1000 | 313.4 | 312.0 | 365.4 | 387.3 | 16.2 | 0.4 |

| Granulometry | <150 µm | 150–300 µm | 300–500 µm | 500–710 µm | 710–1000 µm |

|---|---|---|---|---|---|

| Whole parts 10% |  | ||||

| Whole parts 30% |  | ||||

| A. Plastic Shiny Look | B. Pinholes and Milky Surface | C. Porous Inner Surface | D. Surface Roughness and Porosity | E. Visible Wood Particles |

|---|---|---|---|---|

|  |  |  |  |

| Wood Content | |||||||

|---|---|---|---|---|---|---|---|

| 10% | 10% | 15% | 20% | 25% | 30% | 30% | |

| <150 µm |  | ||||||

| Thickness (mm) | 4.4 ± 0.4 | 4.7 ± 0.6 | 5.4 ± 0.6 | 6.8 ± 1.0 | 7.2 ± 1.4 | ||

| 150–300 µm |  | ||||||

| Thickness (mm) | 4.5 ± 0.5 | 4.9 ± 0.6 | 5.1 ± 0.7 | 5.9 ± 0.5 | 7.3 ± 0.6 | ||

| 300–500 µm |  | ||||||

| Thickness (mm) | 4.2 ± 0.2 | 4.7 ± 0.6 | 5.5 ± 0.6 | 6.6 ± 0.6 | 8.3 ± 1.1 | ||

| Wood Content | |||||

|---|---|---|---|---|---|

| 10% | 15% | 20% | 30% | ||

| <150 µm | Outer Surface |  |  |  |  |

| Inner surface |  |  |  |  | |

| 150–300 µm | Outer Surface |  |  |  |  |

| Inner surface |  |  |  |  | |

| 300–500 µm | Outer Surface |  |  |  |  |

| Inner surface |  |  |  |  | |

| Mean Maximum Force (N) | |||||||

|---|---|---|---|---|---|---|---|

| 10% | 15% | 20% | 25% | 30% | F Value | p-Value | |

| <150 µm | 1115.4 | 9547.3 | 815.2 | 509.9 | 656.6 | 37.5 | 3 × 10−12 |

| 150–300 µm | 1186.4 | 1083.2 | 705.5 | 749.3 | 652.2 | 51.0 | 4 × 10−14 |

| 300–500 µm | 1317.0 | 1122.3 | 1013.2 | 936.6 | 789.0 | 23.1 | 2 × 10−9 |

| F value | 2.9 | 4.8 | 23.4 | 81.0 | 14.9 | ||

| p-value | 0.080 | 0.019 | 4 × 10−6 | 1 × 10−10 | 9 × 10−5 | ||

| Mean Energy (J) | |||||||

|---|---|---|---|---|---|---|---|

| 10% | 15% | 20% | 25% | 30% | F Value | p-Value | |

| <150 µm | 6.4 | 5.3 | 3.3 | 1.8 | 2.3 | 55.3 | 1 × 10−14 |

| 150–300 µm | 3.9 | 3.9 | 1.2 | 3.1 | 1.0 | 2.8 | 0.039 |

| 300–500 µm | 7.2 | 6,3 | 5.3 | 4.2 | 3.9 | 10.1 | 1 × 10−5 |

| F value | 4.0 | 2.7 | 25.8 | 8.0 | 14.9 | ||

| p-value | 0.034 | 0.089 | 2 × 10−6 | 0.003 | 9 × 10−5 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martins, C.I.; Gil, V.; Rocha, S. Thermal, Mechanical, Morphological and Aesthetical Properties of Rotational Molding PE/Pine Wood Sawdust Composites. Polymers 2022, 14, 193. https://doi.org/10.3390/polym14010193

Martins CI, Gil V, Rocha S. Thermal, Mechanical, Morphological and Aesthetical Properties of Rotational Molding PE/Pine Wood Sawdust Composites. Polymers. 2022; 14(1):193. https://doi.org/10.3390/polym14010193

Chicago/Turabian StyleMartins, Carla I., Vitória Gil, and Sara Rocha. 2022. "Thermal, Mechanical, Morphological and Aesthetical Properties of Rotational Molding PE/Pine Wood Sawdust Composites" Polymers 14, no. 1: 193. https://doi.org/10.3390/polym14010193

APA StyleMartins, C. I., Gil, V., & Rocha, S. (2022). Thermal, Mechanical, Morphological and Aesthetical Properties of Rotational Molding PE/Pine Wood Sawdust Composites. Polymers, 14(1), 193. https://doi.org/10.3390/polym14010193